Display device

A display device and display panel technology, which is applied in the direction of optical filters, optics, instruments, etc., can solve the problems that the borderless design cannot be realized, and achieve the effect of ensuring the sense of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

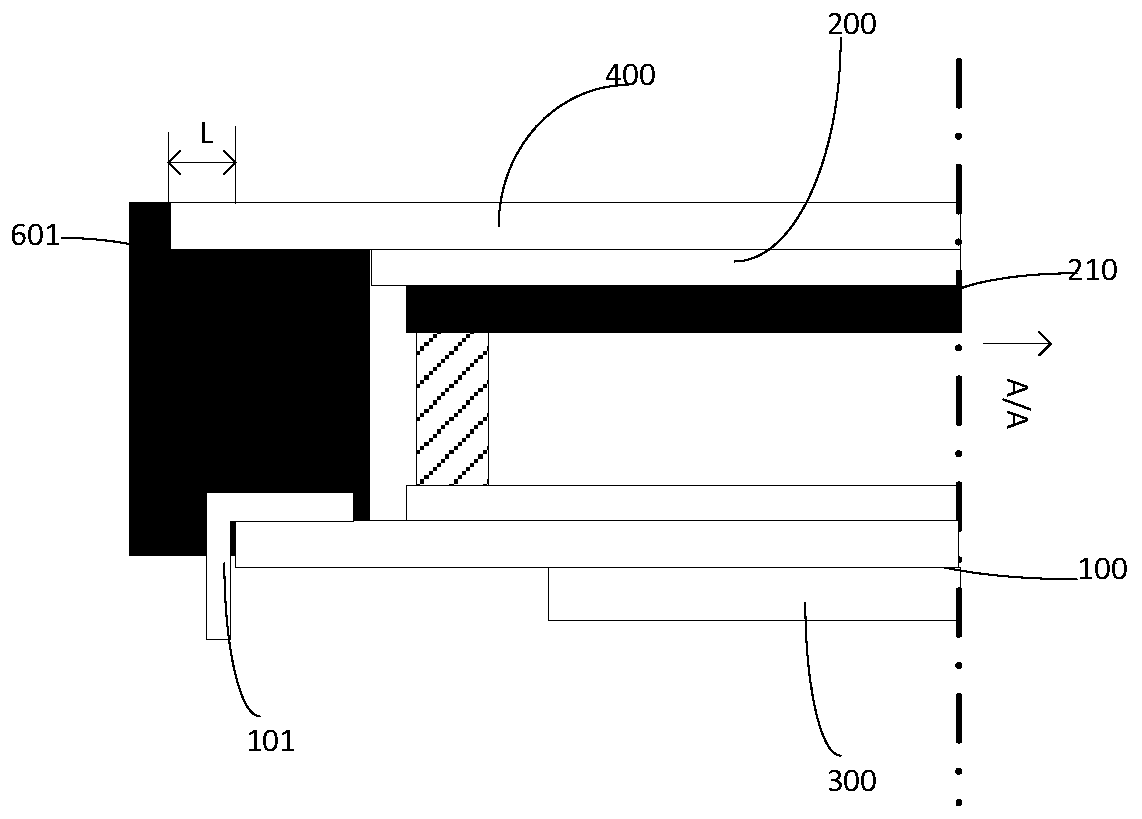

[0063] figure 1 Shown is a schematic structural diagram of the first embodiment of the display device provided by the present invention.

[0064] Such as figure 1 As shown, in this embodiment, the filling part includes: a black filling glue 601 filled between the second polarizer 400 and the binding area of the second substrate 200. A black matrix 210 is provided on the side of the second substrate 200 facing the first substrate 100, and the black filler 601 and the black matrix 210 located at the edge of the second substrate 200 jointly form a light-shielding structure.

[0065] In this structure, the black filler 601 is used to absorb light leakage on the binding side of the display panel. The structure is simple and the implementation process is simple. It only needs to fill black on the binding side after the first substrate 100 and the second substrate 200 are paired. Filling glue 601 is sufficient, which can reduce the complexity of the manufacturing process and reduce the ...

Embodiment 2

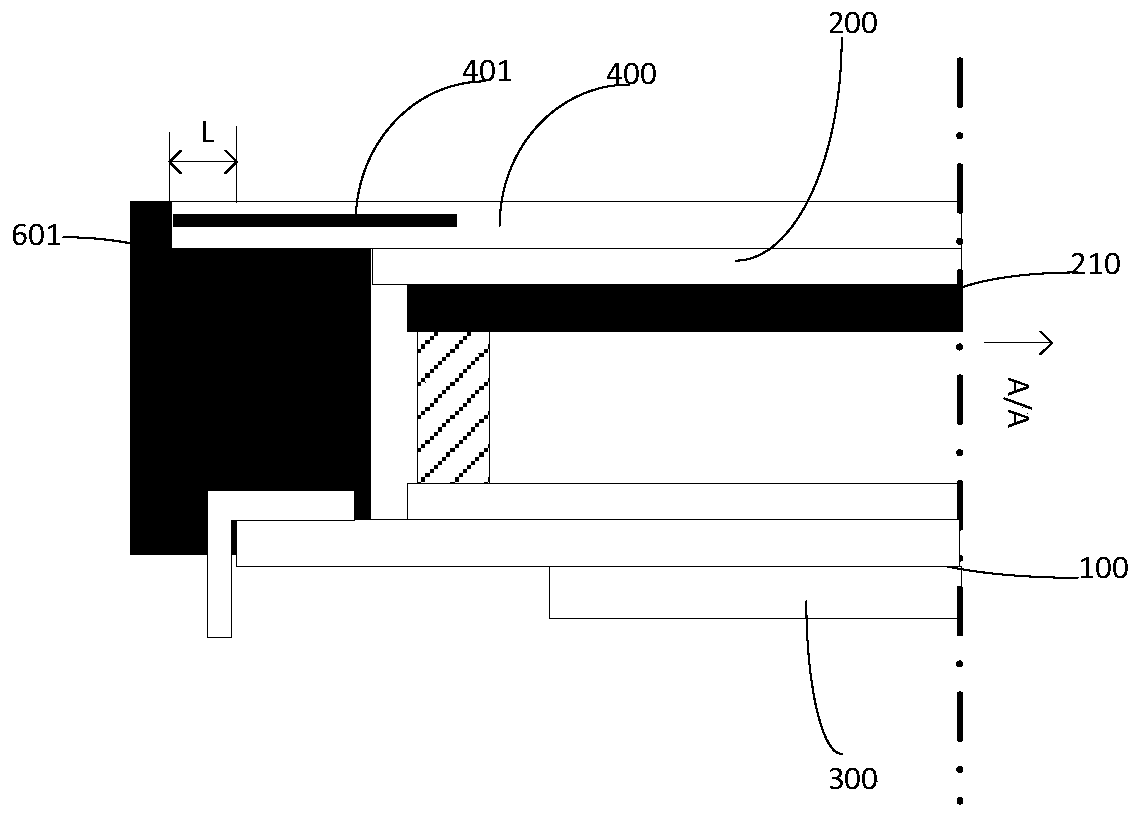

[0073] image 3 Shown is a schematic structural diagram of a second embodiment of the display device provided by the present invention.

[0074] Such as image 3 As shown, the difference between this embodiment 2 and embodiment 1 is that: in the display device provided in this embodiment 2, on the binding side of the display panel, the edge of the second polarizer 400 is further provided with A light-shielding layer 401; in a direction perpendicular to the base substrate of the first substrate, the light-shielding layer 401 covers at least the gap between the black filler 601 and the black matrix 210, and the light-shielding layer 401 The display area of the display panel is not covered.

[0075] With the above solution, in order to further ensure that the gap between the black filler 601 and the black matrix 210 on the second substrate 200 causes light leakage, a light shielding layer 401 may be further provided on the edge of the binding side of the second polarizer 400, The c...

Embodiment 3

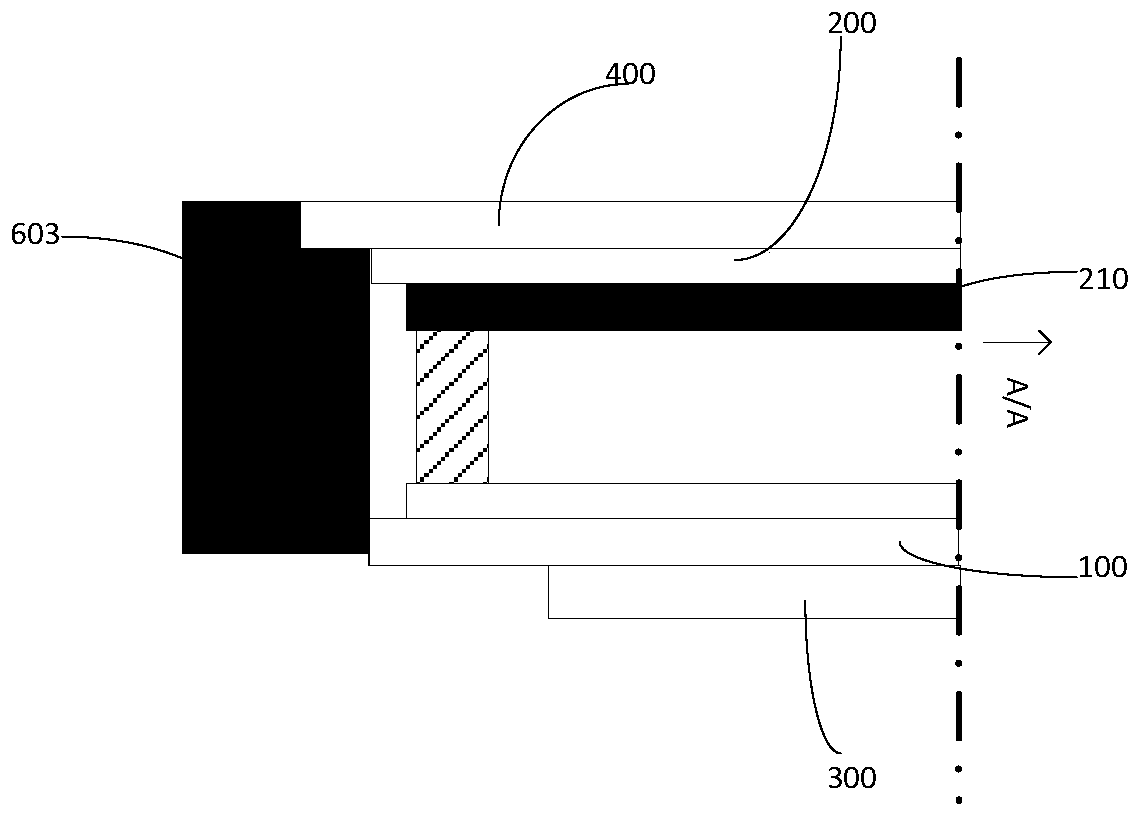

[0080] Figure 4 Shown is a schematic structural diagram of a third embodiment of the display device provided by the present invention.

[0081] Such as Figure 4 As shown, in this embodiment, the filling portion includes: a filling glue 602 filled between the second polarizer 400 and the binding area of the second substrate 200; and The black frame glue 603 outside the filler 602;

[0082] On the binding side of the display panel, the edge of the second polarizer 400 is provided with a light-shielding layer 401. In a direction perpendicular to the base substrate of the first substrate, the light-shielding layer 401 covers at least the The gap between the black frame glue and the black matrix, and the light shielding layer does not cover the display area of the display panel;

[0083] Wherein, the black frame glue 603 overlaps with the projection of the light shielding layer 401 in a direction perpendicular to the base substrate of the first substrate, and the light shielding la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com