Machinery for carrying, turning and laying floor tiles

A floor tile and mechanical technology, which is applied in the direction of construction and building construction, can solve the problems of difficult paving and sticking of mortar, and achieves the effect of simple structure, convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

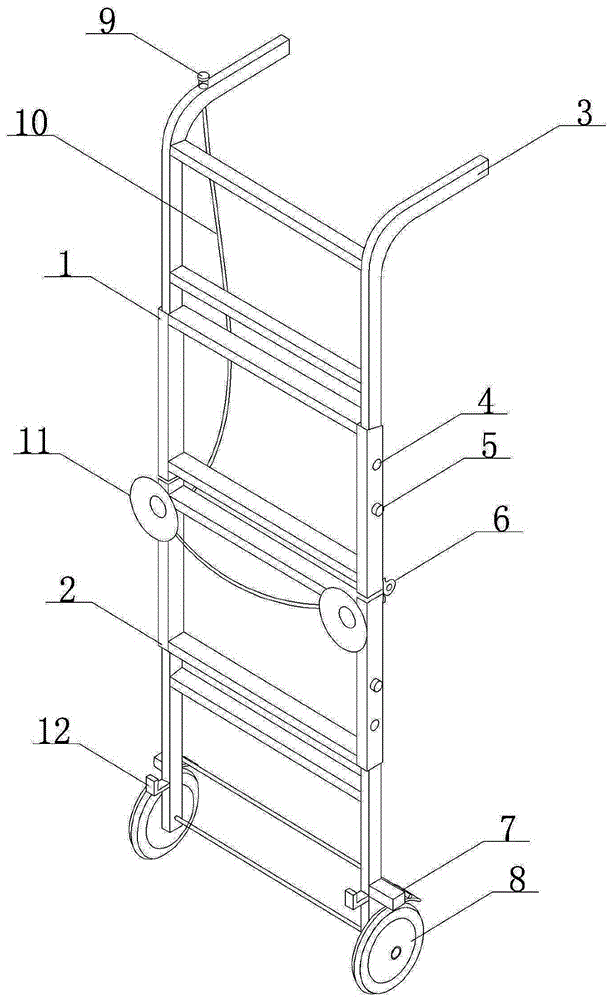

[0013] Please refer to the attached figure 1 , the embodiment of the present invention comprises: bracket 1 and bracket 2, described bracket 1 and bracket 2 are telescopic structure, can adjust the length through positioning hole 4 and V-shaped headed spring telescopically, to adapt to floor tiles of different specifications; The lower end of the support 2 is provided with a wheel 8 and a brake device 7; the lower part of the front of the support 2 is provided with an L-shaped bracket, and the upper part is provided with a vacuum suction cup; the support 1 is connected with the support 2 through a hinge 6 and can be rotated backward Folding; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com