Diesel engine gear abnormal sound identification method based on wav file

An identification method and technology for diesel engines, which are applied in computer-aided design, instruments, complex mathematical operations, etc., can solve problems such as lack of versatility and inability to use diesel engine gear abnormal noise troubleshooting, etc., to achieve efficient data collection and processing, and reduce quality. Inspection steps, quick and targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

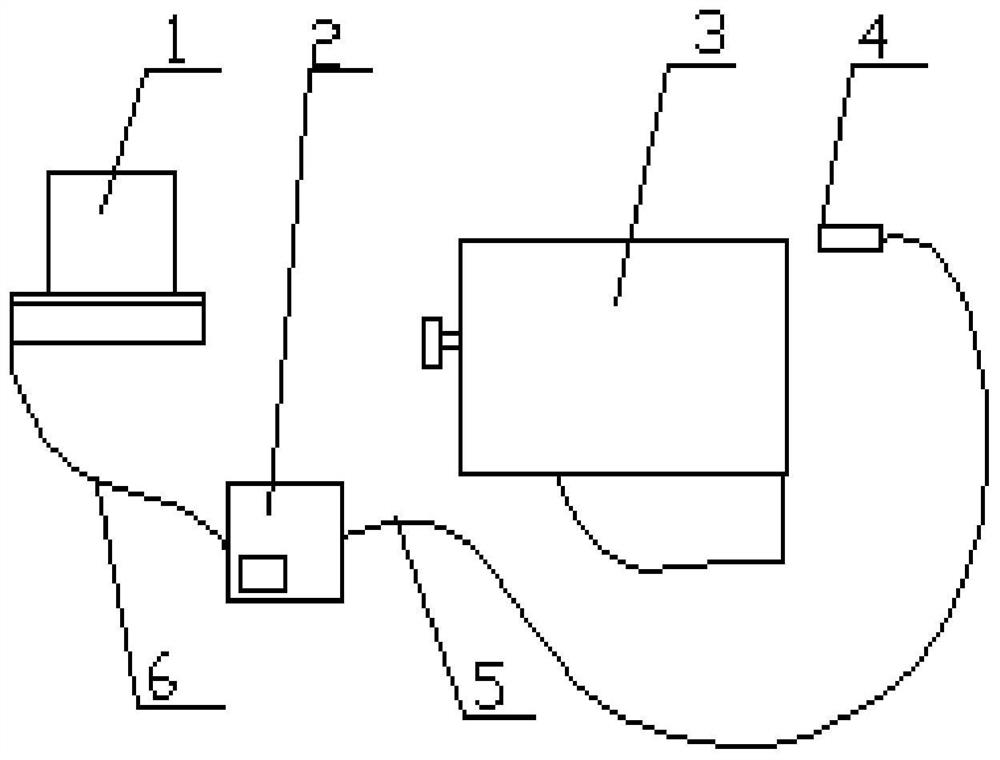

[0074] Whether the diesel engine of the model D20 is delayed, the noise sensor 4 used in this embodiment is BK 1 / 2 "SERIAL NO: 3023196), the noise sensor 4 is mounted on the free end of the diesel engine 3 At 20cm above, the model number of the signal recorder 2 is ZSY2048.

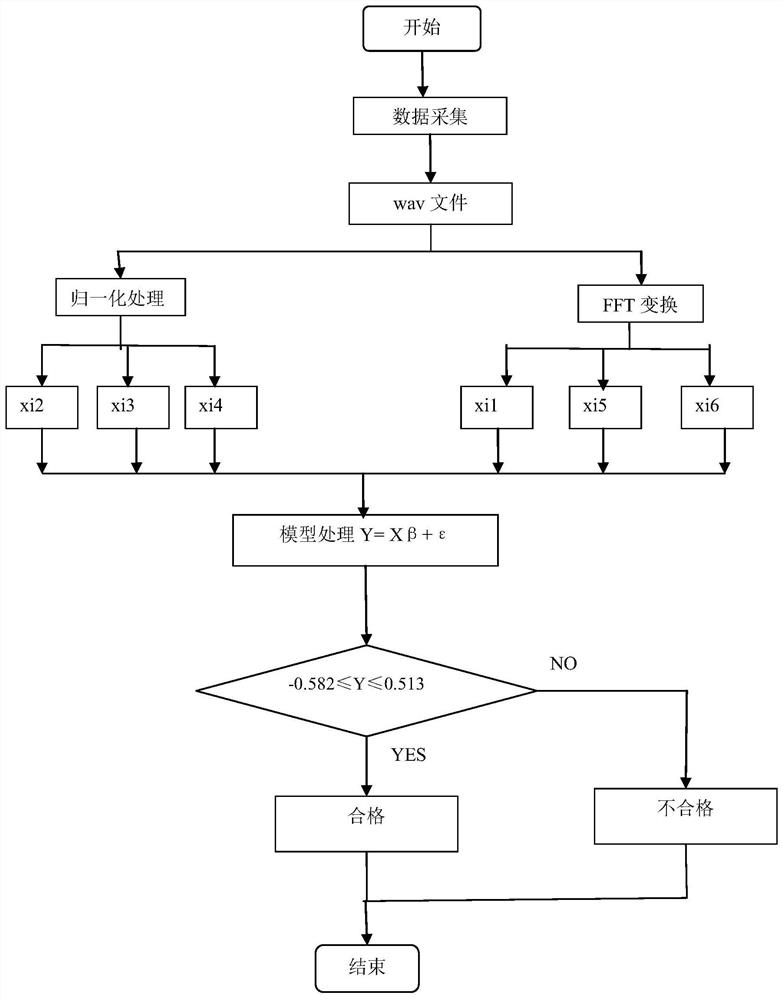

[0075] The WAV noise audio file of N = 28 diesel engine 3 (labeled 1 # -28 #) is collected by the noise sensor 4, respectively, and the 28 diesel engine 3 is qualified.

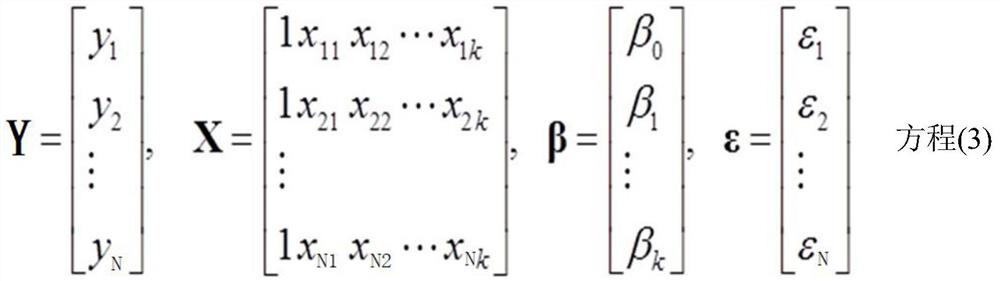

[0076] FFT transformations are performed on 28 WAV noise audio files, and the model parameters XI1, XI5, XI6 are obtained. The signals after the fast Fourier transform are normalized, and the model parameters XI2, XI3, XI4, I∈ [1, 28].

[0077] Calculated according to equations (1) to (5):

[0078] JOURNAL OF PATHOPHYSIOLOGY.

[0079] beta 0 .

[0080] beta 1 BA.

[0081] beta 2 BA.

[0082] ......

[0083] beta 27 JOURNAL OF ANIMAL SCIENCE AND VETERINARY MEDICINE.

[0084] = 0.02937962032596890.

[0085] Thus the model relationship:

[0086]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com