Using method for logistics taking and stacking vehicle used for freight container

A technology for container and yard trucks, applied in the field of logistics yard trucks, can solve the problems of large impact on loading and unloading progress, high labor intensity of operators, low efficiency, etc., and achieve the effect of realizing intelligent operation and improving loading and unloading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

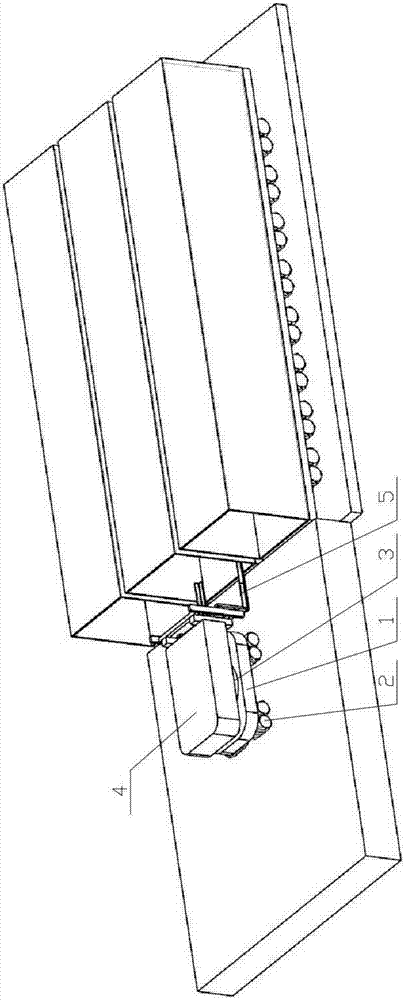

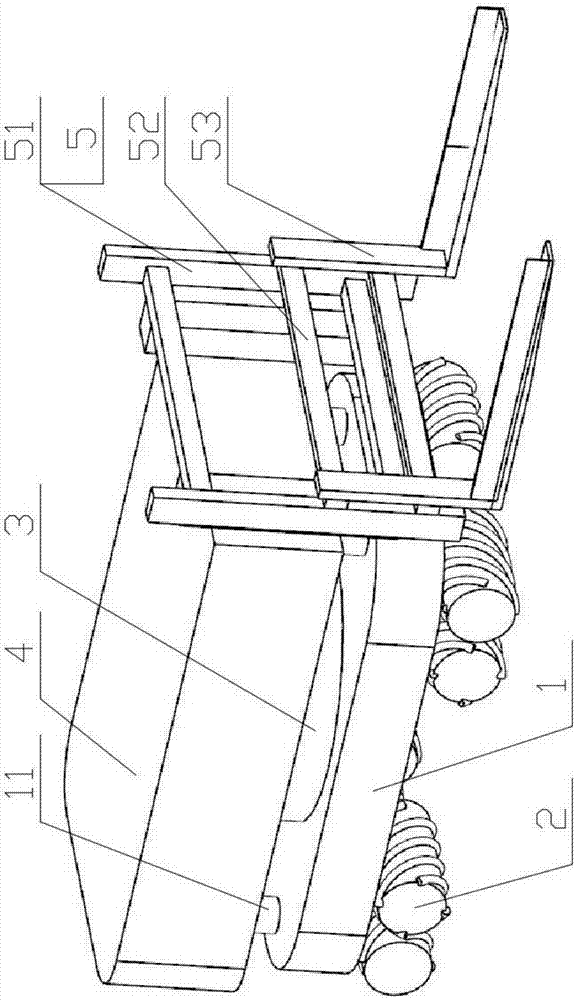

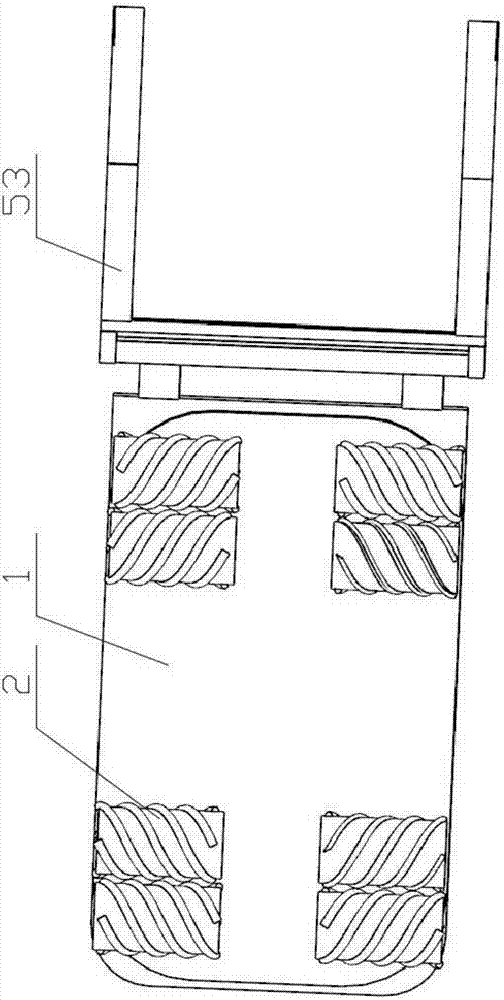

[0032] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the direction in which the working part 5 is installed on the support platform 4 is described as the front).

[0033] Such as figure 1 , figure 2 , Figure 4 As shown, the logistics code picking vehicle suitable for freight containers includes a vehicle frame 1, a running part 2, a slewing bearing 3, a supporting platform 4, a working part 5, a hydraulic system and an electric control system.

[0034] The walking part 2 is arranged at the bottom of the vehicle frame 1, and a driving drive is provided inside the walking part 2, and the support platform 4 is installed on the vehicle frame 1 through the slewing bearing 3, and the slewing bearing 3 is provided with Driven by hydraulic slewing, the setting of slewing bearing 3 can increase the degree of freedom of the logistics code retrieval vehicle, which is suitable for relatively narrow loading and unloadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com