Steel bar straightening, bending and shearing continuous production device

A technology for production device and steel bar, applied in the field of steel bar straightening, bending and shearing continuous production device, it can solve the problems of uneven stress on fasteners, affecting shear quality, looseness, etc. High bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

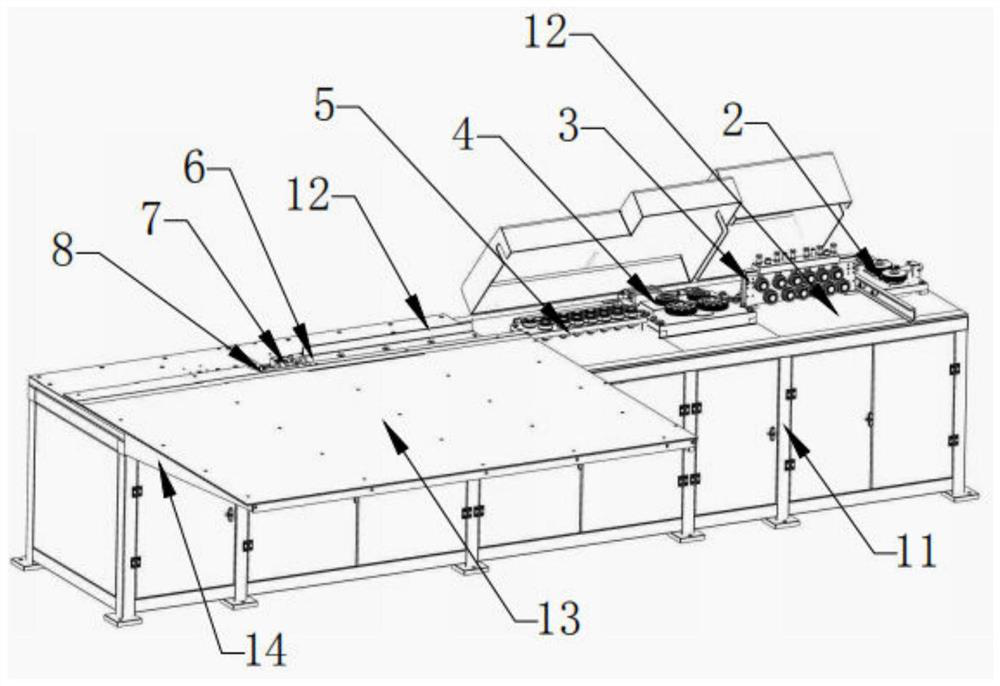

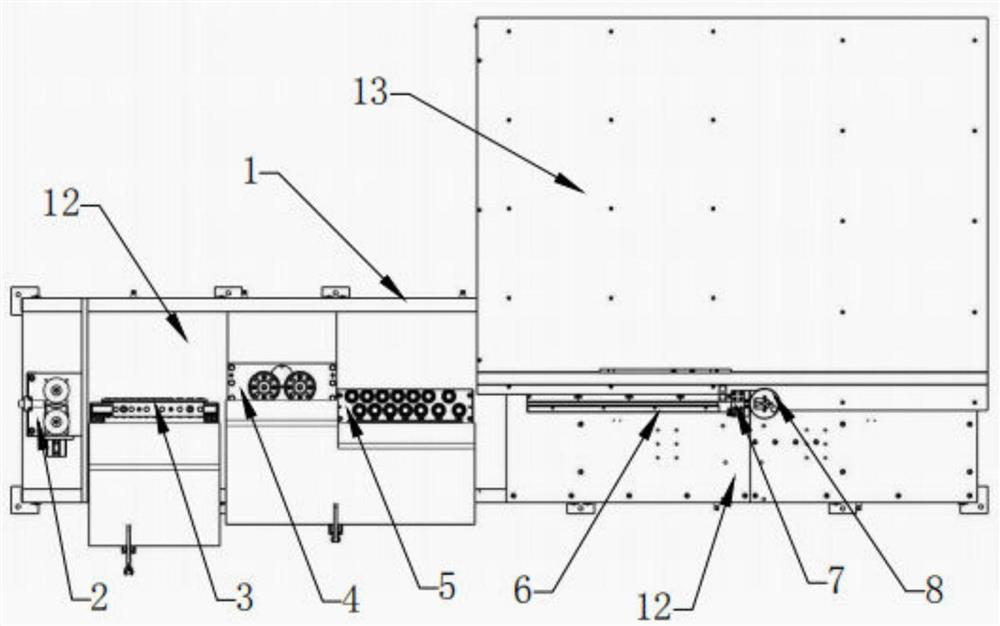

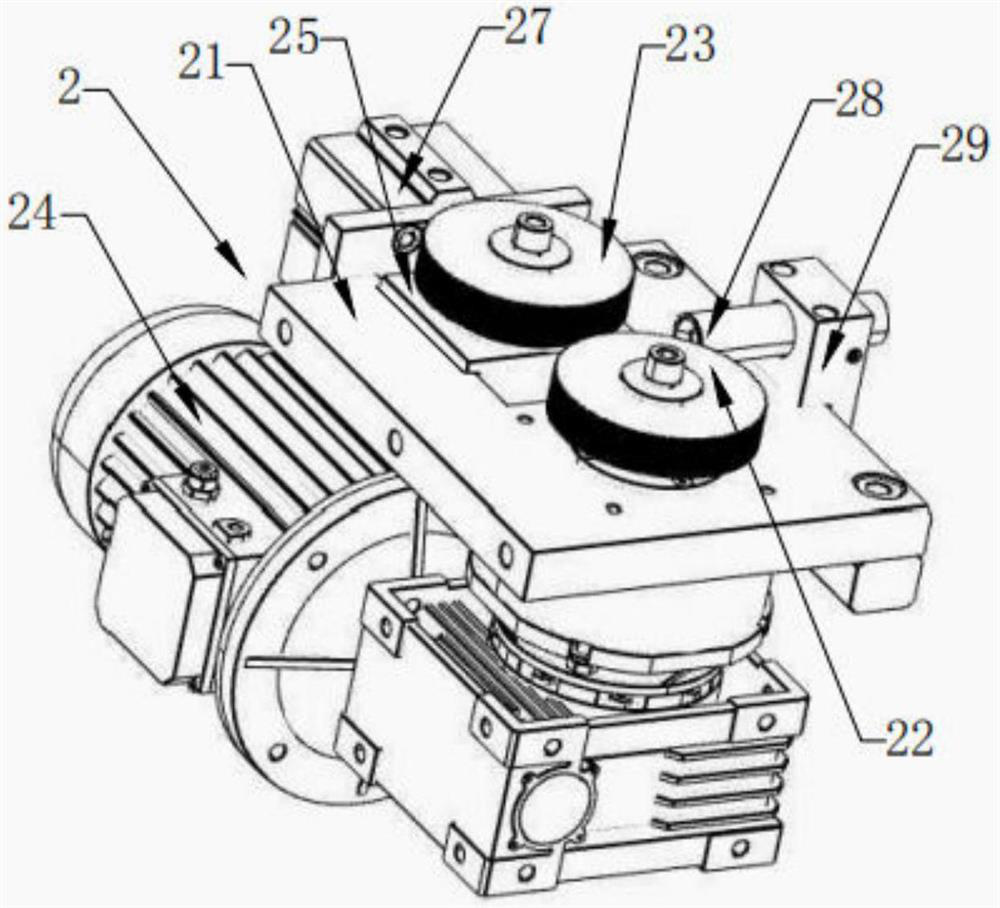

[0036] As shown in the figure, the steel bar straightening, bending and shearing continuous production device provided by this embodiment, the frame 1, on the frame 1, steel bar straightening is installed sequentially from the feed end to the discharge end of the frame 1. Straightening mechanism, steel bar shearing mechanism 7 and steel bar bending mechanism 8, described steel bar straightening mechanism comprises steel bar vertical straightening module 3 and steel bar horizontal straightening module 5, in steel bar vertical straightening module and steel bar horizontal straightening module 5 There is a steel bar feeding mechanism 4 between them; before the steel bar straightening mechanism, there is also a steel bar traction mechanism 2 that can automatically send the whole bundle of steel bars to the horizontal straightening mechanism, and between the steel bar shearing mechanism 7 and the steel bar straightening mechanism There is also a steel bar coarse positioning mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com