Sensor coupling device and damping debugging method suitable for vibration/fluctuation test

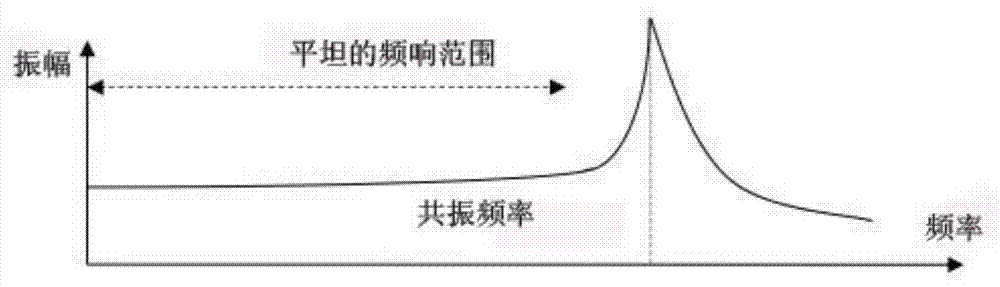

A technology of coupling device and debugging method, which is applied to the components of the damping part of the measuring device, the measuring device, and the measurement of ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low test efficiency and unstable frequency response characteristics of the sensor system, and achieve reduction The effect of small bad contact, improved frequency response range, and stable test signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

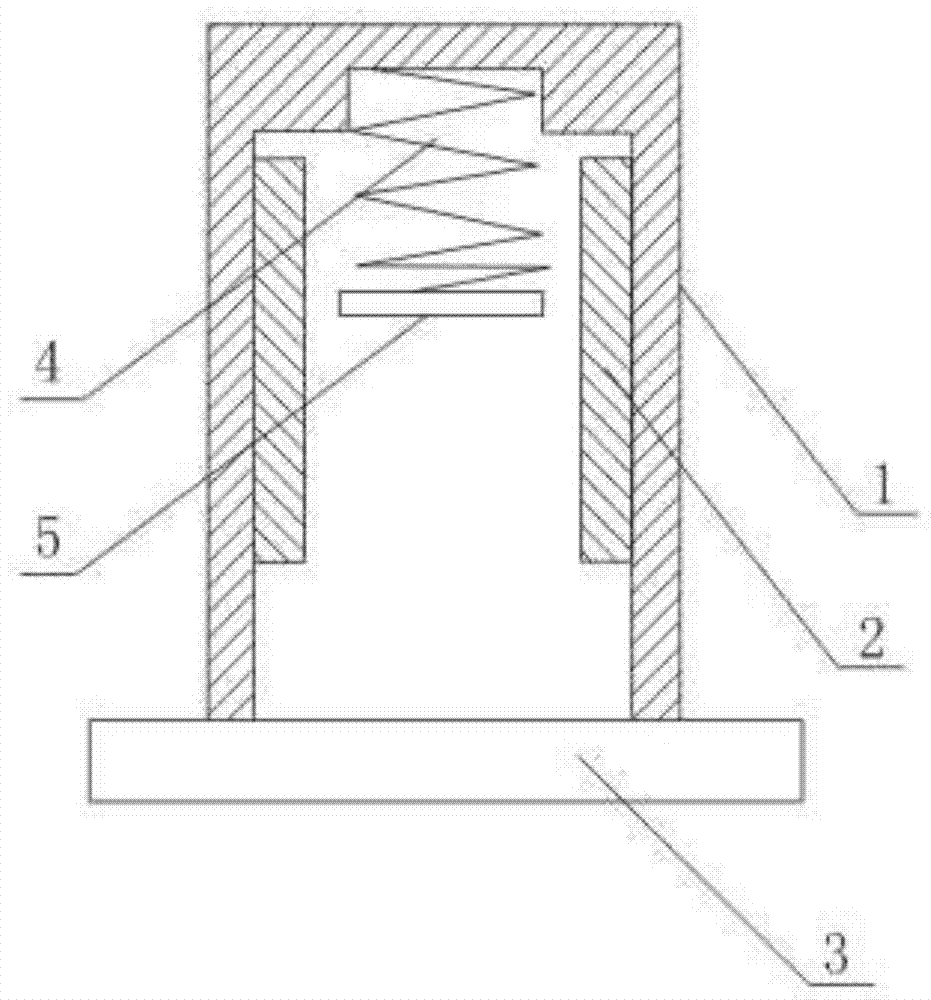

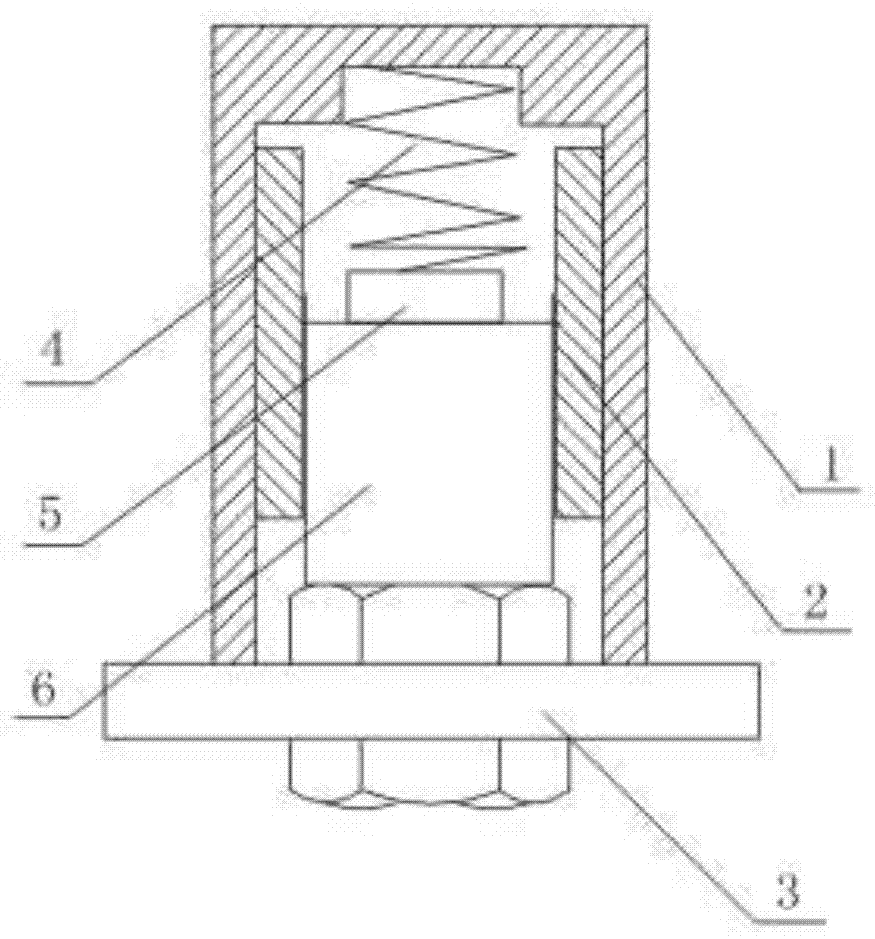

[0045] Such as figure 1 , figure 2 , image 3 As shown, the sensor coupling device suitable for vibration / fluctuation testing includes a headgear 1, a deck 2 set in the headgear 1, and a base 3 fixed at the lower end of the headgear 1. Both the headgear 1 and the deck 2 are hollow structures, and the headgear The lower end of 1 is open, the upper and lower surfaces of the deck 2 are open, and the deck 2 is clamped in the inner cavity of the headgear 1; the inner wall of the deck 2 is coated with a couplant connected with the sensor 6; the upper surface of the base 3 is provided with a sensor 6 holes through which the lower end passes. It also includes a coupling agent arranged between the outer wall of the card seat 2 and the inner wall of the headgear 1 . It also includes a spring 4 and a rubber gasket 5 arranged in the headgear 1 , one end of the spring 4 is connected with the top of the headgear 1 , and the other end is connected with the rubber gasket 5 . The base 3 i...

Embodiment 2

[0086] A damping debugging method for a sensor coupling device suitable for vibration / fluctuation testing, comprising the following steps:

[0087] Include the following steps:

[0088] a) Insert the sensor 6 into the deck 2, and make the lower end of the sensor 6 pass through the hole on the base 3. In this state, a part of the lower end of the sensor 6 will be exposed from the base 3;

[0089] b) Loosen the sensor 6 to make it return to the free state under the action of the spring, and measure its required recovery time t 1 ;

[0090] c) According to the spring coefficient k of the elastic spring z , the natural frequency ω of the sensor 6 system, the mass m of the sensor 6 system, calculate the time t that should be restored after the card holder 2 is coated with coupling agent 2 ;

[0091] d) will test the obtained t 1 with t 2 For comparison, if t 1 fall into t 2 In the range of , the smeared couplant meets the damping ratio requirements required by the test syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com