Barrel inner-wall cutter

A cutter and cylinder technology, applied in the field of mechanical equipment, can solve problems such as plastic deformation and size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

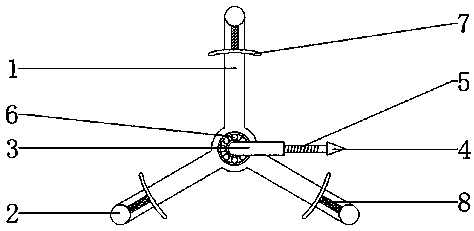

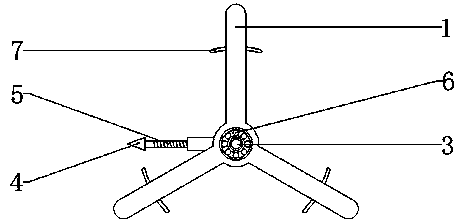

[0017] Combine figure 1 with figure 2 The cylindrical inner wall cutter includes a three-pronged support frame 1. Three columnar columns 2 of equal length are vertically arranged on the three edges of the bottom surface of the support frame 1, and a cylindrical elastic column 8 is vertically arranged on the inner wall of the column 2 , The ends of the three elastic columns 8 are vertically provided with arc-shaped plate-shaped outer wall clips 7, and a bearing 6 is vertically embedded in the center of the support frame 1. The bearing 6 and the three outer wall clips 7 are all coaxial. The ring is fixed and penetrated with an L-shaped round tubular threaded elbow 3. The threaded elbow 3 is located on the bottom side of the support frame 1 and bends vertically. The threaded elbow 3 is provided with a threaded rod 5 that is threaded with it, and the end of the threaded rod 5 is provided There is a cutting head with a pointed tip 4.

[0018] The support frame 1, the column 2, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com