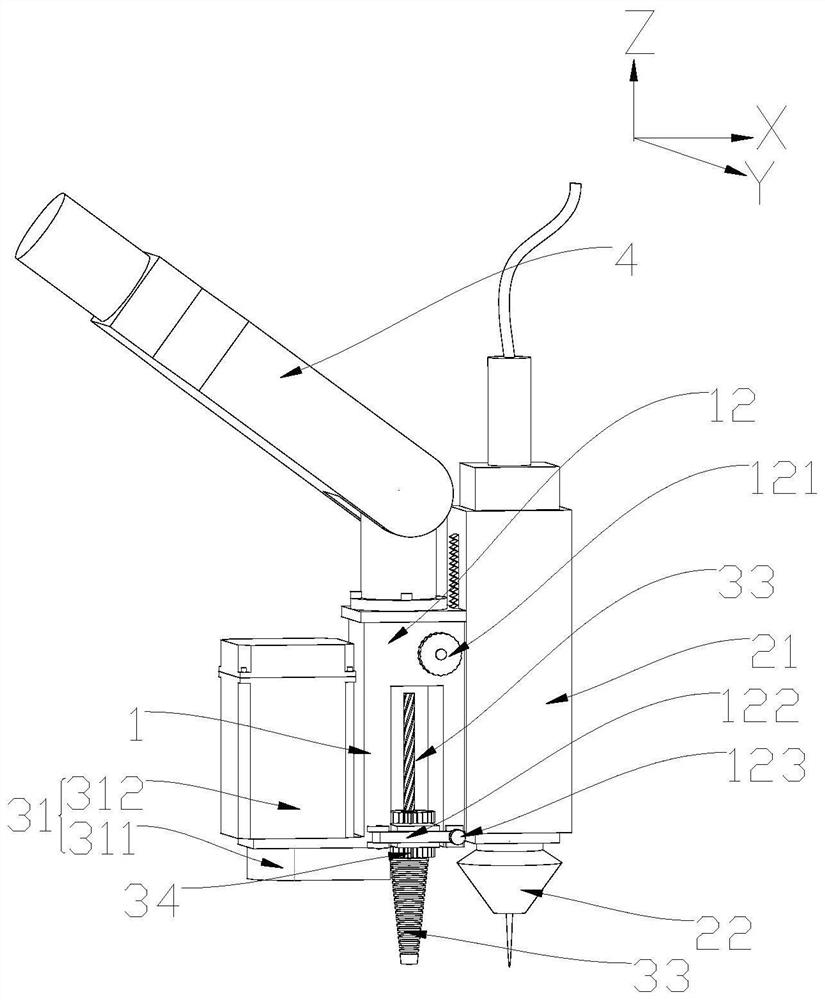

Laser and friction composite additive and subtractive machining device and method

A processing device and a technology of adding and subtracting materials, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the surface roughness of the added metal, forming a stable and continuous unfavorable molten pool, etc., so as to avoid adverse effects , Save processing space and improve manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

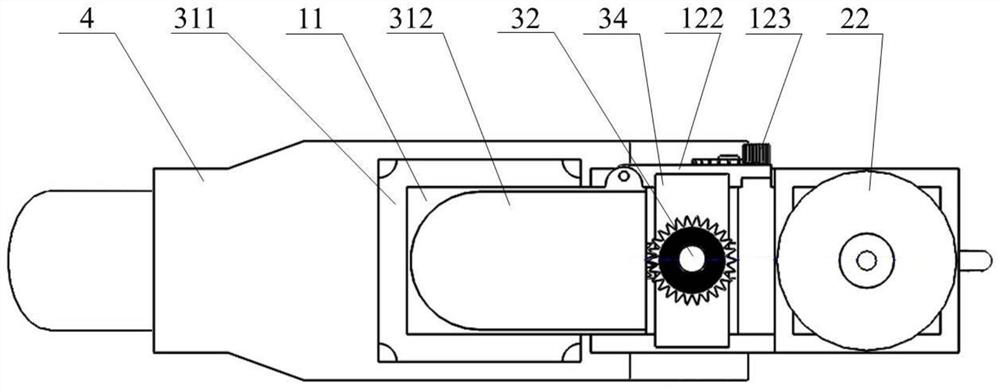

Method used

Image

Examples

Embodiment 1

[0091] The present embodiment provides a composite processing method for additively manufacturing multilayer metal deposition structures on the surface of a workpiece to be processed based on a laser and friction composite material addition and subtraction processing device, which specifically includes the following steps:

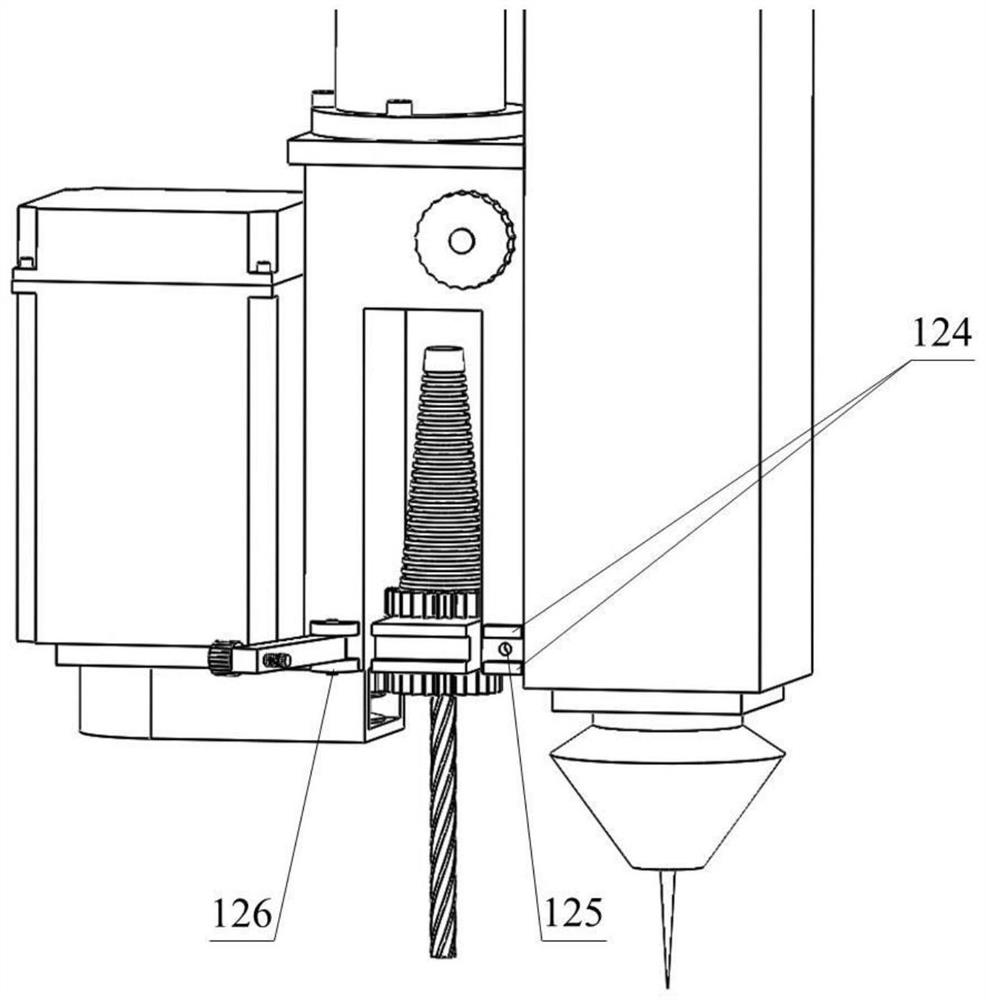

[0092] 1.1. Set the processing parameters of the parts to be processed: the rotational speed V of the rotating friction head 32 1 and the feed rate V 2 , the relative position of the rotating friction head 32 and the surface of the part is the friction depression depth H 1 , the feeding speed of the laser beam is equal to the feeding speed V of the rotating friction head 32 2 , the relative position of the laser beam focus O and the surface of the part is the defocus depth H 2 , the horizontal distance L between the laser beam focus O and the center line of the rotating friction head 32 is determined by the size of the bracket 12, the laser head 21 and t...

Embodiment 2

[0101]This embodiment provides a composite processing method for additively manufacturing a gradient-structured metal deposition structure on the surface of a workpiece to be processed based on a laser and friction composite material increase / decrease processing device. The processing method provided in this embodiment is the same as the processing method in Embodiment 1. The same, the difference is that the last step adopts the following method:

[0102] After the laser-assisted addition, friction addition and mechanical reduction of the first layer of metal are completed, the laser and friction composite addition and subtraction processing device is lifted up by an average height of the deposition layer through the manipulator 46, and steps 1.1 to 1.6 are repeated, that is, After completing the laser-assisted additive, frictional and mechanical subtraction of the former metal, the composition of the metal powder elements needs to be replaced, and the processing parameters, la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com