Automatic device and method for machining curve surface of external spiral space

An external spiral, automatic car technology, applied in the field of mechanical cutting, can solve the problems of high dimensional accuracy, shape accuracy, spatial position accuracy, difficulty in ensuring product quality, low production efficiency, etc., and achieves high production efficiency and simple structure. , the effect of meeting the technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The outer spiral space curved surface automatic turning and milling device and the processing method of the present invention are further illustrated with examples.

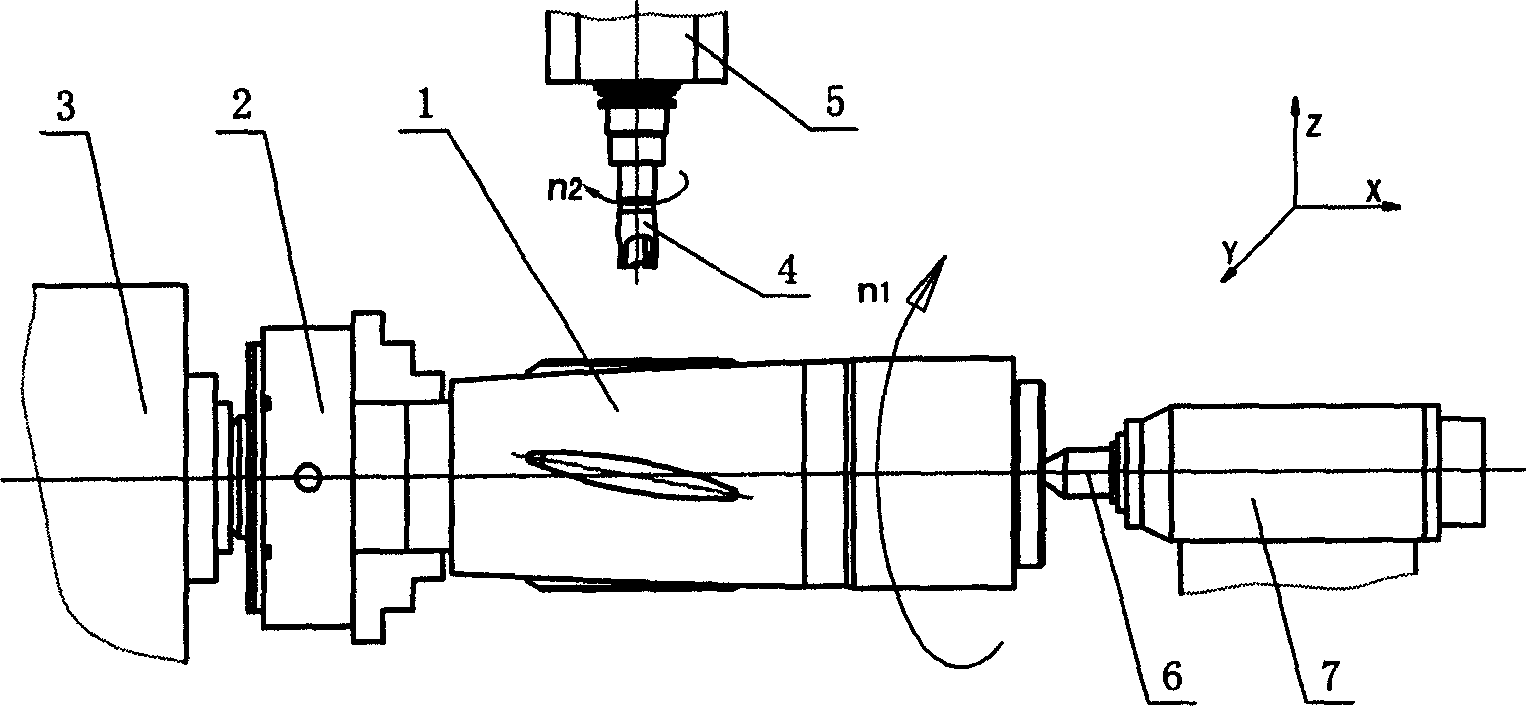

[0011] Such as figure 1 As shown, an automatic turning and milling device and processing method for an outer helical space surface, the diameter of the workpiece is φ120mm, and the processed workpiece has six outer helical space surfaces, and a φ20mm TiN coated four-tooth finger milling cutter is used. The device includes a chuck 2 , a spindle box 3 , a milling cutter 4 , a milling cutter driving unit 5 , a top 6 , and a machine tool tailstock 7 . The chuck 2 is fixed on the main shaft at the front end of the headstock 3, the headstock 3 is fixed on the left end of the bed by screws, the top 6 is installed on the shaft of the machine tool tailstock 7, the machine tool tailstock 7 is arranged on the right end of the bed, and the milling cutter The driving unit 5 is composed of X-direction working slide tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com