Tubular Maillard reaction equipment

A Maillard reaction, Rad reaction technology, applied in applications, food science, chemistry/physics/physicochemical processes, etc., can solve problems such as increased packaging and labor costs, process discontinuity, and low production efficiency. Achieve accurate and constant reaction temperature and reaction time, ensure production efficiency and quality, and ensure the effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

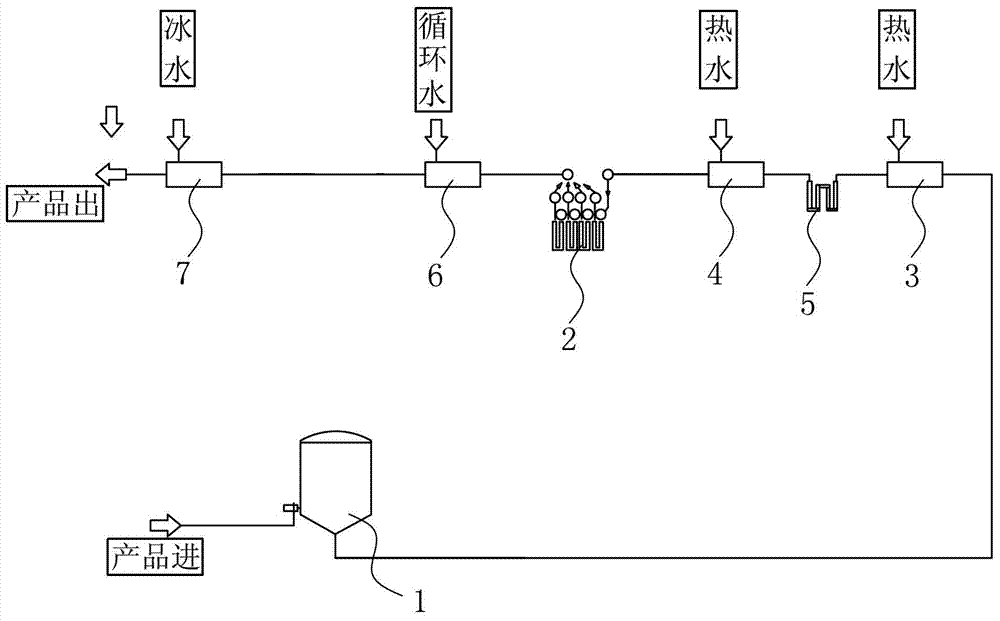

[0022] Embodiment one: see figure 1 As shown, a tubular Maillard reaction equipment includes a storage tank 1, a heating part, a Maillard reaction part, a cooling part, a delivery pipeline connecting each part, and a controller with a software program. The material storage tank is provided with a raw material inlet and a material outlet, and the material outlet is connected to the heating part through the conveying pipeline, and the heated material is sent to the Maillard reaction part through the conveying pipeline. The Maillard reaction section is composed of a Maillard reaction pipeline 2 with an insulating layer, the reacted material is sent to the cooling section through the delivery pipeline, and the cooled product is sent out from the delivery pipeline outlet; wherein, the delivery At least one flowmeter is arranged on the pipeline, and the measured flow rate is u, and the length s of the Maillard reaction pipeline 2 is the flow rate u of the material × the time t of fl...

Embodiment 2

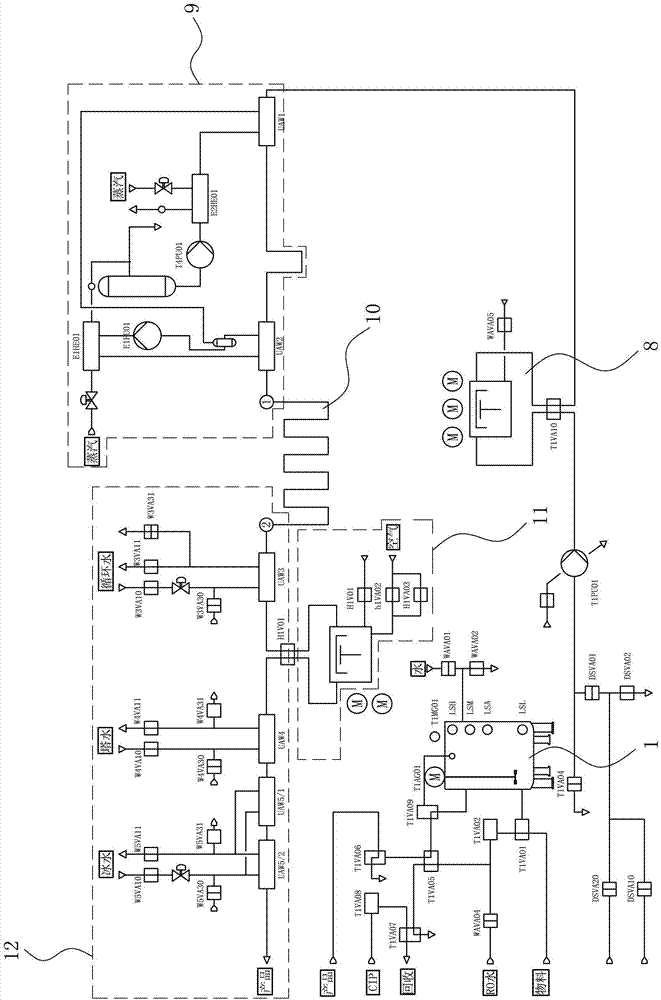

[0025] Embodiment two: see figure 2 As shown, a tubular Maillard reaction equipment includes a storage tank 1, a high-pressure pump 8, a heating part 9, a Maillard reaction part 10, a homogenizer 11, a cooling part 12, and a delivery system connecting the parts. pipeline and a controller with a software program, the storage tank 1 is provided with a raw material inlet, a water inlet, a product return port and a discharge port, the storage tank 1 is provided with a stirring shaft, and the discharge port is The delivery pipeline is connected to the heating part 9, and the heating part 9 is composed of a first-stage steam heater, a second-stage steam heater and a protein stabilization pipeline, and the protein stabilization pipeline is arranged on the first and second Between the steam heaters, the protein stabilization pipeline is a delivery pipeline with an insulating layer, the time for the material to pass through the protein stabilization pipeline is 50 seconds, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com