Pen core automatic displacement method and device

A technology of shifting device and refill, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of increasing the production cost of line drawing equipment, long assembly cycle, etc., and achieve the advantages of saving processing space, simple process and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

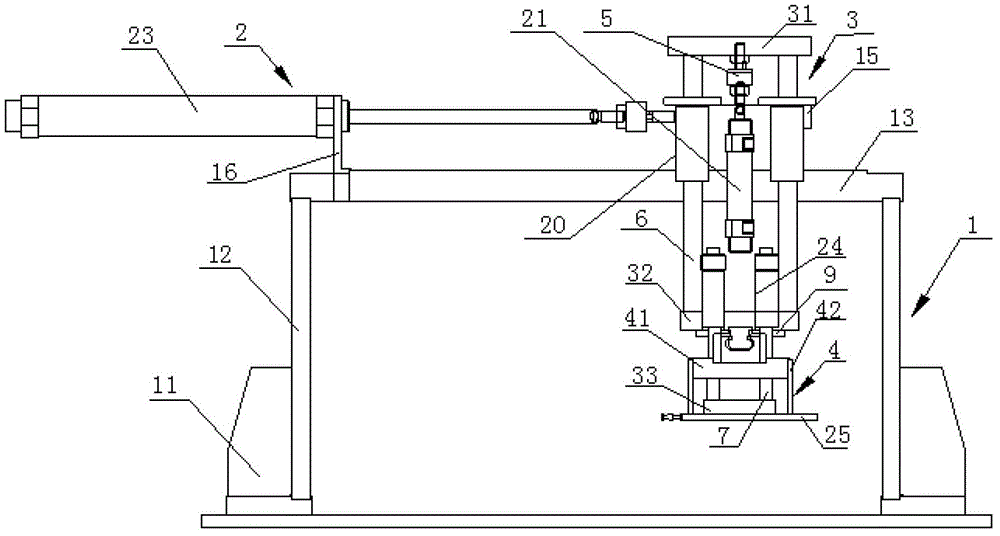

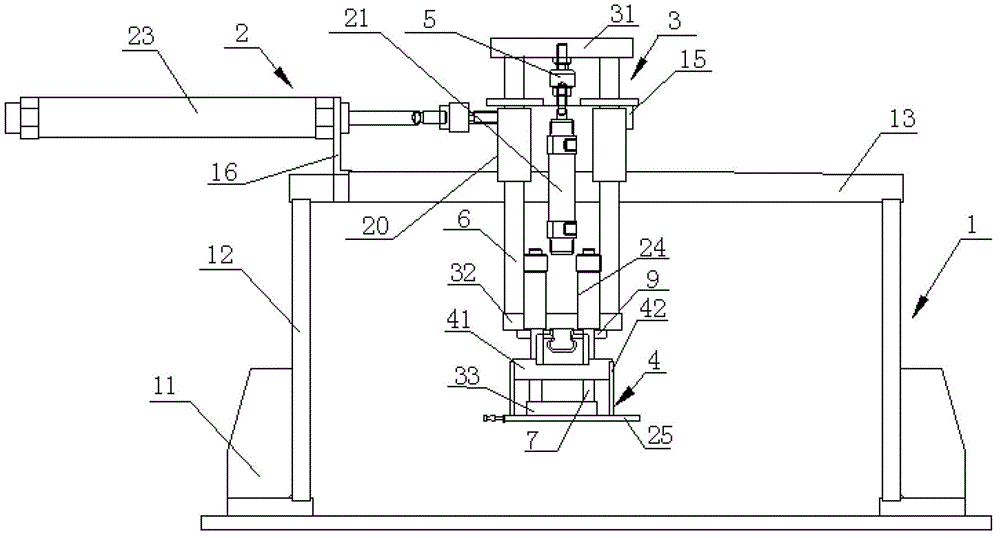

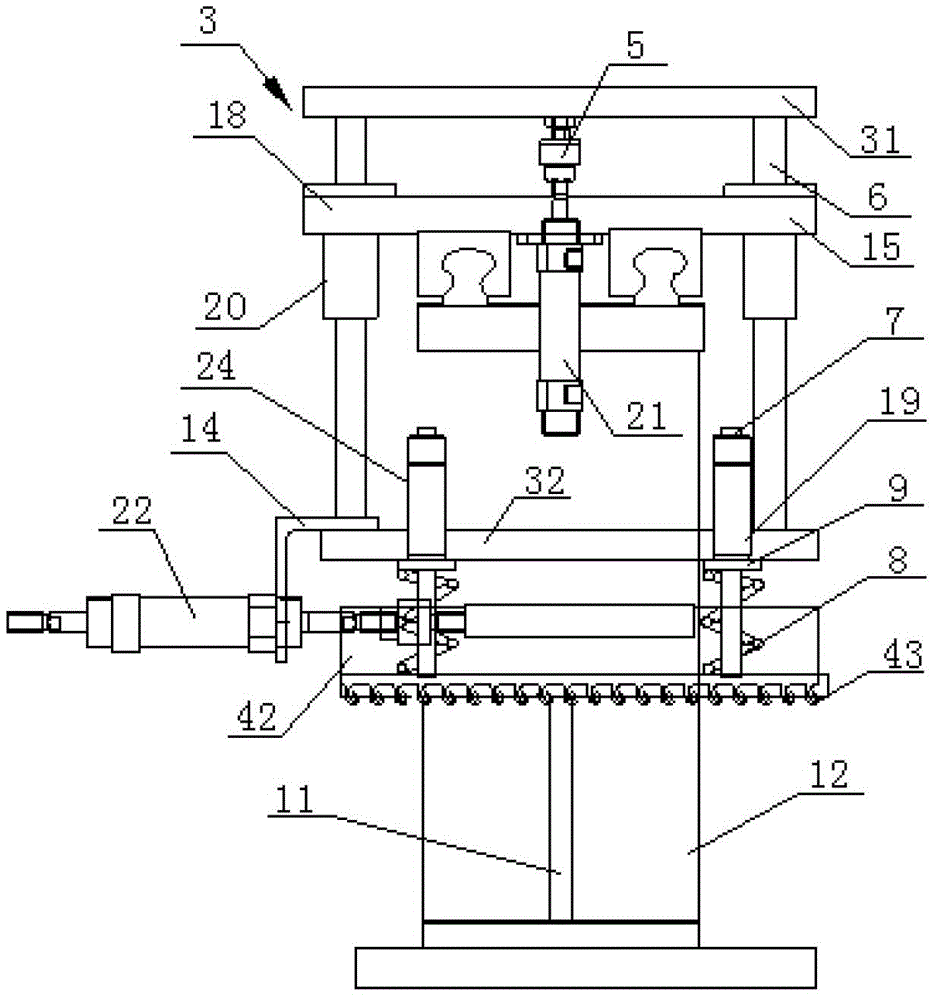

[0028] combine Figure 1 to Figure 3 As shown, the automatic refill device disclosed by the present invention is a part of automatic detection equipment for pens or refills, and is used to displace the refills after passing the line drawing detection from the first assembly line to the second assembly line. On the top, it realizes the synchronous operation of pen refill line detection and protective case installation. It includes a fixed seat assembly 1, an air cylinder 2, a displacement mechanism 3 and a pen core hooking assembly 4 connected with the displacement mechanism 3.

[0029] The fixed seat assembly 1 is used to support the automatic displacement device of the pen core, including a reinforcing seat 11, several fixed brackets 12 and a fixed plate 13, and the fixed plate 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com