A robot production line and control method for large medium and heavy plate workpieces in ships

A production line and robot technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in receiving orders, overcapacity in shipbuilding, low production efficiency, etc., to improve aesthetics and quality, improve welding efficiency, The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

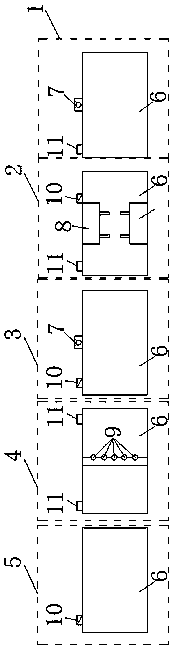

[0019] A robot production line for large medium and heavy plate workpieces disclosed by the present invention, the production line is composed of several conveyor belts 6 to form a transmission system, the transmission system is preset with a plurality of processing stations, the processing The stations in turn include: assembly station 1, robot welding station 2, manual repair station 3, backburning station 4, and handling station 5; above the assembly station 1, there is a handling device, which is controlled manually. The assembly station 1 manually assembles the scattered workpieces and fixes them by spot welding. The conveyor belt 6 corresponding to the assembly station 1 is controlled by the start switch provided on the assembly station 1. The robot welding station 2 part The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com