A Combined Spherical Frame for Inertially Stabilized Platforms

An inertial stable platform and combined technology, applied in directions such as navigation through velocity/acceleration measurement, can solve problems such as axial alignment accuracy, shape and position error of shaft end surface installation, and influence on the constant temperature of inertial instruments, etc. , to achieve the effects of light weight, reduced shape and position error, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

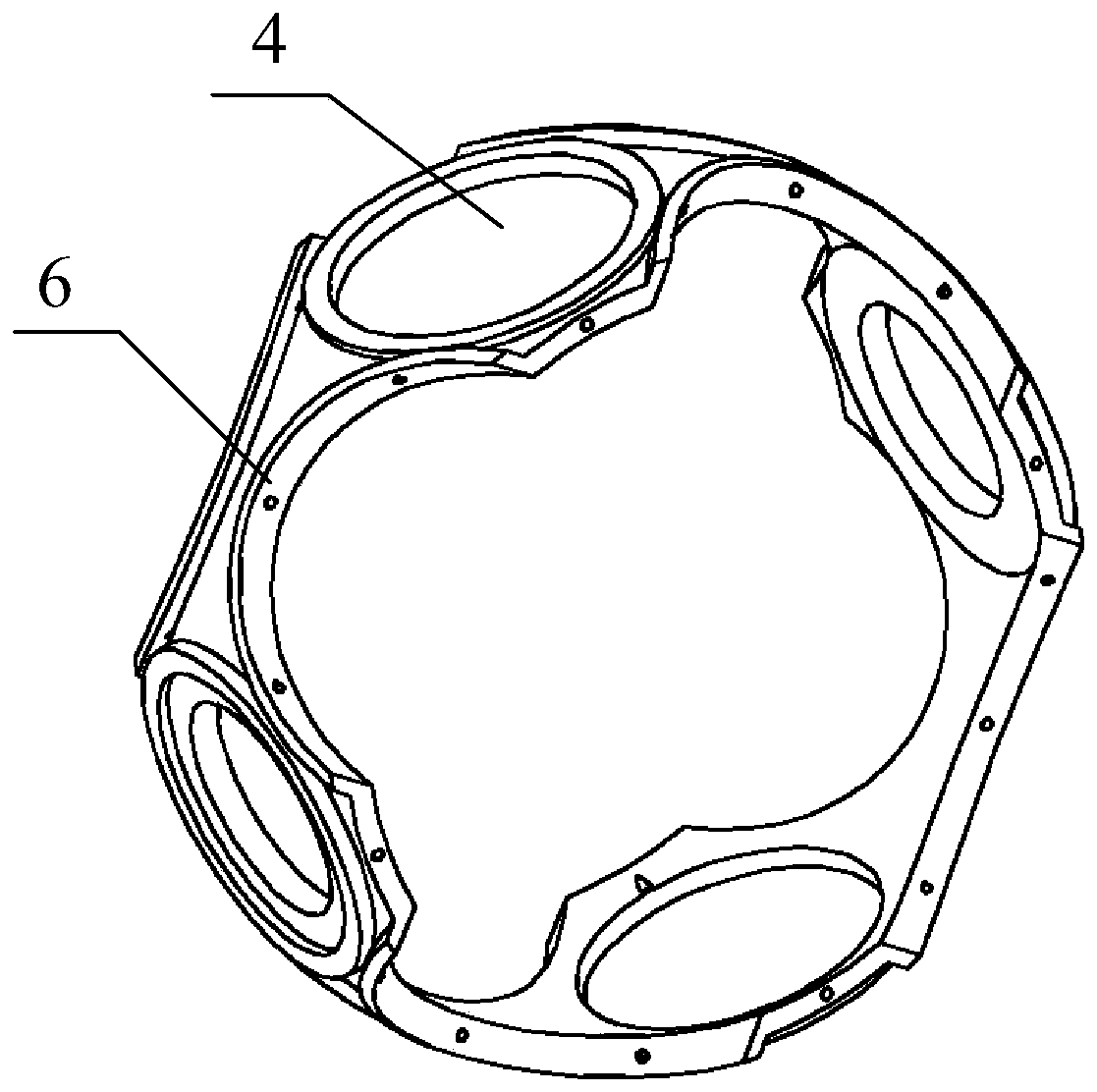

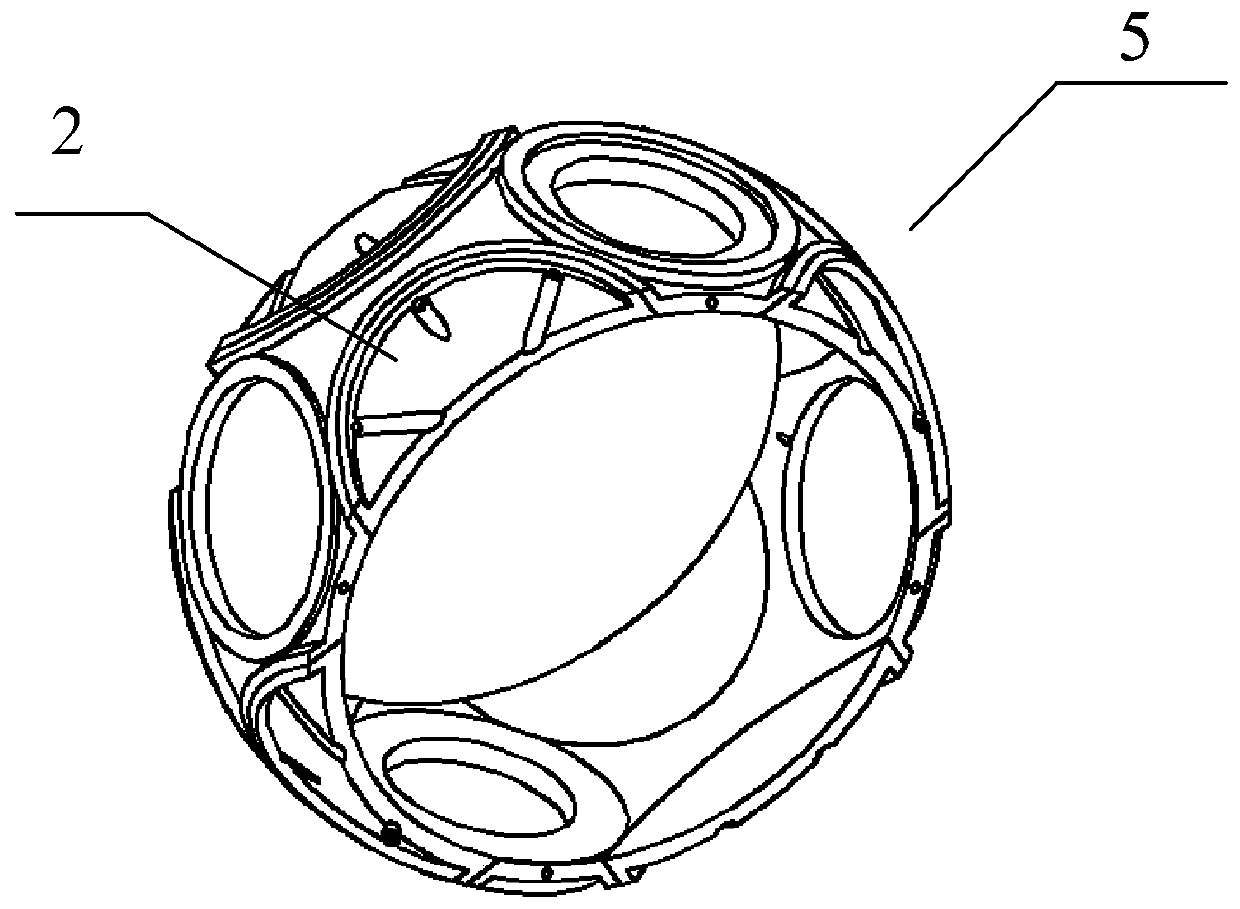

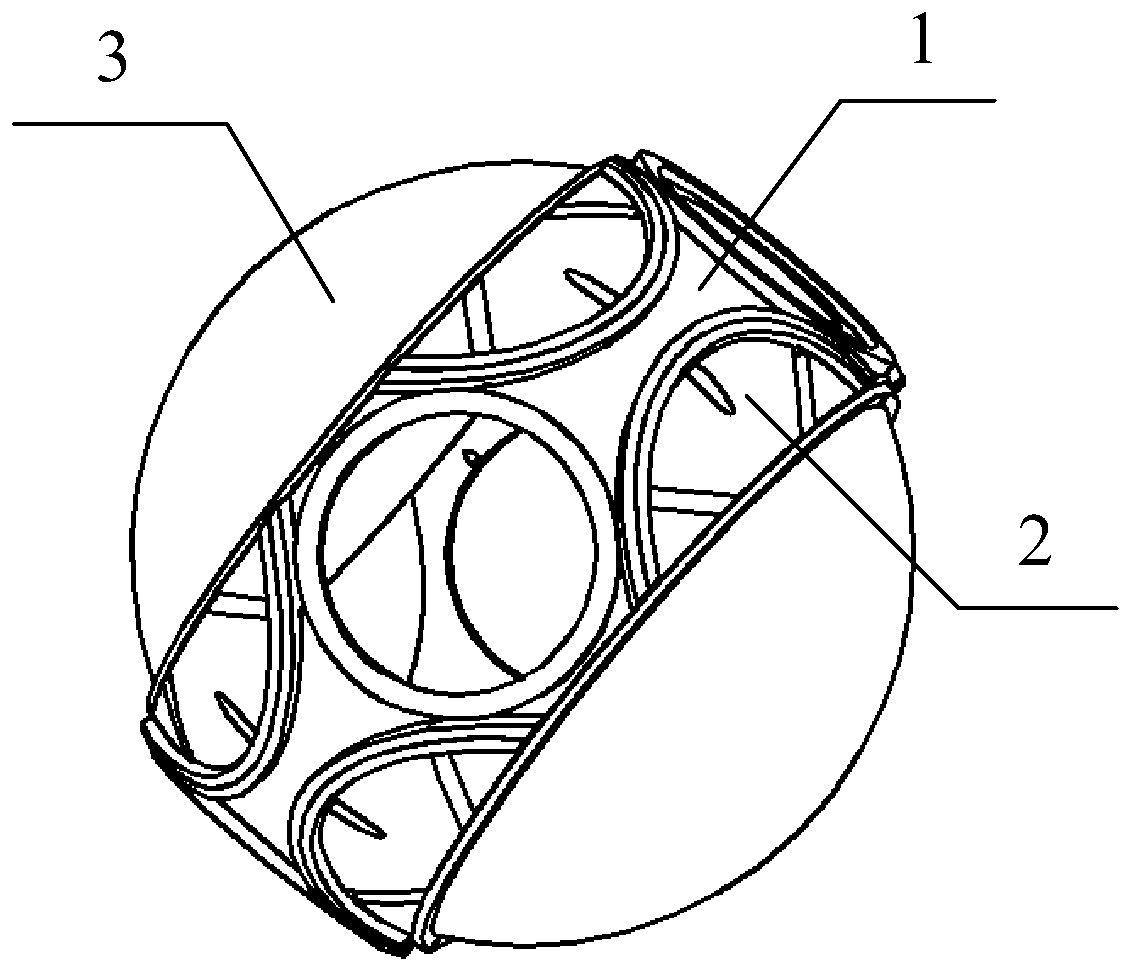

[0052] Such as figure 1 , 2 , 3, the combined spherical frame in this embodiment is a four-axis three-frame structure, and each spherical frame includes an integrated body structure 1, eight arcuate structure bodies 2 and two spherical structures 3. Among them, the surface of the ring frame of the integrated body structure 1 is evenly distributed with four shaft end element installation ports 4, and the connection line between the center points of the two opposite shaft end element installation ports 4 is the same as the other two opposite shaft end element installation ports 4 The connecting lines between the center points are perpendicular to each other, that is, the angle between two adjacent shaft end element installation ports 4 is 90°, and the connecting rod 6 connecting the adjacent two shaft end element installation ports 4 is a spherical arc surface The distance between any point on the inner surface of the spherical arc surface structure and the central point of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com