Mechanical endurance test instrument for high voltage switch

A technology of mechanical life and high-voltage switches, which is applied in the field of measuring testers, can solve problems such as poor control of the time interval of opening and closing operations, increased labor intensity of test personnel, and inaccurate measurement results, so as to shorten the test cycle and shorten the test time. Time, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

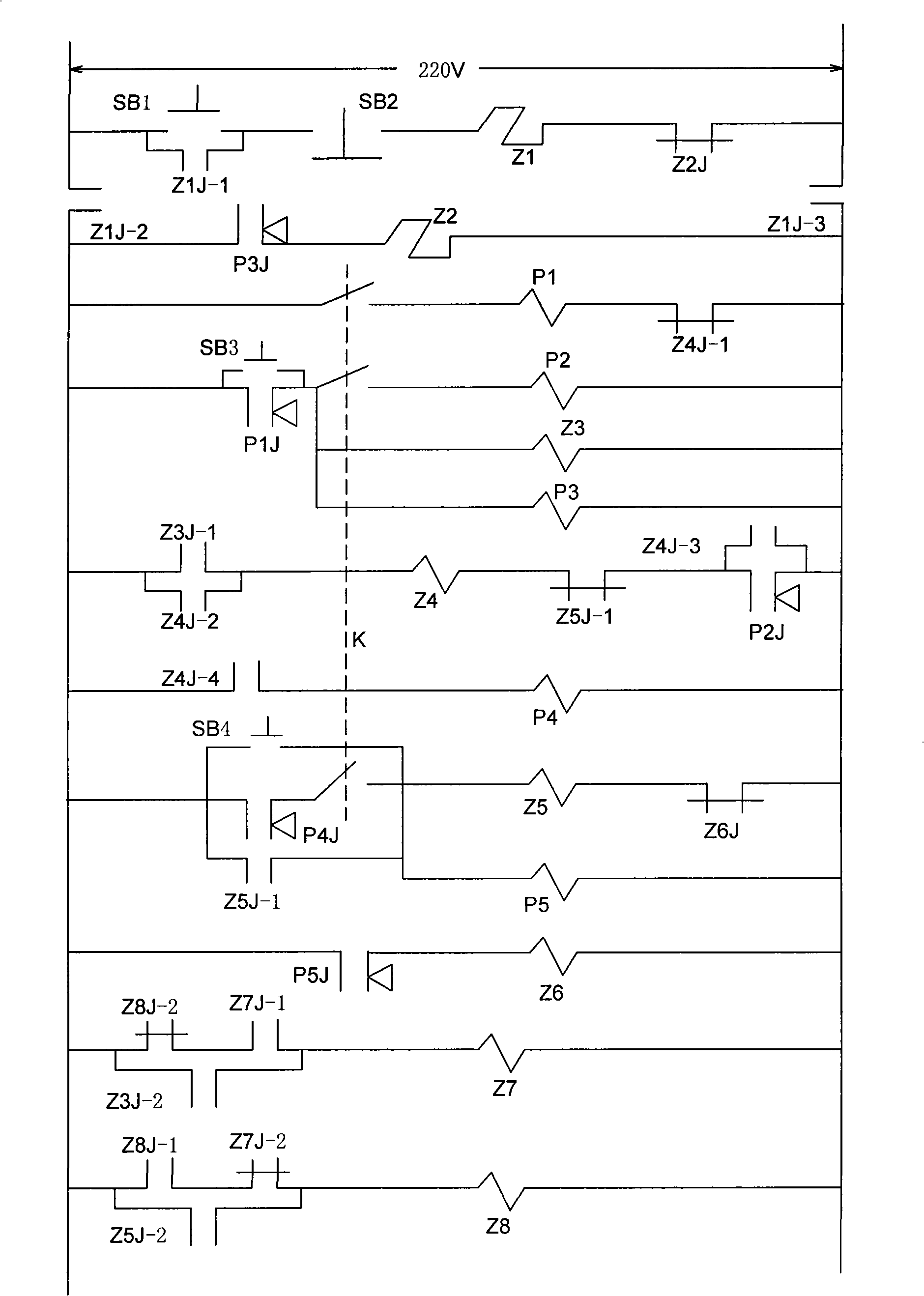

[0017] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

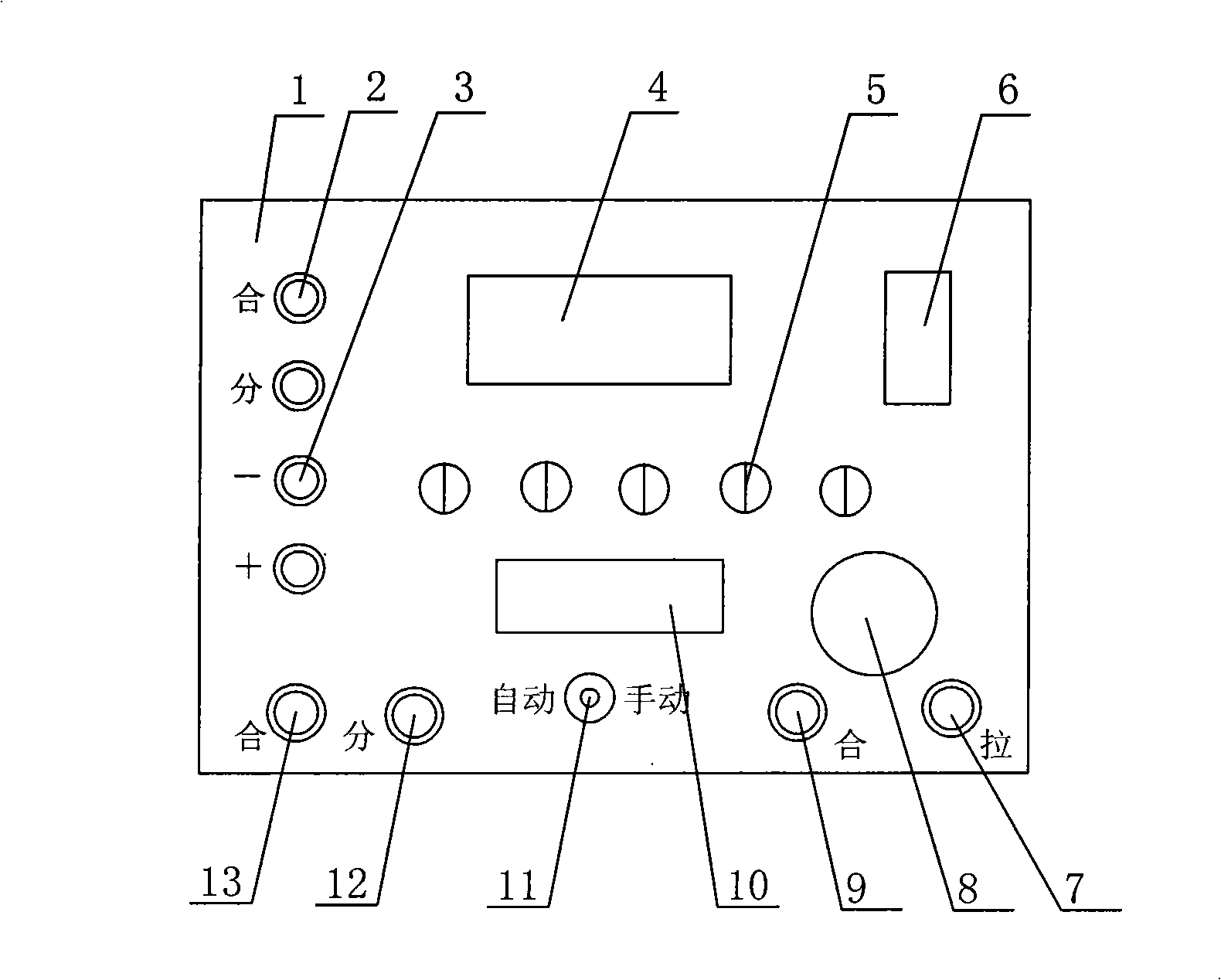

[0018] The high voltage switch mechanical life tester is composed of a shell and its internal control circuit. The appearance and structure of the shell are as follows: figure 1 As shown, on the panel 1 of the housing, there are test terminals 2, DC power input port 3, AC power input port 6, AC voltmeter 4, AC power switch 8, power switch-on button 7, power switch-on button 9, Delay adjustment knob 5 , automatic or manual test selection switch 11 , manual closing button 13 , manual opening button 12 and counting display device 10 .

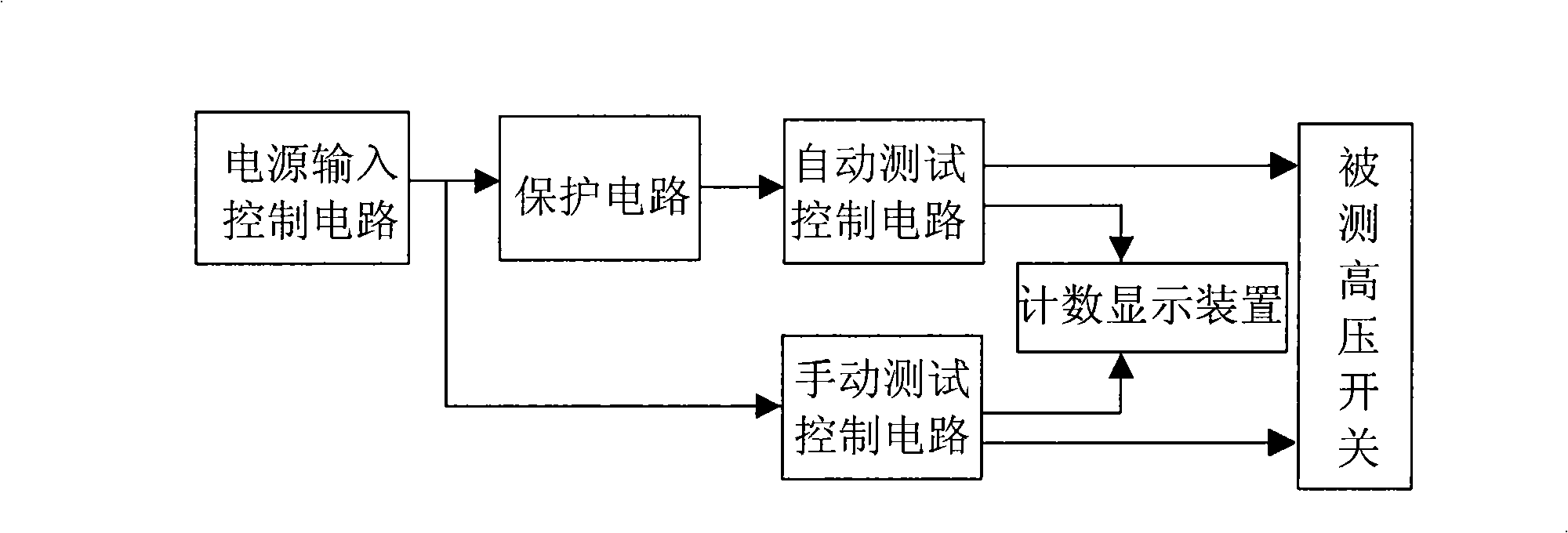

[0019] Such as figure 2 As shown, the control circuit in the shell is composed of power input control circuit, protection circuit, automatic test control circuit and manual test control circuit. The input end of the power input control circuit is connected to the AC power input port on the shell, and its output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com