Putty-less plate processing technology and products of putty-less plates

A kind of processing technology, the technology of greasy board, applied in the direction of covering/lining, construction, building structure, etc., can solve the problems of calcium silicate board fouling, coating delamination, large dust environment, etc., to reduce the overall cost of the project, Improve the quality of decoration and reduce the effect of sandpaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

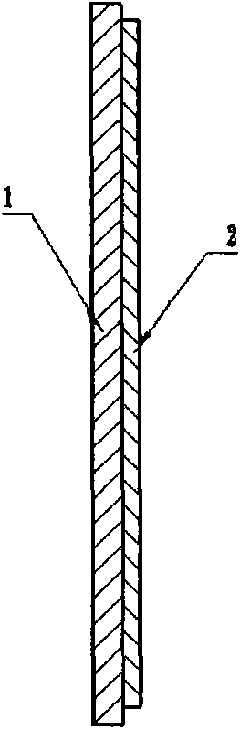

[0023] Embodiment 1 of the present invention, the processing technology of greasy board, is characterized in that it is carried out according to the following specific steps: (1) a substrate is preset; (3) followed by pressing, drying, and polishing to make a greasy-free board.

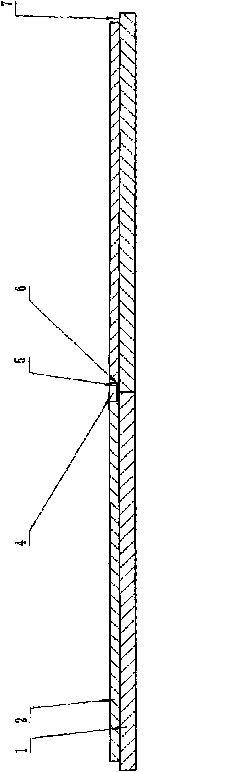

[0024] Embodiment 2 of the present invention, the splicing process of the greasy-free board, is characterized in that it is carried out according to the following specific steps: (1) the substrates of two adjacent greasy-free boards are connected; (2) on the two adjacent sags at the joint Glue, paper tape and putty filling layer are coated in sequence, and the upper surface of the putty filling layer is integrated with the powder adhesive layer of two adjacent greasy-free boards at the same level.

[0025] Embodiment 3 of the present invention, the splicing process of the cut end of the non-g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com