Multi-stage telescopic redundant manipulator

A technology with a degree of freedom and a telescopic arm, which is applied in the field of robots to achieve the effects of good performance in avoiding singularities, large working range and strong load capacity

Active Publication Date: 2011-01-05

TSINGHUA UNIV +1

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide an operating arm, which can combine the advantages of multi-stage telescopic arm and multi-joint redundant manipulator, so that the composite manipulator can go deep into the narrow and long pipeline, and adapt to the special-shaped structure inside the long and narrow pipeline, avoid obstacles, and solve the problem of special-shaped narrow and long pipes. Automatic spraying operations on the inner wall of the pipeline, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

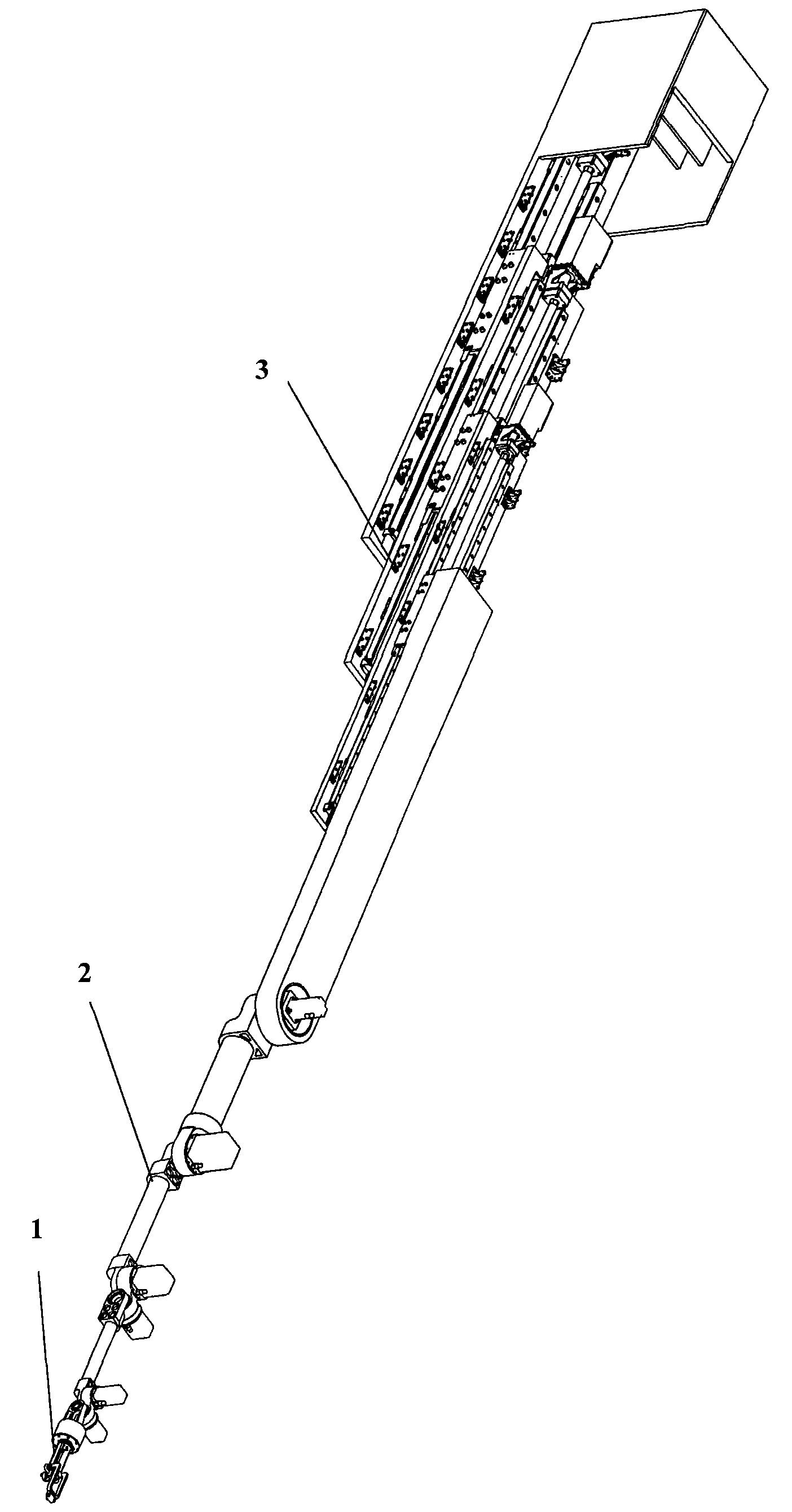

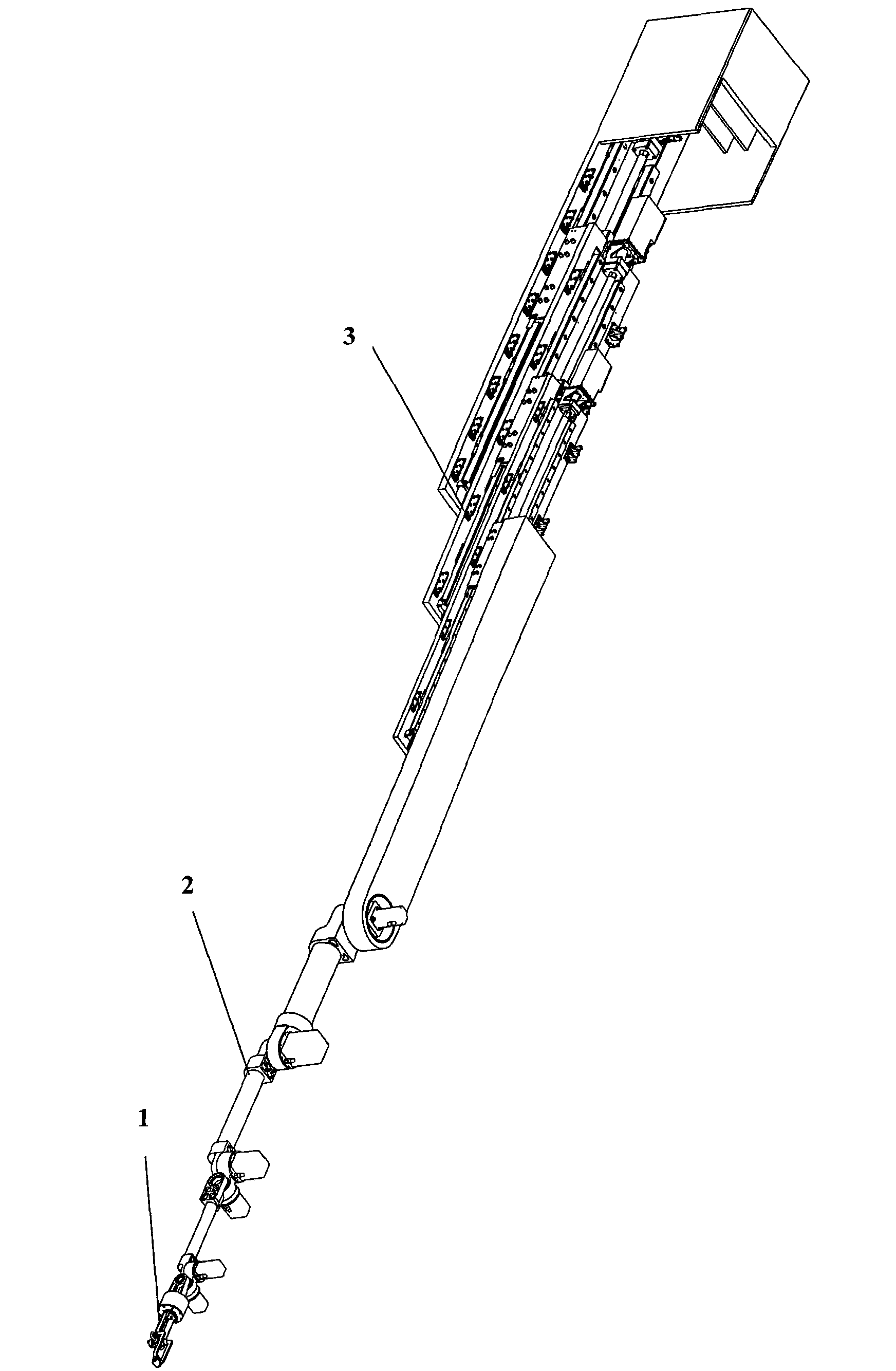

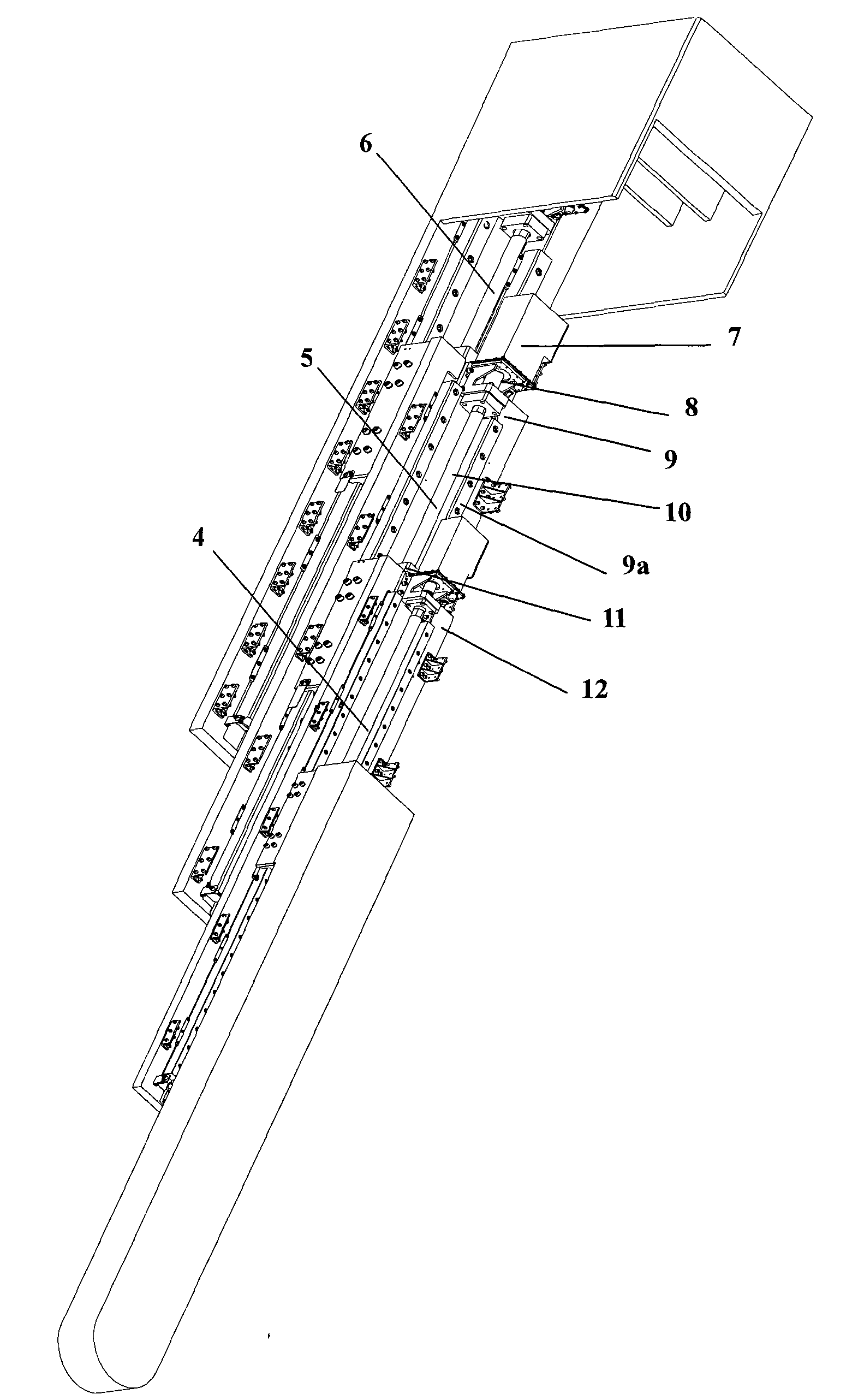

The invention discloses a multi-DOF (degree of freedom) telescopic redundant manipulator comprising a telescopic arm, a crank arm and an end effector, wherein the end effector is mounted at the tail end of the crank arm; the crank arm is mounted at the tail end of the telescopic arm; the multi-DOF telescopic redundant manipulator is characterized in that the crank has the redundant rotational DOF; and the telescopic arm has the multi-linear DOF. The invention further relates to a method for testing whether the multi-DOF telescopic redundant manipulator interferes with the inner wall of a pipe. By combining the advantages of multi-stage telescopic joints and multi-DOF rotary joints, the manipulator of the invention is applicable to the automated spraying and welding operations of inner andouter surfaces of large complex workpieces, in particular to the automated operations of inner surfaces of complex long and narrow deformed piping workpieces.

Description

Multi-stage telescopic redundant degree-of-freedom manipulator arm technical field The invention relates to the technical field of robots, in particular to a multi-stage retractable redundant degree-of-freedom operating arm, which is suitable for working inside special-shaped long and narrow pipelines. Background technique In the field of special industries (such as the field of aerospace), there are many special-shaped narrow and long pipes whose inner surfaces need to be sprayed or welded. Because the inner surfaces of these narrow and long pipes are relatively complicated and the inner space is extremely narrow, it is difficult for technicians to enter, so automatic operations must be used The device is complete. At present, the existing industrial robot products in the world (such as ABB, KUKA, MOTOMAN, etc.) all operate on the outer surface or simple inner wall of the workpiece. When the existing mechanical arm on the market is directly used to work on the inner sur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25J9/04B25J18/04

Inventor 陈恳李金泉付成龙杨向东付铁曹文敦陈明启路敦民刘宗政张传清陈雁邵君奕吴丹杨东超刘莉徐家球郑林斌王力强颜华

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com