Switching macro micro laser high-speed cutting machine tool

A cutting machine, exchange-type technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of complex structure, difficult installation and maintenance, and difficult realization of laser cutting machines, saving processing space and reducing needs time, the effect of reducing the effective inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

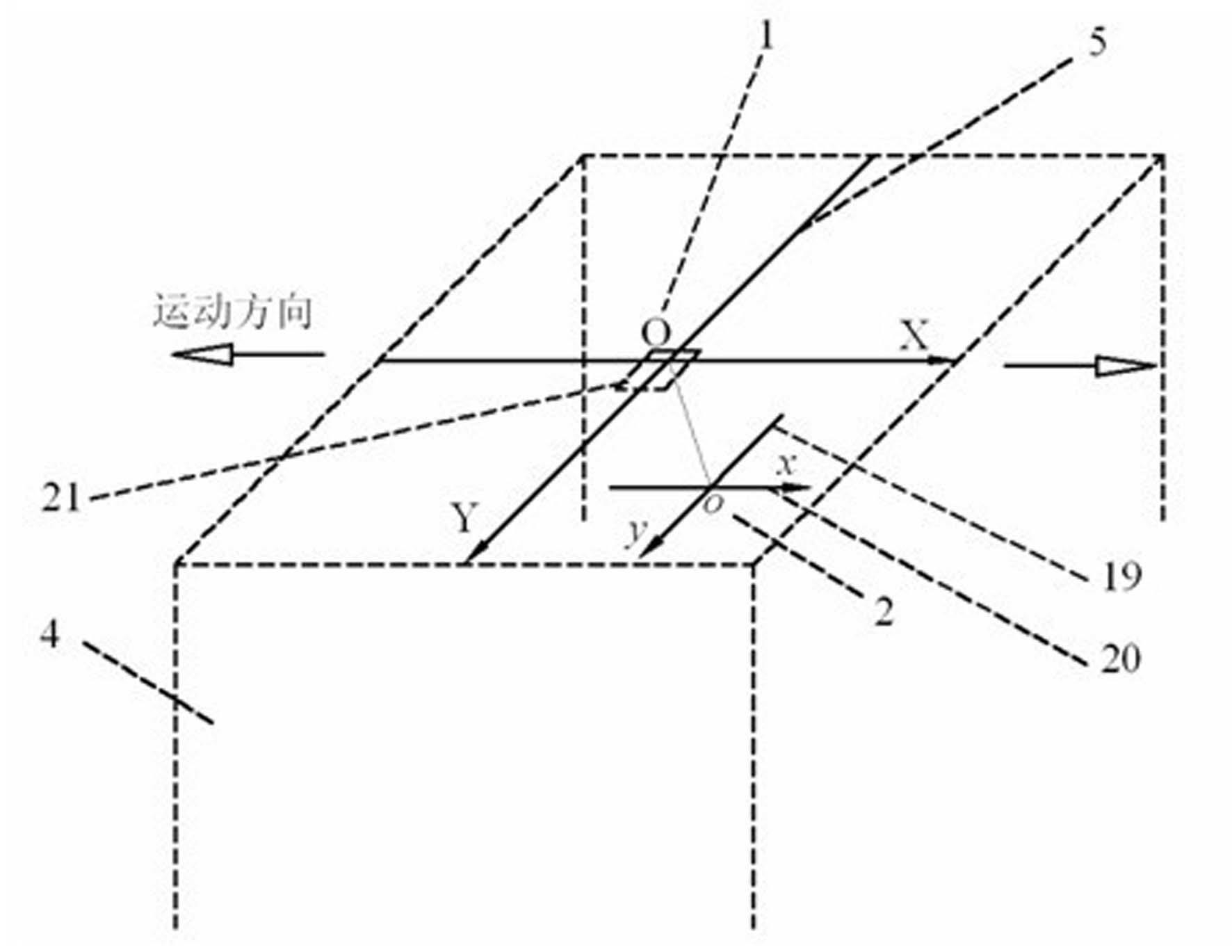

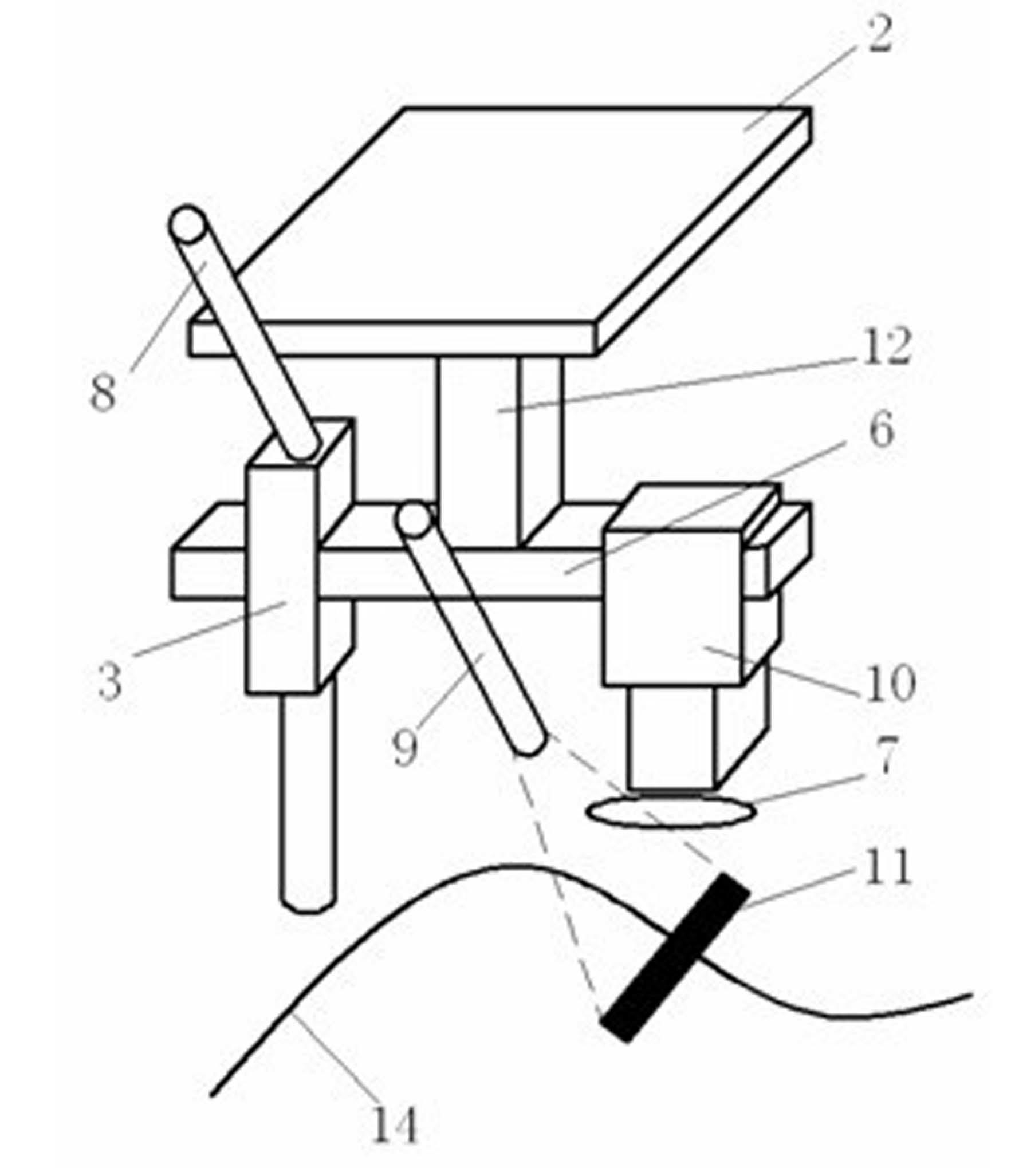

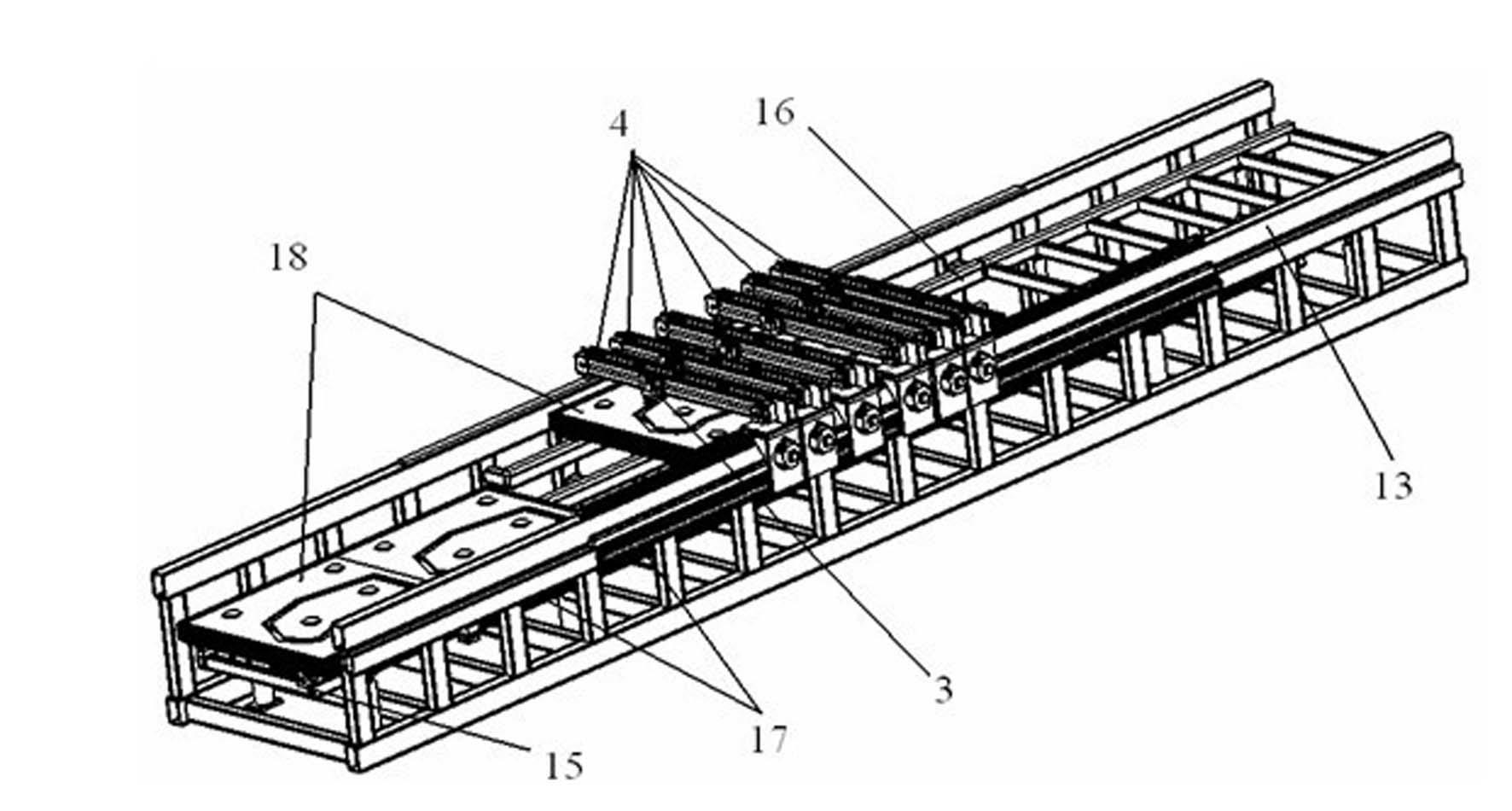

[0011] An exchangeable macro-micro laser high-speed cutting machine tool, comprising a macro-moving table 1 and a micro-moving table 2, a micro-moving table bracket 12 is installed on the micro-moving table 2, a bracket end connecting rod 6 is installed on the micro-moving table bracket 12, and the bracket A structured light vision sensing system and a laser cutting head 3 are installed on the end link 6 . The micro-movement stage bracket 12 is fixedly connected with the slider 21 installed on the macro-movement Y-rail 5 through the micro-movement y-differential rail 19 and the micro-movement x-rail 20 , that is, the micro-movement stage 2 and the slider 21 constitute a two-dimensional slide table. In this way, the micro-movement stage 2 can realize the precise fine-tuning movement in the x and y directions relative to the slider 21 , that is, the micro-movement.

[0012] Since the micro-movement stage 2 is fixedly mounted on the slider 21 on the macro-moving Y guide rail 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com