Patents

Literature

122results about How to "With touch function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

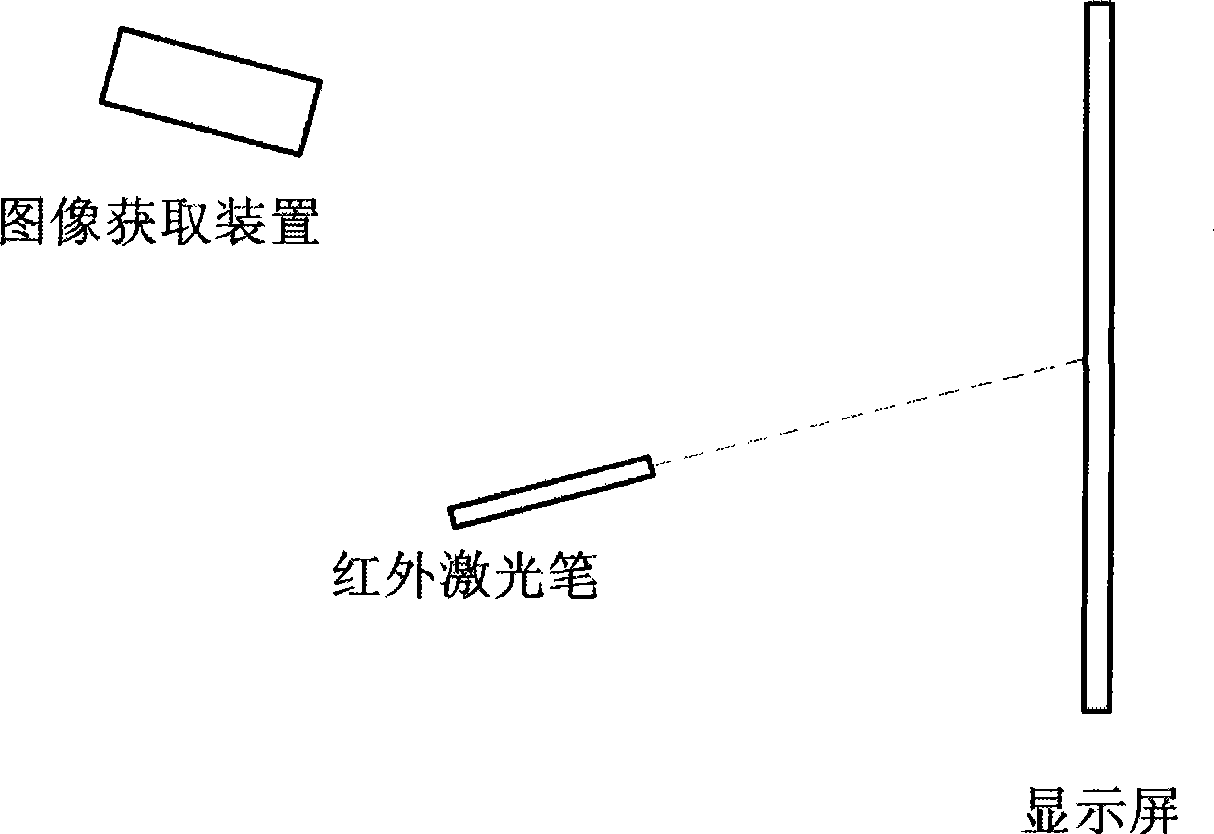

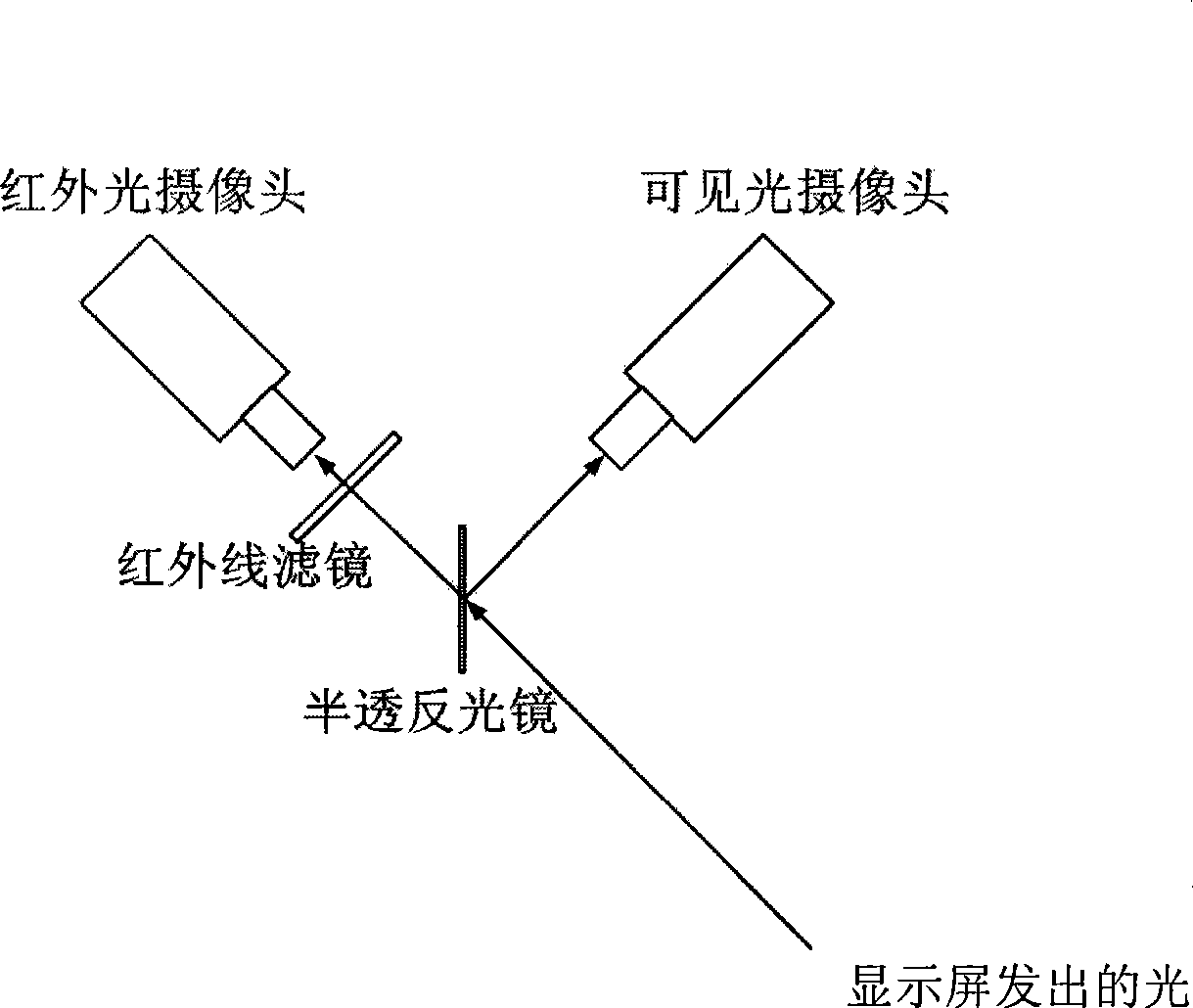

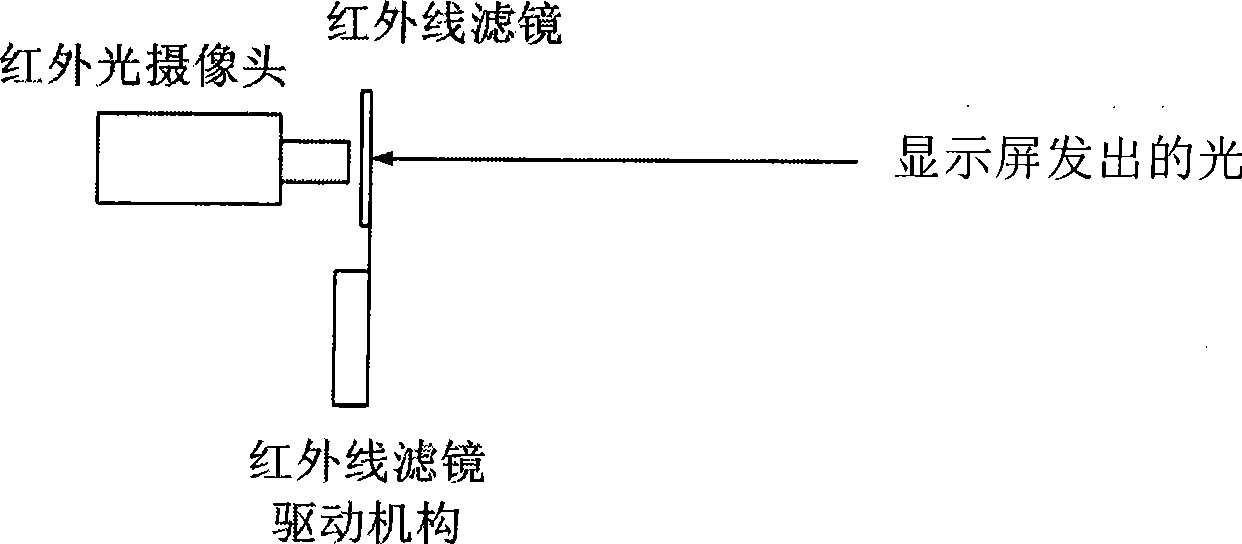

Remote virtual touch system of infrared laser pen

InactiveCN101419513AThe recognition is accurateAvoid position errorInput/output processes for data processingLarge screen displayImage identification

The invention discloses an infrared laser pointer remote pointing and virtual touch system which is characterized in that the system is composed of a computer system, an infrared laser pointer, an image acquisition device and an image identification positioning module; the computer system comprises a display device and a mainframe computer; the infrared laser pointer is provided with an infrared laser emitting key and can emit an infrared laser to point to a display screen; the image acquisition device is arranged in front of the display device to completely contain the display screen in the viewfinder range; the image identification positioning module identifies an infrared laser point and the position thereof in the display screen according to the acquired image, differentiates different operations including light spot instruction, light spot movement and clicking according to the time length and the times of the infrared laser, controls the computer system to generate a light spot at the corresponding position on the display screen and completes the corresponding operation. The invention is especially suitable for large-screen display equipment.

Owner:ANHUI UNIVERSITY +1

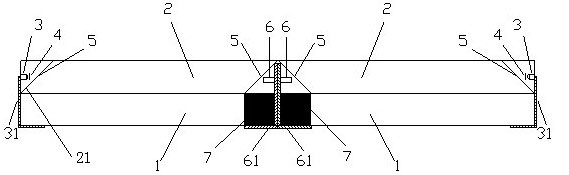

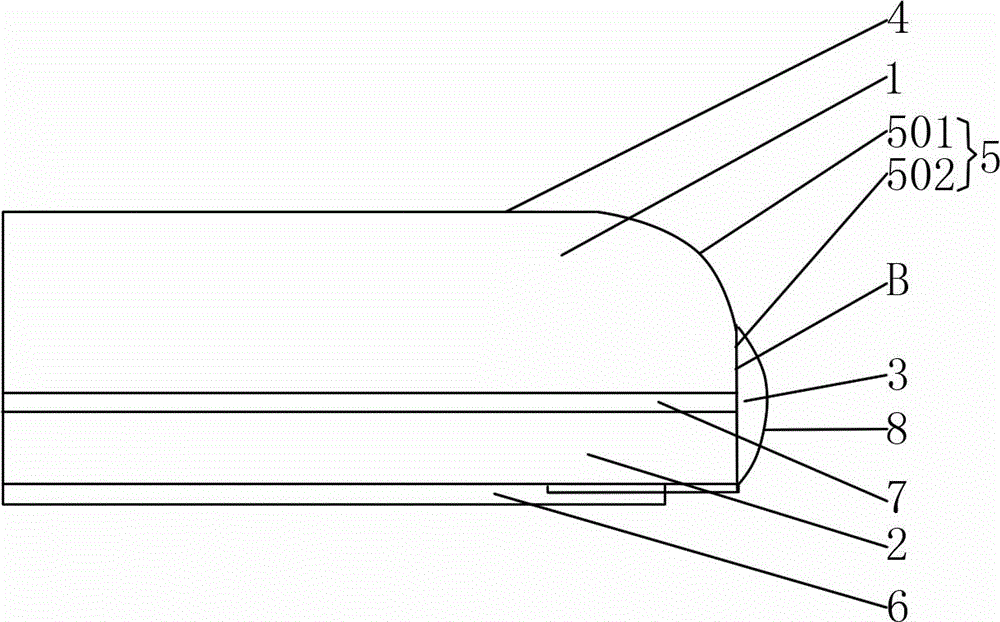

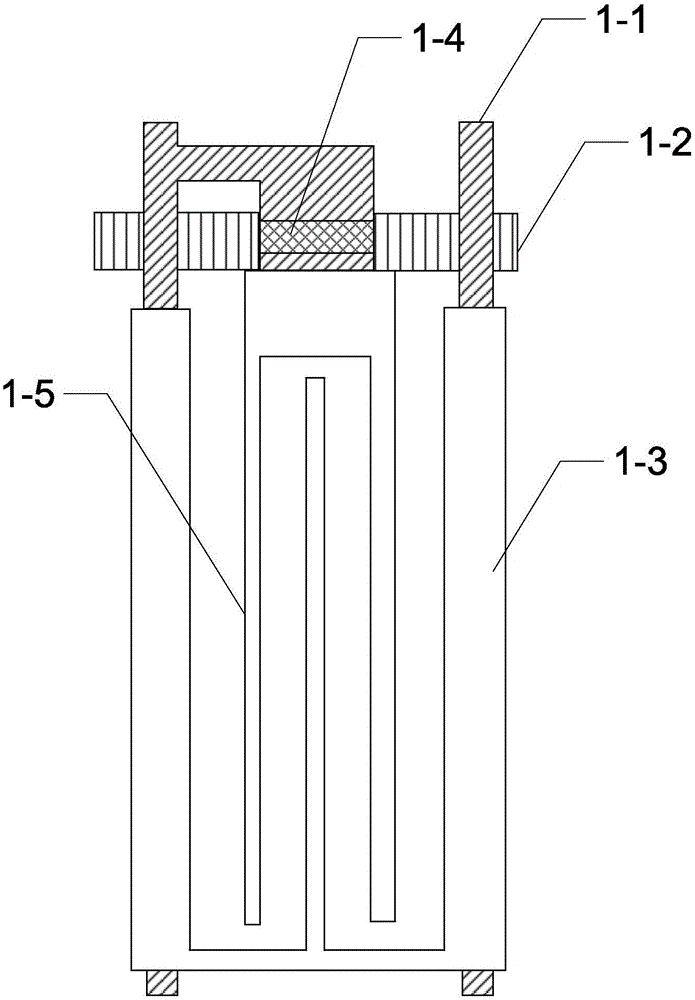

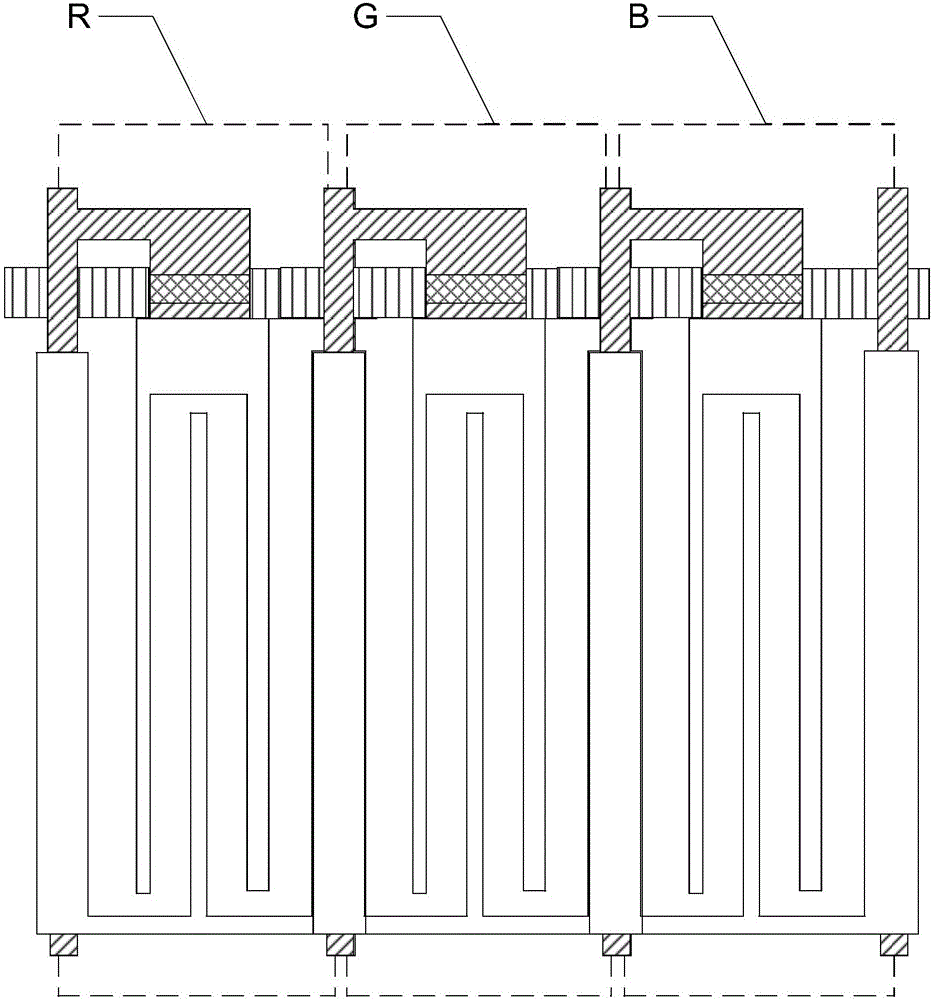

Seamlessly-spliced display screen

The invention relates to a splicing display technology and particularly relates to a seamlessly-spliced display screen. The seamlessly-spliced display screen comprises display screens which are spliced with one another, wherein a first linear polaroid is adhered on the surface of each display screen; the surface of each first linear polaroid is provided with an oblique cube-corner prism with a flat surface and a flat back surface; one side surface of the oblique cube-corner prism, on the same side of a splicing seam formed by splicing with the display, and the opposite surface are mutually parallel oblique surfaces; each of the parallel oblique surfaces is plated with a prism polarization light splitting film; by utilizing the prism polarization light splitting films, parallel oblique surfaces far away from the splicing seam reflect P polarized light which is emitted from the display screen and formed after passing through the first linear polaroid; light emitted by the display screen forms an image block; after reflection by the prism polarization light splitting films, the P polarized light is transmitted to the parallel oblique surfaces at the splicing seam in the oblique cube-corner prism and then reflected into eyes of a human body by the parallel oblique surfaces at the splicing seam; and the splicing seam of the display screen is covered by the image block, and therefore seamless splicing display is realized; and the seamlessly-spliced display screen is simple in structure and low in cost.

Owner:GUANGDONG VTRON TECH CO LTD

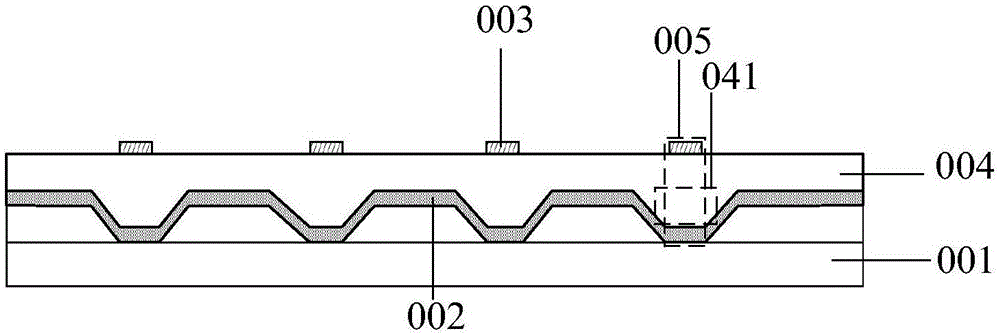

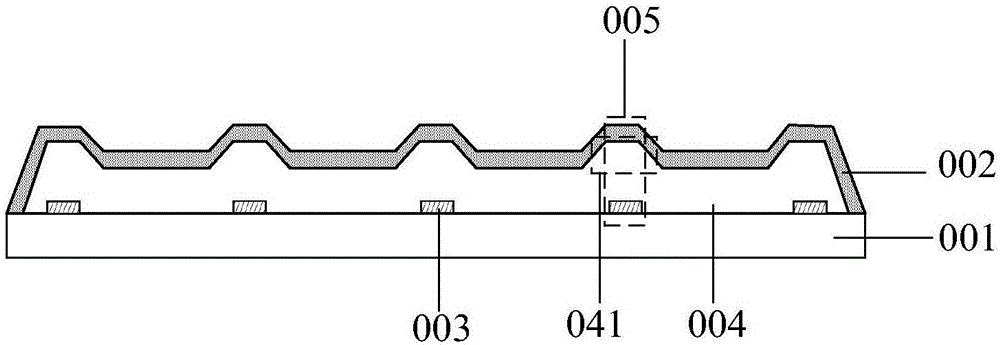

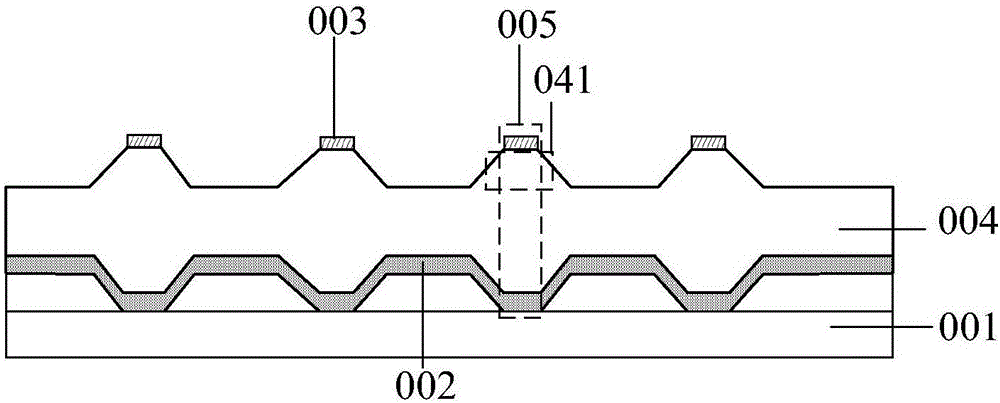

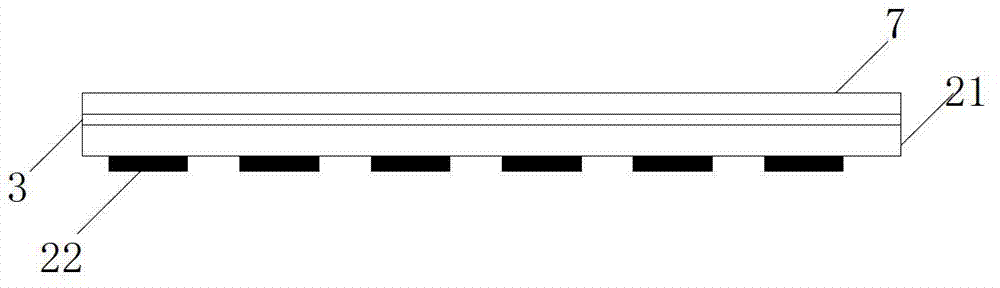

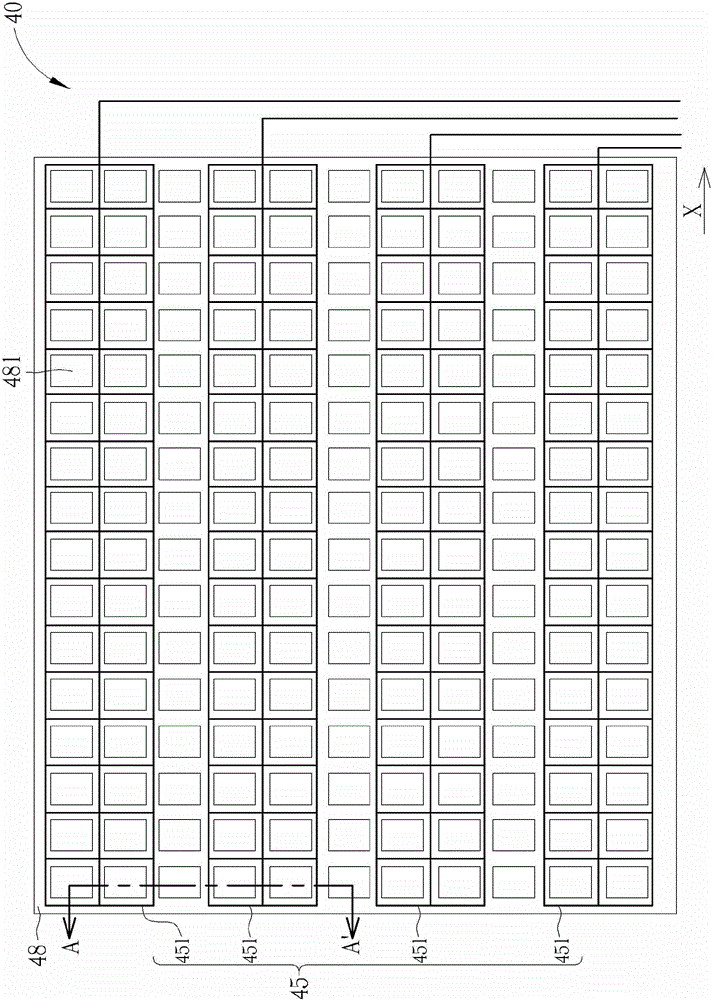

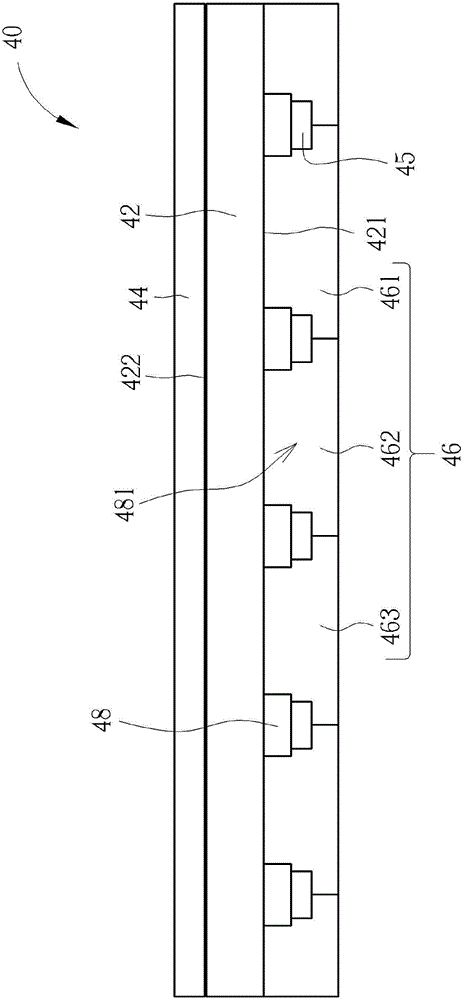

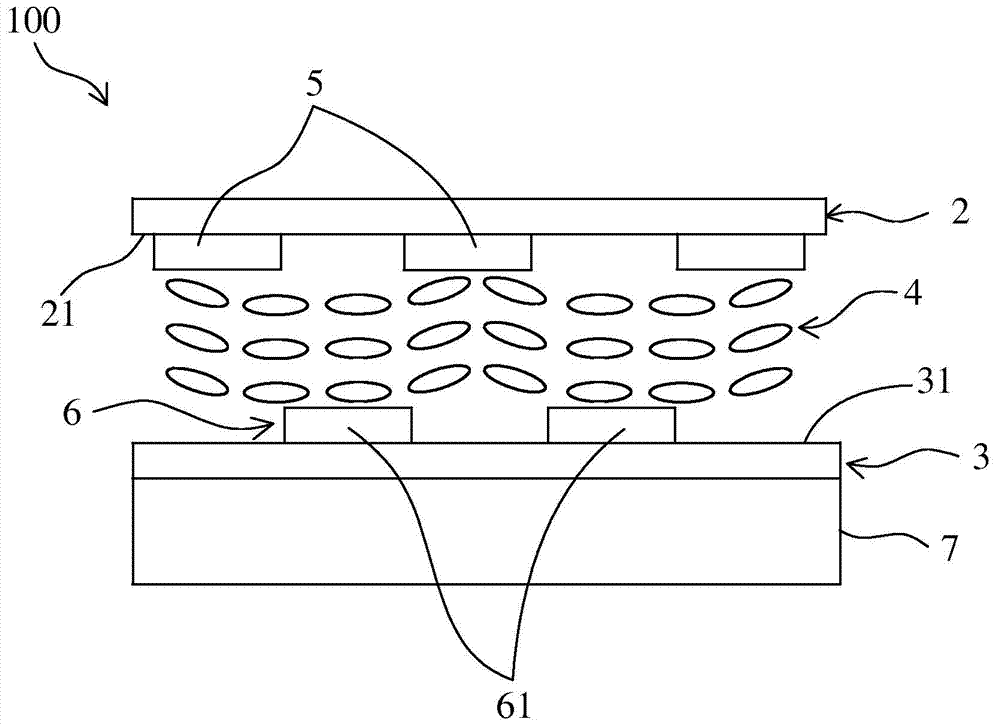

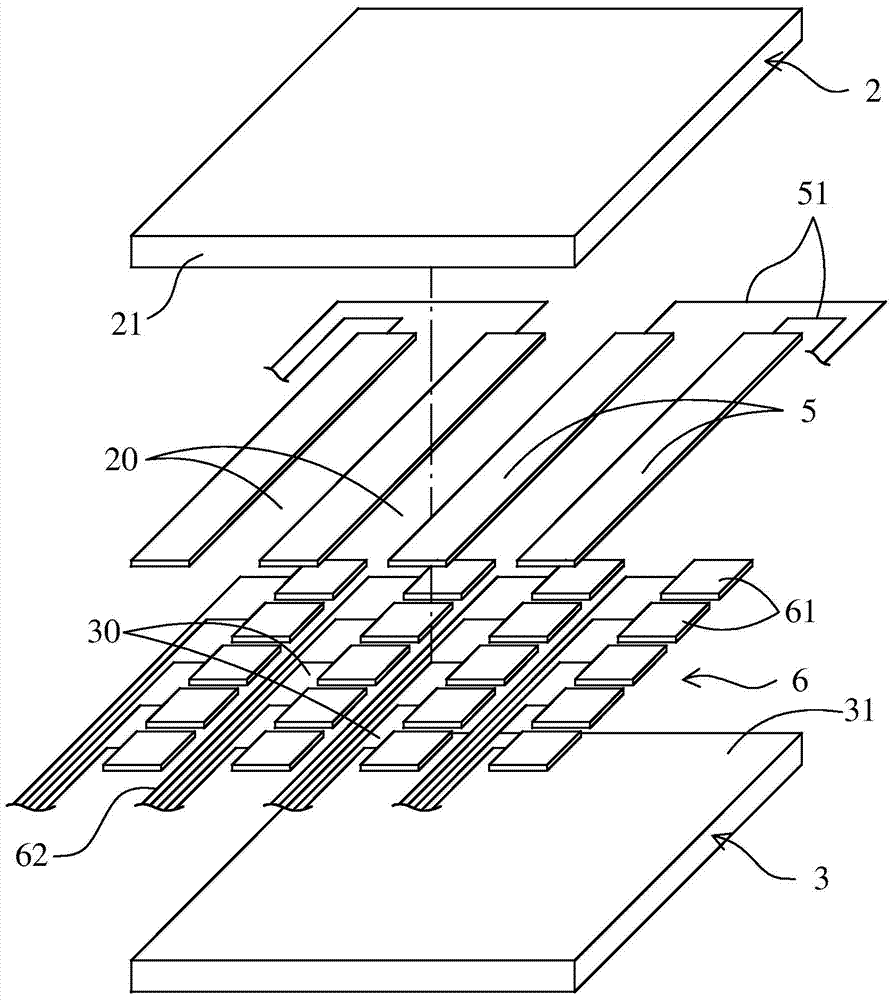

Touch screen, display apparatus and manufacturing method for touch screen

ActiveCN106249975AImprove touch sensitivityReduce distanceNon-linear opticsInput/output processes for data processingCapacitanceMedia layer

Embodiments of the invention disclose a touch screen, a display apparatus and a manufacturing method for the touch screen. The touch screen comprises a substrate, a plurality of first touch electrodes extending in a row direction and arranged on the substrate, a plurality of second touch electrodes extending in a column direction and arranged on the substrate, and medium layers between the first touch electrodes and the second touch electrodes, wherein the thickness of each medium layer in an overlapping area of each first touch electrode and each second touch electrode is greater than the thickness of the medium layer in other area. According to the scheme, in the medium layer between the two layers of touch electrodes, the thickness of the medium layer in the overlapping area of the two layers of touch electrodes is greater than the thickness of the medium layer in other area, such as the edge, correspondingly, the generated capacitance is smaller than the capacitance at the edge, so that the influence on the touch effect is reduced and the touch sensitivity is improved.

Owner:BOE TECH GRP CO LTD

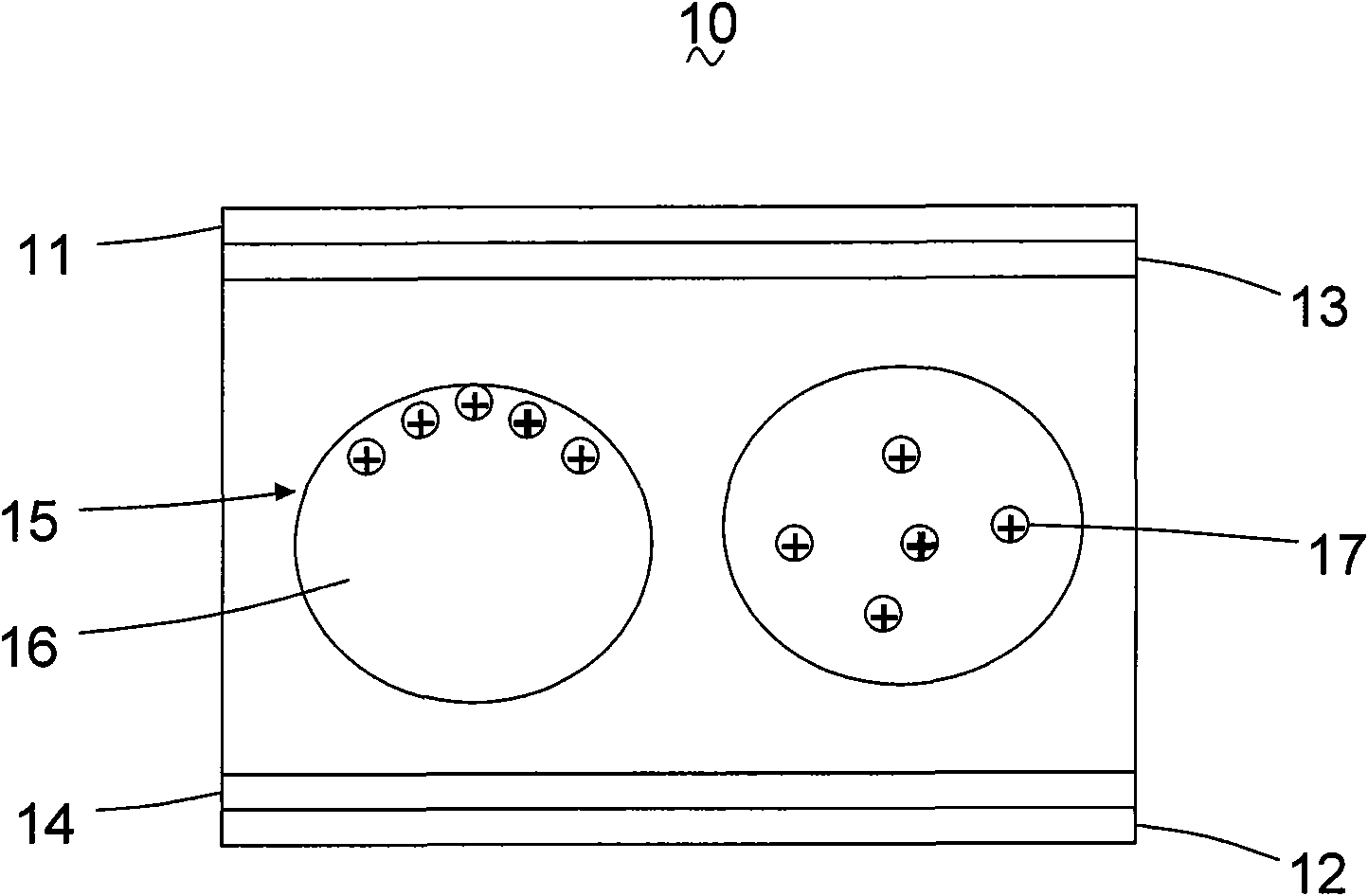

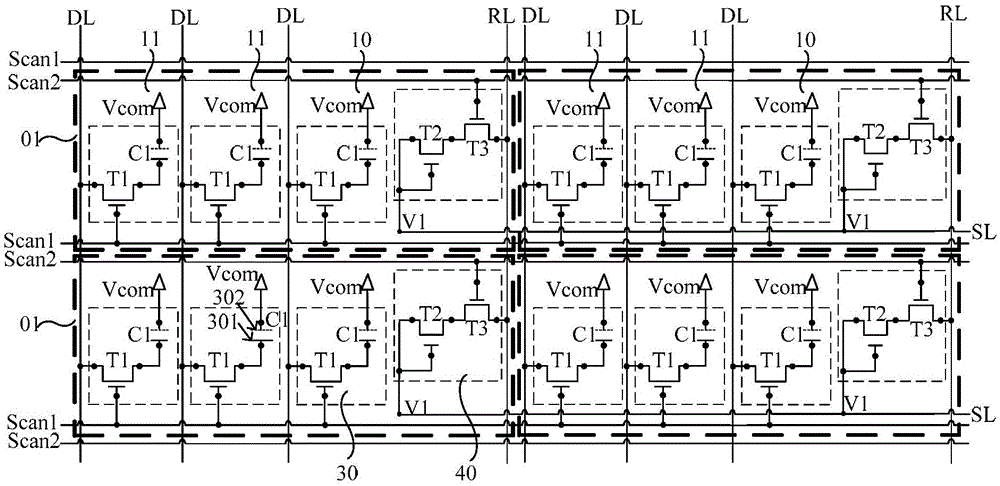

Electronic paper of integrated capacitive touch screen and driving method thereof

ActiveCN101887200ASimple structureWith touch functionStatic indicating devicesNon-linear opticsCapacitanceEngineering

The invention relates to electronic paper of an integrated capacitive touch screen and a driving method thereof. The electronic paper comprises a plurality of scanning lines, a plurality of touch induction lines, a plurality of mutual capacitors and a detecting circuit, wherein the scanning lines are mutually parallel, image scanning signals are input to the scanning lines in sequence and are used for conducting a thin film transistor connected with the scanning lines; the touch induction lines are mutually parallel and respectively intersected with the scanning lines in an insulated mode; the mutual capacitors are used for inducing whether the electronic paper is touched from the exterior or not; and the detecting circuit is used for detecting the capacitance variation of the mutual capacitors and is connected with the touch induction lines. Touch scanning signals are input to the scanning lines in sequence, and the time for inputting the touch scanning signals to the scanning lines is different from the time for inputting the image scanning signals to the scanning lines. The voltage of the touch scanning signals is lower than the conducting voltage of the thin film transistor, the detecting circuit detects the position of the mutual capacitor with capacitance variation, and thus, the touch position of the electronic paper from the exterior is determined.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

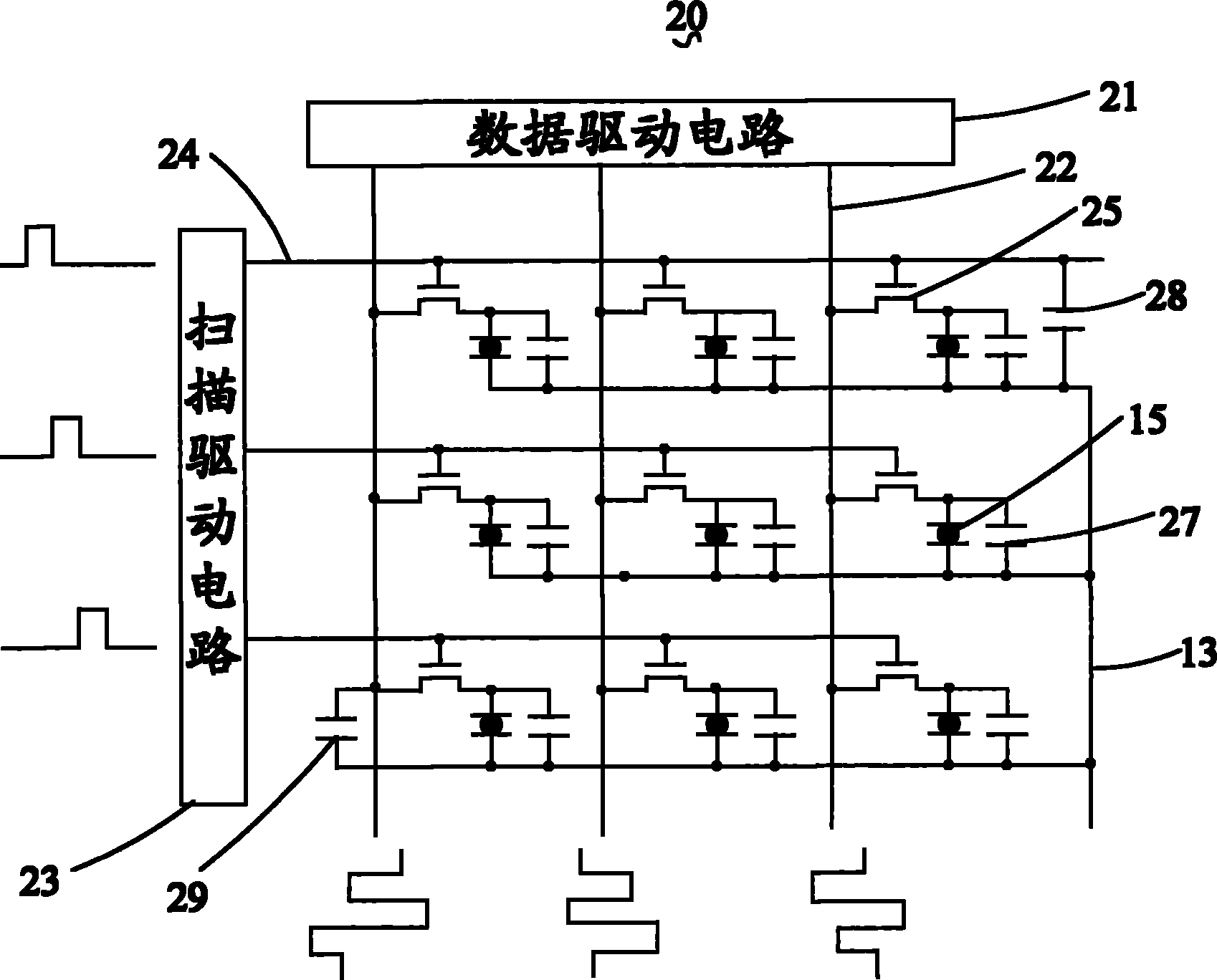

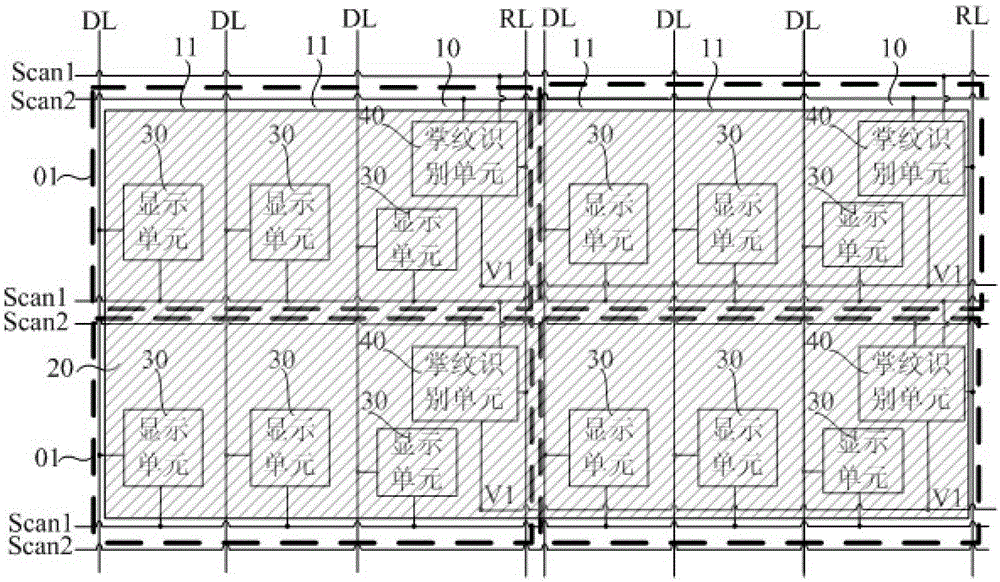

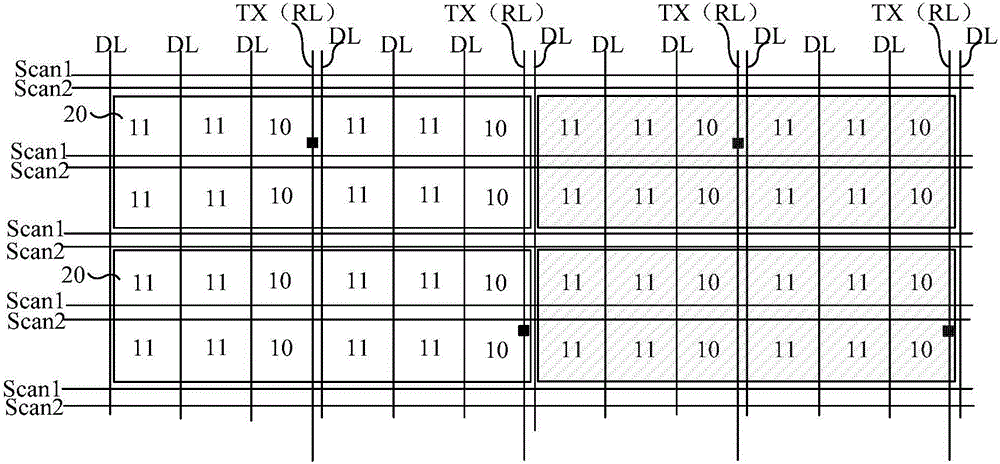

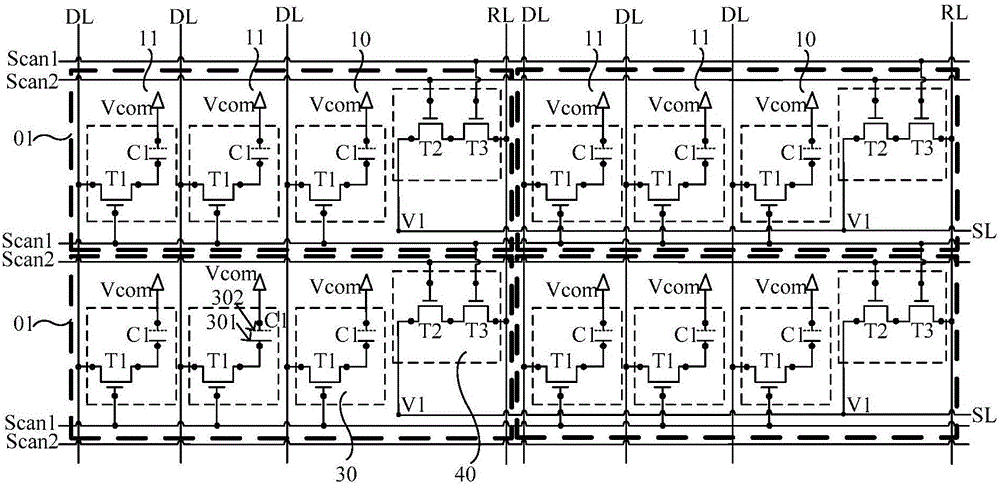

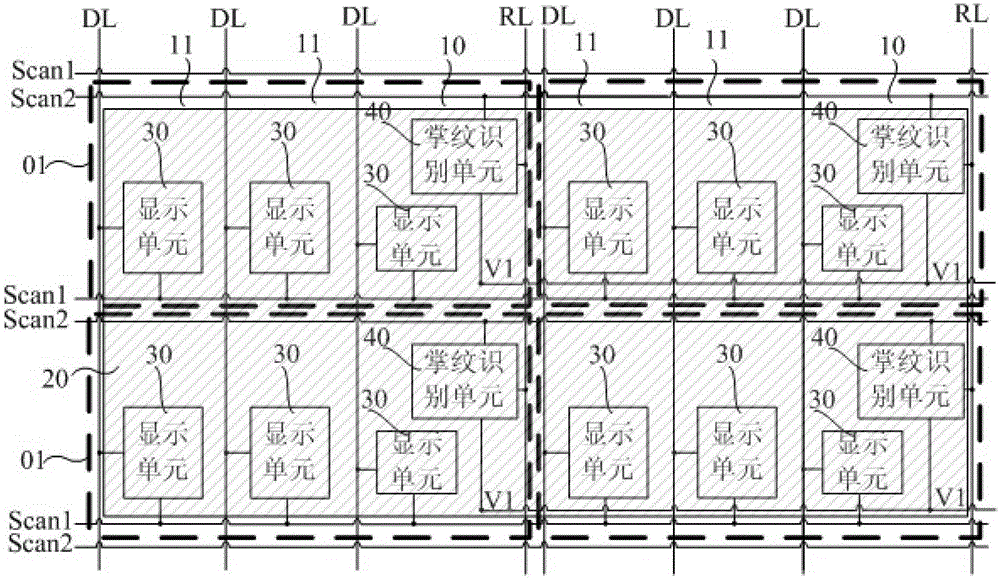

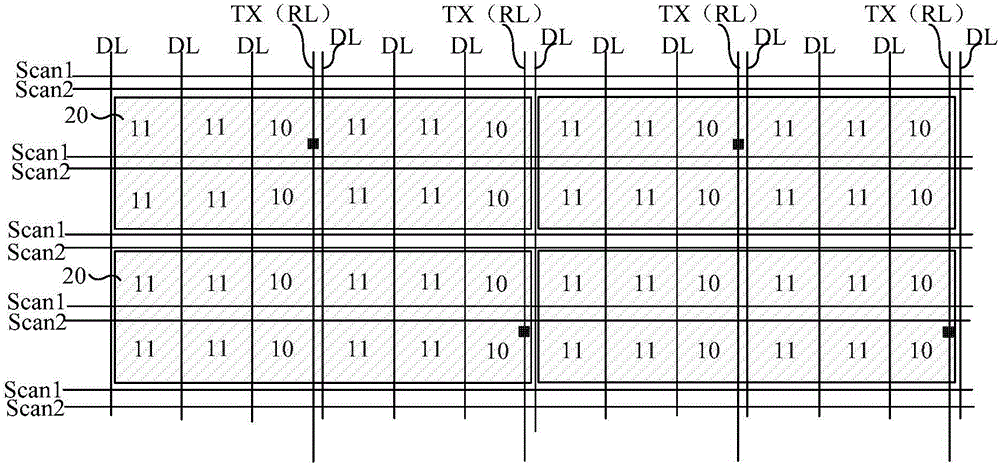

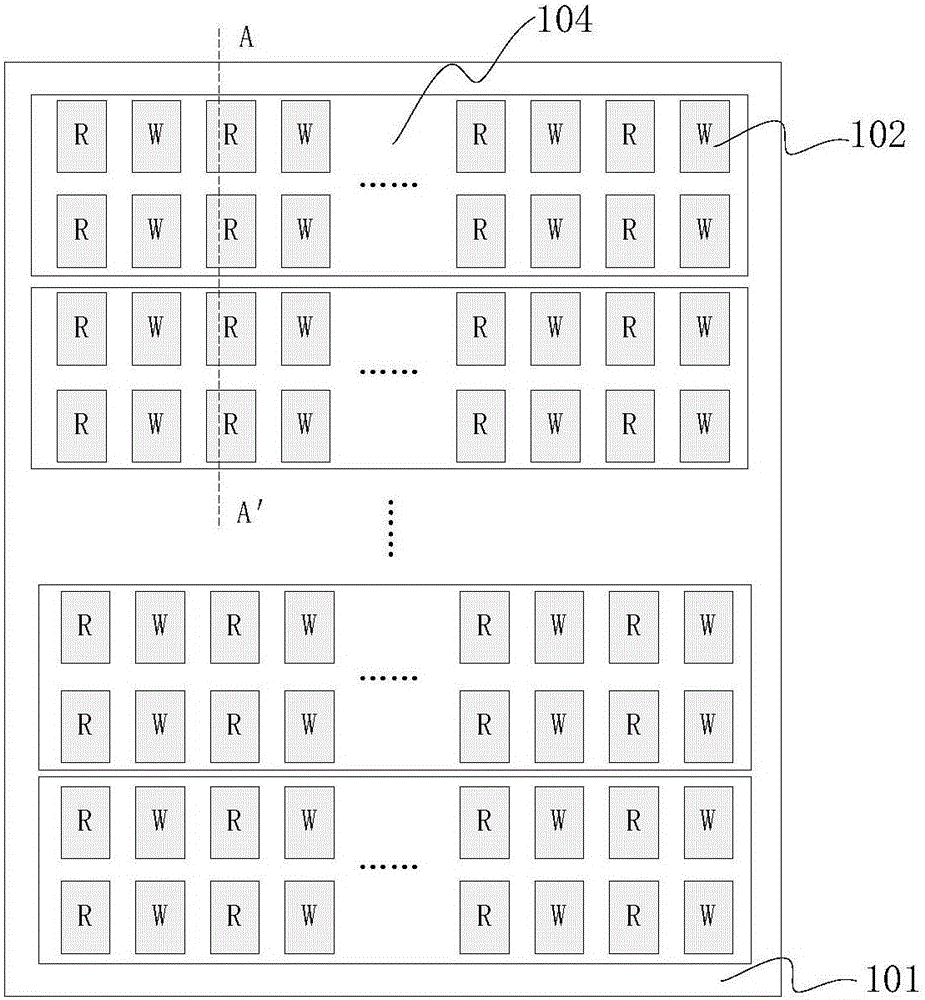

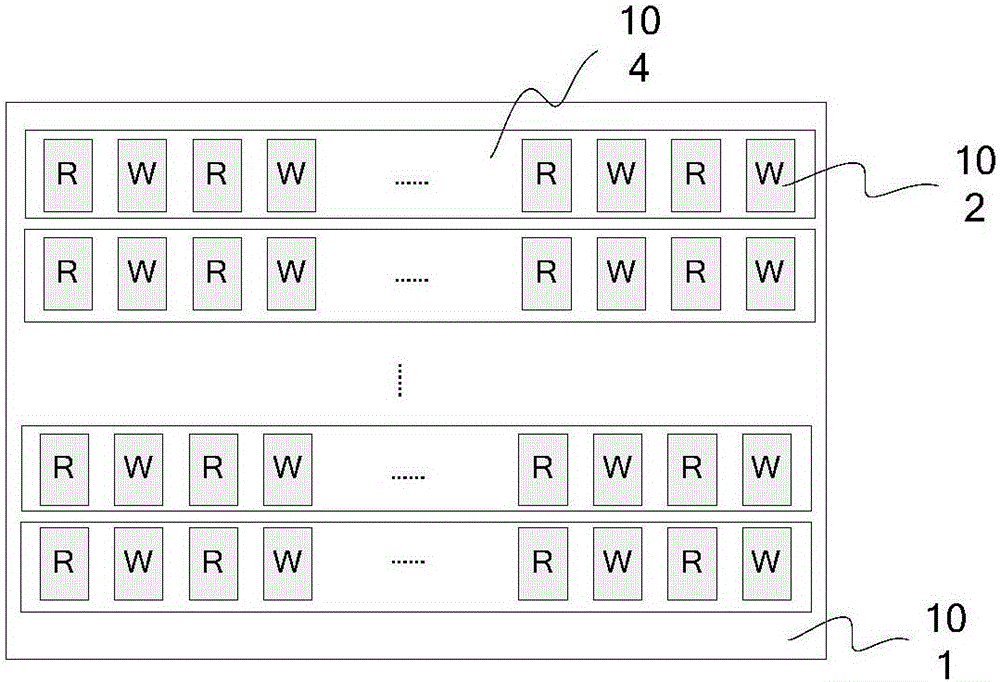

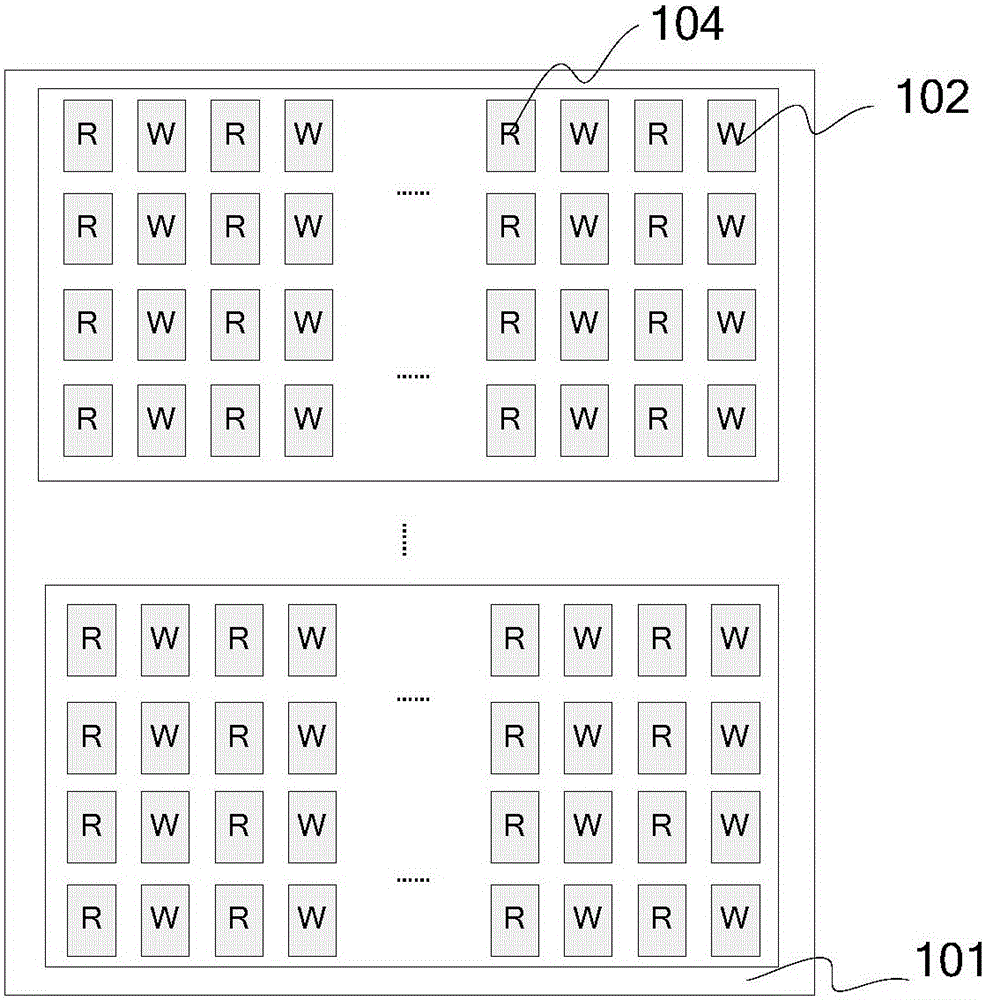

Array base plate, driving method of same, display panel and display device

ActiveCN104991364AWith touch functionNormal image display functionStatic indicating devicesCharacter and pattern recognitionDisplay deviceData signal

The embodiment of the invention provides an array base plate, a driving method of the same, a display panel and a display device and relates to the technical field of displaying. The display device possesses a palmprint recognition function and simple structure. The array base plate comprises a plurality of repeat units. Each repeat unit is formed by a plurality of sub-pixels; each sub-pixel is provided with a displaying unit; one of the sub-pixel is provided with a palmprint recognition unit; the array base plate further comprises a touch control electrode connected with a touch control electrode line; the display unit is formed by a first scanning line and a data line to open or close the display unit controlled by the first scanning line; a data signal can be input by the data line when the displaying unit is opened; the palmprint recognition nit is connected with the first scanning line, a second scanning line, a voltage controlling end and a signal-reading line to collect the palmprint signal under the control of the second scanning line and the voltage controlling end, and to send the collected palmprint signal to the signal-reading line under the control of the first scanning line; and at the signal is sent to the displaying device having the palmprint recognition function.

Owner:BOE TECH GRP CO LTD +1

Array substrate, driving method thereof, display panel and display device

ActiveCN105093611AWith touch functionNormal image display functionStatic indicating devicesDiagnostic recording/measuringDisplay deviceData signal

The embodiment of the invention provides an array substrate, a driving method thereof, a display panel and a display device, pertaining to the field of display technology. Therefore, the display device has a palmprint recognition function and a simple structure. The array substrate comprises multiple repeating units including multiple sub-pixels, each of which is provided with a display unit. One of the sub-pixels is provided with a palmprint recognition unit. The array substrate further comprises a touch electrode connected with touch electrode wires. Each display unit is connected with a first scanning line and data line, which is used for turning on or off each display unit under control of the first scanning line and inputting a data signal by the data line when the display unit is turned on. Each palmprint recognition unit is connected with a second scanning line, a control voltage terminal and a read signal line, which is used for acquiring a palmprint signal under control of the control voltage terminal and transmitting the acquired palmprint signal to the read signal line under control of the second scanning line. The array substrate is used for the display device with palmprint recognition function.

Owner:BOE TECH GRP CO LTD +1

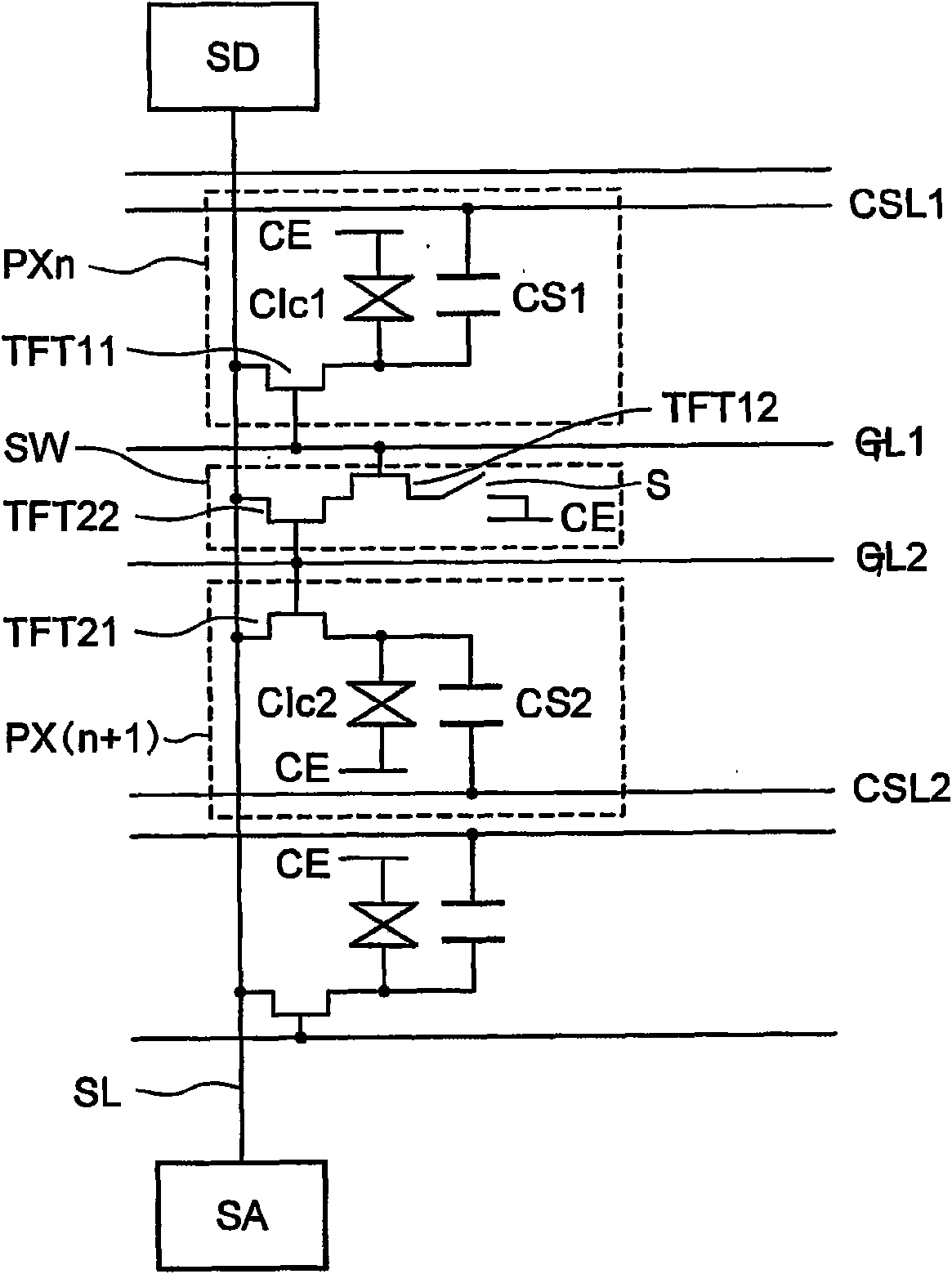

Active matrix display apparatus with touch sensing function

ActiveCN101620333AImprove display qualityWith touch functionStatic indicating devicesNon-linear opticsActive matrixTouch Senses

Owner:INNOLUX CORP

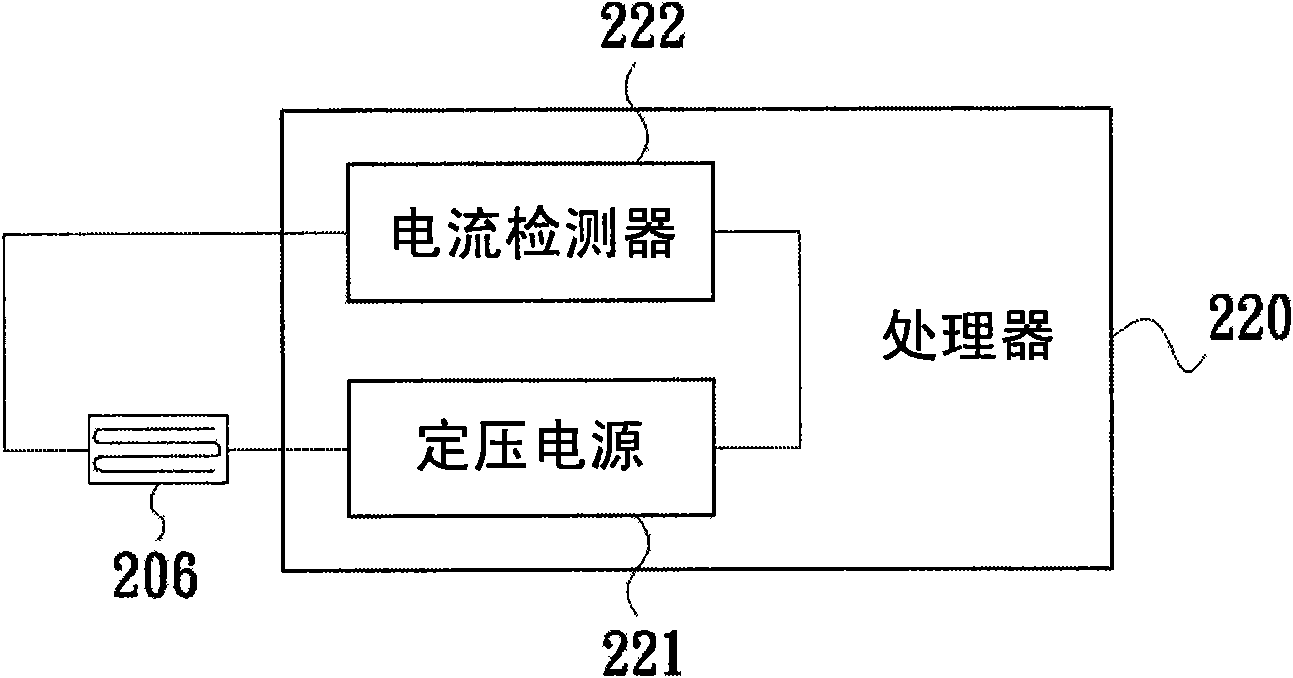

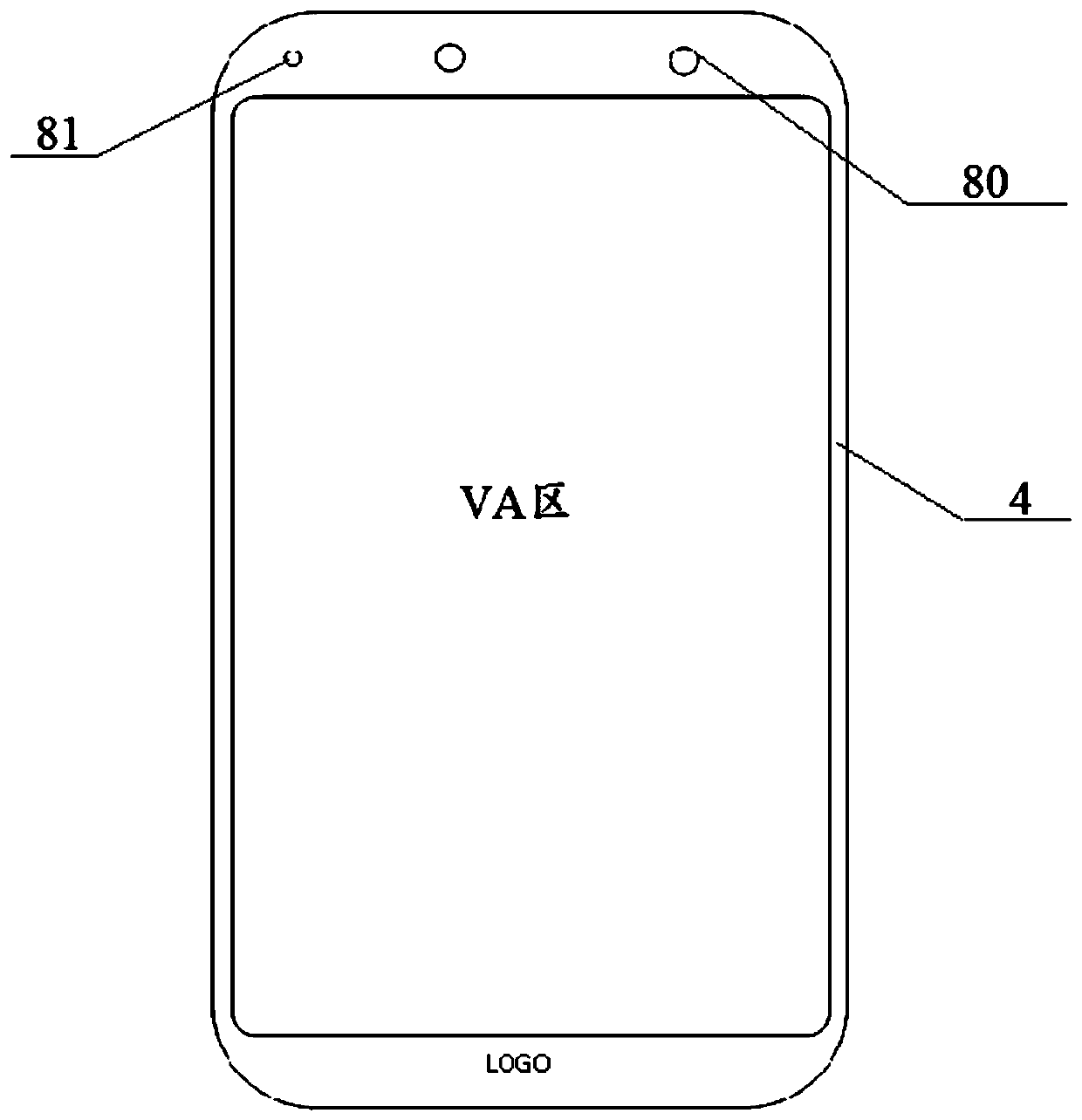

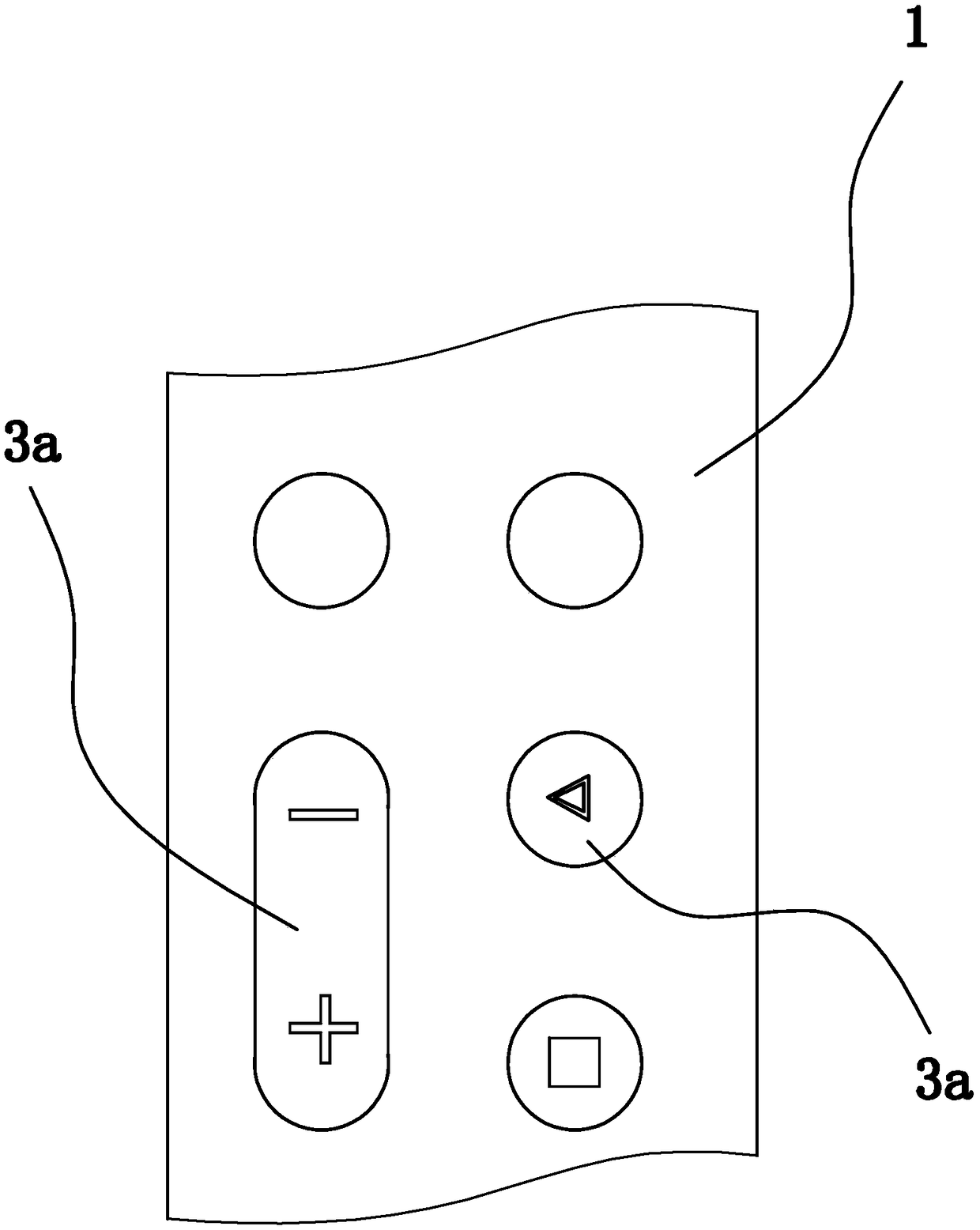

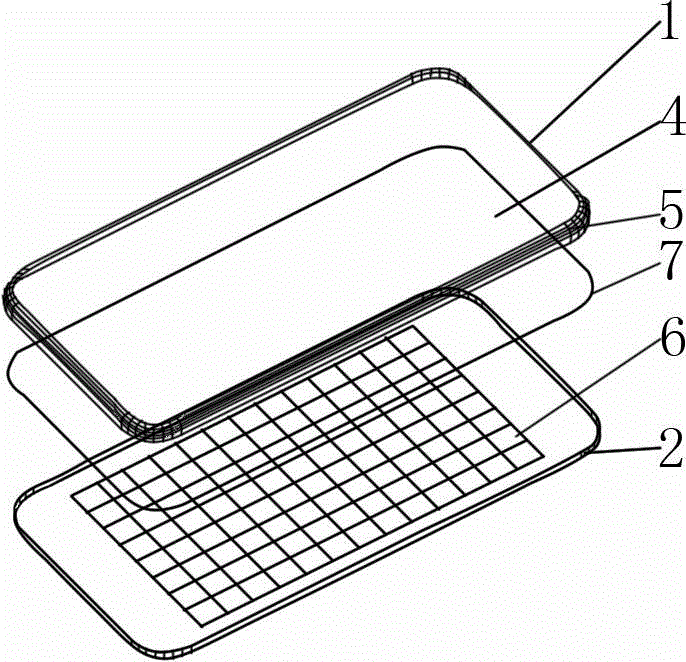

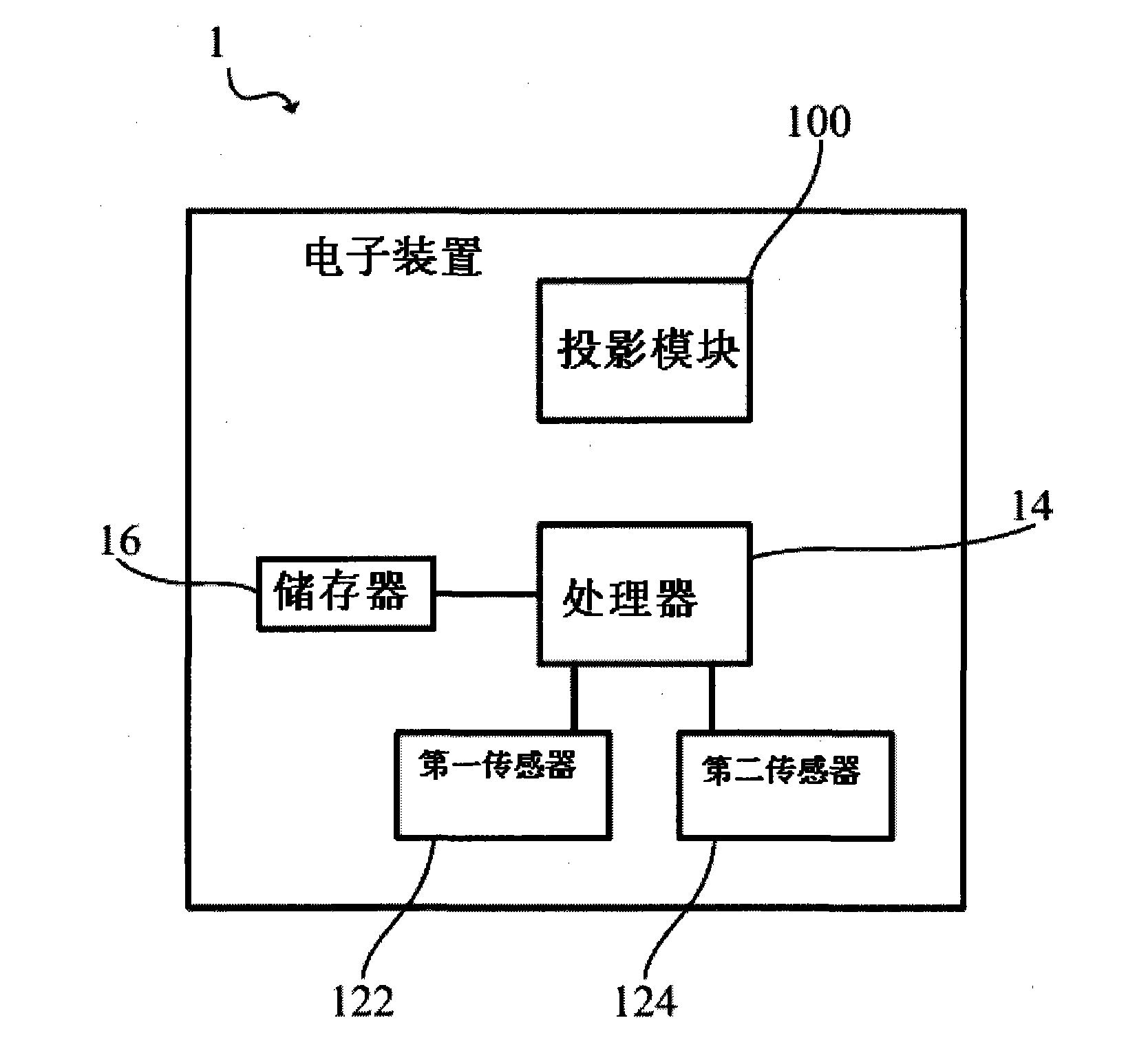

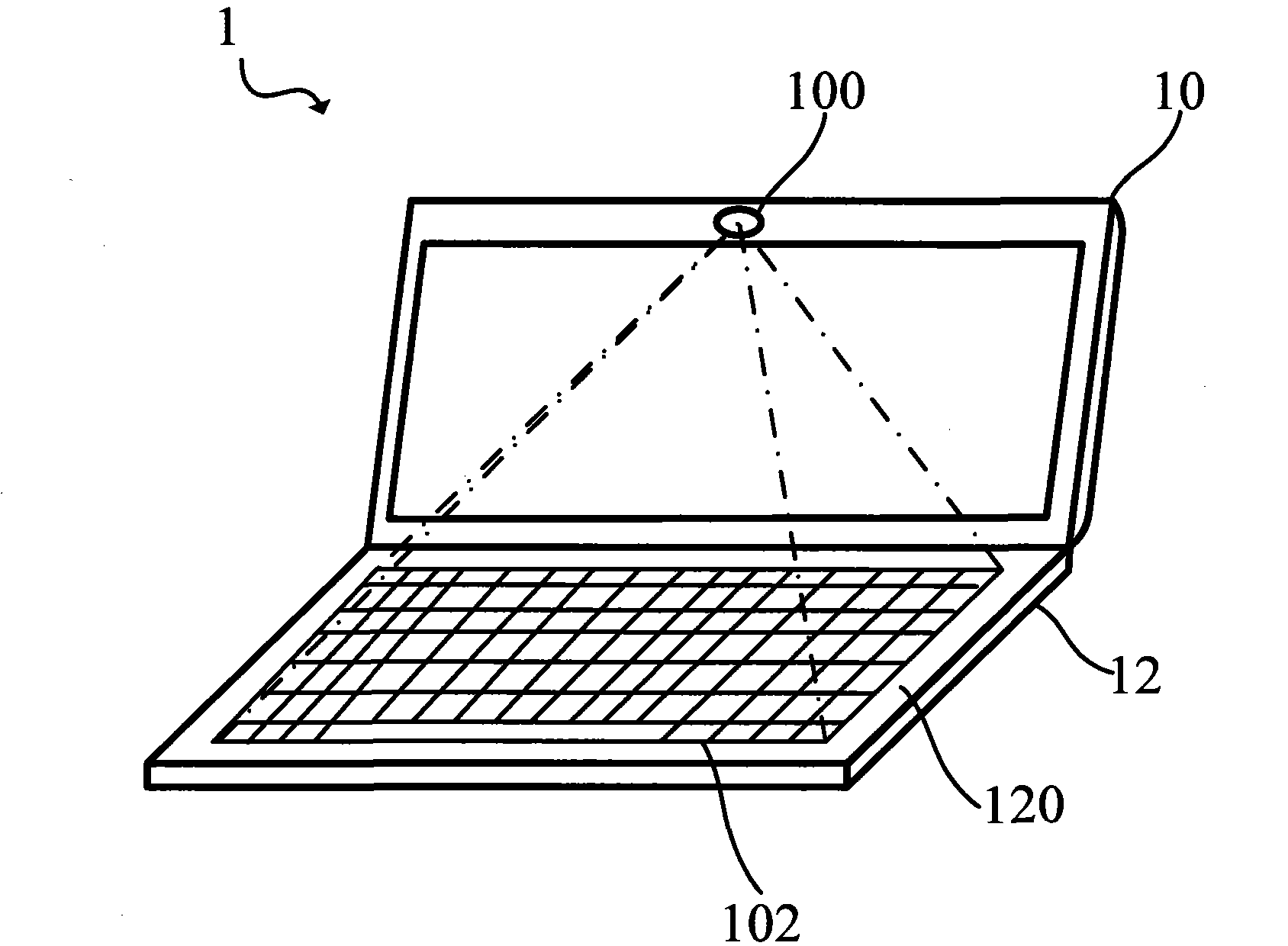

Electronic device

ActiveCN108196714AIncrease the effective display areaWith touch functionDigital data processing detailsTelephone set constructionsHuman–computer interactionControl function

The invention discloses an electronic device. The electronic device includes a body, a display screen fixedly arranged on the body, and a sensor. the display screen has a gap, the gap corresponds to agap region, the sensor is used for obtaining touch input, in the gap region, of an operating body, so that the gap region has a touch control function and the gap region of the electronic device canprovide a function of a key. Besides, all regions, except for the gap, of the display screen can serve as effective display regions, and the effective display regions of the electronic equipment can be increased.

Owner:LENOVO (BEIJING) CO LTD

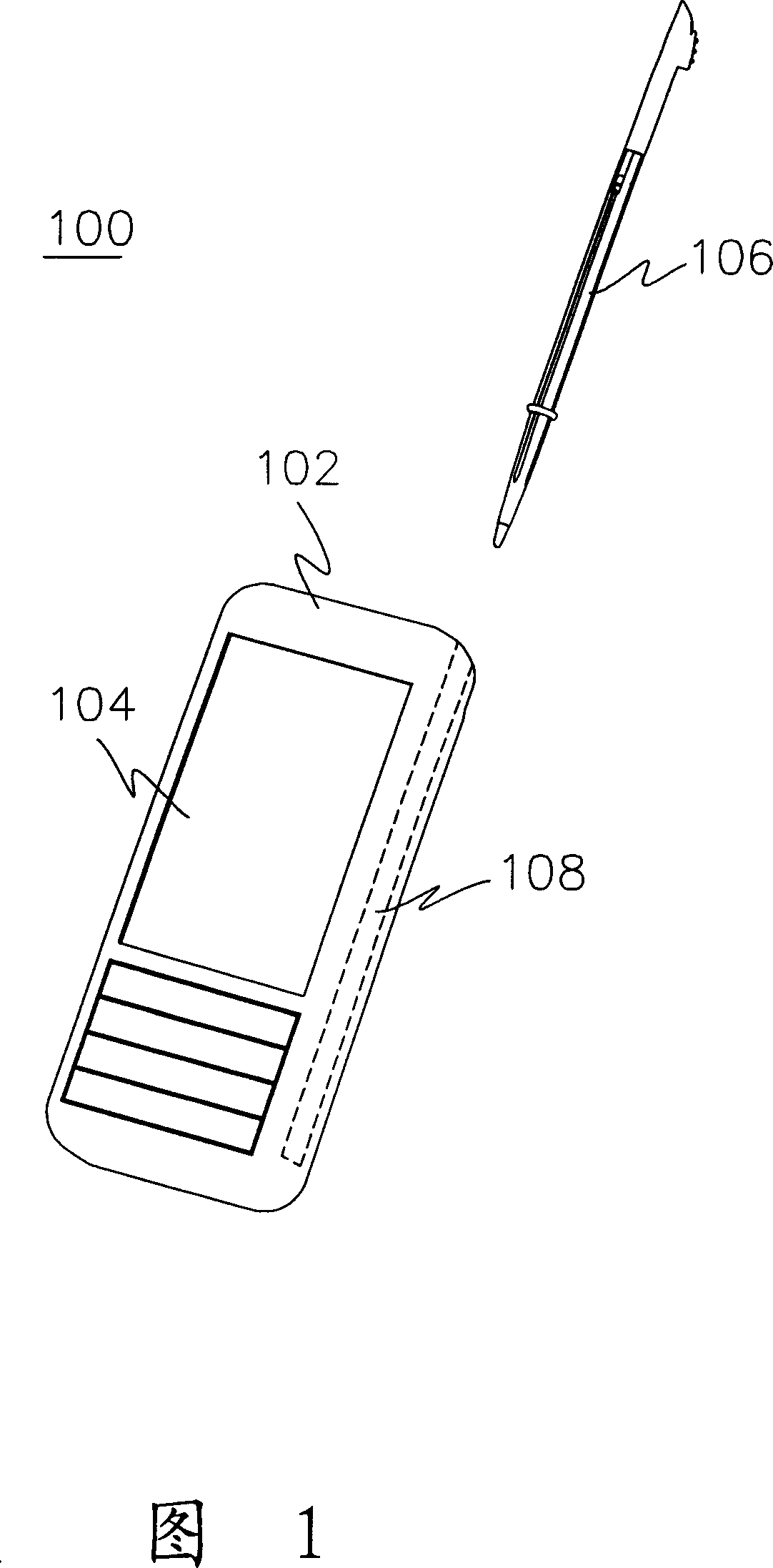

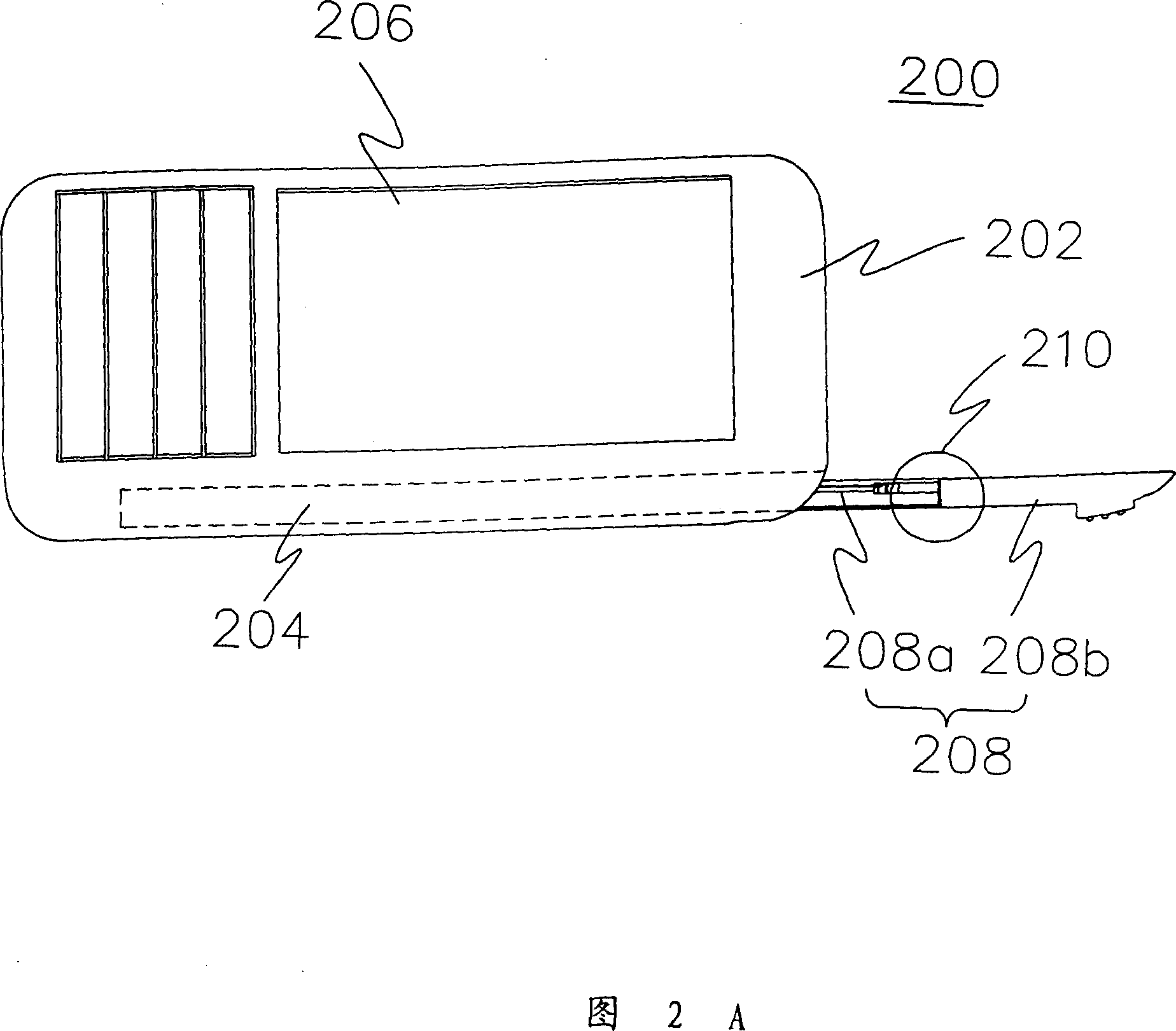

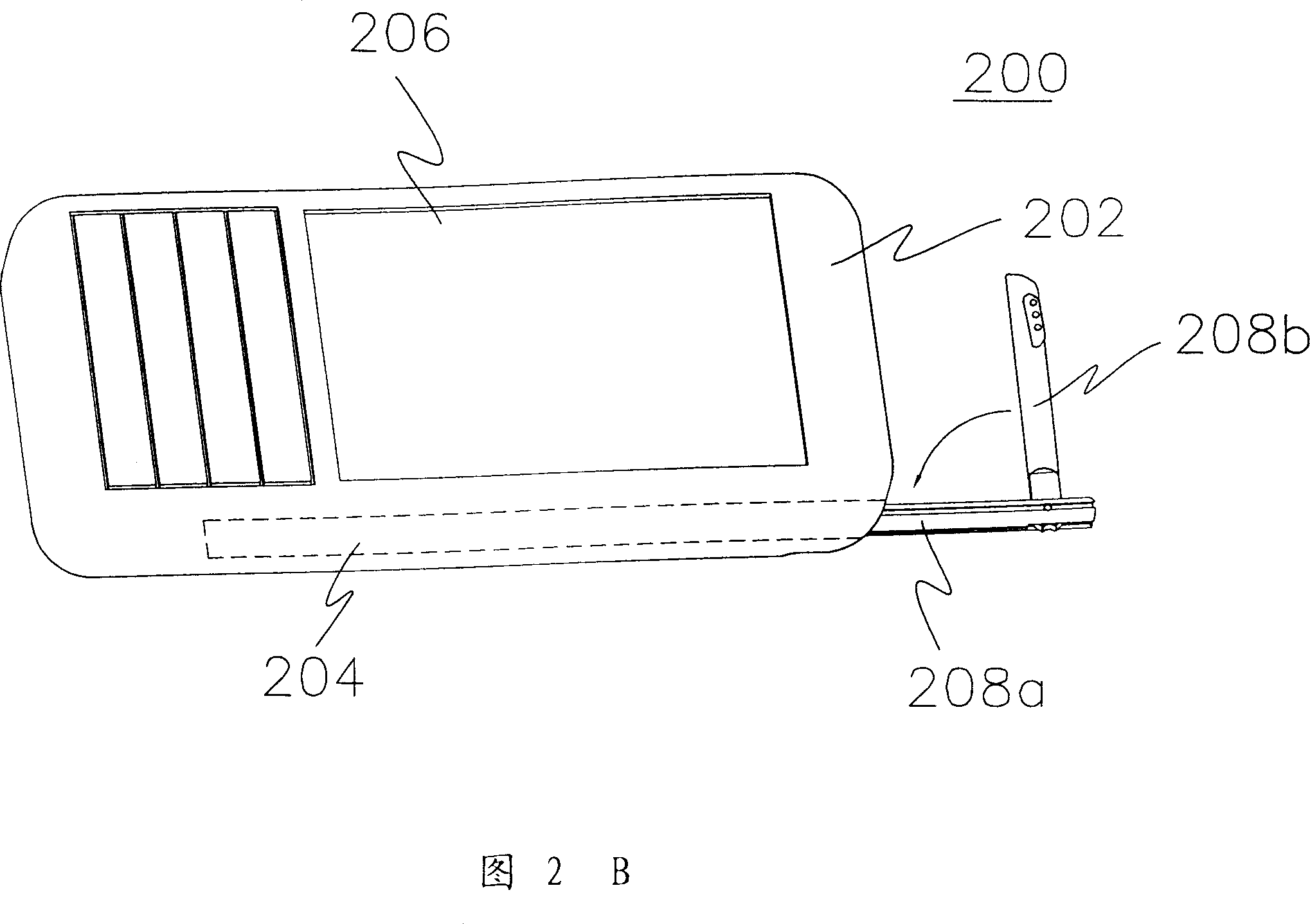

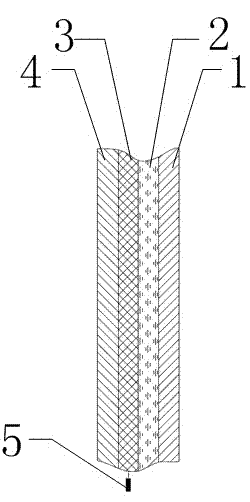

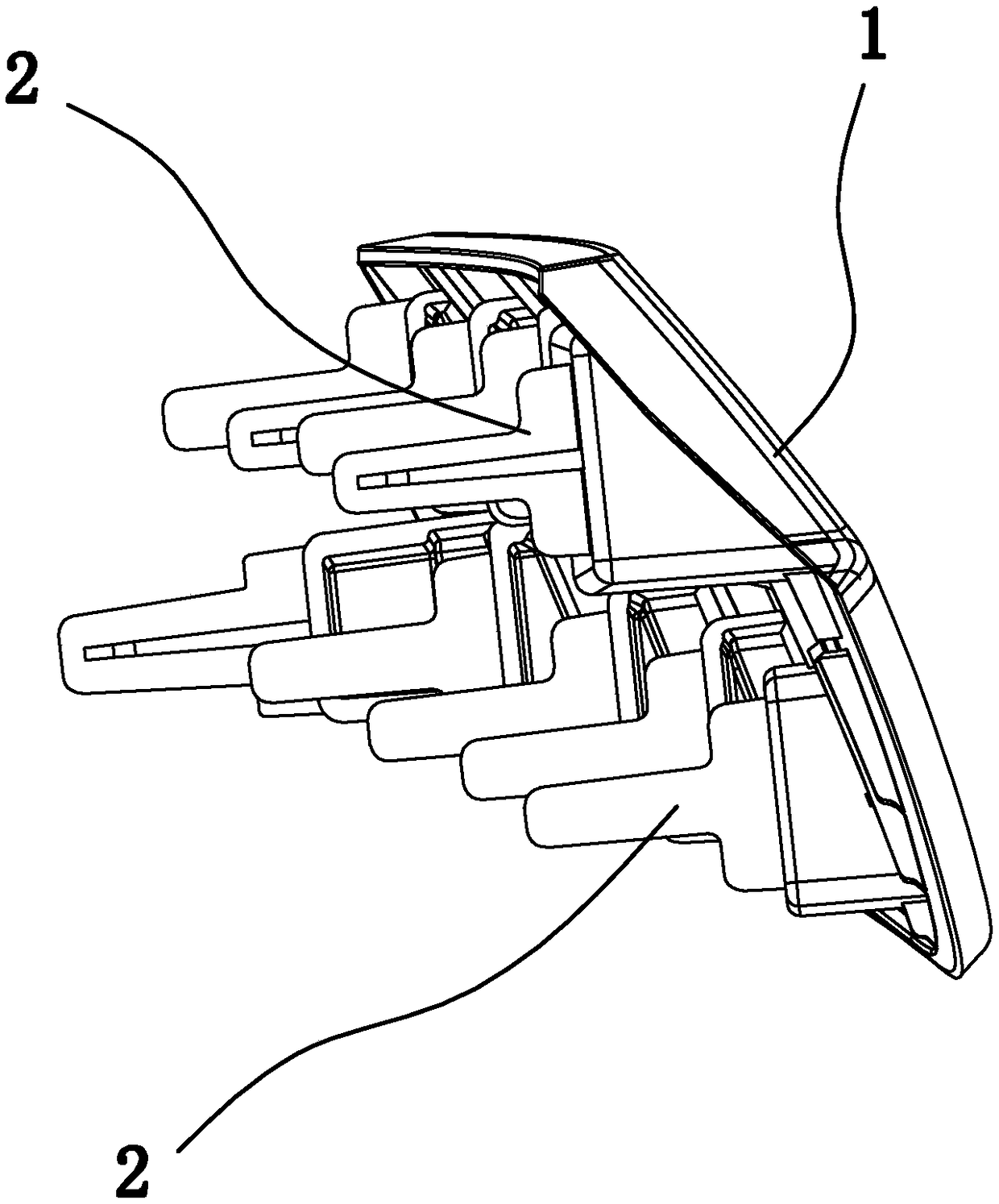

Portable device and touch-control pen

ActiveCN1979393AChange inclineWith touch functionInput/output processes for data processingElastic componentEngineering

The invention is a touch pen for portable devices, comprising: main body part and turning part, where the main body part comprises pointed end and pin-jointing end, the pin-jointing end has two salient ribs; and the turning part comprises locating plate pin-jointed with the salient ribs; a bolt runs through the salient ribs and the locating plate to make the turning part pin-jointed with the main body part at least at a specific turning angle; the locating plate has at least at a locating structure whose section shape is a circular arc hollow; the touch pen also comprises elastic component and locating ball, where the elastic component sustains the locating ball in the locating structure to make the portable devices able to stand on desk. Besides, the side wall of the main body part further has at least a groove, cooperating with elastic card tenons of the portable devices so as to change their gradients.

Owner:HTC CORP

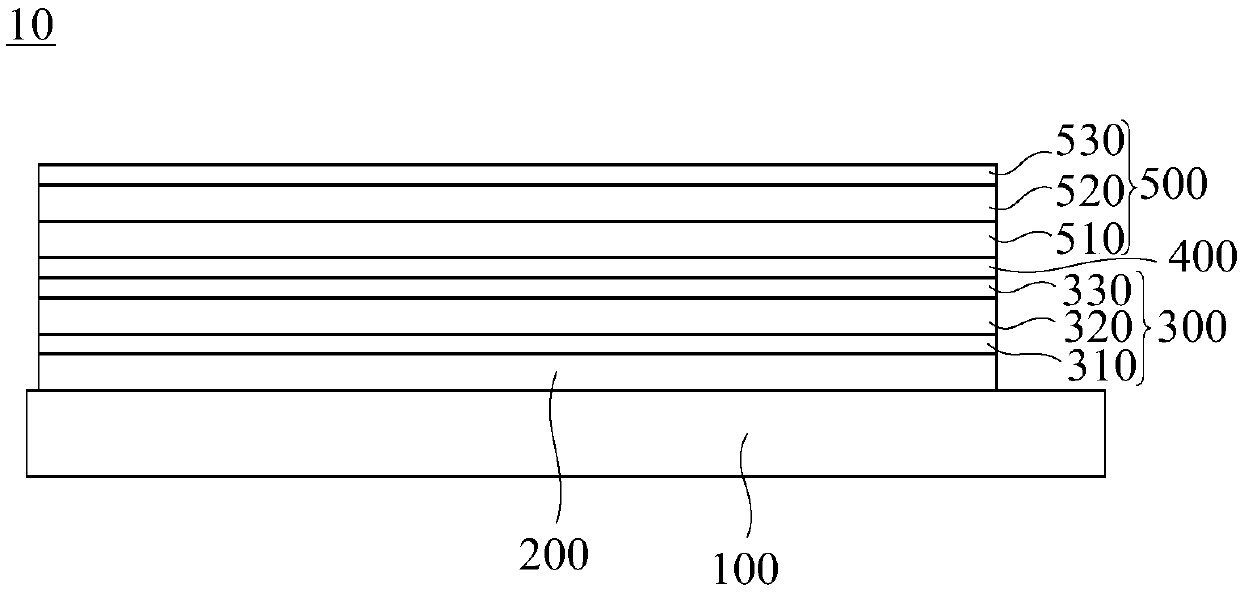

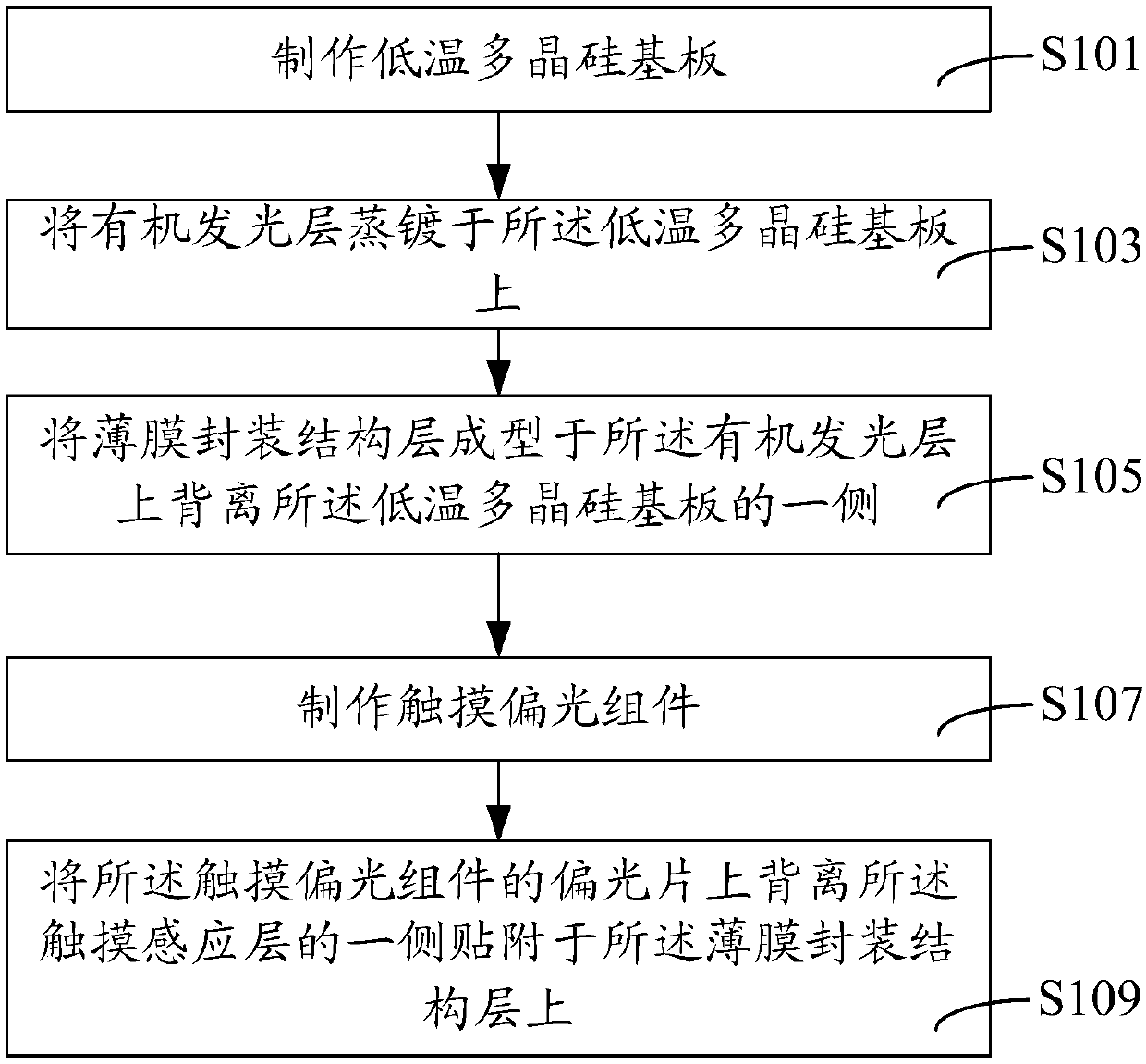

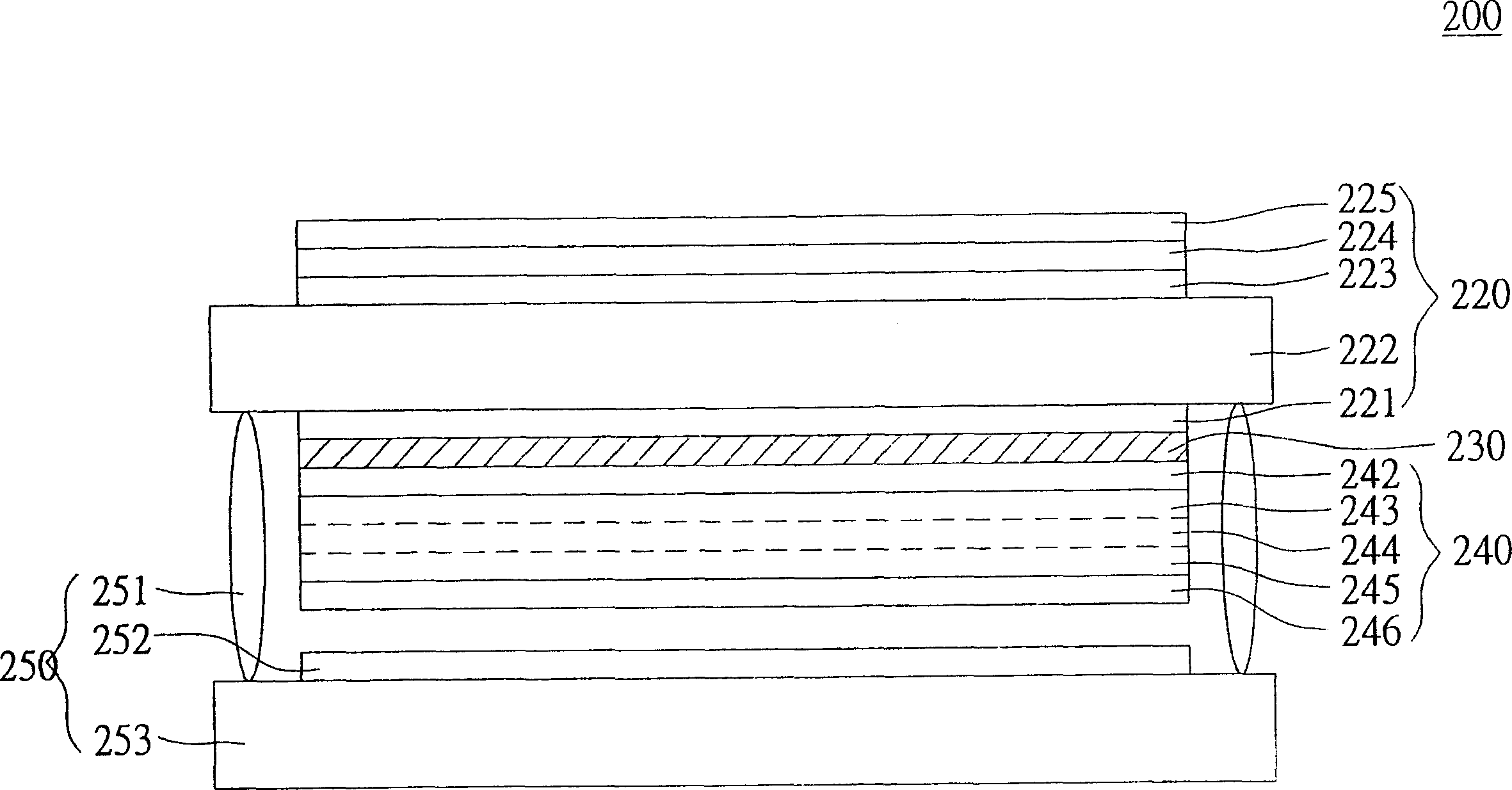

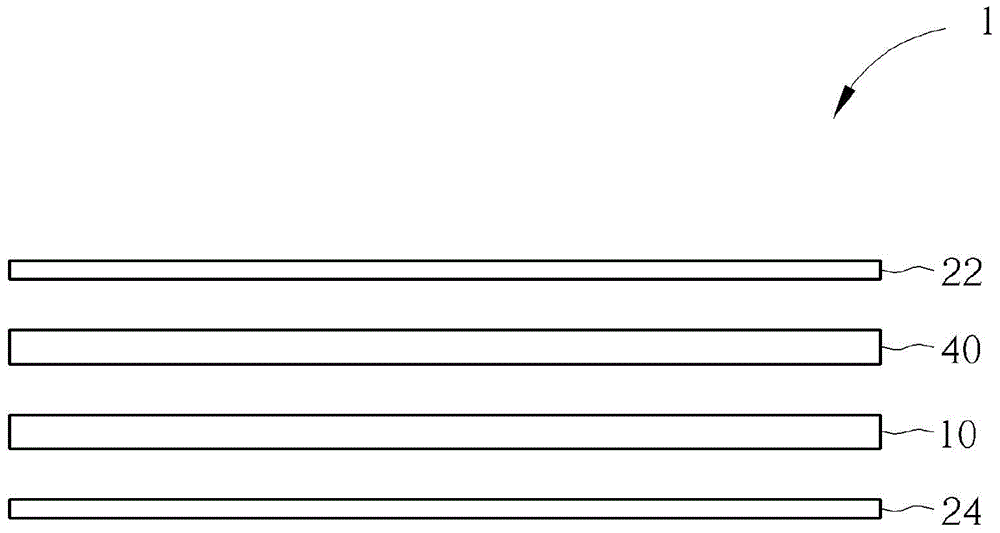

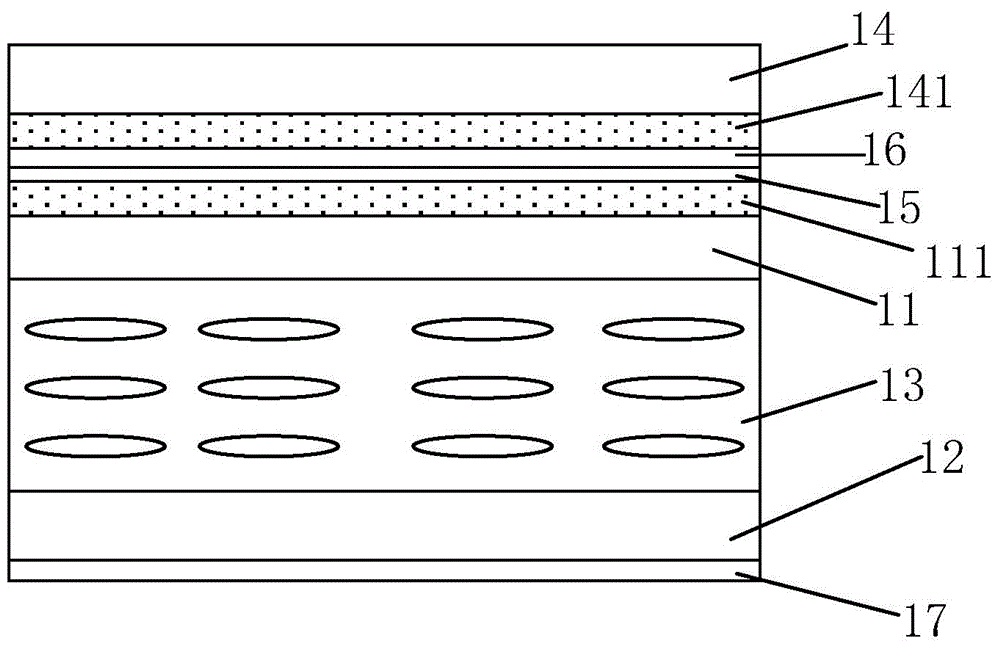

AMOLED module and preparation method thereof

InactiveCN107706216AShort manufacturing cycleShort manufacturing timeSolid-state devicesSemiconductor/solid-state device manufacturingTouch SensesWater vapor

The invention relates to an AMOLED module and a preparation method thereof. The AMOLED module comprises a low-temperature polysilicon substrate, an organic light-emitting layer, a thin film encapsulation structure layer, an adhesive layer and a touch polarized component. The organic light-emitting layer is disposed on the low-temperature polysilicon substrate. The adhesive layer is attached on thethin film encapsulation structure layer. The touch polarized component comprises a polarizer, a touch sensitive layer and a barrier layer. The polarizer is attached onto a far side of the adhesive layer away from the thin film encapsulation structure layer. The polarizer is used for polarizing a light source emitted by the organic light-emitting layer. The touch sensitive layer is attached onto afar side of the polarizer away from the adhesive layer. The barrier layer is attached onto a far side of the touch sensitive layer away from the polarizer. The barrier layer is used for blocking water vapor. Since the barrier layer and the touch sensitive layer are thin and both are made by taking the polarizer as a base material, the base material used for separately making the barrier layer andthe touch sensitive layer is saved, the polarizer is allowed to integrate the functions of moisture vapor blocking and touch sensing at the same time, and the total thickness of the AMOLED module isgreatly reduced.

Owner:TRULY HUIZHOU SMART DISPLAY

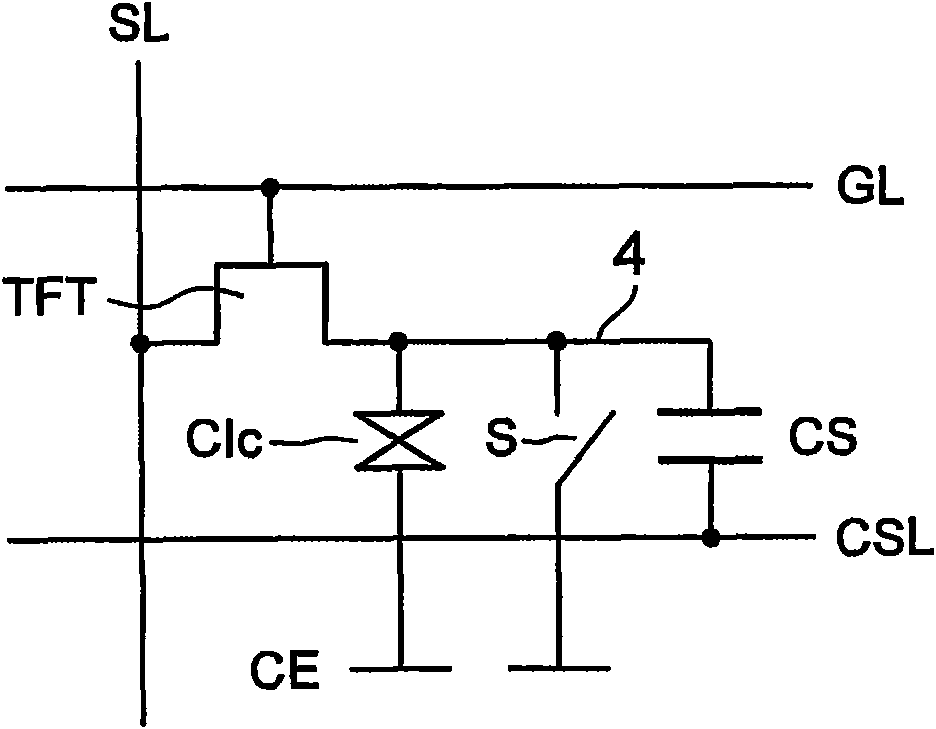

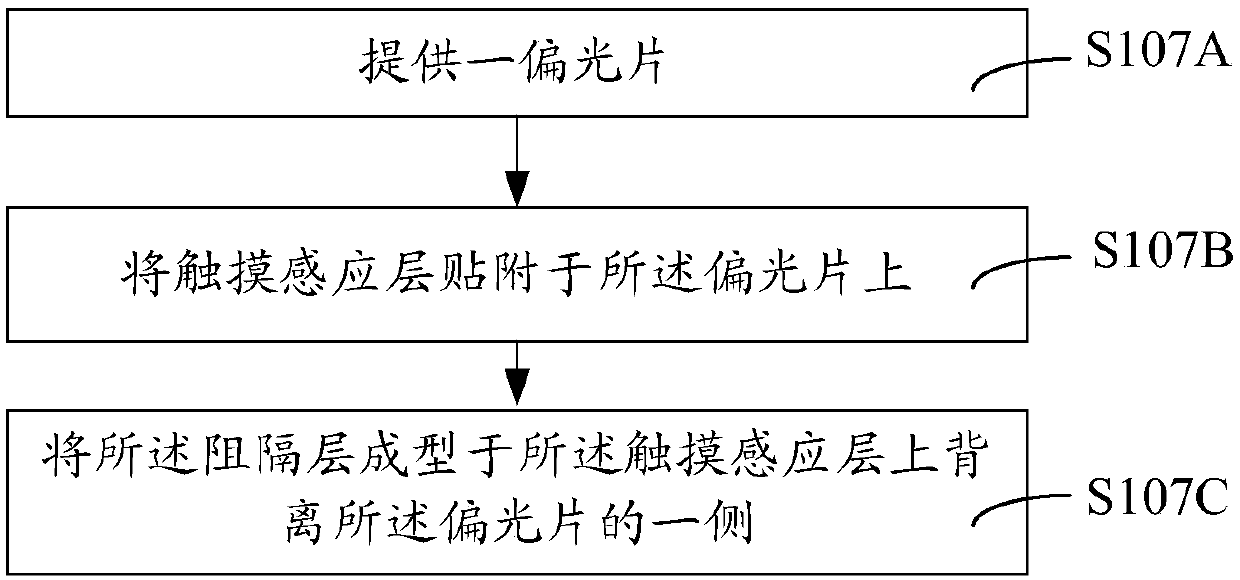

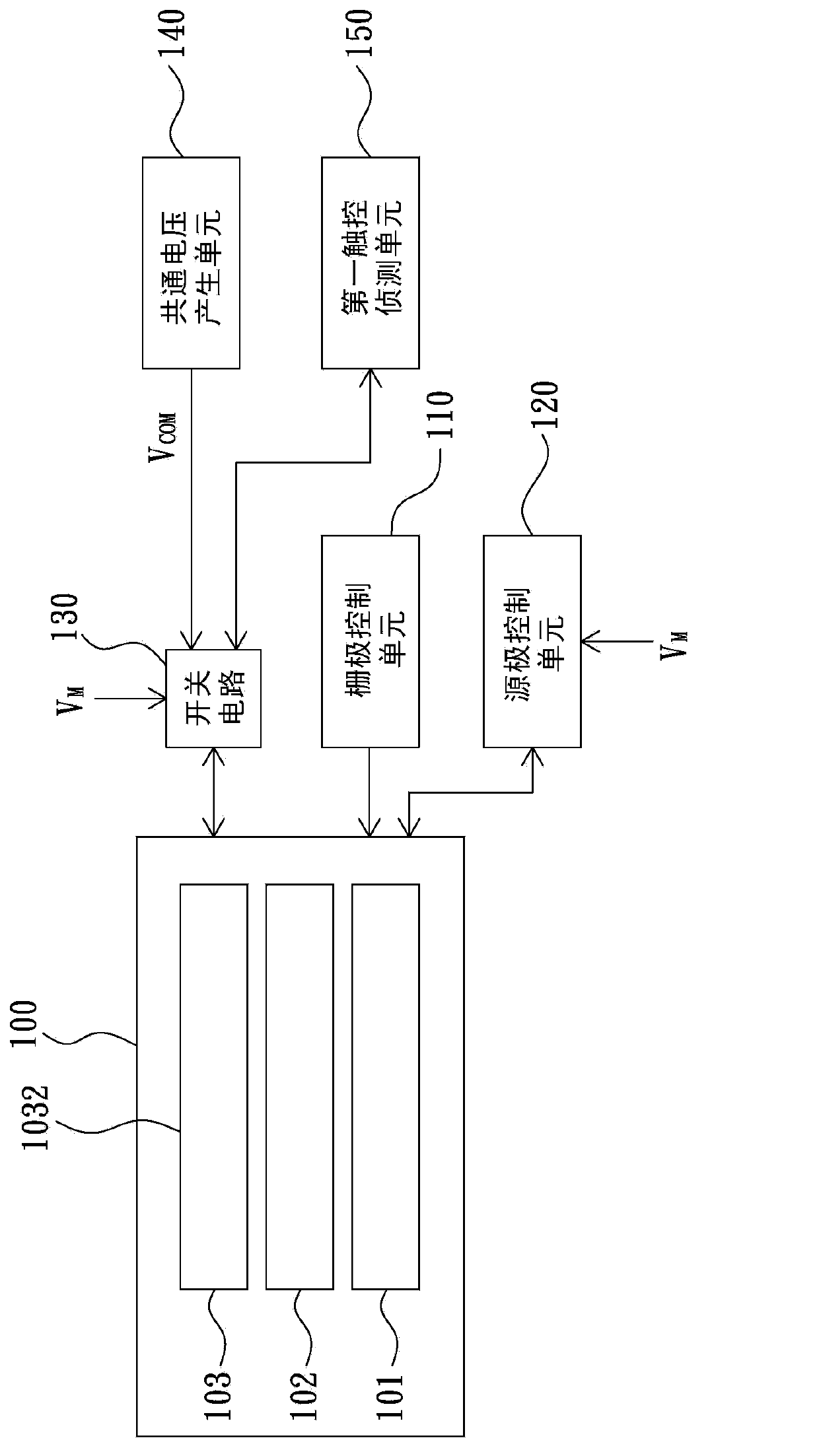

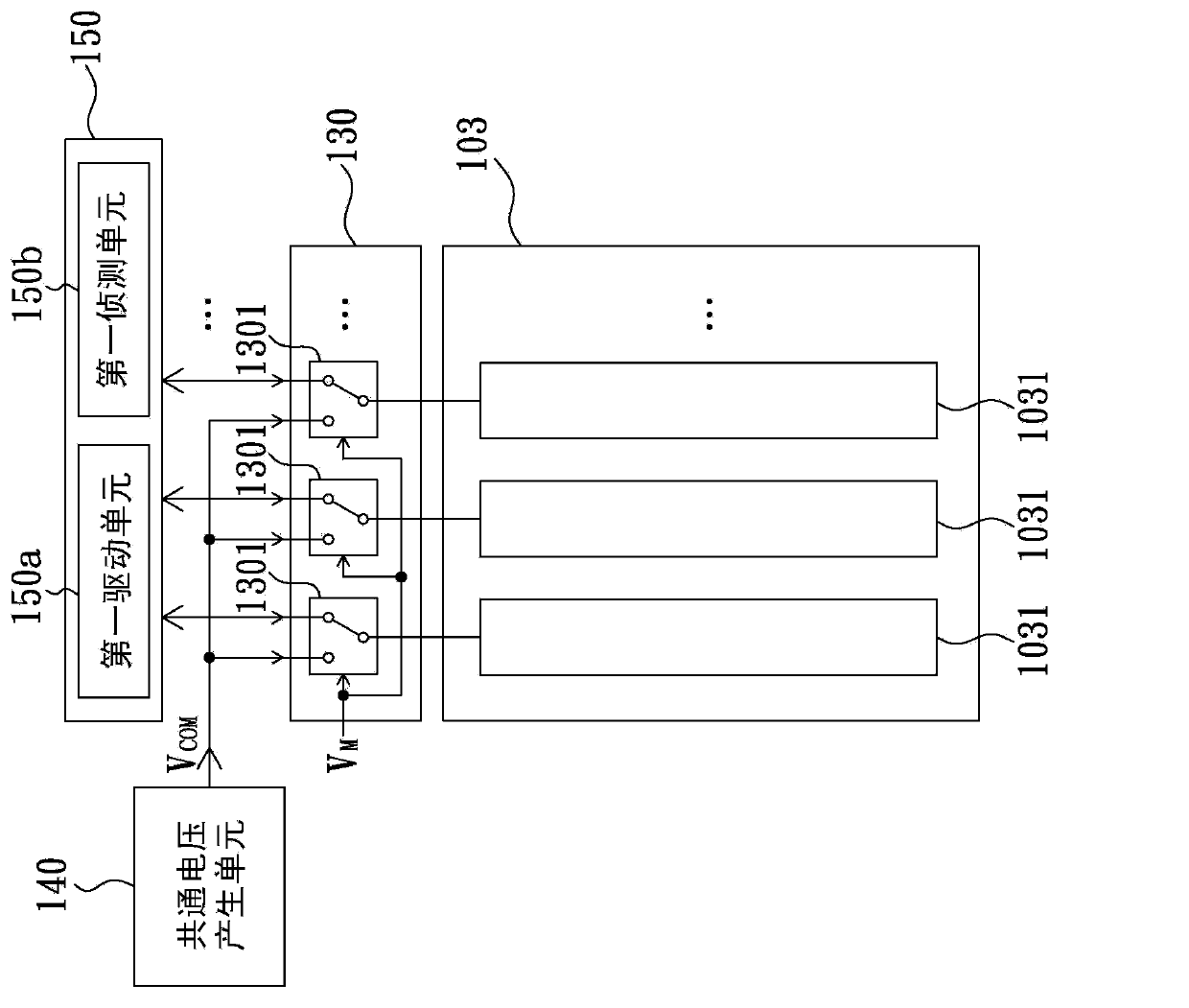

Thin film transistor liquid crystal display apparatus having a touch function

InactiveCN103728755AInnovative designWith touch functionNon-linear opticsInput/output processes for data processingCapacitanceLiquid-crystal display

The invention provides a TFT liquid crystal display apparatus having a touch function, including: a first electrode layer, having multiple first electrodes and multiple thin film transistors, wherein each of the multiple thin film transistors has a source coupled to a source control unit, a gate coupled to a gate control unit, and a drain coupled to one of the multiple first electrodes and to one of multiple storage capacitors; a liquid crystal display layer, located above the first electrode layer; a transparent electrode layer, being located above the liquid crystal display layer and having multiple transparent strip electrodes; and multiple switches, of which each has a control end coupled with a mode control signal, a first contact coupled to one of the multiple transparent strip electrodes, a second contact coupled to a common voltage generation unit, and a third contact coupled to a touch detection unit.

Owner:RICH IP TECH

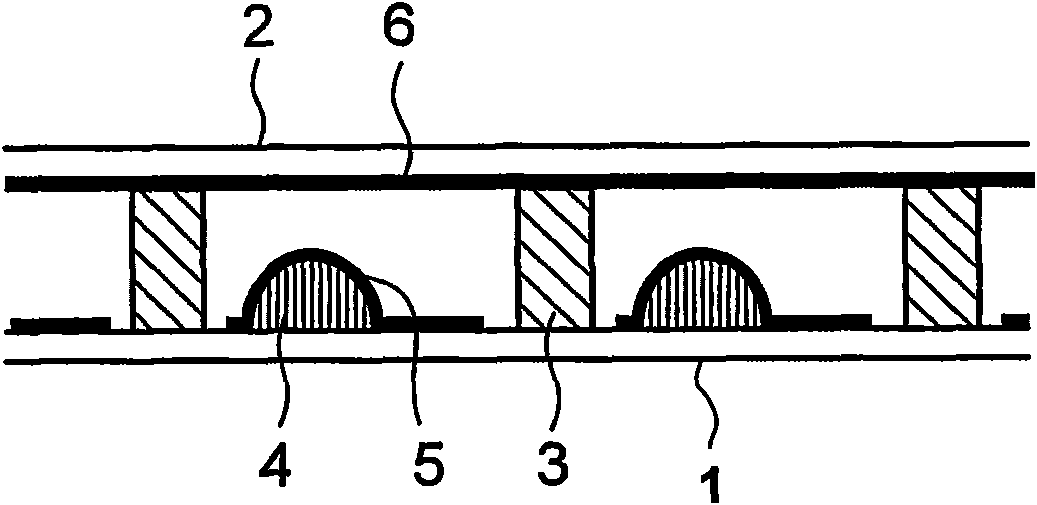

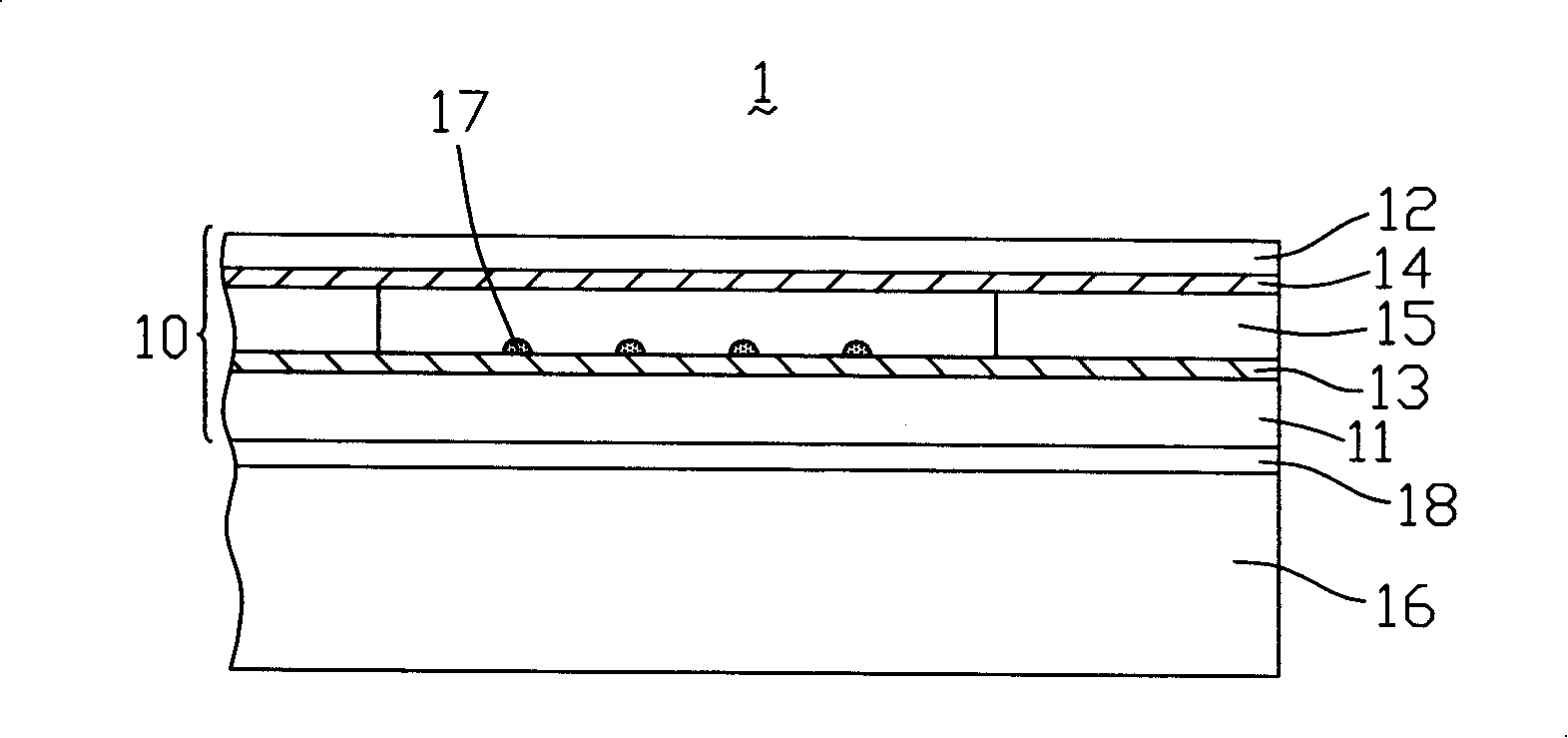

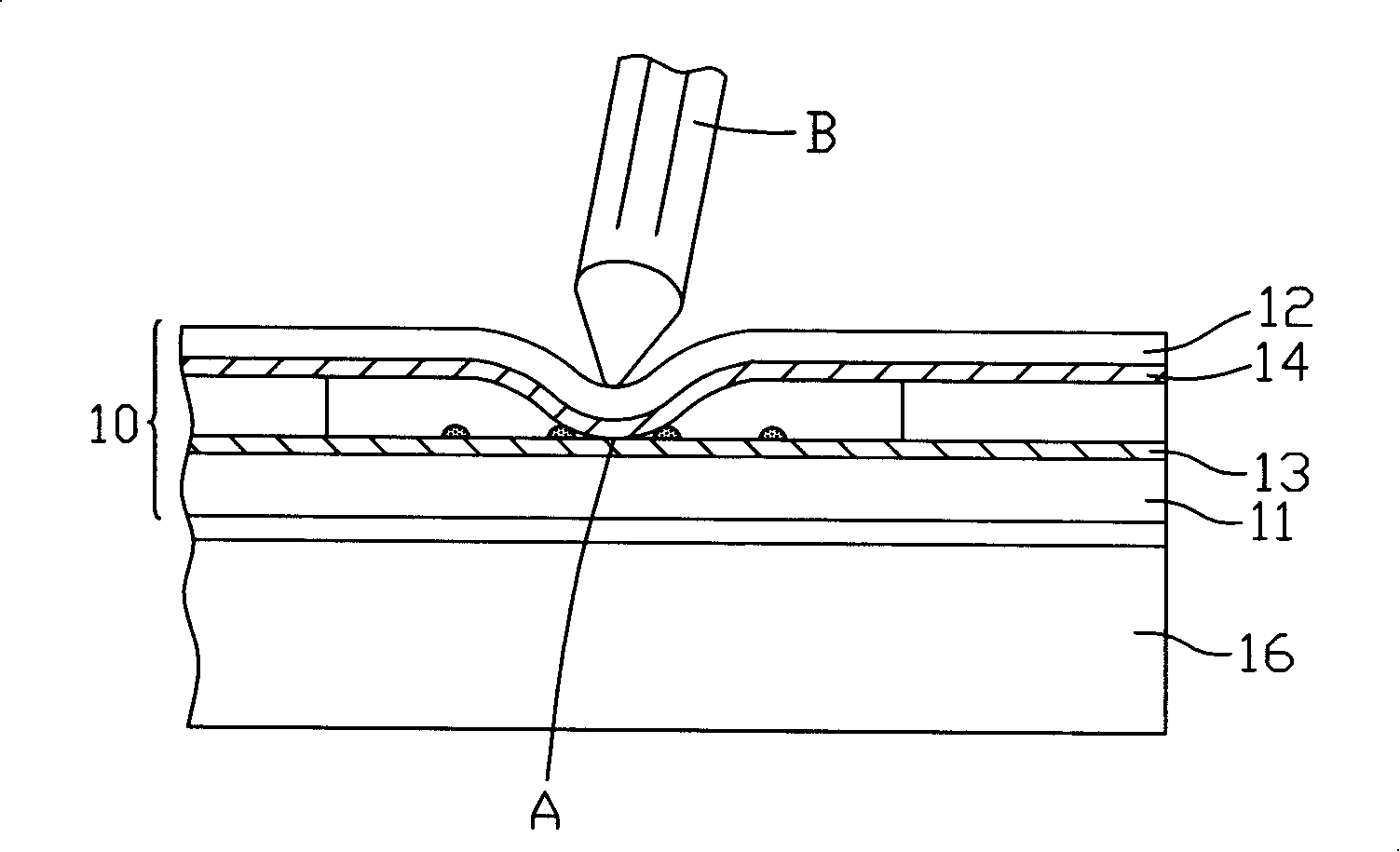

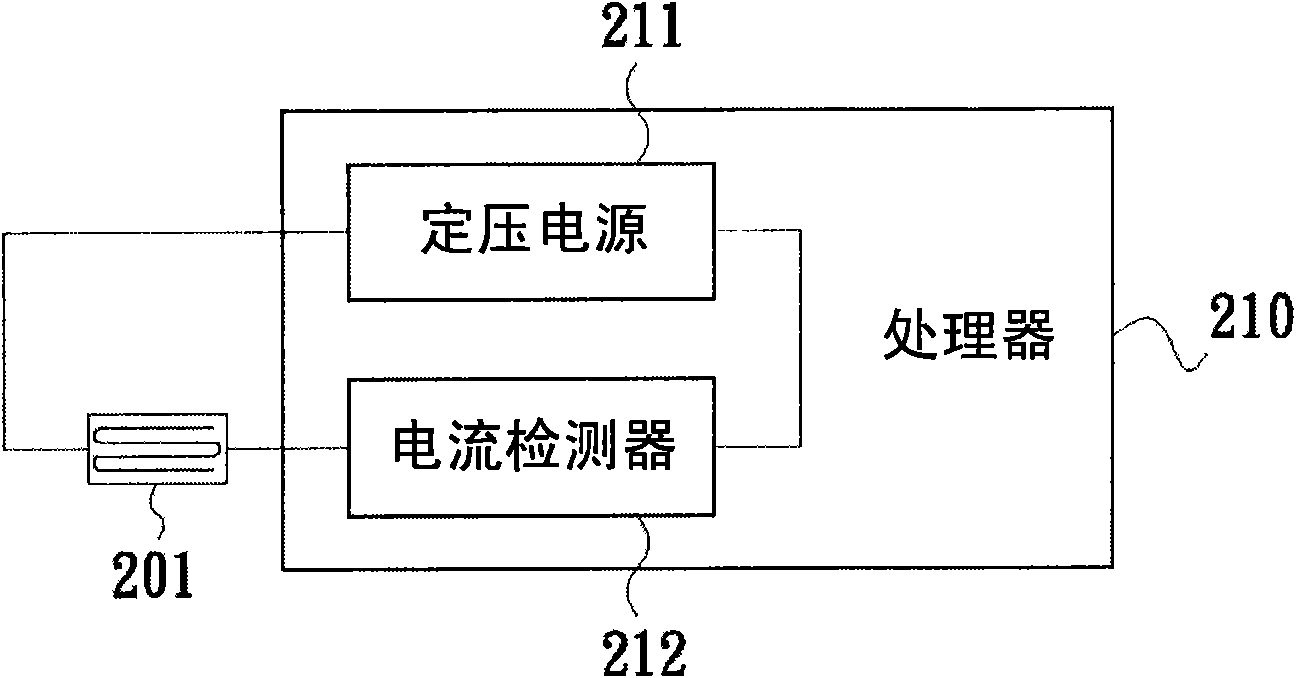

Liquid crystal display panel

ActiveCN101191915AWith touch functionThe overall thickness is thinStatic indicating devicesNon-linear opticsLiquid-crystal displayScan line

A liquid crystal display panel comprises a first basal plate and a second basal plate which are arranged oppositely, and a liquid crystal layer clamped between the first basal plate and the second basal plate. The first basal plate comprises a plurality of scan lines and a plurality of data lines in insulating intersection with the scan lines, wherein, the first basal plate further comprises a plurality of conductive gaskets which are arranged in the region of a plurality of scan lines and are electrically connected with a plurality of scan lines; the second basal plate comprises a plurality of resistance wires and a plurality of conductive contacts; the conductive contacts are arranged on a plurality of resistance wires and correspond to the conductive gaskets of the first basal plate; a gap is arranged between the conductive contacts and the corresponding conductive gaskets; the conductive contacts and the corresponding conductive gaskets are in an electrical insulation state or an electrical connection state. The liquid crystal display panel has touch controlled display function and meets the requirement of thin thickness tendency.

Owner:INNOCOM TECH SHENZHEN +1

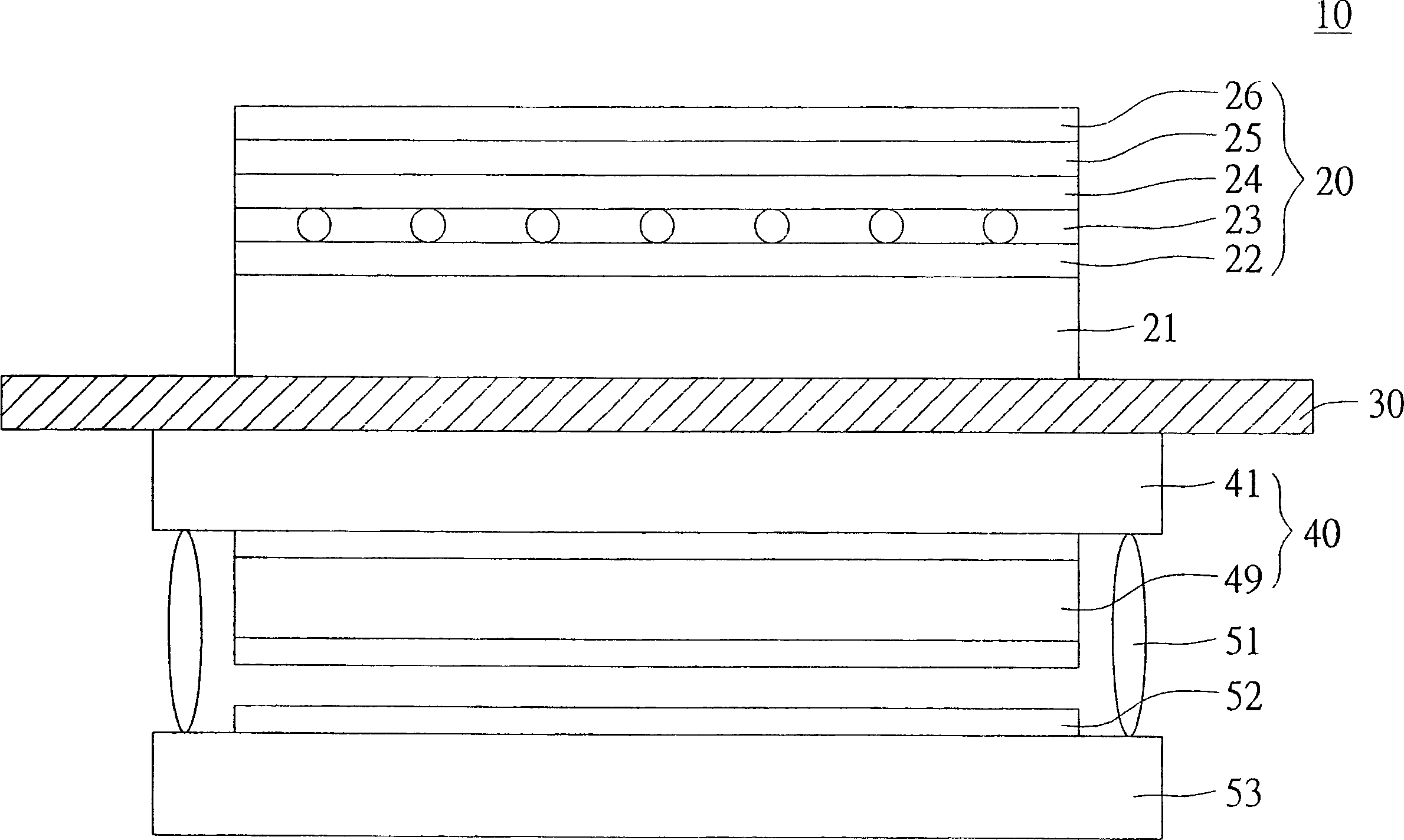

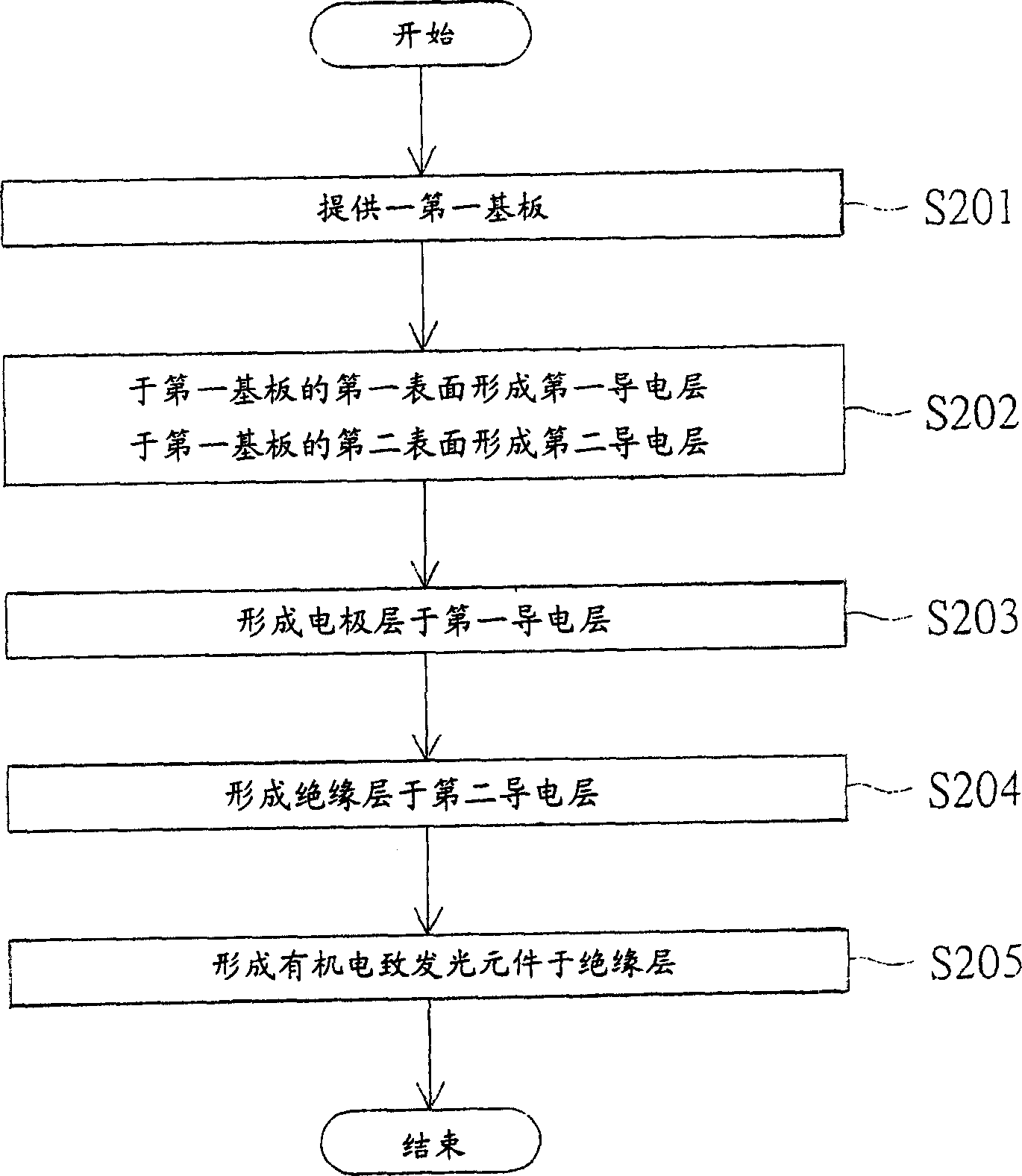

Plane display with touching function and its forming method

ActiveCN1649456AWith touch functionReduce thicknessElectrical apparatusStatic indicating devicesInsulation layerDisplay device

A plane display includes a first base board, a first conduction layer, a first conduction layer of an electrode layer, an insulation layer of an electrode layer, an insulation layer and an organic electro-luminescence display element, among which, the first conduction layer is formed on the first surface of the first base board, the electrode layer is formed on the first conduction layer, the second conduction layer is formed on the second surface of the first base board, the insulation layer is formed on the surface of the second conduction layer and the organic luminous display element is formed on the insulation layer.

Owner:AU OPTRONICS CORP

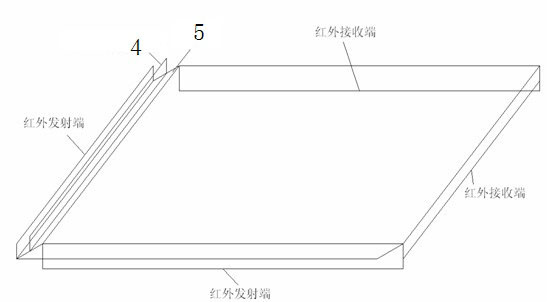

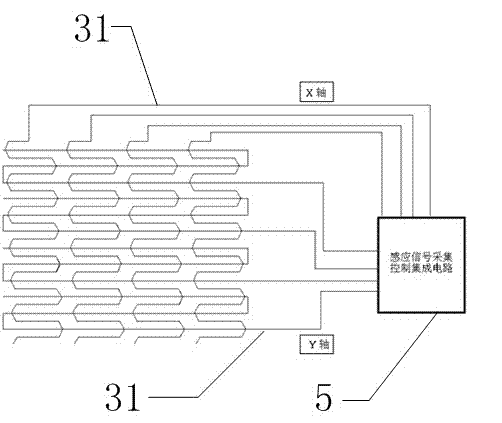

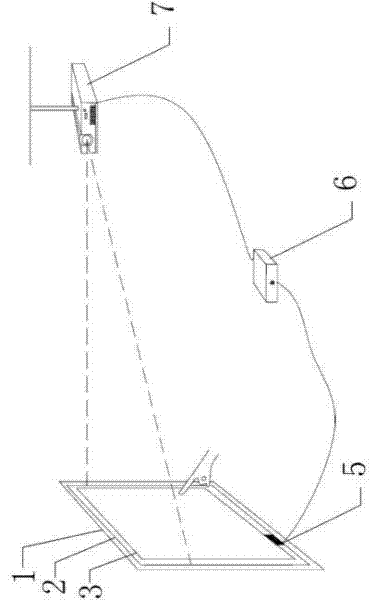

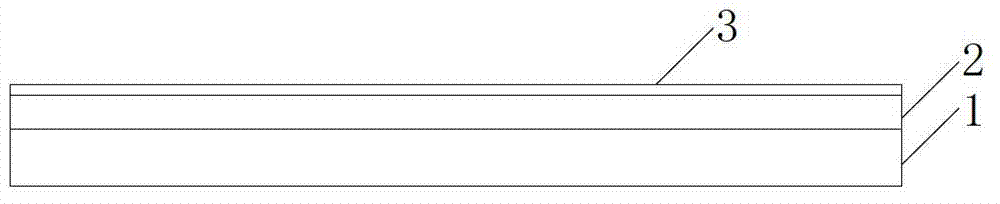

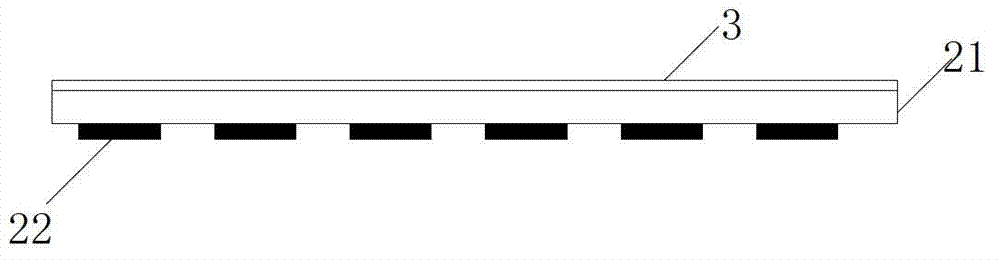

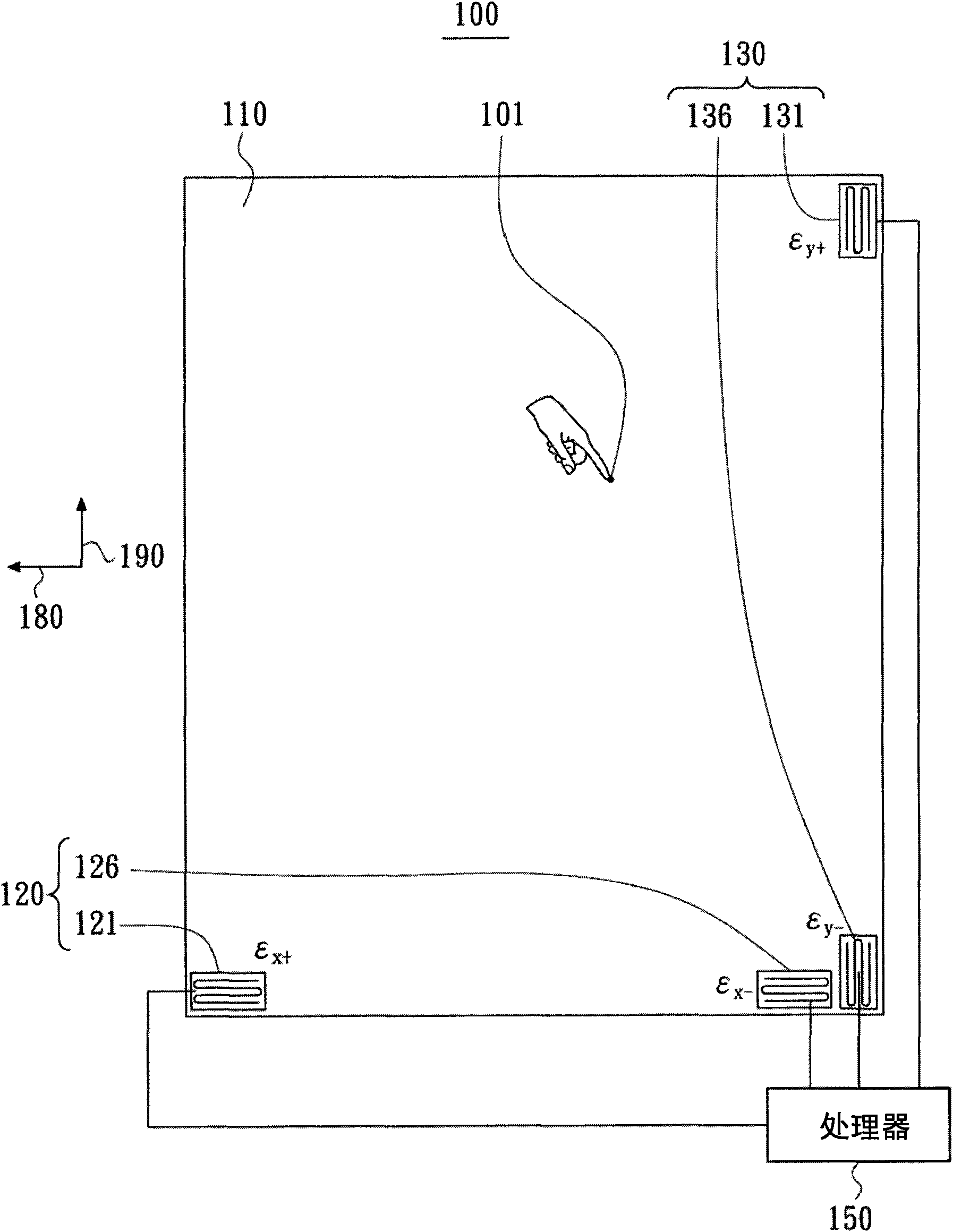

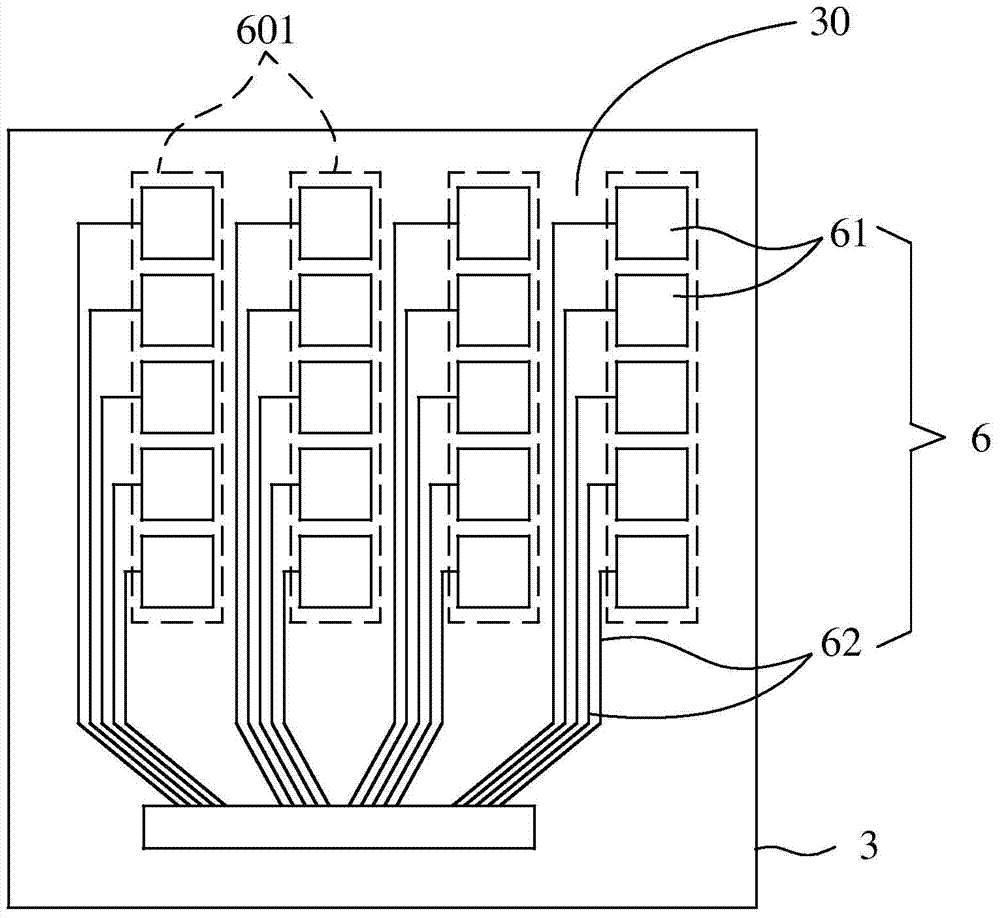

Projection cloth with touch function and imaging touch system of projection cloth

InactiveCN102646001AImprove flexibilityEasy to hideProjectorsInput/output processes for data processingUltra fineIntegrated circuit

The invention discloses a piece of projection cloth with a touch function. The projection cloth comprises a base material, wherein the front surface of the base material is a touch operation surface; an imaging layer and a conducting wire layer which is used for sensing a touch signal are pasted and covered on the back surface of the base material in sequence; the imaging layer is an orthographic projection imaging layer or a back projection imaging layer; the conducting wire layer is a warp and weft net which is formed by winding and crosswise interlacing ultra-fine conducting wires along an X axis direction and a Y axis direction respectively, and the ultra-fine conducting wires are insulted with one another at the cross points; a space defined by each grid forms a sensing unit; and the output end of the conducting wire layer is connected with an induced signal acquisition control integrated circuit. The imaging touch system has an effect of projection imaging and the touch function, can effectively perform human-computer interaction while displaying information, and realizes real-time, convenience and high-efficiency of meetings, school-teaching and lectures.

Owner:UC NANO TECH CO LTD

Three-dimensional touch display

ActiveCN102830839ASimple structureCompact structureInput/output processes for data processingOptical elementsGratingTouch Senses

The invention discloses a three-dimensional display and particularly relates to the three-dimensional touch display with a simple and compact structure. The three-dimensional touch display comprises a display device, a grating structure positioned above the display and a touch sensing circuit, wherein the touch sensing circuit is formed on a grating structure body.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

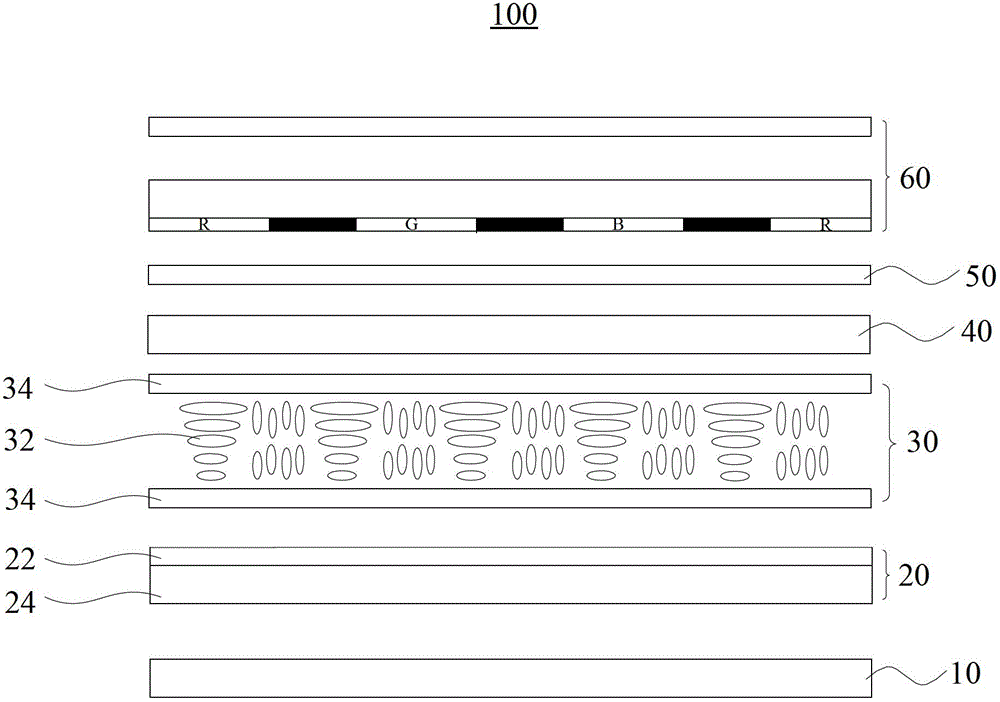

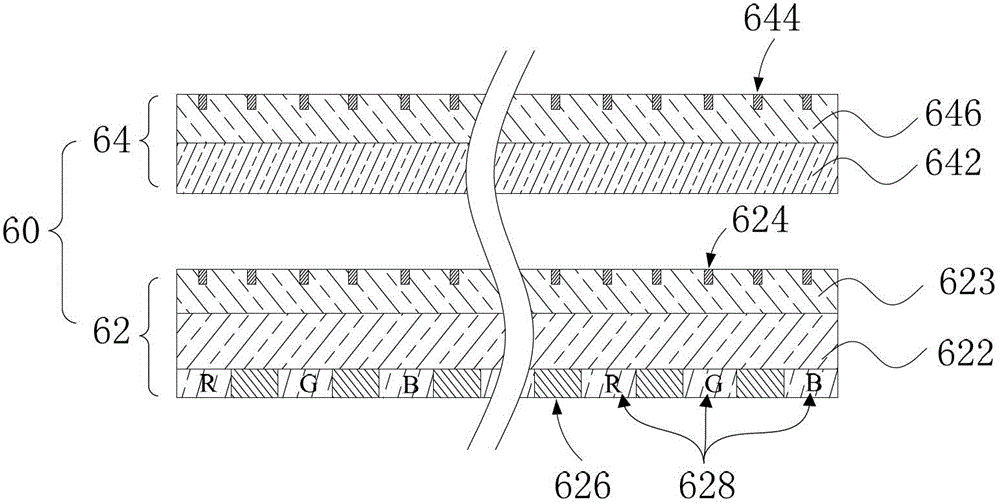

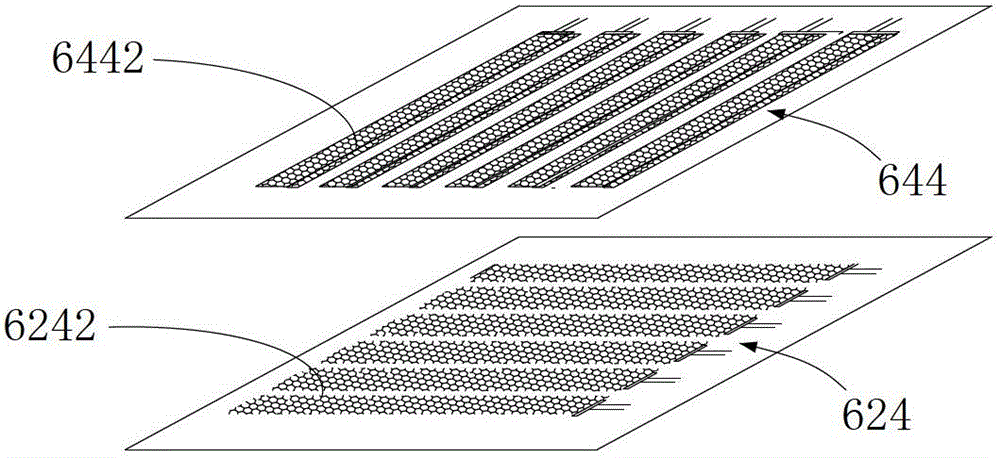

Light polarizing-filtering module and touch display screen using same

ActiveCN103336382AReduce thicknessSave material and assembly costsNon-linear opticsInput/output processes for data processingLine widthOptoelectronics

A light polarizing-filtering module comprises a light filtering assembly and a light polarizing assembly. The light filtering assembly comprises a transparent substrate, a first conducting layer and a light filtering substrate. The light filtering substrate comprises light-tight matrixes and colorful light resistors. The first conducting layer comprises a plurality of first electric conduction units which extend in the first direction and are mutually insulated. The first electric conduction units comprise first electric conduction silk-covered wires, wherein the width of the first electric conduction silk-covered wires is 0.2-5microns. The light polarizing assembly comprises a light polarizing plate and a second conducting layer. The second conducting layer comprises a plurality of second electric conduction units which extend in the second direction and are mutually insulated. The second electric conduction units comprise second electric conduction silk-covered wires, wherein the width of the second electric conduction silk-covered wires is 0.2-5microns. The first direction is not parallel to the second direction. According to the light polarizing-filtering module, touch operation, a light polarizing function and a light filtering function can be achieved at the same time. When used in a display screen, the light polarizing-filtering module can directly enable the display screen to have the function of touch control. A touch screen is not needed to be assembled on the display screen. Therefore, reduction of the thickness of an electronic product is facilitated, and meanwhile material and assembly cost are greatly saved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Touch control module and preparation method thereof

ActiveCN103135865AEasy to prepareLow costInput/output processes for data processingControl modeCoating

The invention relates to a touch control module. The touch control module comprises a touch control component, a shell body and a decorative membrane, wherein the shell body is curved, and is provided with a curved touch area, the touch area is covered by the touch control component, and is used for controlling the touch control component in a touch control mode, and the touch control component, the shell body and the decorative membrane are integrally formed. The invention further relates to a preparation method of the touch control module. The preparation method of the touch control module is mainly used for preparing the touch control module by combining an in-module decorating manufacture procedure and a double-faced membrane coating technology.

Owner:贵州富纳源创科技有限公司 +1

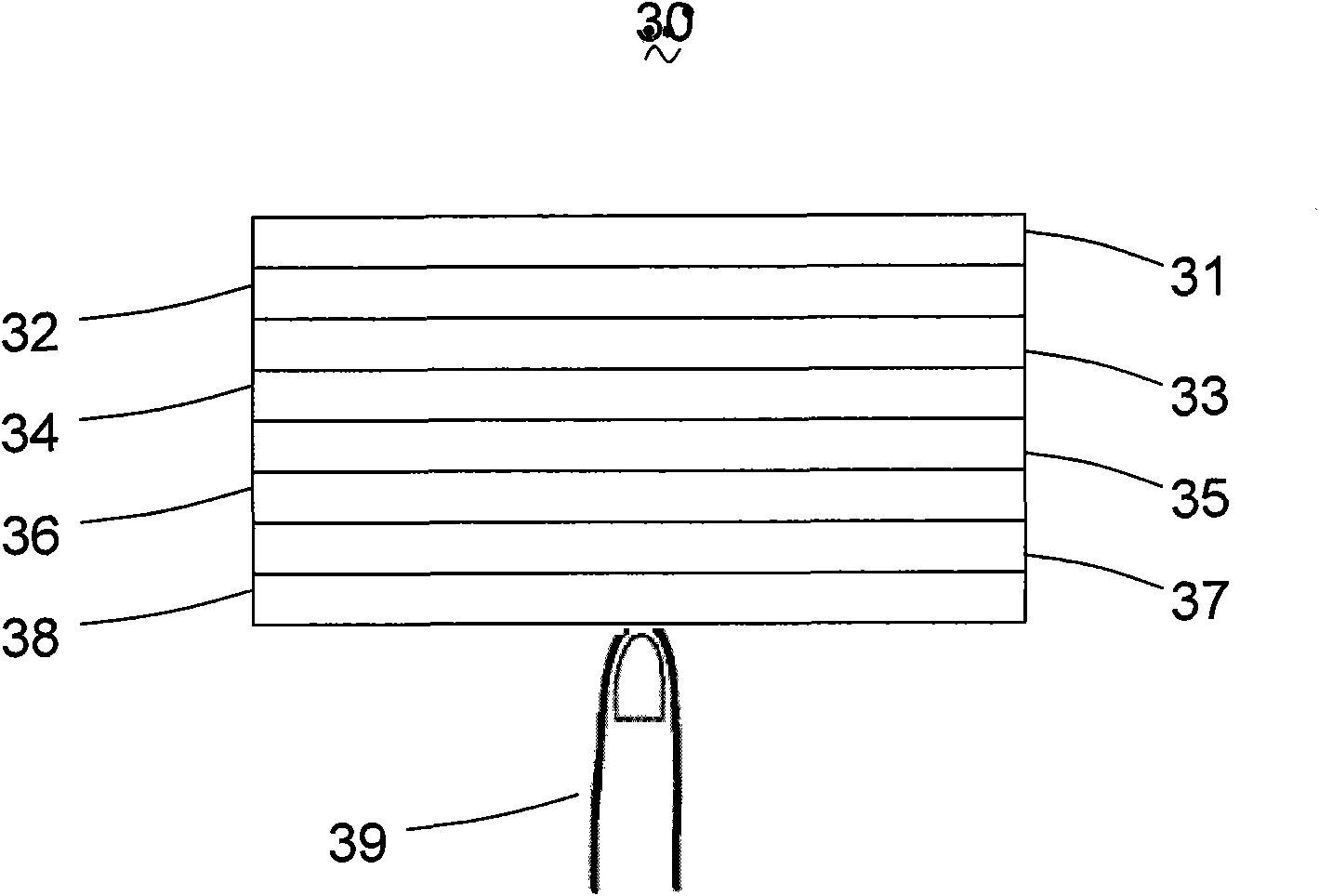

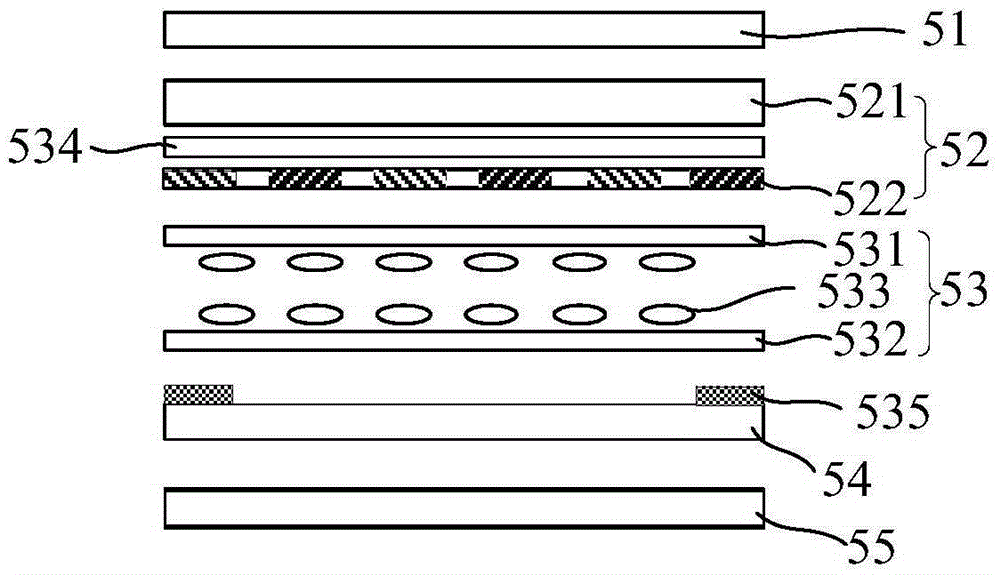

Touch display device and preparation method for same

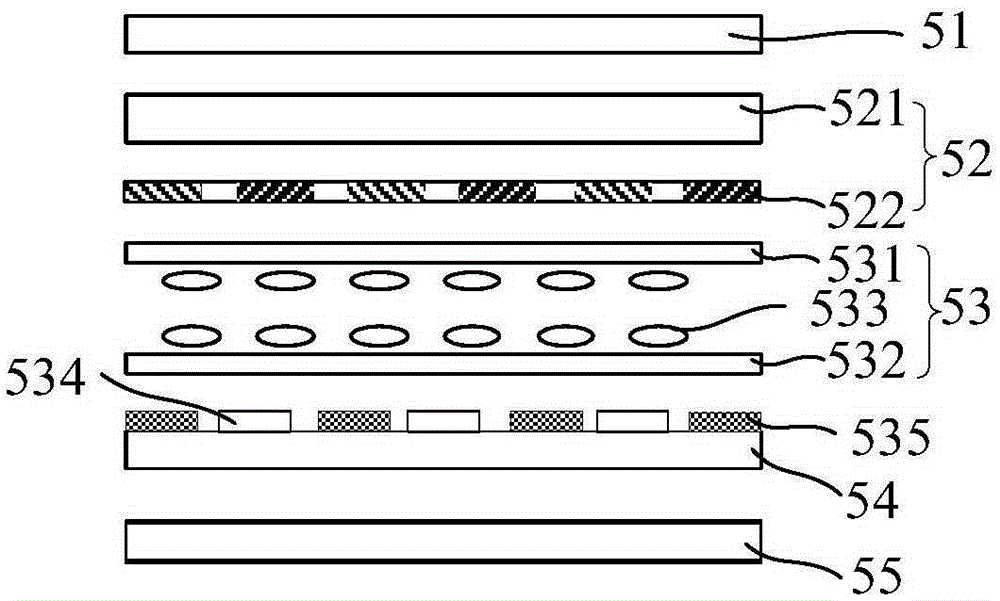

PendingCN106557187AReduce thicknessSave material and assembly costsInput/output processes for data processingPolyimide membraneControl function

The invention relates to a touch display device and a preparation method for the same. The device comprises an upper Polaroid sheet, an optical sheet, a liquid crystal layer, a base plate, a lower Polaroid sheet and a touch sensing layer, wherein the optical sheet is formed by base material and an optical film arranged on the lower surface of the base material; the liquid crystal layer is formed by an upper orientation film, a lower orientation film, liquid crystal clamped between the upper and lower orientation films, and public electrodes and pixel electrodes driving the liquid crystal; the pixel electrode is arranged on the upper surface of the base plate; the touch sensing layer is formed by a polyimides film and a touch control electrode arranged on one surface of the polyimides film; and the touch sensing layer is arranged on the upper and lower surfaces of the upper Polaroid layer, the upper surface of the base material, the lower surface of the optical film, the upper surface of the pixel electrode or the lower surface of the base plate. The touch sensing layer is arranged on elements such as the Polaroid sheets of a display screen, so the display screen has a touch control function and assembly of a touch screen on the display screen is unnecessary; and thickness of the touch display device can be reduced, and material and assembling cost can be reduced.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

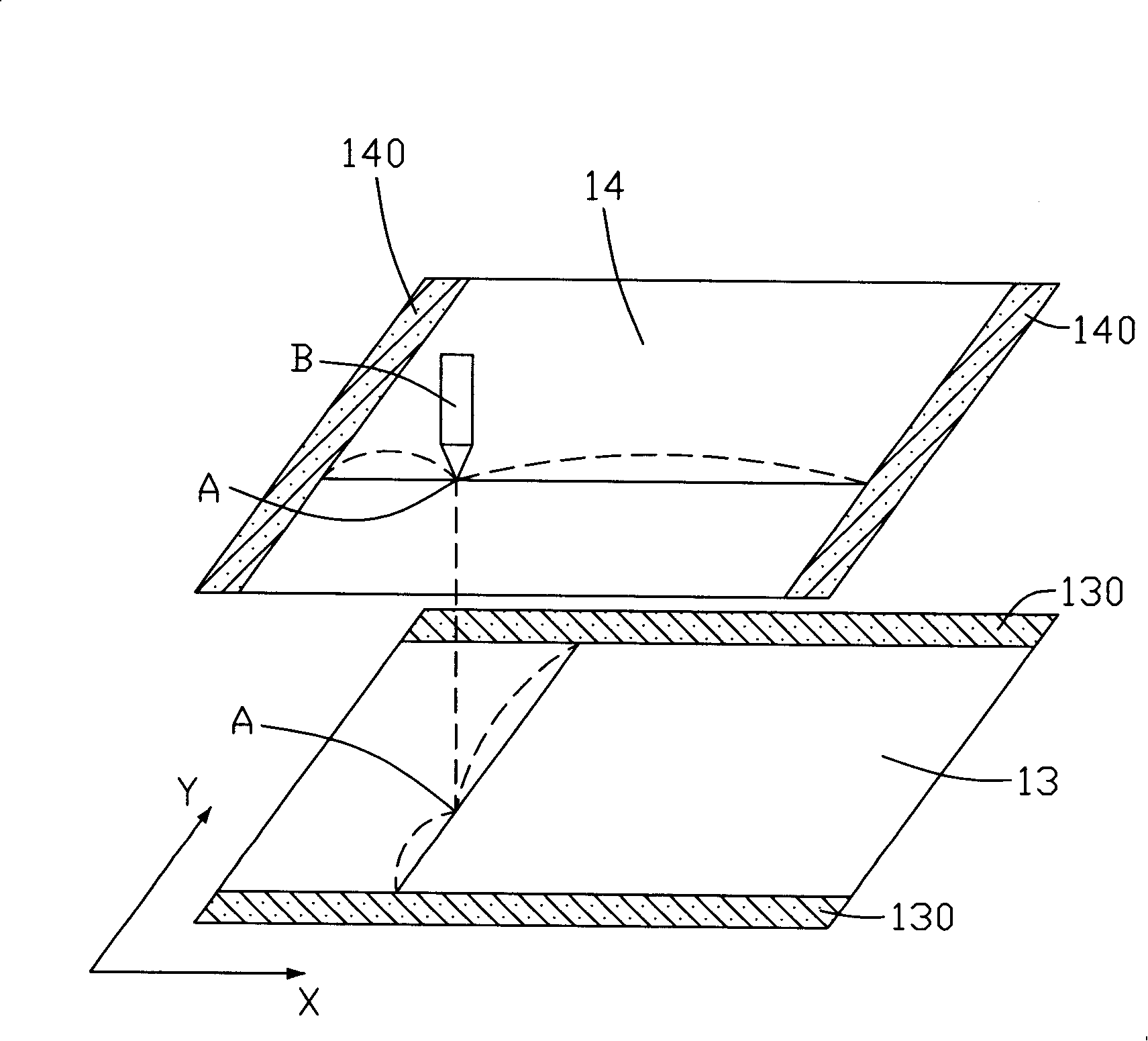

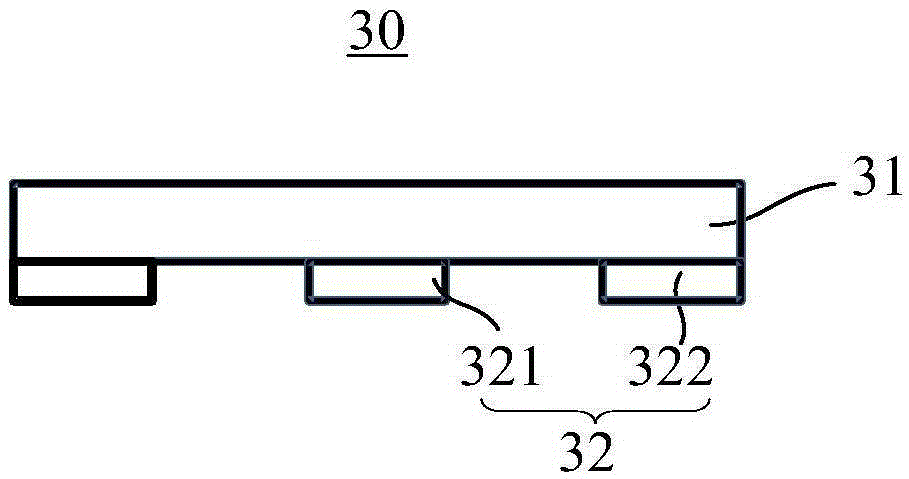

Touch panel, touch detection method thereof and display device with touch function

ActiveCN101593059ASimple structureThe overall thickness is thinStatic indicating devicesInput/output processes for data processingDisplay deviceDirection detection

The invention discloses a touch panel, which is suitable for detecting the touch position of a touch point. The touch panel comprises a substrate and at least one first direction detection device. The first direction detection device is arranged in the first direction of the substrate to detect first direction coordinates of the touch point. Each first direction detection device comprises a first deformation induction device and a second deformation induction device. The first deformation induction device produces deformation in the first direction due to the production of the touch point, and provides a first variable due to the deformation; the second deformation induction device produces deformation in the first direction due to the production of the touch point, and provides a second variable due to the deformation; and the first direction coordinates are decided by the first variable and the second variable. The invention discloses a touch monitoring method for the touch panel and a display device with touch function at the same time.

Owner:CHINA STAR OPTOELECTRONICS INT HK

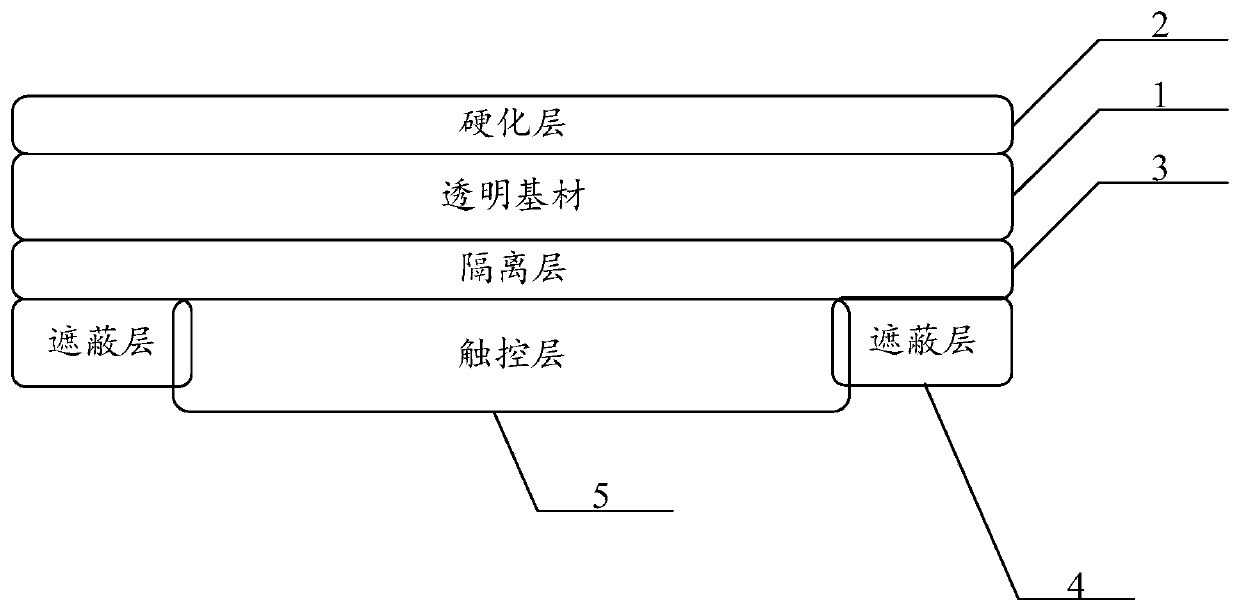

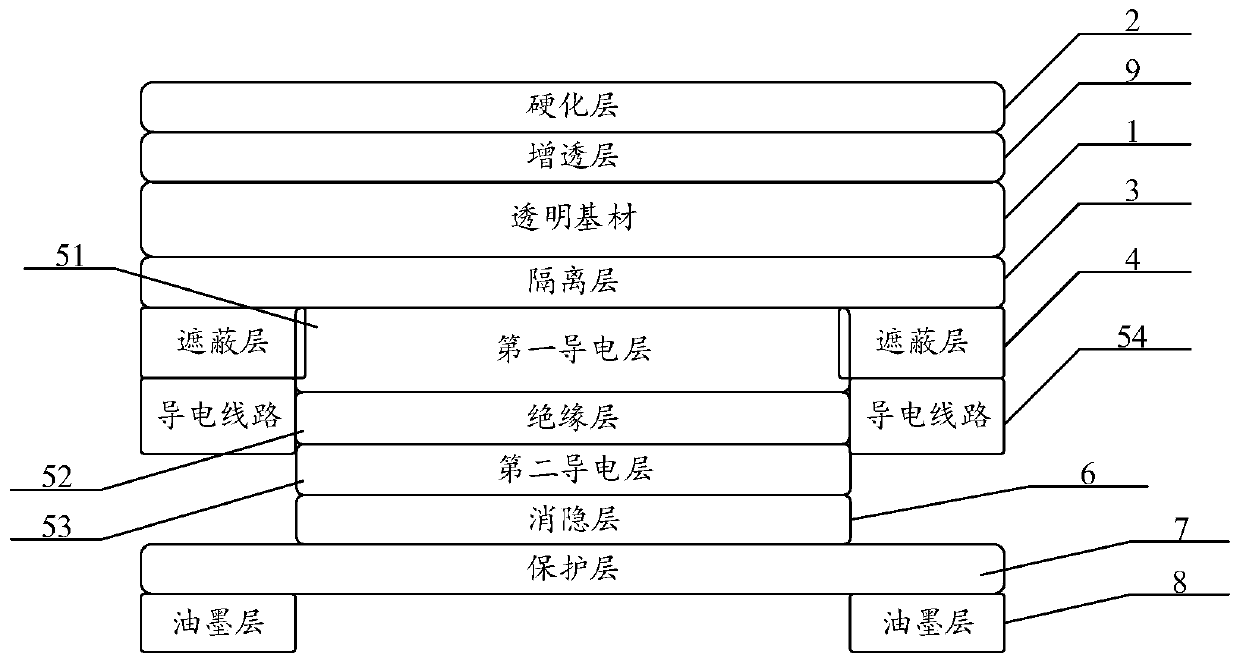

Flexible cover plate, preparation method thereof and flexible OLED display screen

PendingCN110231891AReduce usageReduce thicknessInput/output processes for data processingIdentification meansEngineeringTouch function

The invention discloses a flexible cover plate, a preparation method thereof and a flexible OLED display screen. The flexible cover plate comprises a transparent base material, a hardening layer located on the upper surface of the transparent base material, an isolating layer located on the lower surface of the transparent base material and a shielding layer located at the edge of the lower surface of the isolating layer, and further comprises a touch layer located in an area defined by the shielding layer and making contact with the lower surface of the isolating layer, and a binding area isarranged in the shielding layer. According to the technical scheme disclosed by the invention, the touch layer is integrated on the flexible cover plate, so that the flexible cover plate has a touch function, the thickness of the flexible OLED display screen is reduced, the light and thin design of the flexible OLED display screen is realized, and the preparation process of the flexible OLED display screen is simplified. In addition, the touch layer is integrated on the flexible cover plate, so that the influence on the flexible OLED due to the operation on the packaging material of the flexible OLED can be reduced, and the yield of the flexible OLED display screen can be improved.

Owner:LENS TECH CHANGSHA

A manufacturing process of an automobile decorative part and an automobile decorative part

ActiveCN109204182APrevent scratchesGood friction resistanceSuperstructure subunitsSurface perceptionEngineering

The invention provides a manufacturing process of an automobile decorative part and an automobile decorative part, belonging to the mechanical technical field. The invention solves the problem that the function of the existing decorative parts is single. The manufacturing process comprises the following steps of: a, adopting a light-transmissive fabric, thick suede-like or real wood material to manufacture a sheet-like and light-transmissive decorative panel with a thickness of 0.5-0.8 mm, adopting a transparent material to make a framework, and fixing a light guide strip or a film sheet witha pattern on the framework, wherein the thickness of the sheet-like and light-transmissive decorative panel is 0.5-0.8 mm; B, mounting the light source on the frame. The automobile decorative part comprises a decorative panel made of transparent fabric, thick suede or real wood material and a frame made of transparent material, wherein the decorative panel is in the form of sheet, the frame is fixed on the back of the decorative panel and the frame is fixed with light guide strips or printed film sheets, and a light source is arranged on the frame. Under the premise of the original surface perception, the automobile decorative parts show the function of backlight control without leaving any trace, which enriches the function of the decorative parts.

Owner:吉利亚欧(宁波梅山保税港区)科技有限公司 +2

Color film base plate and manufacturing method thereof as well as display panel and display device

InactiveCN105892125AWith touch functionDoes not affect the display effectSolid-state devicesNon-linear opticsLiquid-crystal displayTouch Senses

The invention discloses a color film base plate, a manufacturing method thereof, a display panel and a display device. The color film base plate comprises a substrate base plate, sub-pixel color resistors, black matrixes and a touch electrode layer, wherein the sub-pixel color resistors are arranged on the substrate base plate and are laid in an array manner; the black matrixes are arranged on the substrate base plate and are used for separating each sub-pixel color resistor; the touch electrode layer is arranged on the substrate base plate and is used as a flat layer; the touch electrode layer is segmented into multiple mutually insulating touch sensing electrodes; the orthographic projection, on the substrate base plate, of segmentation gaps between the touch sensing electrodes are located in an area where the black matrixes are located. According to the color film base plate which is provided by an embodiment of the invention, the touch electrode layer is used as the flat layer at the same time, so as to enable the color film base plate to have a touch function at the same time; the thickness and the weight of a display screen are reduced; and the yield loss caused in a process of abutting a touch screen and a liquid crystal display screen is avoided when an externally hung touch screen is used.

Owner:BOE TECH GRP CO LTD

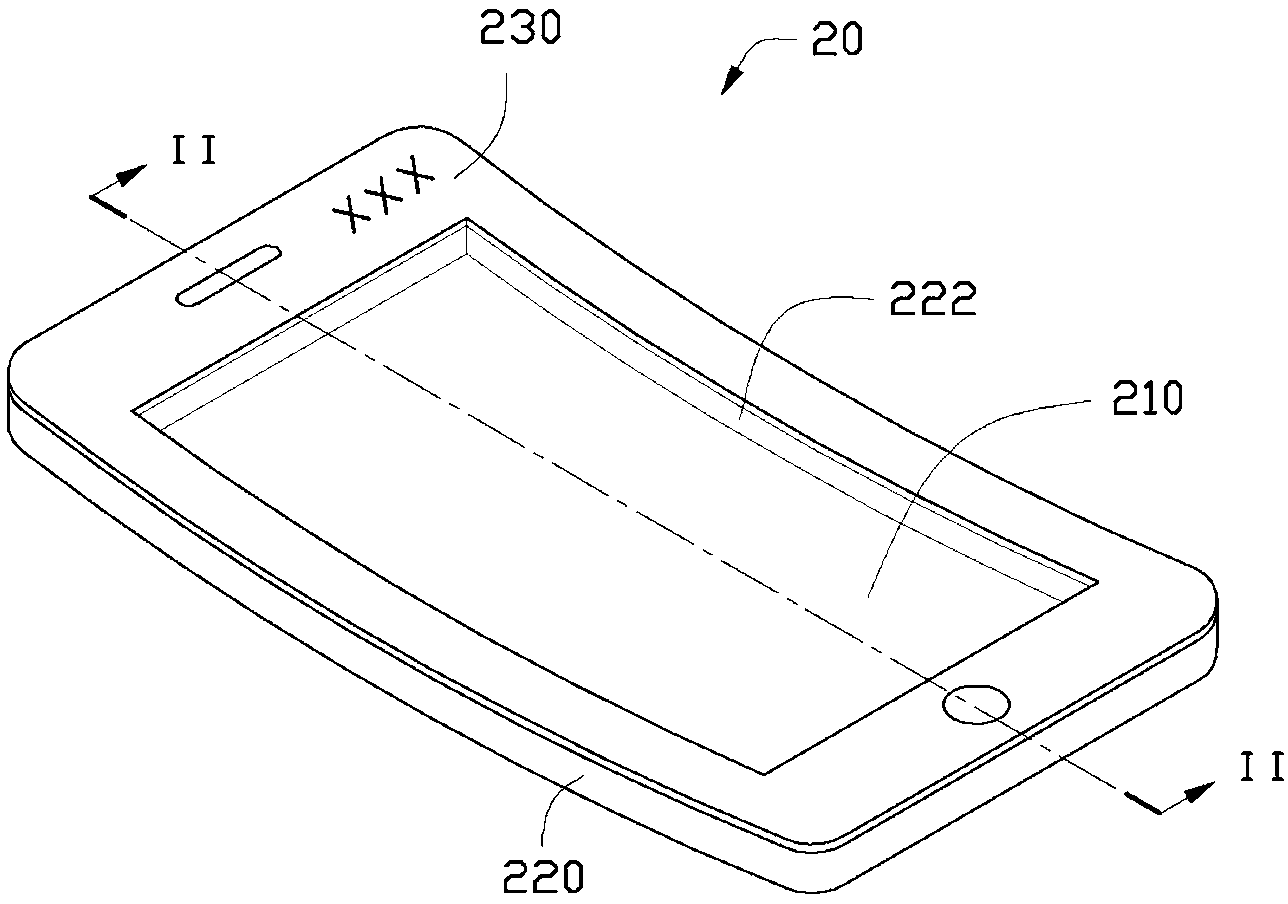

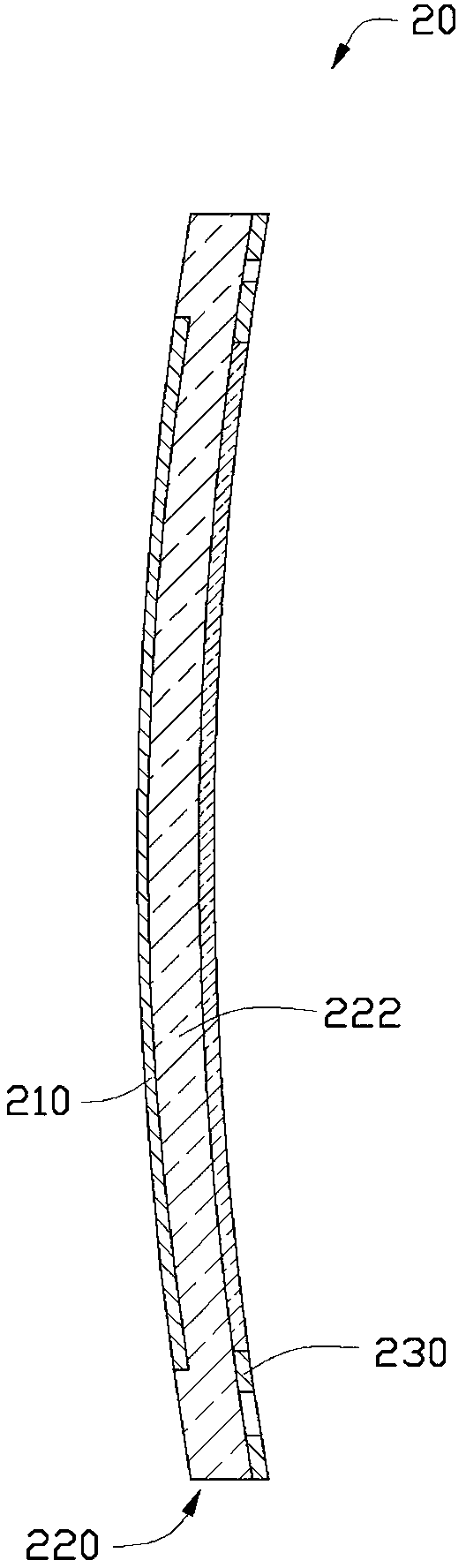

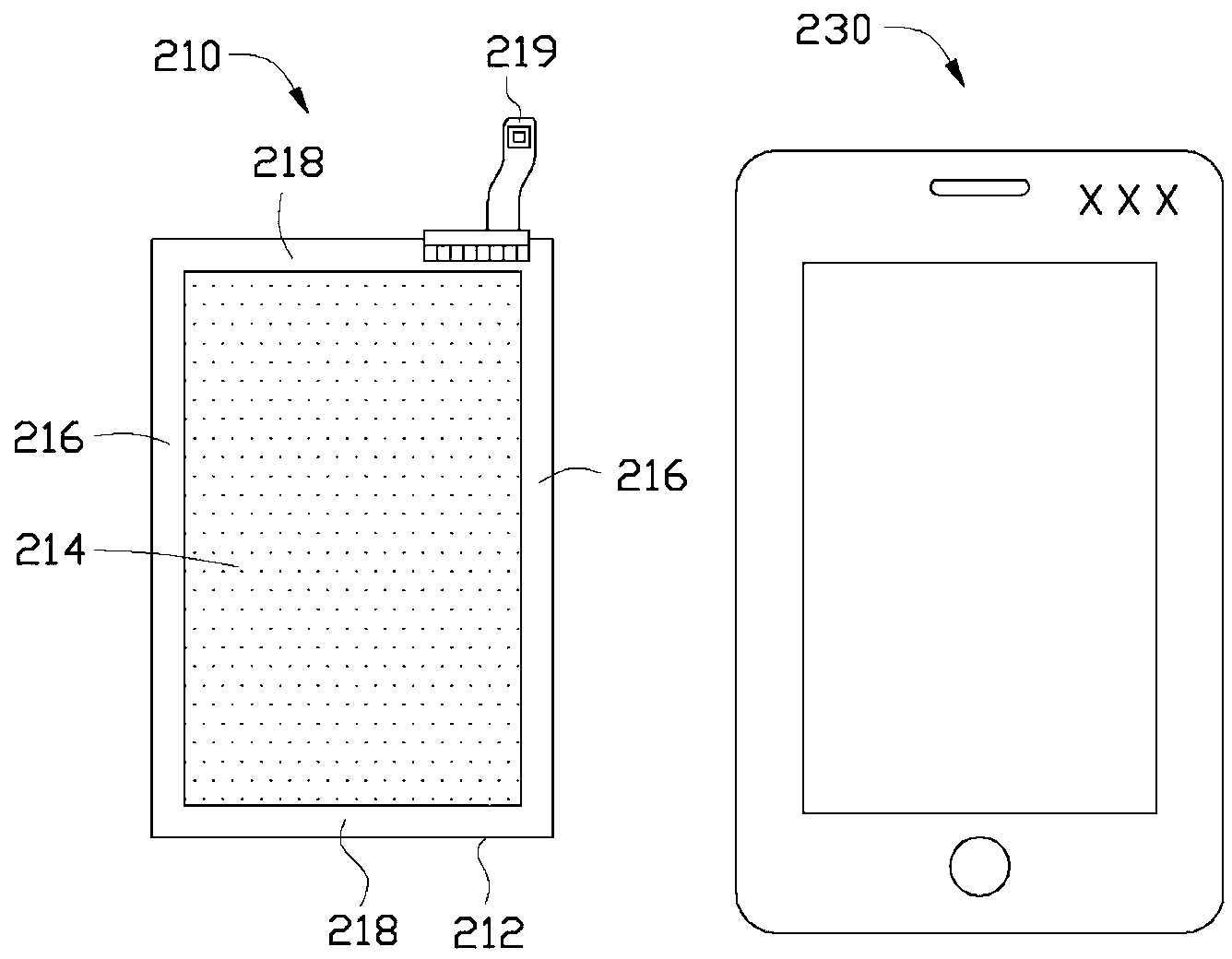

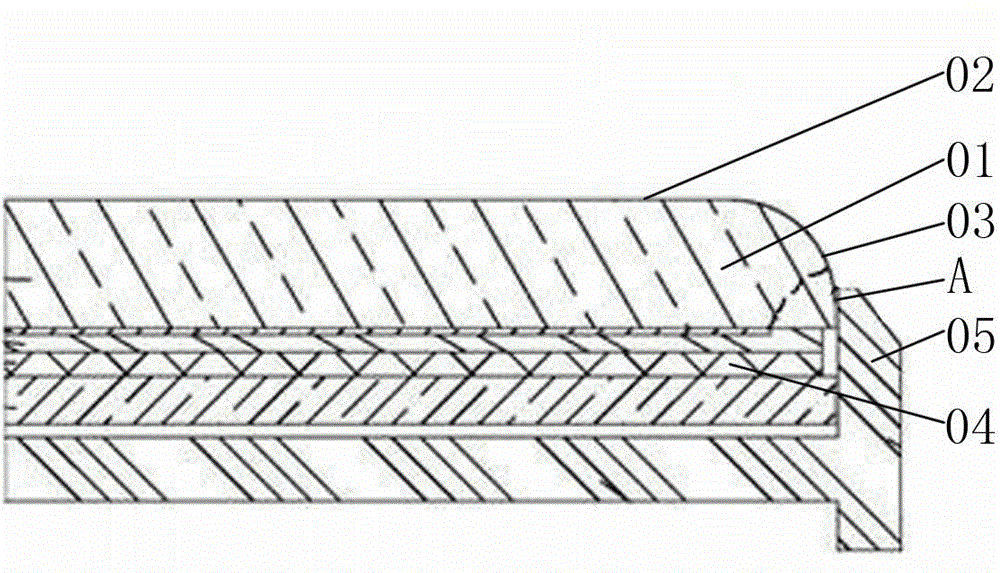

Cambered surface lens and manufacturing method thereof

ActiveCN104898885AImprove impact resistanceWith touch functionInput/output processes for data processingPlanar substrateDisplay device

The invention relates to a cambered surface lens which comprises a first substrate and a second substrate. The inner side surface of the first substrate is a plane, the outer side surface of the first substrate comprises a middle plane and an edge cambered surface, the second substrate is a plane substrate, a touch induction circuit layer is arranged on the inner side surface of the second substrate, and the outer side surface of the second substrate is attached on the inner side surface of the first substrate through a transparent adhesive layer. As the cambered surface lens is set into a double-layer structure, the edge of the second substrate does not need to be polished into a cambered surface, the second substrate can be a transparent plate with fine impact resistance, a joint between the cambered surface lens and a shell can have high strength, the impact applied on the surface of the cambered surface lens can be buffered by the transparent adhesive layer, the stress at the joint between the cambered surface lens and the shell is reduced, and the cambered surface lens has fine impact resistance. As the second substrate is the plane substrate, the touch induction circuit layer is set according to an existing process, a common flat display instead of an embedded touch display can be selected, and cost is reduced.

Owner:SHANTOU GOWORLD DISPLAY TECH CO LTD

Liquid crystal display device with touch sensor and driving method of liquid crystal display device

InactiveCN106292105AWith touch functionReduce penetrationStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a liquid crystal display device with a touch sensor and a driving method of the liquid crystal display device, and relates to the technical field of liquid crystal display. In order to solve the problem that the penetration rate of a display in the prior art is greatly reduced, a touch function is added in pixels of the liquid crystal display device; the touch function is realized through a touch lead; a common electrode covered by a data line between a blue sub-pixel and a red sub-pixel of two adjacent pixel units is configured as the touch lead. The touch lead serves as a touch line in a touch scanning stage, and serves as a common electrode in a non-touch scanning stage. The liquid crystal display device is mainly applied to liquid crystal flat panel displays.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

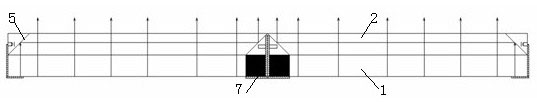

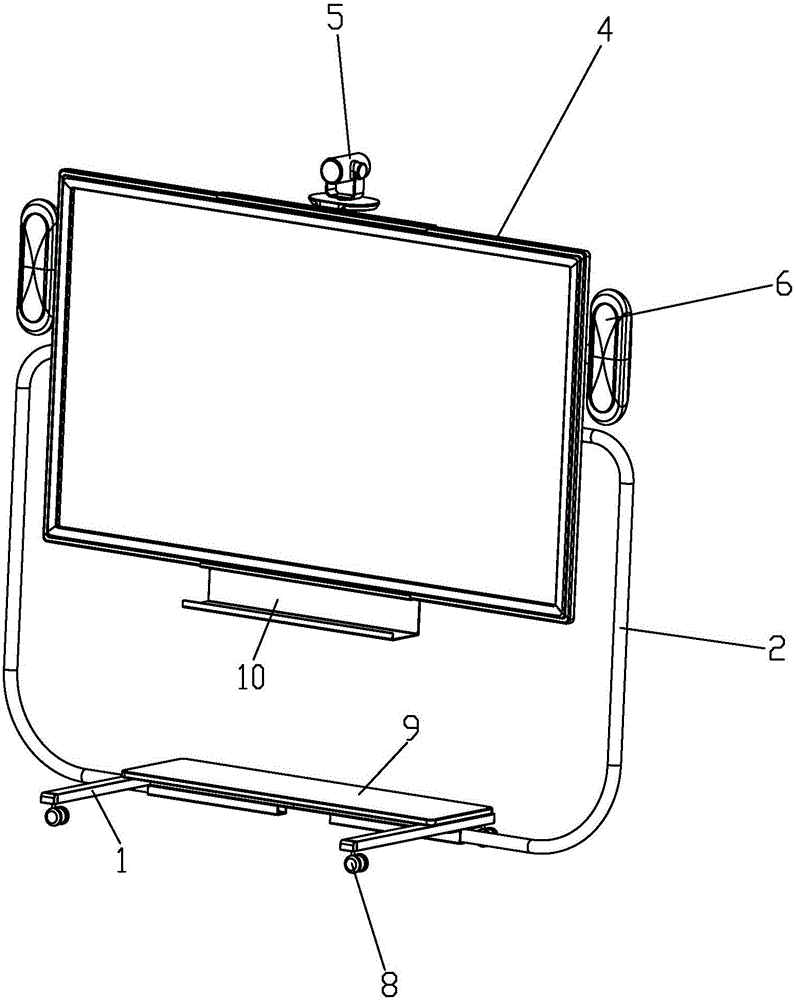

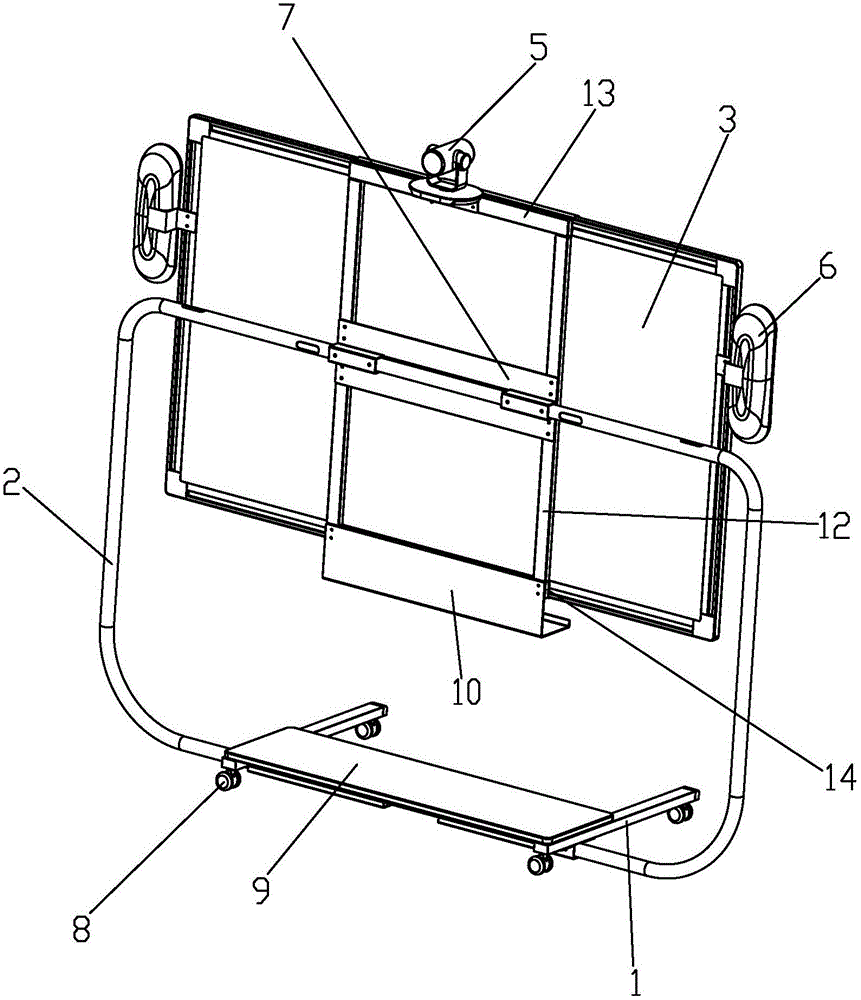

Movable-type teaching touch integrated machine

InactiveCN105976661ASolve the touch functionWith touch functionElectrical appliancesMovable typeDisplay device

The invention discloses a movable-type teaching touch integrated machine, and the main points of the technical scheme of the invention are that the machine comprises a sliding bottom frame; a display is disposed above the bottom frame, and the periphery of the display is provided with a touch frame; two sides of the display are provided with supporting rods which are fixedly connected with the bottom frame; the system also comprises a camera for video conference; and the touch frame is an infrared touch frame. The machine combines a conventional television and a computer, solves a problem that the teaching effect is affected because there is a barrier on a projection path in a conventional projector system, and enables the display to have a touch function through the installation of the touch frame. The machine integrates the functions of teaching, academic reporting, conference, comprehensive discussion, demonstration and communication, remote teaching, remote correction, remote class, remote setting of themes, and remote conference.

Owner:ZHONGSHAN JIASHI OPTOELECTRONICS TECH

Touch component and flat panel display device

ActiveCN104461182AOmit settingWith touch functionNon-linear opticsInput/output processes for data processingTouch functionComputer science

The invention discloses a touch component and a flat panel display device. Two direction sensing electrodes which respectively represent an X-axis sensing component and a Y-axis sensing component in the flat panel display device are respectively arranged on two sides of a substrate of a color filter. One direction sensing electrode is arranged in a black matrix in one surface of the substrate, and the other direction sensing electrode is arranged on the other surface, which is opposite to the color filter, of the substrate. The touch component and the flat panel display device have the advantages that the flat panel display device with a touch function is light and thin and is low in flat panel signal interference.

Owner:HANNSTOUCH SOLUTION

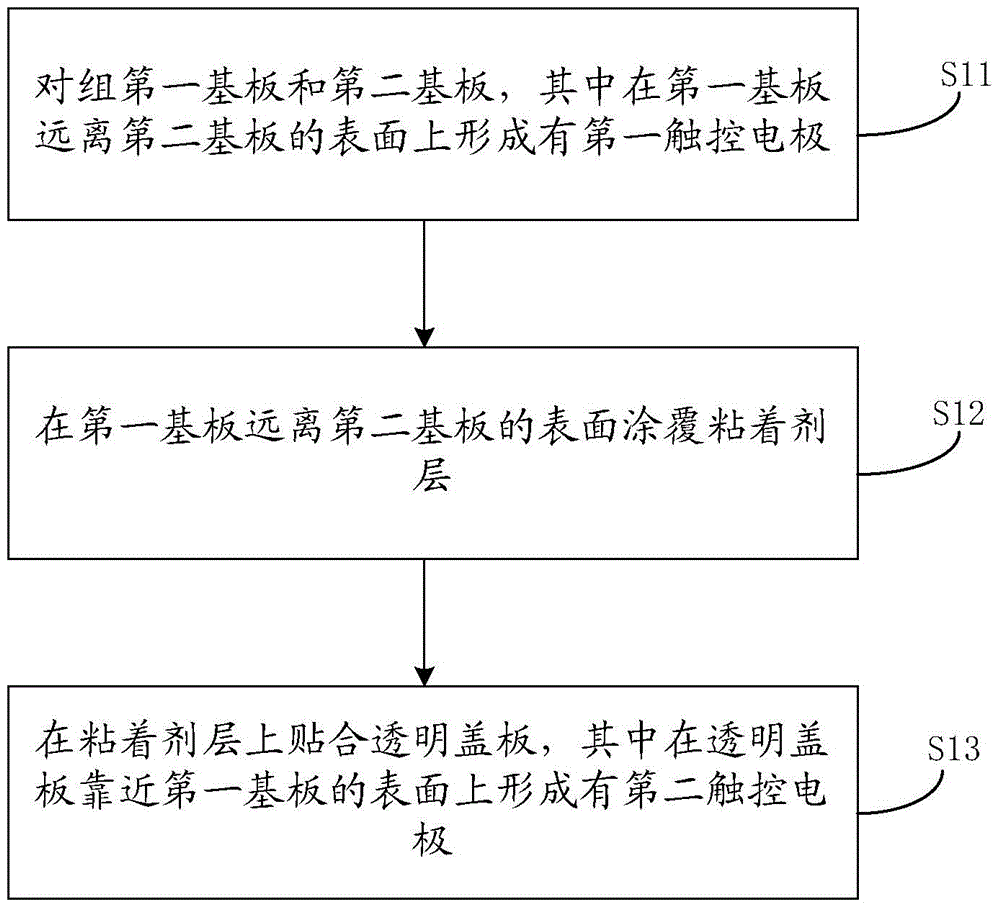

Display panel with touch function and manufacturing method of display panel

InactiveCN104460131AWith touch functionFacilitate thinningNon-linear opticsInput/output processes for data processingEngineeringTouch function

The invention discloses a display panel with a touch function and a manufacturing method of the display panel. The display panel comprises a first substrate and a second substrate which are oppositely arranged and a liquid crystal layer arranged between the first substrate and the second substrate, the display panel further comprises a transparent cover plate, a first touch electrode and a second touch electrode, the transparent cover plate is arranged oppositely to the surface, away from the second substrate, of the first substrate, the first touch electrode is formed on the surface, away from the second substrate, of the first substrate, and the second touch electrode is formed in the surface, close to the first substrate, of the transparent cover plate. By the above mode, the display panel with the touch function is further thinned and thinning of electronic equipment of cell phones and the like using the display panel are benefited.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Lens layer of open type three-dimensional touch display device and electrode structure thereof

The invention discloses a lens layer of an open type three-dimensional touch display device and an electrode structure of the lens layer. The lens layer comprises an upper base plate, a lower base plate, a liquid crystal layer, a plurality of strip-shaped electrodes and a contact electrode; the strip-shaped electrodes are formed on the upper base plate and opposite to the contact electrode; the contact electrode comprises a plurality of block shaped contact parts which are arranged on the lower base plate and electrically connected to a touch circuit. According to the lens layer, the plurality of block shaped contact parts are utilized, so that the thickness of the whole open type three-dimensional touch display device can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

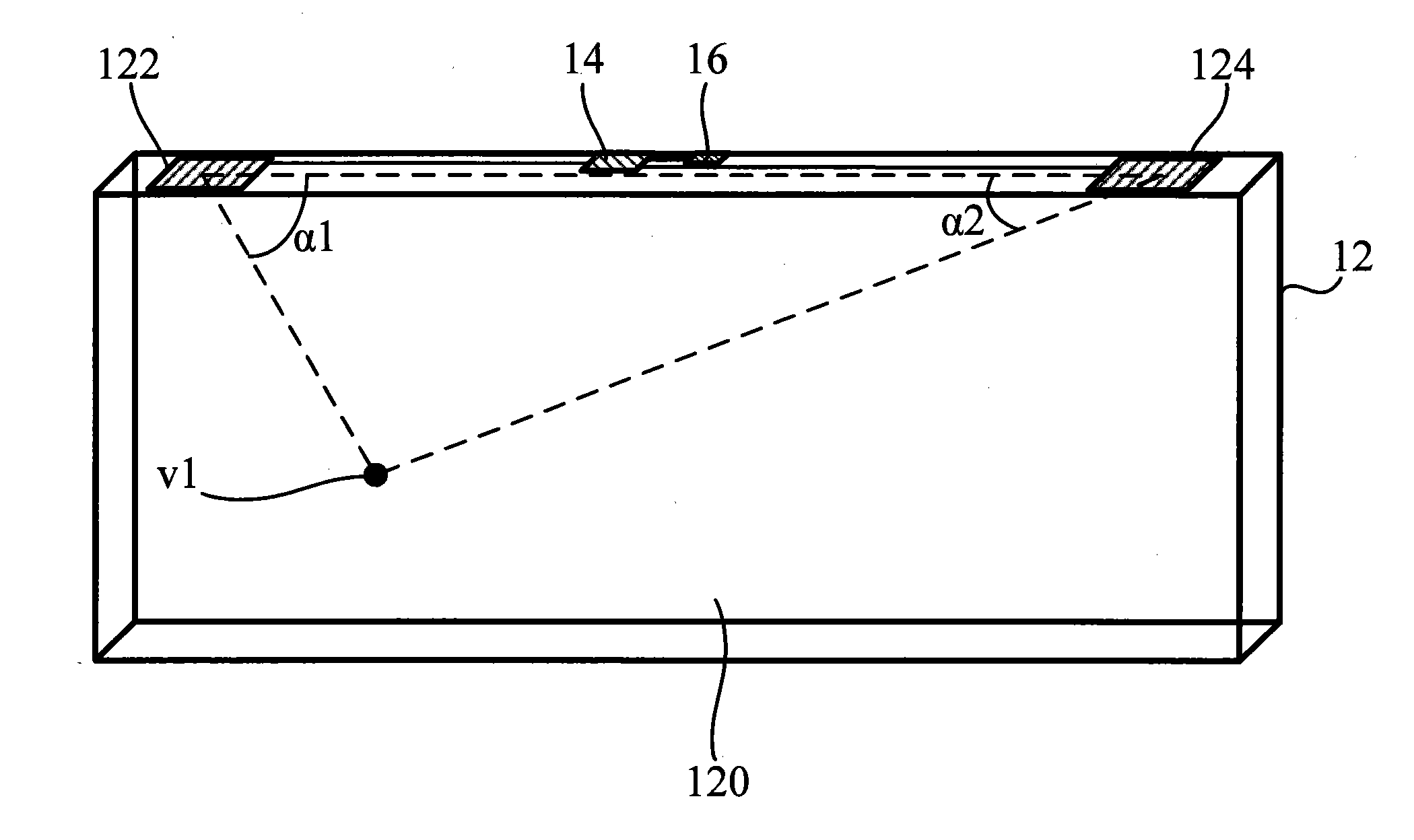

Electronic device

InactiveCN102103423AWith touch functionAchieve touch effectDigital data processing detailsInput/output processes for data processingVibration senseVibration sensing

The invention discloses an electronic device, which comprises a first body and a second body. The second body is pivoted on the first body and comprises a transparent base plate, a first sensor and a second sensor, wherein the transparent base plate is used for touching by the user; the first sensor is arranged on the transparent base plate and is used for sensing the touch of the user so as to output first sensing information; and the second body comprises a second sensor, a processor and a storage. By employing a vibration sensing technology for positioning the touch point of the user and touching the position coordinate to produce a command, the electronic device achieves the touch effect. Therefore, compared with the prior art, the electronic device can greatly reduce the components and has a touch function.

Owner:INVENTECSHANGHAI TECH

Array substrate and manufacturing method thereof

ActiveCN107275341AWith touch functionSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerTouch function

The invention provides an array substrate and manufacturing method thereof. The array substrate includes a gate line and a data line which are crisscrossed, a touch control wire, a plurality of pixel regions defined by intersection of the gate line and the data line, a TFT switch at the intersection of the gate line and the data line, a gate insulation layer located on the gate line, an oxide semiconductor located on the gate insulation layer, a first insulation layer that covers the oxide semiconductor and the data line, a third insulation layer that covers the first insulation layer, pixel electrodes located on the third insulation layer and located in the pixel regions, a pad layer located under the touch control wire, a second insulation layer that covers the touch control wire and pixel electrodes, and a plurality of common electrodes located on the second insulation layer. The array substrate uses a gray scale mask plate, through a reduced number of mask processes, the array substrate having a touch control function is prepared, and compared with a conventional design, the array substrate preparation process is obviously simplified, the yield of array substrates is improved, and the cost is reduced.

Owner:NANJING CEC PANDA FPD TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com