Soft capsule cleaning machine

A cleaning machine and soft capsule technology, applied in the field of cleaning, can solve the problems of getting dirty, can not achieve thorough cleaning, low recycling rate of cleaning liquid, etc., and achieve the effect of saving manual handling, convenient and fast cleaning, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

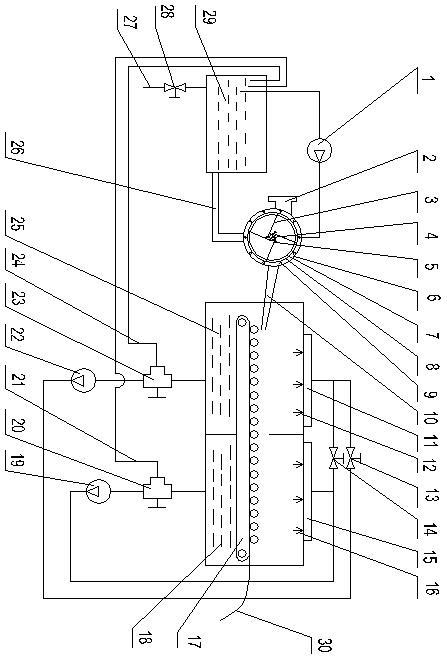

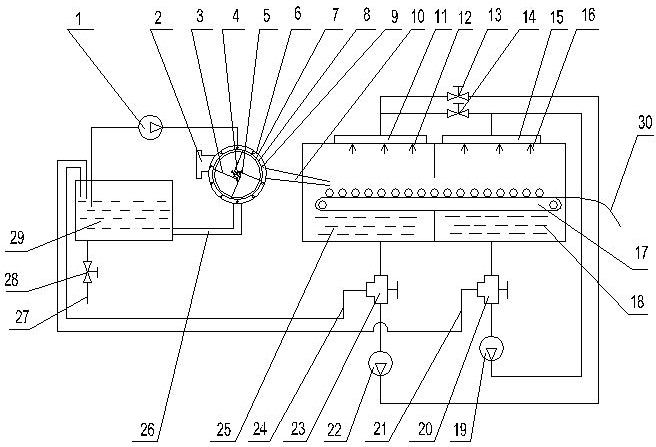

[0010] In the accompanying drawings, a soft capsule washing machine includes a drum spray washing device identical to the prior art.

[0011] As shown in the drawings, the drum spraying device is composed of a cavity 6, a cylinder body 7, a spraying water pipe 8, a spraying pump 1, a spraying liquid tank 29, a plurality of first nozzles 9 and a second nozzle 5.

[0012] As shown in the drawings, the barrel 7 is rotatably supported in the cavity 6 by a hollow central shaft 4 , and the second spray heads 5 are evenly distributed on the central shaft 4 . The number of the second shower heads 5 depends on the length of the central axis 4 .

[0013] In the drawings, four partitions 3 are arranged inside the cylinder body 7 , an inlet 2 is arranged on one side of the cavity 6 , and an outlet 10 is arranged on the other side of the cavity 6 .

[0014] The radial and axial frames of the spraying water pipes 8 are arranged on the surface of the cylinder body 7 , and the first nozzles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com