Electroplating unit capable of conveniently adjusting liquid level of electroplating water tank

A technology of electroplating unit and tank liquid, applied in the direction of plating tank, electrolysis process, electrolysis components, etc., can solve the problems of manual operation delay and error, unable to fill the electroplating solution, etc., and achieve the effect of avoiding manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

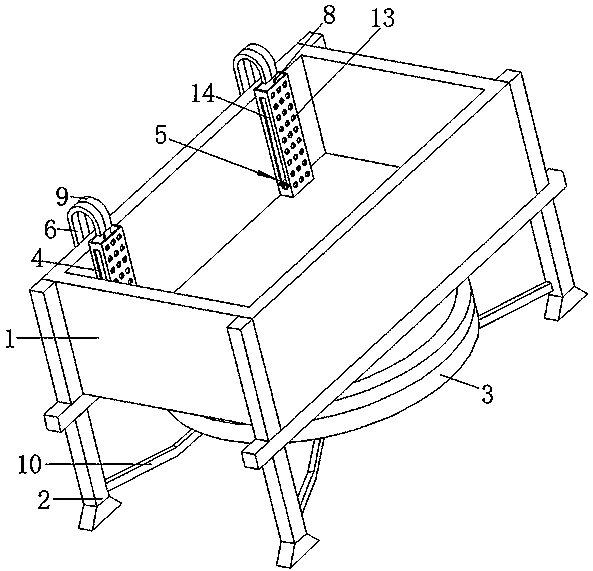

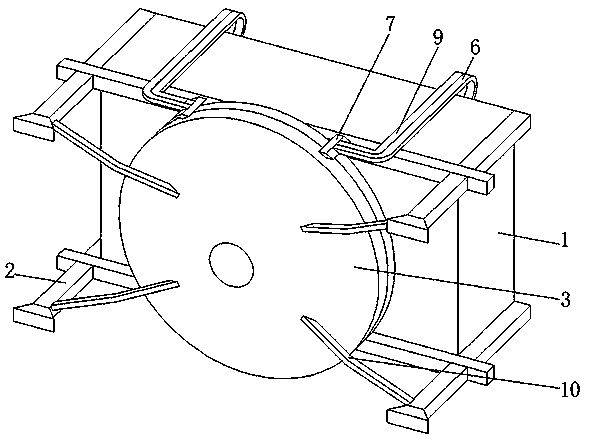

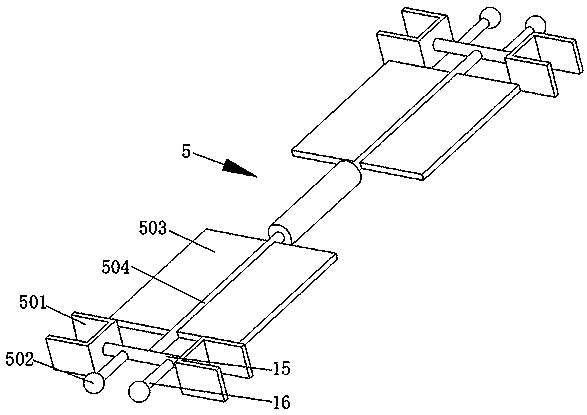

[0038] refer to figure 1 , figure 2 , Figure 4 , an electroplating unit that is convenient for adjusting the liquid level of an electroplating water tank, comprising an electroplating water tank 1, symmetrical legs 2 are fixedly connected to the four corners of the bottom of the electroplating water tank 1, an electroplating solution storage tank 3 is provided at the bottom of the electroplating water tank 1, and the electroplating water tank 1 The inner wall is fixedly connected with a liquid level tube 4, and the floating plate 5 is slidably connected to the liquid level tube 4. The outer wall of the electroplating water tank 1 is fixedly connected with a serpentine sleeve 6, and the top of the serpentine sleeve 6 is placed on the bottom of the liquid level tube 4. Above, the bottom end of the serpentine casing 6 extends downward and is connected to the electroplating solution storage tank 3 through the fixed block 7, and the floating plate 5 is connected to the serpentin...

Embodiment 2

[0041] refer to figure 1 , figure 2 , Figure 4 , Figure 5 , an electroplating unit that is convenient to adjust the liquid level of the electroplating water tank, which is basically the same as that of Embodiment 1, furthermore, a water pump 11 is provided in the filling pipe 9, and a water pipe 12 is connected to the water outlet end of the water pump 11, and the water pipe 12 is far away from the water pump 11 One end of the pipe extends to the top of the filling pipe 9. The existence of the water pump 11 is beneficial to absorb the electroplating solution entering the filling pipe 9 into the water pipe 12, and discharge it into the liquid level pipe 4 through the water pipe 12, so as to realize the electroplating solution. Liquid filling.

Embodiment 3

[0043] refer to Figure 1-8 , an electroplating unit that is convenient for adjusting the liquid level of an electroplating water tank, comprising an electroplating water tank 1, symmetrical legs 2 are fixedly connected to the four corners of the bottom of the electroplating water tank 1, an electroplating solution storage tank 3 is provided at the bottom of the electroplating water tank 1, and the electroplating water tank 1 The inner wall is fixedly connected with a liquid level tube 4, and the floating plate 5 is slidably connected to the liquid level tube 4. The outer wall of the electroplating water tank 1 is fixedly connected with a serpentine sleeve 6, and the top of the serpentine sleeve 6 is placed on the bottom of the liquid level tube 4. Above, the bottom end of the serpentine casing 6 extends downward and is connected to the electroplating solution storage tank 3 through the fixed block 7, and the floating plate 5 is connected to the serpentine casing 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com