Method for manufacturing spectacle frame and forming mould thereof

A manufacturing method and technology of spectacle frames, which are applied to other household appliances, frames, household appliances, etc., can solve the problems of unguaranteed product quality, high production cost, high defective rate, and achieve semi-automatic production, optimization of molds, Increase the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

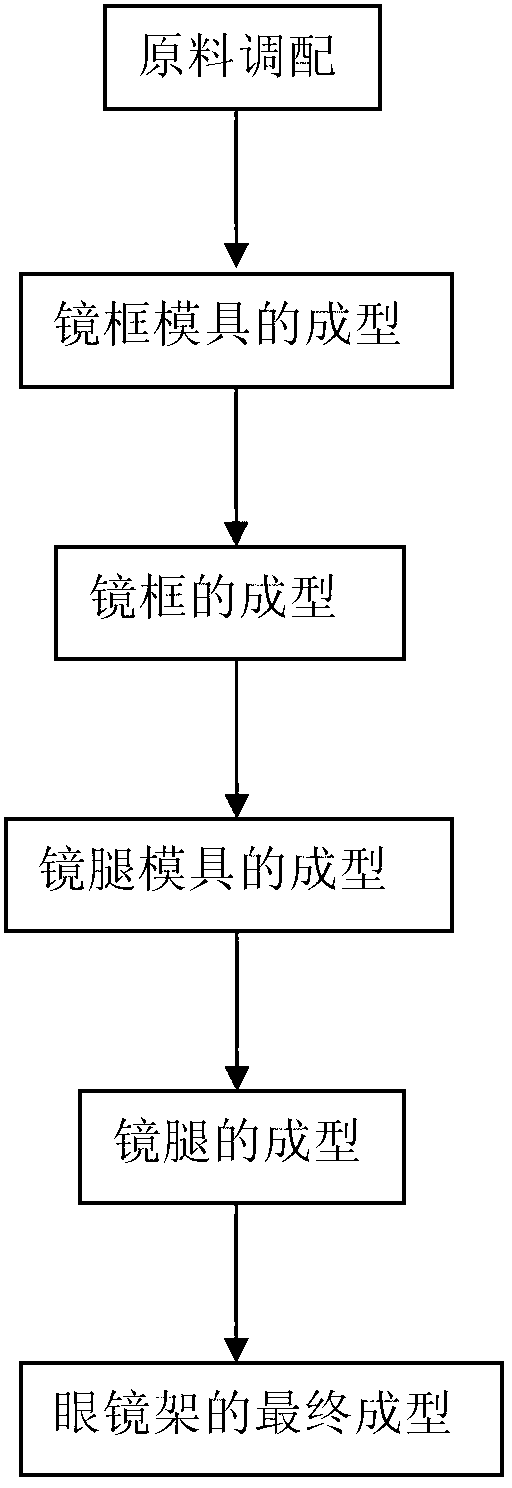

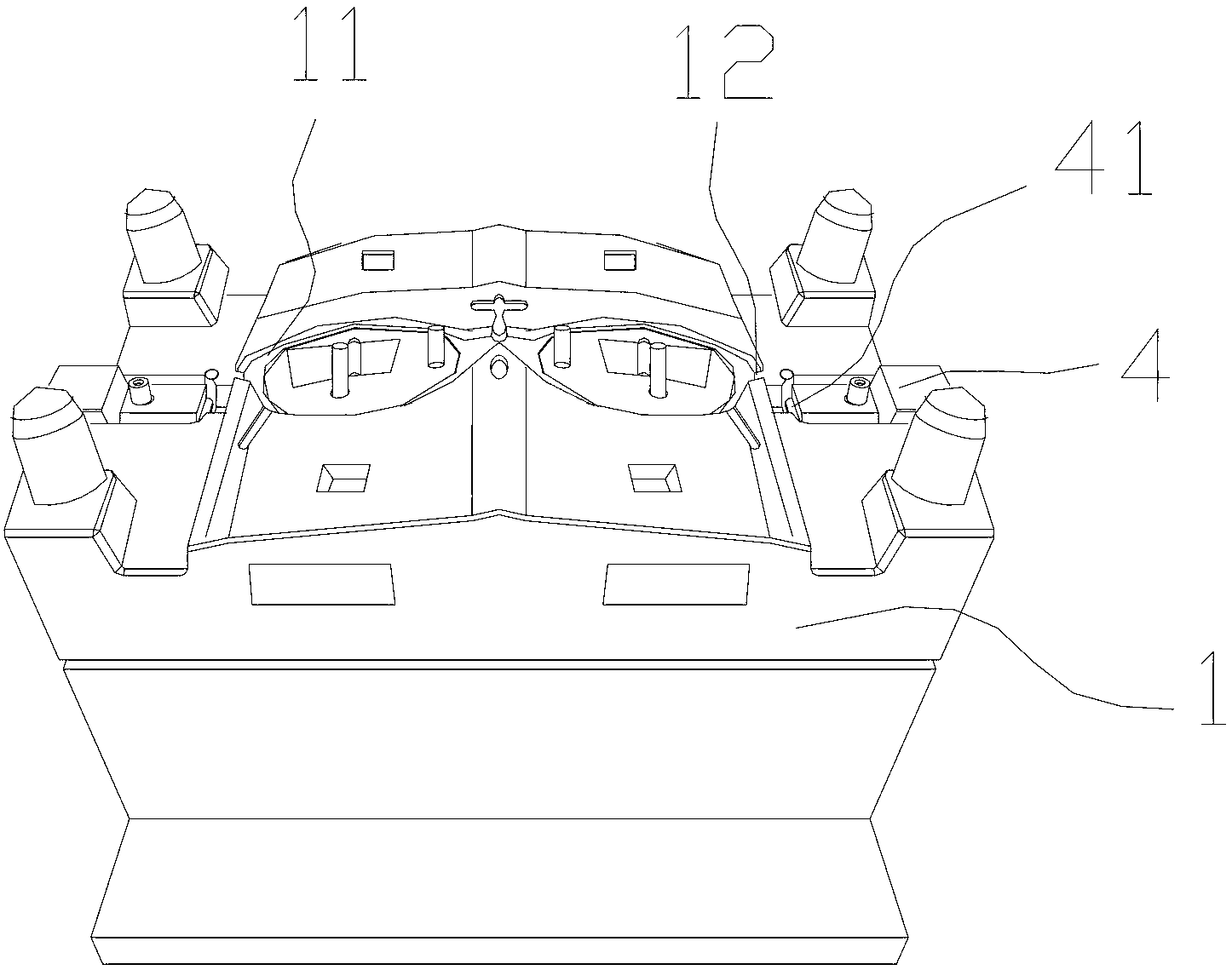

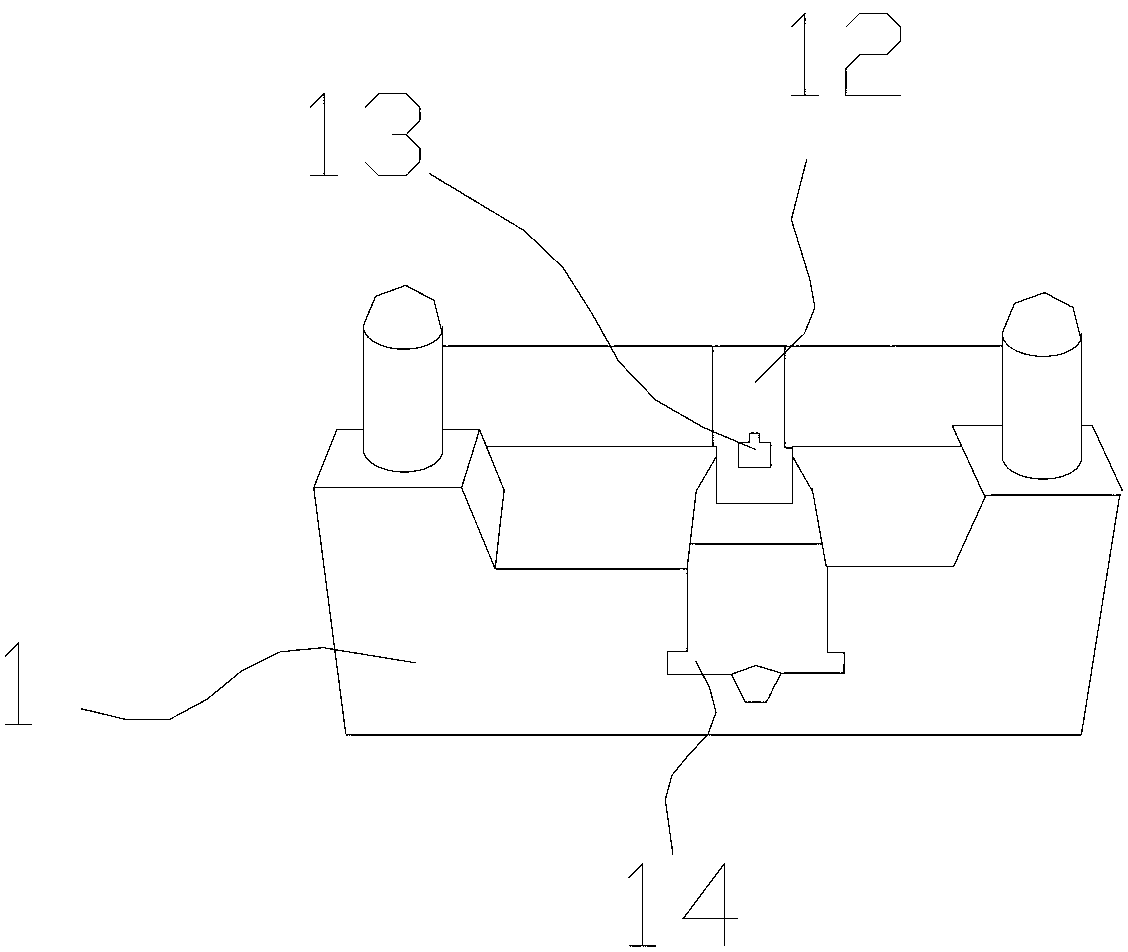

[0023] Figure 1 to Figure 5 A method for manufacturing a spectacle frame according to the present invention and its forming mold are schematically shown.

[0024] According to one aspect of the present invention, there is provided a method for manufacturing a spectacle frame, the process comprising the steps of:

[0025] Raw material blending: the raw materials are separately prepared from different colors of pigments or toners to form melts of the desired color, and the raw materials can be PC plastic, PVC, CP, TR90 and other materials.

[0026] Forming steps of the frame mold: Process one end of the mold to form two frame grooves with the basic shape of the frame. There are hinge slots for metal hinges.

[0027] Forming steps of the frame: Fix any metal hinge that can rotate 180° in the hinge groove, prepare the raw materials of the frame and heat it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com