Blast furnace throat temperature estimation method based on multilayer ore-coke ratio distribution model

A distribution model, blast furnace throat technology, applied in the field of blast furnace throat temperature estimation based on multi-layer ore coke ratio distribution model, can solve problems such as long maintenance period, difficult replacement, failure, etc., to ensure production efficiency and product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

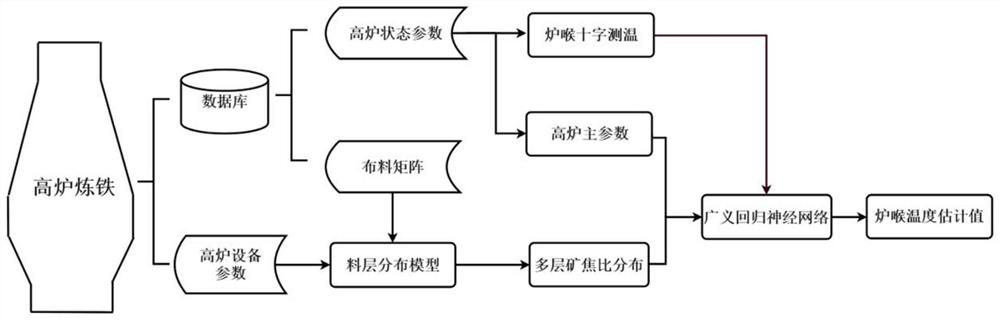

[0046] figure 1 The overall flow of the furnace throat temperature estimation method based on the multi-layer ore-coke ratio distribution model according to the embodiment of the present invention is given. Blast furnace equipment parameters, material distribution matrix and blast furnace state parameters are used to establish the distribution model of blast furnace charge layer. Perform data processing on blast furnace state parameters and cloth matrix, including sampling synchronization, data cleaning and feature selection. Combine the processed state parameters with the distribution of multi-layer ore-coke ratios to obtain the required input data. The GRNN algorithm is used to obtain the estimated value of the furnace throat temperature.

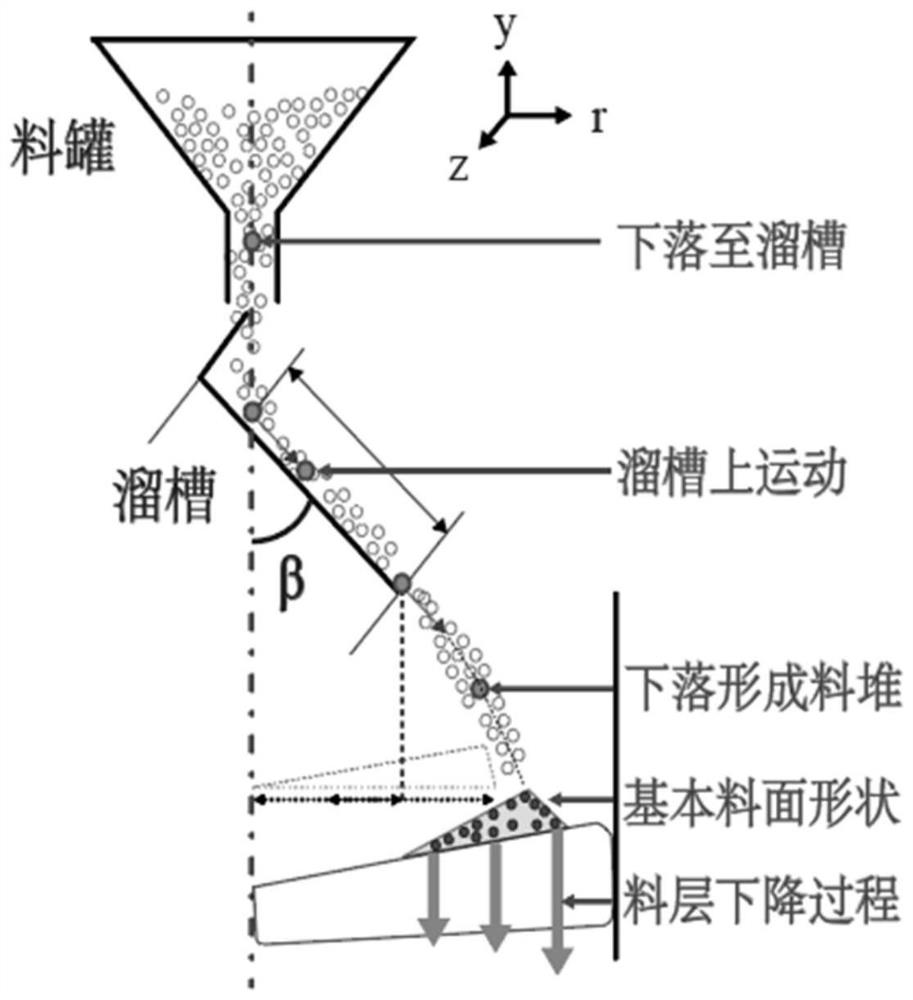

[0047] In order to realize the modeling process of the material layer structure, the following assump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com