Cement based powder and application thereof in cement concrete and in highway construction

A technology of base powder and cement, which is applied in the field of cement base powder and its application on concrete and roads, which can solve the problems of reduced driving comfort and increased road construction costs, and achieves increased flexural strength, low construction difficulty, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

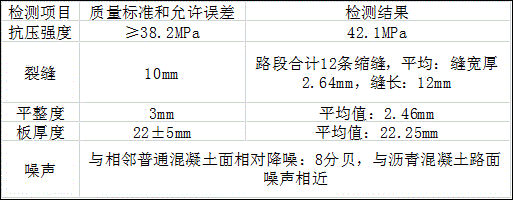

[0023] Specific embodiment 1: The present invention discloses a cement-based powder and its application on the road surface of trucks at an airport. The length of the test section is 200 meters, the width of the road surface is 7 meters, the thickness is 0.2 meters, and the concrete strength standard is C30.

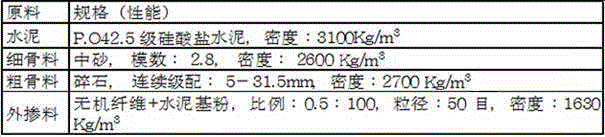

[0024] 1. Raw materials:

[0025]

[0026] The above cement-based powder includes 100 parts by weight of 50-mesh waste rubber particles, 0.5 parts by weight of fiber, and 30 parts by weight of silica fume. The average fiber length of the fiber material is 5 mm, and the organic fiber is acrylic fiber.

[0027] The preparation steps are as follows:

[0028] 1) Mix and stir inert inorganic powder materials, waste rubber particles and fiber materials for 20-40 minutes;

[0029] 2) The mixture in step 1 is processed by high-speed shearing, so that the inert inorganic powder and fiber material are embedded in the waste rubber powder.

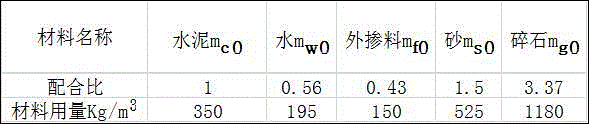

[0030] The formula of hydraulic conc...

Embodiment 2

[0047] Embodiment 2: The present invention discloses a cement-based powder and its application on the pavement of a car parking lot, including 100 parts by weight of waste rubber particles with an average particle diameter of 10 mesh, 10 parts by weight of diatomite with a particle diameter of 100 mesh, 200 10 parts by weight of fly ash and 0.2 parts by weight of fiber material, the average fiber length of the fiber material is 1mm, and the fiber material is inorganic ceramic fiber.

[0048] The preparation steps of the cement-based powder are as follows:

[0049] 1) Mix and stir inert inorganic powder materials, waste rubber particles and fiber materials for 20 minutes;

[0050]2) The mixture in step 1 is processed by mechanical rolling, screw extrusion, high-speed shearing, jet mill collision, and ultrasonic blending, so that inert inorganic powder and fiber materials are embedded in waste rubber powder.

[0051] Prepare concrete with 22.3 parts by weight of cement-based po...

Embodiment 3

[0052] Embodiment 3: This embodiment discloses a cement-based powder, including 100 parts by weight of waste rubber particles with an average particle diameter of 10 mesh, 50 parts by weight of fly ash with a particle diameter of 200 mesh, and 2 parts by weight of polyacrylonitrile fiber material , The average fiber length of the fiber material is 10mm.

[0053] The preparation steps of the cement-based powder are as follows:

[0054] 1) Mix and stir inert inorganic powder materials, waste rubber particles and fiber materials for 20-40 minutes;

[0055] 2) The mixture in step 1 is processed by mechanical rolling, screw extrusion, high-speed shearing, jet mill collision, and ultrasonic blending, so that inert inorganic powder and fiber materials are embedded in waste rubber powder.

[0056] Prepare concrete with 22.3 parts by weight of cement-based powder prepared above, 400 parts of cement, 636 parts of sand, 1172 parts of coarse aggregate, 138 parts of water, and 3.2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com