Multi-functional polyester fiber production equipment

A polyester fiber and production equipment technology, which is applied in the field of polyester fiber production equipment, can solve problems such as the inability to remove dust on the surface of polyester fiber, the lack of cutting function of polyester fiber, and uneven mixing of raw materials, so as to ensure heating and drying efficiency and meet The effect of processing operation requirements and ensuring the uniformity of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

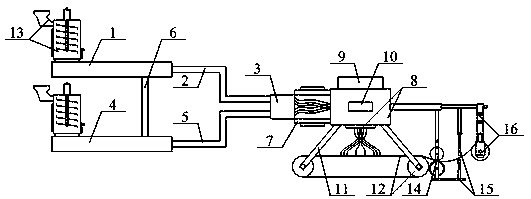

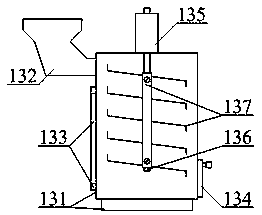

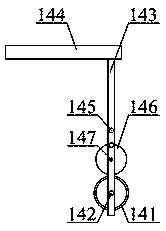

[0036] The present invention is described in detail below in conjunction with accompanying drawing, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of production equipment of multifunctional polyester fiber comprises the first fiber extruder 1, the first fiber conveying pipe 2, spinneret Head 3, second fiber extruder 4, second fiber conveying pipe 5, support frame 6, hardening fan 7, suction chamber 8, high-pressure air pump 9, control panel 10, bracket 11, conveyor belt 12, raw materials for polyester fiber processing Mixed observation processing machine structure 13, adjustable surface dust cleaning wheel structure 14 after fiber processing, adjustable polyester fiber cutting blade structure 15 and detachable adjustable polyester fiber yarn storage disc wheel structure 16, the first fiber conveying One end of the pipe 2 is threaded to the spinneret 3, and the other end is threaded to the right outlet of the first fiber extruder 1; one end of the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com