Invisible hosiery knitter jacquard device having sinker cap adjusting function

A technology of raw gram cover and invisible socks, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of reducing the beauty and comfort of knitted socks, the effect is difficult to meet the needs, and the tightness of the socks cannot be controlled. The effect of improving reliability and effectiveness, improving aesthetics and quality, and reducing commissioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing.

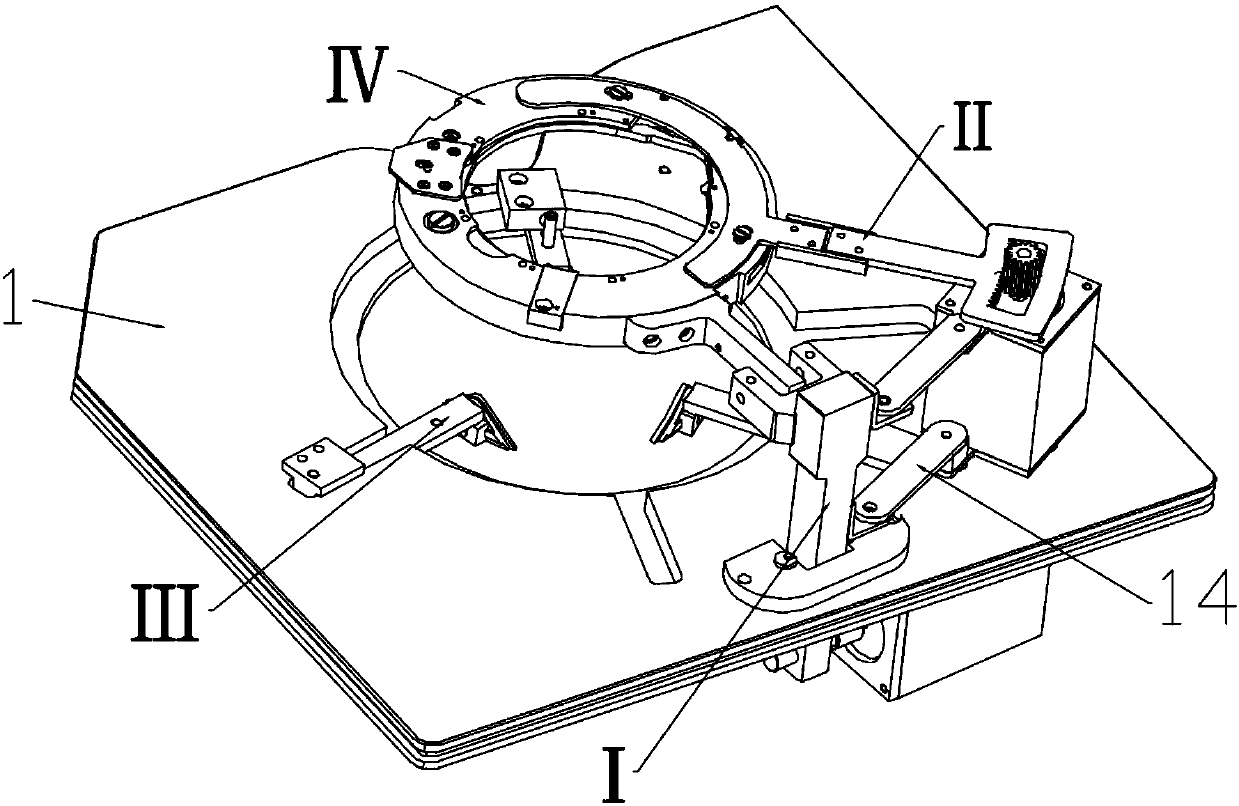

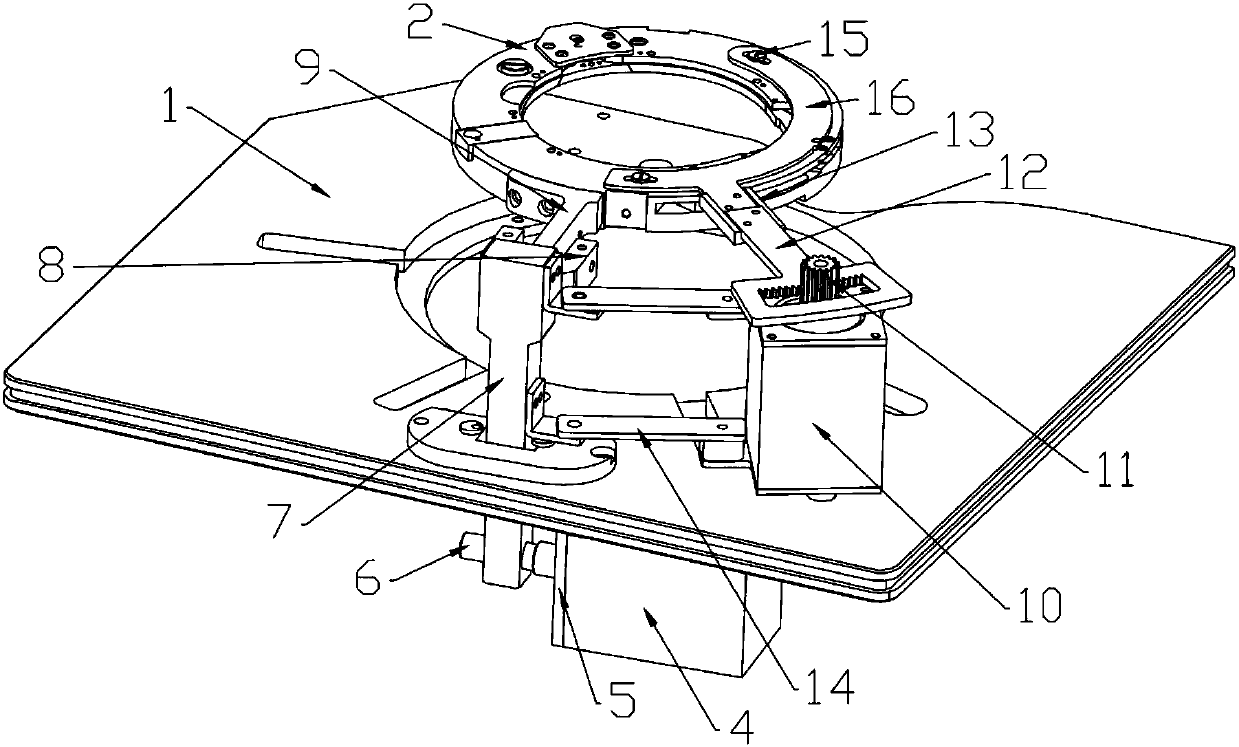

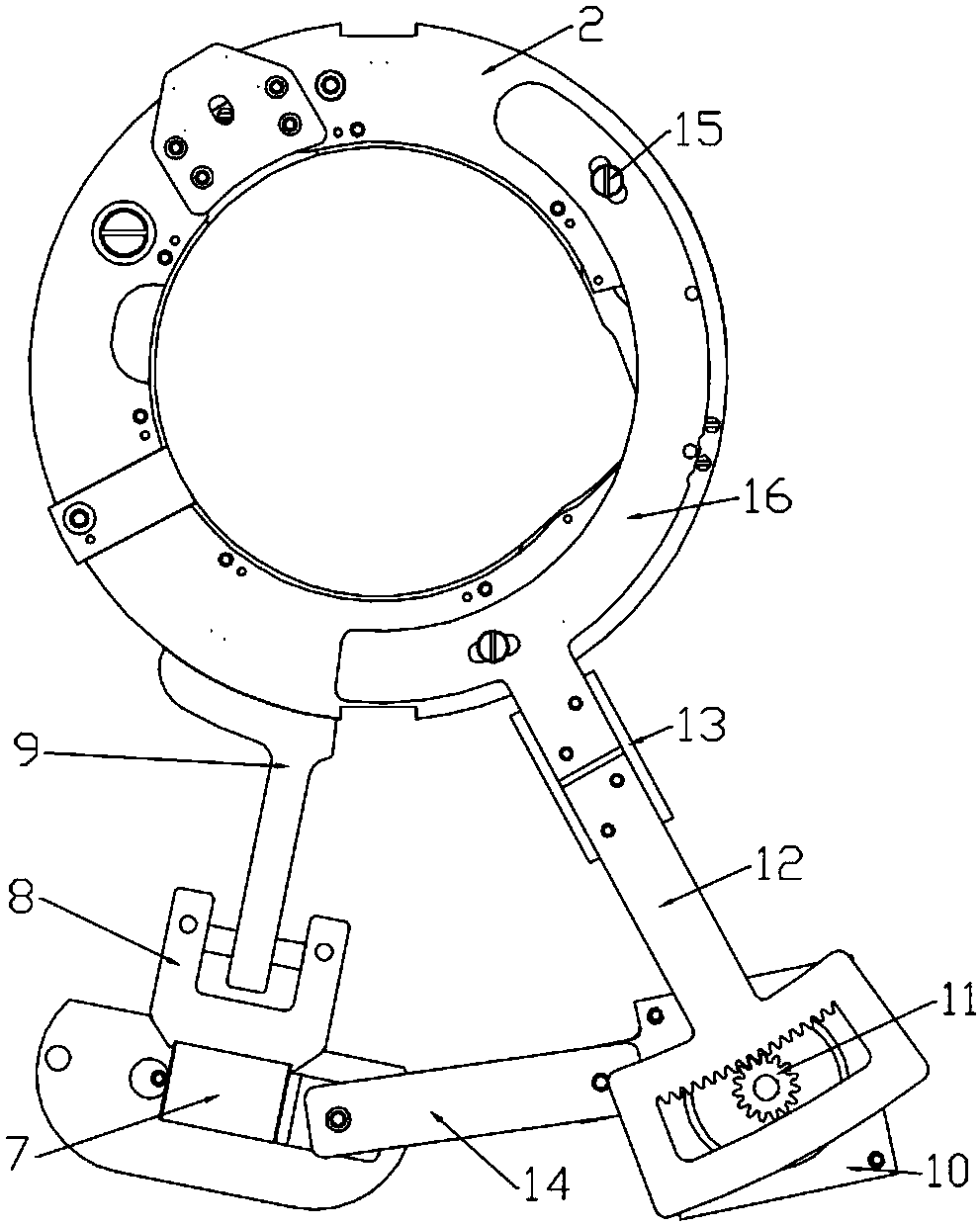

[0049] Such as figure 1 , 2 , 4 and 5, an invisible hosiery knitting machine jacquard device with the function of adjusting the cover, including a support plate 1, a connecting rod 14, a cover adjustment mechanism I, a left and right eyebrow adjustment mechanism II, a jacquard device III and a raw Gram cover IV. Shengke cover comprises casing 2, middle eyebrow 3, left eyebrow 18 and right eyebrow 19. The casing 2 is circular. The inner ring of the casing 2 is set on the needle cylinder of the sock knitting machine. The casing 2 is arranged coaxially with the needle cylinder of the hosiery machine. The housing 2 and the frame of the hosiery machine form a rotary pair with the axis of the housing 2 as the common axis. Middle eyebrow 3, left eyebrow 18 and right eyebrow 19 are all installed in the casing 2, and the middle part of left eyebrow and right eyebrow is all hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com