Tiller key groove grooving device and using method thereof

A tiller and keyway technology, applied in the field of tiller keyway slotting devices, can solve the problems of low efficiency and high processing cost, and achieve the effects of improving processing efficiency, reducing processing time and cost, and saving processing time and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

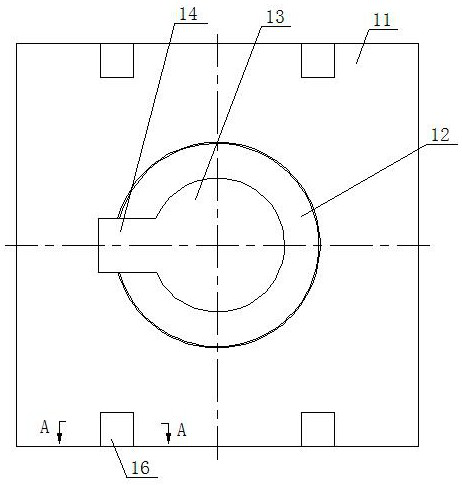

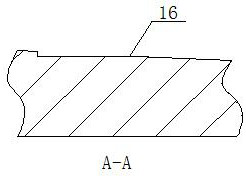

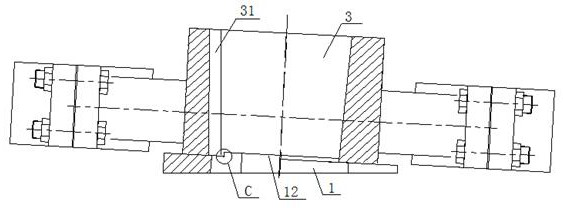

[0067] see Figure 1-Figure 7 , a tiller keyway slotting device, comprising a bottom plate 1, a tiller wire cutting correction disc 2, the upper end surface 11 of the bottom plate 1 is an inclined surface whose inclination is consistent with the taper of the tiller taper hole 3, and the upper end surface 11 Both sides of both sides are provided with countersinking flat 16, and the center of upper end face 11 is provided with the boss 12 that is inserted into the small-diameter end that fits with the tiller taper hole 3, and the upper end face 11 is provided with a ring that surrounds the lower end edge of boss 12. No. annular groove 15, the boss 12 is perpendicular to the upper end surface 11, and the boss 12 is axially provided with a machining hole 13 and a groove 14 for keyway machining. The groove 14 for keyway machining is located outside the machining hole 13 and The processing hole 13 is connected, and the size of the groove 14 for keyway processing is greater than the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com