Bending process of u-shaped furnace tube using bending roll distance sensor and pressure-holding finalization

A distance sensor and furnace tube bending technology, which is applied in the field of manufacturing furnace tubes of heating furnaces, can solve the problems of low shape accuracy, long processing process, uneven processing deformation, etc., and achieve the effect of small processing space and continuous bending process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

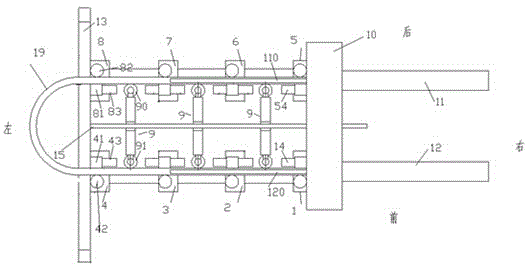

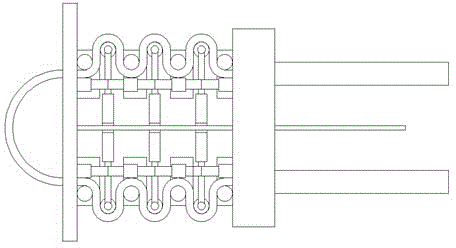

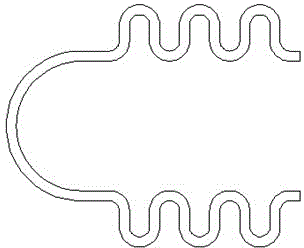

[0028] Attached below Figure 1-3 The present invention will be described in detail.

[0029] A U-shaped heating furnace tube bending process using a bending roll distance sensor and performing pressure-holding and shaping. It uses a furnace tube bending device. The U-shaped furnace tube bending device includes a left frame 13 and a pushing mechanism 10. The pushing Mechanism 10 is on the right side of left frame 13, and guide rod 15 is fixedly arranged at the middle position on the right side of said left frame 13. Guide rod 15 extends horizontally in the left-right direction. The frame 13 is fixedly connected, and the right end of the guide rod 15 is slidably connected with the middle part of the pushing mechanism 10. The left frame 13 is provided with the original U-shaped furnace tube loading and unloading for the completed process. passageway through; on the guide rod 15, three bending hydraulic devices 9 are sequentially slid between the left frame 13 and the pushing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com