Fast automatic lathing and milling processing method for large thin wall cylindrical grids parts

An automatic processing and grid technology, applied in the field of mechanical cutting, can solve the problems of low rigidity and strength, low yield, low production efficiency, etc., and achieve the effect of simple processing technology, meeting technical requirements and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

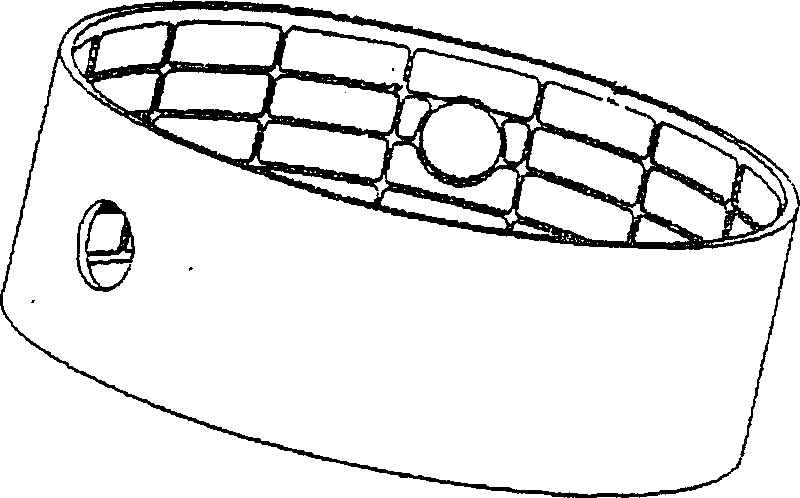

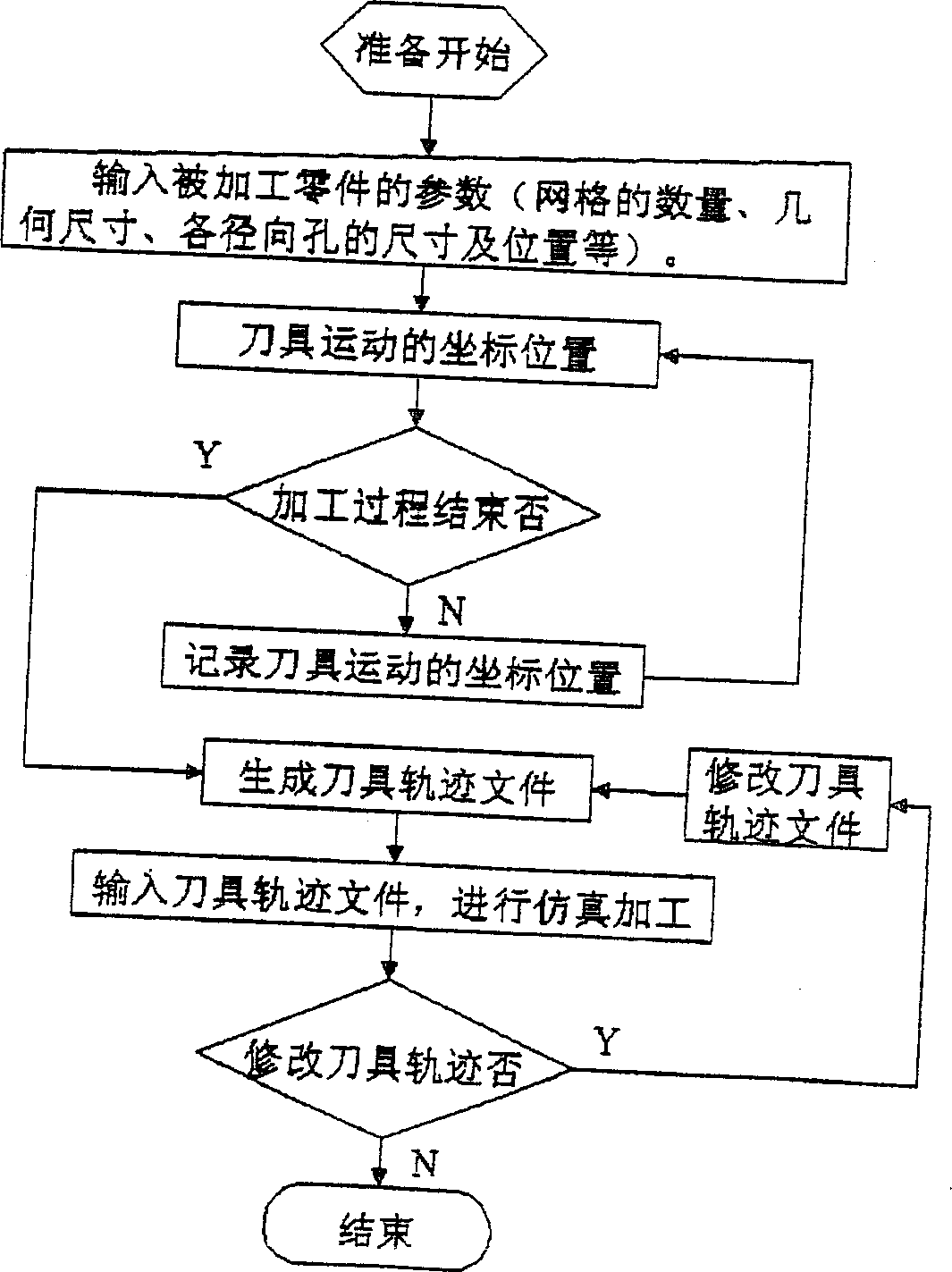

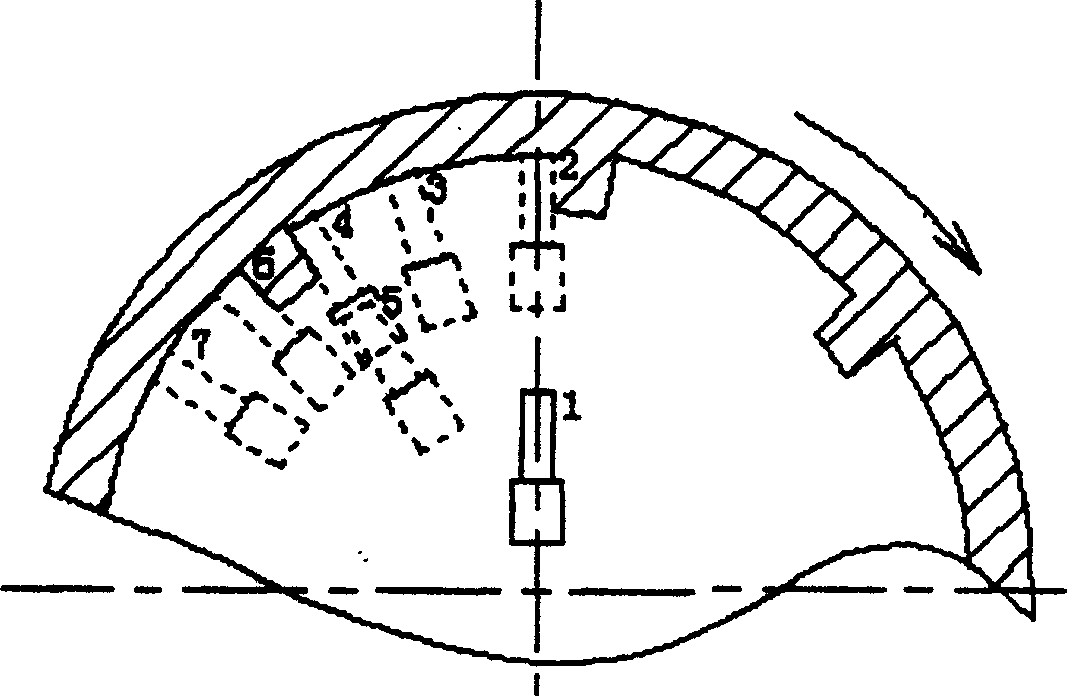

[0011] The technical method of the high-speed turning and milling of the cylindrical mesh of the present invention is further illustrated in conjunction with examples. For example, processing, a thin-walled part of a rotating body with a diameter of 1500mm, a wall thickness of 6mm, and a height of 450mm. Such as figure 1 As shown, the inner surface has a cylindrical grid structure. Using an elevated five-axis linkage processing machine tool, the first step: first process the reference plane, outer circle and inner hole of the part; the second step: forming and processing the cylindrical grid, using a φ20mm TiN coated four-tooth finger milling cutter, the tool The fast forward speed is 45m / min, the tool speed is 12000r / min, and the cutting feed speed is 2.5mm / s. High-speed wind cooling is adopted, and the wind pressure is 5-6Mpa. At room temperature, the tool continuously processes the cylindrical mesh according to the processing program. The trajectory of the tool movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com