Manufacturing method for enameled glass screen printing plate and enameled glass

A production method and technology of glass mesh, applied in printing plate preparation, printing, etc., can solve the problems that glazed glass screen plates cannot be produced, the space occupied by the plate printing machine is large, and the safety hazard of screen plate flipping can be solved, so as to save processing space , easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

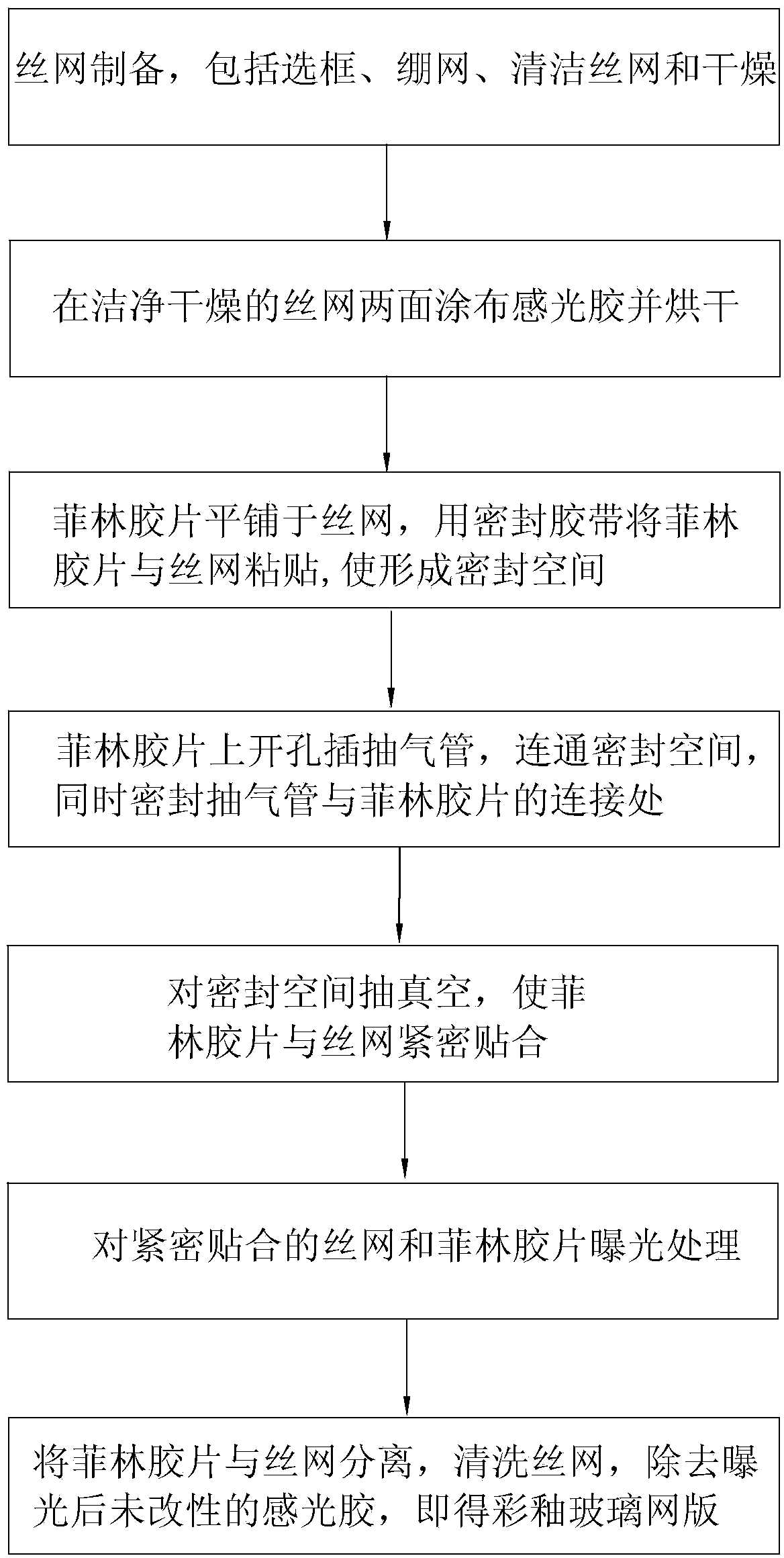

[0026] Such as figure 1 Shown, a kind of manufacture method of colored glaze glass screen plate, comprises the following steps:

[0027] The silk screen is prepared by using the known silk screen production method of colored glaze glass, including frame selection, stretching, cleaning and drying the screen, wherein the mesh number of the prepared screen is 200-300 mesh;

[0028] Coating of photosensitive glue can be done manually or by automatic coating machine; it is necessary to place the screen frame at a certain angle, first coat the photosensitive glue on the printing surface three to five times, and then apply it on the scraping surface Coat the photosensitive glue for three to five times. After finishing, put the screen plate into the oven to dry at 35-40°C. The drying temperature can be properly adjusted accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com