Fixing method for sheathed thermocouple

An armored thermocouple and scheme technology, which is applied in the field of post-weld heat treatment temperature measurement in electric power construction, can solve the problems of inaccurate temperature measurement, uneven surface material of welding seam, weak contact of thermocouple hot end, etc. Operation, good for uniformity, consistency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

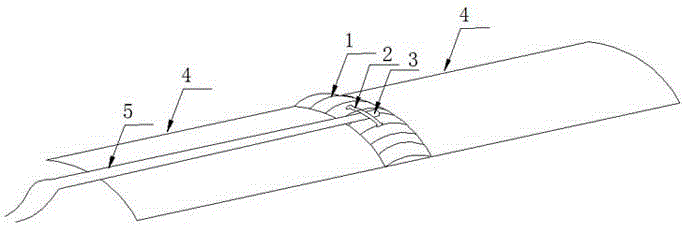

[0021] The armored thermocouple fixing method of the present embodiment may further comprise the steps:

[0022] 1) After the welding construction of the base metal 4 is completed, the self-inspection of the weld 1 is qualified;

[0023] 2) Take a section of welding wire 2 with the same material as that of welding seam 1, the diameter of the welding wire 2 is 2.4mm, and the length is 45mm;

[0024] 3) Spot weld one end of the welding wire 2 intercepted in step 2) on the surface of the weld 1 to be measured. The welding wire used by the welding machine for spot welding is the same material as the intercepted welding wire 2; place the hot end 3 of the armored thermocouple on the In the middle position of the welding wire 2, spot weld the other end of the welding wire 2 on the surface to be measured;

[0025] 4) Perform heat treatment on weld 1;

[0026] 5) After the heat treatment, use a grinder to grind off the spot weld of the welding wire 2, and smooth the surface of the we...

Embodiment 2

[0028] The armored thermocouple fixing method of the present embodiment may further comprise the steps:

[0029] 1) After the welding construction of the base metal 4 is completed, the self-inspection of the weld 1 is qualified;

[0030] 2) Take a section of welding wire 2 with the same material as that of welding seam 1, the diameter of the welding wire 2 is 2.4mm, and the length is 50mm;

[0031] 3) Spot weld one end of the welding wire 2 intercepted in step 2) on the surface of the weld 1 to be measured. The welding wire used by the welding machine for spot welding is the same material as the intercepted welding wire 2; place the hot end 3 of the armored thermocouple on the In the middle position of the welding wire 2, spot weld the other end of the welding wire 2 on the surface to be measured;

[0032] 4) Perform heat treatment on weld 1;

[0033] 5) After the heat treatment, use a grinder to grind off the spot weld of the welding wire 2, and smooth the surface of the we...

Embodiment 3

[0035] The armored thermocouple fixing method of the present embodiment may further comprise the steps:

[0036] 1) After the welding construction of the base metal 4 is completed, the self-inspection of the weld 1 is qualified;

[0037] 2) Take a section of welding wire 2 with the same material as that of welding seam 1, the diameter of the welding wire 2 is 2.5mm, and the length is 55mm;

[0038] 3) Spot weld one end of the welding wire 2 intercepted in step 2) on the surface of the weld 1 to be measured. The welding wire used by the welding machine for spot welding is the same material as the intercepted welding wire 2; place the hot end 3 of the armored thermocouple on the In the middle position of the welding wire 2, spot weld the other end of the welding wire 2 on the surface to be measured;

[0039] 4) Perform heat treatment on weld 1;

[0040] 5) After the heat treatment, use a grinder to grind off the spot weld of the welding wire 2, and smooth the surface of the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com