Patents

Literature

67results about How to "Avoid the disadvantages of manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

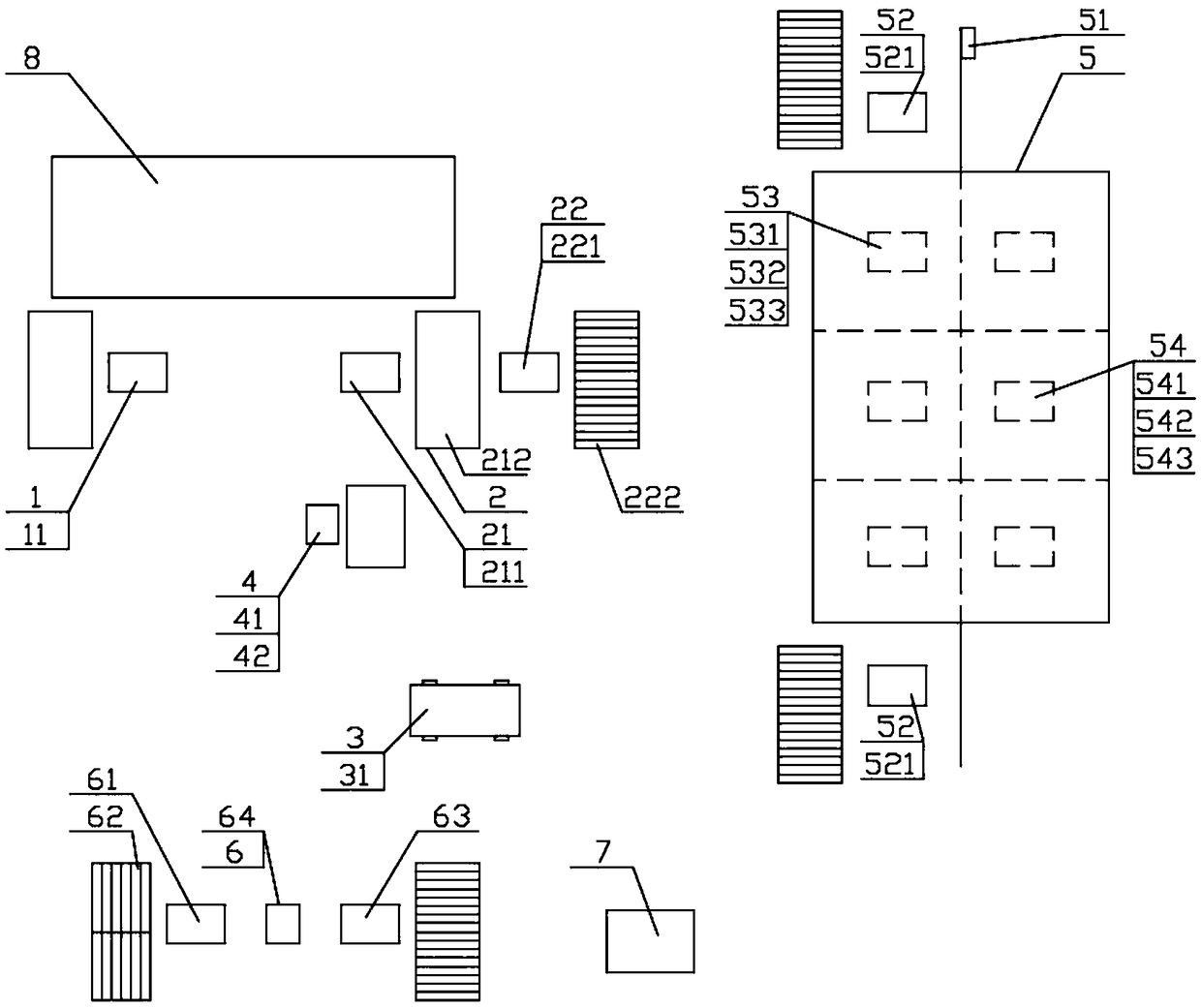

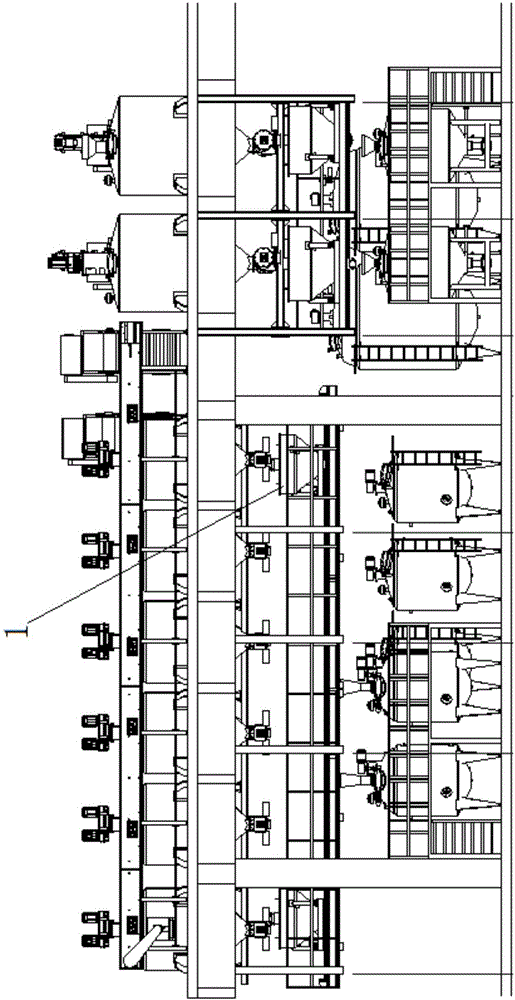

Artificial intelligence sheet metal part producing system

ActiveCN105642781AGuarantee product qualityAvoid DimensionsMetal-working feeding devicesMaterial gluingElectronic control unitMaterial supply

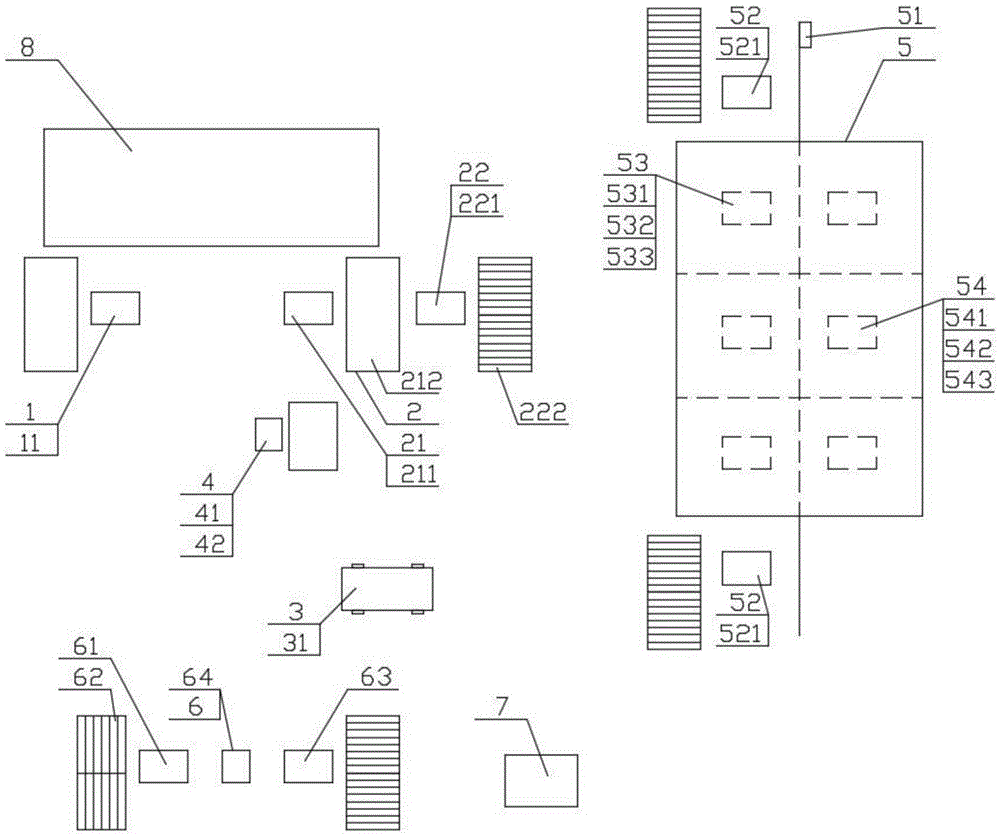

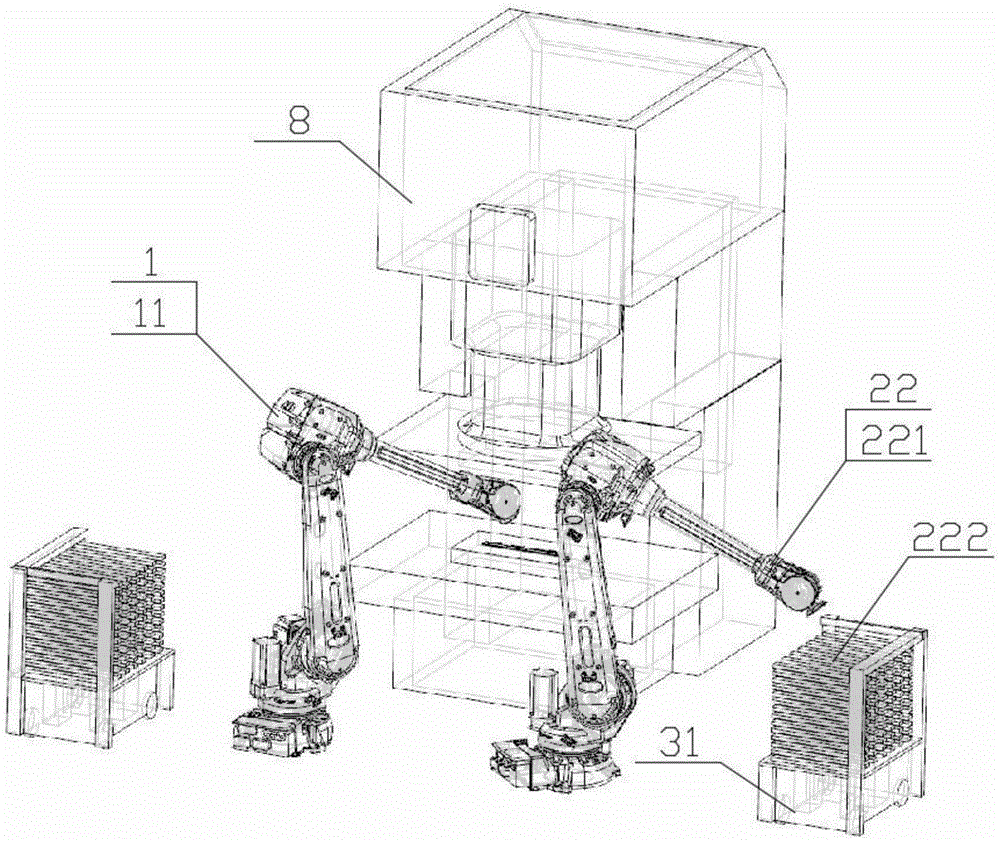

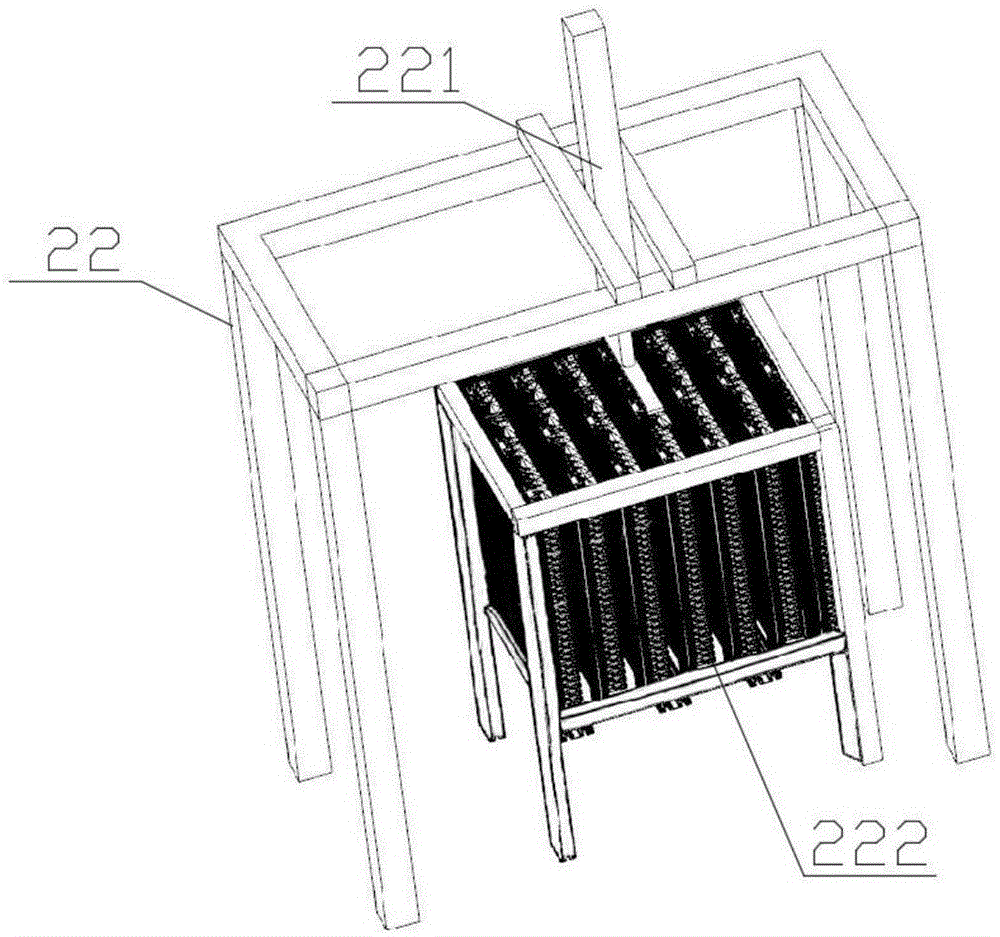

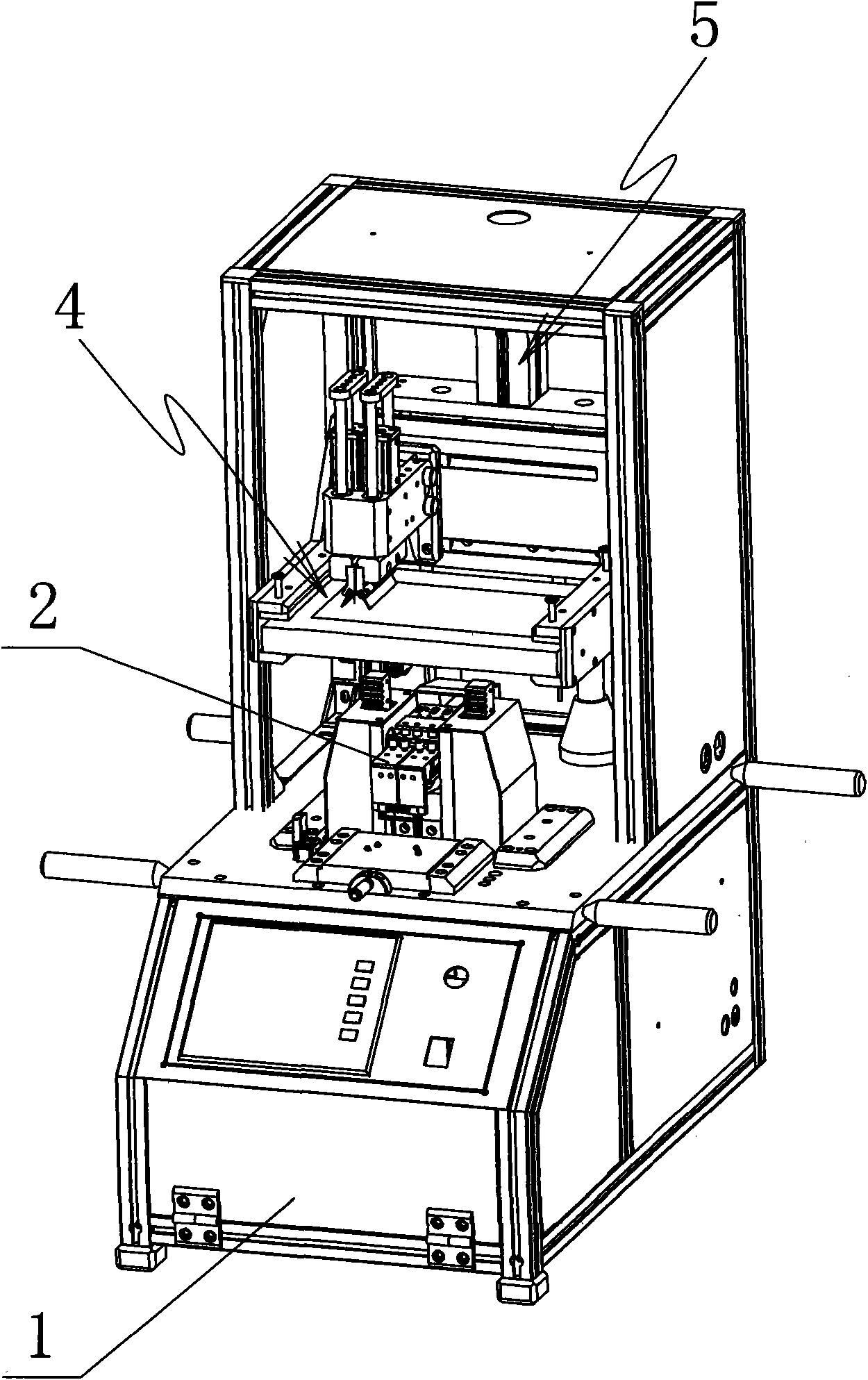

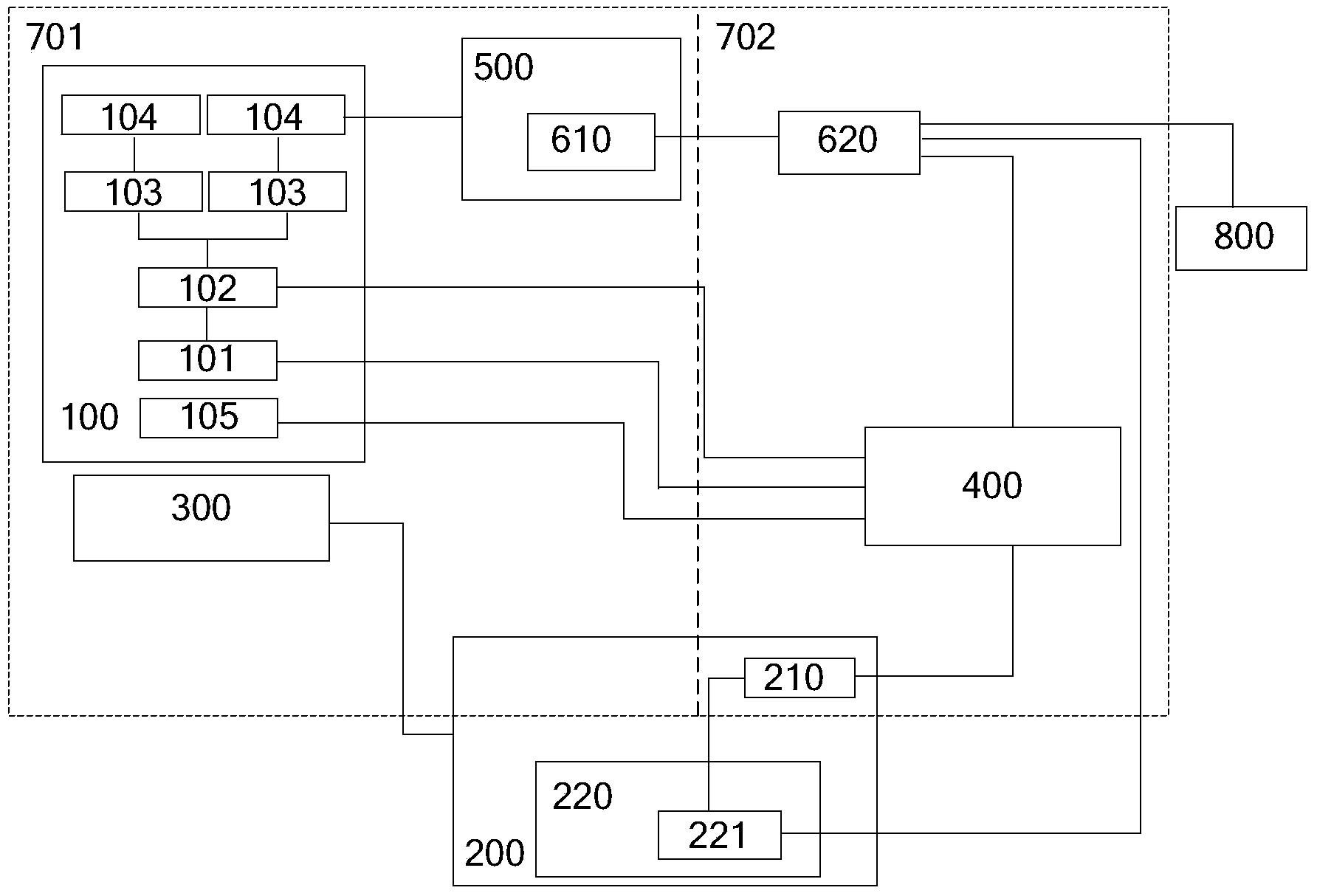

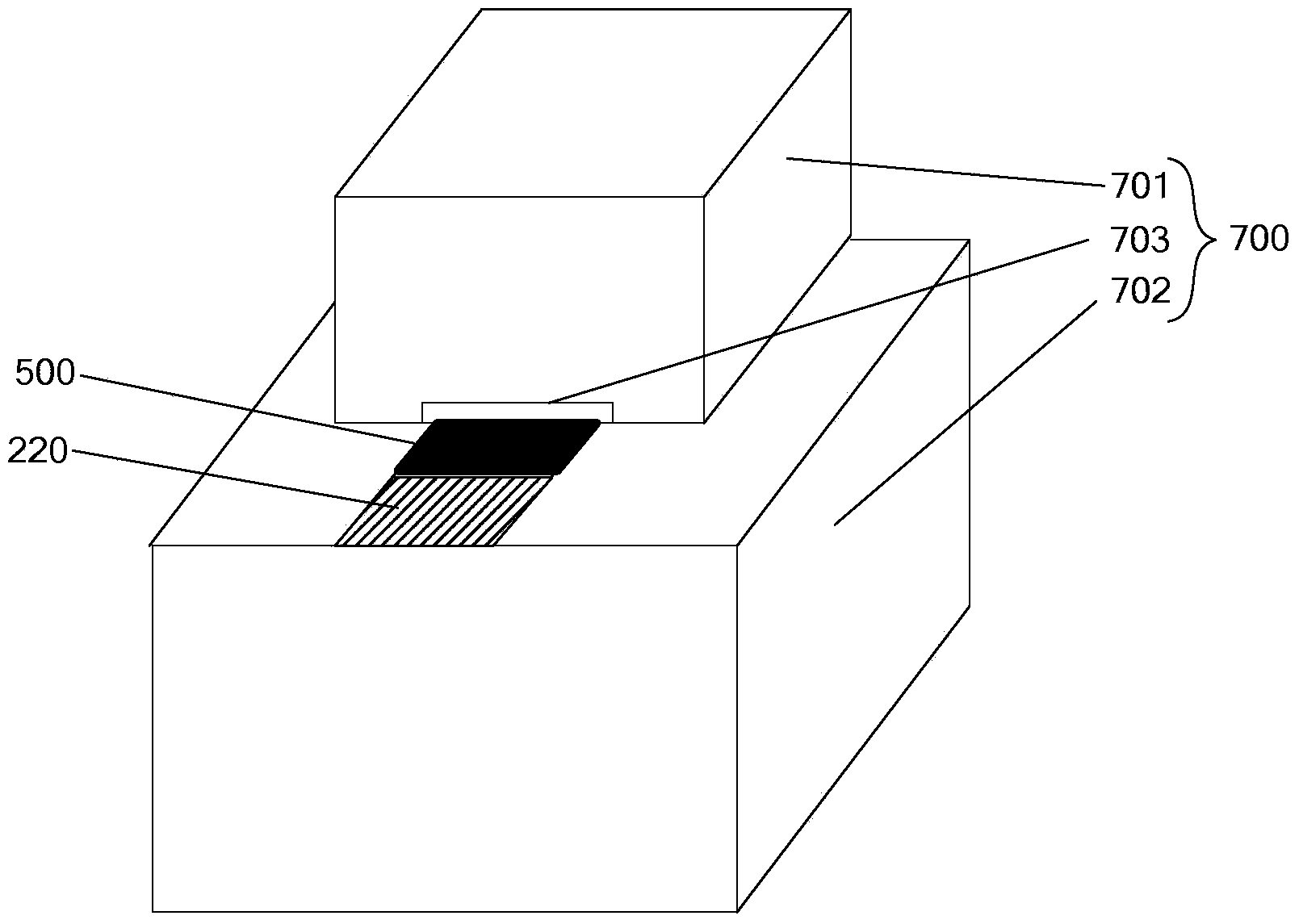

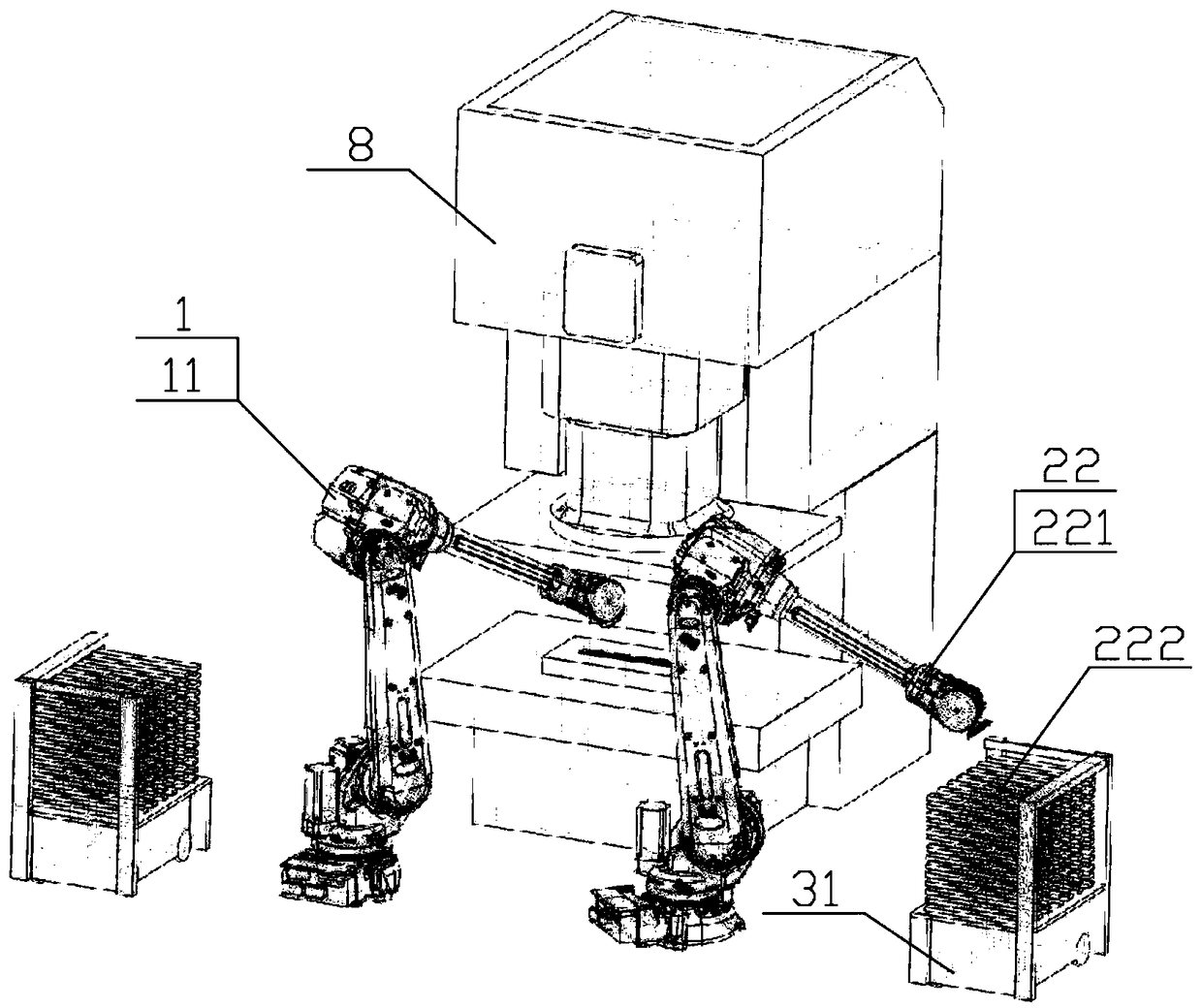

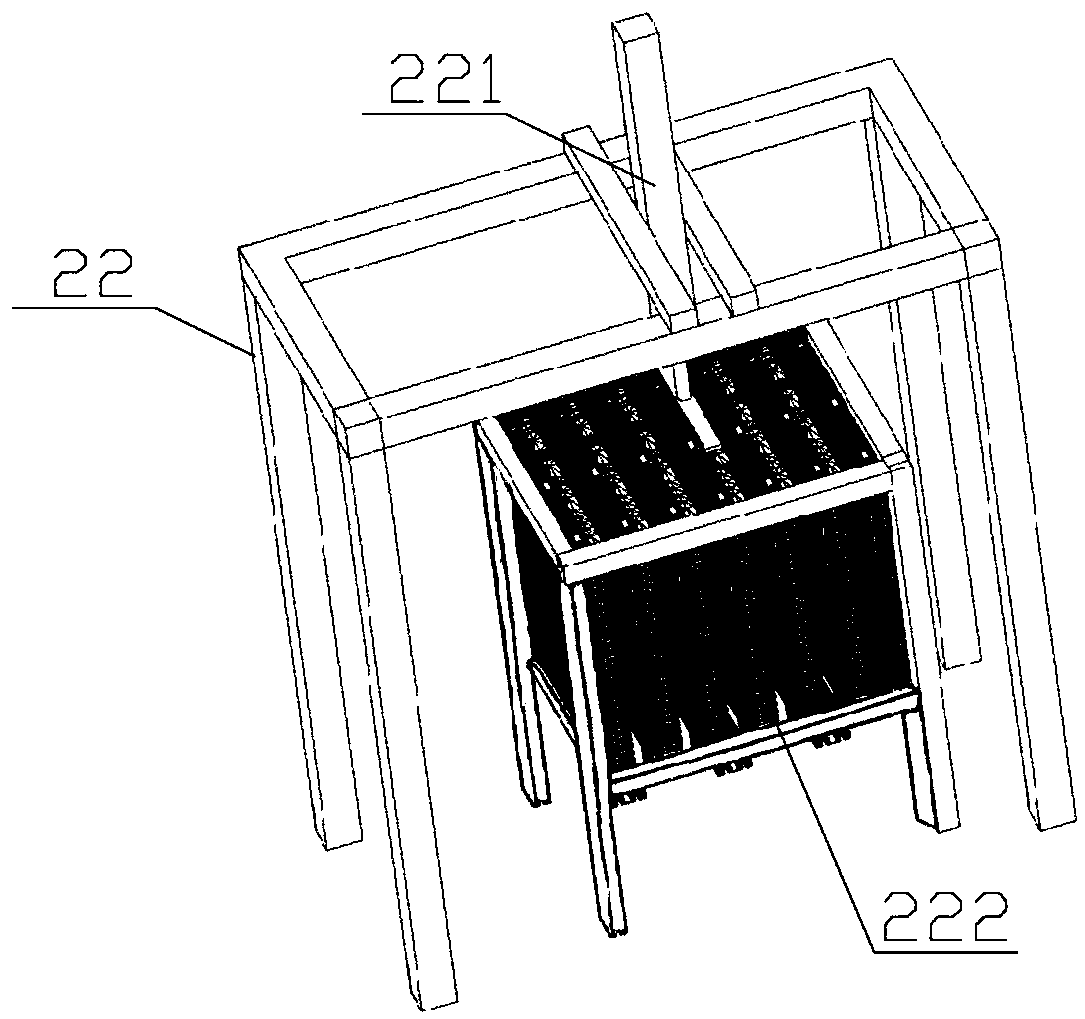

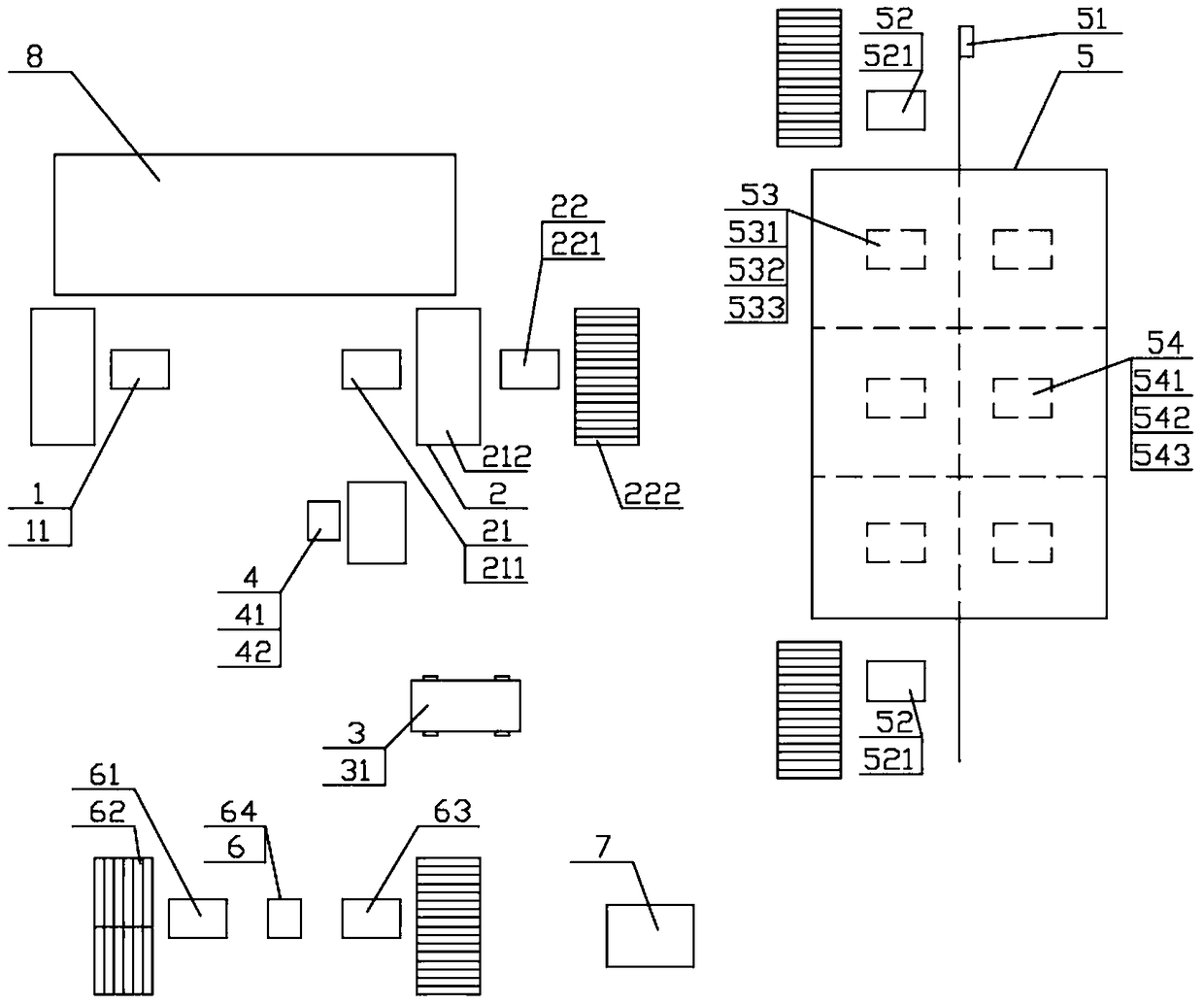

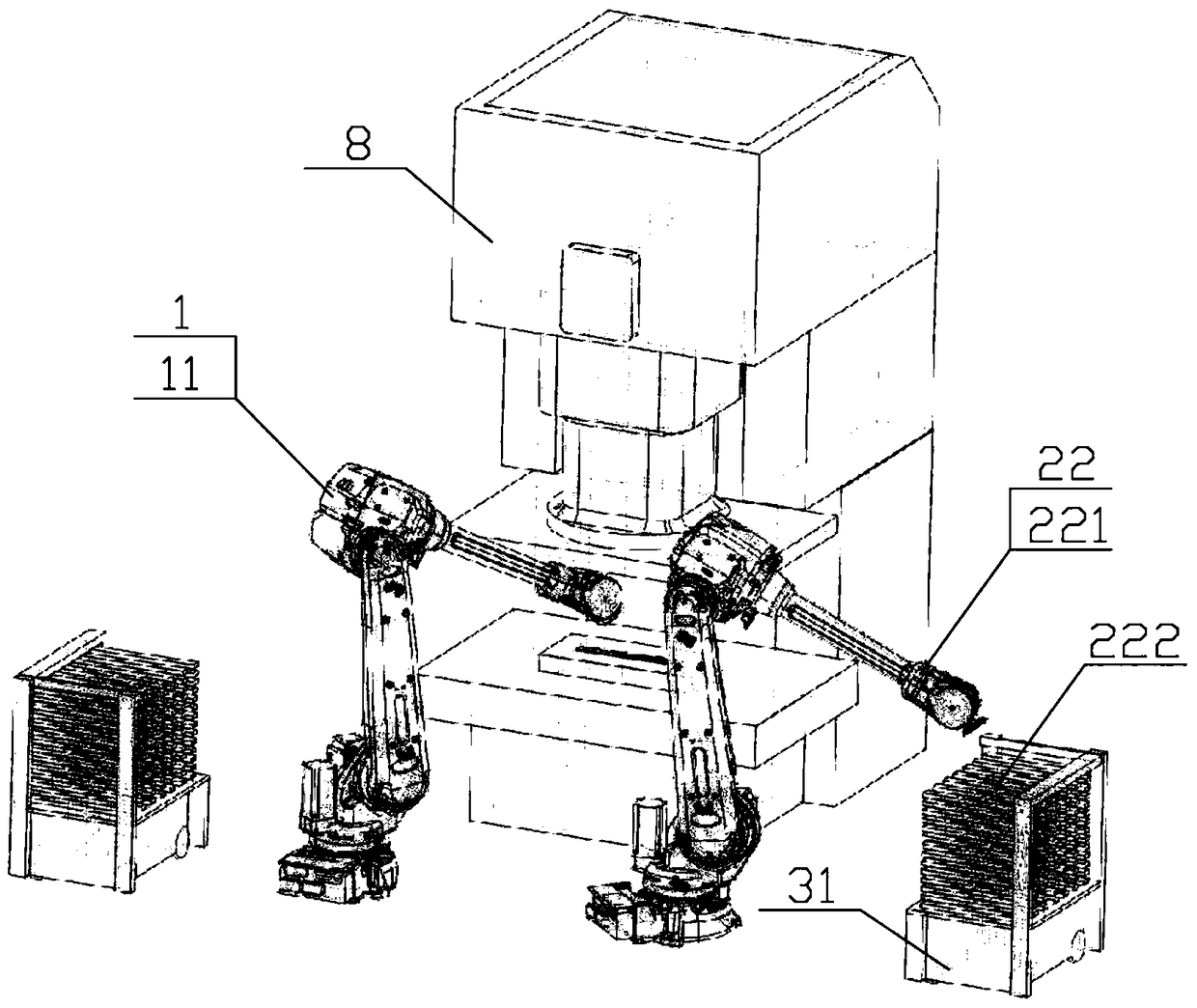

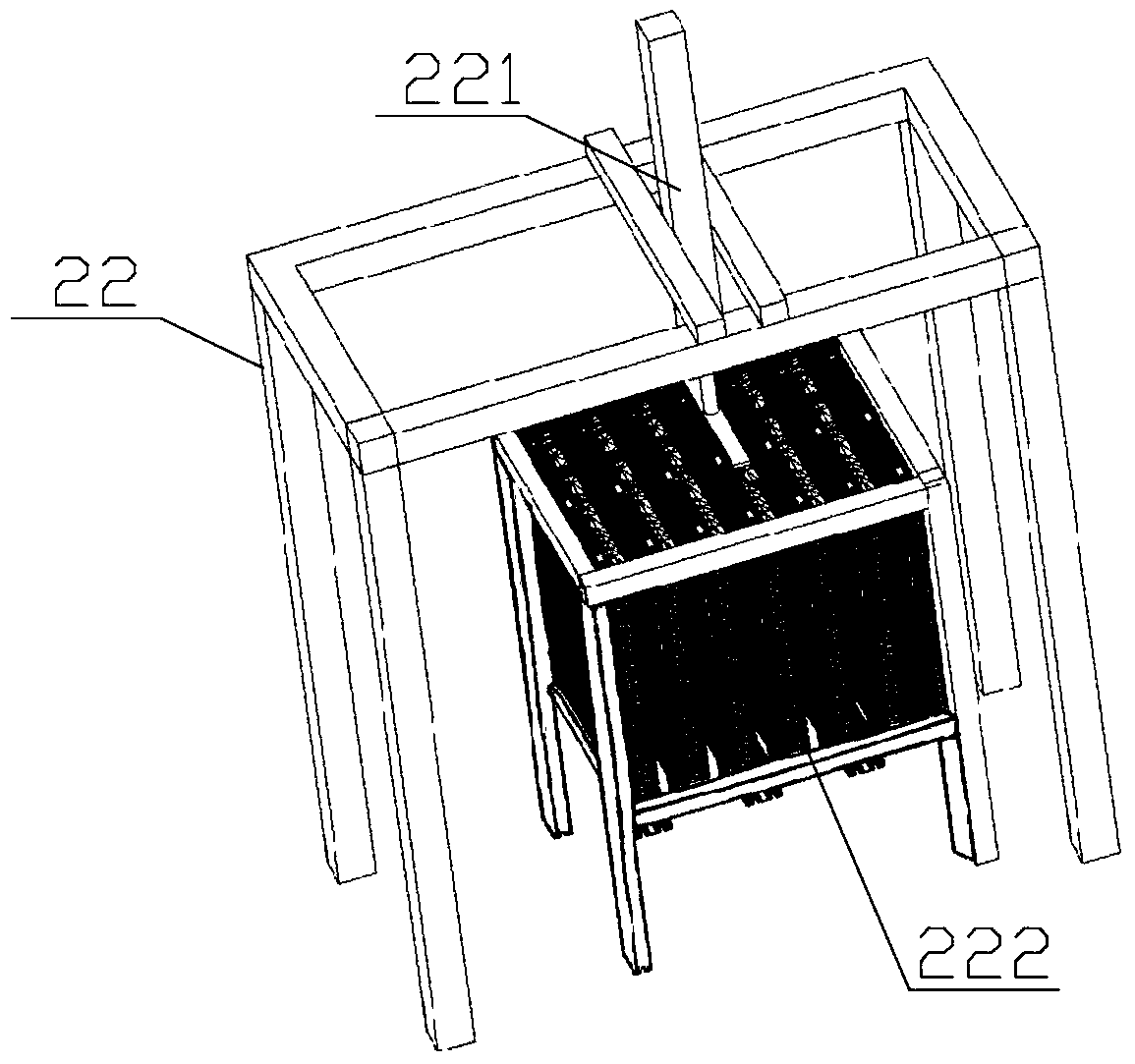

The invention discloses an artificial intelligence sheet metal part producing system. The system comprises a material supply unit (1), a formed sheet metal part automatic taking and stacking unit (2), an intelligent logistics carrying and transporting unit (3) and a centralized electronic control unit (7). The formed sheet metal part automatic taking and stacking unit comprises a plurality of counting and stacking devices (22) arranged nearby the discharging end of a sheet metal machining device (8); each counting and stacking device comprises a grabbing and stacking part II(221), a stacking bracket (222) and an electronic control part; and each stacking bracket comprises a plurality of containing spaces (2221) evenly arranged in the horizontal and vertical direction and an electronic control mechanism. According to the artificial intelligence sheet metal part producing system, the grabbing and stacking parts II controlled by a microcomputer stretch into the sheet metal machining device and are used for grabbing punched and formed sheet metal parts from the discharging end and sequentially stacking the sheet metal parts in the containing spaces of the stacking brackets, and the artificial intelligence sheet metal part producing system is a digital control system and can be seamlessly connected with a digital bus in a factory to achieve centralized digital management.

Owner:XUZHOU DKEC ELECTRICAL TECH

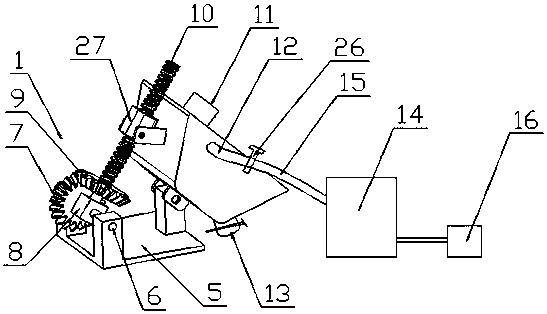

Automatic soldering instantaneous welder

InactiveCN101607335AAvoid the trouble of brushing solder pasteImprove welding efficiencyLine/current collector detailsMetal working apparatusSolderingManipulator

The invention discloses an automatic soldering instantaneous welder which comprises a welder frame provided with a pedestal. The automatic soldering instantaneous welder is characterized in that the pedestal is rotatably connected with a welding manipulator, and the front end of the welding manipulator is provided with a welding joint. The pedestal is also provided with a first driving assembly which can drive the welding manipulator to turn over forward and backward to force the welding joint to switch between a welding station and a solder brushing station. Above the solder brushing station of the welding joint, the welder frame is also provided with a soldering assembly for brushing solder paster on the welding joint and a second driving assembly for driving the soldering assembly to move horizontally. The automatic soldering instantaneous welder can directly brush solder paster on the welding joint of the welder to enhance welding efficiency.

Owner:NANZHANG MINGRUI ELECTRONICS MATERIALS CO LTD

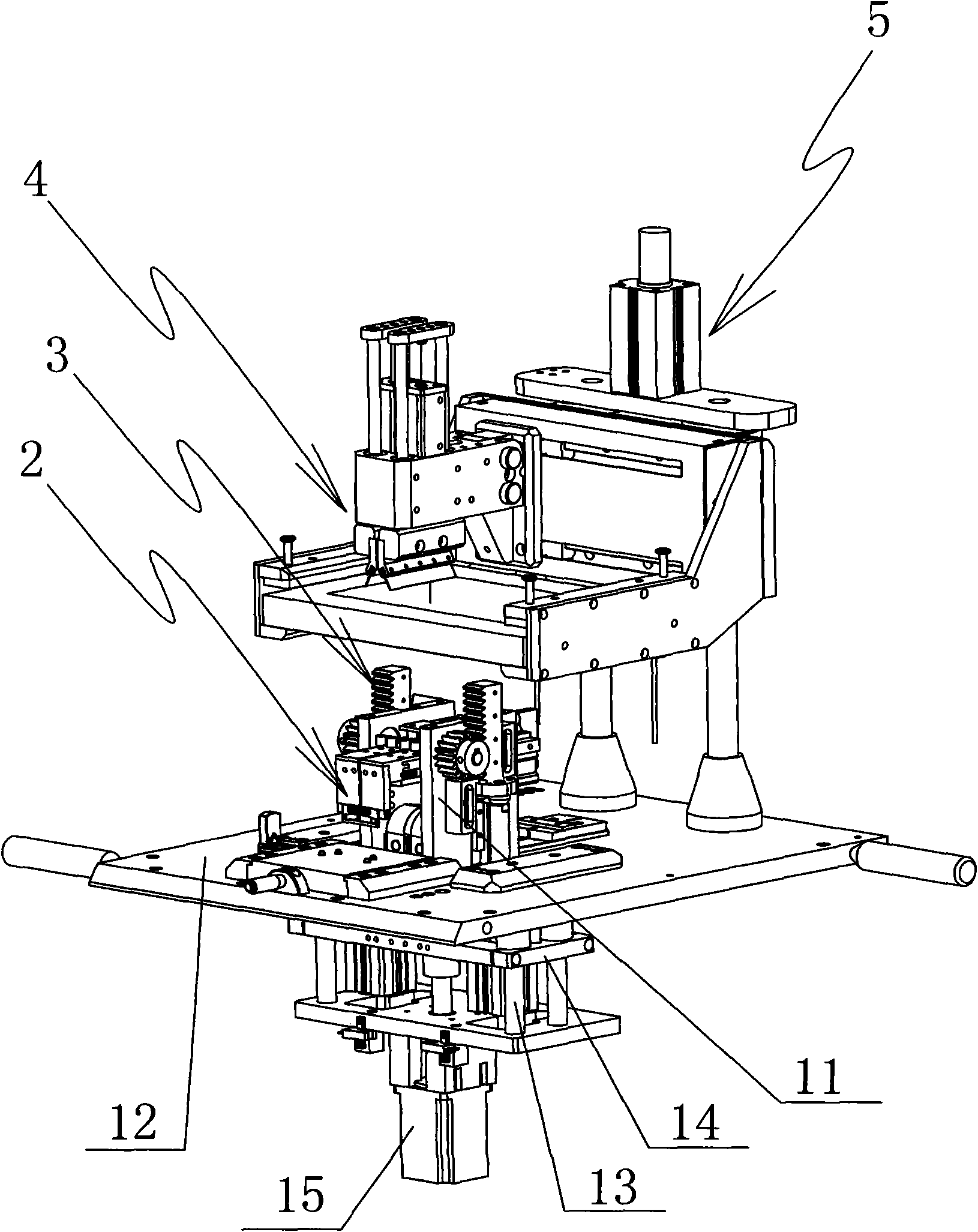

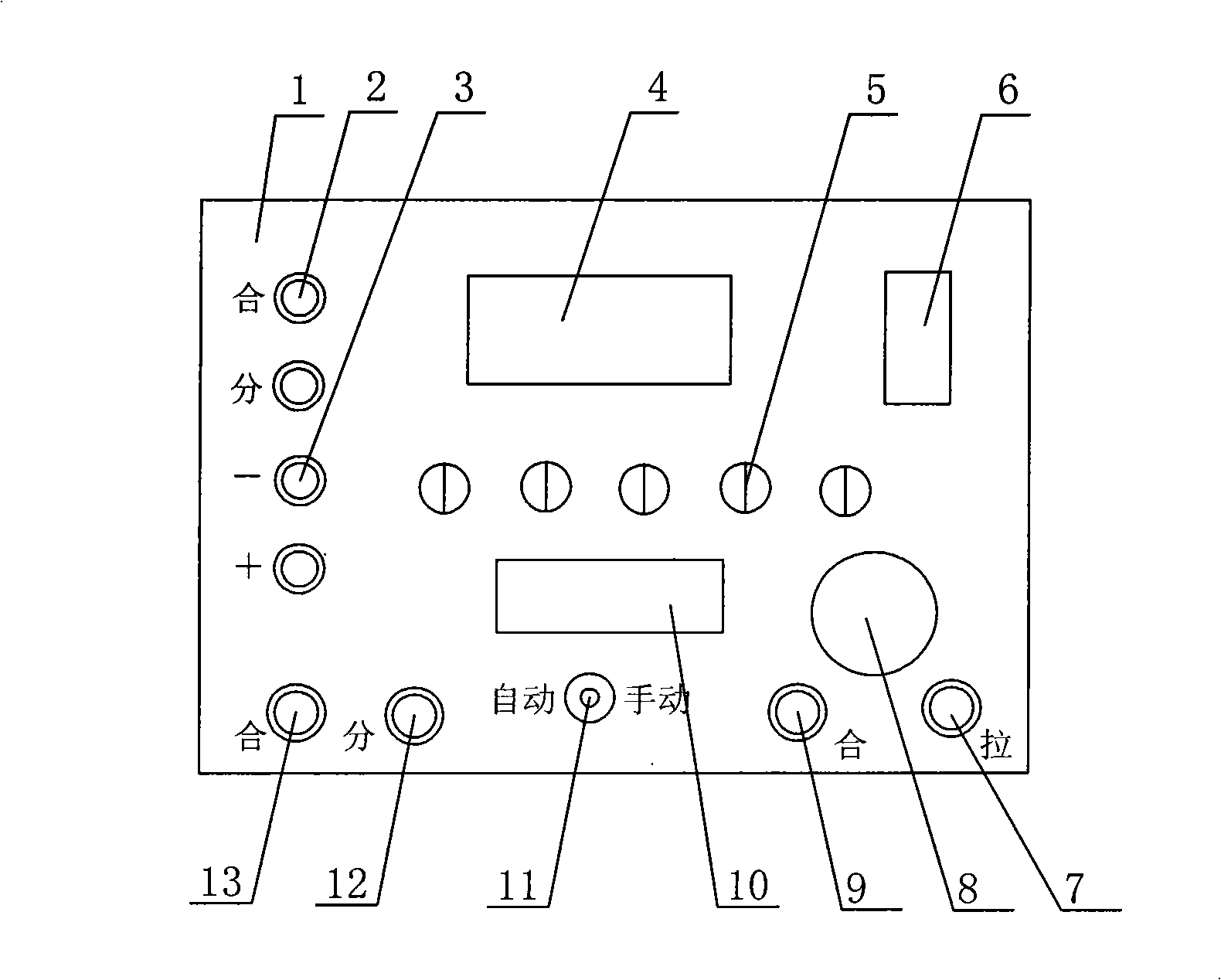

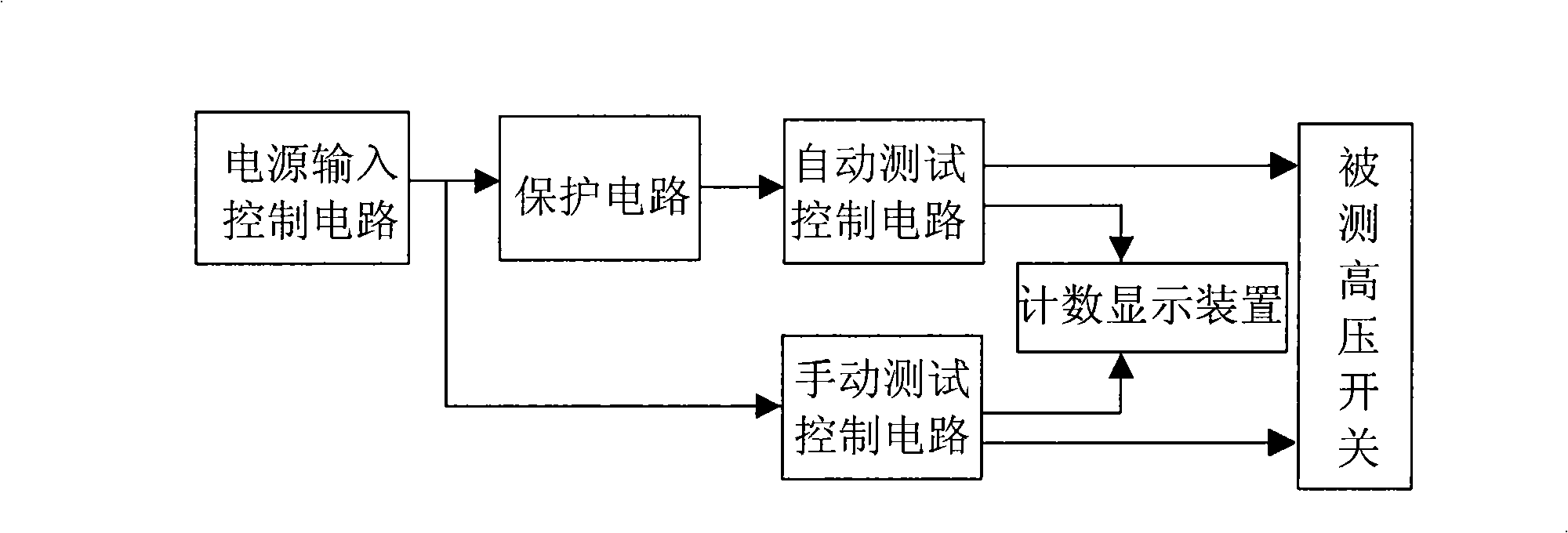

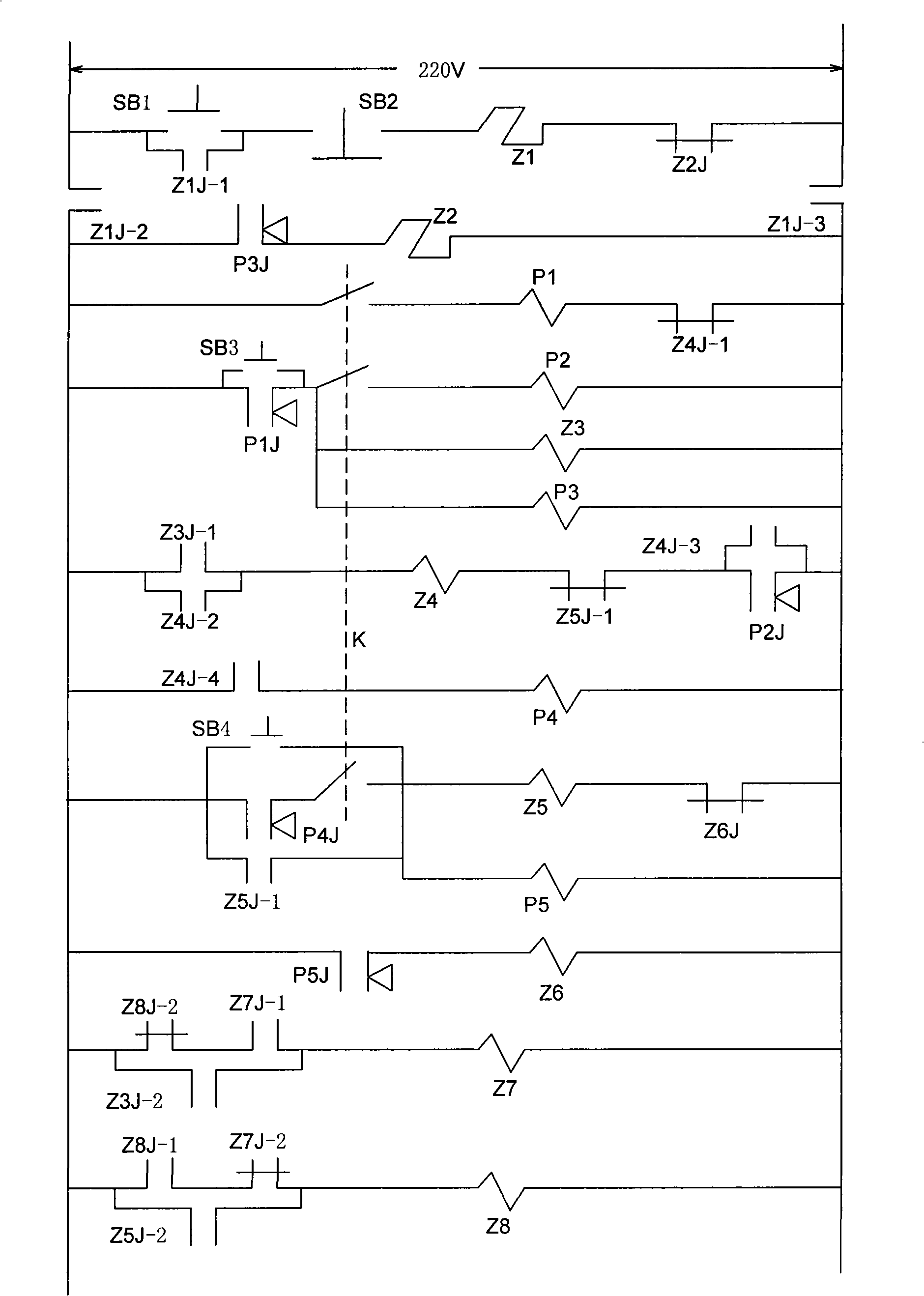

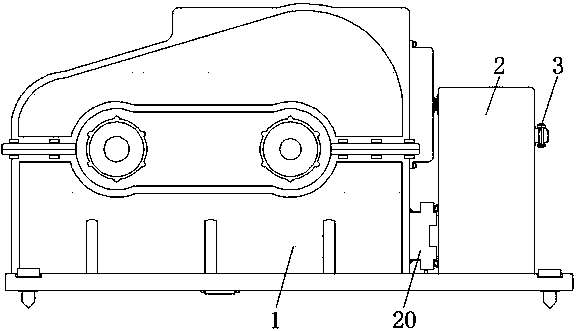

Mechanical endurance test instrument for high voltage switch

ActiveCN101344574AReduce labor intensityShorten the test cycleStructural/machines measurementCircuit interrupters testingDisplay deviceInput control

The invention relates to a high voltage switch mechanical service-life tester which comprises a casing and an internal control circuit thereof. The control circuit is composed of a power-supply input control circuit, a protective circuit, an automatic test control circuit and a manual test control circuit. An input terminal of the power-supply input control circuit is connected with an AC power-supply input port on the casing and an output terminal thereof is respectively connected with the protective circuit and the manual test control circuit; the protective circuit is connected with the automatic test circuit; the automatic test circuit and the manual test circuit are simultaneously connected with a test terminal and a counting display device on the casing; the counting display device is connected with a DC power supply input port. The structural design of the invention is proper; the operation is convenient and the capability is safe and reliable; the work efficiency is enhanced so as to free testing staff from heavy work; the test time is reduced and the time accuracy of switching on and off the high voltage switch is enhanced so as to guarantee the measurement accuracy.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

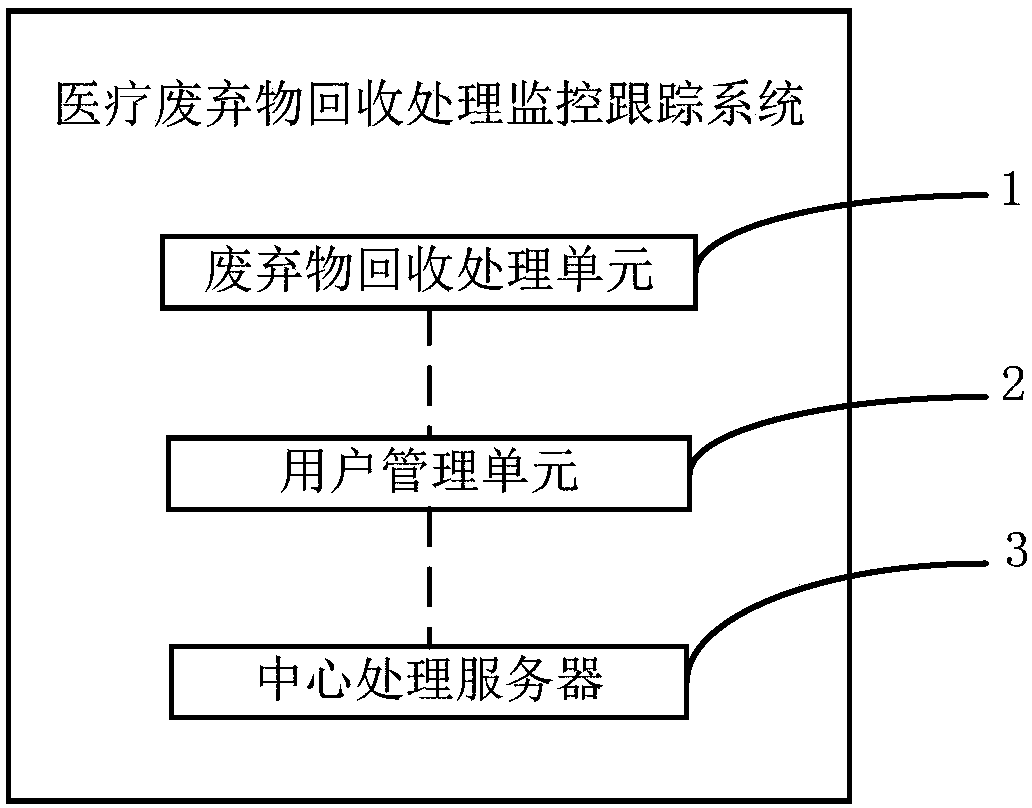

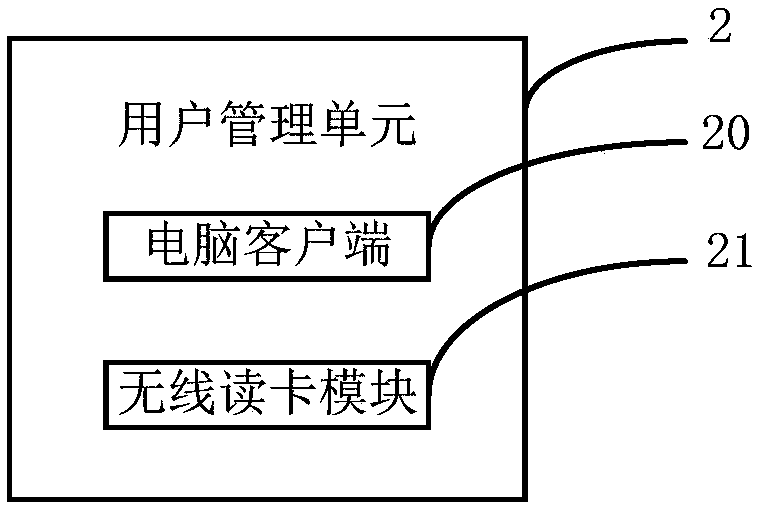

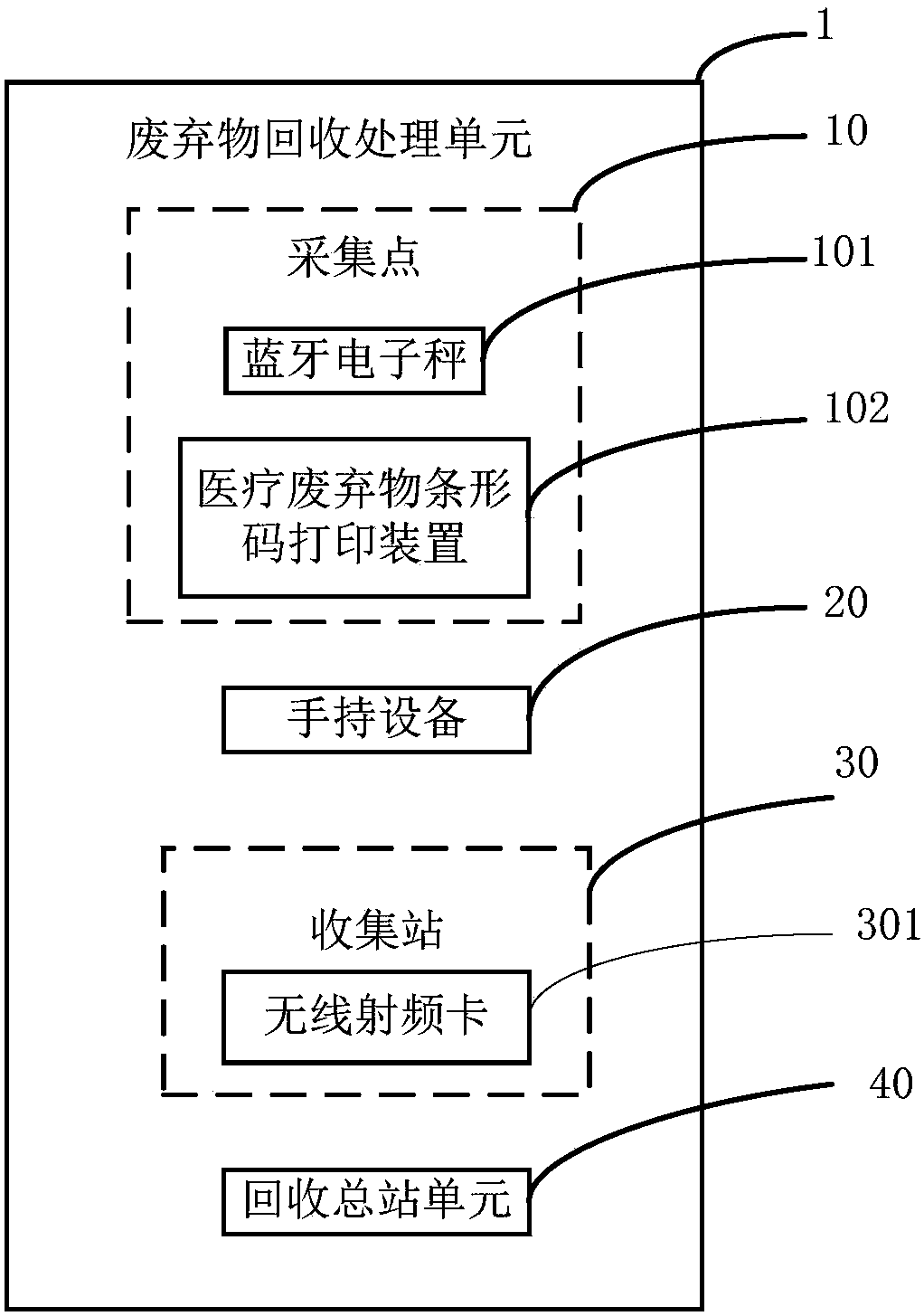

Medical-waste recycling processing monitoring and tracking system

InactiveCN108427976AEasy to transportEasy to recycleCo-operative working arrangementsMedical wasteClient-side

The embodiment of the invention provides a medical-waste recycling processing monitoring and tracking system. The system includes a waste recycling processing unit, a user management unit and a central processing server. The waste recycling processing unit is used for recycling medical waste. The user management unit includes a computer client and a wireless card reading module, reads informationin a wireless card through the wireless card reading module, transfers the information read by the wireless card reading module to the computer client, and manages the waste recycling processing unitand reports management information through the computer client. The central processing server is used for receiving a message sent by the user management unit, and can send processing information to the user management unit to manage the waste recycling processing unit. The central processing server carries out real-time comparison and monitoring on the received packaged information uploaded by the computer client and a type and weight which are of the waste transported in a transport vehicle and in the waste recycling unit, realizes monitoring and tracking of waste recycling processing, and manages the waste recycling processing unit.

Owner:深圳市俊海思创科技开发有限公司

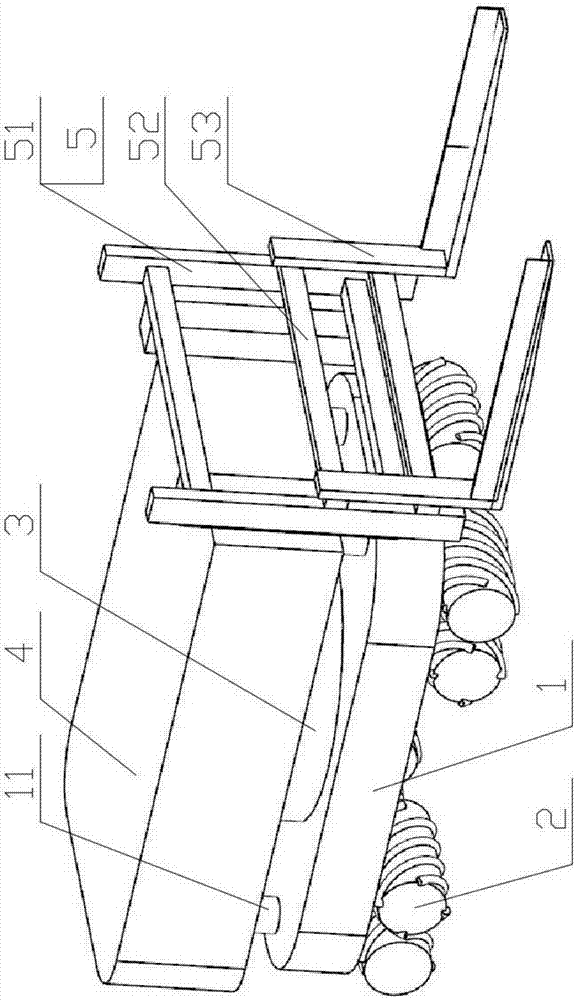

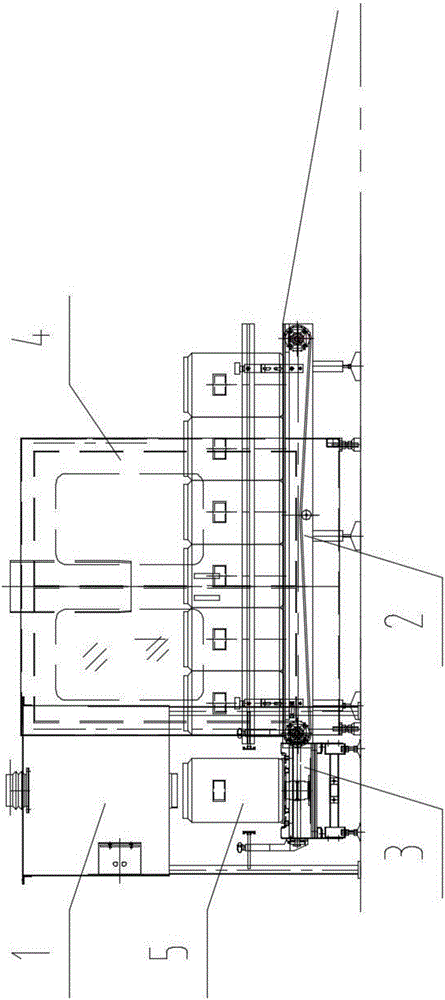

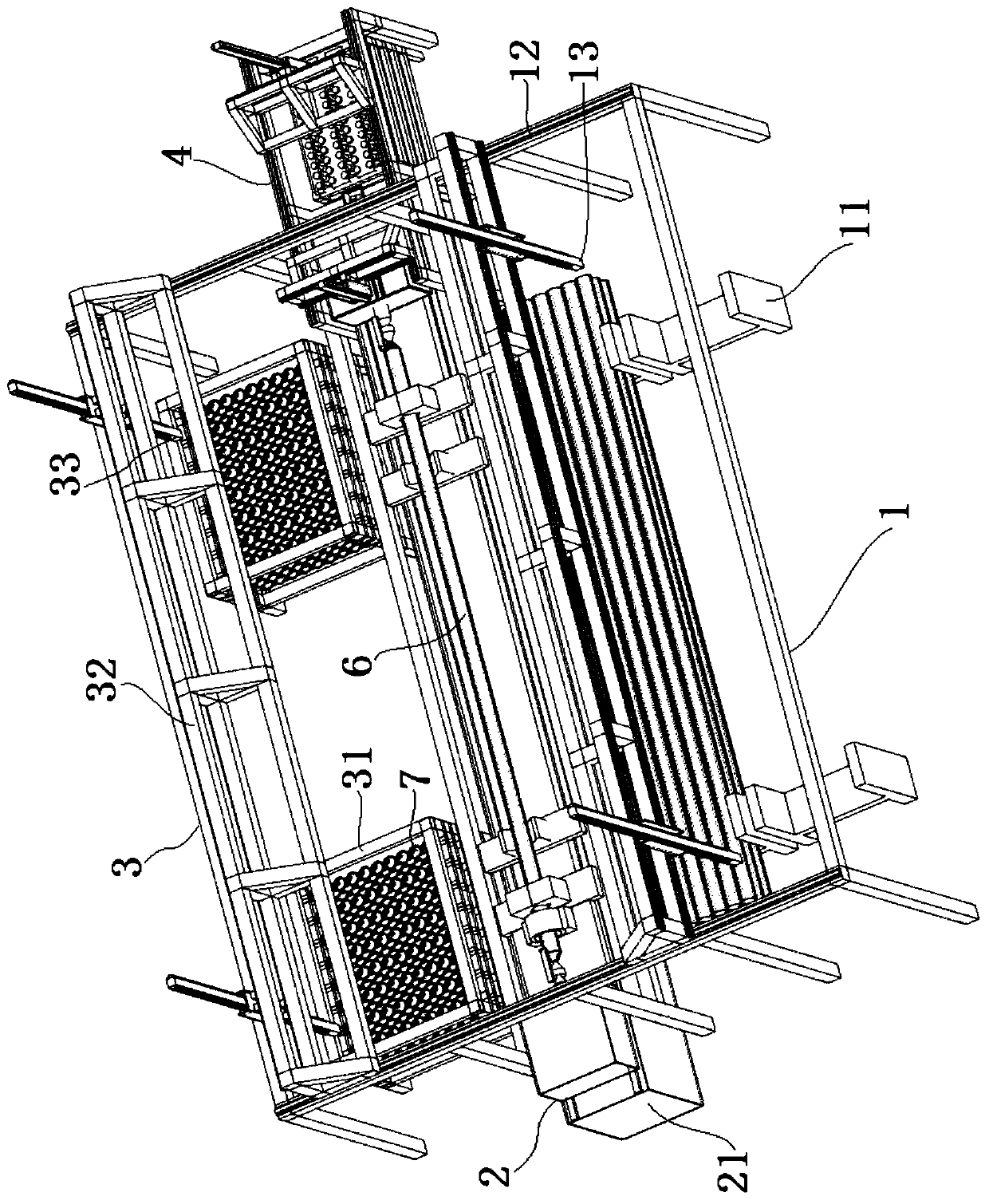

Using method of logistics collecting and stacking system suitable for freight containers

ActiveCN107380869ARealize digital controlAvoid operating skill proficiency limitsLifting devicesStacking articlesLogistics managementData information

The invention discloses a using method of a logistics collecting and stacking system suitable for freight containers. The using method includes the steps of loading and unloading preparation, binning operation, unloading operation and the like. According to the using method of the logistics collecting and stacking system suitable for the freight containers, automatic operation is completely controlled by a computer; after a data input and output port inputs the cargo binning position information of the freight containers, a stowage scheme, cargo packaging box stacking coordinate positions, cargo packaging box dimensions and internal dimension data information of the freight containers to the industrial control computer of an electric control device, the industrial control computer controls a supporting undercarriage to make coordinate movement front and back on longitudinal guide rails, and meanwhile a sorting mechanical arm, a ribbon conveyer and a forklift loader are in collaborative operation so that automatic binning or unloading operation can be achieved; and automatic operation is completely controlled by the computer, the defects of manual operation are avoided thoroughly, loading and unloading efficiency is high, and the using method is particularly suitable for cargo loading and unloading stacking operation of the freight containers in logistics storage container shipping.

Owner:XUZHOU DKEC ELECTRICAL TECH

Control method of automatic welding production system of net rack connecting rods

ActiveCN110480120AGuaranteed uniformityAutomate operationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a control method of an automatic welding production system of net rack connecting rods. The control method includes the steps of steel pipe line delivering, automatic welding,finished product line releasing and the like. Accurate coordinate grabbing and stacking of steel pipe workpieces can be achieved through a steel pipe line delivering unit and a steel pipe line releasing unit, accurate axial positioning of the steel pipe workpieces can be achieved through steel pipe radial clamping and positioning devices, bolts can be subjected to accurate coordinate grabbing andput in the ends of the steel pipe workpieces before welding through an automatic bolt implanting unit, accurate coordinate grabbing and coordinate positioning and connecting of sealing plate or cone head workpieces can be achieved through a sealing plate or cone head supply unit, the sealing plate or cone head workpieces can be accurately and coaxially coordinate-positioned at the welding ends ofthe steel pipe workpieces through sealing plate or cone head pushing devices, through cooperative work of steel pipe rotation drive devices and welding gun devices, one-time welding forming of complete annular weld joints can be achieved, and the control method is especially suitable for welding procedures of the net rack connecting rods.

Owner:浩德重工科技(江苏)有限公司

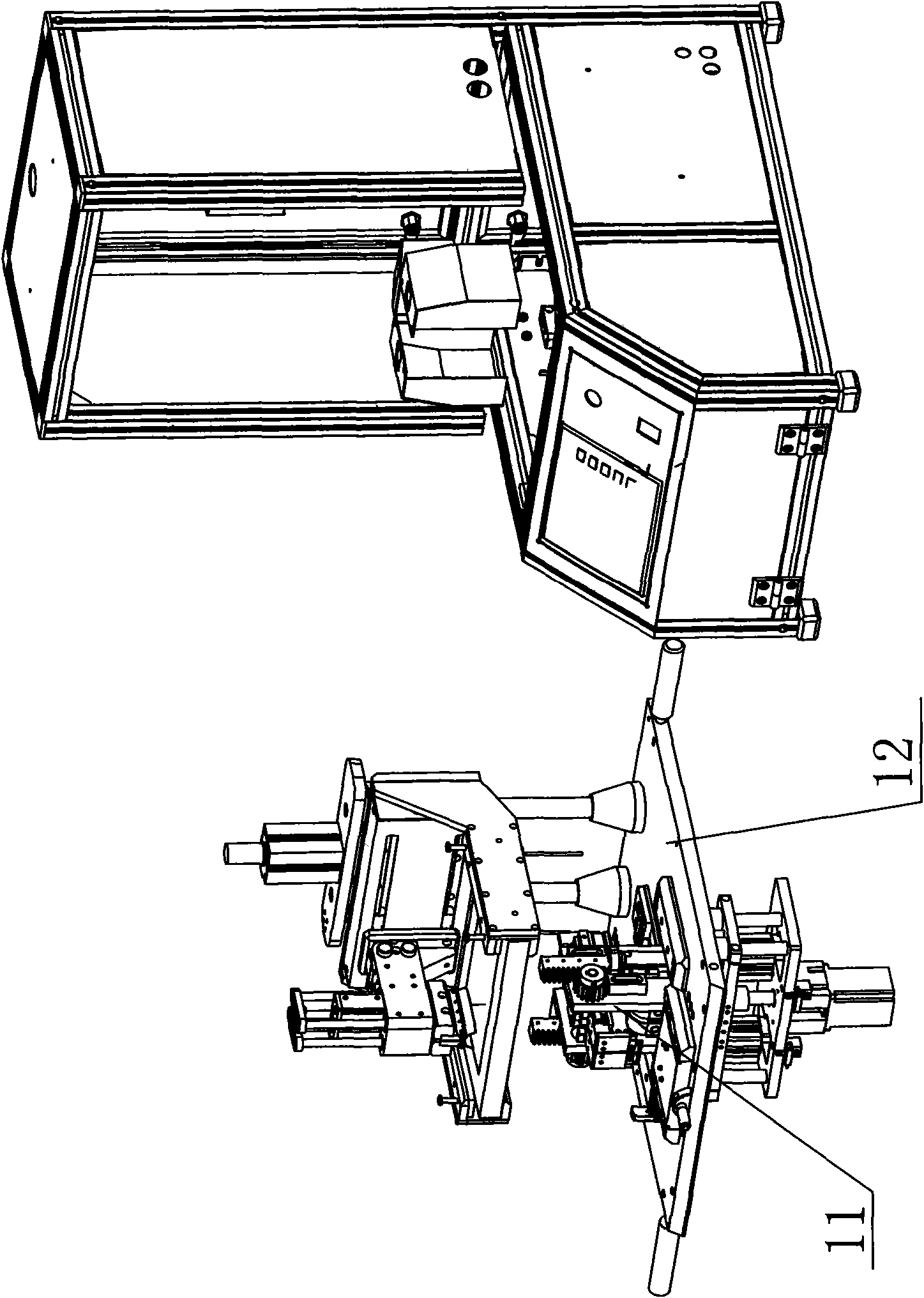

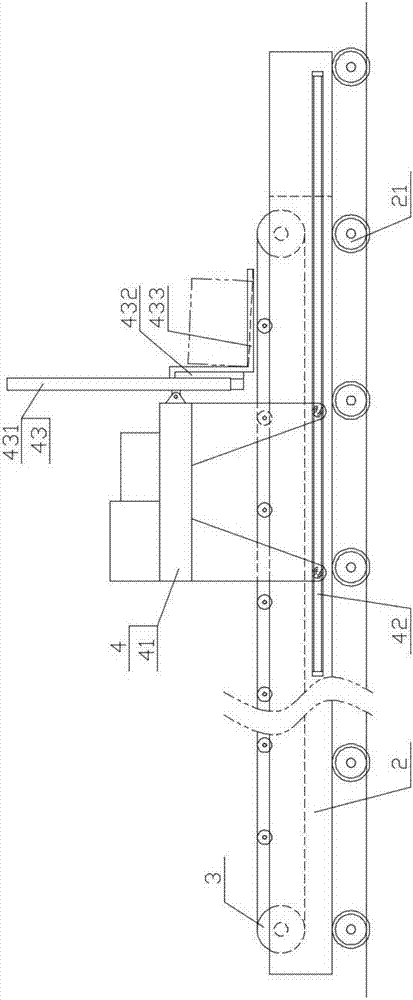

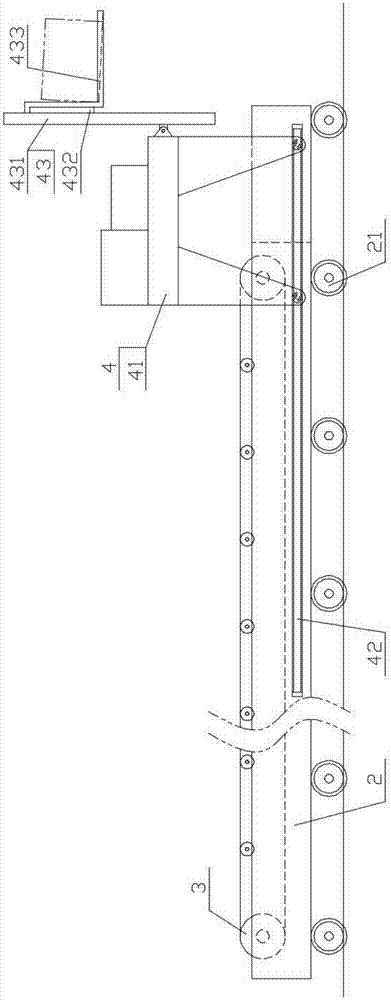

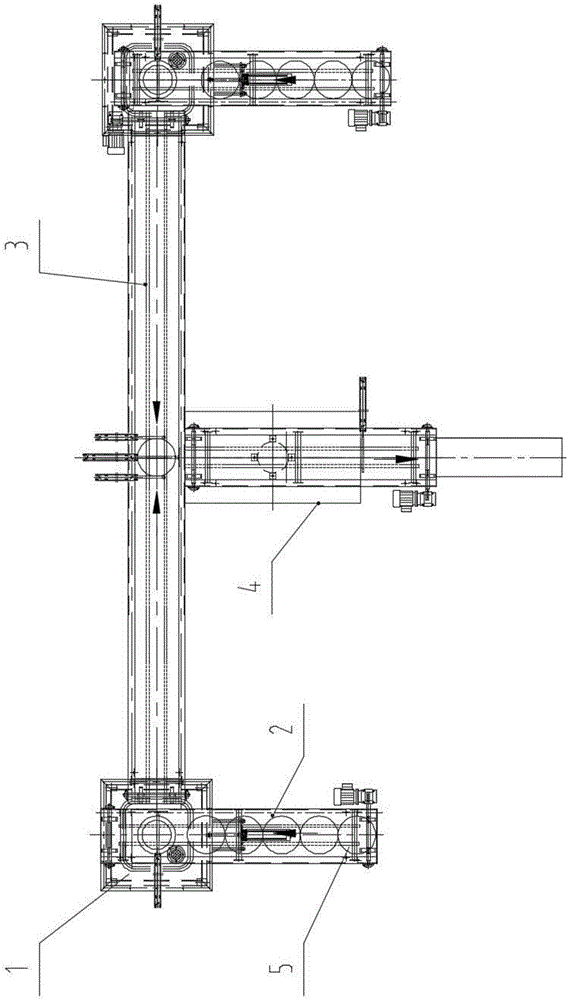

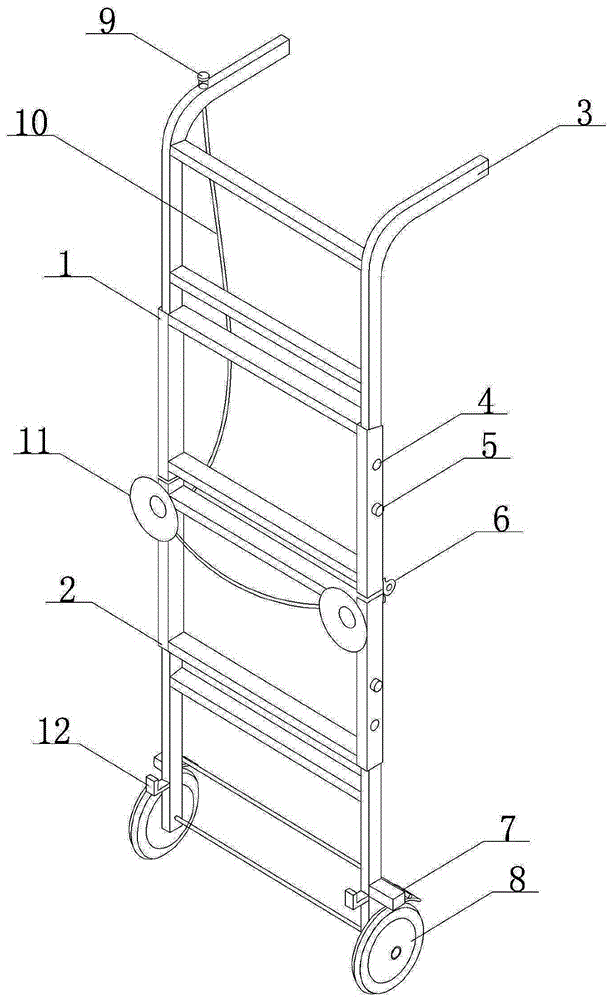

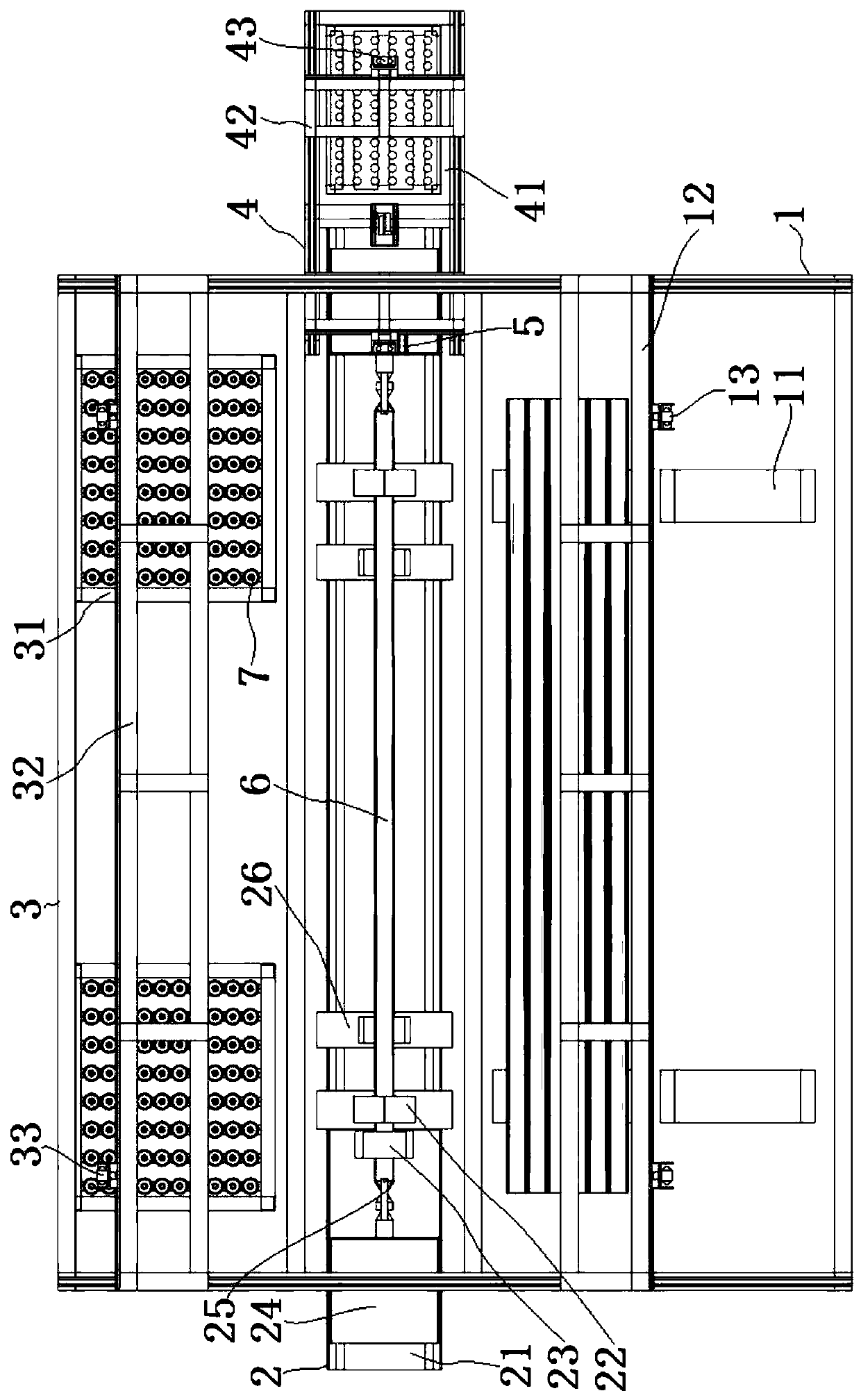

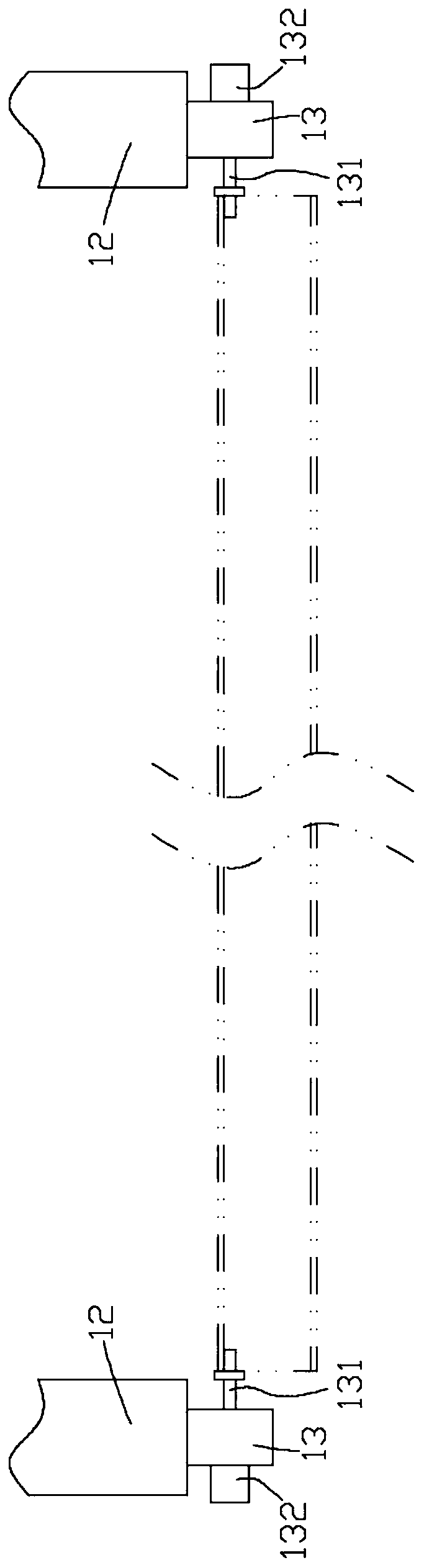

Using method for logistics taking and stacking vehicle used for freight container

ActiveCN107499802AAvoid operating skill proficiency limitsAvoid the disadvantages of manual operationStorage devicesHydraulic cylinderLogistics management

The invention discloses a using method for a logistics taking and stacking vehicle used for a freight container. The using method comprises the steps of loading and unloading preparation and loading and unloading operation. A working part comprises a door frame, a freight fork frame and freight forks. According to the using method for the logistics taking and stacking vehicle used for the freight container, computer control automatic operation is completely adopted, after cargo encasement position information, a stowage scheme, a cargo stacking coordinate position, cargo sizes and inner sizes of the freight container are input to an industry control computer of an electric control system through an data input and output port, the industry control computer controls action coordinates of a walking part to move according to the input cargo information, meanwhile, the industry control computer can automatically adjust the span distance between the freight forks according to the input cargo information, and a mathematical model of the fork loading position and the fork loading depth is established, and then a door frame pitch hydraulic cylinder and a fork frame lifting hydraulic cylinder conduct automatic fork loading and stacking according to the mathematical model.

Owner:XUZHOU DKEC ELECTRICAL TECH

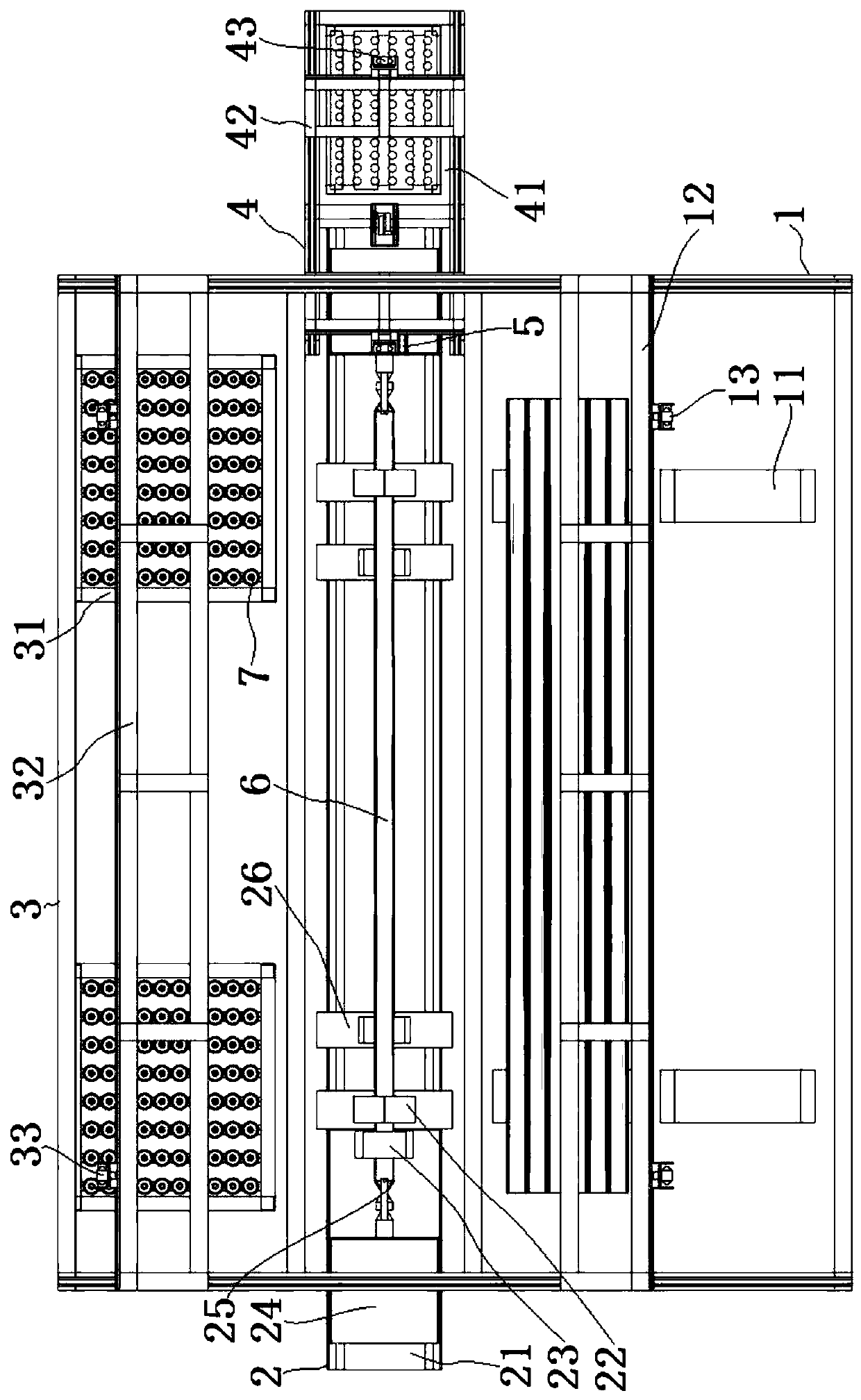

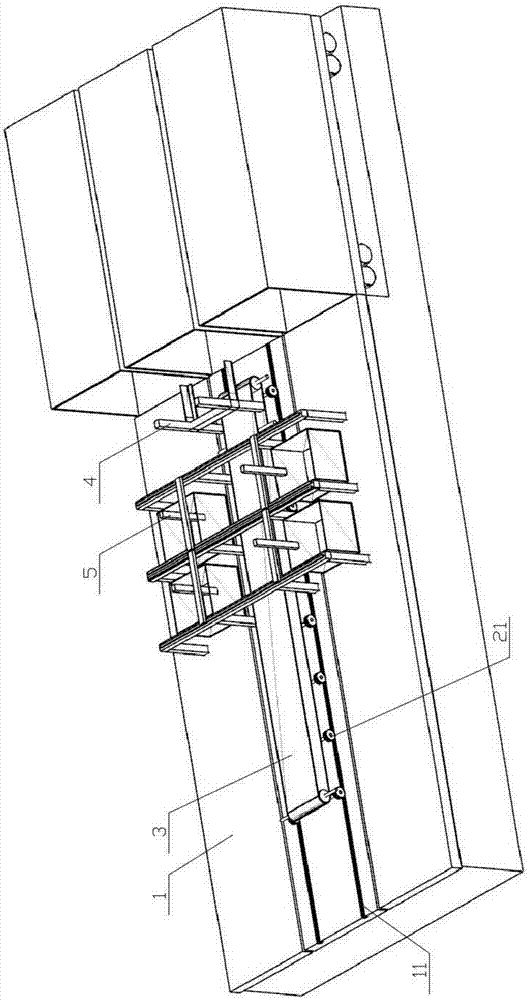

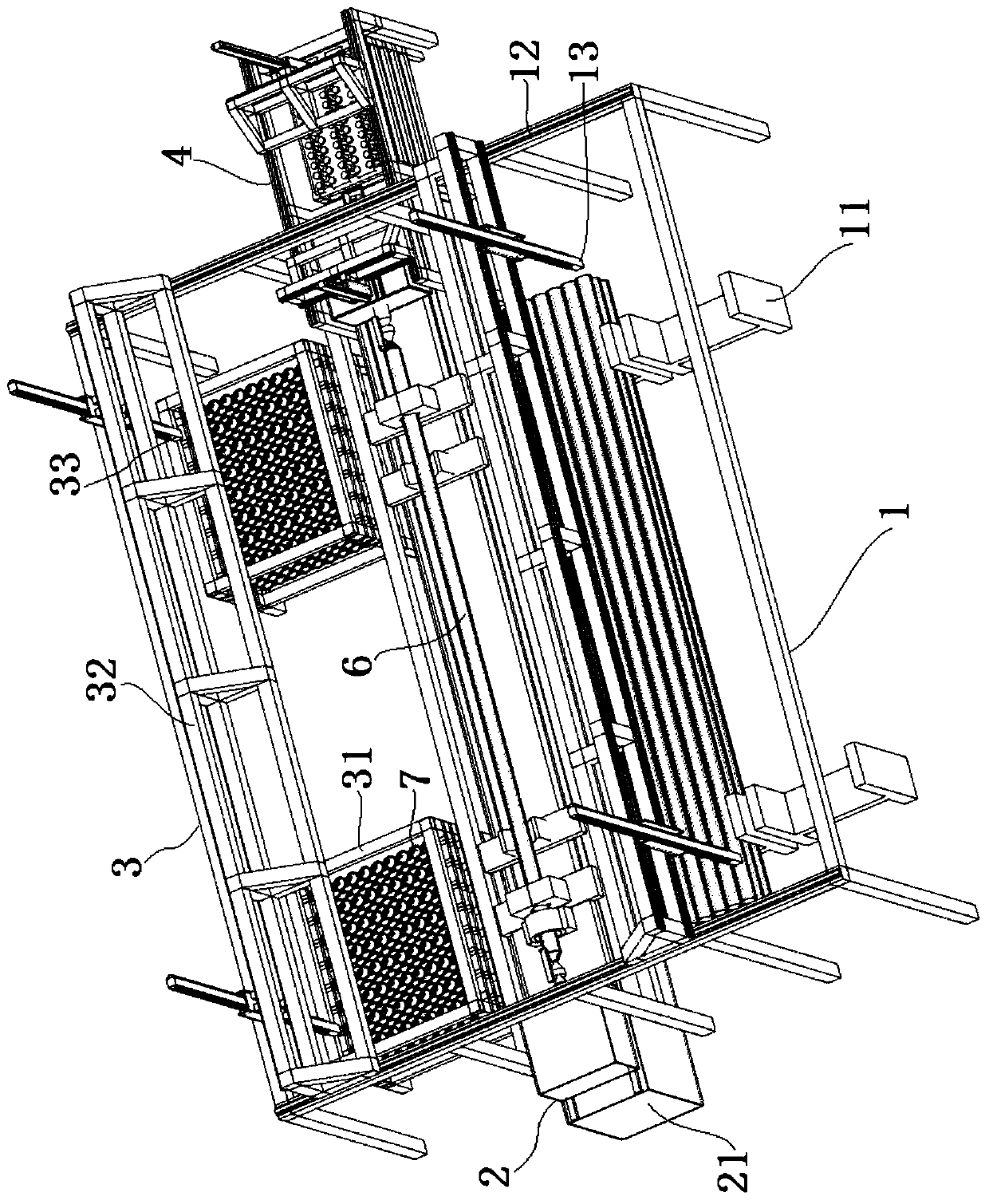

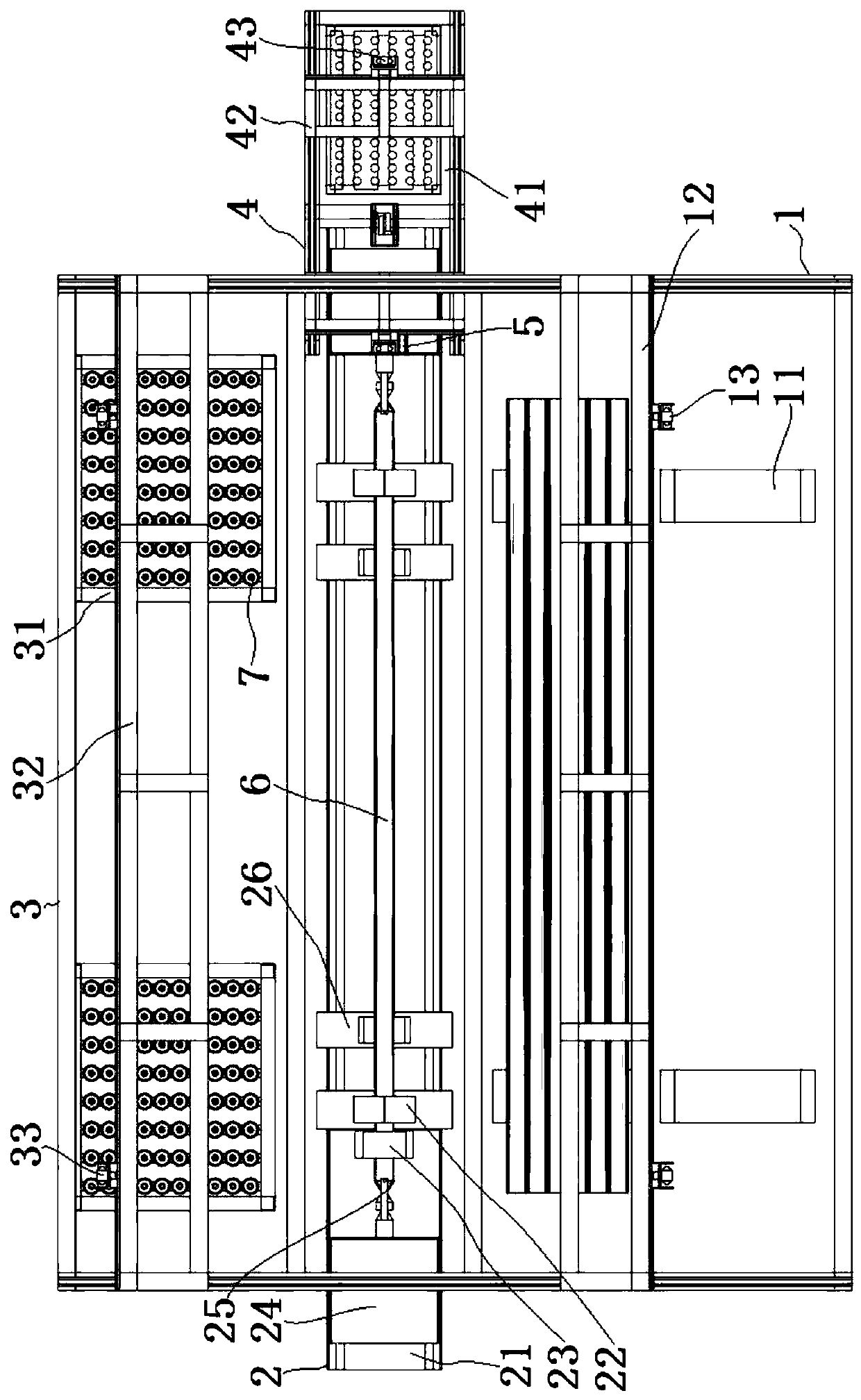

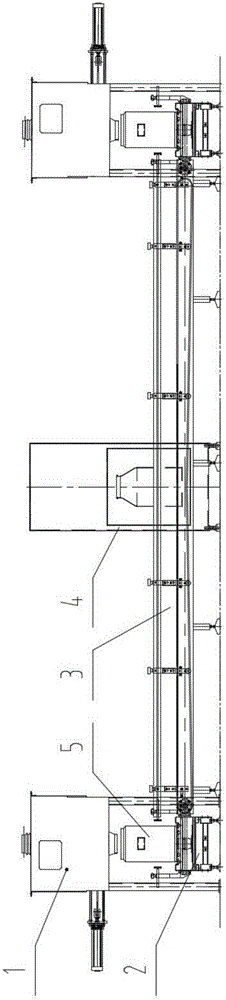

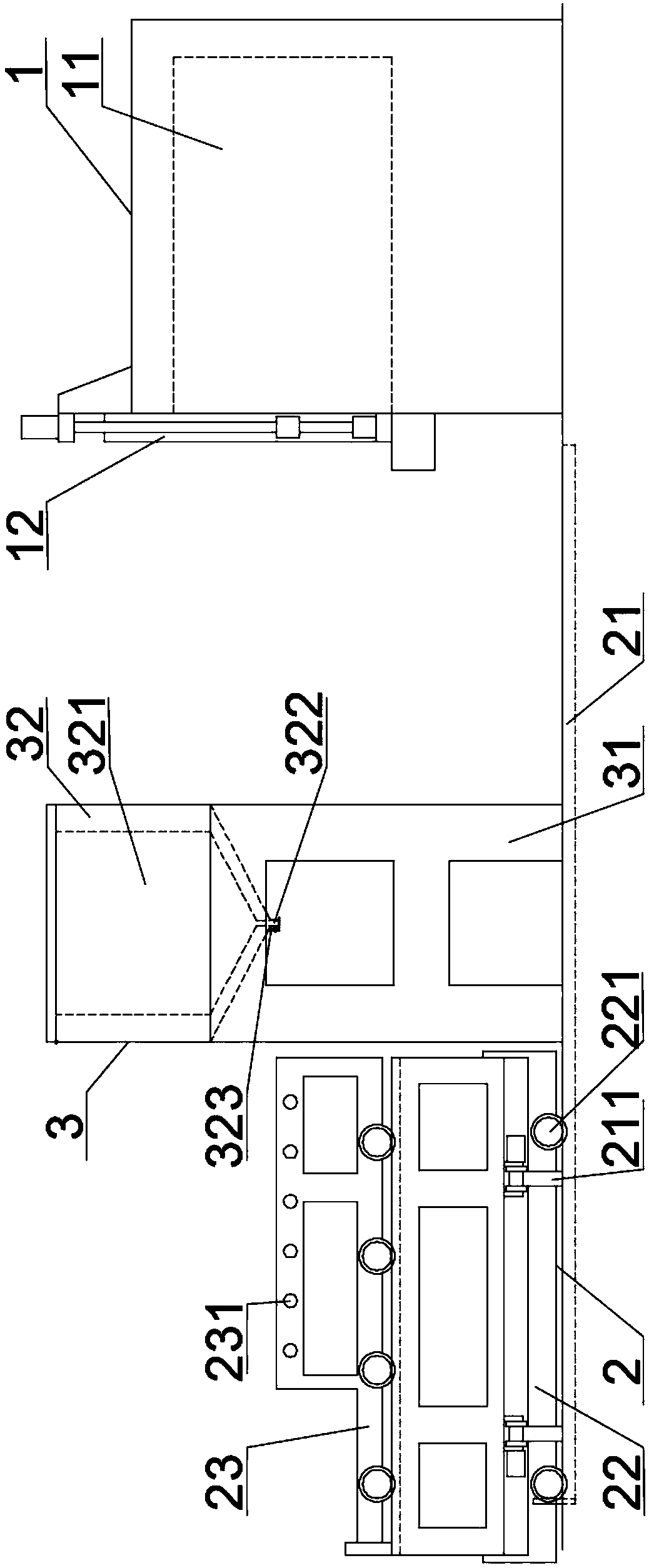

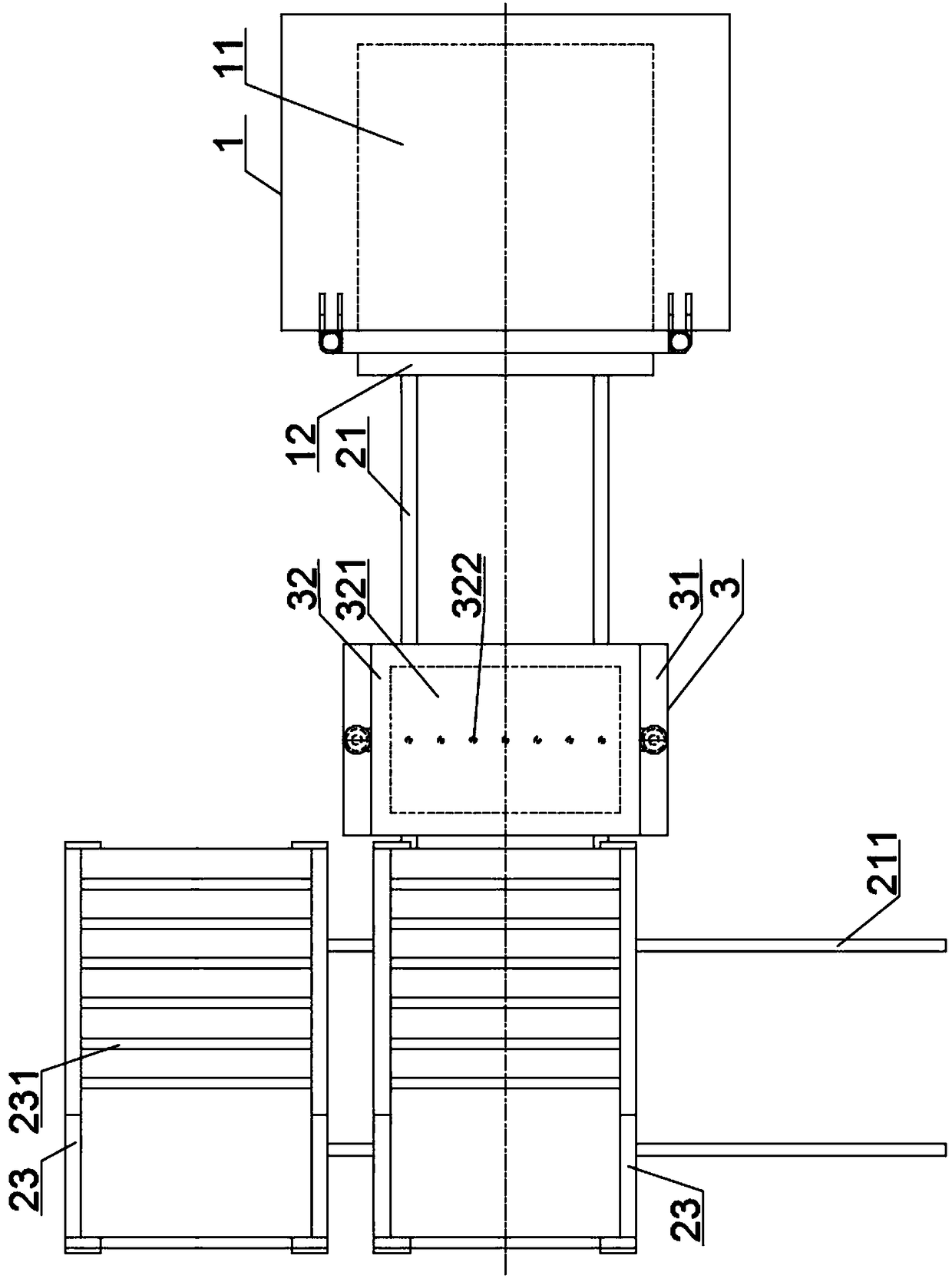

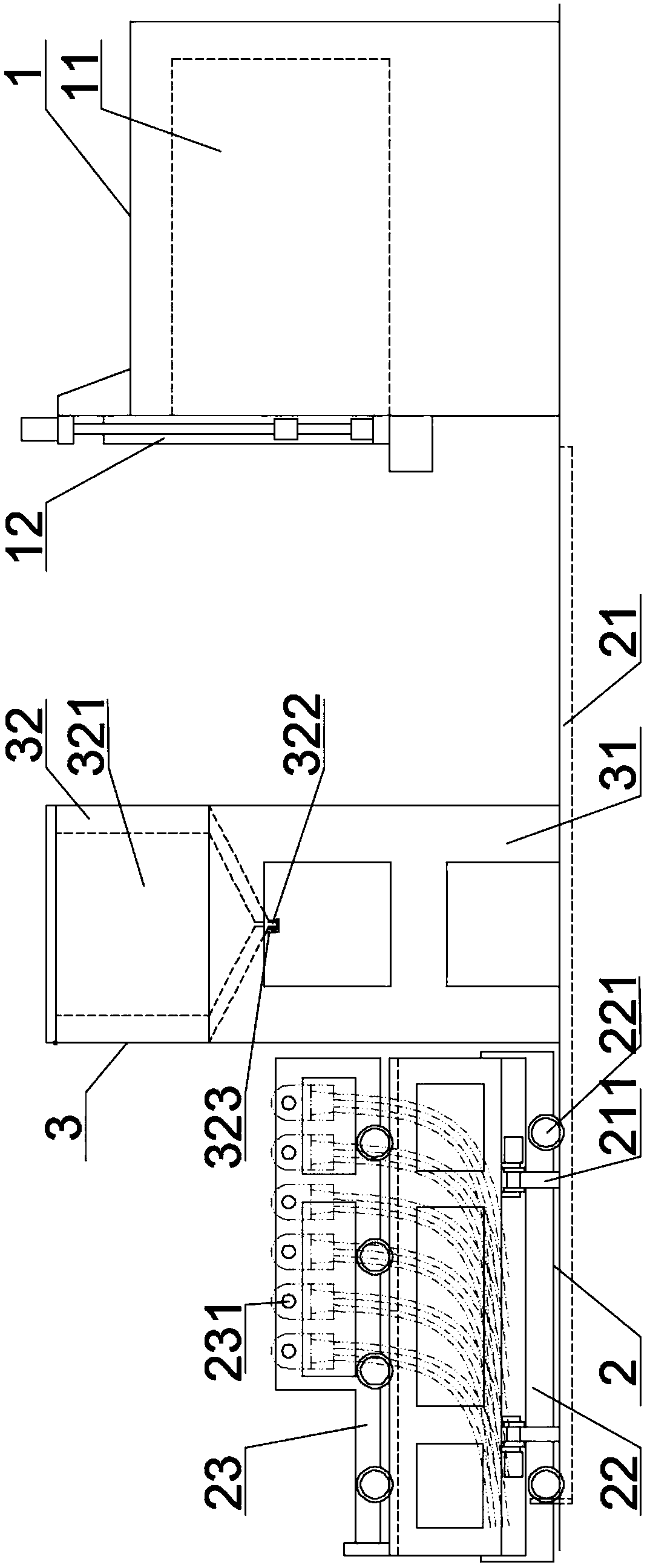

Logistics code taking system suitable for freight containers

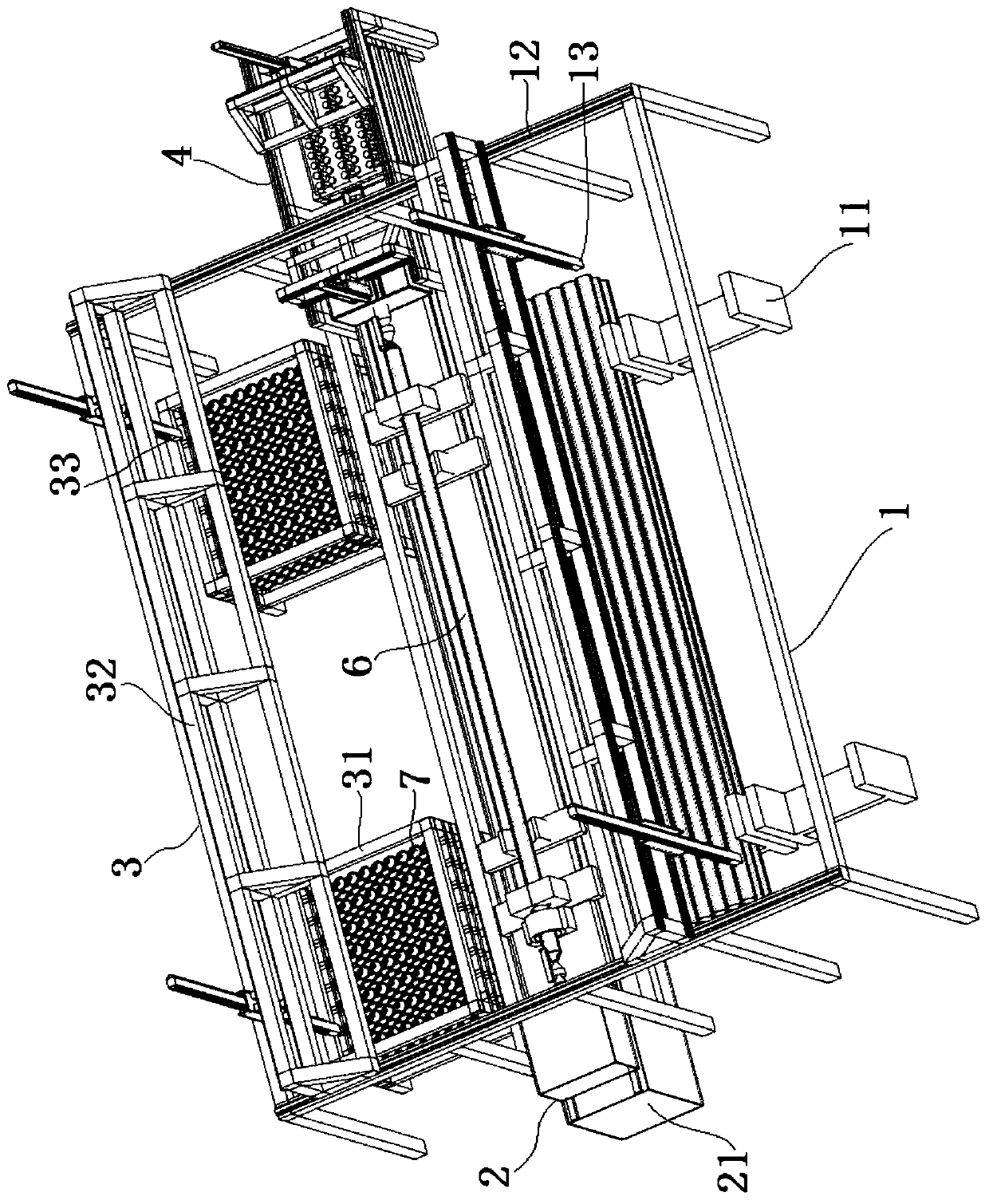

ActiveCN107352207ARealize digital controlAvoid operating skill proficiency limitsLifting devicesStacking articlesLogistics managementElectric control

The invention discloses a logistics code taking system suitable for freight containers. The system comprises a loading / unloading platform, a loading / unloading device, a sorting device and an electric control device; the loading / unloading platform is provided with longitudinal guide rails in parallel in front-back direction; the loading / unloading device comprises a support chassis, a belt conveyor and a forklift; a walking part is arranged at the bottom of the support chassis; the belt conveyor comprises a chassis conveyor electric control mechanism; the forklift comprises a forklift electric control mechanism; the sorting device comprises multiple sorting mechanical arms arranged on the left and right sides of the loading / unloading device, and a mechanical arm electric control mechanism; and the electric control device comprises an industrial control computer, a support chassis control loop, a belt conveyor control loop, a forklift control loop and a sorting stacking control loop. The logistics code taking system suitable for the freight containers is higher in automation degree, can realize intelligent operation, improves the loading / unloading efficiency, and in particular, is suitable for the goods loading / unloading stacking operation of the freight containers in container transportation of logistics warehousing.

Owner:XUZHOU DKEC ELECTRICAL TECH

Self-help stamping system

The invention provides a self-help stamping system which is used for conducting stamping on an object to be stamped. The self-help stamping system comprises a master control computer, an entity stamping mechanism and a true and false identification mechanism. Both the entity stamping mechanism and the true and false identification mechanism are connected with the master control computer. The true and false identification mechanism is used for conducting identification on the object to be stamped. Only when a sent-in object is identified and determined to be the preset object to be stamped, will the true and false identification mechanism send an instruction to the master control computer, and therefore the entity stamping mechanism is driven to implement the stamping action. Through the introduction of the master control computer and the entity stamping mechanism, the self-help stamping system realizes stamping action automation, overcomes the defects of manual operation and saves the labor cost and the energy of workers. Meanwhile, due to the fact that the true and false identification mechanism is adopted, identification and determining can be conducted on the sent-in object before stamping, and only when the sent-in object is determined to be the preset object to be stamped, can the entity stamping mechanism be driven to implement the stamping action.

Owner:SHANGHAI HUAHONG JITONG SMART SYST +1

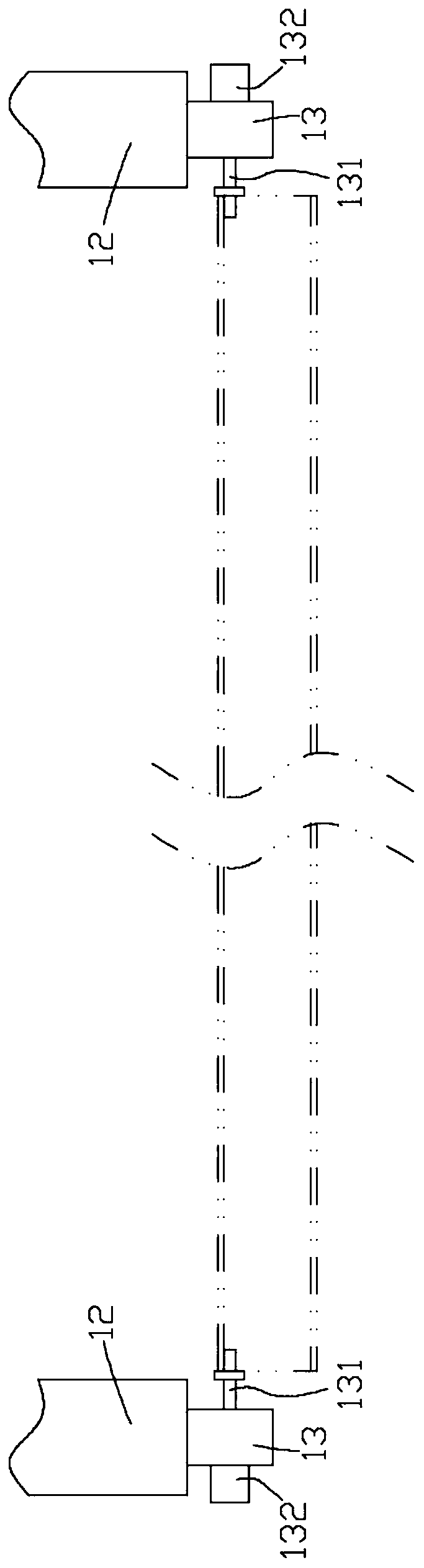

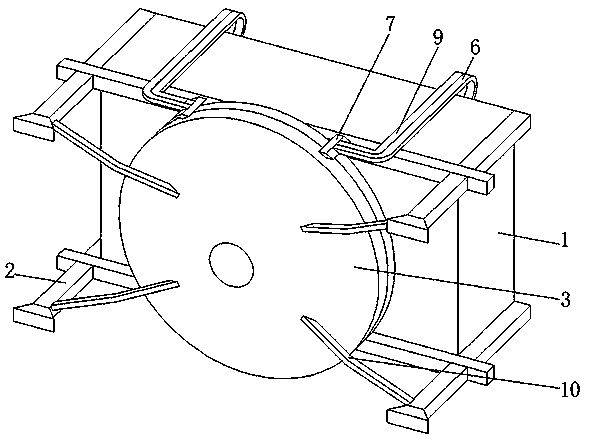

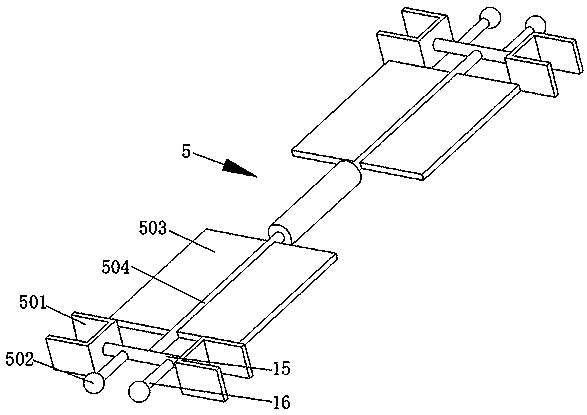

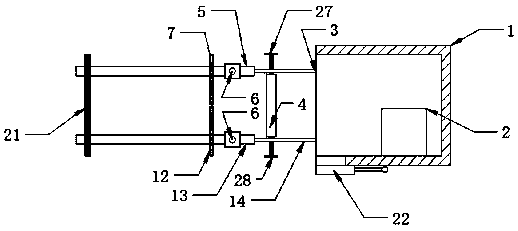

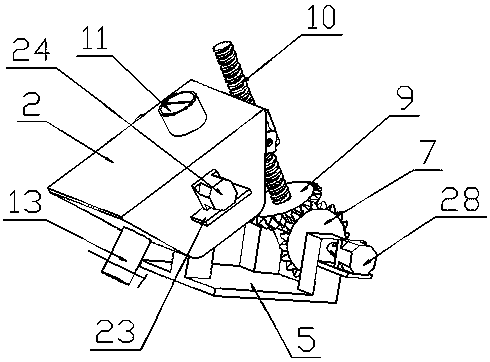

Metal halide lamp electrical arc tube and neck ampulla contracting shell interlocking machine, forming and necking method

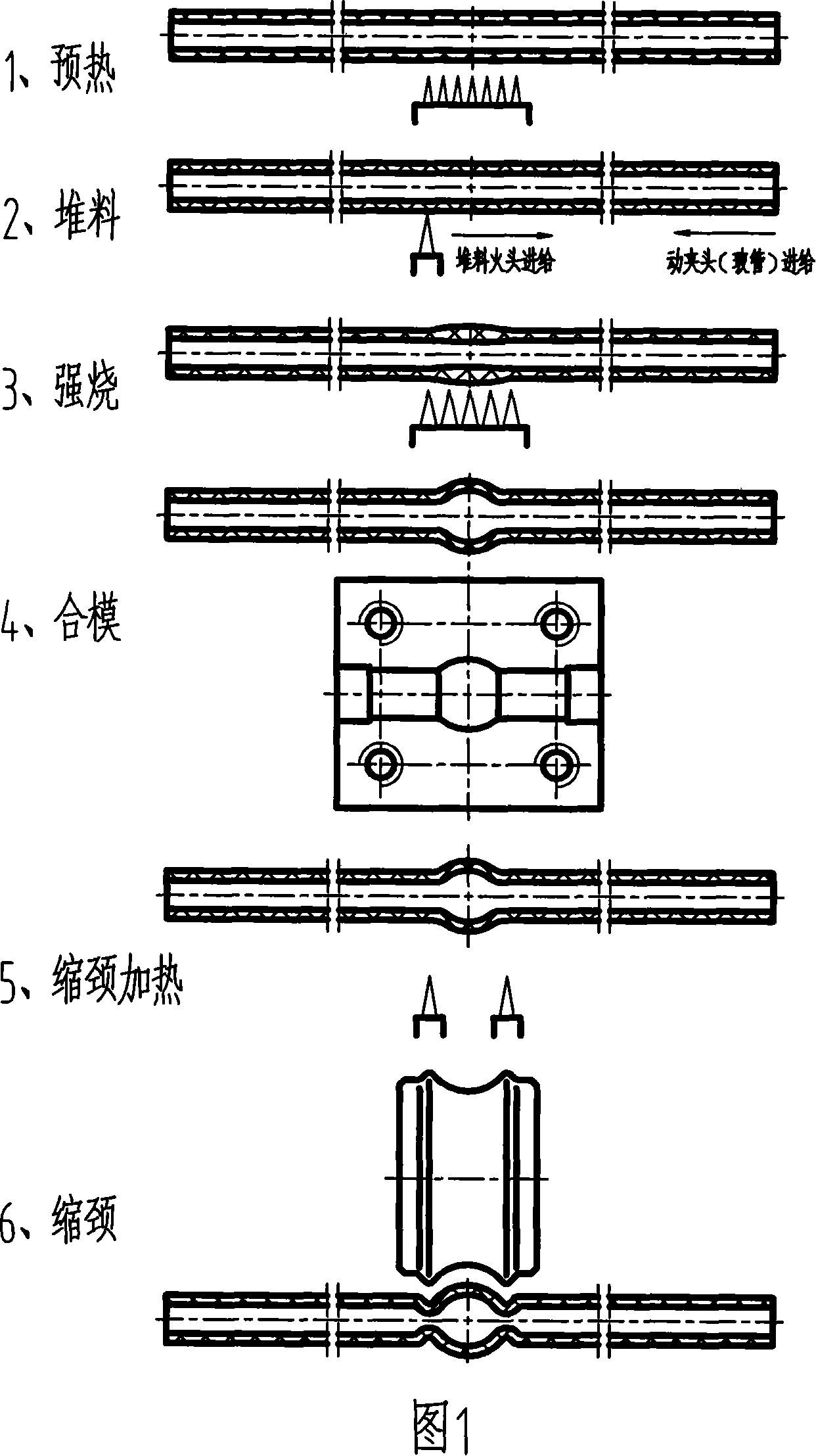

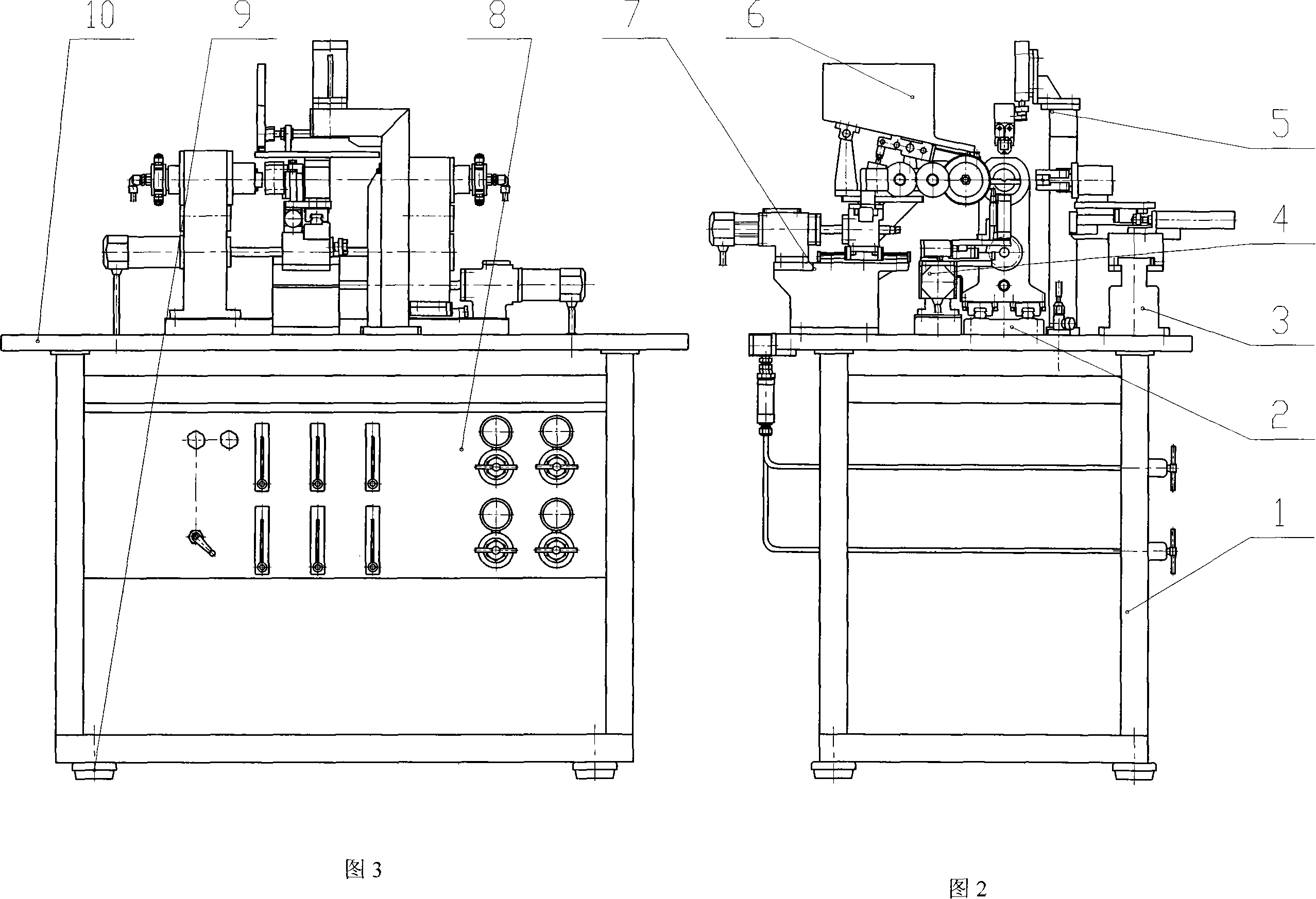

InactiveCN101172764AUniform wall thicknessGood shape and size consistencyGlass reforming apparatusGlass productionMetal-halide lampAmpulla

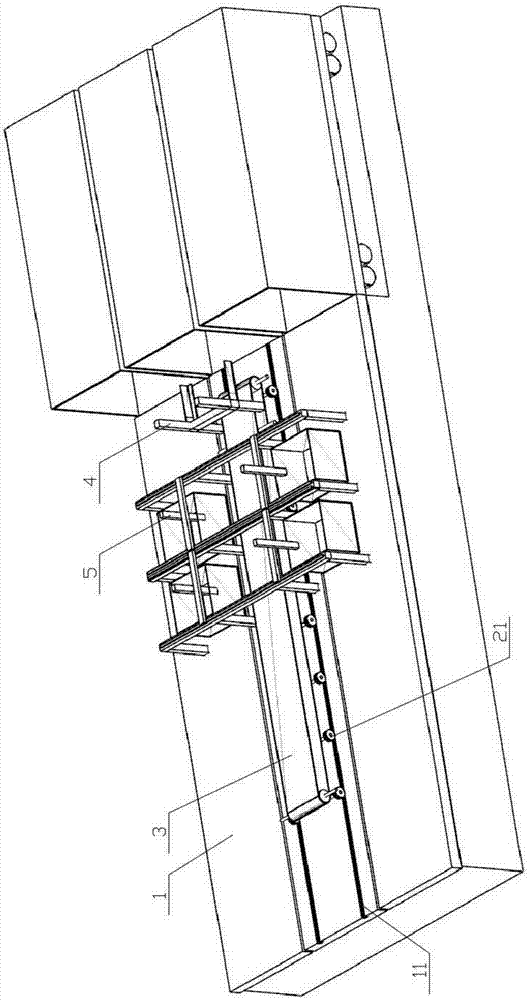

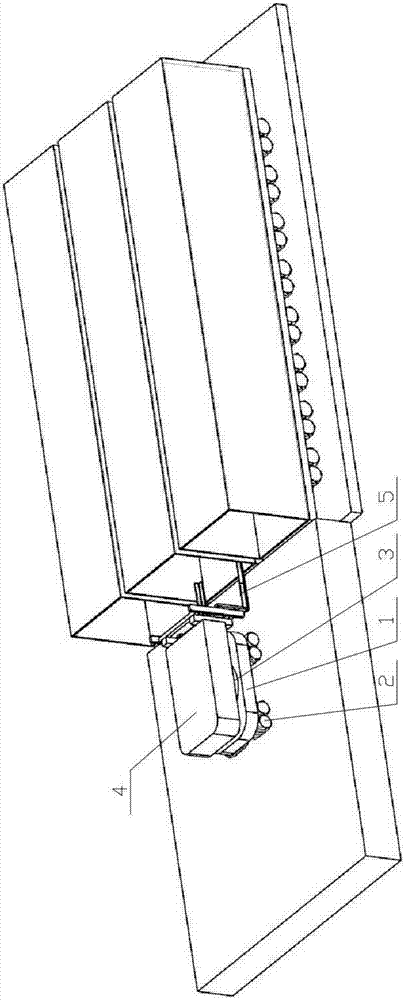

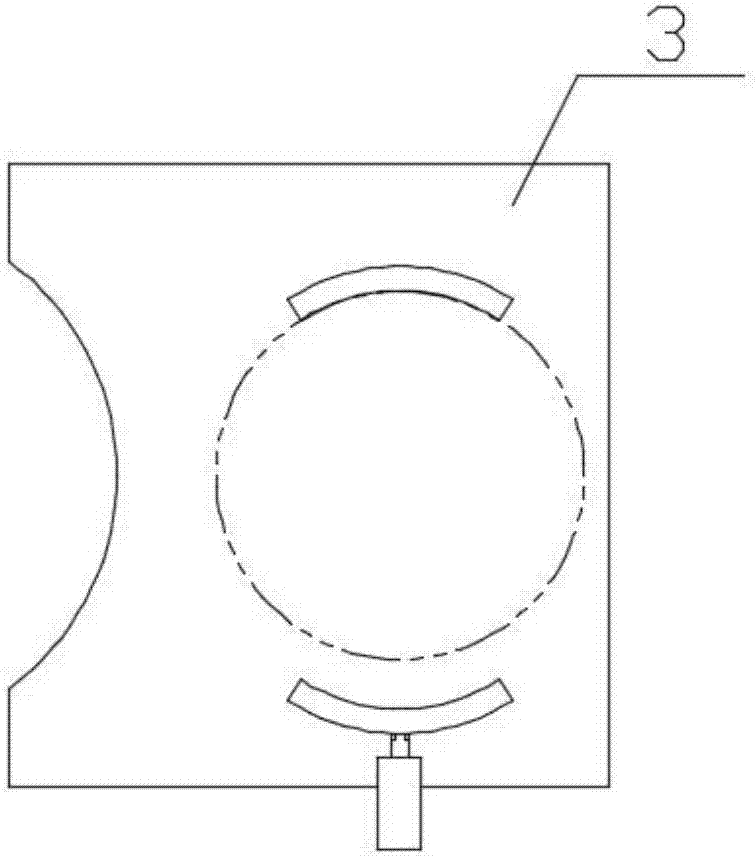

The invention discloses a metal halide lamp arc tube shrank neck shell interlocking machine and the shaping and neck shrinking method thereof. The interlocking machine comprises a machine frame (1), a clamp head and driving and reversing mechanism (2), a mould driving and reversing and mould closing shaping mechanism (3), a fire head moving mechanism (4), an automatic blanking mechanism (5), an automatic feed mechanism (6), a shrank neck trolley driving and reversing mechanism (7) and a fire head air supplying mechanism (8). The shaping and neck shrinking method comprises preheating, material piling, strongly burning, mould closing, and shrank neck heating and shrinking neck. Using the invention and the shaping and neck shrinking method ensure that the appearance and the size of the shell have good consistency and even wall thickness. The internal hole on the shrank neck part is controllable with good consistency, high production efficiency and rate of finished products.

Owner:SOUTHEAST UNIV

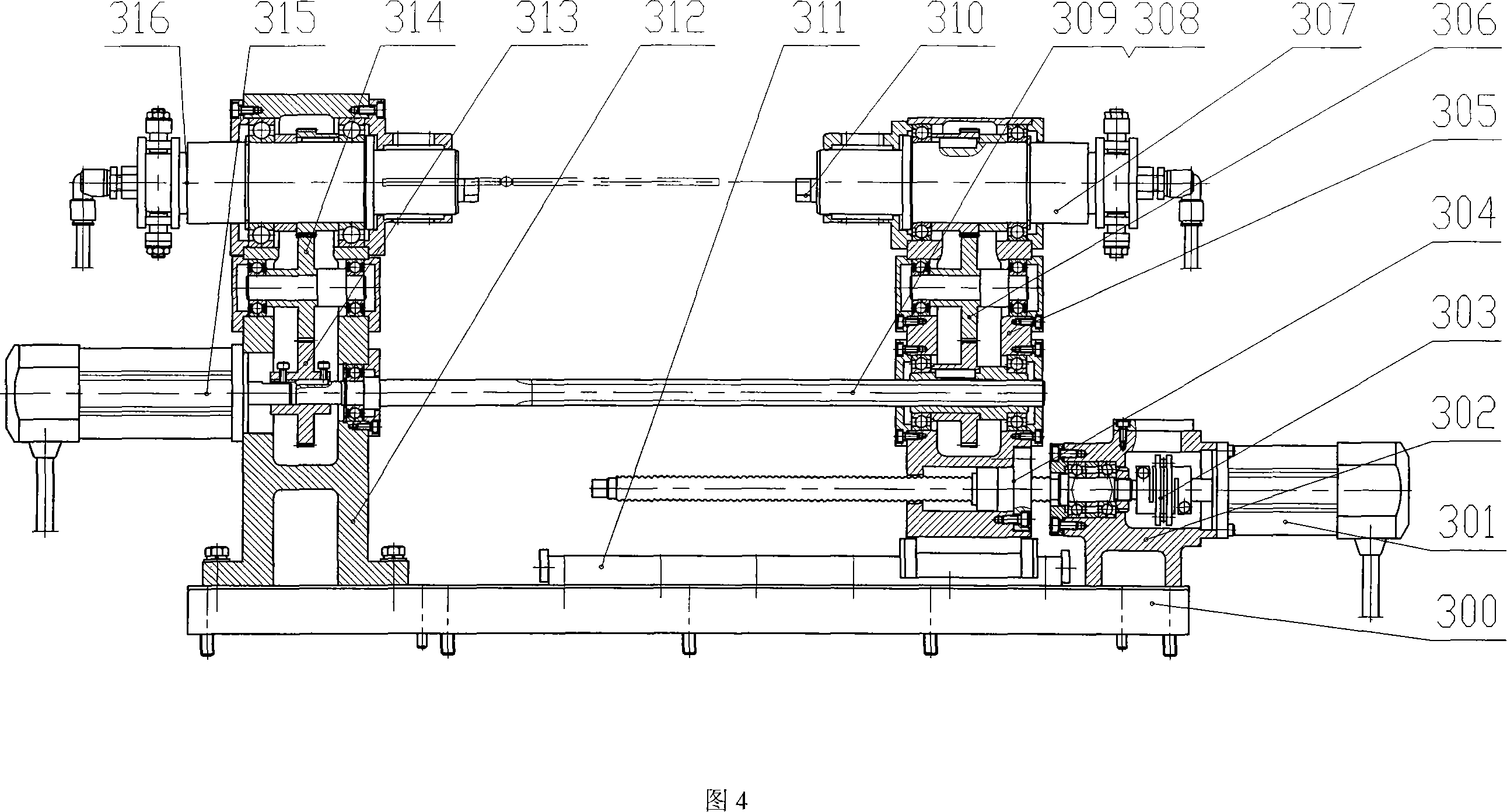

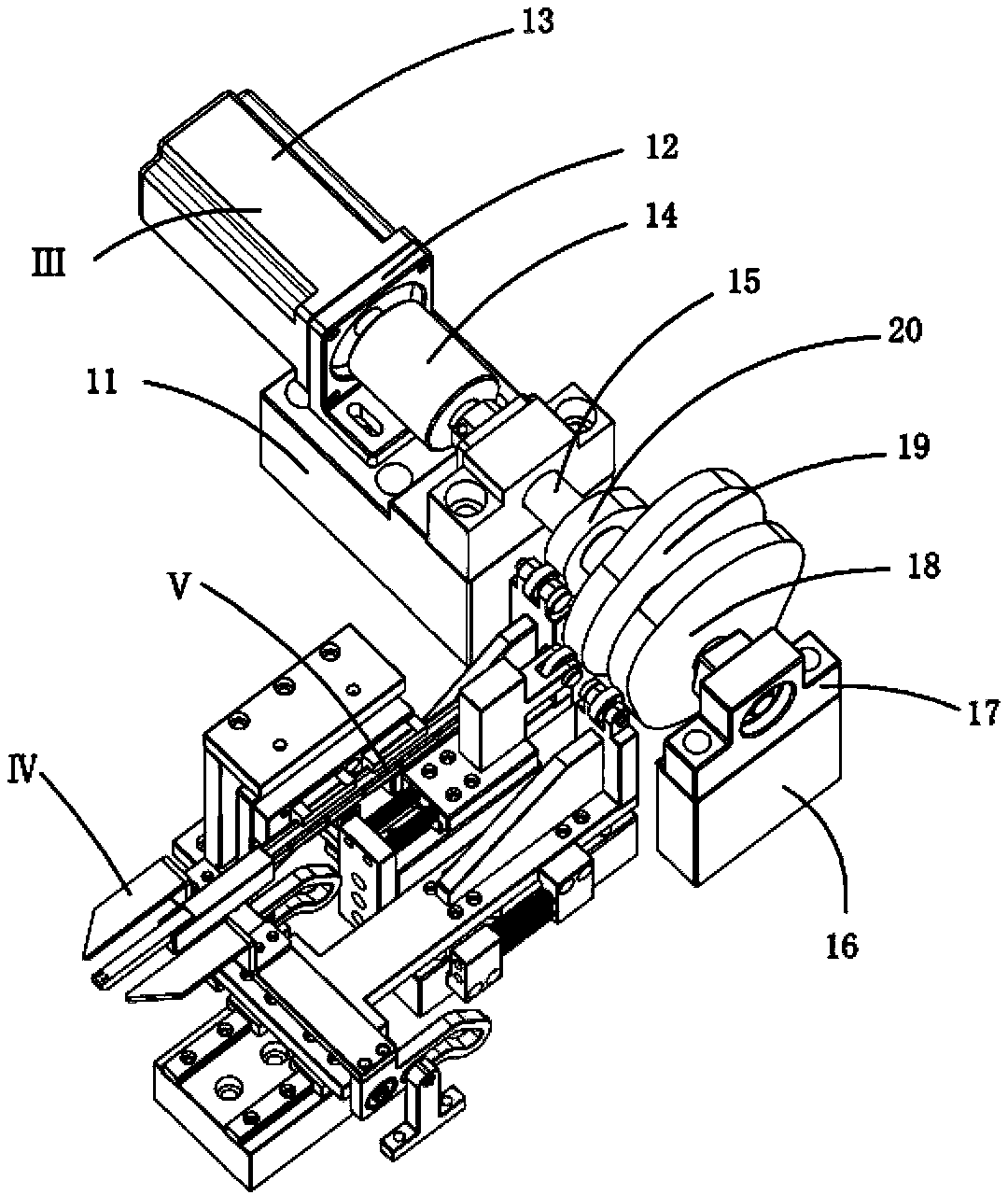

Bolt automatic placing unit for net rack connecting rod automatic welding production system

PendingCN110480295AAutomate operationHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectric control

The invention discloses a bolt automatic placing unit for a net rack connecting rod automatic welding production system. The position corresponding to a sealing plate or a conical head pushing deviceis arranged at the left end and / or the right end of a welding working platform; and the bolt automatic placing unit comprises a bolt feeding bracket, a bolt grabbing and stacking mechanical arm, a bolt grabbing and stacking manipulator and a bolt automatic placing electric control device. For the bolt automatic placing unit for the net rack connecting rod automatic welding production system, a bolt automatic placing controller can calculate an offset according to feedback of a pattern recognition sensor and then performs adjustment on the position of the bolt grabbing and stacking manipulatoraccording to the calculated offset, so that bolts in reverse directions can be subjected to accurate coordinate grabbing and placed into the end part of a steel pipe workpiece before welding through the bolt grabbing and stacking mechanical arm and the bolt grabbing and stacking manipulator, the automation degree is high, the defects of manual operation can be avoided, and the bolt automatic placing unit is particularly suitable for the net rack connecting rod automatic welding production system.

Owner:浩德重工科技(江苏)有限公司

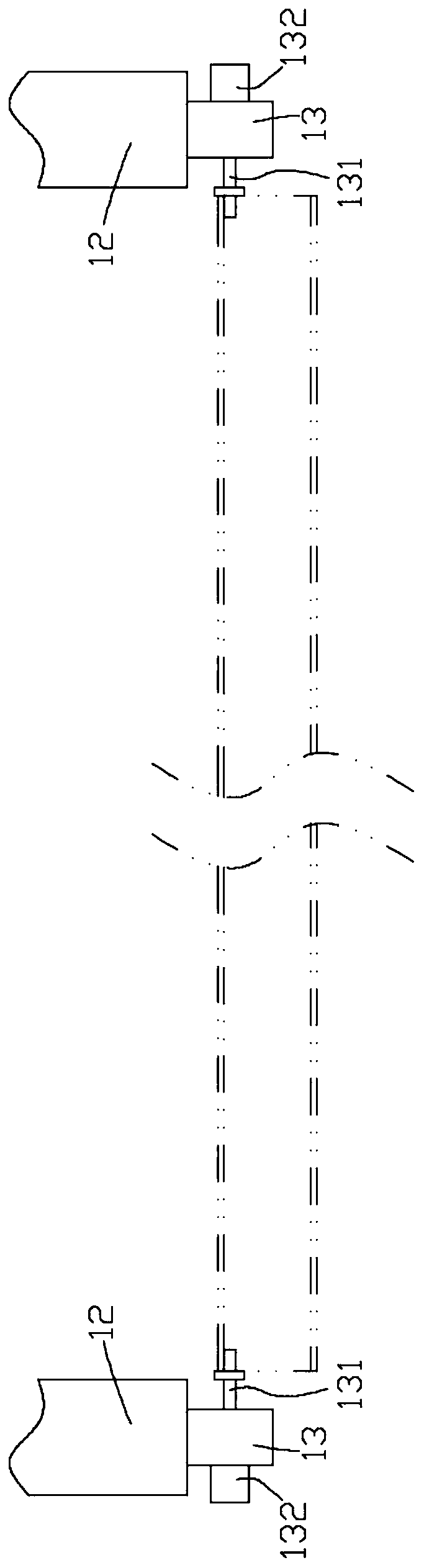

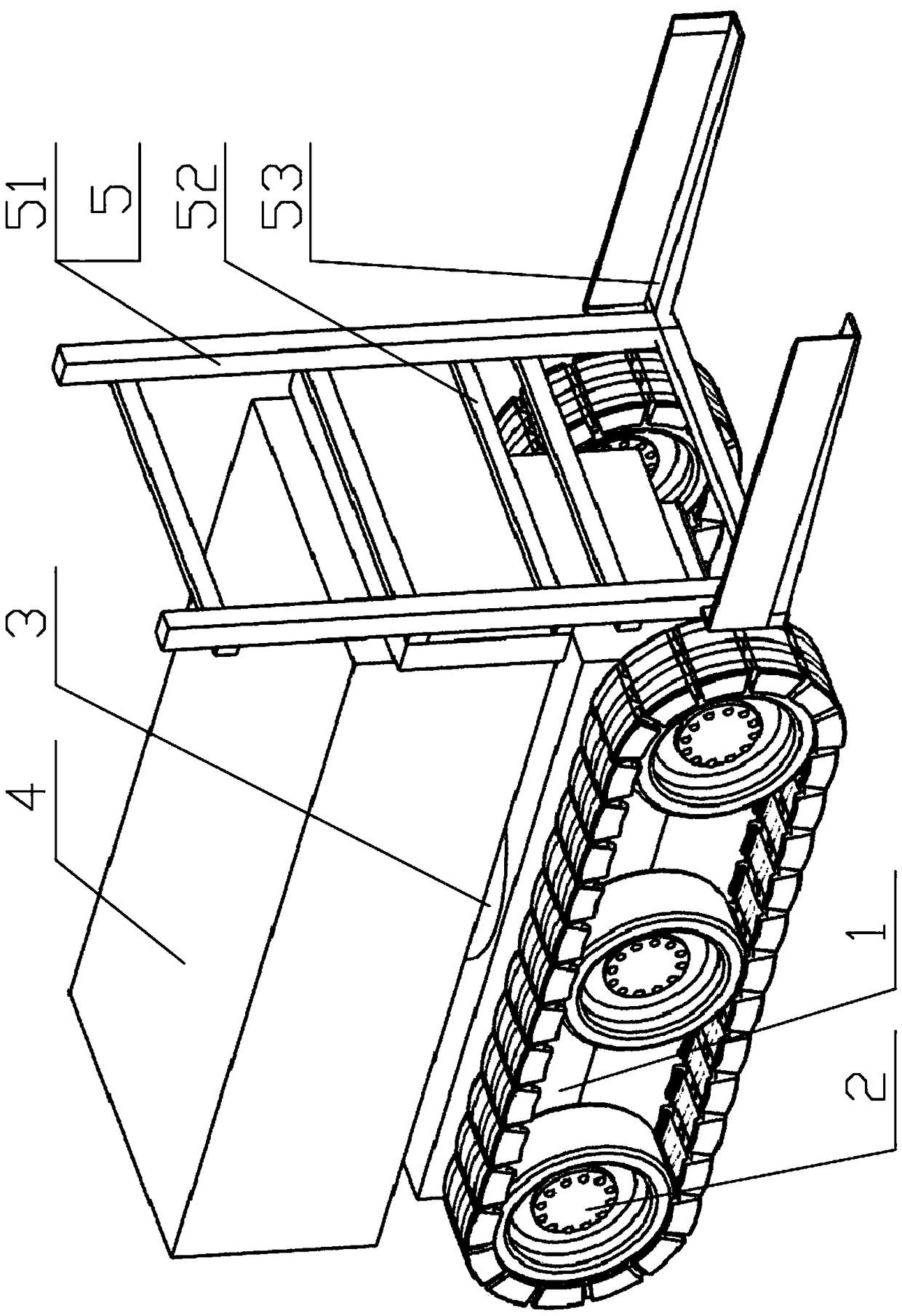

Logistics code fetching vehicle suitable for freight container

PendingCN107311081ARealize intelligent operationImprove loading and unloading efficiencyLifting devicesVehicle frameSlewing bearing

The invention discloses a logistics code fetching vehicle suitable for a freight container. The logistics code fetching vehicle comprises a vehicle frame, a walking part, a slewing bearing, a supporting platform, a work part, a hydraulic system and an electric control system. The work part comprises a door frame, a fork carrier and a fork. The electric control system comprises a battery set, an industrial control computer, a power loop, a data input and output port, a positioning chip, a positioning coordinate moving control loop, a distance feedback control loop, a fork span adjusting loop and a transshipment control loop. Whole geographical position coordinate information of an unloading platform is set in the industrial control computer, and the industrial control computer is electrically connected with the battery set, the data input and output port, the walking part, the hydraulic system, a fork pushing part, a code scanning recognition device on the fork carrier and a distance sensor. The logistics code fetching vehicle suitable for the freight container is relatively high in automation degree, capable of achieving intelligent operation and improving the loading and unloading efficiency and particularly suitable for freight loading and unloading stacking operation during containerized transportation of logistics warehousing.

Owner:XUZHOU DKEC ELECTRICAL TECH

Intelligent sheet metal part production system capable of adhering sponge automatically

ActiveCN108790193AGuarantee product qualityAvoid DimensionsMetal-working feeding devicesMaterial gluingMicrocomputerControl system

Owner:XUZHOU DKEC ELECTRICAL TECH

Speed reducer lubricating oil automatic adding mechanism with addition amount convenient to control

InactiveCN110500397AEasy to control the amount addedRealize quantitative addition functionGear lubrication/coolingAutomatic controlGear drive

The invention discloses a speed reducer lubricating oil automatic adding mechanism with the addition amount convenient to control. The mechanism comprises a substrate, fixing plates and a micro motor.An oil collecting box is mounted on the right side of the substrate through bolts, and an oil inlet is formed in the outer surface of the oil collecting box. The micro motor is mounted at the upper end of the oil collecting box, and an output end of the micro motor is fixedly connected with a cooling fan. The cooling fan is connected with the inner surface of the substrate. First air inlets are formed in the inner surface of the upper end of the substrate, and the inner surface of the substrate is fixedly connected with the fixing plates. According to the speed reducer lubricating oil automatic adding mechanism with the addition amount convenient to control, when lubricating oil in the device is consumed after long-time working or evaporates under a high temperature, the height of a movable floating block is moved downwards, accordingly, a transmission gear drives six seal blocks to automatically open through relative reset force of a torsional spring, accordingly, lubricating oil addition work is automatically performed, and an automatic lubricating oil addition function with the addition amount automatically controlled is achieved.

Owner:董涛

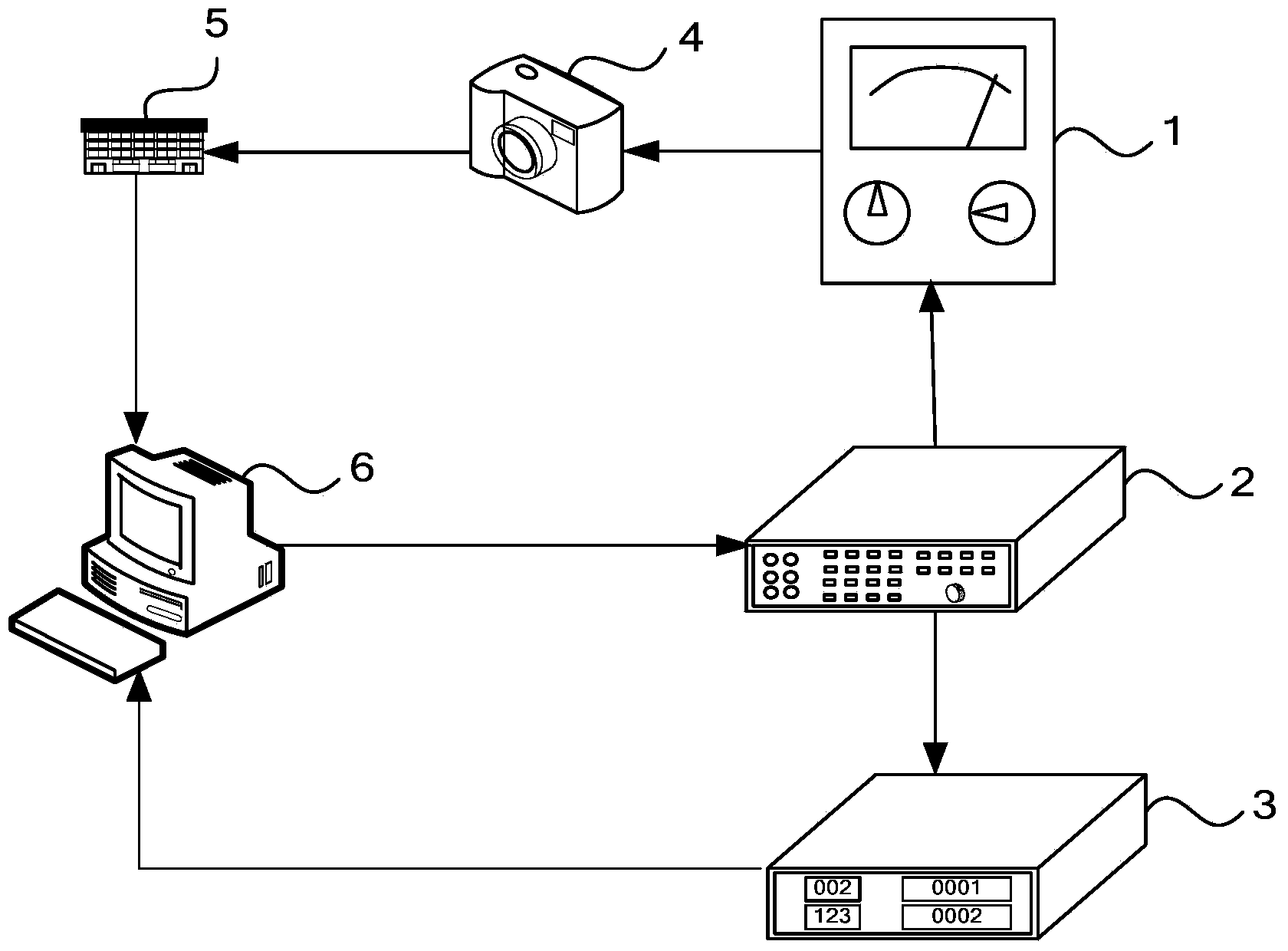

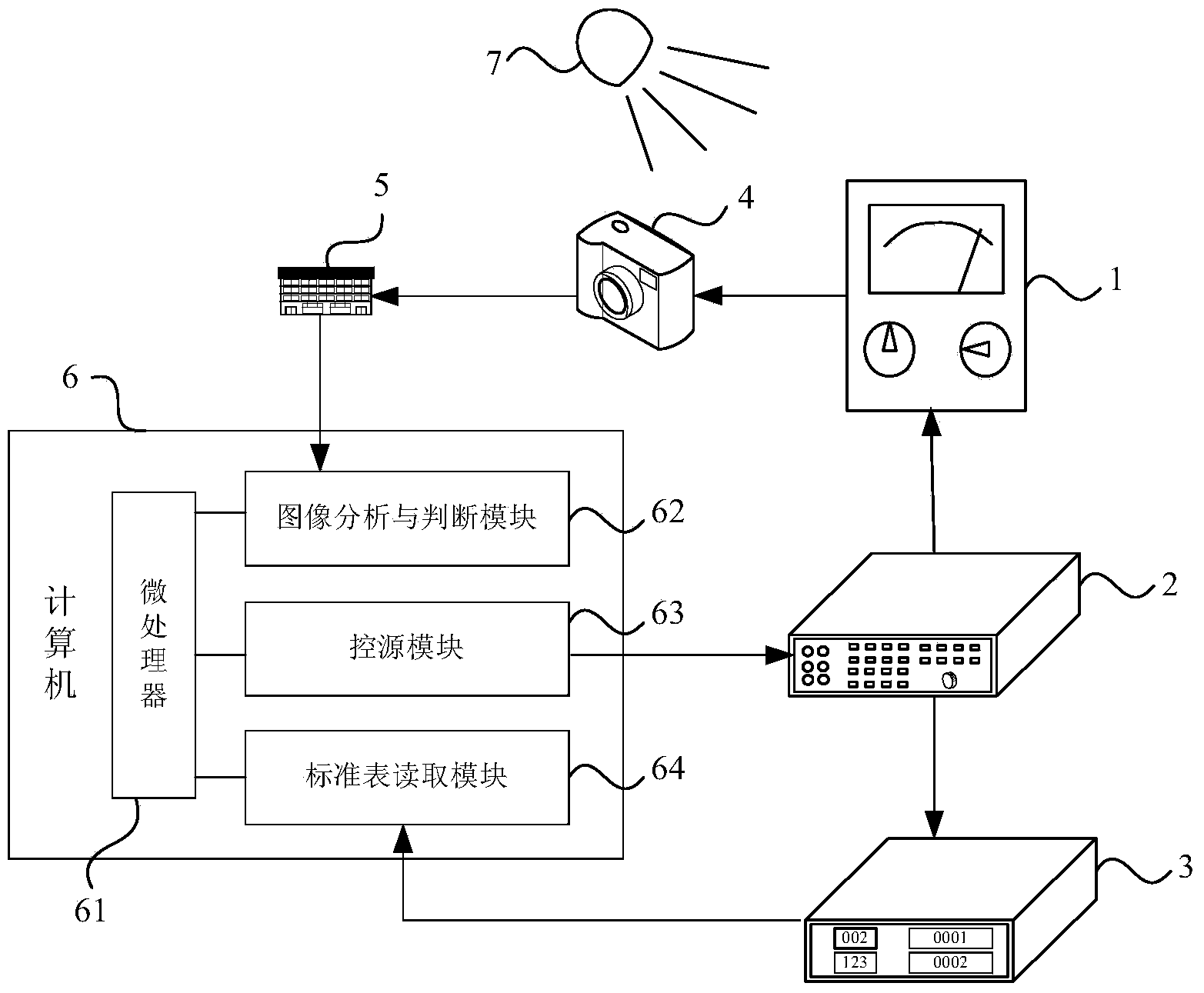

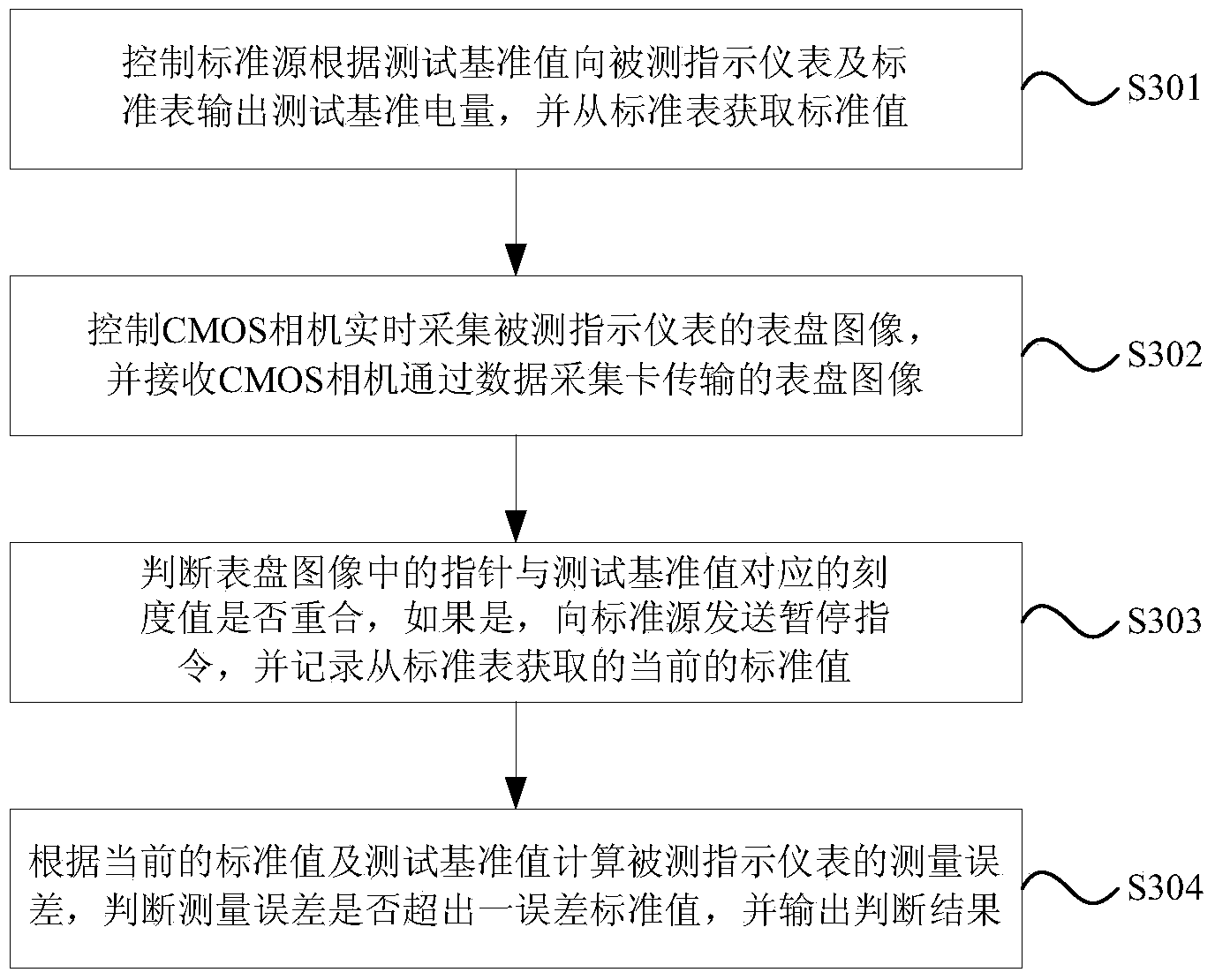

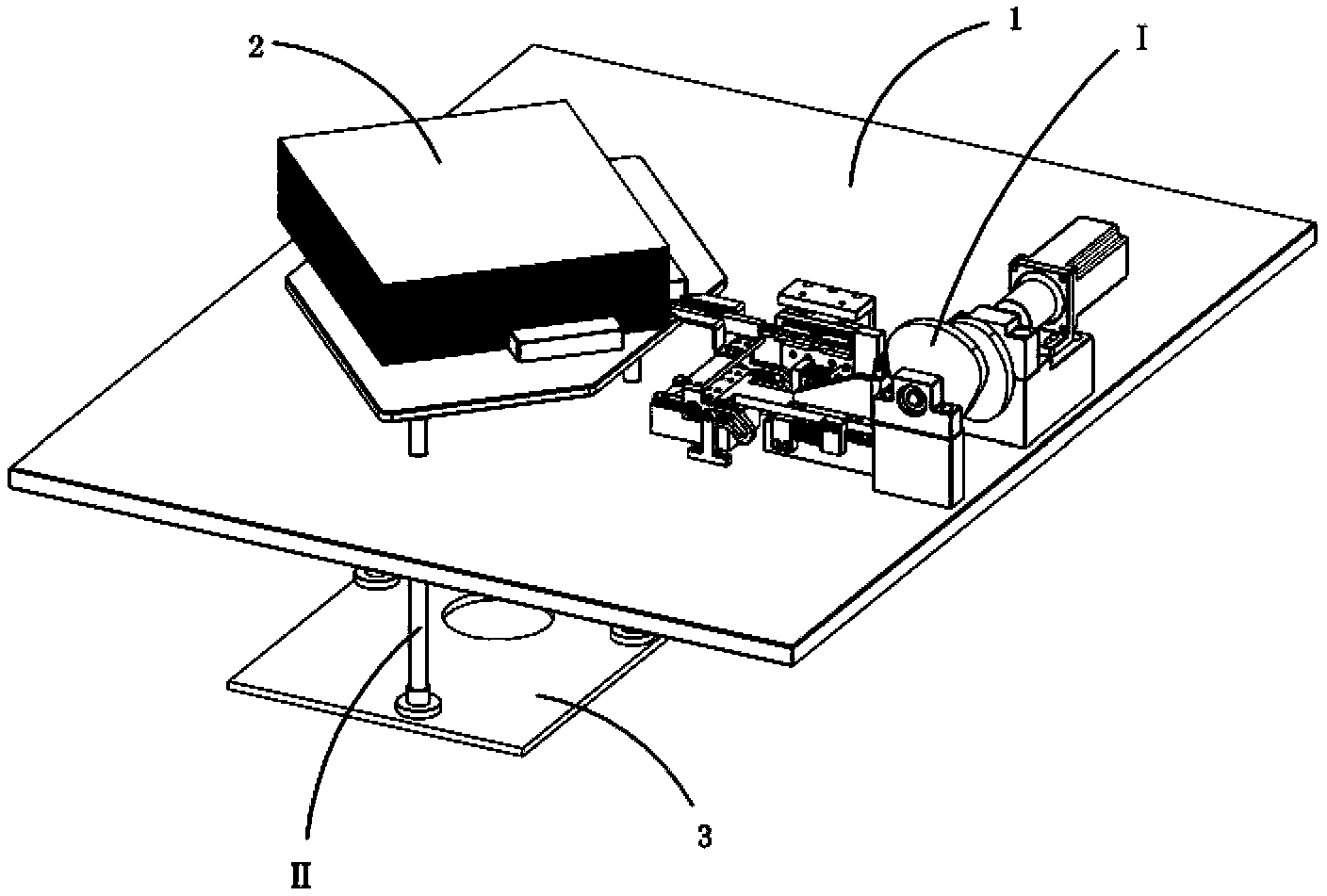

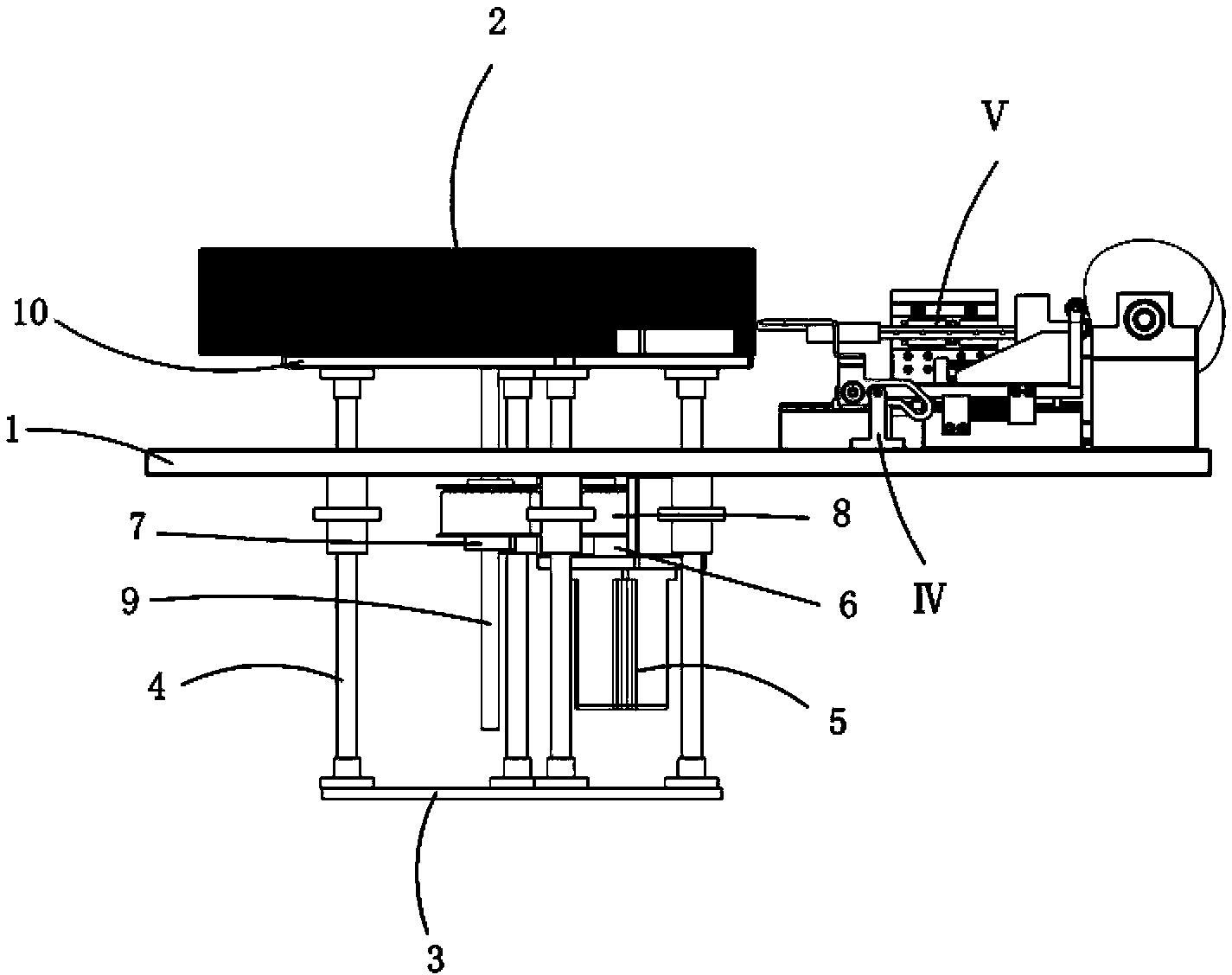

Indicating instrument detecting system and method

InactiveCN103983935AAvoid manual operationImprove detection efficiencyElectrical measurementsCMOSElectricity

The invention provides an indicating instrument detecting system and method. The detecting system comprises a detected indicating instrument, a standard source, a standard meter, a CMOS camera, a data acquisition card and a computer, wherein the standard source is connected with the detected indicating instrument, the standard meter and the computer, the CMOS camera is connected with the data acquisition card, and the data acquisition card is inserted into a card slot of the computer; the standard source outputs testing benchmark electricity quantity to the detected indicating instrument and the standard meter according to a testing benchmark value; the standard meter outputs a standard value generated according to the testing benchmark electricity quantity to the computer; the CMOS camera acquires an image of the dial plate of the detected indicating instrument in real time, and the image of the dial plate is transmitted to the computer through the data acquisition card; when a pointer in the image of the dial plate coincides with a scale value corresponding to the testing benchmark value, the computer sends a stopping instruction to the standard source, and a current standard value output by the standard meter to the computer is recorded; whether error exceeds an error standard value or not is judged by the computer according to the current standard value and the testing benchmark value, and a judgment result is output.

Owner:STATE GRID CORP OF CHINA +1

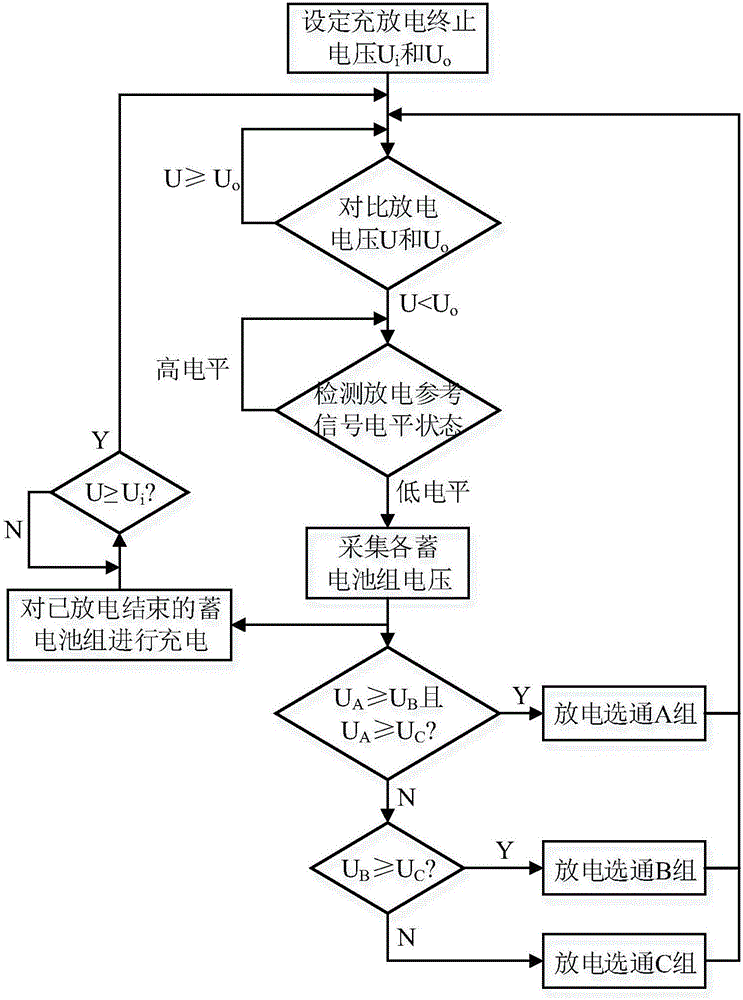

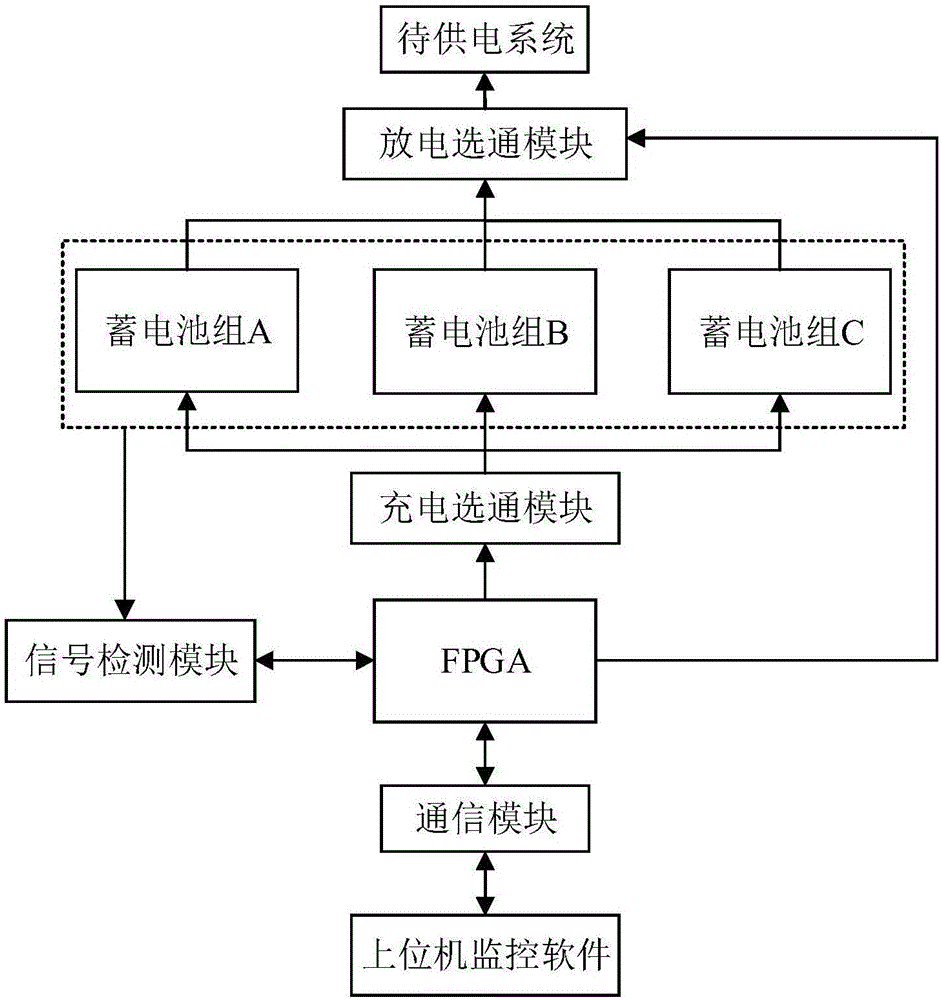

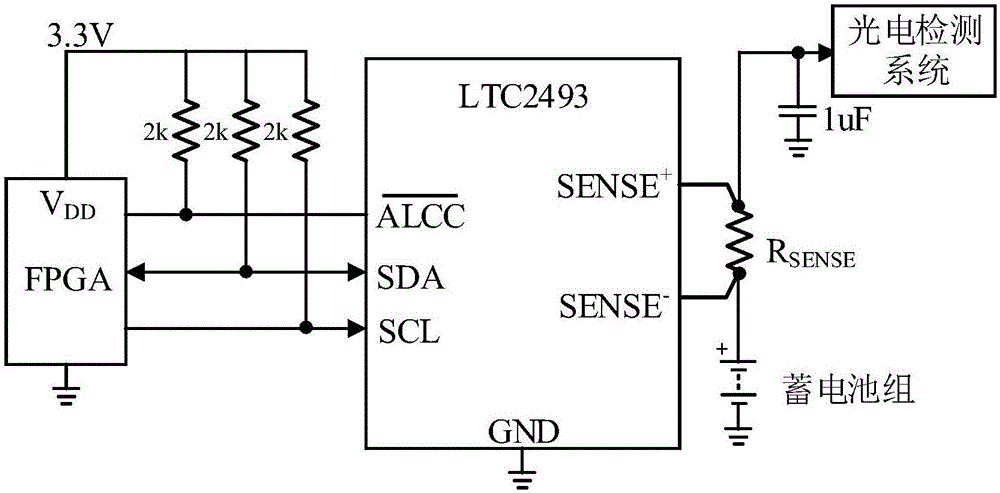

Automatic switching method and apparatus with remote monitoring function for backup storage battery packs

InactiveCN106549481ASimple design and operationHigh degree of intelligenceEnd cell switching arrangementsContinuous/uninterruptedComputer monitoring

The invention discloses an automatic switching method and apparatus with a remote monitoring function for backup storage battery packs. The automatic switching apparatus comprises a signal detection module, an FPGA, a discharge gating module, a charging gating module, a communication module and an upper computer monitoring module, wherein the automatic switching of the backup storage battery packs is realized through a synergistic effect of the modules by taking the voltage of each storage battery pack as basis. By adoption of the automatic switching method and apparatus, the automatic switching and remote monitoring of the backup storage battery packs can be realized, so that continuous and uninterrupted work of a to-be-powered system can be ensured; and in addition, the automatic switching apparatus is simple in operation, high in intelligent degree, capable of avoiding shortcomings existing in manual operation, and applicable to application occasions which has relatively high requirement on the quality of the power supply and needs long-term uninterrupted power supply.

Owner:HEFEI UNIV OF TECH

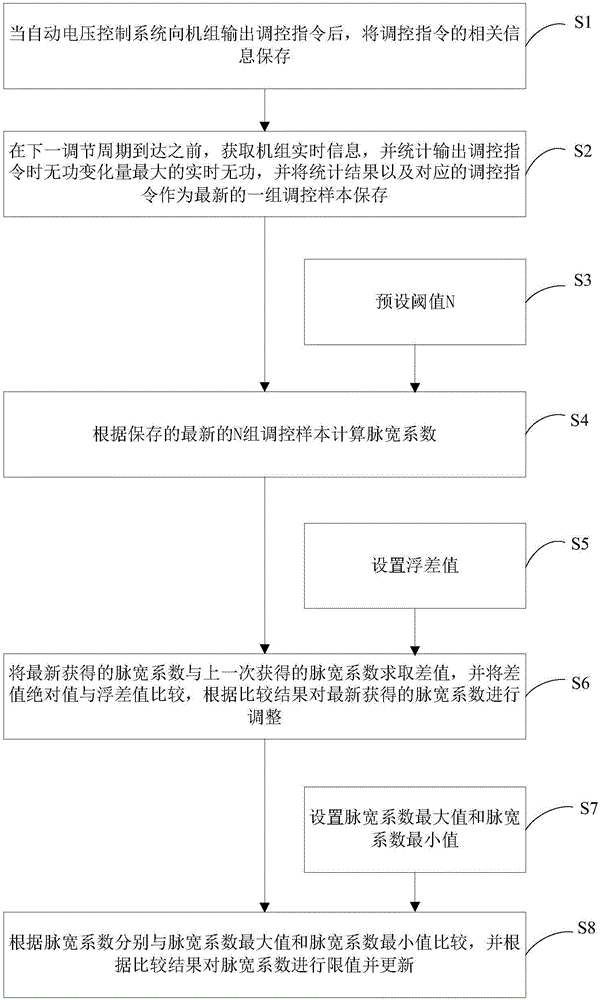

Pulse coefficient calculation method for automatic voltage control system of thermal power plant

ActiveCN106786811AConvenient statisticsHigh speedSingle network parallel feeding arrangementsTime informationAutomatic control

The invention discloses a pulse coefficient calculation method for an automatic voltage control system of a thermal power plant. The pulse coefficient calculation method comprises the following steps of S1, storing related information of a control instruction after the automatic voltage control system outputs the control instruction to a machine set; S2, acquiring real-time information before the next regulation period is reached, counting real-time reactive power with maximum reactive power change quantity during outputting the control instruction, and taking a counting result and a corresponding control instruction as a group of newest control samples to be stored; S3, presetting a threshold value N; and S4, calculating a pulse coefficient according to the N groups of newest control samples which are stored. According to the pulse coefficient calculation method, the pulse coefficient of the machine set is automatically calculated in real time according to each control instruction emitted from the automatic voltage control system to the machine set during the running process of the machine set, the defect of manual operation is prevented, and the calculation accuracy and efficiency of the pulse coefficient are favorably improved.

Owner:LEADZONE SMART GRID TECH

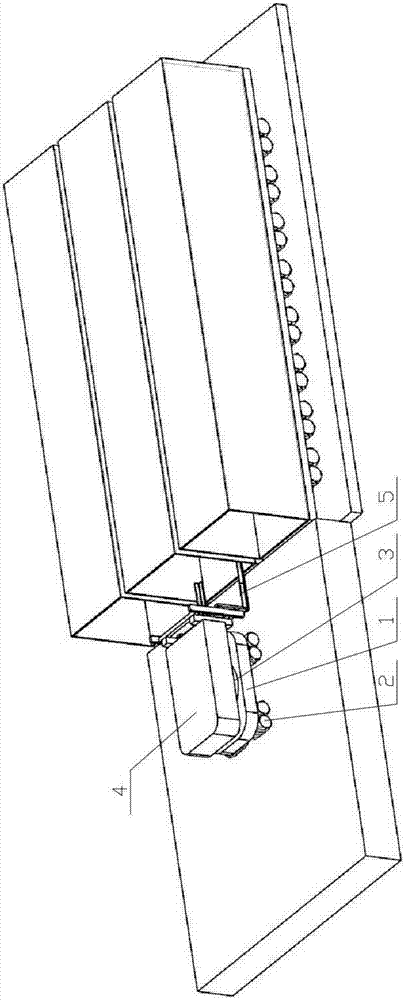

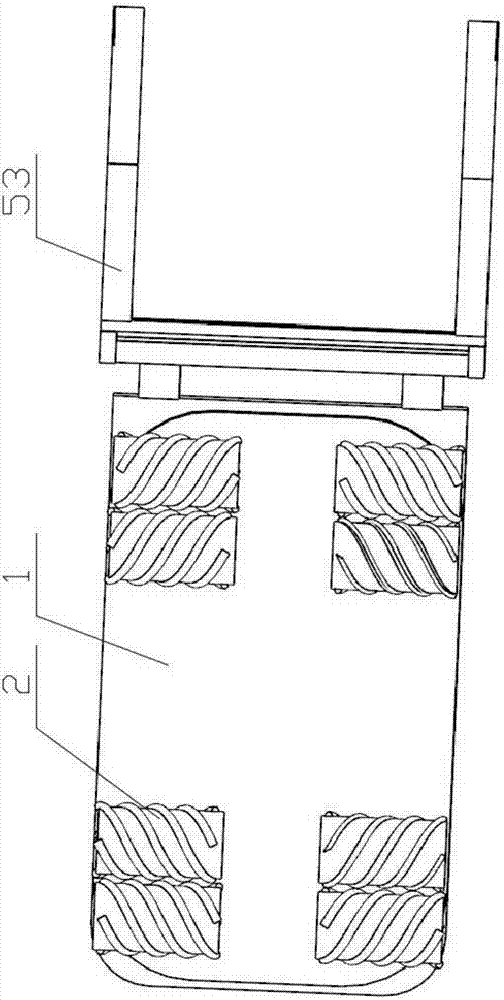

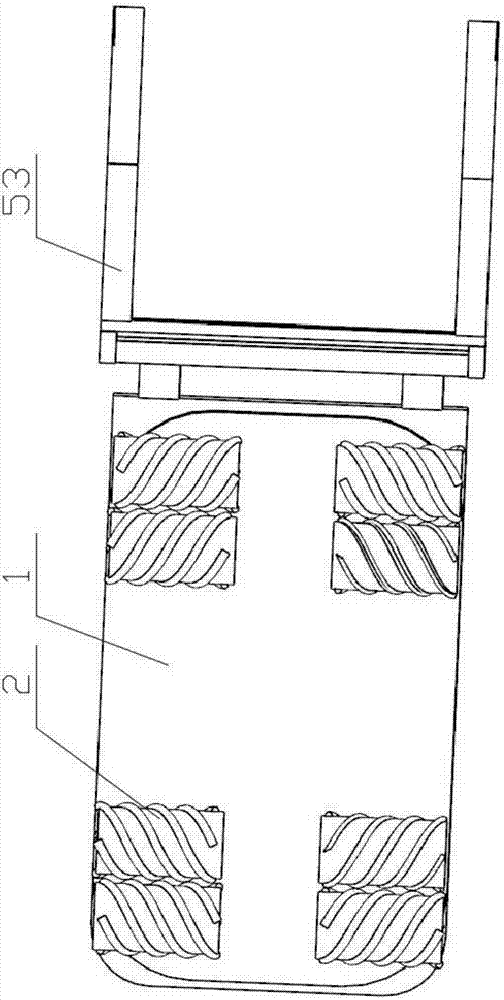

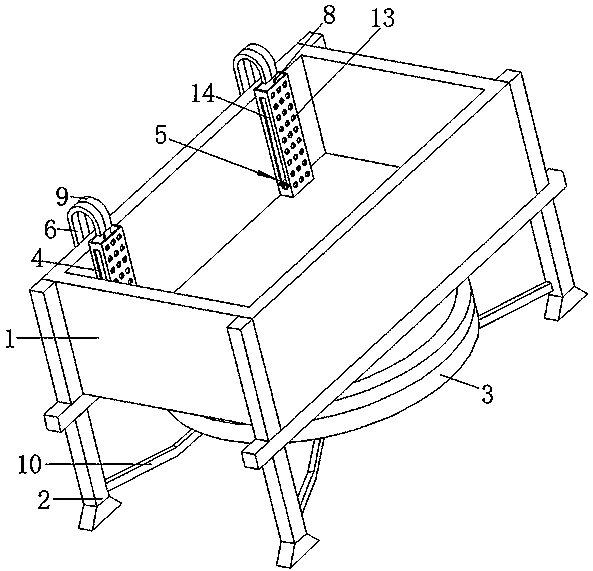

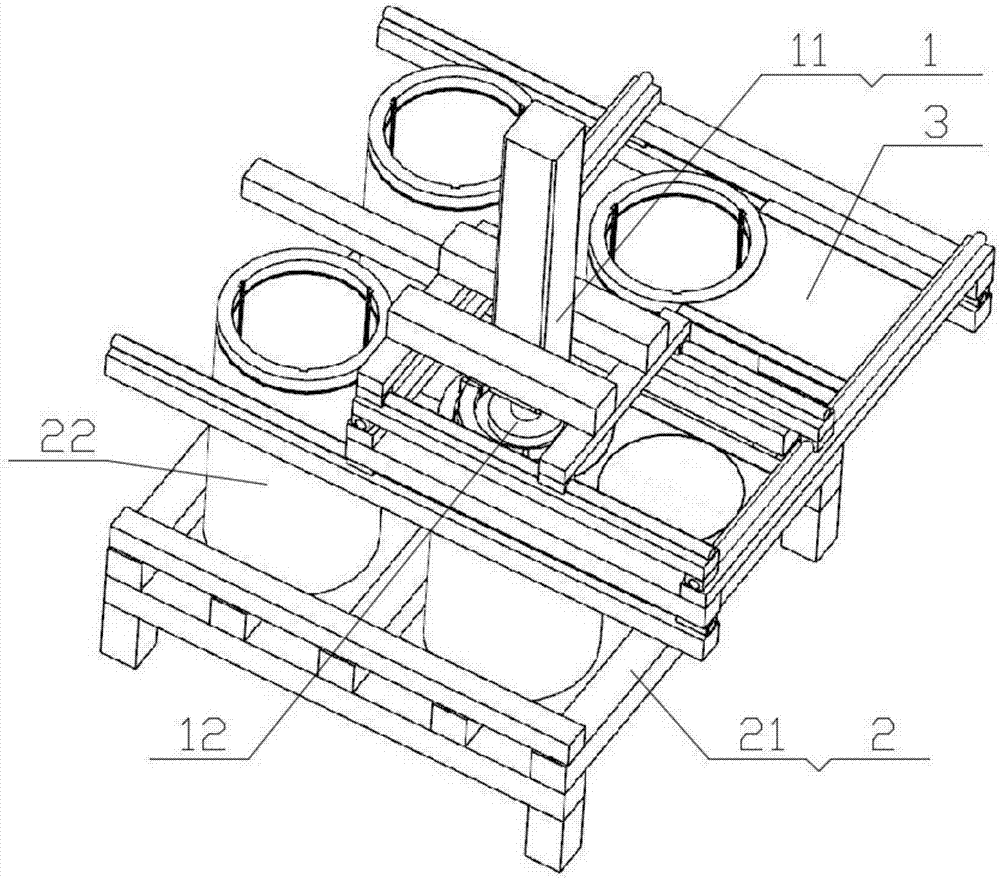

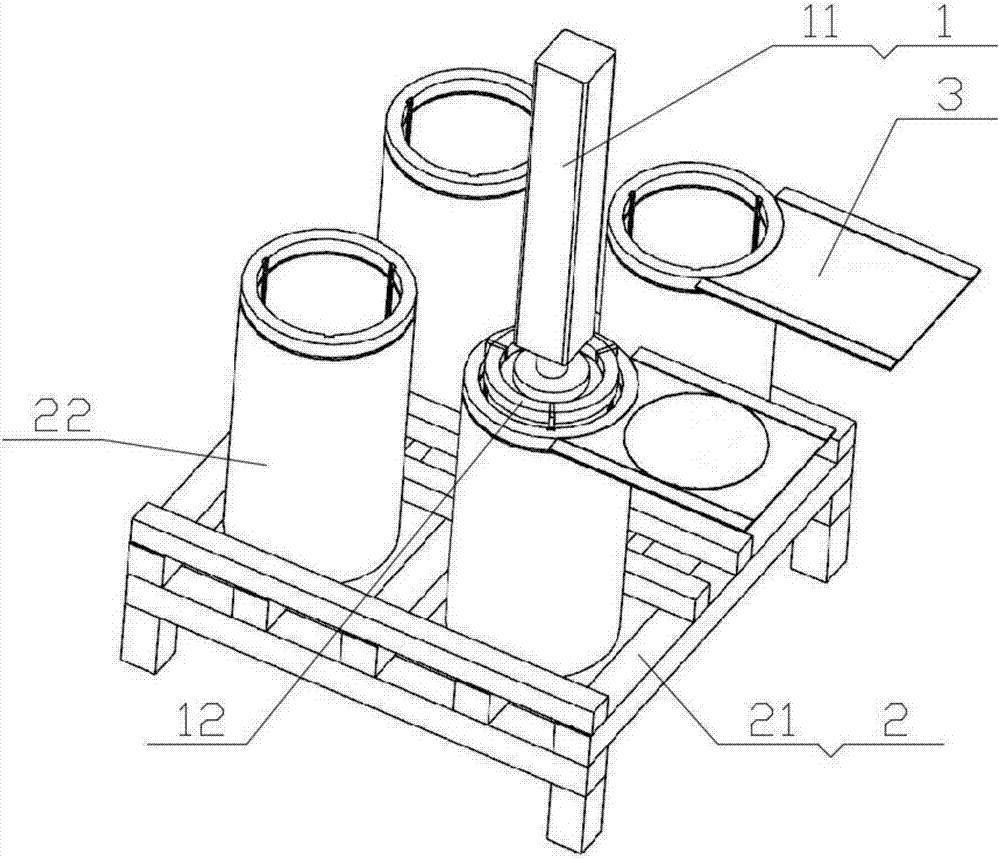

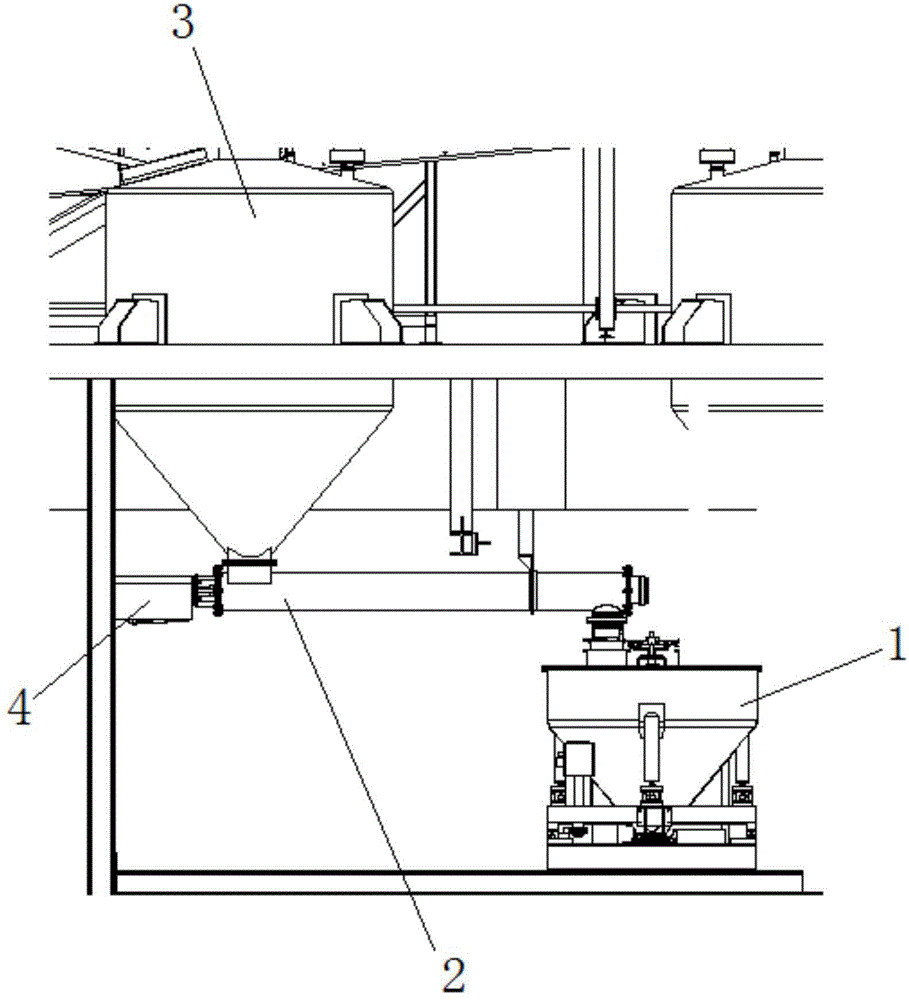

Full-automatic locking barrel type sampling, sample preparation and packaging system for bulk materials

ActiveCN106428658AOperating skill proficiency limitAvoid the impact of production schedulePackaging automatic controlSolid materialProduction scheduleElectric control

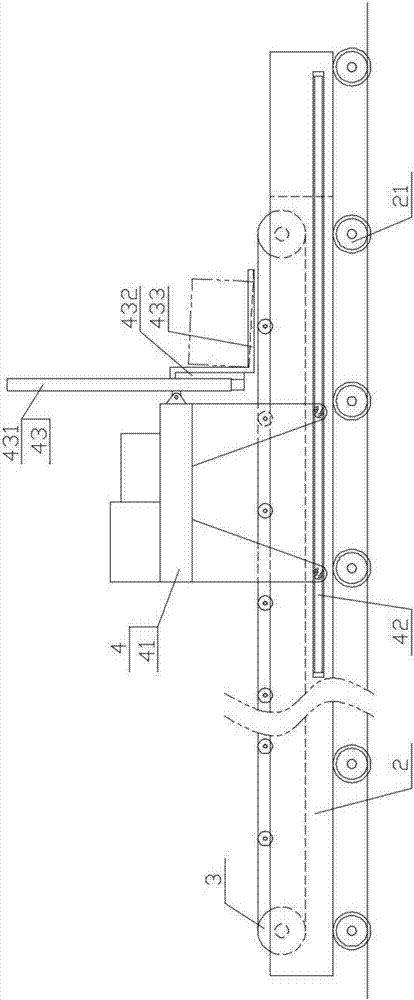

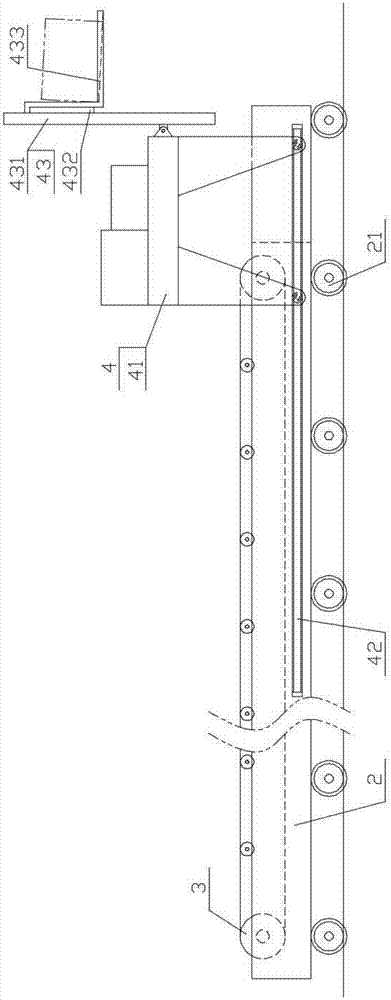

The invention discloses a full-automatic locking barrel type sampling, sample preparation and packaging system for bulk materials. The system comprises filling devices (1), barrel supply conveying devices (2), a transfer conveying device (3), a sealing device (4), a packaging barrel (5) and an electric control device. The system completely adopts computer-controlled automatic operation of filling and packaging, the effect of human factors such as responsibility, emotions and the like of operators on the production schedule can be avoided through the automatic operation, meanwhile, the limitation of proficiency of the operating skill of the operators can be avoided, human and sample separation can be realized, man-made cheating can be avoided, and defects of manual operation can be completely avoided; the state of the packaging barrel is completely controlled, a manager can inquire the working condition of the packaging barrel in real time, and use data of the packaging barrel can be recorded by a central control computer and can be checked conveniently at any time; and samples have the higher safety, and the system is particularly applicable to filling and packaging of the bulk materials for sampling and sample preparation.

Owner:国能南京煤炭质量监督检验有限公司 +1

Electroplating unit capable of conveniently adjusting liquid level of electroplating water tank

The invention discloses an electroplating unit capable of conveniently adjusting the liquid level of an electroplating water tank, and belongs to the technical field of electroplating machining. The electroplating unit capable of conveniently adjusting the liquid level of the electroplating water tank comprises the electroplating water tank, symmetrical supporting legs are fixedly connected with the four corners of the bottom of the electroplating water groove, an electroplating liquid storage box is arranged at the bottom of the electroplating water tank, a liquid level pipe is fixedly connected with the inner wall of the electroplating water tank, a floating plate is in sliding connection with the liquid level pipe, an S-shaped sleeve pipe is fixedly connected with the outer wall of theelectroplating water tank, the top end of the S-shaped sleeve pipe is arranged above the liquid level pipe, the bottom end of the S-shaped sleeve pipe is extended downwards and is connected with the electroplating liquid storage box through a fixing block, the floating plate is connected with the S-shaped sleeve pipe through a traction rope, and the traction rope sequentially penetrates through the S-shaped sleeve pipe and the fixing block and extends into the electroplating liquid storage box. Operation is convenient, the operation that electroplating liquid is added through manual observation is abandoned, defects of manual operation are avoided, and automatic adding of the electroplating liquid is achieved.

Owner:湖州金业表面科技有限公司

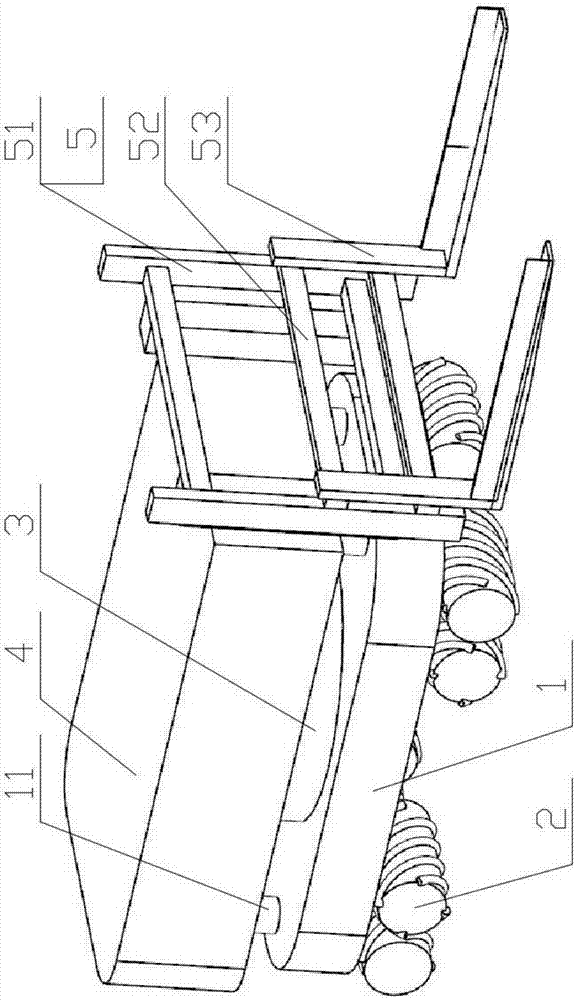

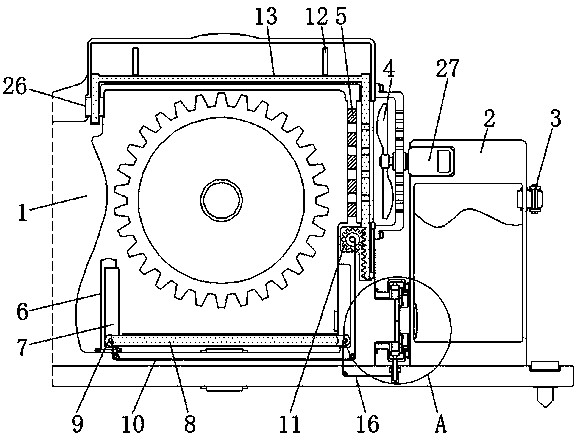

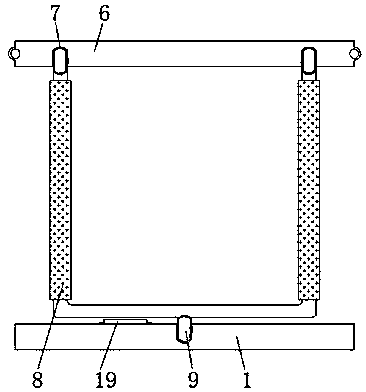

Punching sheet metal factory thin flat plate separation grabbing and stacking unit

ActiveCN106966181ARealize split captureAvoid responsibilityConveyorsStacking articlesPunchingBarrel Shaped

The invention discloses a punching sheet metal factory thin flat plate separation grabbing and stacking unit. The punching sheet metal factory thin flat plate separation grabbing and stacking unit comprises a grabbing and stacking mechanical arm, a stacking bracket, a stacking platform and an electronic control device. The grabbing and stacking mechanical arm comprises a mechanical arm body and a grabbing and stacking manipulator. The grabbing and stacking manipulator is installed at the tail section of the mechanical arm body and comprises a grabbing mechanism of a planar structure. The stacking bracket comprises a bracket body and plate stacking frames. Each plate stacking frame is of a vertically-arranged barrel-shaped structure. An annular port is formed in the top end of each barrel-shaped structure. The size of the inner surface of each barrel-shaped structure is in clearance fit with the shape size of a thin flat plate type sheet metal part. A workpiece positioning mechanism and a position sensor are arranged on the upper surface of the stacking platform. The electronic control device comprises an industrial control computer, a positioning grabbing and stacking loop and a pushing and separation loop. The punching sheet metal factory thin flat plate separation grabbing and stacking unit can achieve intelligent operation, avoids the potential safety hazards of manual operation meanwhile improves the production efficiency, and is especially suitable for automatic grabbing and stacking of thin flat plate type sheet metal parts of regular shape structures.

Owner:XUZHOU DKEC ELECTRICAL TECH

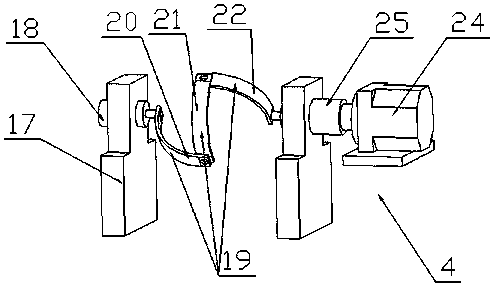

Steel wire rope end and anchor head lock automatic pouring system and control method thereof

InactiveCN108145130AAvoid the disadvantages of manual operationIncrease productivityMolten metal pouring equipmentsCasting safety devicesElectricityEngineering

The invention discloses a steel wire rope end and anchor head lock automatic pouring system and a control method of the system. The system comprises a preheating constant temperature furnace, a workpiece transfer device, a constant temperature pouring furnace and an integrated electric control device. The preheating constant temperature furnace comprises a furnace body, a furnace door and a preheating furnace electric control mechanism. The workpiece transfer device comprises a guide rail, a workpiece bracket and a workpiece transfer electric control mechanism. The constant temperature pouringfurnace comprises a supporting chassis, an electric melting furnace and a pouring furnace electric control mechanism. The integrated electric control device comprises a central controller, a preheating control loop, an electric melting furnace melting control loop, a workpiece transfer control loop and a pouring control loop. The steel wire rope end and anchor head lock automatic pouring system is a digital control system, workpiece preheating, workpiece transfer and workpiece pouring can be automatically completed in sequence through concentrated control of a central control computer of theconcentrated electric control device, the production efficiency is high, potential safety hazards are low, and the system is particularly applicable to a pouring working procedure for steel wire ropedeep machining in a pouring way.

Owner:徐州道亨机械科技有限公司

Machinery for carrying, turning and laying floor tiles

The invention discloses machinery for carrying, turning and laying floor tiles. The machinery comprises an upper support frame and a lower support frame, wherein the upper support frame and the lower support frame are of telescopic structures and are connected through a hinge; an armrest is arranged on the upper support frame; an air inlet press button switch is arranged on the armrest; wheels, a braking device and an L-shaped bracket are arranged at the lower part of the lower support frame; the upper part of the lower support frame is provided with a vacuum suction disc; the vacuum suction disc is in open connection with the air inlet press button through a rubber pipe; in the use process, the machinery only needs to extend to be flatly put onto the ground; the floor tiles are put into the L-shaped bracket and on the vacuum suction disc; mortar is smeared; the armrest is held to stand up by the hand and is pushed to the laying positions; a brake pedal is pedaled down; the wheels are used as fulcrums; the lower support frame rotates towards the front lower side; the upper support frame backwards folds; the floor tiles can be easily turned and put into the pasting position; the air inlet press button switch is pressed down, so that the floor tiles are released by the vacuum suction disc. The machinery has the advantages that the structure is simple; the use is convenient; the work intensity is greatly reduced; the work efficiency is improved.

Owner:李晨晨

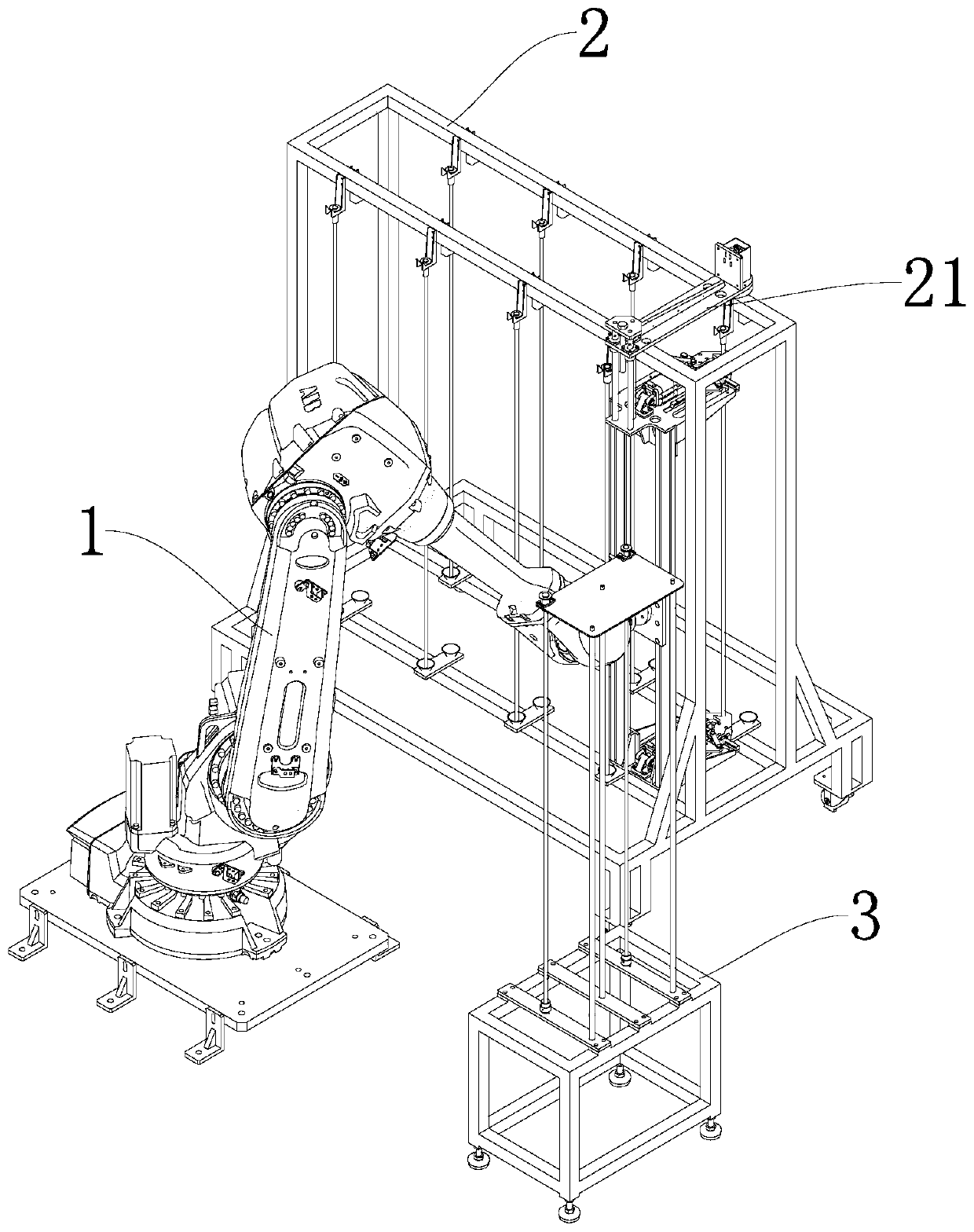

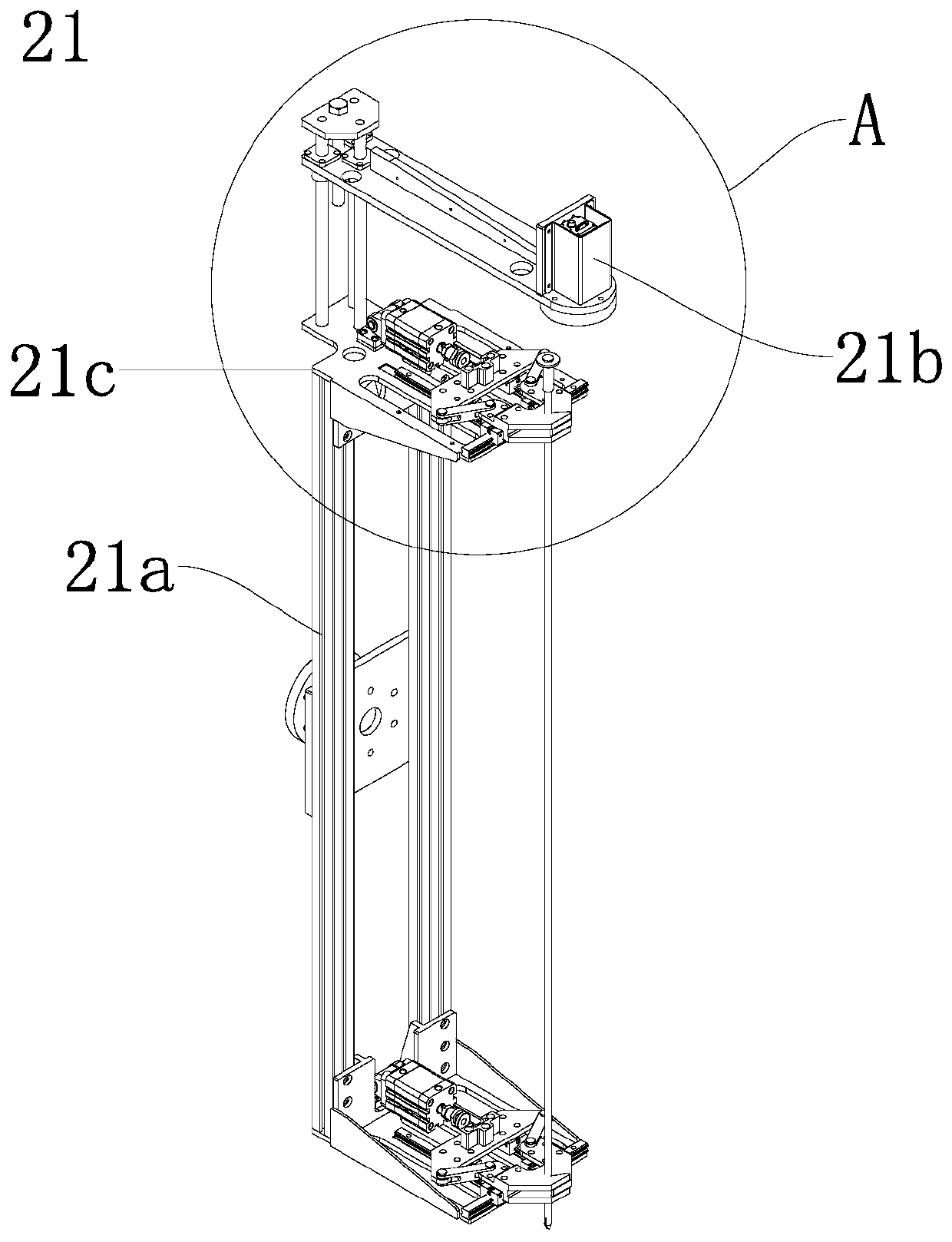

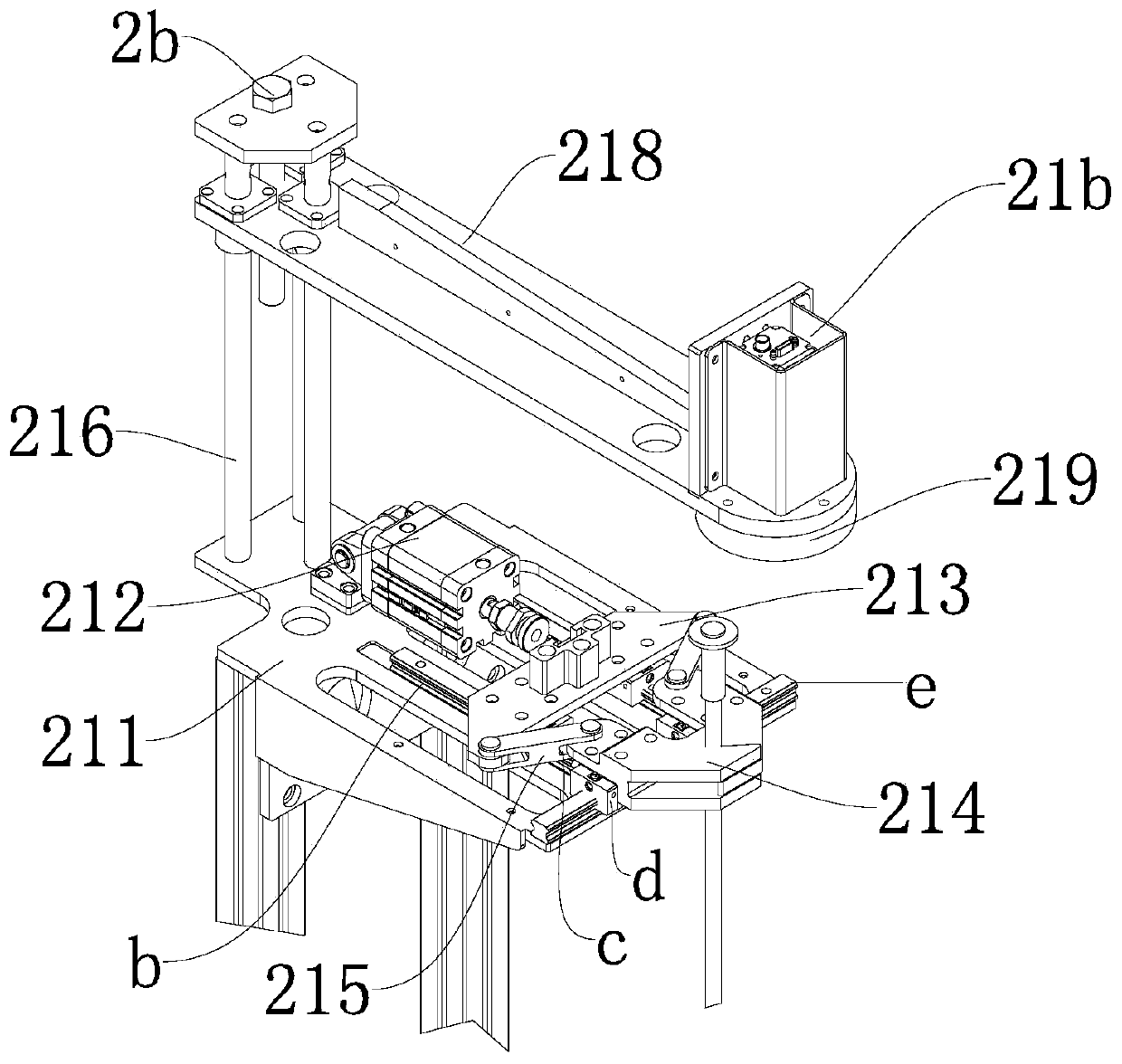

Robot hanging system

PendingCN111003489APrevent fallingAccurate captureConveyor partsVision processingControl engineering

The invention discloses a robot hanging system which includes an industrial robot and a hanger car. The hanger car is provided with a hanger table in a connected manner, the hanger table includes a bracket, a camera system and a jig table, the jig table is connected to the bracket, the camera system is connected to the upper end of the fixture table, the camera system is used for photographing a hanger and transmitting photos to a visual processing system, and the visual processing system performs processing and analyzing on the collected photos to obtain position information of the hanger andsends the position information to the industrial robot. The robot hanging system directly collects and processes the position information of the hanger, so that errors of the stop position of the hanger car and the installation position of the hook are eliminated, and accurate grasping of the hanger by the industrial robot is facilitated; and meanwhile, the robot hanging system can also avoid disadvantages of manual operation, saves labor cost and increase the production efficiency by more than 10%.

Owner:XIAMEN TUBETECH INC

An artificial intelligence sheet metal production system

ActiveCN105642781BGuarantee product qualityAvoid DimensionsMetal-working feeding devicesMaterial gluingMicrocomputerLogistics management

The invention discloses an artificial intelligence sheet metal part producing system. The system comprises a material supply unit (1), a formed sheet metal part automatic taking and stacking unit (2), an intelligent logistics carrying and transporting unit (3) and a centralized electronic control unit (7). The formed sheet metal part automatic taking and stacking unit comprises a plurality of counting and stacking devices (22) arranged nearby the discharging end of a sheet metal machining device (8); each counting and stacking device comprises a grabbing and stacking part II(221), a stacking bracket (222) and an electronic control part; and each stacking bracket comprises a plurality of containing spaces (2221) evenly arranged in the horizontal and vertical direction and an electronic control mechanism. According to the artificial intelligence sheet metal part producing system, the grabbing and stacking parts II controlled by a microcomputer stretch into the sheet metal machining device and are used for grabbing punched and formed sheet metal parts from the discharging end and sequentially stacking the sheet metal parts in the containing spaces of the stacking brackets, and the artificial intelligence sheet metal part producing system is a digital control system and can be seamlessly connected with a digital bus in a factory to achieve centralized digital management.

Owner:XUZHOU DKEC ELECTRICAL TECH

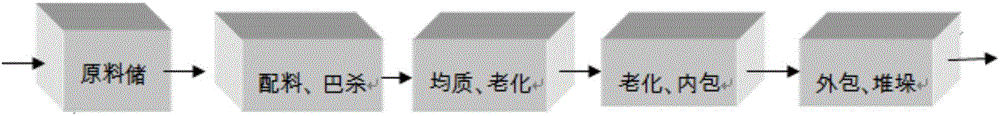

Charging and weighing system and charging and weighing method for cream production line

ActiveCN105966941AReduce dynamic errorHigh precisionConveyorsLiquid transferring devicesProduction lineButt joint

The invention relates to a charging and weighing system for a cream production line. The system comprises a powder material charging and weighing device and a liquid material charging and weighing device; the powder material charging and weighing device comprises powder material storage tanks, a spiral propelling mechanism, a weighing trolley and a variable-frequency motor; the initial end of the spiral propelling mechanism is horizontally and fixedly arranged at the lower part of the powder material storage tank, the variable-frequency motor is used for driving the spiral propelling mechanism; the lower part of the tail end of the spiral propelling mechanism is in butt joint with a feeding hole of the weighing trolley; the weighing trolley is in matched butt joint with a row of corresponding powder material storage tanks above a horizontal track; the weighing trolley is in signal connection with a PLC of the variable-frequency motor, the variable-frequency motor gradually decelerates according to a weighing signal, and the weighing trolley stops rotation after reaching a target weight; the liquid material charging and weighing device comprises liquid material storage tanks and pipeline type mass flowmeters which are connected with each other; and an electromagnetic stop valve is arranged at the tail end of the pipeline of each pipeline type mass flowmeter, and the opening and closing of the electromagnetic stop valve respectively control the operation and stop of liquid material charging.

Owner:SHANGHAI HI ROAD FOOD TECHNOLOGY CO LTD

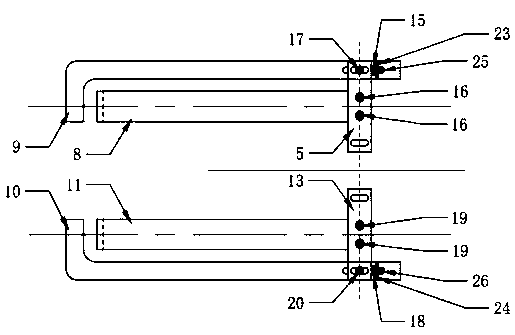

Automatic welding unit of automatic welding production system of net rack connecting rods

PendingCN110480121AAutomate operationHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManipulator

The invention discloses an automatic welding unit of an automatic welding production system of net rack connecting rods. Steel pipe workpieces can be axially positioned accurately through steel pipe radial clamping and positioning devices, bolts can be accurately coordinate-grabbed and put in the ends of the steel pipe workpieces before welding through a bolt grabbing and stacking mechanical arm and a bolt grabbing and stacking mechanical hand, sealing plate or cone head workpieces can be accurately and coaxially coordinate-positioned at the welding ends of the steel pipe workpieces through sealing plate or cone head pushing devices, through cooperative work of steel pipe rotation drive devices and welding gun devices, the steel pipe workpieces can be controlled through the cooperation ofwelding guns and the steel pipe rotation drive devices to circumferentially rotate to complete one-time welding forming of complete annular weld joints, the automation degree is high, the defects of manual operation can be avoided, the uniformity of the welding weld joints can be guaranteed on the premise of guaranteeing the coaxiality of through holes of sealing plates or cone heads and steel pipe bodies, and the automatic welding unit is especially suitable for the automatic welding production system of the net rack connecting rods.

Owner:浩德重工科技(江苏)有限公司

Logistics forklift capable of automatically balancing weight of cargos

InactiveCN109292680ARealize intelligent operationImprove loading and unloading efficiencyLifting devicesPower circuitsDistance sensors

The invention discloses a logistics forklift capable of automatically balancing weight of cargos. The logistics forklift comprises a frame, a travelling part, a slewing bearing, a supporting platform,a working part, a hydraulic system and an electric control system, wherein the working part comprises a portal frame, a fork frame and a fork; the electric control system comprises a battery pack, anindustrial control computer, a power circuit, a data input and output port, a positioning chip, a positioning coordinate movement control loop, a distance feedback control loop, a fork span adjustment loop and a transfer control loop, wherein whole geographic position coordinate information of a loading and unloading platform is arranged inside the industrial control computer, and the industrialcontrol computer is electrically connected with the battery pack, a data input and output port, the travelling part, the hydraulic system, a fork pushing and moving part, a code scanning and identifying device on the fork frame and a distance sensor correspondingly. The logistics forklift capable of automatically balancing the weight of the cargos is high in automation degree and capable of achieving intelligent operation, the loading and unloading efficiency is improved, and is particularly suitable for loading and unloading cargo stacking operation in logistics storage.

Owner:徐州涡轮空间汽车科技有限公司

Cam paper-counting mechanism

The invention relates to a cam paper-counting mechanism comprising a base plate, a cam mechanism, a lift mechanism and paper sheets. A motor of the cam mechanism drives a cam A, a cam B and a cam C, the cam A drives a bearing A to rotate, a sliding plate A pushes forwards a guide plate, and a guide groove rotates around a pin roll to drive a push plate to move to allow a press board to move forwards and press downwards; the guide groove slides forwards under the cam B through a bearing B to drive a cam follower to move in the guide groove to allow a needle to move back and forth; the cam C drives a sliding plate C to move forwards to allow a bearing D to rotate so as to drive a wedge-shaped connecting plate to ascend as well as the needle, the needle ascends and moves forwards to touch one corner of one paper sheet and push the same to move forward, the press board then moves forwards to be inserted into the paper sheets and press downwards, one paper sheet is separated from those on the upper portion, meanwhile, the lift mechanism lowers the height of the paper sheets, when the cam mechanism rotates in one circle, the height of one paper sheet is just lowered, so that the number of paper sheets can be counted in repeated motions of the cam paper-counting mechanism.

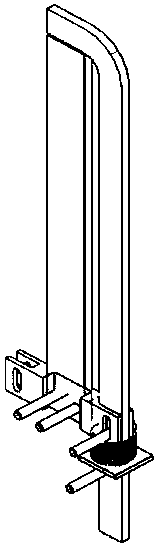

A clamp-type high-temperature extensometer with adjustable spacing

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A pretreatment device for testing the content of feces

InactiveCN105675377BComplete dilutionAvoid the disadvantages of manual operationPreparing sample for investigationHuman bodyDecomposition

The present invention relates to the technical field of medical and healthcare clinical examination. A pre-treatment device for examining fecal contents, wherein the technical solution is as follows: the pre-treatment device for examining fecal contents comprises a drive means (1), a fluid storage cylinder (2), a cleaning means (3) and a stirring means (4) disposed in the fluid storage cylinder (2). The beneficial effect thereof is as follows: the processes of dilution, stirring and filtering of feces are all carried out by mechanical means, which is highly efficient and can ensure that the feces are in contact with air for aerobic respiration to cause damage or decomposition to the formed elements, thus avoiding the drawback of requiring manual operations in conventional examining devices. Moreover, after addition of water or saline, by actuating a motor A (24), the fluid storage cylinder (2) can be shaken from side to side, such that feces on sidewalls of the fluid storage cylinder (2) can be diluted more thoroughly, thus avoiding residual solidified clumps of feces from forming on the sidewalls of the fluid storage cylinder (2); and placing the feces in the fluid storage cylinder (2) prevents pungent odor of feces from affecting the human body, thus eliminating sensory discomfort for operators.

Owner:南通市京山锦纶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com