Coil winder wire-guiding device

A winding machine and wire technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of uneven ends, uneven wire spacing, low efficiency, etc., to achieve wire coil The density is consistent, the effect of improving quality and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

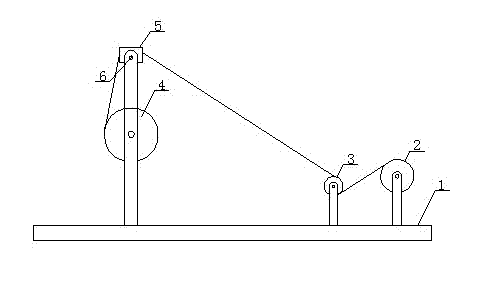

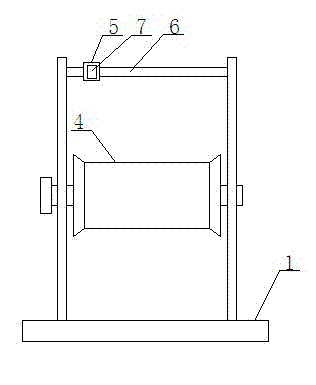

[0013] like figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the connection of the pulleys of the present invention, a wire device of a wire winding machine, including a bracket 1, a pay-off wheel 2, a guide wheel 3 and a take-up wheel 4, and the pay-off wheel 2, the guide wheel 3 and the take-up wheel 4 are arranged and installed in sequence On the support 1 , a slider 5 is arranged above the take-up wheel 4 . Slide block 5 is enclosed within on a slide bar 6. Slide bar 6 is parallel to take-up reel 4, and take-up reel 4 isometric. The slider 5 is provided with a displacement sensor 7 .

[0014] A slider 5 is set above the take-up wheel 4 to guide the displacement of the wire. The slider 5 is provided with a displacement sensor 7. During the uniform motion process, when it encounters the brackets 1 at both ends, it will automatically turn back and reciprocate, driving the wire to move freely. Sequential arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com