Thin Film Transistor, Array Substrate and Method of Forming the Same

a thin film transistor and array substrate technology, applied in the field of display technology, to achieve the effect of preventing photoresist from shedding, ensuring evenness and smoothness of the surface, and reducing the production power of the second copper layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]For the purpose of description rather than limitation, the following provides such specific details as a specific system structure, interface, and technology for a thorough understanding of the application. However, it is understandable by persons skilled in the art that the application can also be implemented in other embodiments not providing such specific details. In other cases, details of a well-known apparatus, circuit and method are omitted to avoid hindering the description of the application by unnecessary details.

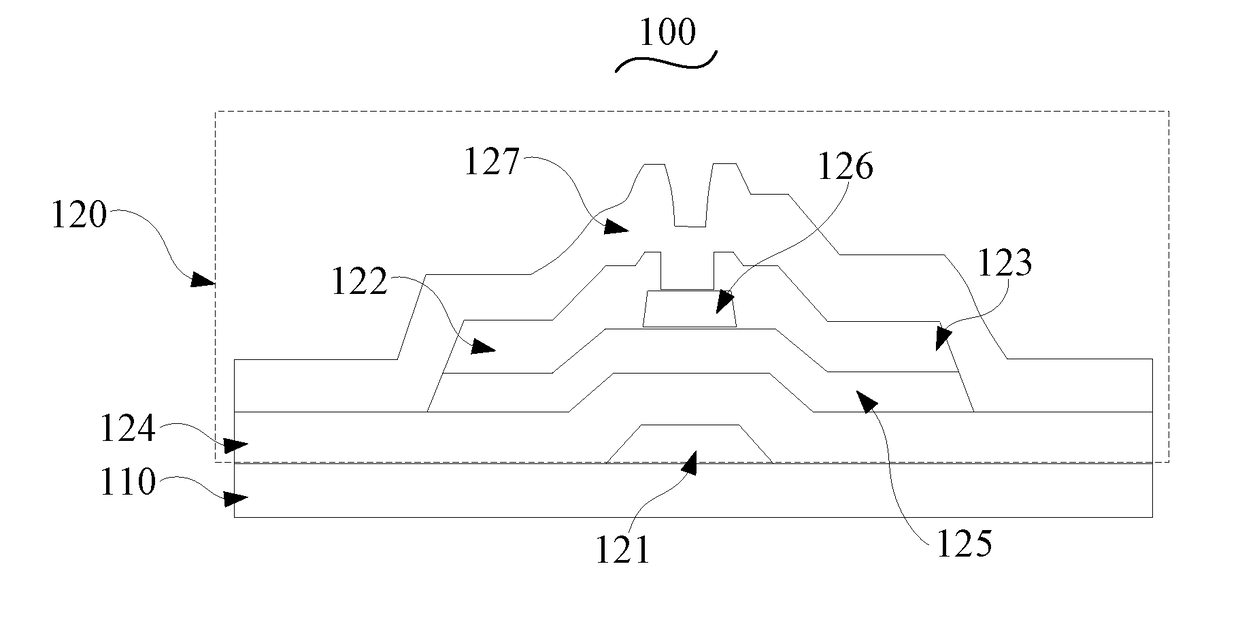

[0024]Please refer to FIG. 1. FIG. 1 is a structure diagram of an embodiment of the array substrate of the present invention. In the present embodiment, an array substrate 100 comprises a substrate 110 and a plurality of TFTs 120 (FIG. 1 only shows one TFT 120 on the substrate 110 as an example). The substrate 110 can be a transparent substrate made of glass or other insulating materials. The TFT 120 comprises a gate 121, a source 122 and a drain 123 install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| resistance-capacitance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com