Patents

Literature

39results about How to "Ensure production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

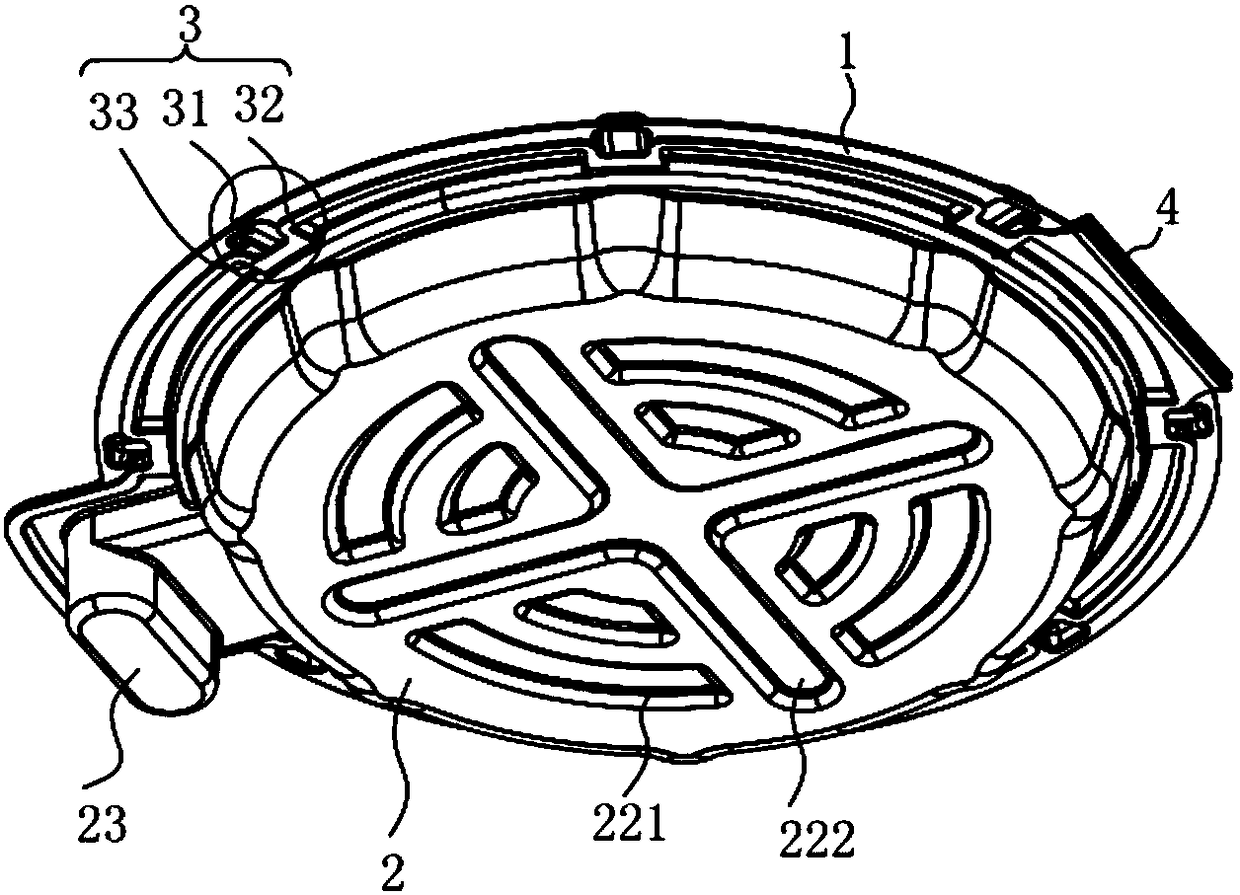

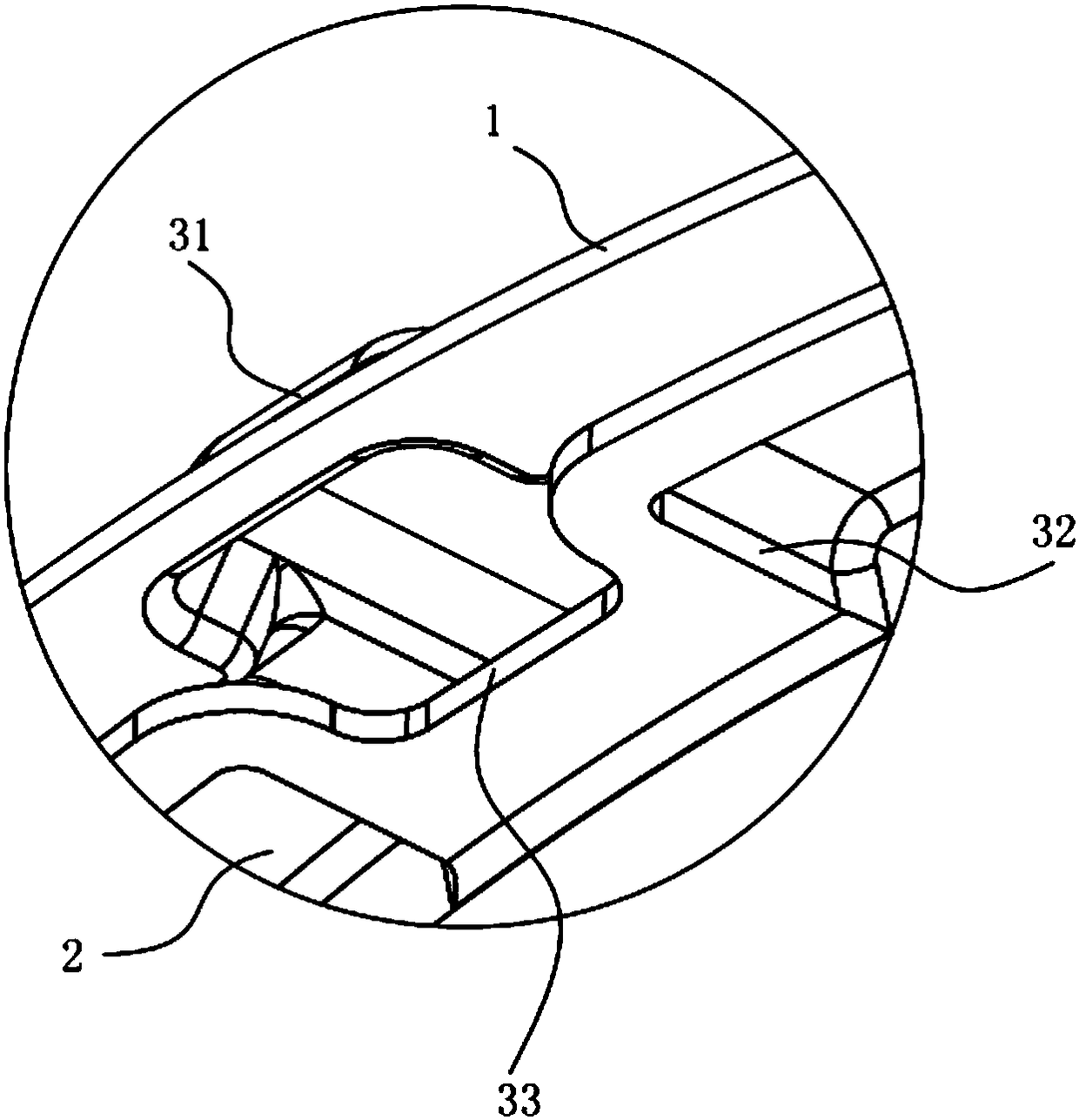

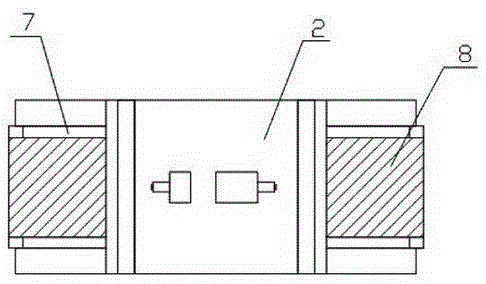

Method for manufacturing spectacle frame and forming mould thereof

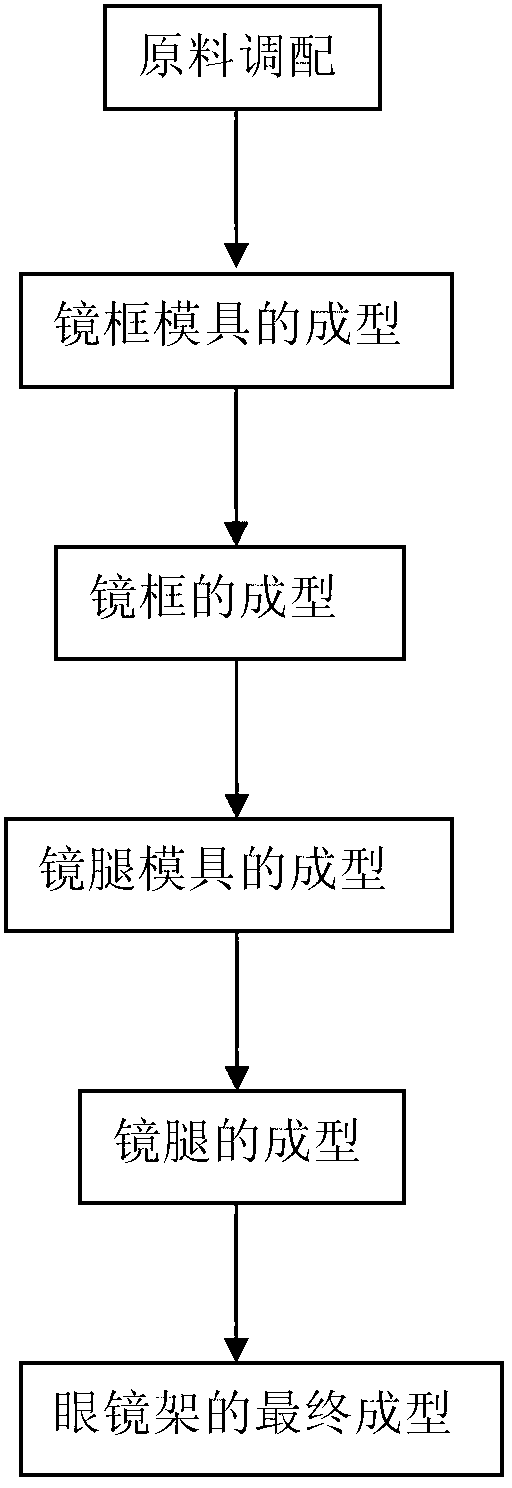

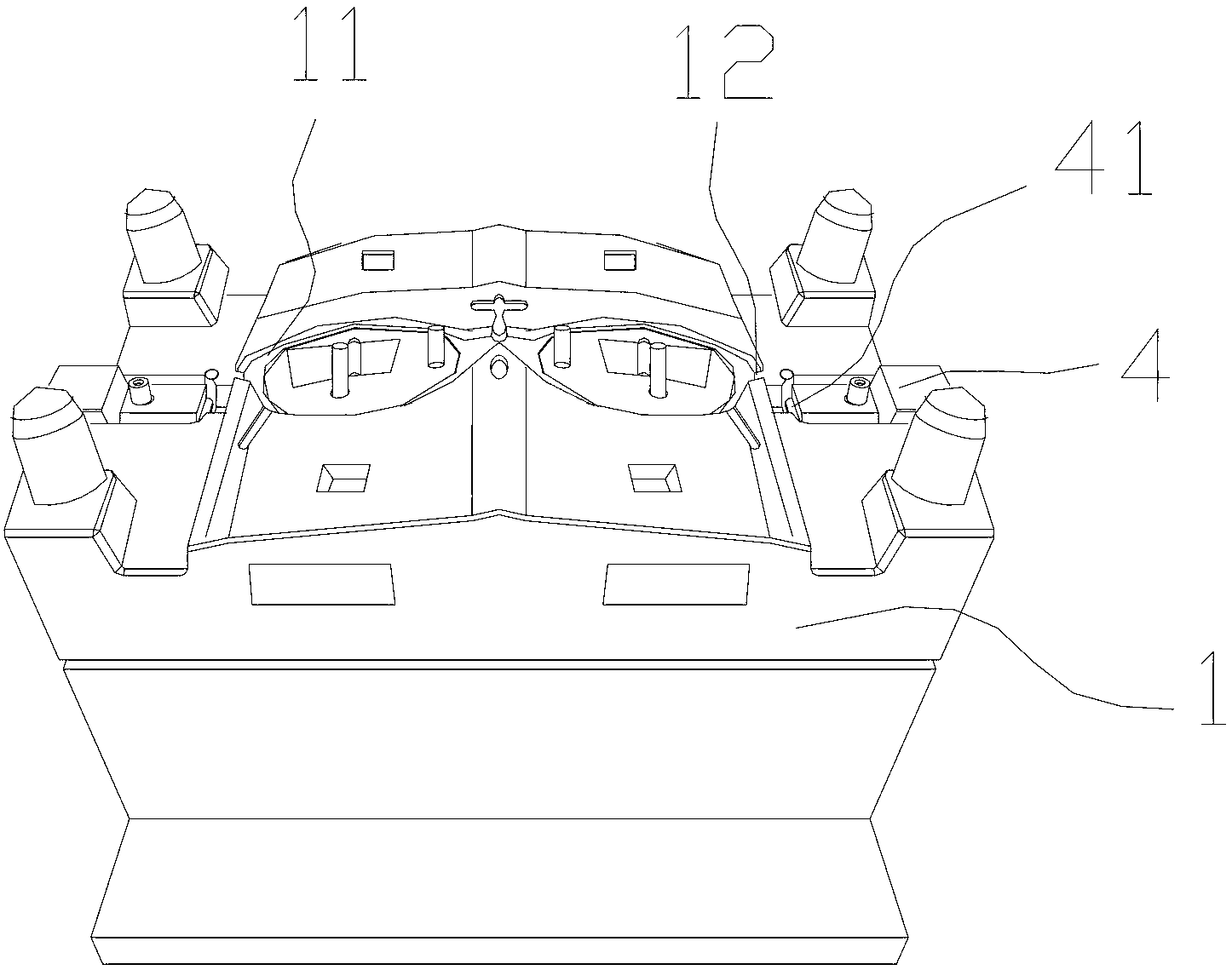

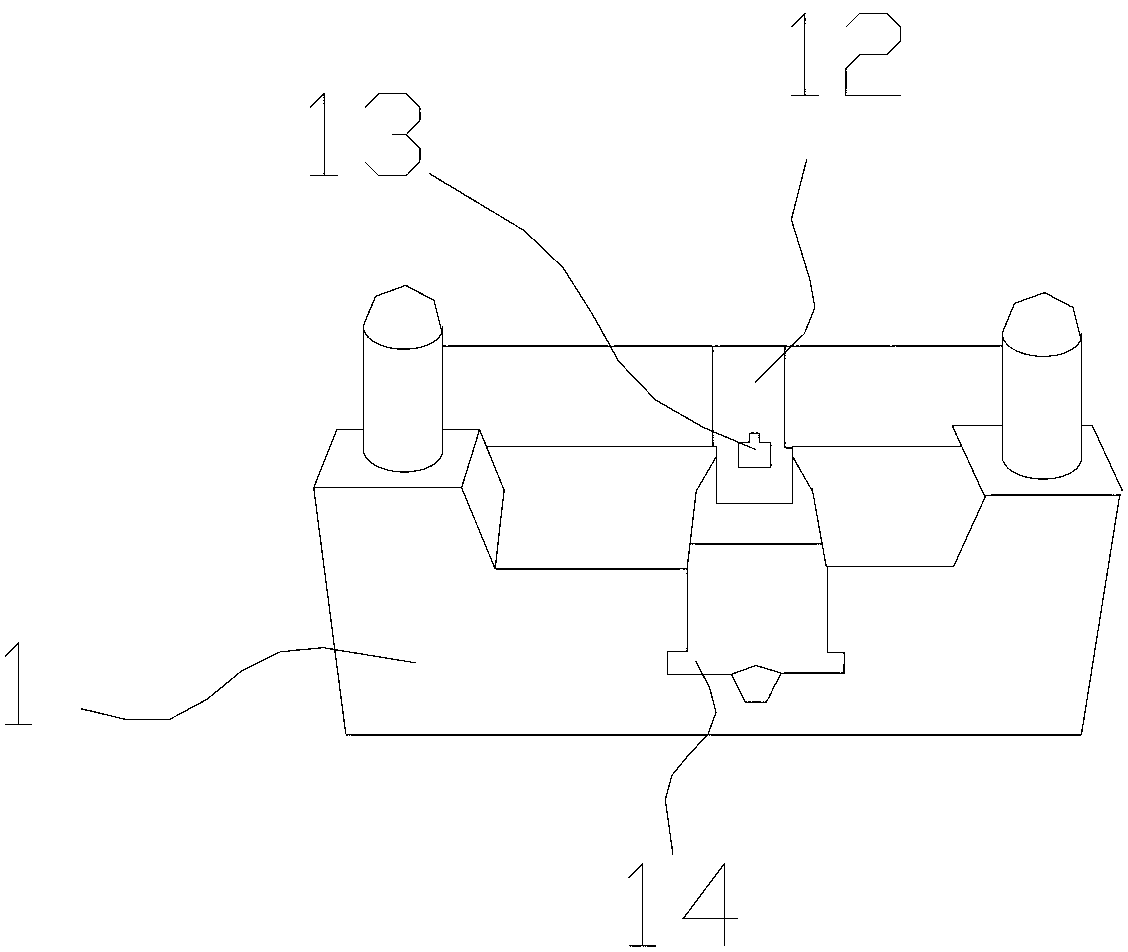

The invention discloses a method for manufacturing a spectacle frame, comprising the following steps of: machining one end plane of a mould to form two spectacle frame grooves with a basic shape of the spectacle frame, wherein the two spectacle frame grooves are communicated by a crossbeam groove, two pile head grooves are extent form two ends of the spectacle frame groove, and a hinge groove for accommodating a metal hinge is arranged on each pile head groove. Any metal hinge capable of 180-degree rotation is fixed in each hinge groove, raw materials of the spectacle frame are blended, are heated to form a melt material, then are injected into the spectacle frame grooves, simultaneously flow into the crossbeam groove, the pile head grooves and the hinge grooves, are then cooled and solidified, to form the spectacle frame which is integrally formed with the metal hinges. Two spectacle legs are respectively pivoted on the metal hinges. The method uses an injection molding technology of integration forming of the spectacle frame / spectacle legs and the metal hinges, and can implement automation production, and reduction of management, personnel production cost. A finished product cannot appear traces any more, a product structure is more firmly, and product quality guarantee is increased. The invention further discloses a spectacle frame mould for implementing the manner.

Owner:胡海鹏

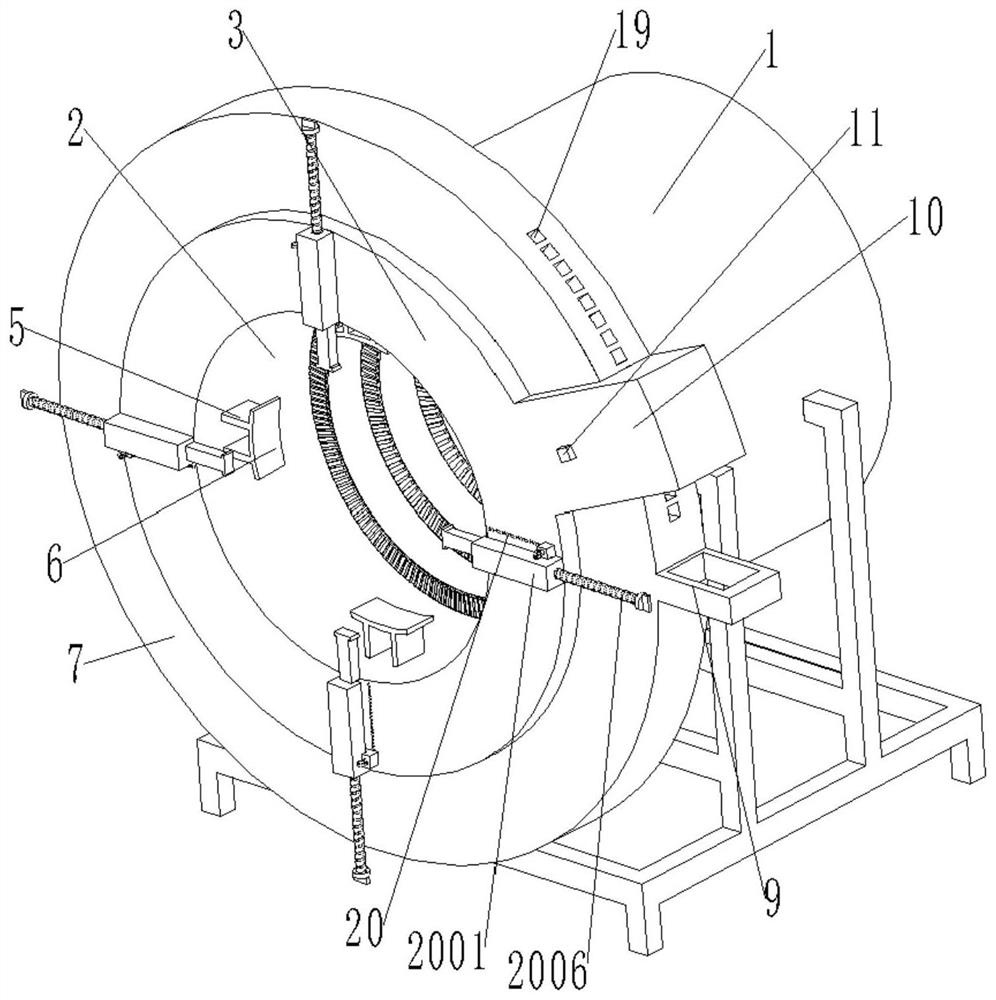

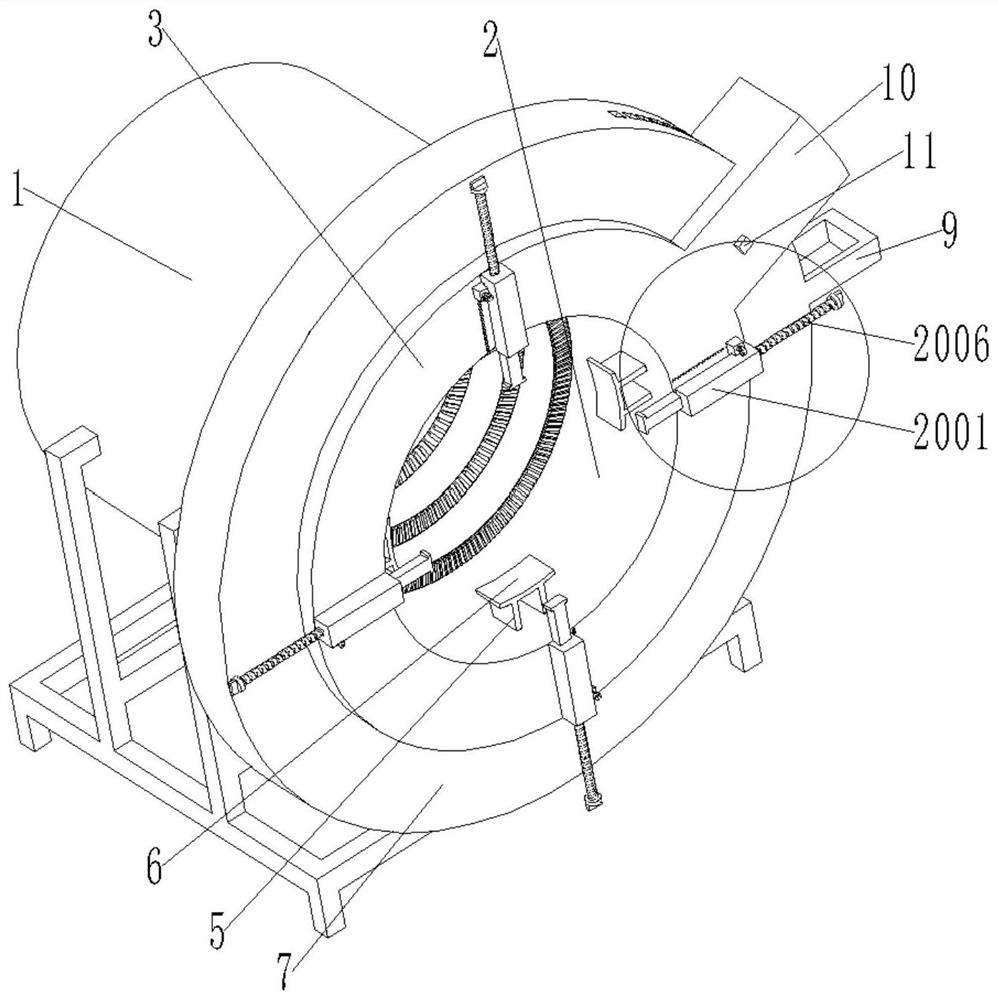

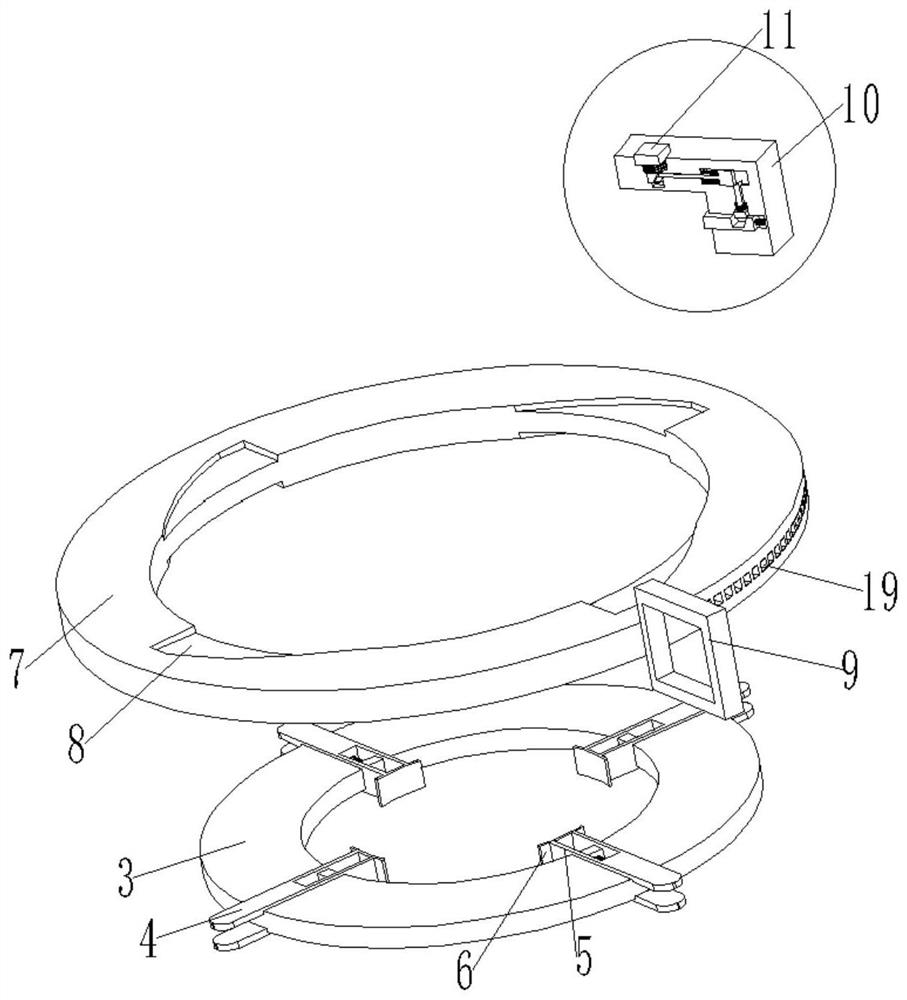

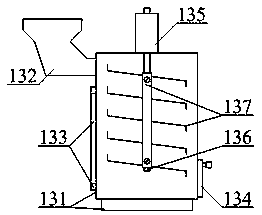

Novel pipe head heat treatment equipment

InactiveCN111850277AStable heat treatmentQuality assuranceFurnace typesHeat treatment furnacesMechanical engineeringIndustrial engineering

The invention discloses novel pipe head heat treatment equipment. The novel pipe head heat treatment equipment comprises a heat treatment equipment body, a placing opening and position correcting mechanisms. According to the novel pipe head heat treatment equipment, when the pipe head of a pipe bundle heat exchanger is in the heat treatment process, only the pipe head is subjected to heat treatment work through the arranged heat treatment equipment body, the placing opening and fixing rings, the influence on a heat exchange pipe by high temperatures is avoided in the heat treatment work of thepipe head, and therefore the heat treatment working quality of the pipe head is guaranteed and the production quality of products is improved; and moreover, the position of the pipe head of the pipebundle heat exchange pipe can be well fixed due to the arrangement of a first moving concave plate, a second moving concave plate, an arc-shaped clamping plate and a moving lantern ring, stable operation of pipe head heat treatment work is ensured and thus working economic benefits are guaranteed.

Owner:山东正诺化工设备有限公司

Fabrication process of high-end fully plaid-matching stripe-matching shirt

ActiveCN103948200AQuality improvementHigh-qualityClothes making applicancesCuffMechanical engineering

Owner:苏州新超针纺织有限公司

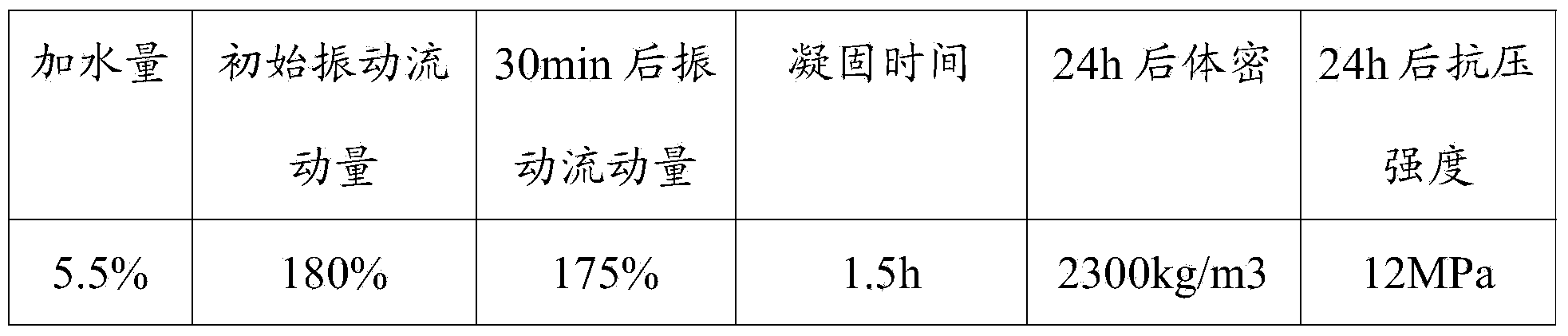

Composite additive and refractory castable

InactiveCN104130003AImprove liquidityAccelerate solidificationHydration reactionUltimate tensile strength

The invention discloses a composite additive and a refractory castable. The composite additive comprises the following components in percentage by weight: 20-60 percent of hydration reaction regulator, 20-50 percent of dispersing agent and 40-80 percent of matrix components. According to the composite additive, initial ion concentration of OH<-> regulated by the hydration reaction regulator is extremely low, so that a hydration reaction of calcium aluminate cement can be inhibited in a certain time, and the refractory castable keeps excellent liquidity in long enough time, i.e., enough working time is provided for construction operation. Moreover, after construction is ended, the ion concentration of OH<-> rapidly rises, so that the refractory castable is rapidly solidified and hardened, the maintenance time is shortened, the refractory castable has relatively high early strength, and the construction efficiency is improved.

Owner:SUZHOU UNIV

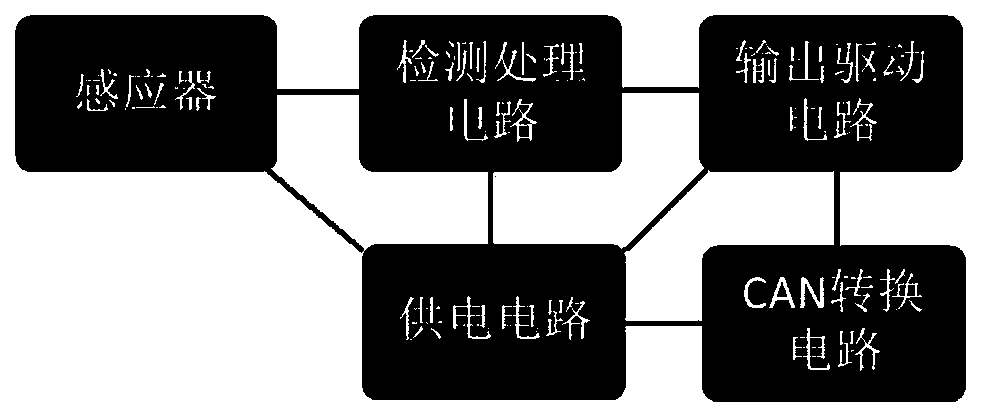

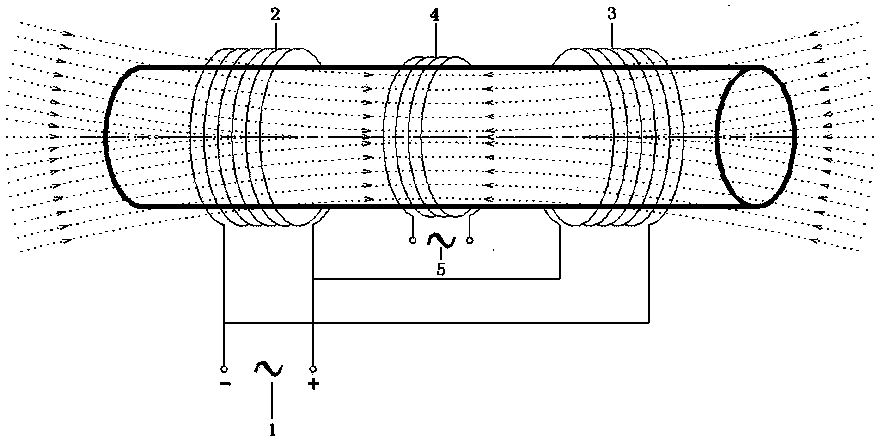

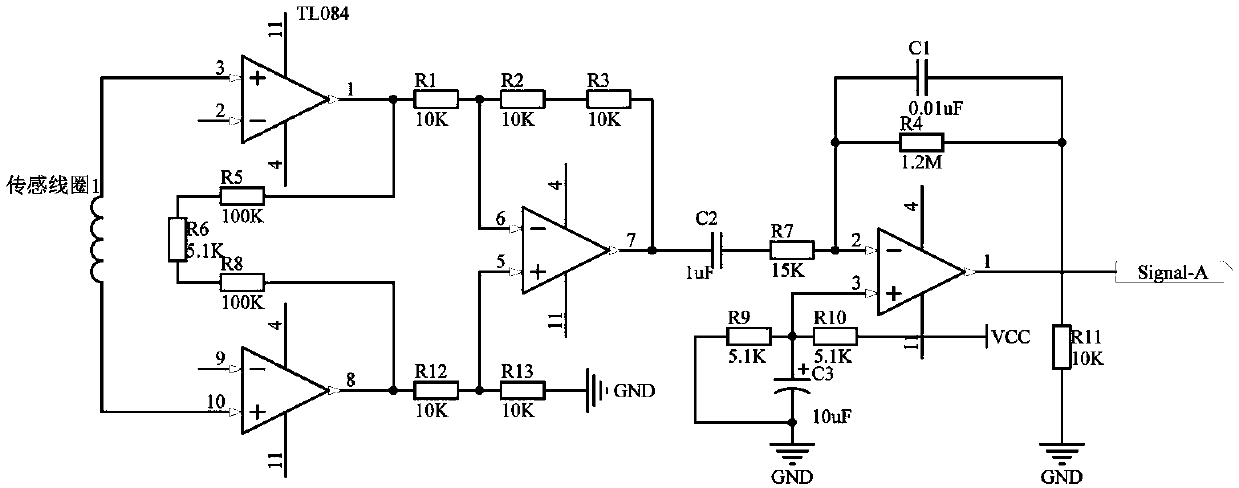

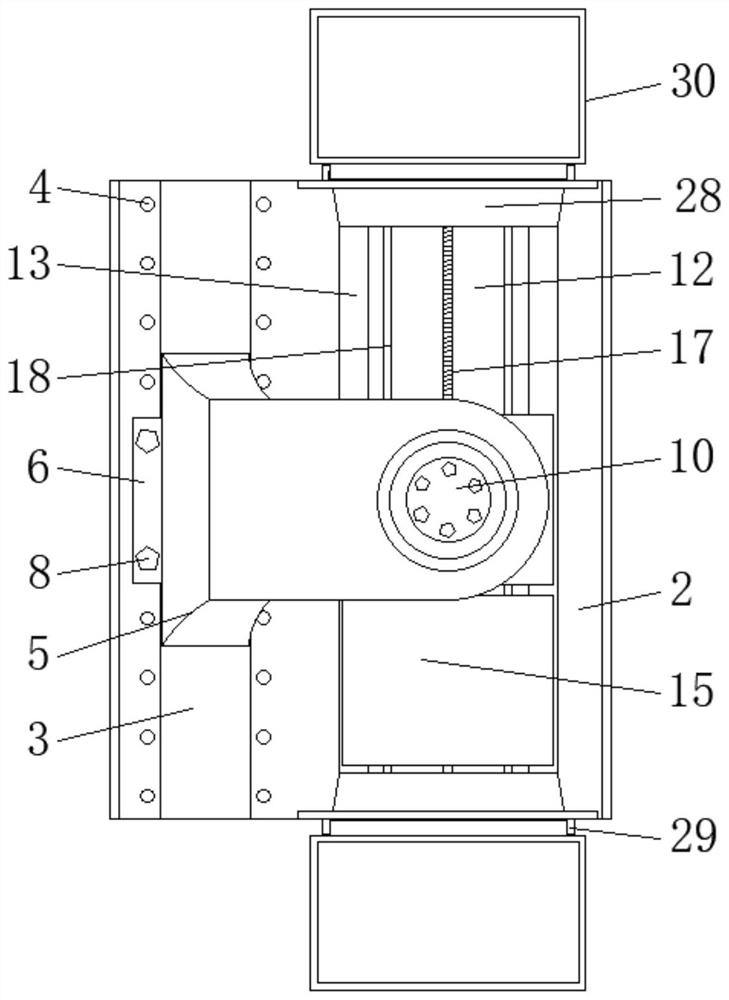

Magnetic force line balanced detection sensor employing wire rope

InactiveCN104215687AImprove accuracyImprove the accuracy and improve the safety of the steel wire rope under testMaterial magnetic variablesForce linesEngineering

The invention provides a magnetic force line balanced detection sensor employing a wire rope. The magnetic force line balanced detection sensor comprises an inductor, a detecting and processing circuit, an output drive circuit, a CAN conversion circuit and a power supply circuit, wherein the inductor is provided with an excitation source, two exciting coils and an induction coil; the excitation source is respectively connected with the two exciting coils and generates magnetic force lines which are the same in size and opposite in direction; the induction coil is arranged between the two exciting coils; and the output end of the induction coil is connected with the detecting and processing circuit. The magnetic force line balanced detection sensor is capable of accurately measuring all defects inside and outside the wire rope without a dead zone, and overcoming the influence of shaking of the wire rope on the measurement result. The magnetic force line balanced detection sensor is high in technological content, advanced in technology, stable and reliable to work, and wide in application range; the measurement sensitivity and accuracy are greatly improved; the damaged condition of the wire rope can be relatively easily and accurately found out; the sensor is stable, reliable, and easy to maintain by adopting the latest and most advanced components and modular structures in process; complicated environments of the applications are considered to the maximal extent; and field interference is eliminated, thereby stably working.

Owner:山西科为磁感技术有限公司

Fabrication process for high-grade pure cotton shirt

InactiveCN103948199AEnsure production efficiencyQuality assuranceClothes making applicancesCuffMechanical engineering

Owner:苏州新超针纺织有限公司

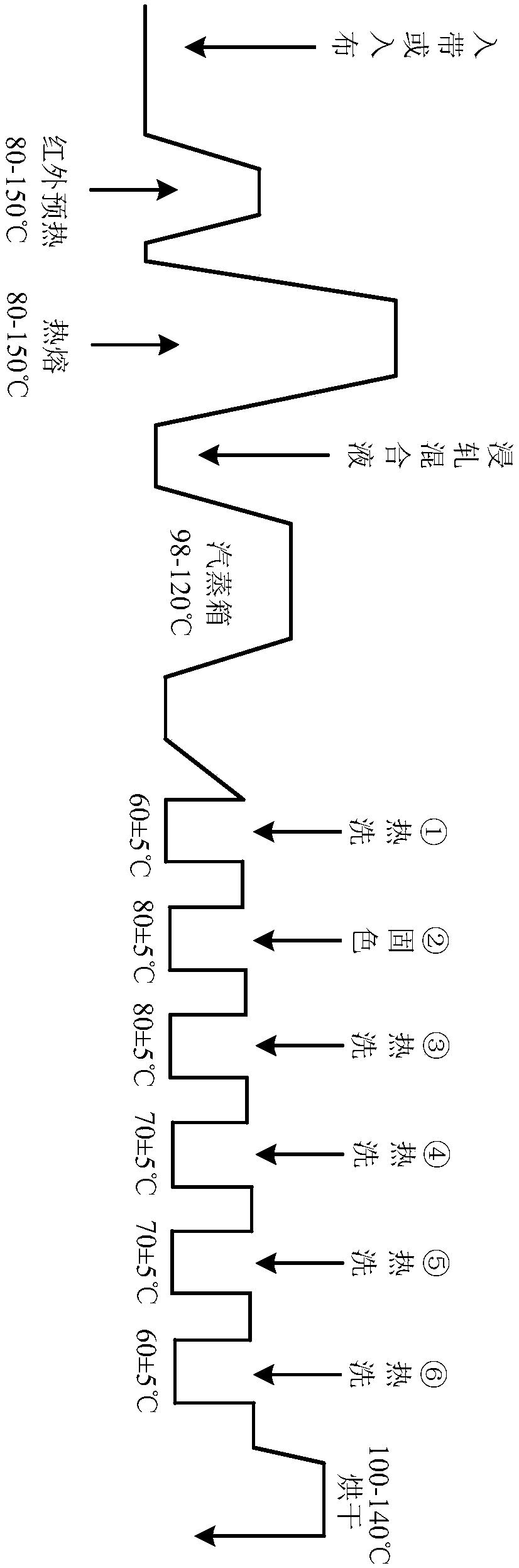

Acid dye continuous pad dyeing method for polyamide woven tapes

The invention discloses an acid dye continuous pad dyeing method for polyamide woven tapes. The acid dye continuous pad dyeing method sequentially includes steps of 1, pretreating the polyamide woventapes; 2, drying the polyamide woven tapes by infrared rays or hot air; 3, simultaneously carrying out pad dyeing by acid dye liquor and color fixing agents; 4, carrying out steaming dyeing and primary color fixing treatment; 5, carrying out hot washing; 6, carrying out secondary color fixing treatment; 7, carrying out hot washing; 8 carrying out drying; 9, dropping tapes. The acid dye continuouspad dyeing method has the advantages that the polyamide woven tapes have bright colors by the aid of acid dye steaming processes and color fixing one-bath dyeing schemes, the dye depths of the polyamide woven tapes can be effectively increased, the acid dye continuous pad dyeing method is good in deep dyeing property in polyamide woven tape dyeing procedures, and the polyamide woven tapes can be dyed with rich dark colors by the aid of the acid dye continuous pad dyeing method; pad dyeing is carried out on the polyamide woven tapes by acid dye, combined effects can be realized by an early color fixing scheme and a late color fixing scheme, the dye and the woven tapes are firmly combined with one another by chemical bonds, and the problem of poor color fastness of existing polyamide woven tapes after burning-preventive finishing is carried out on the existing polyamide woven tapes can be effectively solved by the aid of the acid dye continuous pad dyeing method.

Owner:CHENGDU HAIRONG TECHNICAL TEXTILES CO LTD

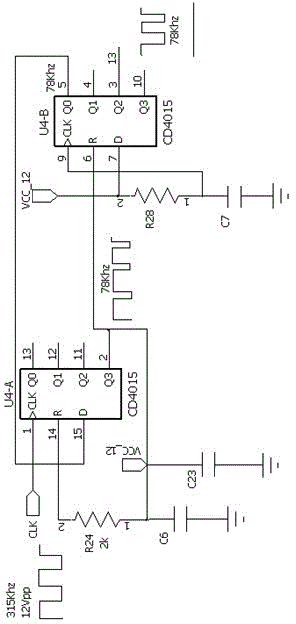

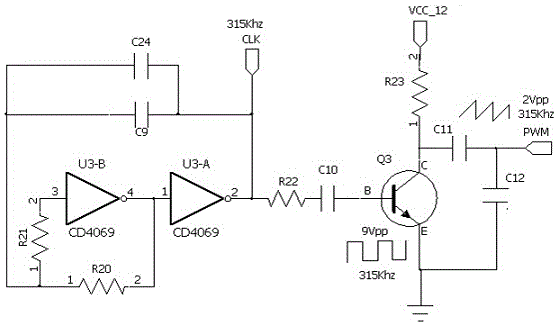

Inductive microcurrent cutter breaking detection circuit

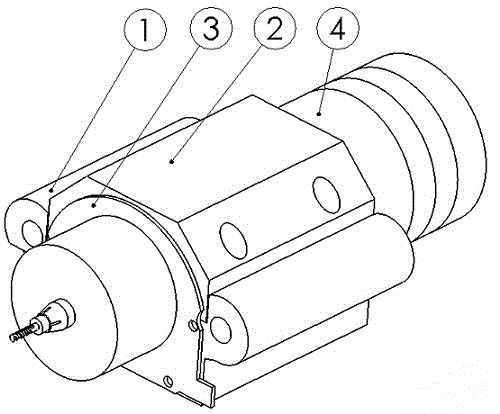

ActiveCN104786265ATimely detection of knife breakageHigh detection sensitivityMetal working apparatusDetection using electromagnetic wavesSignal processing circuitsEngineering

The invention discloses an inductive microcurrent cutter breaking detection circuit. The circuit comprises an excitation signal generation circuit, an excitation signal conversion circuit, a signal transmitting circuit, a signal induction circuit and a signal processing circuit, all of which are in sequential signal connection. The inductive microcurrent cutter breaking detection circuit further comprises a power module supplying power to all function modules. The signal transmitting circuit and the signal induction circuit adopt magnetic loop coils. The coils are arranged outside a spindle in a sleeving mode to be fixed to a spindle seat through screws. The excitation signal generation circuit outputs an oscillation signal at the fixed frequency to a transmitting coil. When a cutter drills a workpiece, an induction coil will generate induction current. When equipment normally runs, a detection loop will output a detection signal every time a hole is drilled, and meanwhile a PC compares a current position with an average value of the current position in real time, so that whether a drill bit is broken or not is judged. Compared with the prior art, the inductive microcurrent cutter breaking detection circuit can detect the condition of the machine tool cutter in real time, the cutter breakage phenomenon is found in time, the detection sensitivity is high, and the production quality and efficiency can be effectively ensured.

Owner:遂川天马数控有限公司

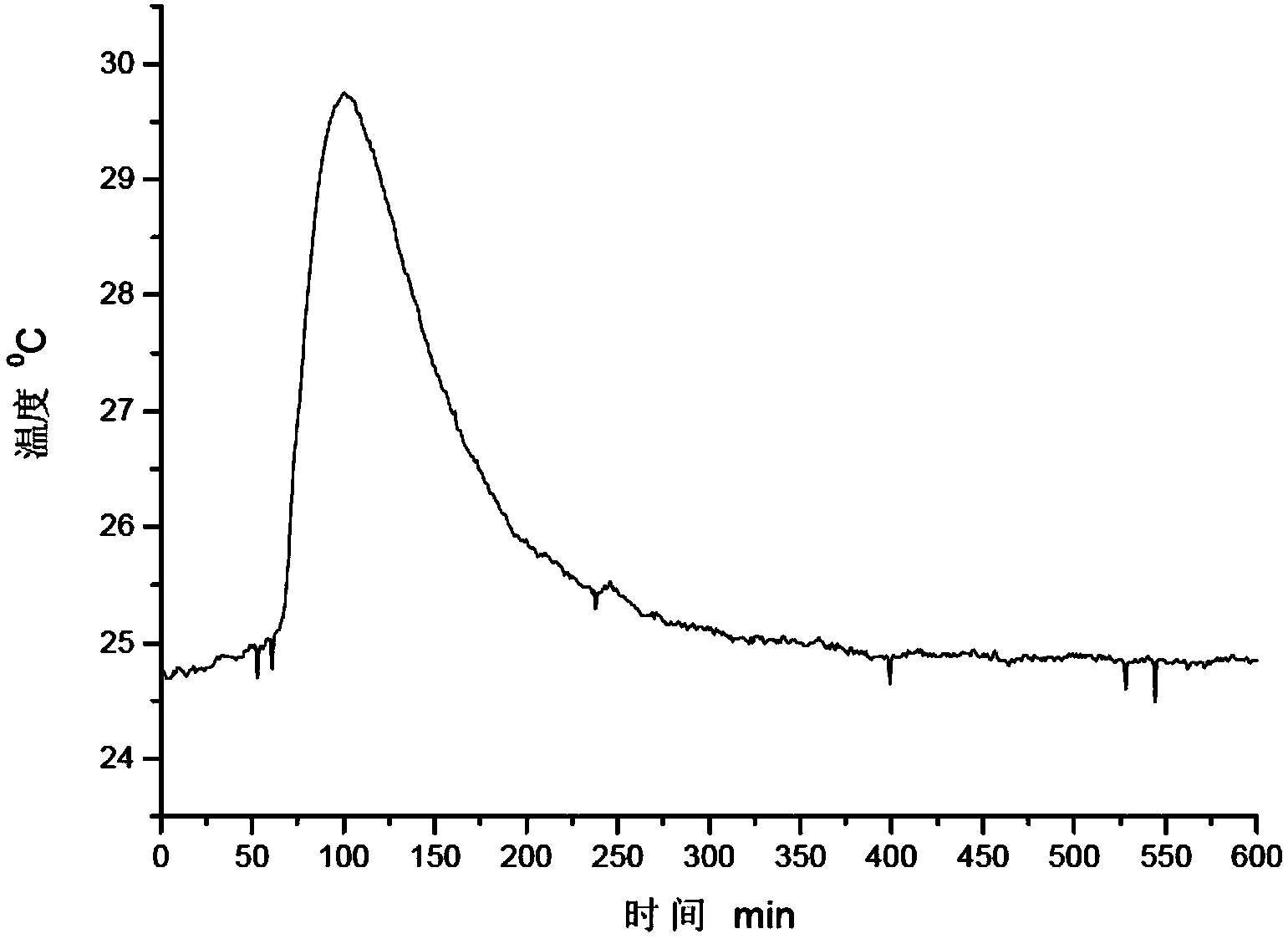

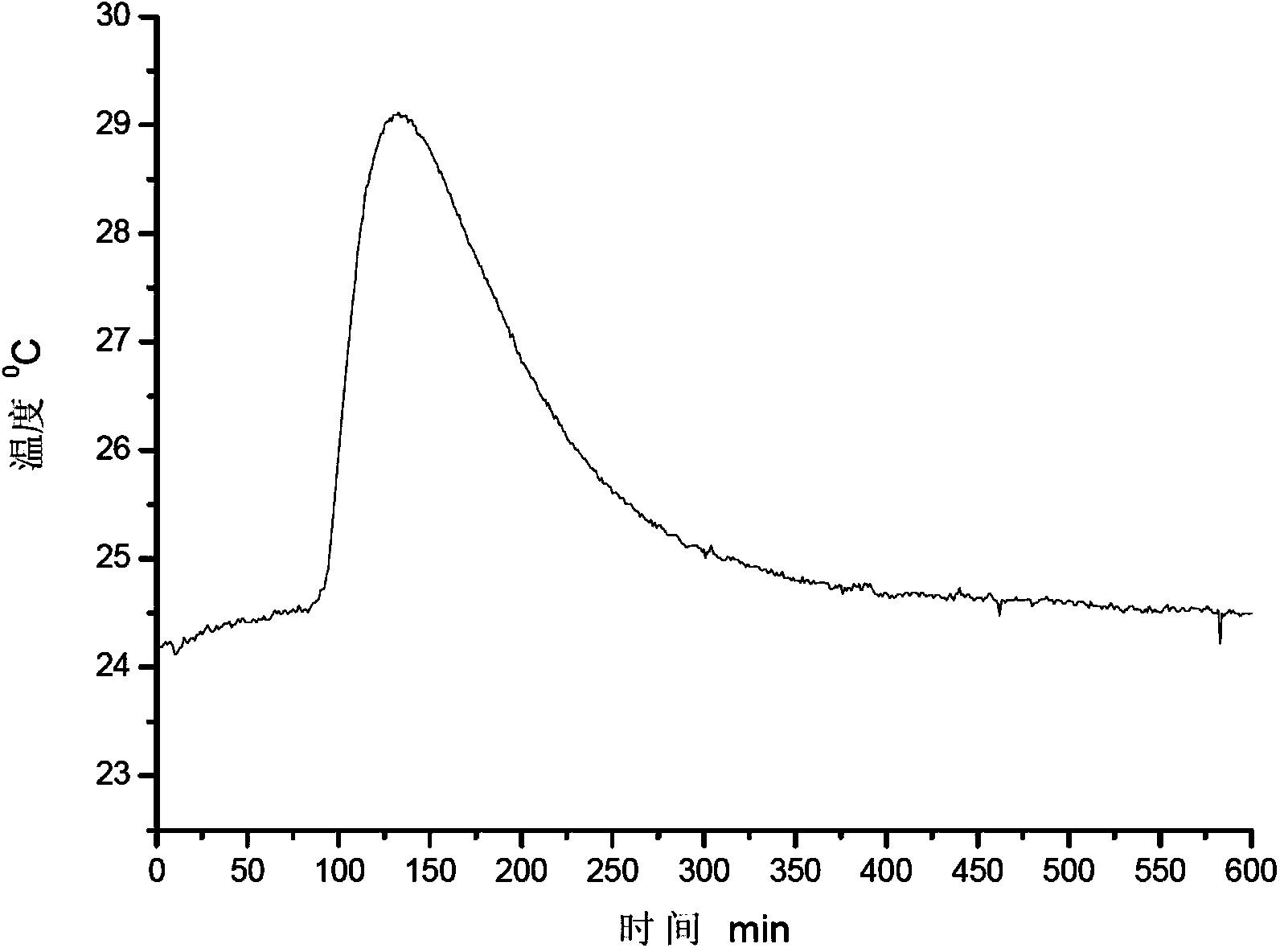

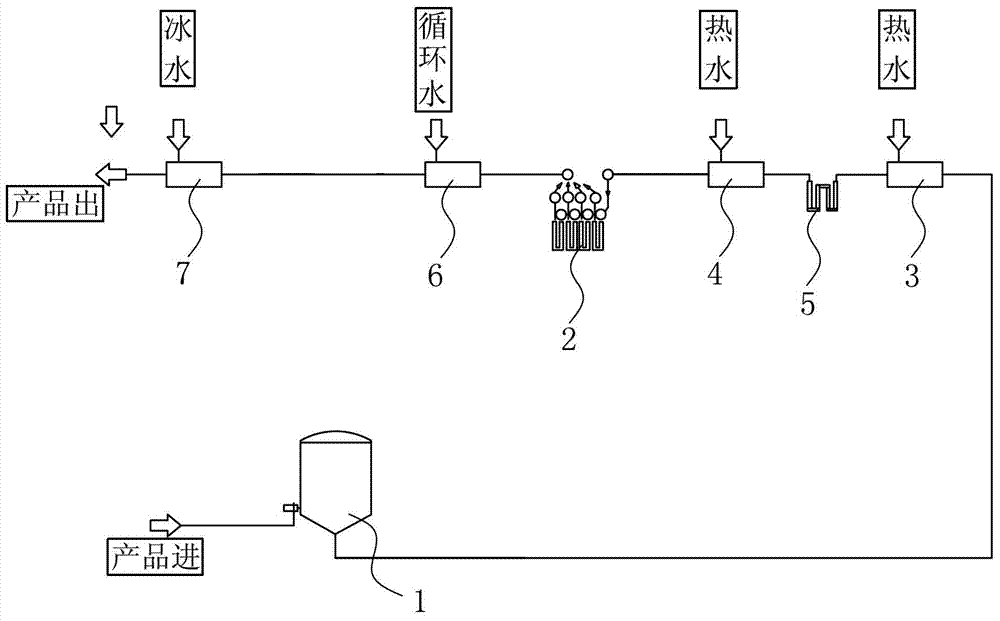

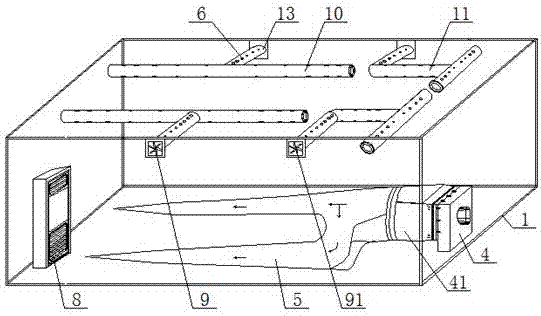

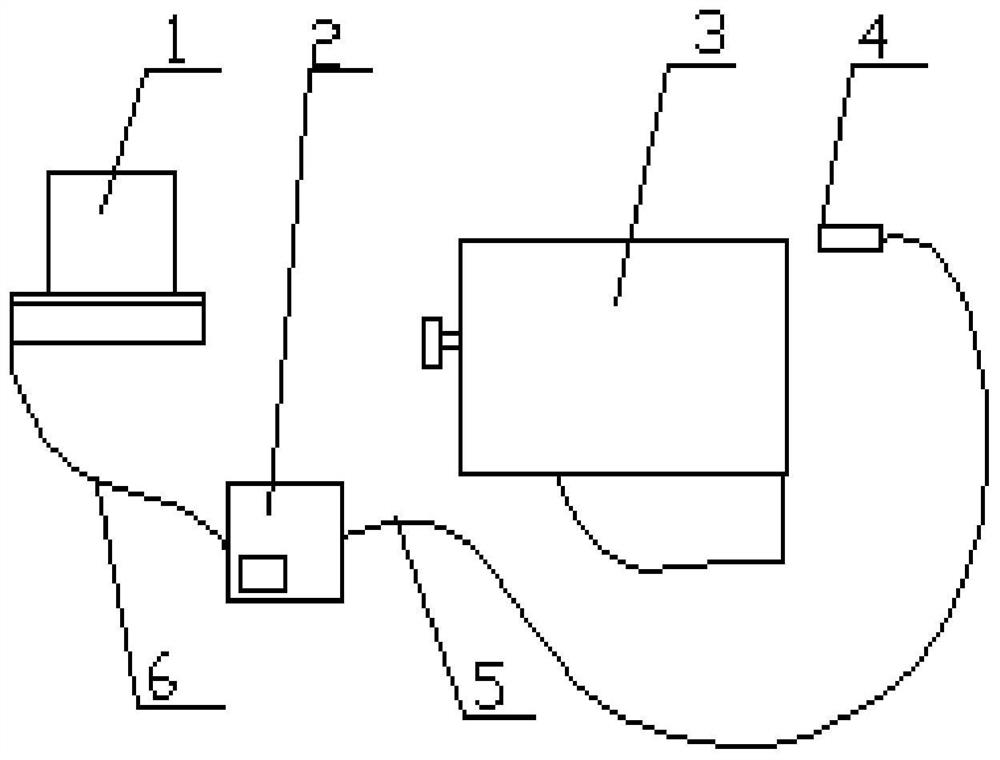

Tubular Maillard reaction equipment

ActiveCN103480312AEnsure consistencyStable reaction temperatureFood shapingChemical/physical/physico-chemical processesMaillard reactionProcess engineering

The invention discloses tubular Maillard reaction equipment, which is characterized by comprising a material storage tank, a heating part, a Maillard reaction part, a cooling part and a conveying pipeline for connecting all the components, wherein a raw material inlet and a material outlet are formed in the material storage tank; the material outlet is connected with the heating part through one of the conveying pipeline; heated materials are conveyed to the inside of the Maillard reaction part through the conveying pipeline; the Maillard reaction part is formed by a Maillard reaction pipeline provided with a heat preservation layer; the materials after reaction are conveyed to the inside of the cooling part through the conveying pipeline; cooled products are conveyed out of the equipment through the conveying pipeline; at least a flow meter is arranged on the conveying pipeline; the length value of the Maillard reaction pipeline is equal to the product of the material flow velocity and the flow through time. According to the invention, the continuous Maillard reaction manner is realized, the consistency and stability of reaction speed and reactants are improved, the production cost is reduced, and the tubular Maillard reaction equipment is applicable to the requirements of various kinds of Maillard reaction processing.

Owner:GEA PROCESS ENG ASIA LTD

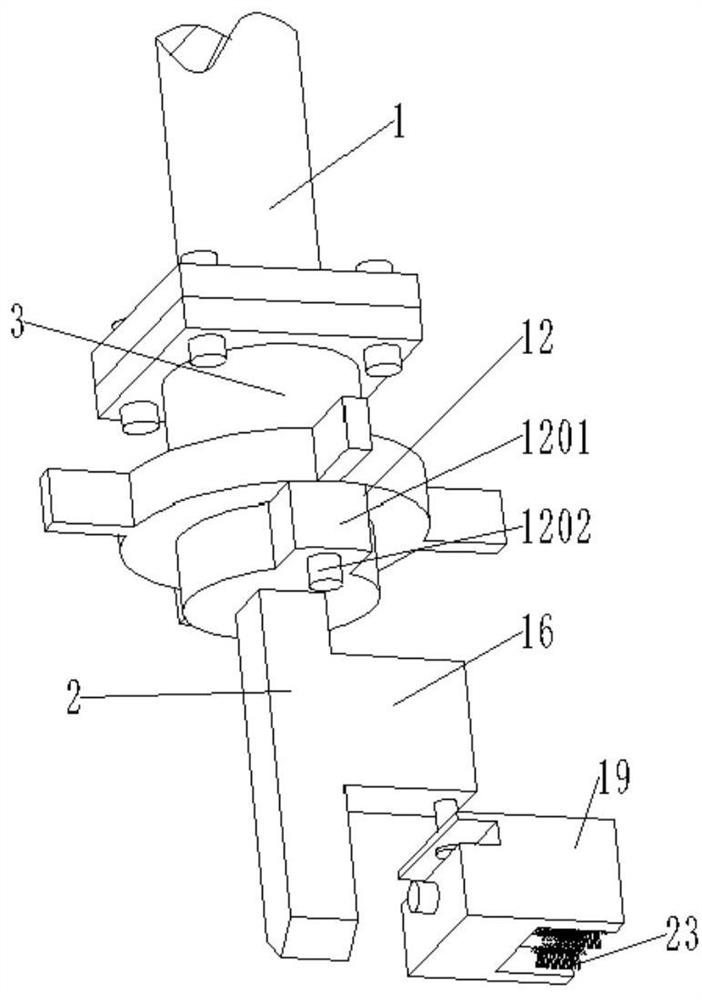

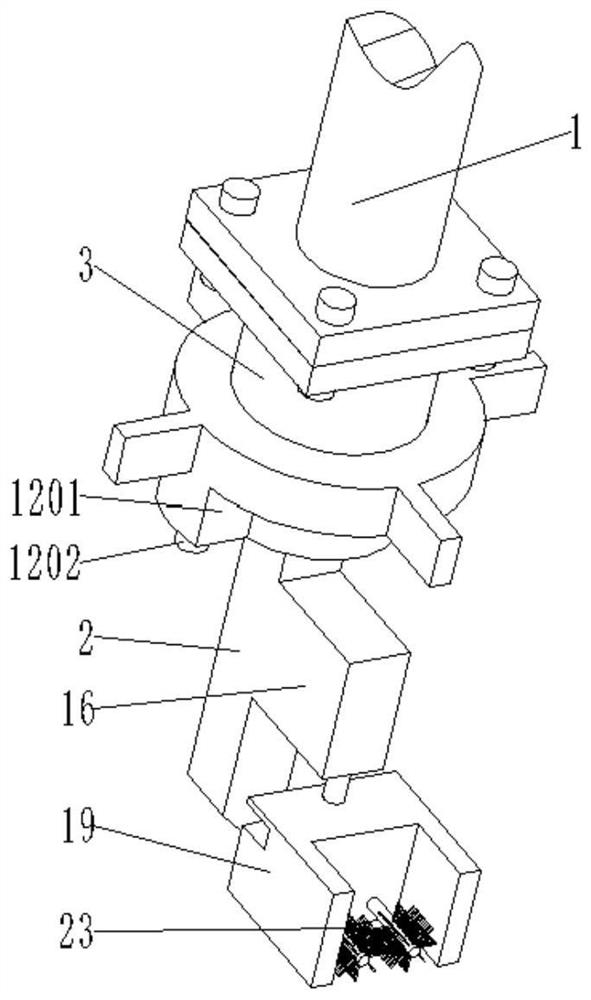

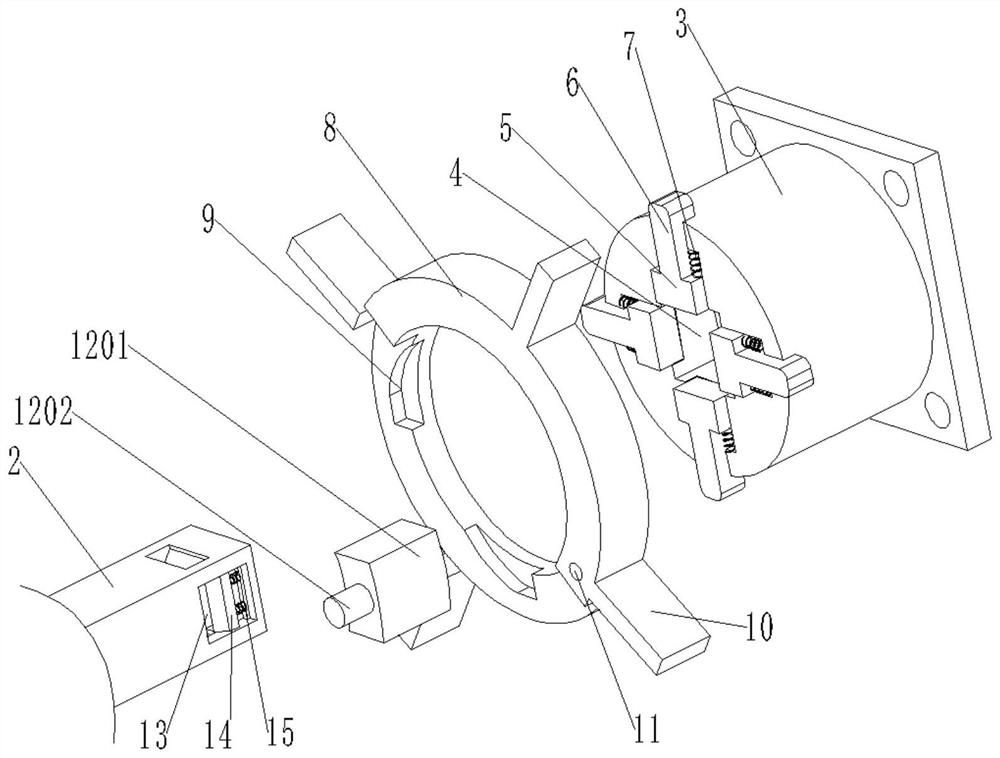

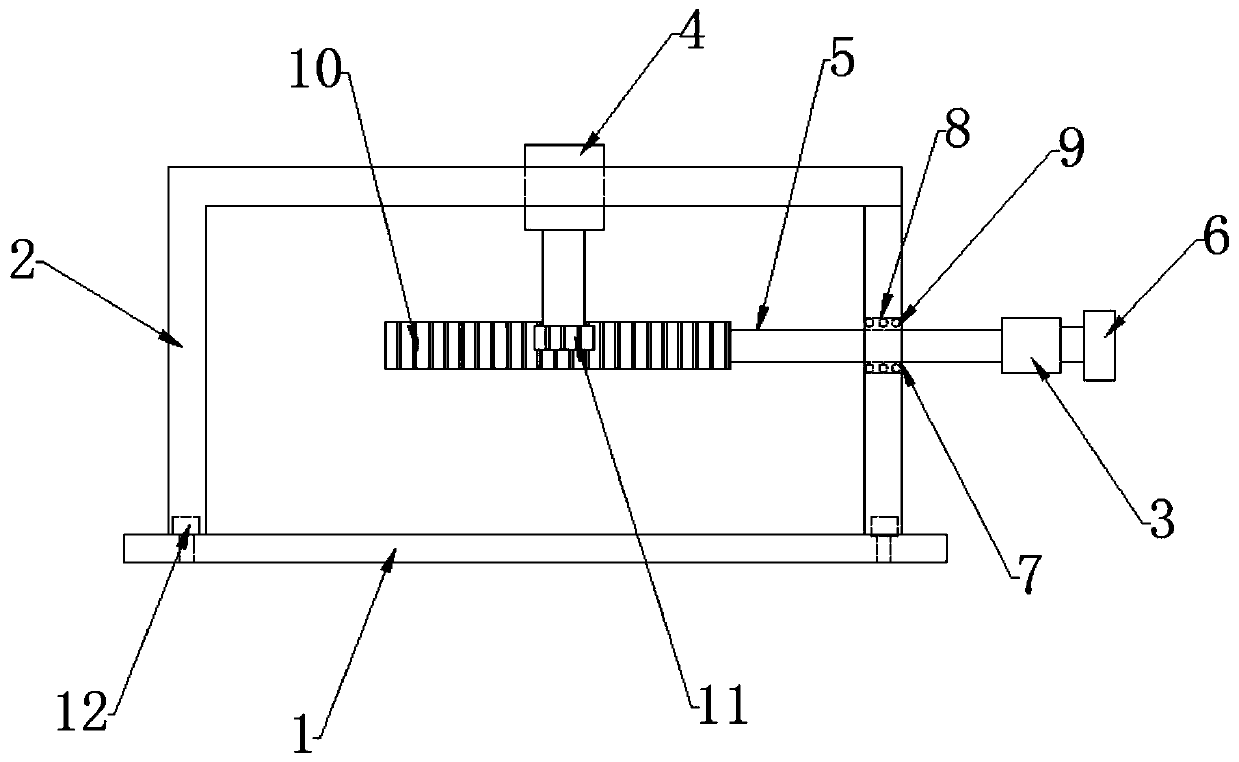

Turning tool structure of steel bar friction welding machine

InactiveCN111922367AGuarantee the quality of workEasy to removeAuxillary equipmentTurning toolsFriction weldingGear wheel

The invention discloses a turning tool structure of a steel bar friction welding machine. According to the turning tool structure, a turning tool connecting structure, a fixing block, a transmission gear set and a removing brush are arranged; after a turning tool on the steel bar welding machine is subjected to convex edge cutting work, residues left on a blade can be well removed, a worker does not need to wipe the residues with hands, convenience is brought to the worker, safety guarantee is provided, the working efficiency is improved, then the working quality of steel bar machining and production is guaranteed, and the working economic benefits are guaranteed; a connecting column is connected and fixed to the turning tool, convenience is provided for later maintenance, repair and replacement work of the turning tool, rapid fixing and assembling of the turning tool are guaranteed, and the production and working efficiency is guaranteed; and in addition, a locking mechanism is arranged, and therefore the firmness and stability of connection and fixing of the turning tool can be guaranteed.

Owner:绍兴市知凡机械有限公司

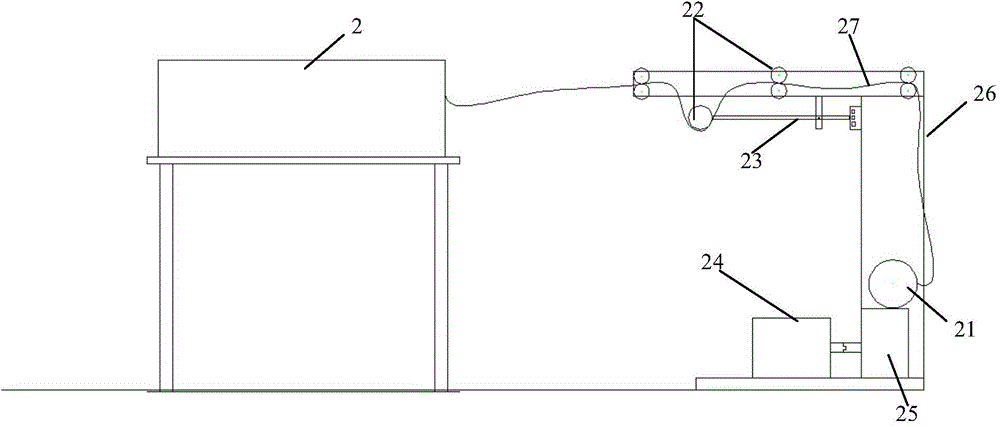

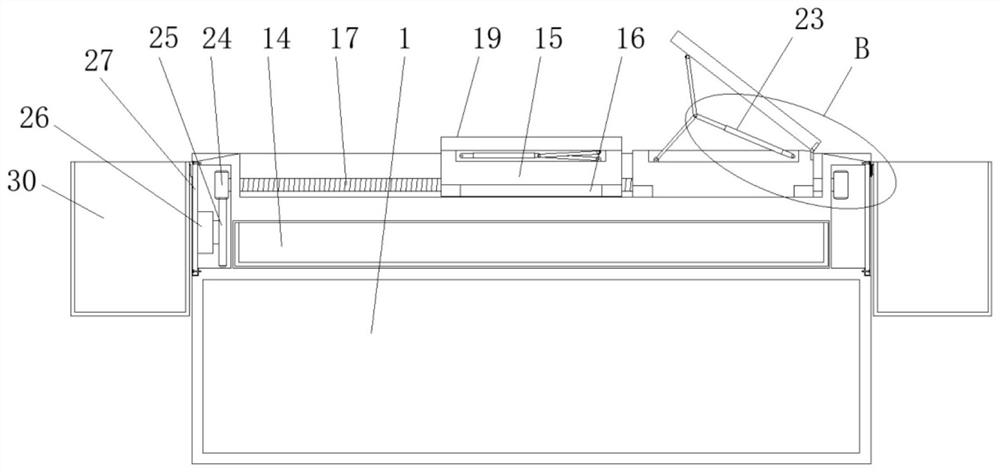

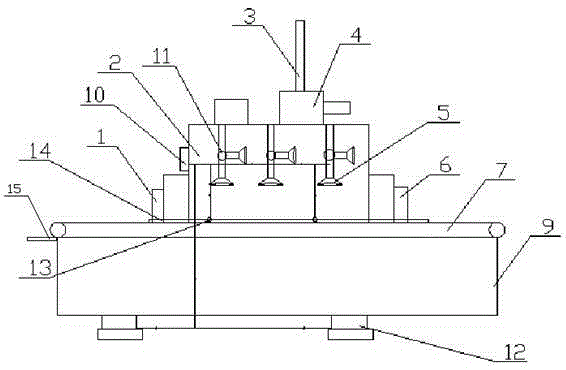

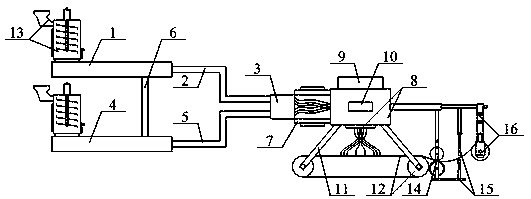

Tinned copper belt production line for solar cell module

ActiveCN104966765AEnsure production efficiencyEnsure production qualitySemiconductor/solid-state device testing/measurementFinal product manufactureTinningWinding machine

The invention relates to a tinned copper belt production line for a solar cell module, and the production line sequentially comprises a feeding mechanism, a bright annealing furnace, a calendar, a tinning furnace and a winding machine in a feeding direction. The production line employs the automatic feeding mechanism to replace manual regulation for feeding, and guarantees the production efficiency and quality. A tin furnace in the tinning equipment employs an inclined bottom design. Because there is temperature difference between tin and water, stannic oxide can move to a low temperature side far from a heating part, and flows to a residue collection basket for collection, thereby guaranteeing the production quality. The winding machine in the production line serves as a compound winding detection device, is simple in structure, is easy to operate, can quickly and accurately detect whether a tinned copper belt has impurities or not, and guarantees the quality of a tinned copper belt.

Owner:TAICANG JUREN PV MATERIAL

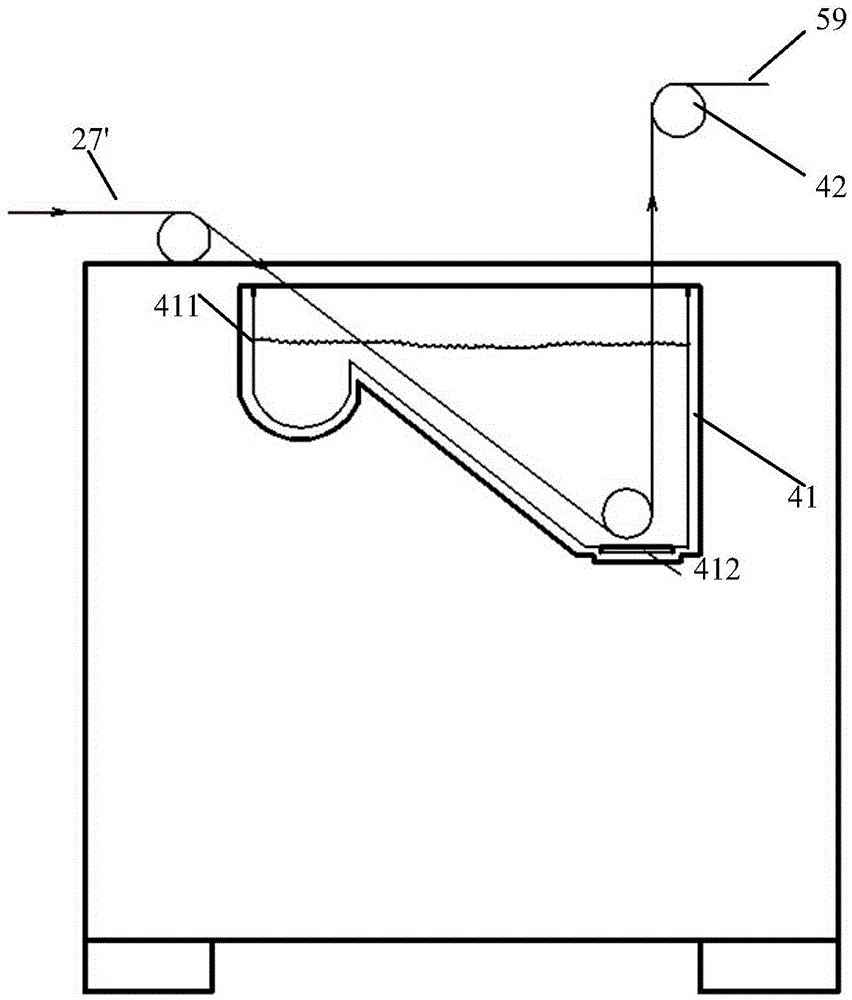

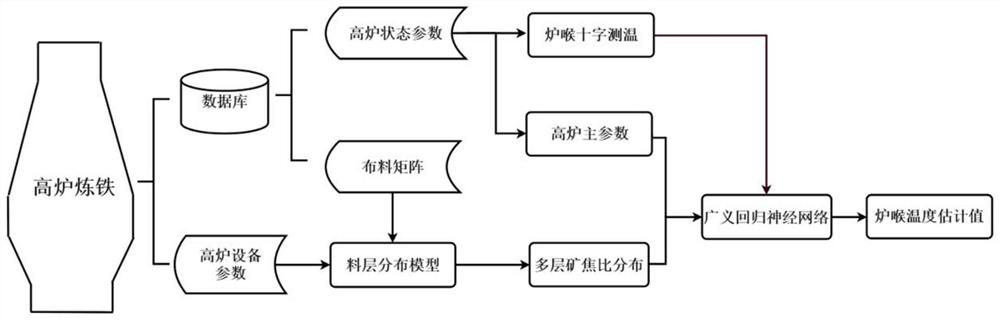

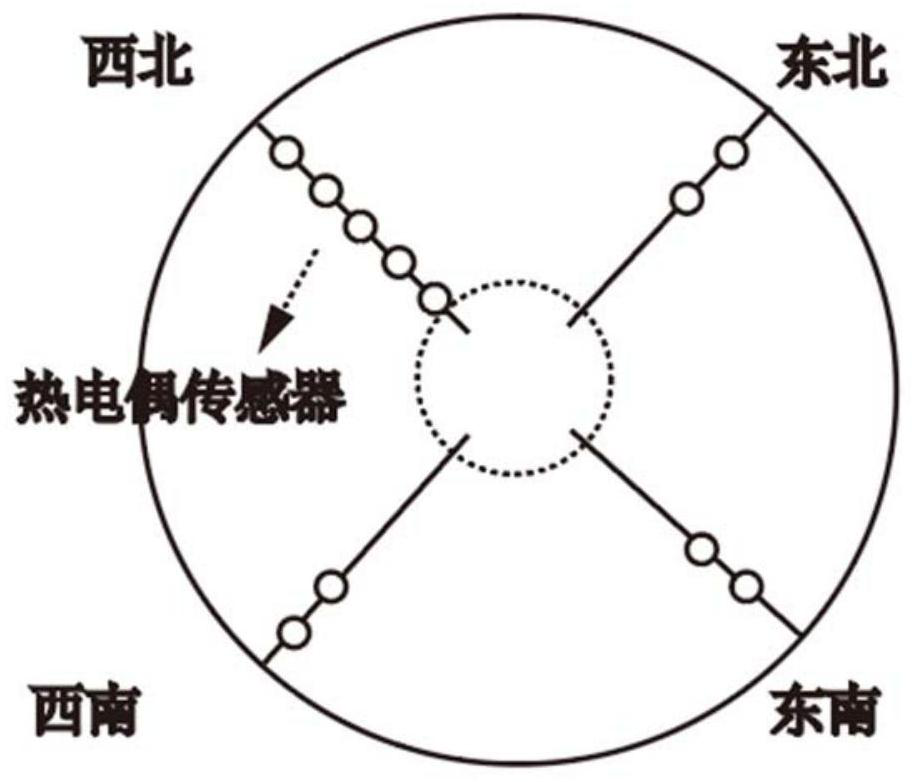

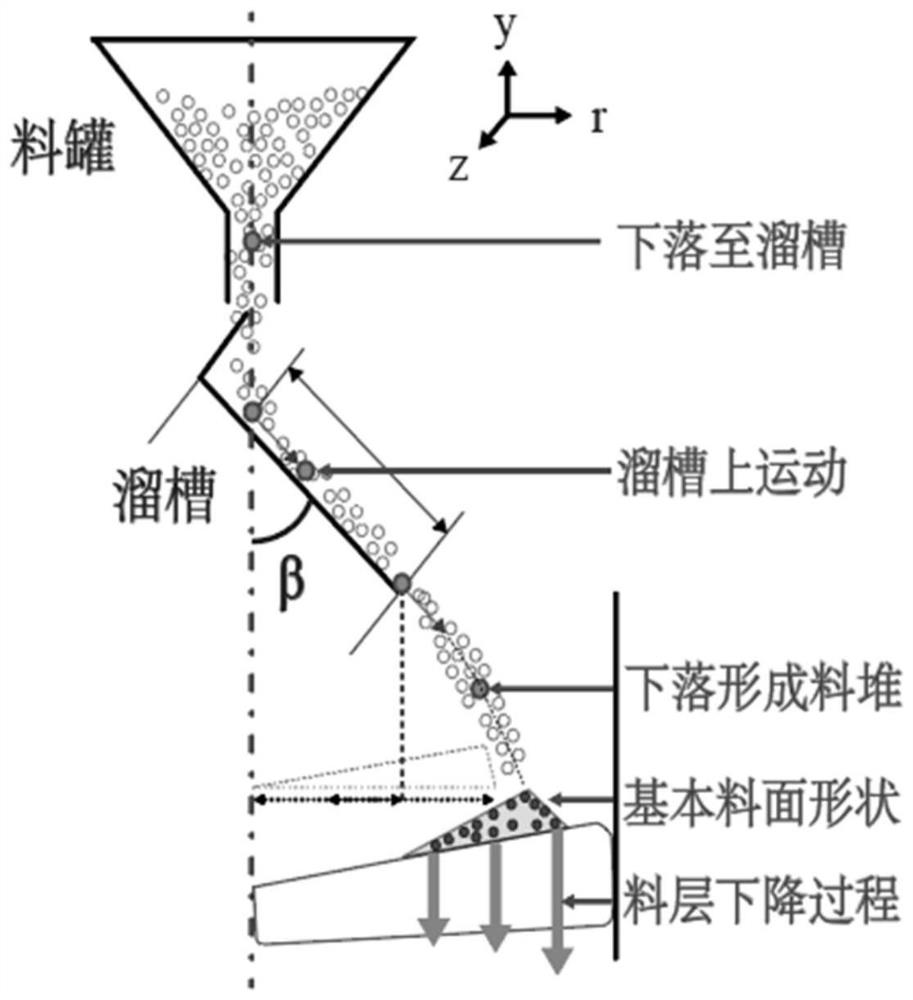

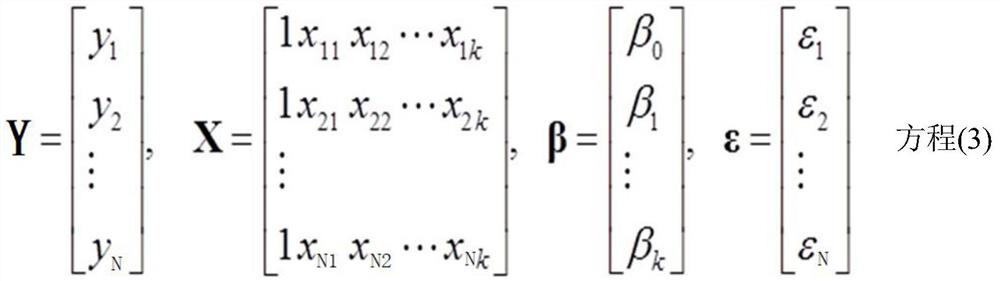

Blast furnace throat temperature estimation method based on multilayer ore-coke ratio distribution model

ActiveCN113139275AEffective monitoring of operationsAchieve estimatesSteel manufacturing process aspectsBlast furnace detailsDynamic monitoringBlast furnace smelting

The invention discloses a blast furnace throat temperature estimation method based on a multilayer ore-coke ratio distribution model. According to the method, blast furnace equipment parameters and a material distribution matrix are utilized, the material surface shape of each layer is calculated according to the material distribution movement process, a material layer distribution model is established in combination with the descending process, and the ore-coke ratio of each material layer is obtained. According to the method, multi-layer ore-coke ratio distribution and main parameters of a blast furnace are used as input, a generalized regression neural network is used for estimating the temperature of a furnace throat temperature measurement corresponding position, and furnace throat temperature monitoring in the blast furnace smelting process is achieved. According to the blast furnace operation data, the in-furnace material layer distribution structure is established, the influence of the multi-layer ore-coke ratio in the furnace top gas flow distribution forming process is considered, and estimation of the furnace throat temperature is achieved. In the production and operation process of the blast furnace, when the furnace throat temperature measuring device breaks down or needs to be replaced, the temperature estimation method provided by the invention can keep high-precision, effective and dynamic monitoring on the furnace throat temperature, and normal production is ensured.

Owner:ZHEJIANG UNIV

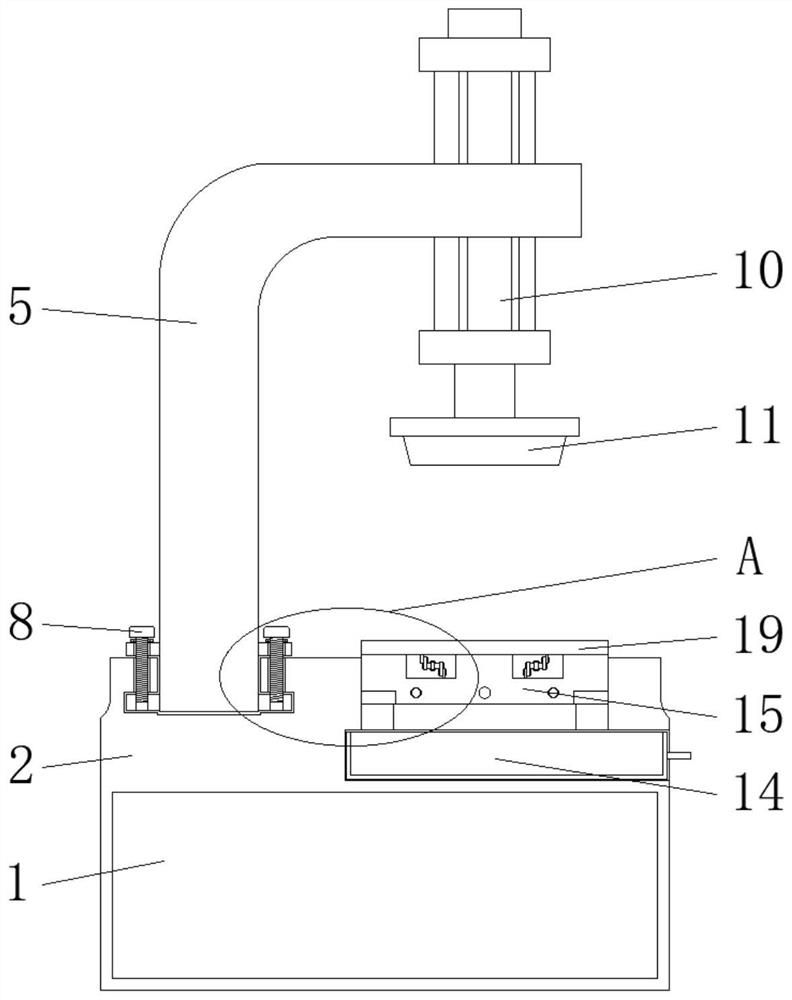

Hot press capable of realizing automatic discharging for thin-film capacitor production

ActiveCN112420406ASafe and stable unloading useRapid serial productionCapacitor manufactureCapacitanceThin membrane

The invention discloses a hot press capable of realizing automatic discharging for thin-film capacitor production. The hot press comprises a cabinet, a heating plate, a screw rod, a telescopic rod anda gliding tabletop, a worktable is fixed on the top end surface of the cabinet, a slideway is formed in the left side of the top end of the cabinet, a connecting hole is formed in the outer side of the slideway, and a supporting column is connected to the inner side of the slideway; a fixing plate is arranged on the outer side of the bottom of the supporting column, a fixing bolt is connected tothe inner side of the fixing plate, a sliding groove located in the top of the workbench is formed in the lower portion of the heating plate, a table plate is arranged in the sliding groove, a bottomplate is fixed to the bottom end of the table plate, and a first supporting rod is connected to the inner side of the base plate. And the top end of the screw rod is connected with a transmission wheel. According to the hot press capable of achieving automatic discharging and used for thin-film capacitor production, adjusting operation can be conducted, discharging and using can be conducted safely and stably, rapid continuous production operation can be conducted conveniently, and the production operation efficiency can be guaranteed.

Owner:扬州日精电子有限公司

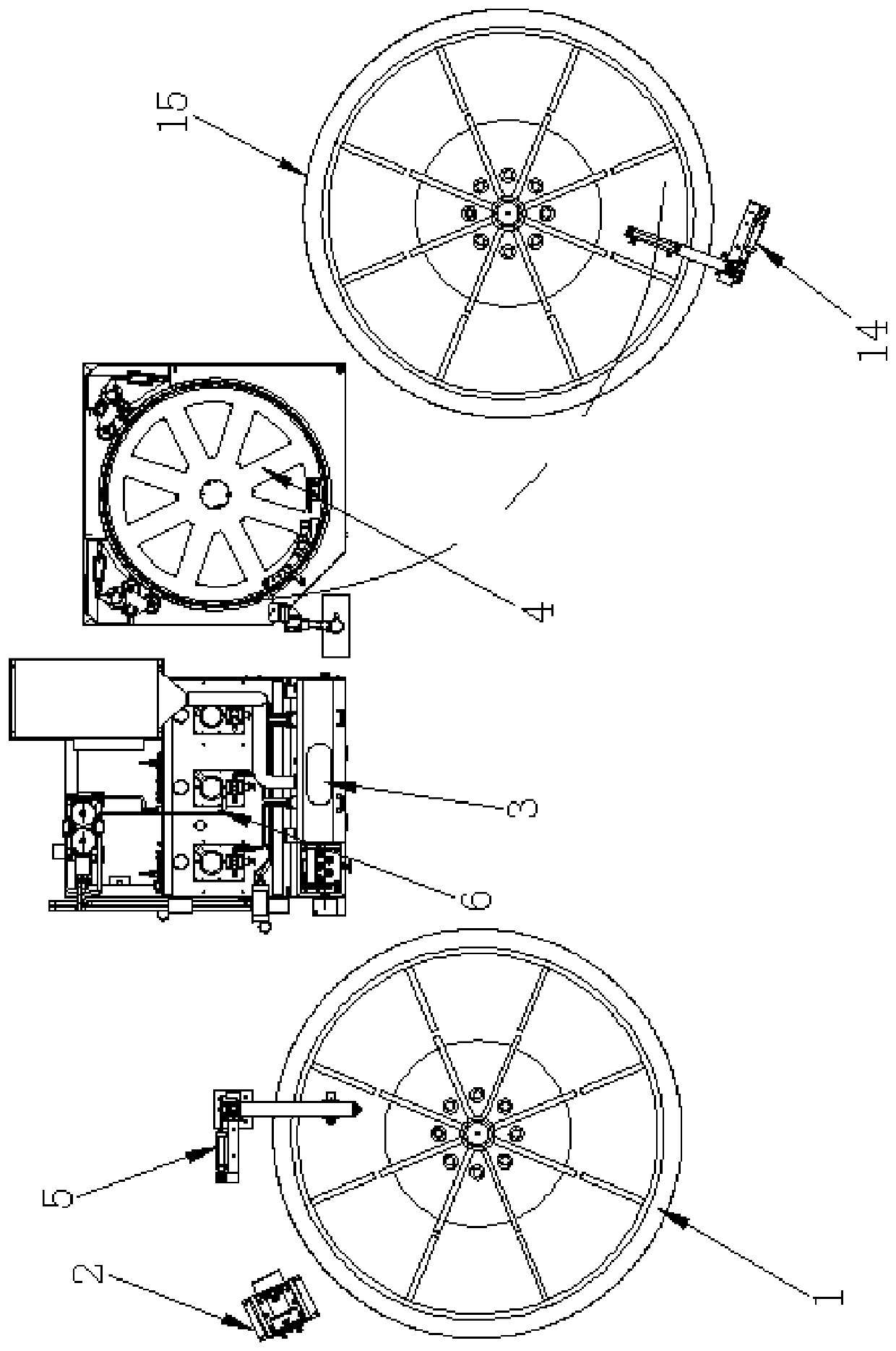

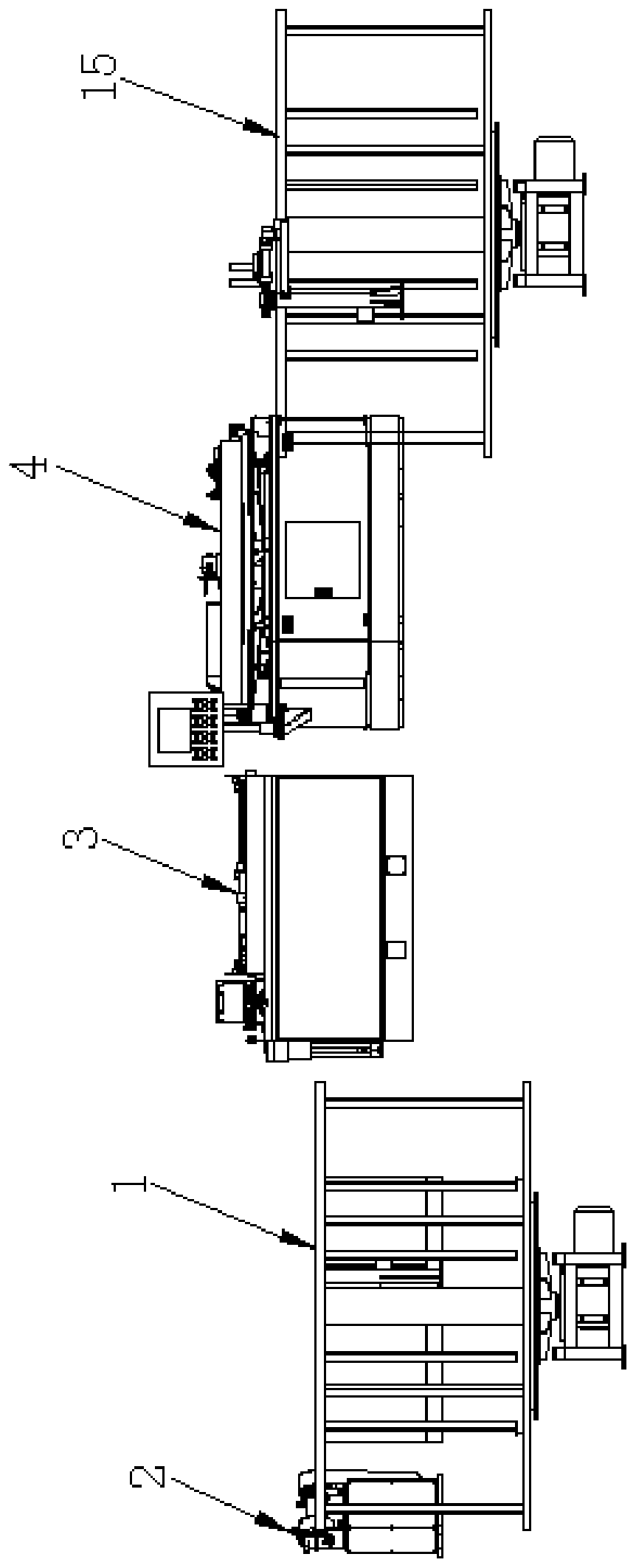

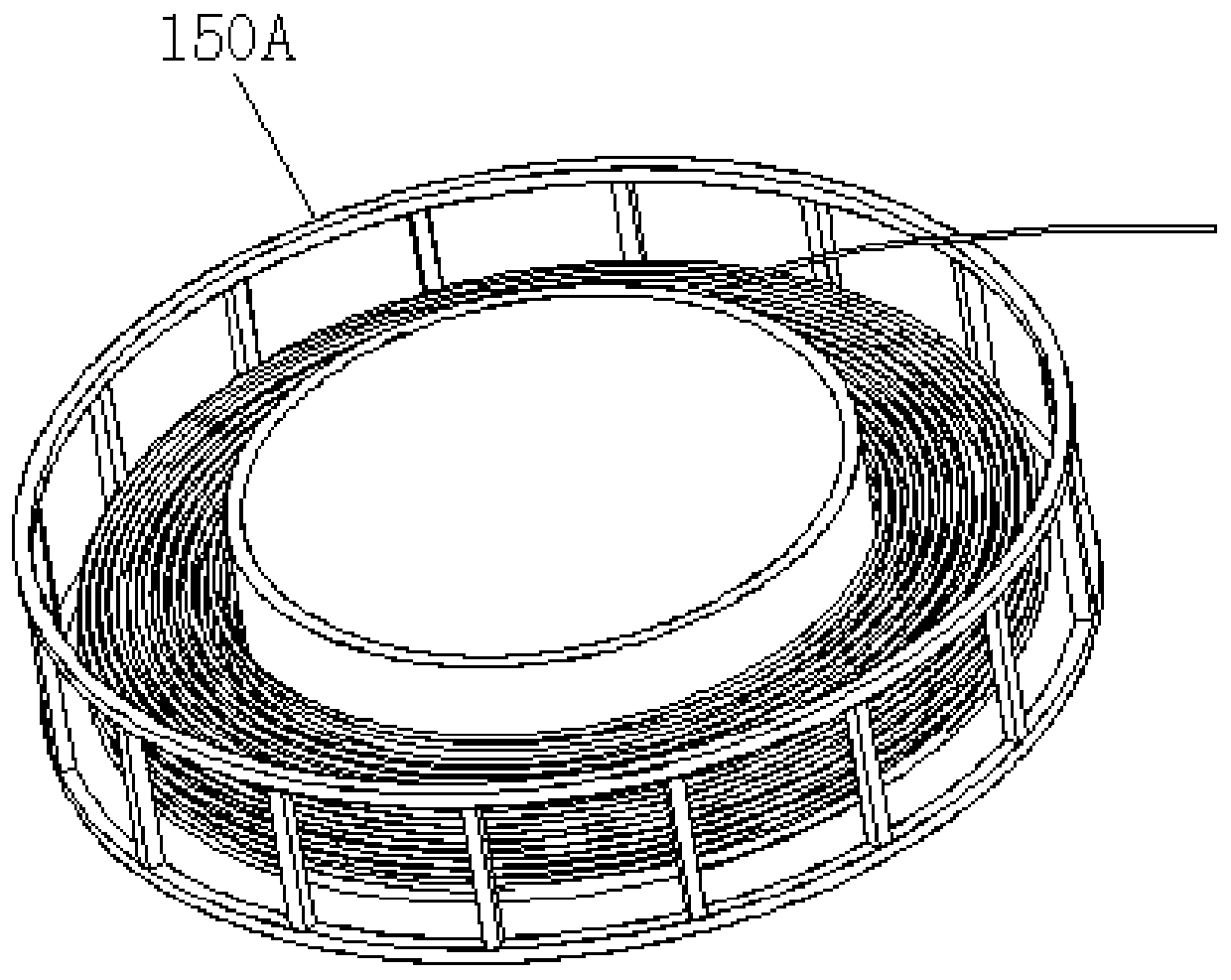

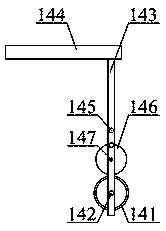

Internal threaded pipe forming and receiving integrated production line

The invention discloses an internal threaded pipe forming and receiving integrated production line. The production line comprises a placement device for receiving and releasing a metal hollow pipe tobe machined, a rotary forging head making machine for extruding the head section of the pipe into a solid shape, a spinning forming machine for performing internal thread forming machining on the pipeobtained after head making machining is performed, and a drawing device for performing drawing treatment on the pipe obtained after internal thread forming is performed. Particularly, the productionline further comprises a straightening device for performing straightening treatment on the pipe obtained after drawing treatment is performed, a length measuring device for measuring the length of the straightened pipe, a tension device for performing tension drawing treatment on the straightened pipe, a forming device for bending the pipe, and a take-up device for performing take-up operation onthe pipe. The production line can machine the pipe into a regular coil pipe, a user can conveniently use the pipe finally, and the yield and the production efficiency of the pipe are effectively ensured.

Owner:SUZHOU AOZHI INTELLIGENT EQUIP CO LTD

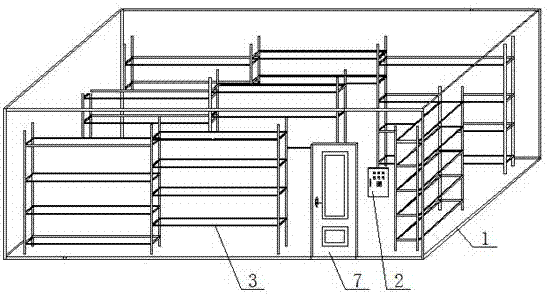

Rapid reduced pressure drying room for venenum bufonis and drying method of venenum bufonis

ActiveCN107456773AReasonable structureEasy to set upAmphibian material medical ingredientsFood processingEngineeringSlurry

The invention discloses a rapid reduced pressure drying room for venenum bufonis. The rapid reduced pressure drying room comprises a drying room body, a room door and a square round pipe, wherein the room door is hinged to the wall of the drying room body, the drying room body is of a cube shape, a two-channel cloth bag is arranged on the other terrace, an air inlet of the two-channel cloth bag is fixedly connected with a round hole of the square round pipe, and a fan heater is arranged on a square hole of the square round pipe; two exhaust fans I and two exhaust fans II are symmetrically arranged on the walls on two sides of the drying room body, the exhaust fans I are connected with horizontally arranged straight pipes through exhaust pipes, and the exhaust fans II are connected with T-shaped pipes through the exhaust pipes; and at least one goods shelf is arranged between channels of the two-channel cloth bag below the exhausting pipes and between the two-channel cloth bag and the wall close to the fan heater. The reduced pressure drying room is reasonable in structure, convenient to build, environmentally friendly, safe and easy to operate and control; and the venenum bufonis slurry on the goods shelf is subjected to rapid reduced pressure drying by virtue of the cooperation among the two-channel cloth bag, the pipelines and the exhaust fans, so that the production efficiency and quality of the venenum bufonis are guaranteed.

Owner:海门区杨一堂蟾蜍养殖场

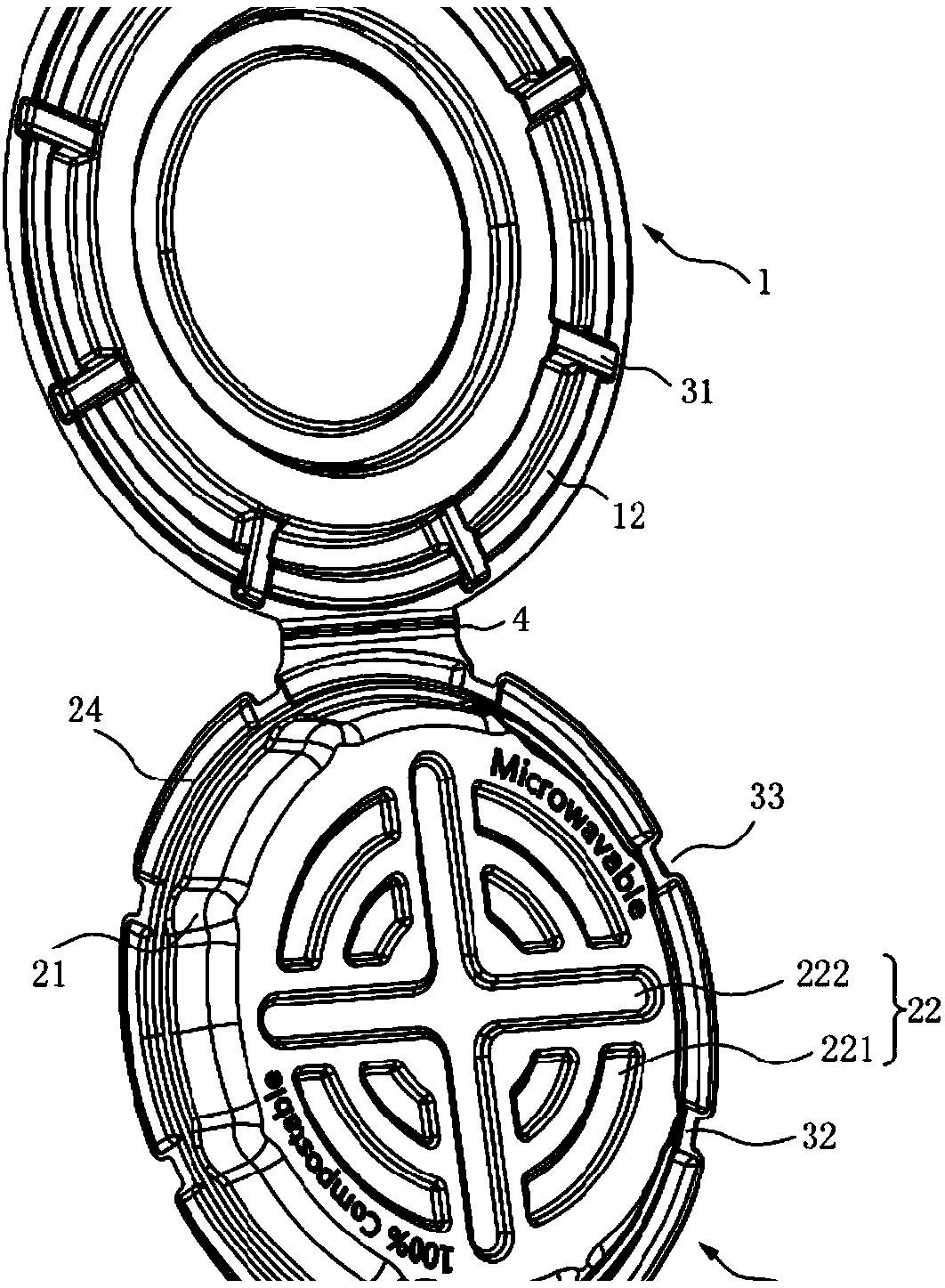

Food container and thermal forming wet press technology thereof

PendingCN108216841AAvoid spillingImprove insulation effectVenting meansContainer/bottle contructionWater vaporUltimate tensile strength

The invention relates to a food container. The food container comprises an upper cover and a box body. The upper cover is located on the top of the box body and is used for tightly covering the box body. One or more first gas guide grooves which are used for exhausting gas are formed in the outer edge of the side wall, making contact with the box body, of the upper cover, and / or one or more secondgas guide grooves which are used for exhausting gas are formed in the top wall, making contact with the upper cover, of the box body. According to the food container, hot gas exhaust holes are formedby the first gas guide grooves and second openings together, and due to the mode that the hot gas exhaust holes are formed, the phenomena that condensing water vapor in a packaging box intrudes intofood, and the original taste is damaged can be avoided. Due to the structure of the first gas guide grooves of the upper cover, the structural strength and the deformation resistance of a whole packaging box body can be conveniently improved. Compared with a food container characterized in that hot gas exhaust holes are only formed in a box body, the food container with the structure has the advantages that the structural strength of the box body can be improved, deformation is avoided, and the phenomenon that dust with the small size drops to the food from the top can be avoided.

Owner:深圳市波尔兴科技开发有限公司

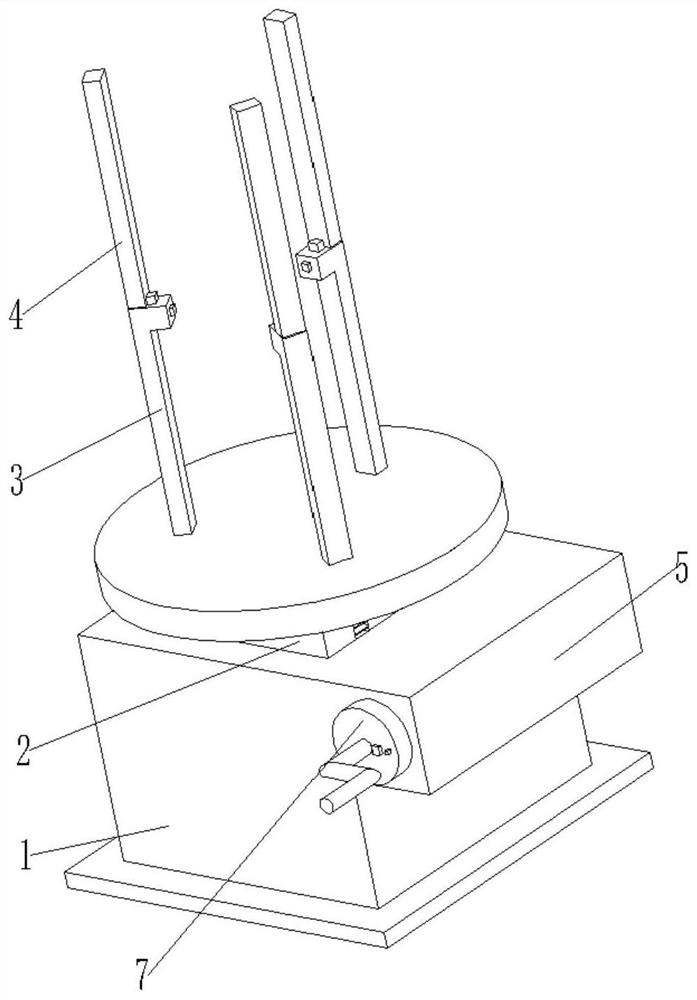

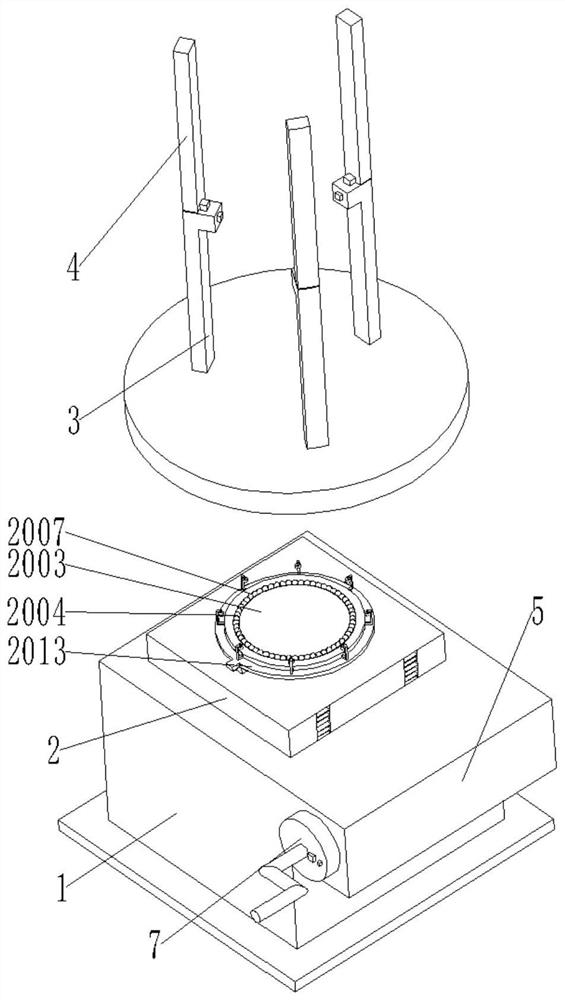

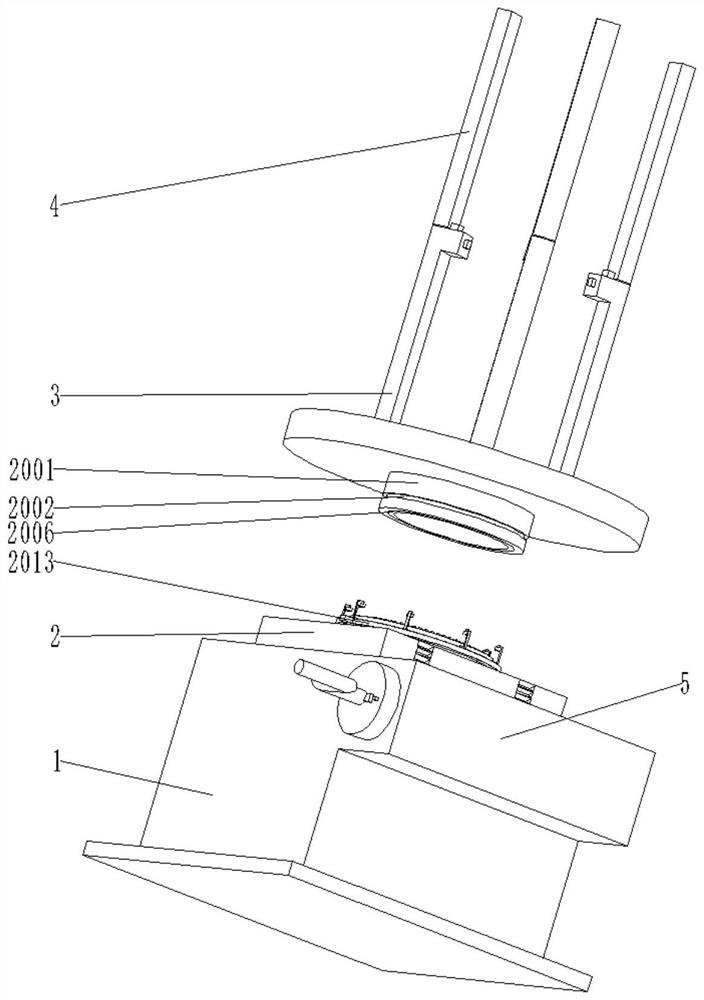

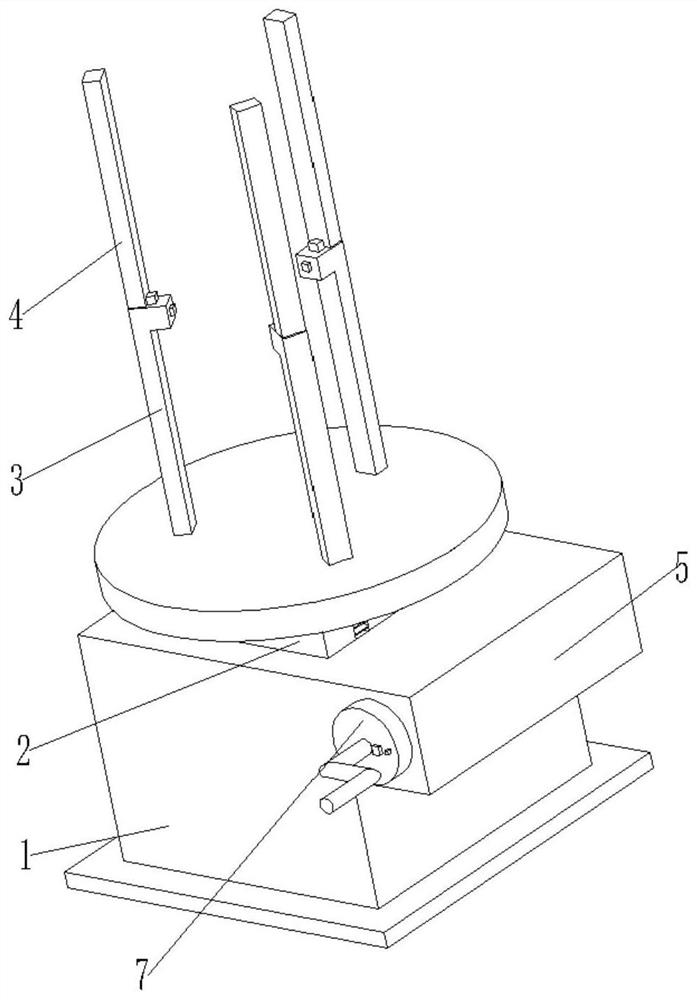

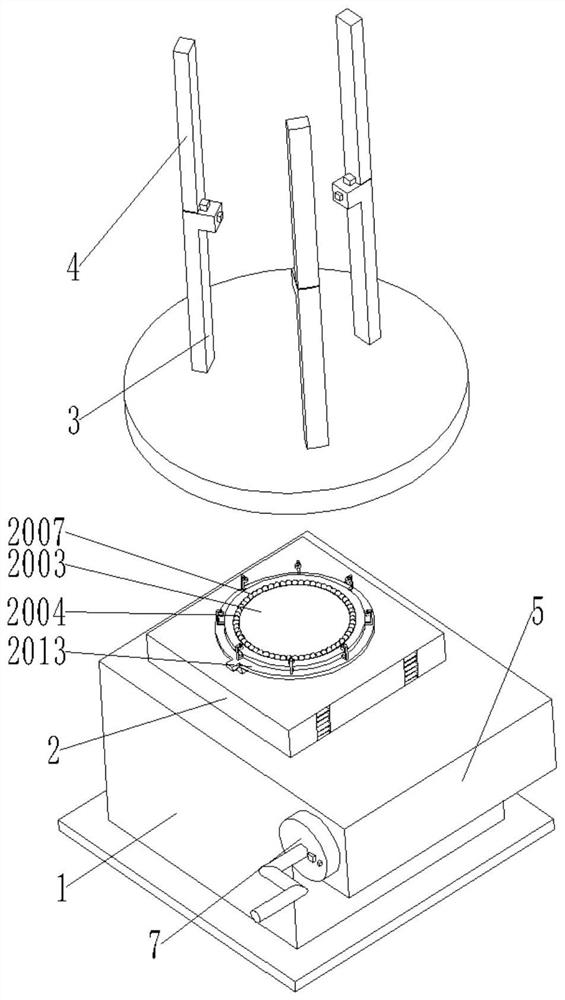

Rotary conveying device for reinforcement cage seam welding machine

ActiveCN111974908AEasy to placeGuaranteed to proceed normallyWire networkEconomic benefitsSeam welding

The invention discloses a rotary conveying device for a reinforcement cage seam welding machine. According to the rotary conveying device, by arranging a rotation mechanism, when the seam welding machine is performing the welding operation on twisted reinforcements, the twisted reinforcements can be rotationally conveyed, so that the twisted reinforcements are conveyed more smoothly, and the normal welding operation on the twisted reinforcements is ensured; in addition, by arranging a first support rod and a second support rod which are detachable, the twisted reinforcements are placed more conveniently, convenience is provided for the staff, through a telescopic body, a base and a transmission structure which are connected to the bottom end of the rotation mechanism, the position height of twisted reinforcement coils can be adjusted, then the effect that the twisted reinforcement coils are at a suitable height position is ensured, and convenience is provided for the welding operationon the twisted reinforcements, the situation that the position height of the twisted reinforcement coils decreases as the number of twisted reinforcement coils decreases during the reinforcement winding process is avoided, and then the work efficiency is improved, so that the economic benefits of production and processing are ensured.

Owner:江西博展自动化科技有限公司

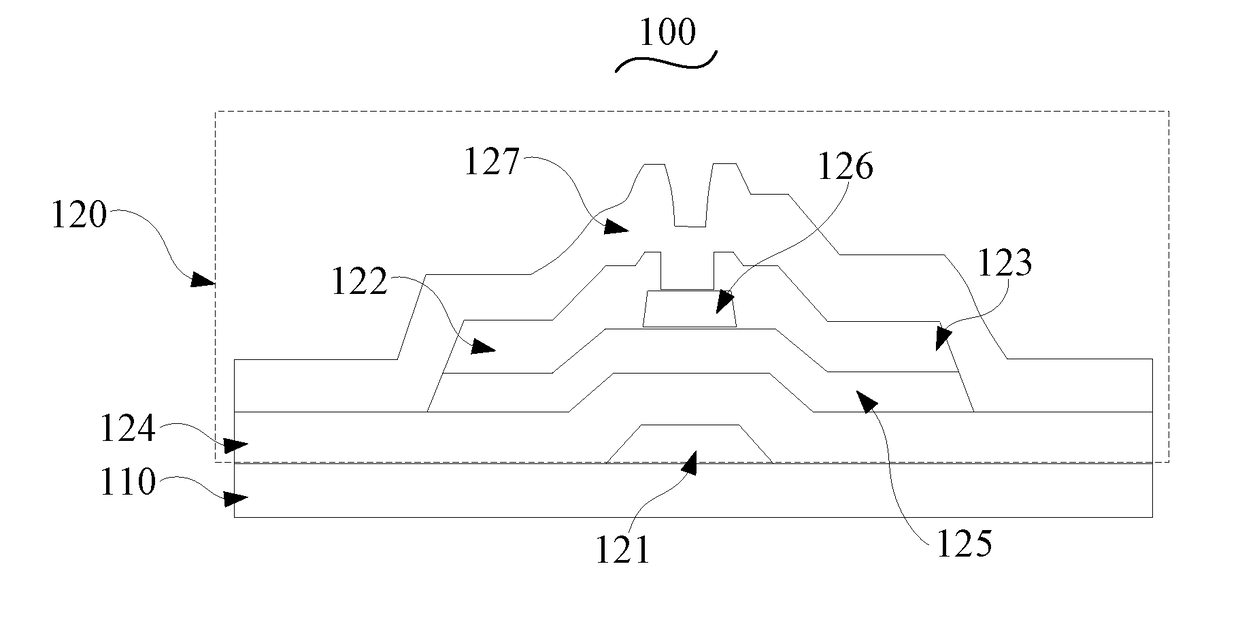

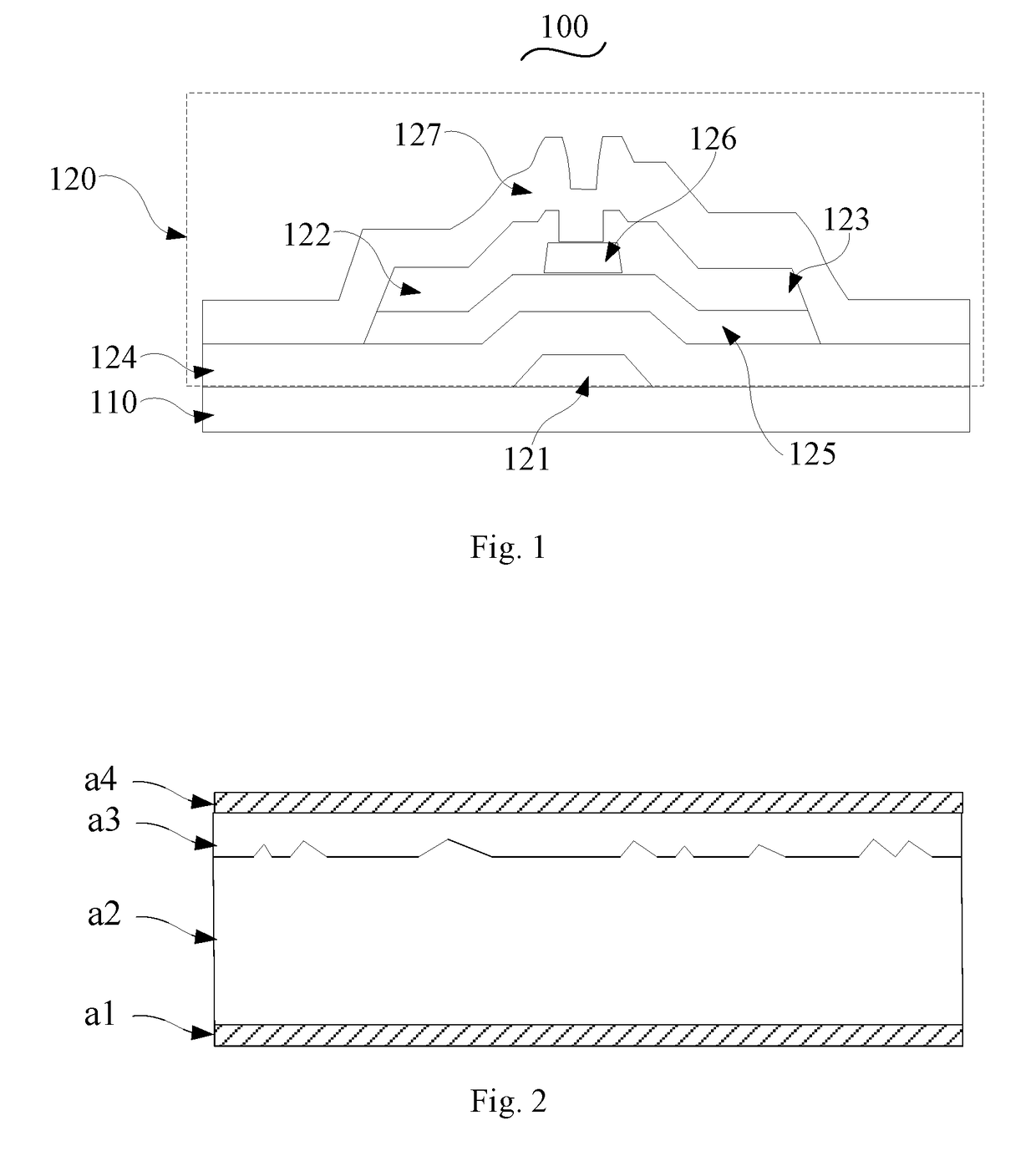

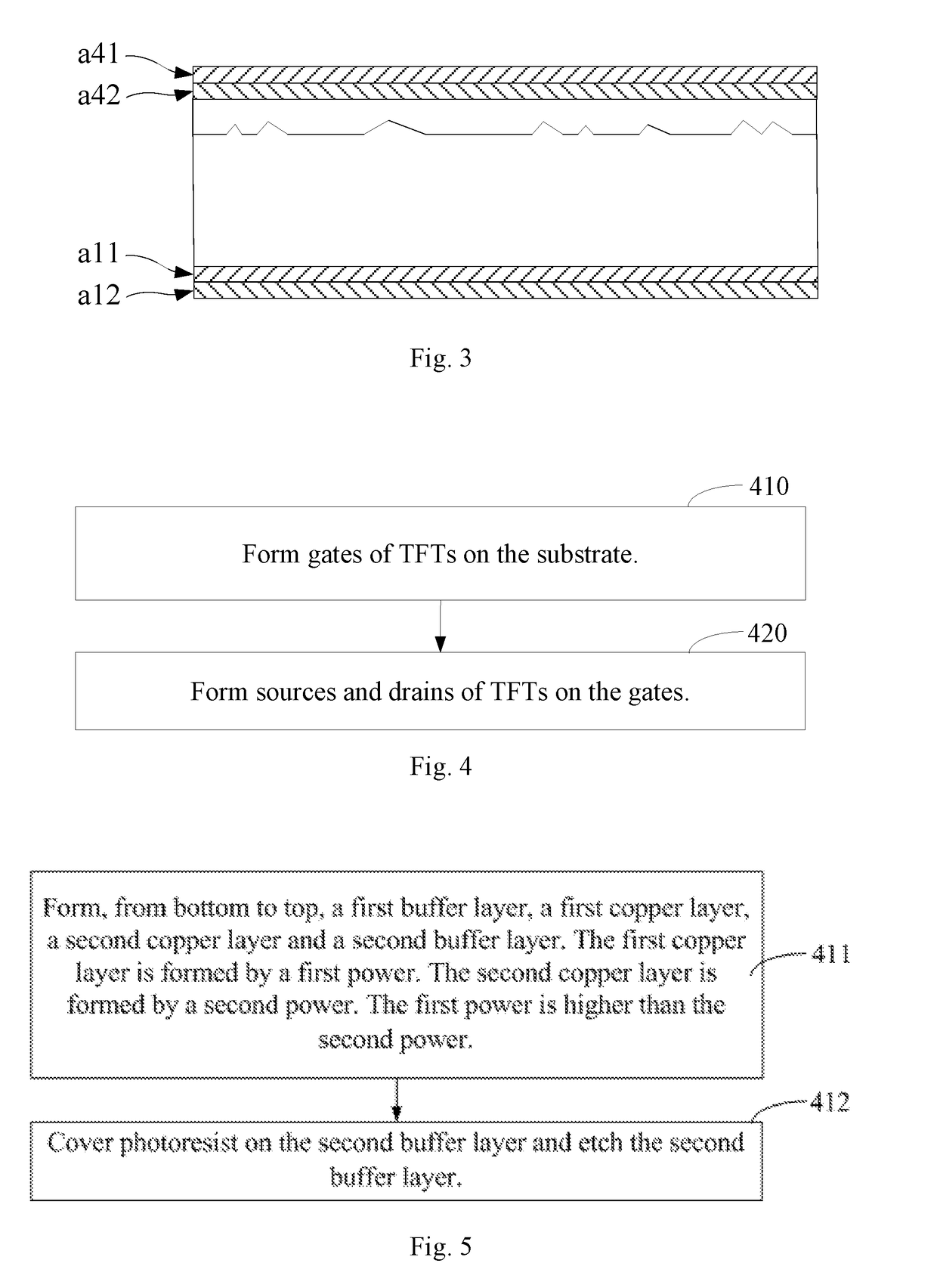

Thin Film Transistor, Array Substrate and Method of Forming the Same

ActiveUS20170125449A1Ensures evennessEnsures smoothness of surfaceTransistorSolid-state devicesOptoelectronicsCopper

The present disclosure proposes a TFT. The source and the drain of the TFT are disposed on the same side as the gate. The gate includes a first buffer layer, a first copper layer, a second copper layer and a second buffer layer that are stacked from bottom to top, and the second buffer layer is disposed on the side that is close to the source and drain. The source and drain include a first buffer layer, a first copper layer, a second copper layer and a second buffer layer that are stacked, and the first buffer layer is disposed on the side that is close to the gate. The first copper layer is deposited by a first power, the second copper layer is deposited by a second power lower than the first power. Through the above method, it is prevents photoresist from shedding when etching.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

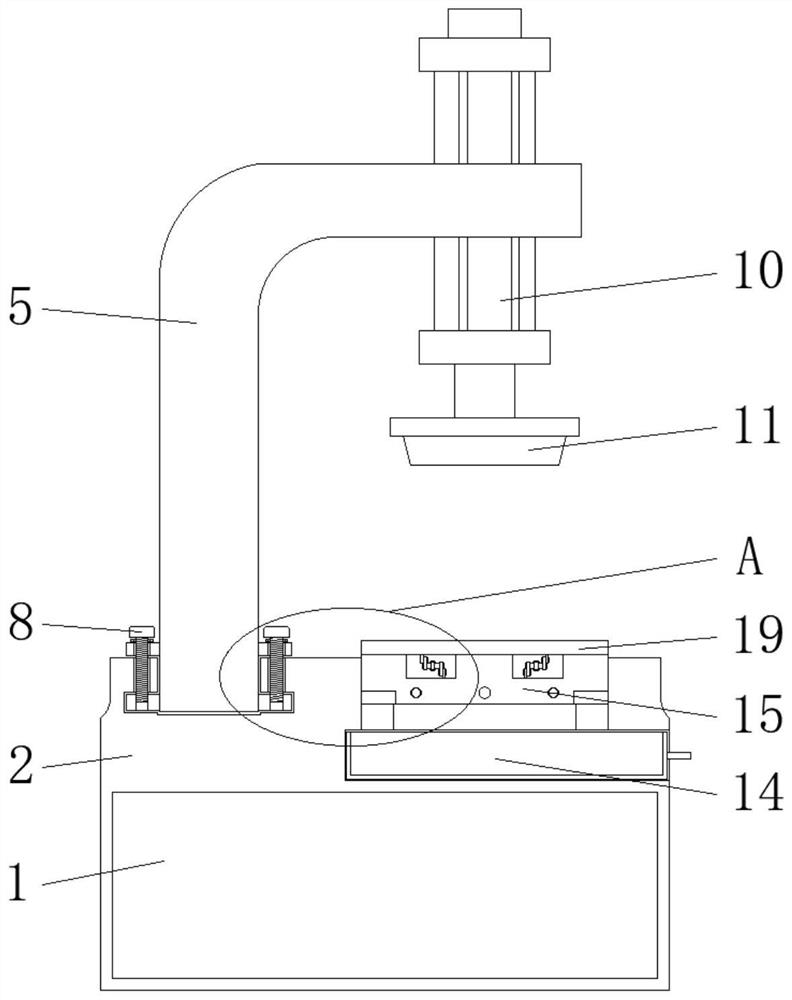

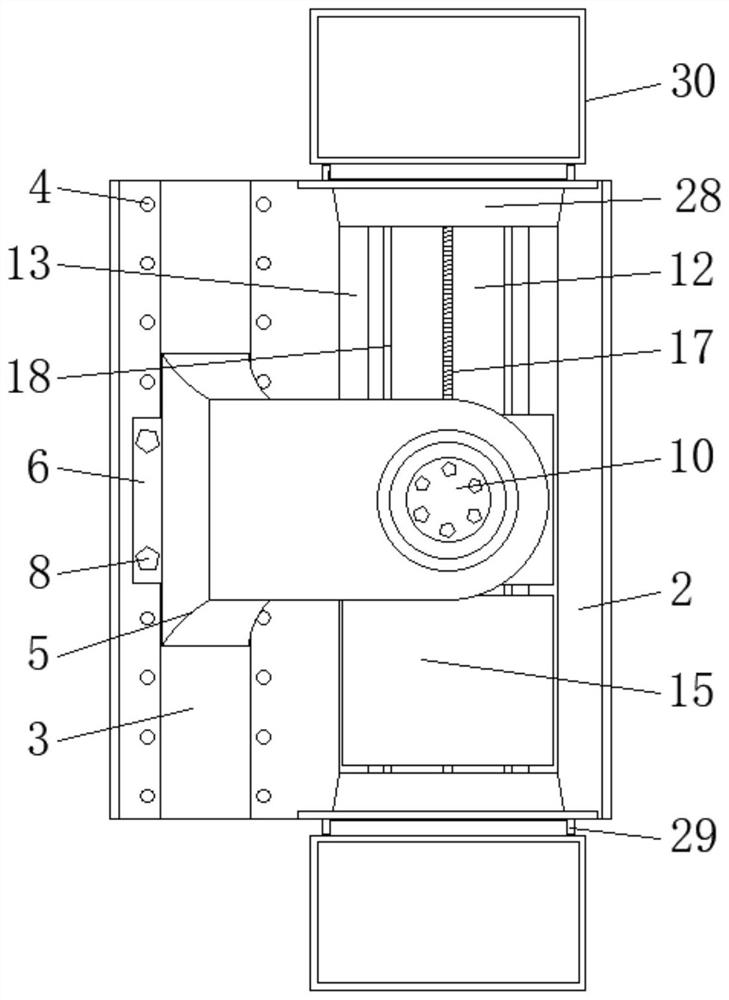

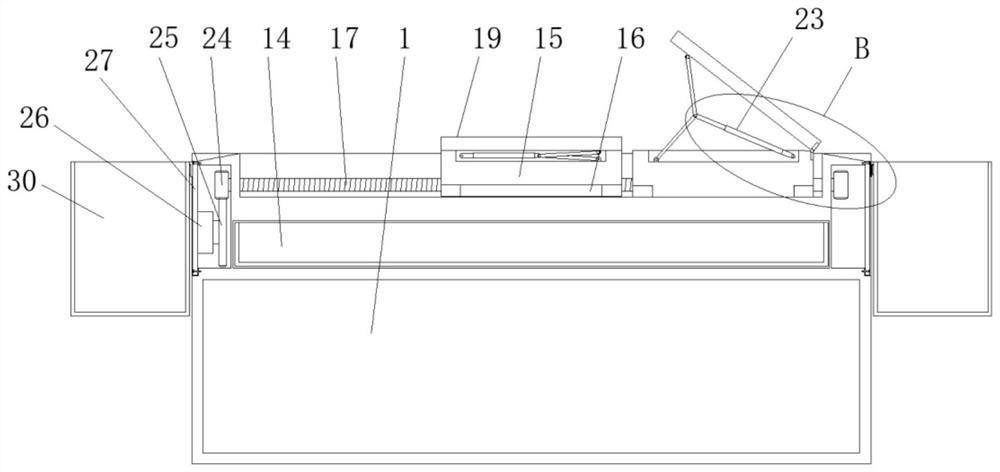

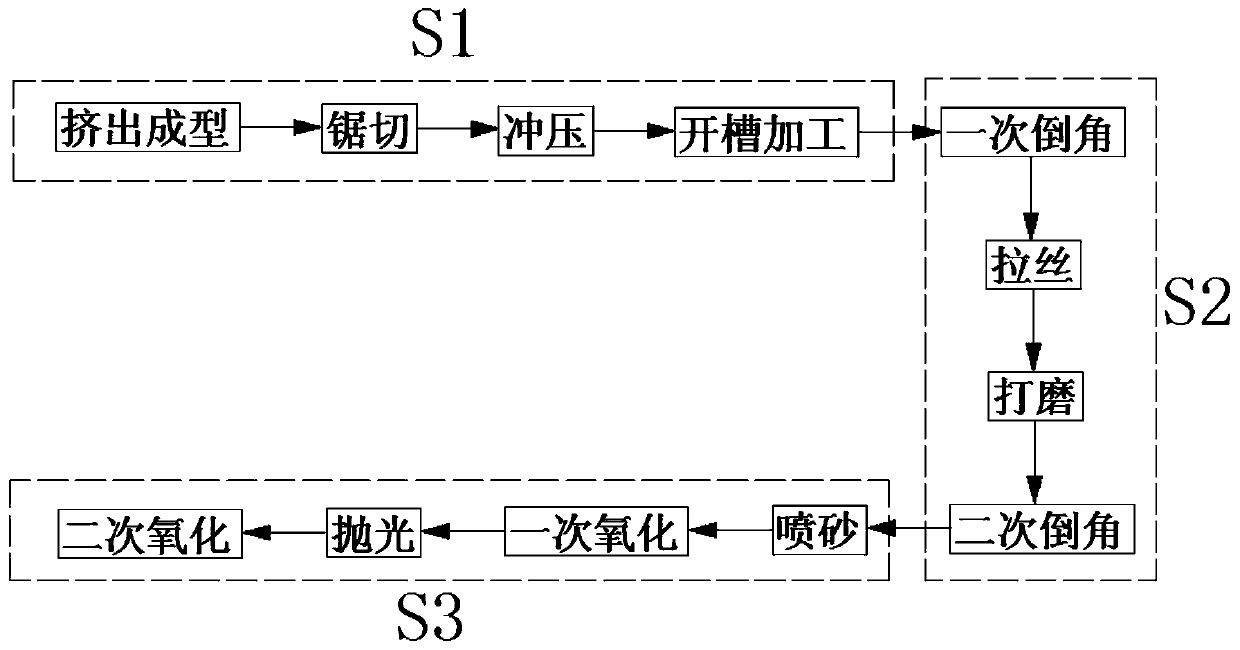

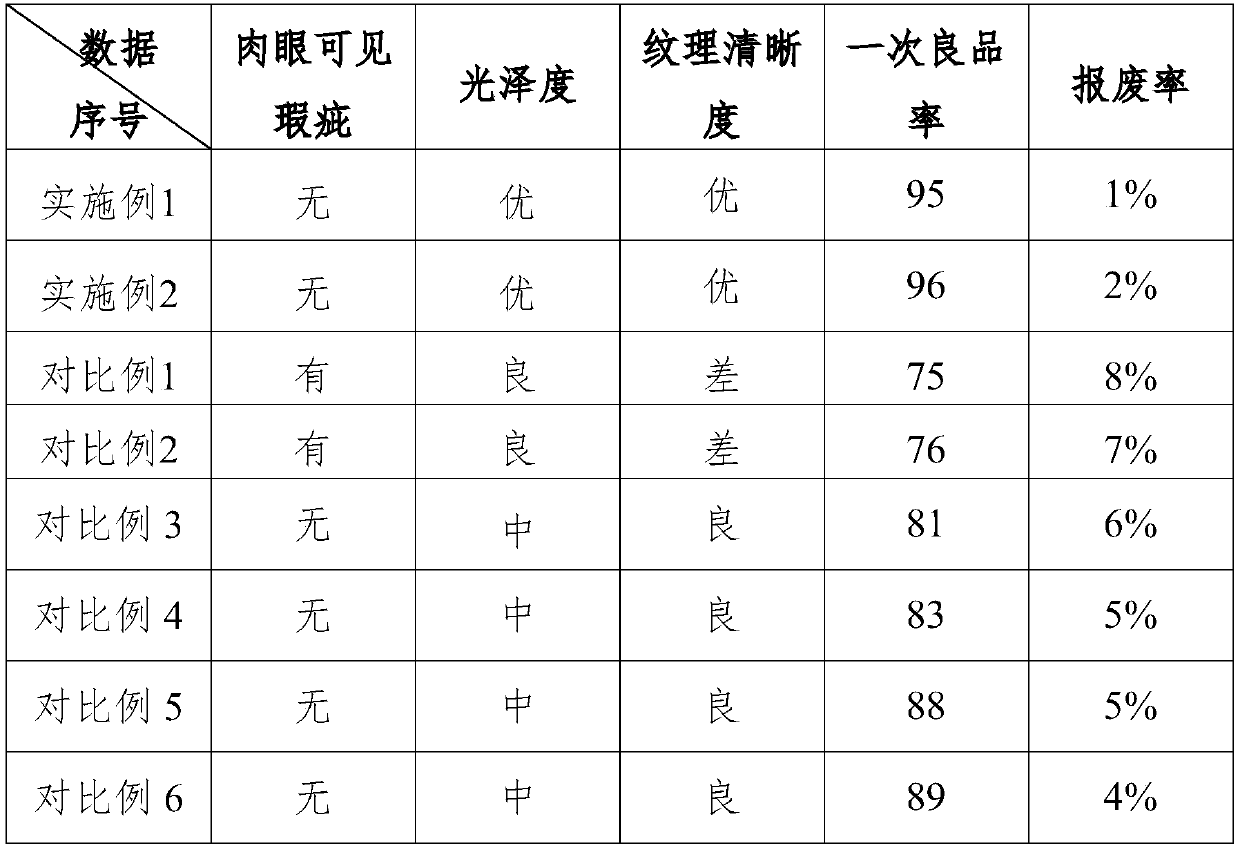

Production process and production equipment of refrigerator door frame handle

InactiveCN109822297AEliminate appearance blemishesImprove first-time yieldOther manufacturing equipments/toolsEngineeringGrinding wheel

The invention discloses a production process and production equipment of a refrigerator door frame handle. The production process comprises the following three steps of preparing a refrigerator door frame handle blank; finish machining the refrigerator door frame handle blank surface and maintaining the refrigerator door frame handle blank surface. The production equipment comprises a bottom plate, an inverted-U-shaped support, a grinding wheel driving stepping motor, a connecting shaft driving stepping motor, a connecting shaft, a grinding wheel and a controller are arranged on the bottom plate. The production process is simple and convenient to operate, the appearance effect of the refrigerator door frame handle produced by the process is better and fine, the one-time yield during the production of the handle is improved, and the rejection rate of the product is reduced; the production equipment is simple in structure and convenient for industrial application implementation of the process.

Owner:泰州星瑞精密工业有限公司

A rotary conveying device of a steel cage roll welding machine

ActiveCN111974908BEasy to placeGuaranteed to proceed normallyWire networkEconomic benefitsEngineering

The invention discloses a rotary conveying device of a steel cage roll welding machine. With the rotating mechanism provided in the present invention, when the roll welder performs welding work around the bar, the function of rotating and transporting the around bar can be performed, so that the transport of the around bar The work is smoother, ensuring the normal progress of the welding work around the rebar, and through the set of detachable first support rod and second support rod, it is more convenient to place the rebar and provide convenience for the staff. The bottom end of the mechanism is connected with the telescopic body, the base and the transmission structure, so that the position and height of the winding ring can be adjusted to ensure that it is at a suitable height position, which provides convenience for the welding work of the winding and avoids welding during the winding process. In the process, with the reduction of the number of coils, the position of the coils will be lowered, thereby improving work efficiency and ensuring the economic benefits of production and processing.

Owner:江西博展自动化科技有限公司

A hot press machine for film capacitor production that can realize automatic unloading

ActiveCN112420406BSafe and stable unloading useRapid serial productionCapacitor manufactureCapacitanceThermodynamics

Owner:扬州日精电子有限公司

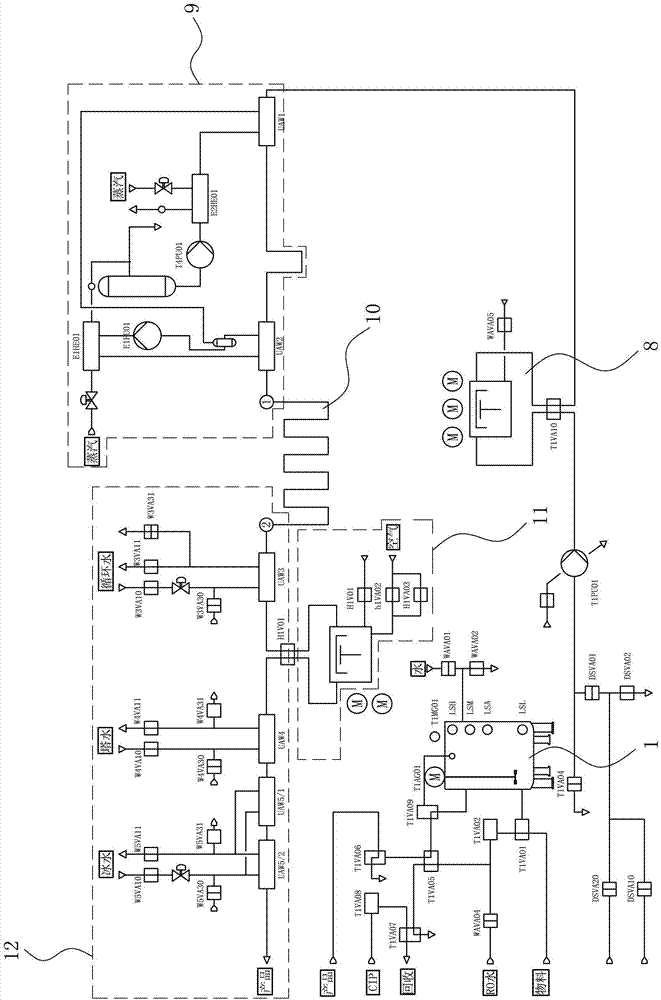

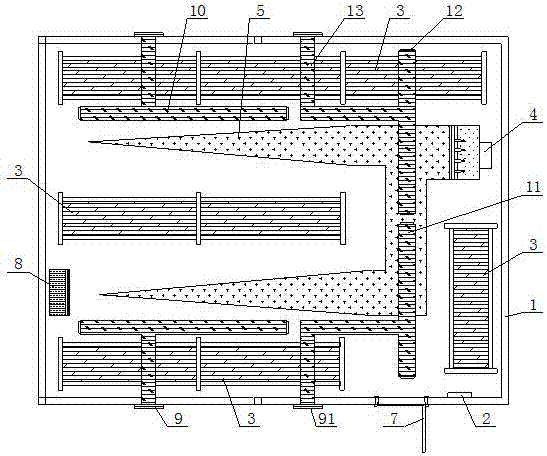

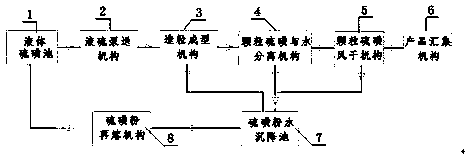

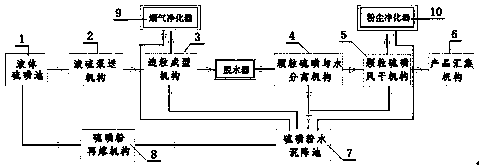

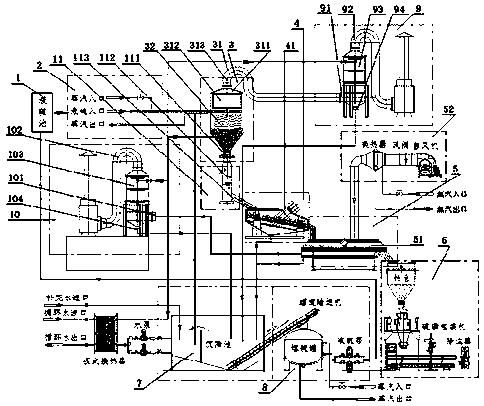

Sulfur underwater granulation system with reasonable structure

PendingCN109126626AImprove dehydration efficiencyEasy to recycleDrying gas arrangementsGranulation by liquid drop formationSulfurFlue gas

The invention relates to a sulfur underwater granulation system with a reasonable structure. The sulfur underwater granulation system contains a liquid sulfur tank, a liquid sulfur pumping mechanism,a liquid sulfur granulation and molding mechanism, a granulated sulfur and water separation mechanism, a granulated sulfur air drying mechanism, a sulfur powder remelting mechanism, a product collection mechanism, and a sulfur powder water settling mechanism. The granulating and molding mechanism is arranged in a closed type with a controllable air pressure, which can prevent liquid sulfur and sulfide flue gas from overflowing and ensure safe and efficient production; a flue gas purifier and a dust purifier with sulfur gas separation and powder-gas separation functions are arranged between a liquid sulfur dropping device and a sulfur powder water settling tank and between the granulated sulfur air drying mechanism and the sulfur powder water settling tank respectively, which is beneficialto environmental protection and resource recycling; and a dehydrator with a function of reducing the accompanying grain water output is arranged between a forming water tank and a dehydration vibrating screen, so that the loads of solid-water separation and air drying facilities can be reduced, the service life can be ensured, the shutdown maintenance probability can be reduced, the production cost can be reduced, the dehydration and air drying efficiency of the formed particles can be improved, and the product quality and the high-efficiency output of the system can be ensured. The sulfur underwater granulation system achieves remarkable results and is a major innovation in this field.

Owner:SHANGHAI RUIBAO GRANULATOR CO LTD

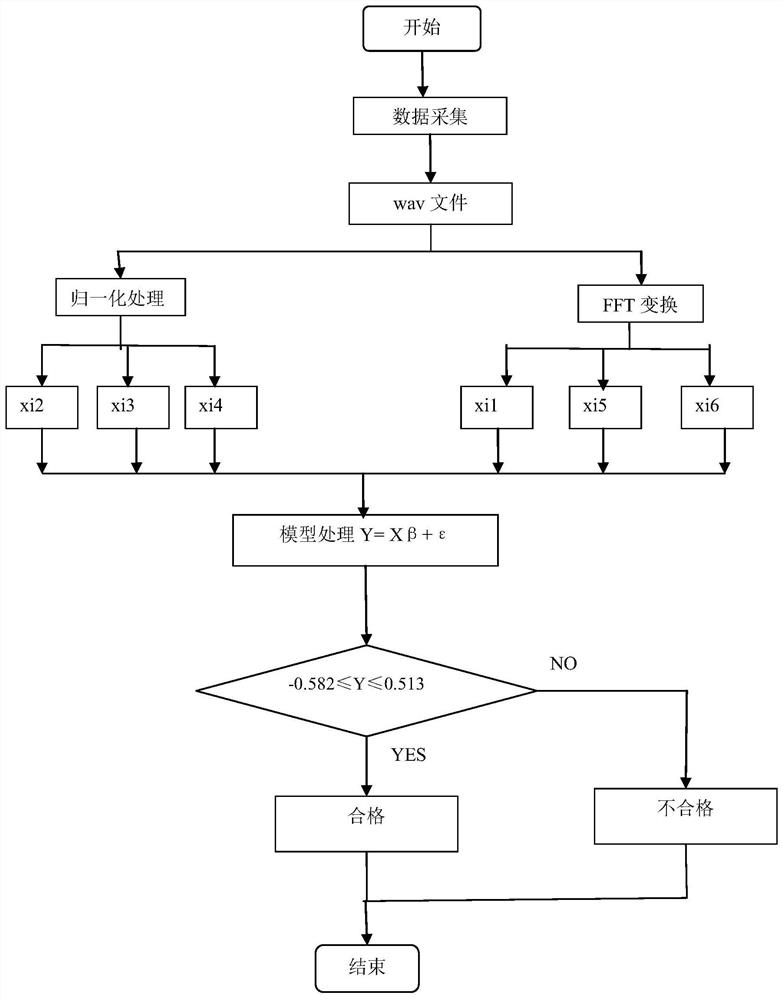

Diesel engine gear abnormal sound identification method based on wav file

PendingCN113609692AImprove accuracyImprove adaptabilityDesign optimisation/simulationComplex mathematical operationsNoiseGear wheel

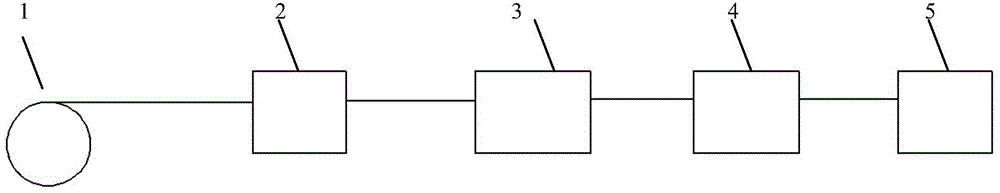

The invention discloses a diesel engine gear abnormal sound recognition method based on a wav file. The method comprises the following steps step 1, arranging a noise sensor (4) above a diesel engine (3) to collect a wav noise audio file; step 2, transmitting the wav noise audio file to a computer (1) through a signal recorder (2); step 3, collecting wav noise audio files of N diesel engine samples, and recording gear abnormal sound fault states corresponding to the wav noise audio files; step 4, establishing a gear abnormal sound recognition model based on the N wav noise audio files, wherein the input of the gear abnormal sound recognition model is the wav noise audio files, and the output of the gear abnormal sound recognition model is a judgment value Y; and step 5, inputting any wav noise audio file of the diesel engine into the gear abnormal sound recognition model, and judging whether the diesel engine is qualified or not according to the judgment value Y. According to the invention, the on-line product qualification condition can be checked in real time during diesel engine production, the troubleshooting accuracy is high, and the production rate of the diesel engine is not affected.

Owner:上海新动力汽车科技股份有限公司

Predispersed master batch of multifunctional rubber ingredient PDM and preparation method thereof

The invention discloses a predispersed master batch of a multifunctional rubber ingredient PDM, which is composed of the following components in parts by weight: 74-76 parts of N,N'-m-phenylenedimaleimide, 10-16 parts of rubber carrier, 3-5 parts of EVA (ethylene-vinyl acetate) resin, 1-6 parts of stearic acid, 1-5 parts of plasticizer and 1-10 parts of industrial white oil. By using the rubber base as the carrier, the preparation method of the predispersed master batch is simple and easy to operate. The prepared master batch can effectively maintain the original activity of PDM, does not aggregate at room temperature, is easy for proportioning and compounding, and thus, is convenient and accurate for proportioning. After being used in the rubber product, the master batch can not cause flying dust or cause the skin allergy of operating personnel and the environmental pollution phenomenon in the rubber production process. Besides, the master batch can greatly improve the dispersion speed and dispersion quality of the PDM in the rubber, lower the compounding temperature, shorten the compounding time, enhance the dispersion uniformity and ensure the production efficiency and production quality of the rubber product.

Owner:NINGBO ACTMIX POLYMER

Manufacturing process of a double-layer knitted warm shirt with liner

ActiveCN103960787BEnsure production efficiencyQuality assuranceWarp knittingNon-woven fabricsMechanical engineeringIndustrial engineering

The invention provides a technology for making a double-layer knitted inner container thermal shirt. The technology comprises the steps of material selection, material arrangement, cutting, sewing, finished product detection and the like. The mode of combining and sewing an inner layer and an outer layer and the mode of separating sewing are adopted in the sewing process. The technological steps and specific parameters of the double-layer knitted inner container thermal shirt are specifically specified in detail, meanwhile, in the making technology, manual operation and a machine are combined together, the making and producing efficiency of the shirt is guaranteed, meanwhile, the quality of the shirt is further guaranteed, the shirt made according to the technical scheme is superior in quality and style, the wearing effect is high in grade, and the shirt is a high-grade double-layer thermal shirt. The mode of combining and sewing the inner layer and the outer layer and the mode of separating sewing are adopted, the method is diversified, and the situation that after the finished shirt is washed, the shirt is wrinkled, the inner container of the shirt is exposed, or interlayer cotton is reduced and tightened, and the overall appearance of a wearer is influenced is avoided.

Owner:苏州新超针纺织有限公司

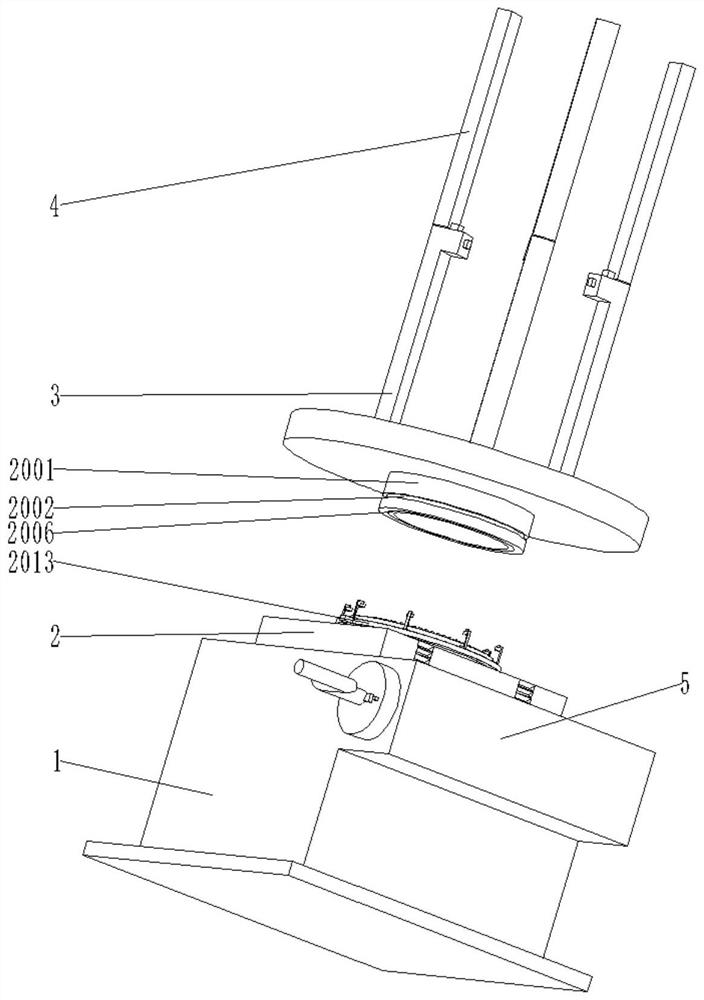

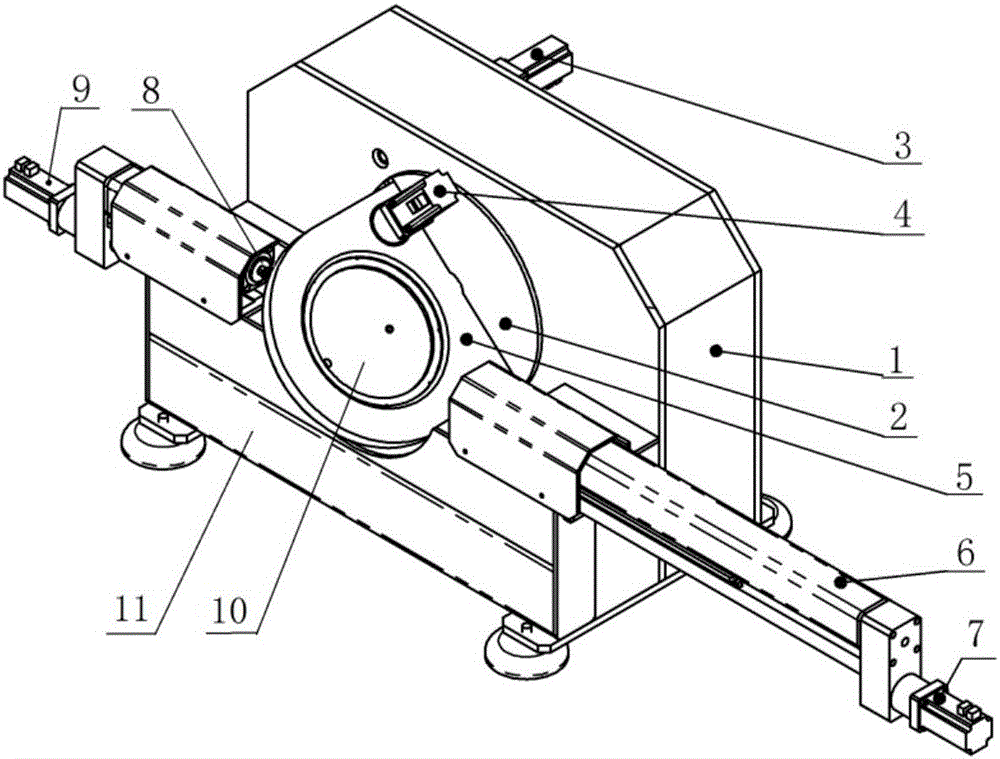

Two-freedom-degree concentric-rotating hole-lapping device of ultrahigh back-pressure glass ball

InactiveCN106827254AEnsure accuracy andEnsure production efficiencyWorking accessoriesStone-like material working toolsGlass ballEngineering

Provided is a two-freedom-degree concentric-rotating hole-lapping device of an ultrahigh back-pressure glass ball. A hemi-ball installing disc (10) is installed in an X-axis rotating seat (5), an inner drilling mechanism (6) and an outer drilling mechanism (8) are coaxially and oppositely installed on a rack (1), the X-axis rotating seat (5) is located between the inner drilling mechanism (6) and the outer drilling mechanism (8), a central line plane of the X-axis rotating seat (5) vertically penetrates through a diameter extension line of a Z-axis rotating disc (2), and the middle axes of the inner drilling mechanism (6) and the outer drilling mechanism (8) penetrate through the center of the hemi-ball installing disc (10). The Z-axis rotating disc is mutually matched with the X-axis rotating seat to achieve accurate control of two freedom degrees. In addition, a ball body is coaxially and oppositely clamped by using the inner drilling mechanism and the outer drilling mechanism, a drill bit rotating at high speed is controlled to rapidly advance, work-feed and rapidly reverse for lapping with respect to the center of the ball, rough lapping and finish lapping are performed in a linkage mode, manual hole lapping is completely replaced, and hole-lapping precision and production efficiency are ensured.

Owner:浙江云灵信息技术有限公司

Self-controlled UV curing system with double light sources

InactiveCN105312211ADissipate heat in timeReduce the temperaturePretreated surfacesCoatingsUV curingElectric control

The invention discloses a self-controlled UV curing system with double light sources. The system comprises a UV curing machine body, wherein a feeding port, a discharging port, an exhaust fan and a transmission platform are formed in and arranged on the UV curing machine body; on the aforementioned basis, an electric control device is additionally arranged and is mounted on the feeding port in the UV curing machine body; two UV lamps are arranged and correspondingly equipped with a blue-light wick which can generate blue light and a purple-light wick which can generate purple light; the two UV lamps are correspondingly rotatably mounted in the UV curing machine body through rotating bearings, wherein the rotating bearings are connected with the electric control device through wires and are controlled to rotate through the electric control device. According to the system, the double light sources are used, so that the system can achieve two purposes; in addition, the blue-light wick and the purple-light wick are packaged into the same LED lamp; a control unit can adjust the luminance of the blue-light wick and the purple-light wick all the time according to the specific use environment, so as to ensure the use; a waste collecting box is arranged in front of the transmission table; the waste collecting box is obliquely mounted, and a concave structure is arranged in the middle of the waste collecting box; a rubber layer is arranged on the surface of the waste collecting box, so that the environmental pollution can be avoided.

Owner:WUHU CHUNYUAN PHOTOELECTRIC EQUIP TECH CO LTD

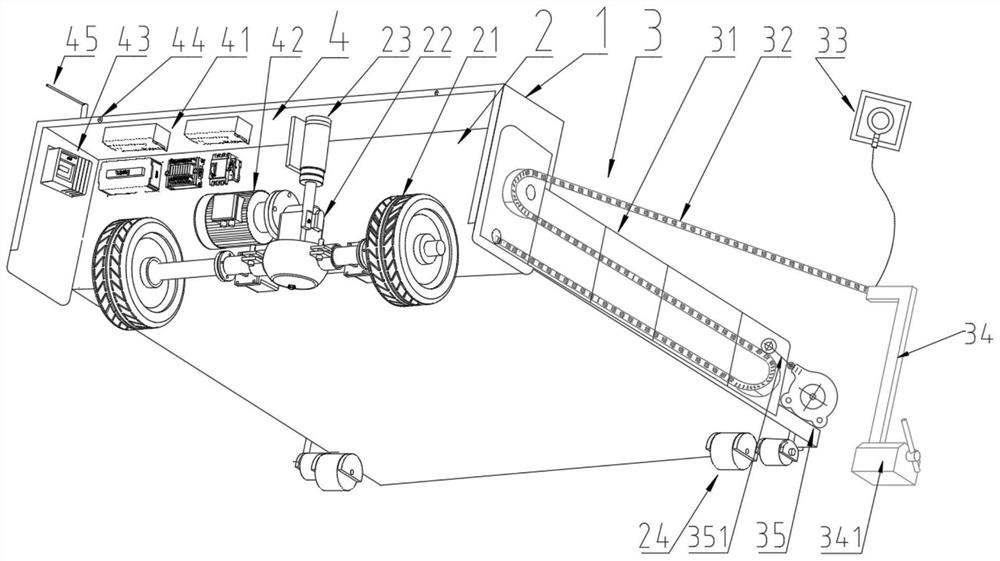

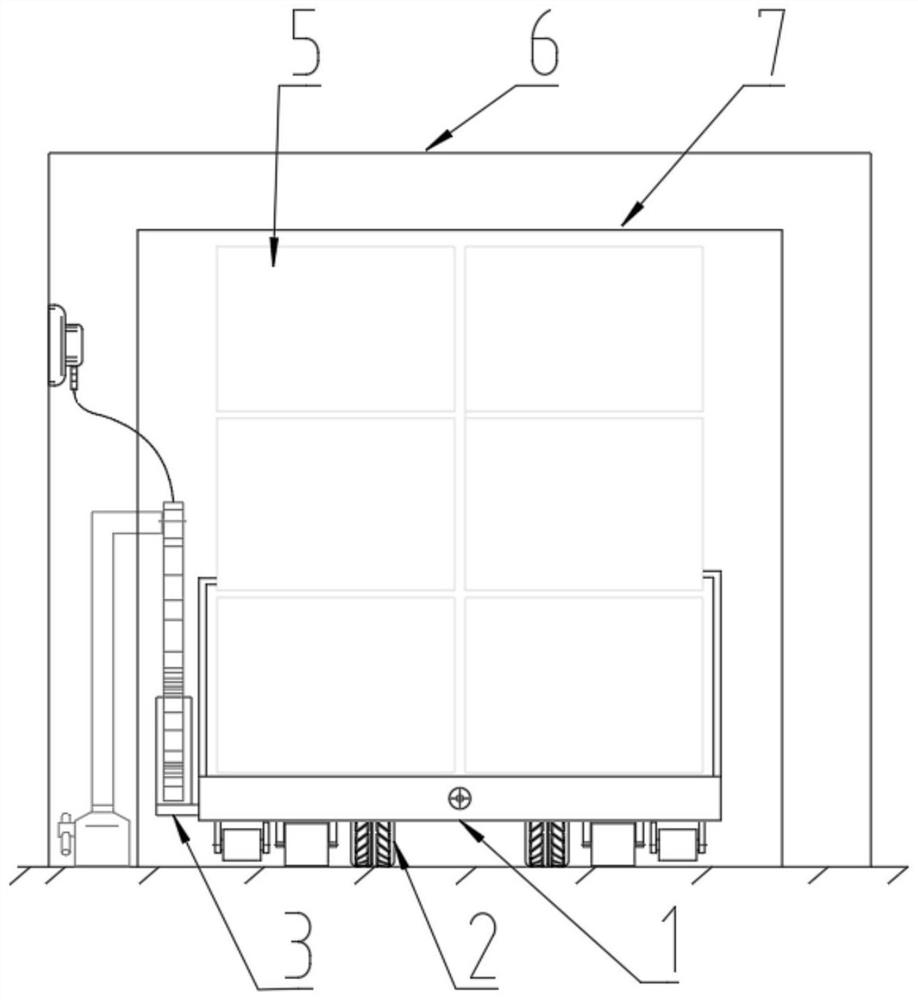

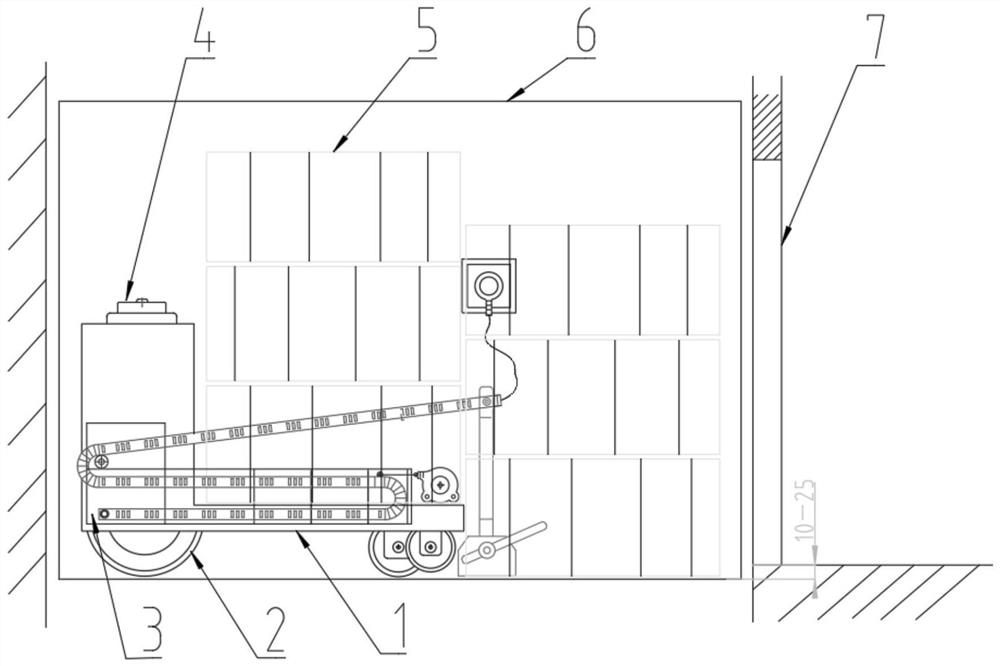

Connection vehicle for conveying tobacco leaf box in-out space limited elevator and operation method of connection vehicle

PendingCN114253208AImprove securityEnsure safetyProgramme control in sequence/logic controllersDrive wheelVehicle frame

The invention discloses a connection vehicle for conveying a tobacco box in-out space limited elevator, which comprises a frame (1), a transmission mechanism (2), a cable take-up and pay-off assembly (3) and an electric control system (4), and is characterized in that the transmission mechanism comprises a driving wheel (21), a mechanical transmission assembly (22), an electric parking mechanism (23) and a driven wheel set (24); the cable take-up and pay-off assembly comprises a drag chain circuitous bridge (31), a bridge type crawler drag chain (32), a car power supply (33), a magnetic fixed hanging bracket (34) and an elastic balancer (35), and the electric control system comprises a direct current driving device (41), a direct current motor (42), a PLC (Programmable Logic Controller) (43), an infrared distance measuring sensor (44) and a remote control receiver (45). According to the invention, the tobacco leaf box conveying work of the connection vehicle in the elevator with limited space is smoothly realized, the normal production operation efficiency is ensured, and the safety of the elevator in the using process is ensured.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Multi-functional polyester fiber production equipment

InactiveCN111270326AGuaranteed uniformityEasy to stir and mixSpinning head liquid feederArtificial thread manufacturing machinesPolyesterFiber

The invention provides multi-functional polyester fiber production equipment. The multi-functional polyester fiber production equipment comprises a first fiber extrusion machine, a first fiber conveying pipe, a spinning head, a second fiber extrusion machine, a second fiber conveying pipe, a support frame, a hardening fan, a suction chamber, a high-pressure air pump, a control screen, a support and a conveying belt. By virtue of the arrangement of a raw material processing and mixing and stirring hopper, a feeding hopper, an observation window, a cleaning plate, a mixing and stirring motor, amixing and stirring shaft and a stirring auger, mixing and stirring of the processed raw materials are facilitated, thereby guaranteeing the raw material uniformity, and then further guaranteeing thepolyester fiber the processing efficiency; the raw materials are placed in the raw material processing and mixing and stirring hopper through the feeding hopper, and the mixing and stirring motor is controlled through the control screen to drive the mixing and stirring shaft and the stirring auger to rotate, so that the continuously placed raw materials are stirred to ensure the processing effect;meanwhile, through the observation window, the mixing and stirring condition can be observed, so that the mixing and stirring efficiency can be ensured and blocking is avoided; and by taking down thecleaning plate, the raw materials in the raw material processing and mixing and stirring hopper can be cleaned, and the operation is convenient.

Owner:曹学民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com