Cam paper-counting mechanism

A technology of cam and lifting mechanism, applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problem of low efficiency of manual operation, and achieve the effect of accurate number of sheets, high efficiency, and avoidance of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

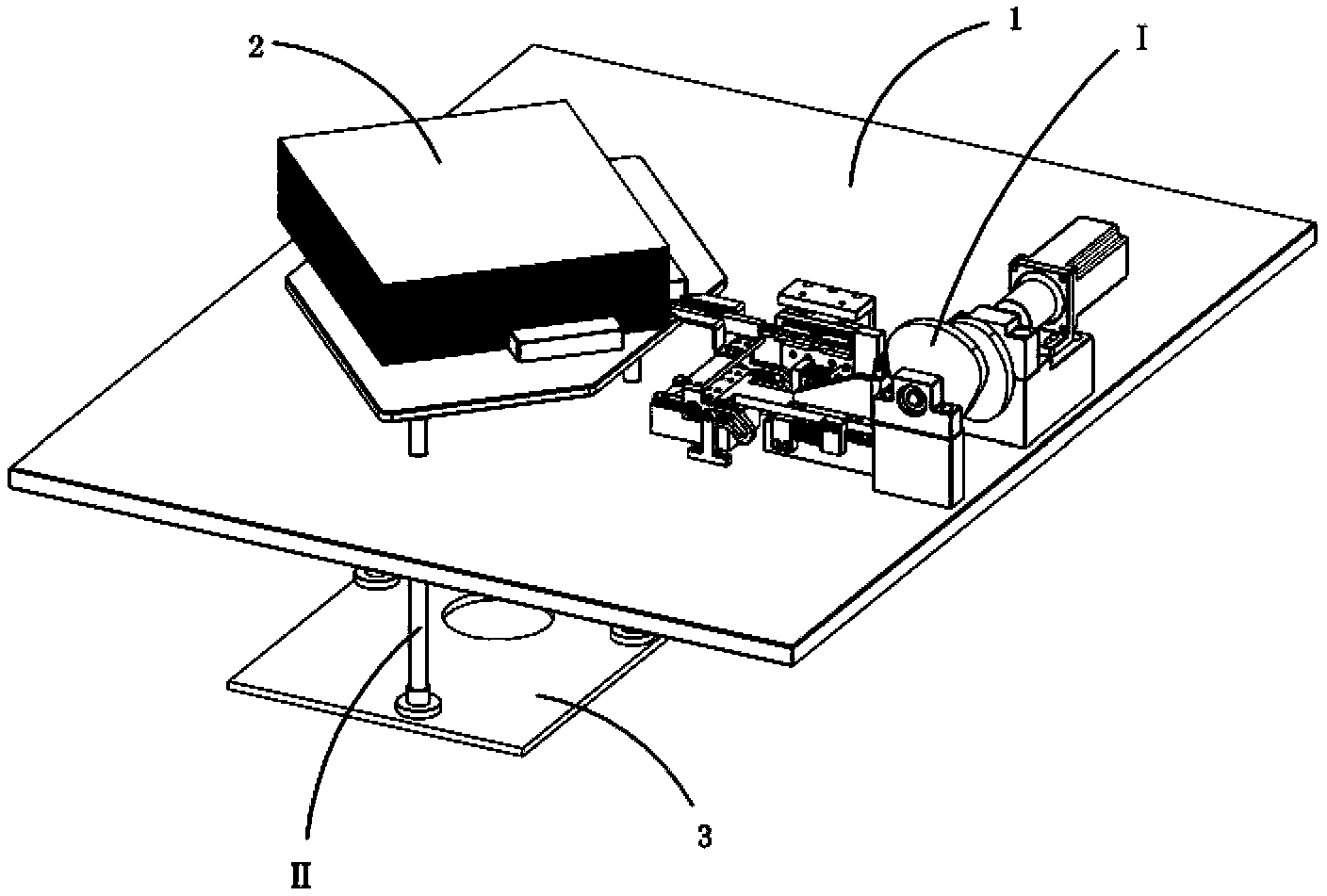

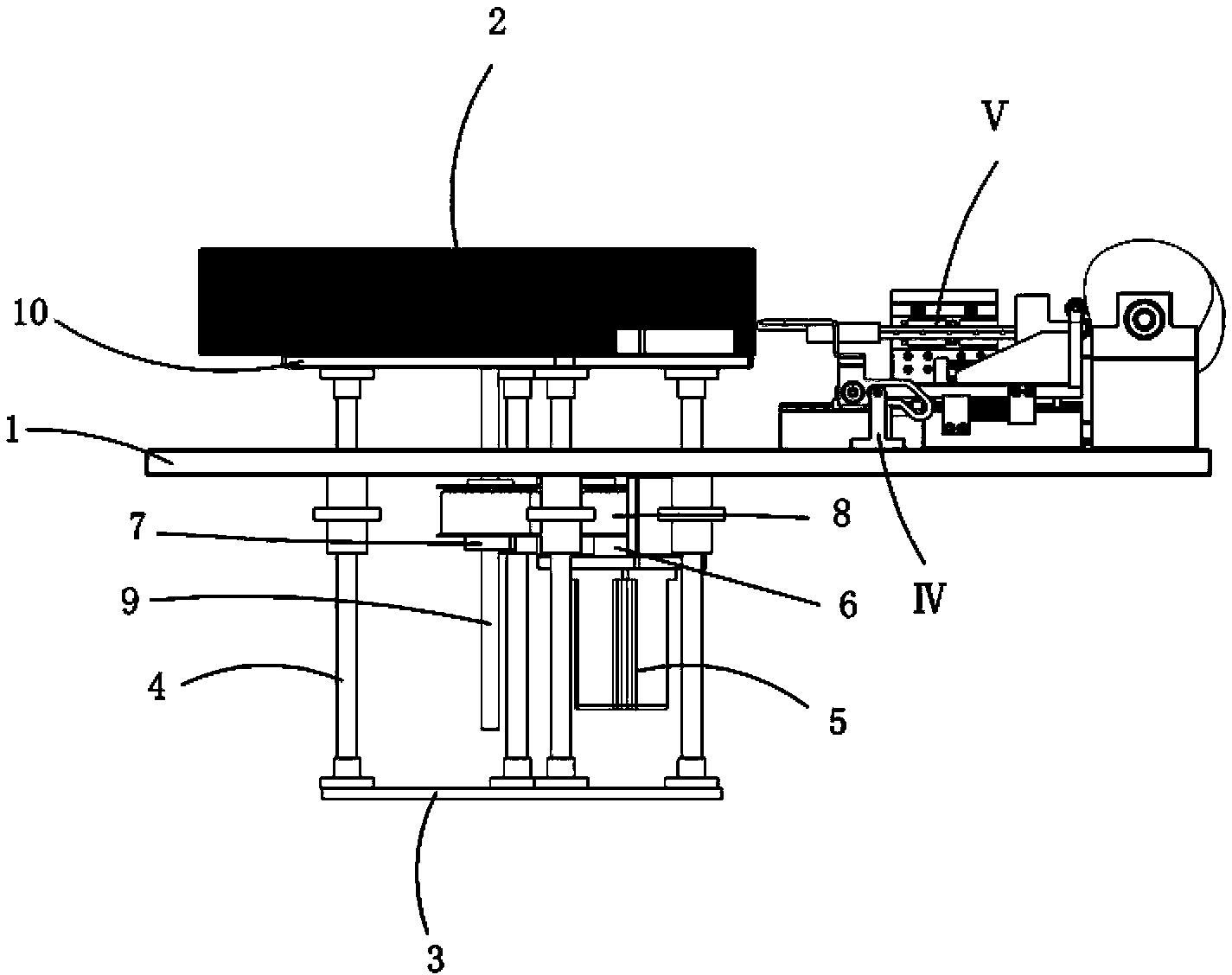

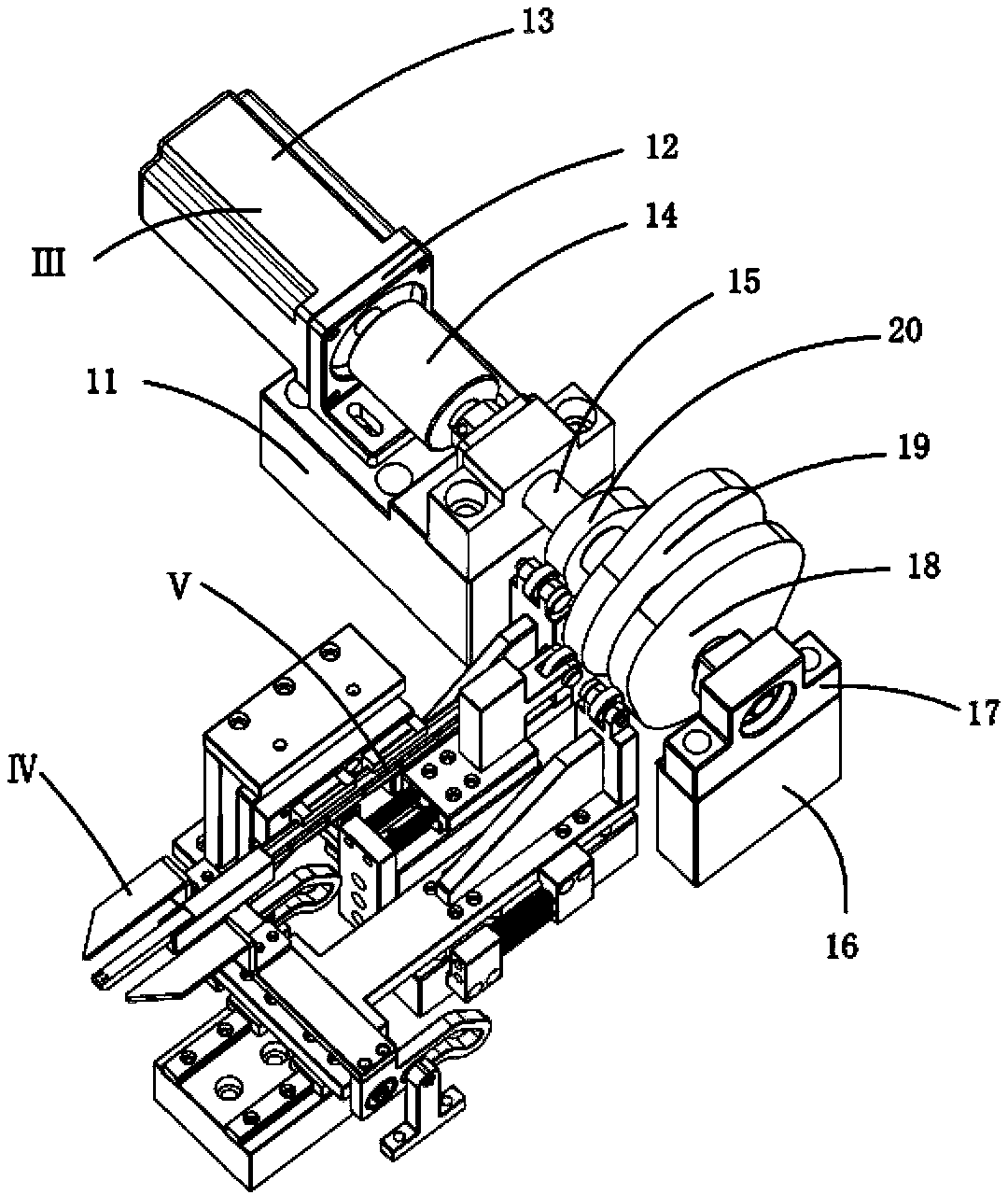

[0031] Examples, see attached Figure 1~9 , a cam counting paper mechanism, which includes a bottom plate 1, a cam mechanism I, a lifting mechanism II and paper 2, the cam mechanism is installed on the bottom plate; the lifting mechanism includes a seat plate 3, a sliding shaft 4, a lifting motor 5, Synchronous pulley 6, driven wheel 7, belt 8, screw mandrel 9 and carrier plate 10, four slide shafts are connected on the described seat plate, and the slide shaft passes through base plate, and the upper end of the slide shaft is connected with the carrier plate; Multiple sheets of paper are stacked on the board; the lifting motor, synchronous wheel, driven wheel and belt of the lifting mechanism are all located at the bottom of the base plate, and the driven wheel drives the screw to rotate, and the screw passes through the base and is connected to the carrier.

[0032]The cam mechanism includes a driving device III, a paper pressing mechanism IV and a paper pushing mechanism V,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com