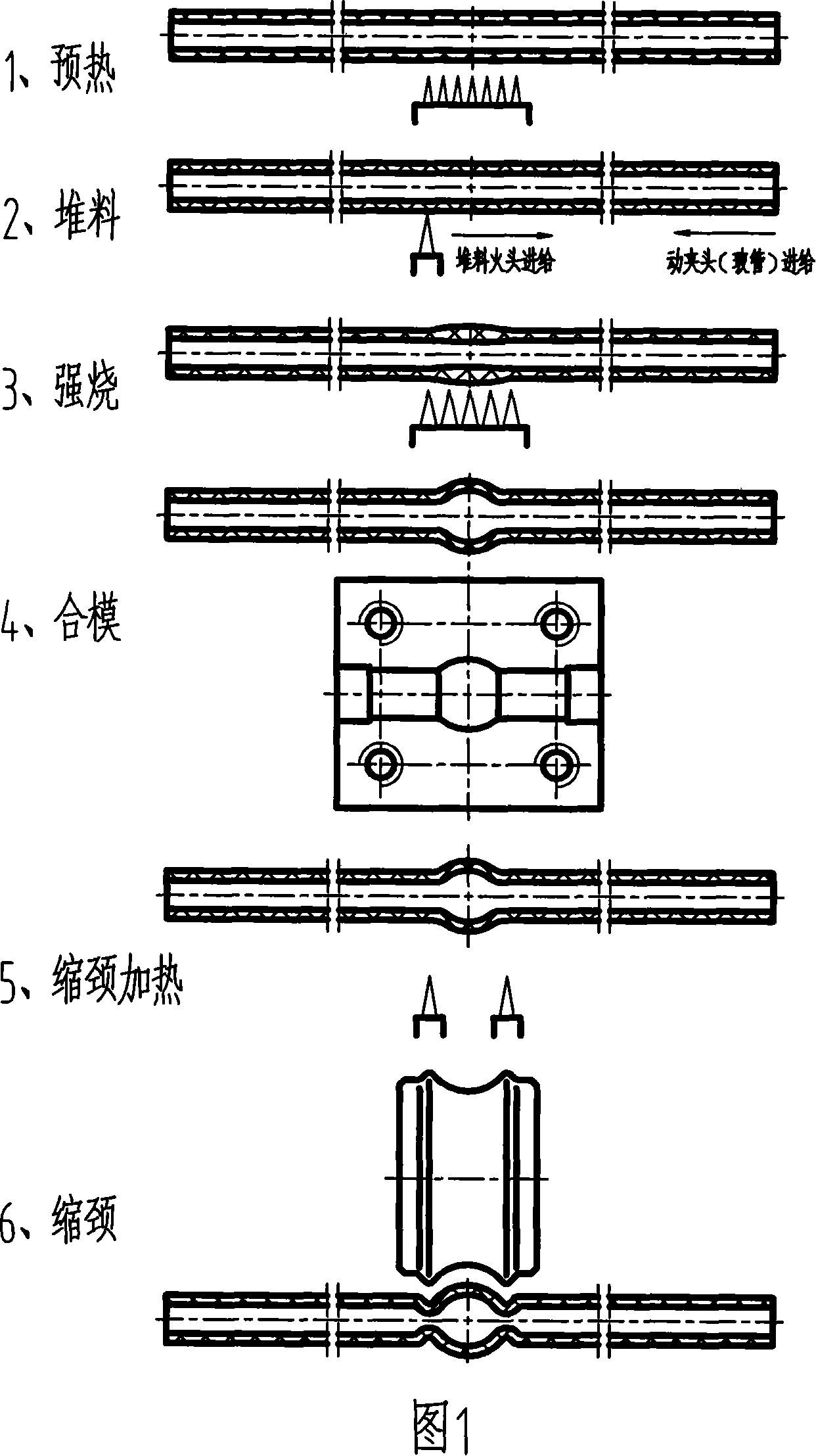

Metal halide lamp electrical arc tube and neck ampulla contracting shell interlocking machine, forming and necking method

A metal halide lamp, arc tube technology, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problem of poor uniformity of inner hole size, large error of outer diameter, deformation of bulb shape, etc. problems, to achieve the effect of good shape and size consistency, good straightness, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

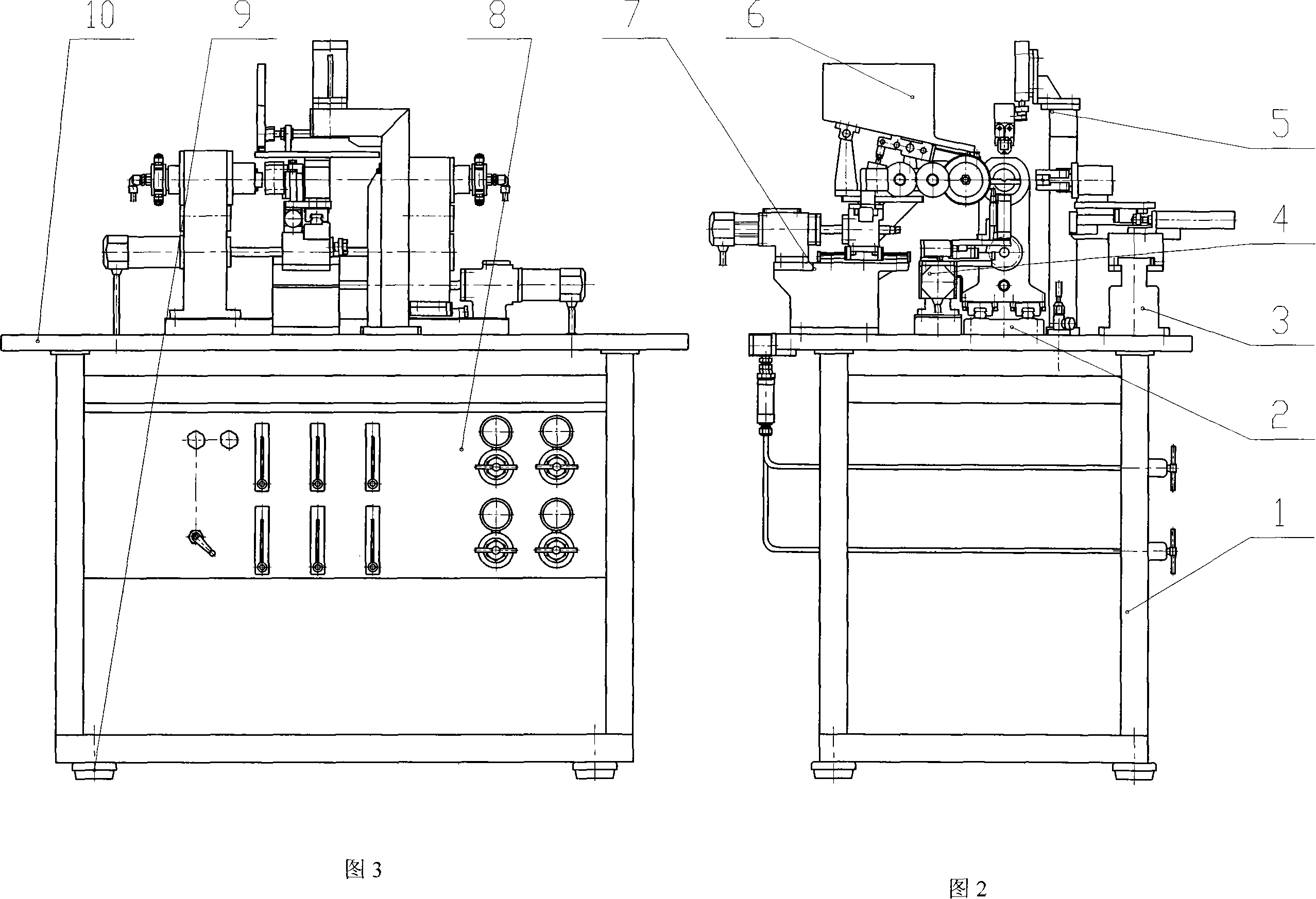

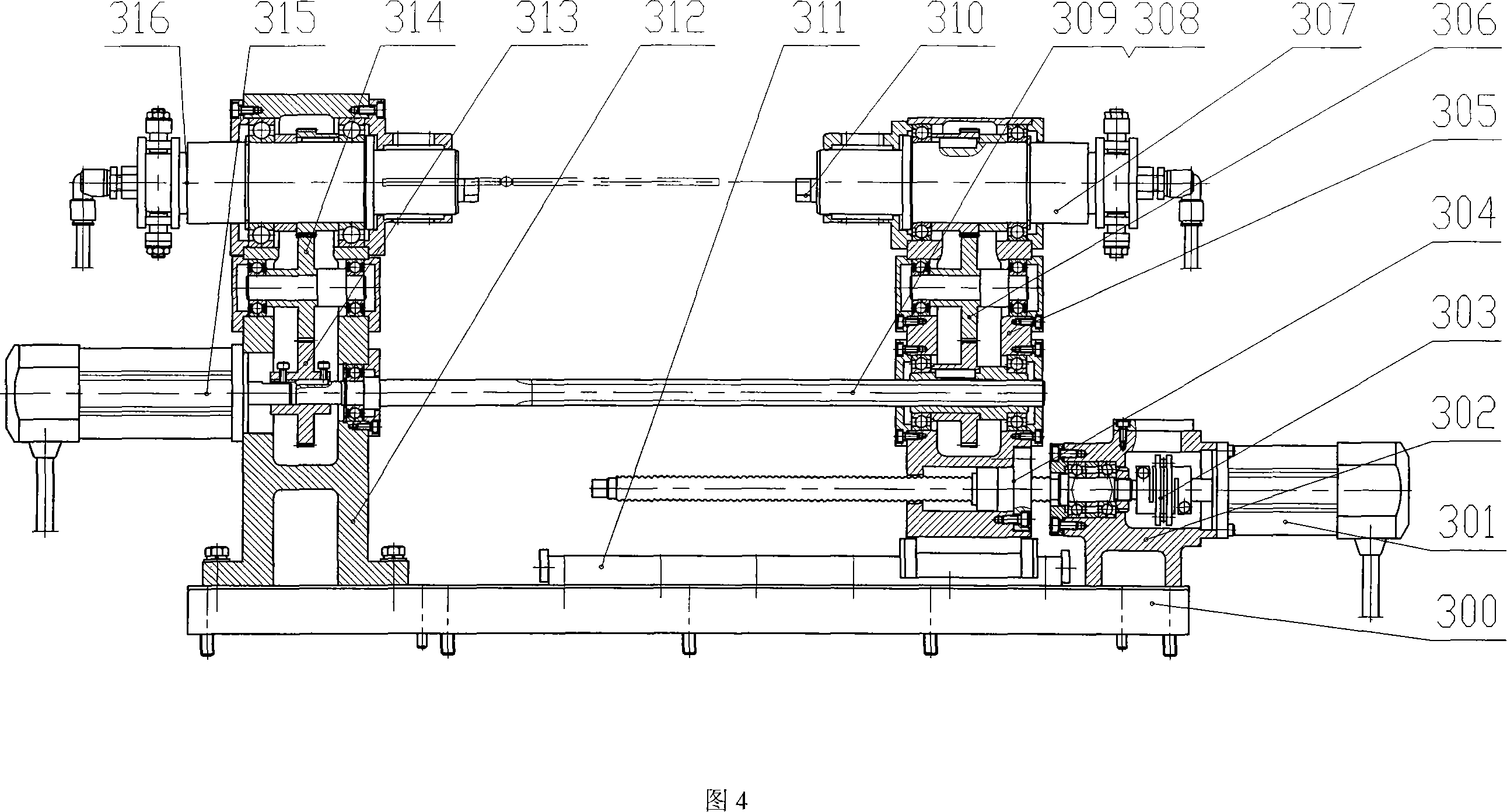

[0030] The structure and working process of the present invention will be described below in conjunction with the accompanying drawings. A metal halide lamp arc tube necking bulb linkage, the metal halide arc tube necking bulb linkage includes a frame 1, a chuck and advance and retreat mechanism 2, mold advance and retreat and mold clamping forming mechanism 3, fire head moving mechanism 4, feeding manipulator 5, automatic feeding mechanism 6, necking roller advance and retreat mechanism 7 and fire head air supply mechanism 8, among which chuck and advance and retreat mechanism 2, The mold advancing and retreating and clamping forming mechanism 3 and the necking roller advancing and retreating mechanism 7 are all fixedly connected to the table panel of the frame 1, and the mold clamping and forming mechanism 3 and the necking roller advancing and retreating mechanism 7 are respectively located on both sides of the chuck and the advancing and retreating mechanism 2 , the automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com