Multifunctional guillotine shear

A shearing machine, multi-functional technology, applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problem of single function of the shearing machine, and achieve the effect of beautiful appearance, lower input cost and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

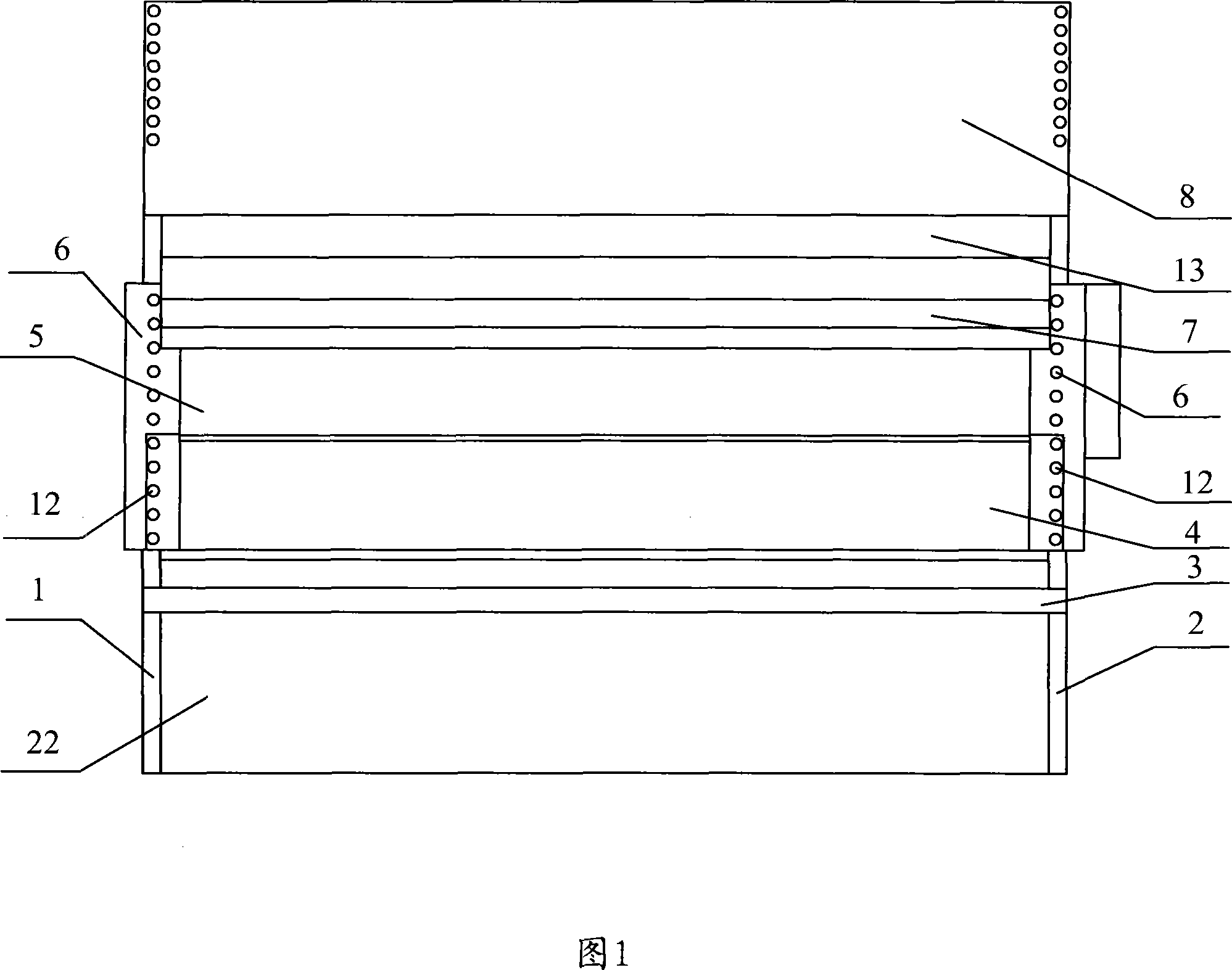

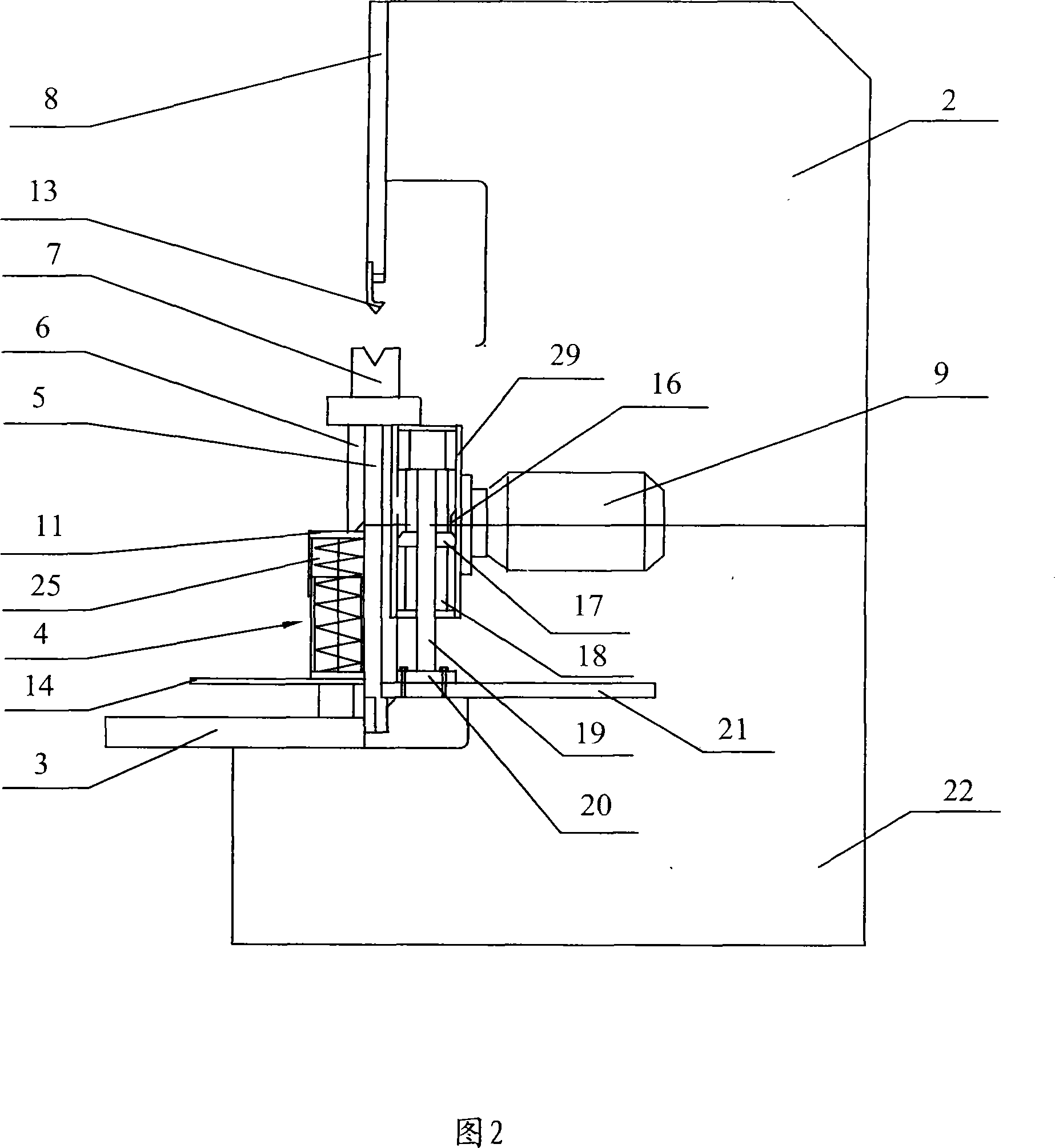

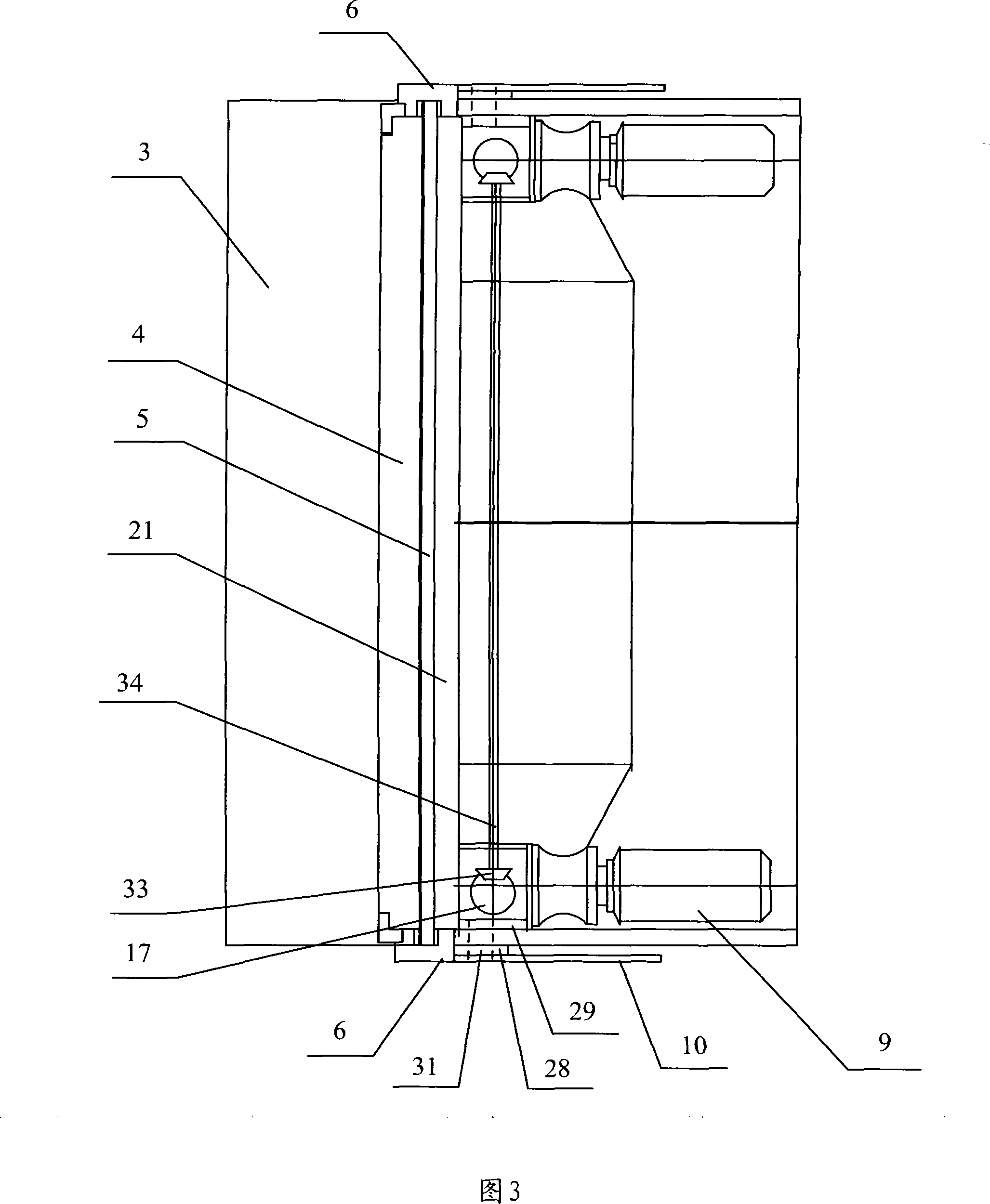

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and shown in Fig. 5, the multifunctional plate shearing machine of the present invention comprises a left side plate 1, a right side plate 2, and a base 22, which are arranged between the lower parts of the left and right side plates There is a bottom knife rest 3, and a bent top plate 8 is fixed between the left and right side plate tops. Large guide rails 6 are respectively arranged on the left and right side plates, and the large guide rails 6 are connected with the left and right side plates through pin shafts; A bending / punching machine bottom mold 7 is fixed on the top of the upper knife rest 5, and a bending / punching machine top mold 13 is fixed on the bottom of the bending top plate 8. In order to prevent the upper knife rest from bending, a reinforcing plate 21 is provided on the back of the upper k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com