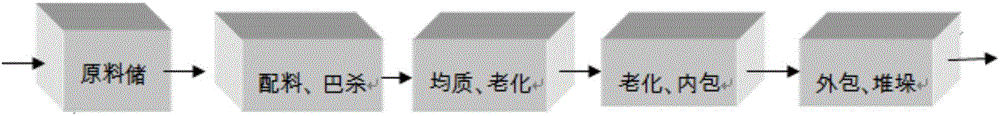

Charging and weighing system and charging and weighing method for cream production line

A production line and material weighing technology, applied in loading/unloading, special distribution devices, conveyors, etc., can solve the problems of poor quality control of feeding materials, low quality control of quality, unfavorable product quality control, etc., to achieve work The effect of high efficiency, ingenious design, and enhanced measurement security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

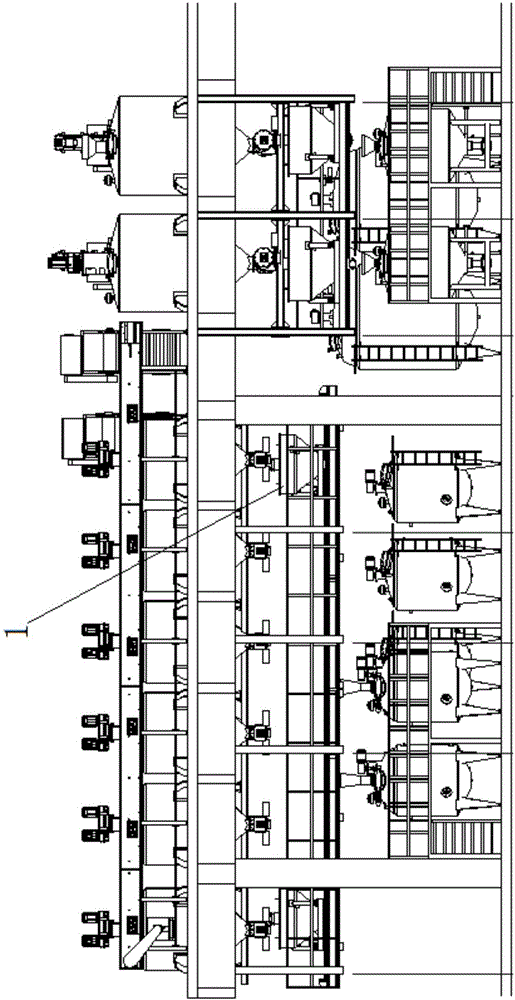

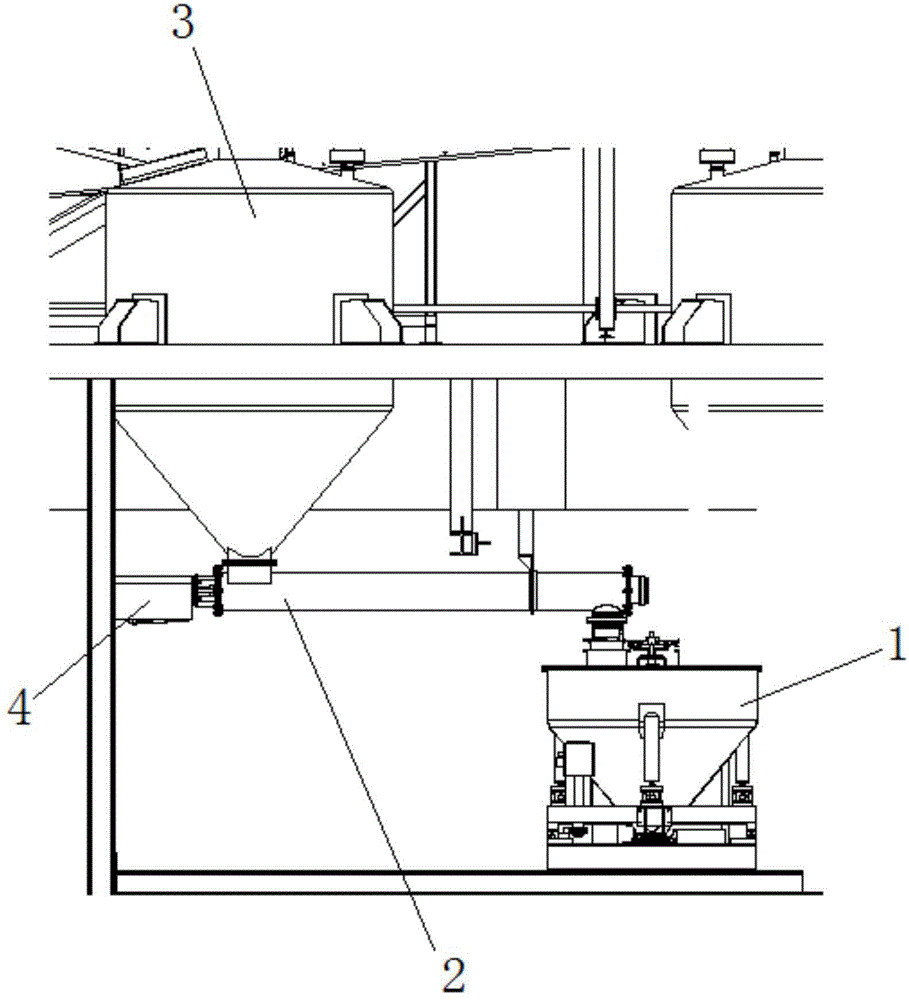

[0022] see Figure 1-Figure 3 , a feeding and weighing system for a cream production line, comprising a powder feeding and weighing device, and a liquid feeding and weighing device; the powder feeding and weighing device includes a powder storage tank 3, a screw propulsion mechanism 2, a weighing trolley 1, The variable frequency motor 4; the starting end of the screw propulsion mechanism 2 is fixed horizontally on the lower part of the powder storage tank 3, and the frequency conversion motor 1 and the screw propulsion mechanism 2 are coaxially arranged to drive the screw propulsion mechanism 2; the screw propulsion mechanism 2 The lower part of the end can be docked with the feed port of the weighing trolley 1; the weighing trolley 1 can move on a horizontal track, and be matched with a row of powder storage tanks 3 above the track; the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com