Automatic bending device for hollow glass aluminum parting strip

A bending device and aluminum spacer technology, applied in the field of mechanical devices, can solve the problems of inability to fold out the aluminum frame, unsightly folded corners, low precision, etc., to improve efficiency, save manpower handling, and improve bending accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

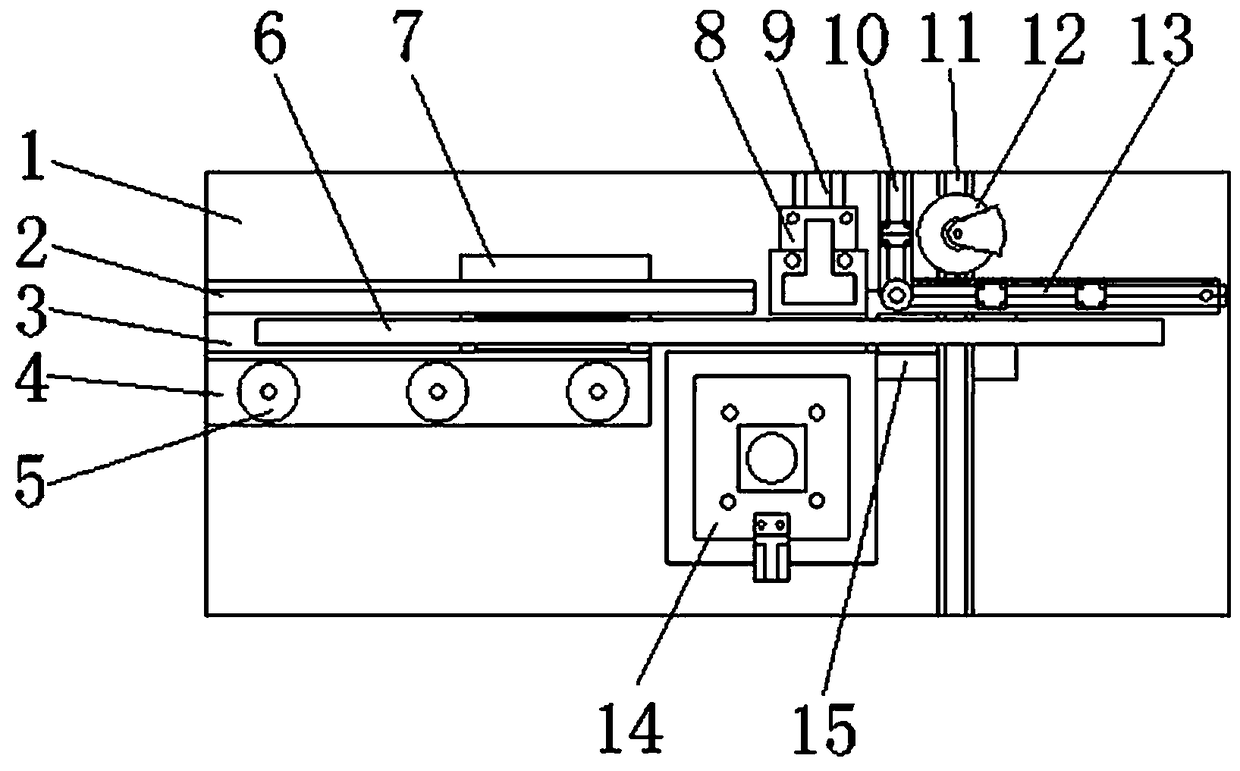

[0018] An automatic bending device for hollow glass aluminum spacers, including a box body 1, a baffle plate 2 is arranged inside the box body 1, a material inlet 3 is on the left side of the box body 1, a conveyor belt 4 is located below the baffle plate 2, and a conveyor belt 4 There is a rotating roller 5 inside, a pushing device 7 is arranged on the inside of the baffle 2, the fixing device 8 is on the right side of the baffle 2, and the fixing device 8 is installed on the track 9, and the hydraulic device 10 is on the right side of the fixing device 8, and the hydraulic device 10 is connected to Bending arm 13, hydraulic device 10 right side is provided with extruding roller 12, and extruding roller 12 is installed on guide rail 11, and conveyor belt 4 right side is bending die 14, and bending die 14 upper right corner is provided with travel sensor 15. An application method of an automatic bending device for hollow glass aluminum spacers is as follows: the aluminum strip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com