Method for measuring solid content of catalytic slurry oil

A technology of catalytic oil slurry and measurement method, which is applied in the field of analysis and measurement of solid content in catalytic oil slurry, particle enrichment, particle size measurement, and solid content of catalytic oil slurry, which can solve the problem of large solid content measurement results and measurement problems in oil slurry. Low precision and accuracy, time-consuming measurement methods, etc., to save filtering time, shorten experiment time, and shorten experiment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The organic filter is packed into a weighing bottle, together with the evaporating dish, dried in a vacuum desiccator (the temperature is 105°C, 30min), cooled for a period of time in the desiccator, and the dried evaporating dish, organic filter and The centrifuge tube is weighed and ready for use;

[0051] Preheat the Dagang oil slurry in the raw material tank first, heat it to 80°C and make it flow, then stir at a constant temperature for 15 minutes, take 25g of oil slurry and add it to three 50mL centrifuge tubes, then add 25mL diesel oil to the three centrifuge tubes, and use A high-speed centrifuge is used for centrifugal treatment, the centrifugal speed is 3000r / min, and the centrifugal time is 5min.

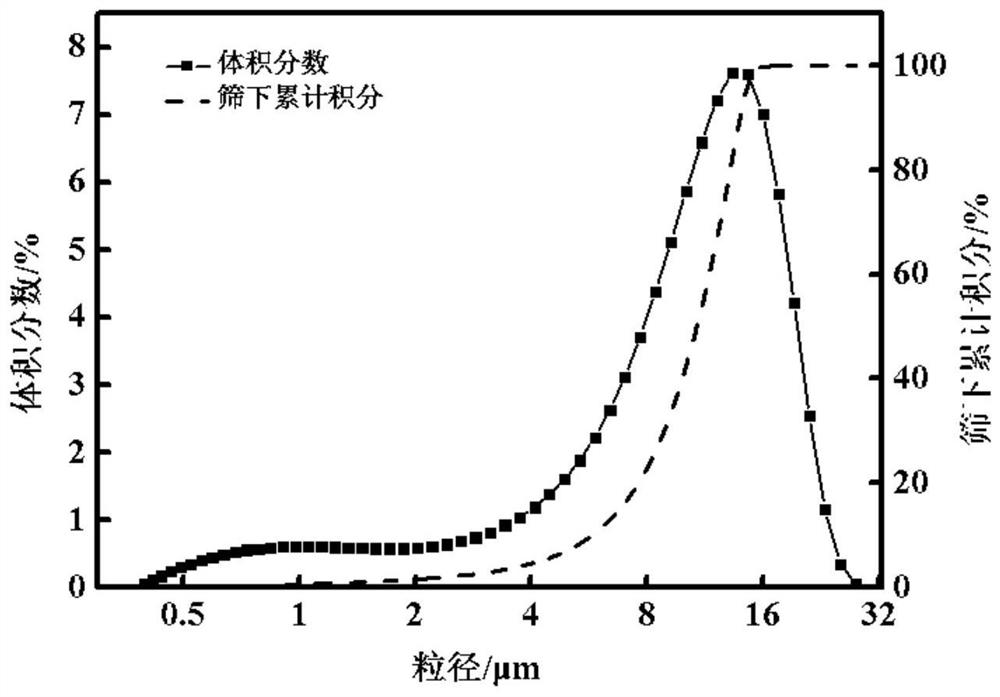

[0052] Then the centrifuge tube was taken out, kept in a water bath at 70°C for 5 minutes, and then taken out and placed in a centrifuge for centrifugation twice. After the centrifugation, the upper liquid phase product is filtered under reduced pressure using a p...

Embodiment 2

[0054] The organic filter is packed into a weighing bottle, together with the evaporating dish, dried in a vacuum desiccator (the temperature is 105°C, 30min), cooled for a period of time in the desiccator, and the dried evaporating dish, organic filter and The centrifuge tube is weighed and ready for use;

[0055] Preheat the Changqing oil slurry in the raw material tank, heat it to 70°C and make it flow, then stir at a constant temperature for 15 minutes, take 20g of the oil slurry and add it to three 50mL centrifuge tubes, then add 30mL kerosene to the three centrifuge tubes respectively, Centrifuge with a high-speed centrifuge, the centrifugal speed is 2000r / min, and the centrifugation time is 3min.

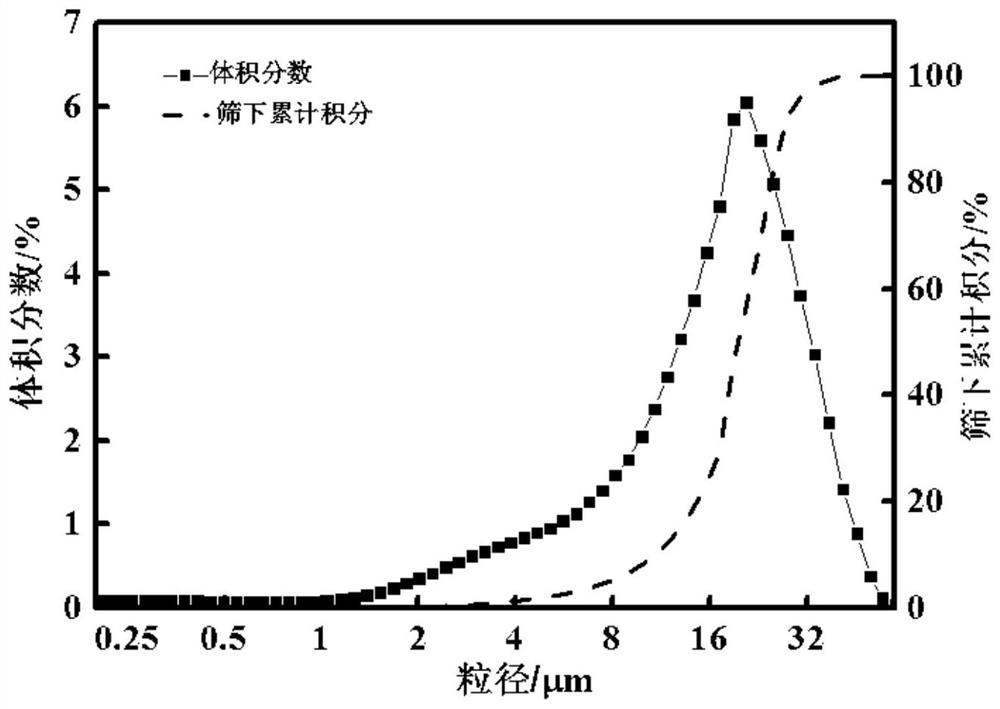

[0056] Then the centrifuge tube was taken out, kept in a water bath at 65°C for 8 minutes, and then taken out and placed in a centrifuge for centrifugation for 3 times. After centrifugation, select the polypropylene organic filter membrane with a pore size of 0.25 μm to filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com