Process for preparing super fine cerium oxide for polishing

A cerium oxide and cerium salt technology, applied in chemical instruments and methods, inorganic pigment processing, fibrous fillers, etc., can solve the problems of unsuitability for large-scale production, high price, no economic value, etc., and achieve good shape consistency, Low cost and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

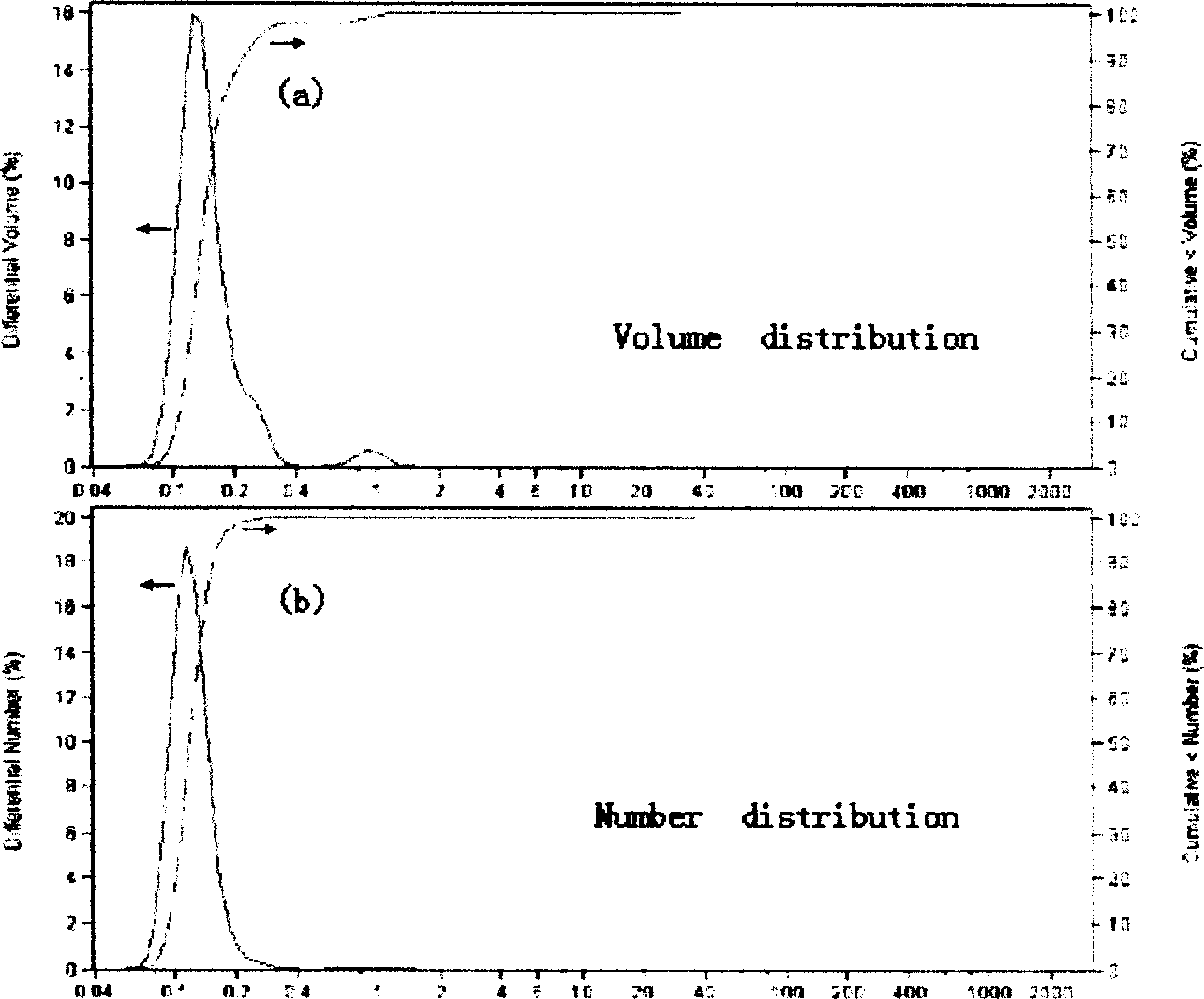

Image

Examples

Embodiment 1

[0031] 2.2kg cerium carbonate (CeO 2 ≥45%) with 1.23LHNO 3 Dissolve, and add 5.48L deionized water to make solution A, add 29.7g polyethylene glycol to form solution B therein. Take 6.76L2.5mol / L of NH 4 HCO 3 into solution C. Then, under the condition of stirring, solution C is added dropwise to solution B. During the process of dropping, the pH value of the solution increases continuously. After solution C is dropped, the pH value of the reaction system is 6.5; at this time, a white Precipitate, and stir the precipitate for 0.2 hours to form suspension D. Take 2.86kg oxalic acid and make solution E with 19.1L deionized water. Then E was added dropwise to the suspension D. During the dropwise addition, the pH value of the solution decreased continuously. After the solution E was dropped, the pH value of the reaction system was 2.2. Continue stirring for 0.1 hour, filter the precipitate, and use Wash with ionized water for 3 to 4 times, then dry the precipitate in static...

Embodiment 2

[0033] 2.5kg Ce(NO 3 ) 3 ·6H 2 O and 4.80L of deionized water were made into solution A, to which 31.9g of polyethylene glycol was added to form solution B. Take 8.13L1.5mol / L of NaHCO 3 into solution C. Then, under the condition of stirring, solution C is added dropwise to solution B. During the process of dropping, the pH value of the solution increases continuously. After solution C is dropped, the pH value of the reaction system is 5.8; at this time, a white Precipitate, and stir the precipitate for 0.5 hours to form suspension D. Take 3.125kg oxalic acid and make solution E with 25L deionized water. Then E was added dropwise to the suspension D. During the dropwise addition, the pH value of the solution decreased continuously. After the solution E was dropped, the pH value of the reaction system was 2.5. Continue stirring for 0.2 hours, filter the precipitate, and use Wash with ionic water for 3 to 4 times, then dry the precipitate in static air at 800°C for 12 hour...

Embodiment 3

[0035] 0.8kg cerium oxide (CeO 2 ≥99%) with 1.00LHNO 3 Dissolve, and add 4.65L deionized water to make solution A, add 28g polyethylene glycol to form solution B therein. Take 4.67L of 3.0mol / L ammonia water to form solution C. Then, under the condition of stirring, solution C is added dropwise to solution B. During the dropping process, the pH value of the solution increases continuously. After solution C is dropped, the pH value of the reaction system is 7.5; at this time, brown Precipitate, and stir the precipitate for 0.2 hours to form suspension D. Take 1.08kg oxalic acid and make solution E with 5.4L deionized water. Then E was added dropwise to the suspension D. During the dropwise addition, the pH value of the solution decreased continuously. After the solution E was dropped, the pH value of the reaction system was 1.5. Continue stirring for 0.2 hours, filter the precipitate, and use Wash with ion water for 3 to 4 times, then dry the precipitate in static air at 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com