Patents

Literature

82results about How to "Avoid Dimensions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

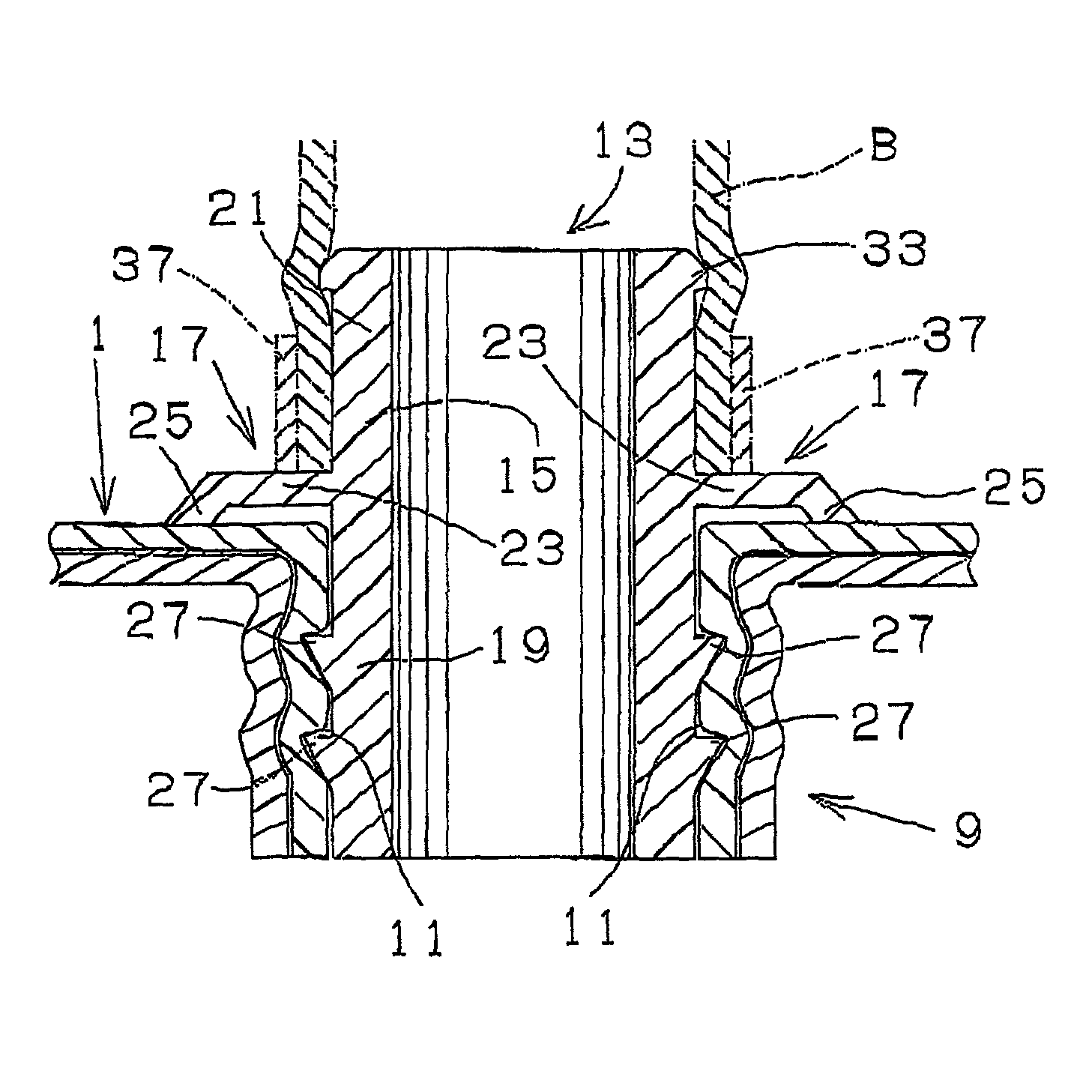

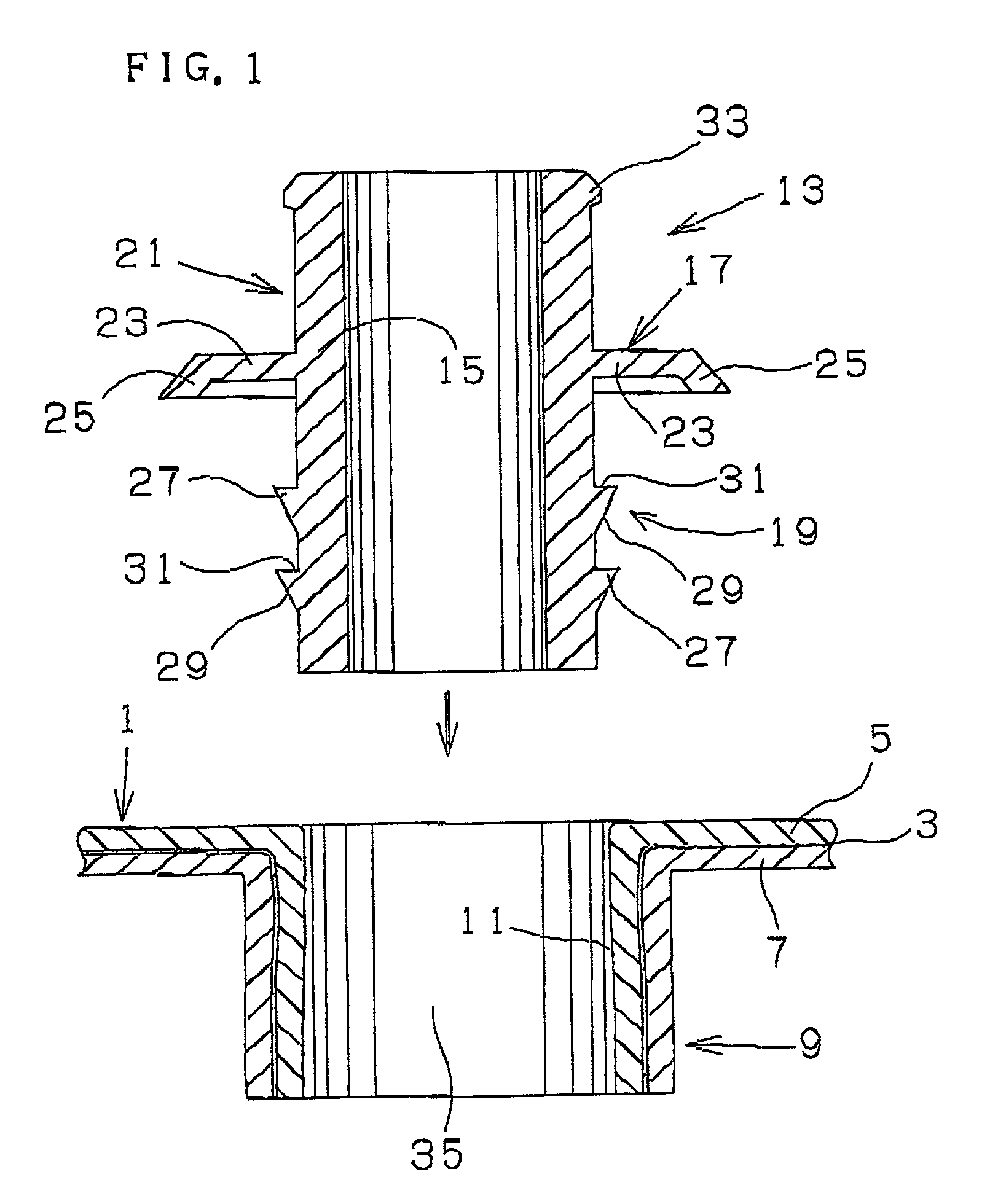

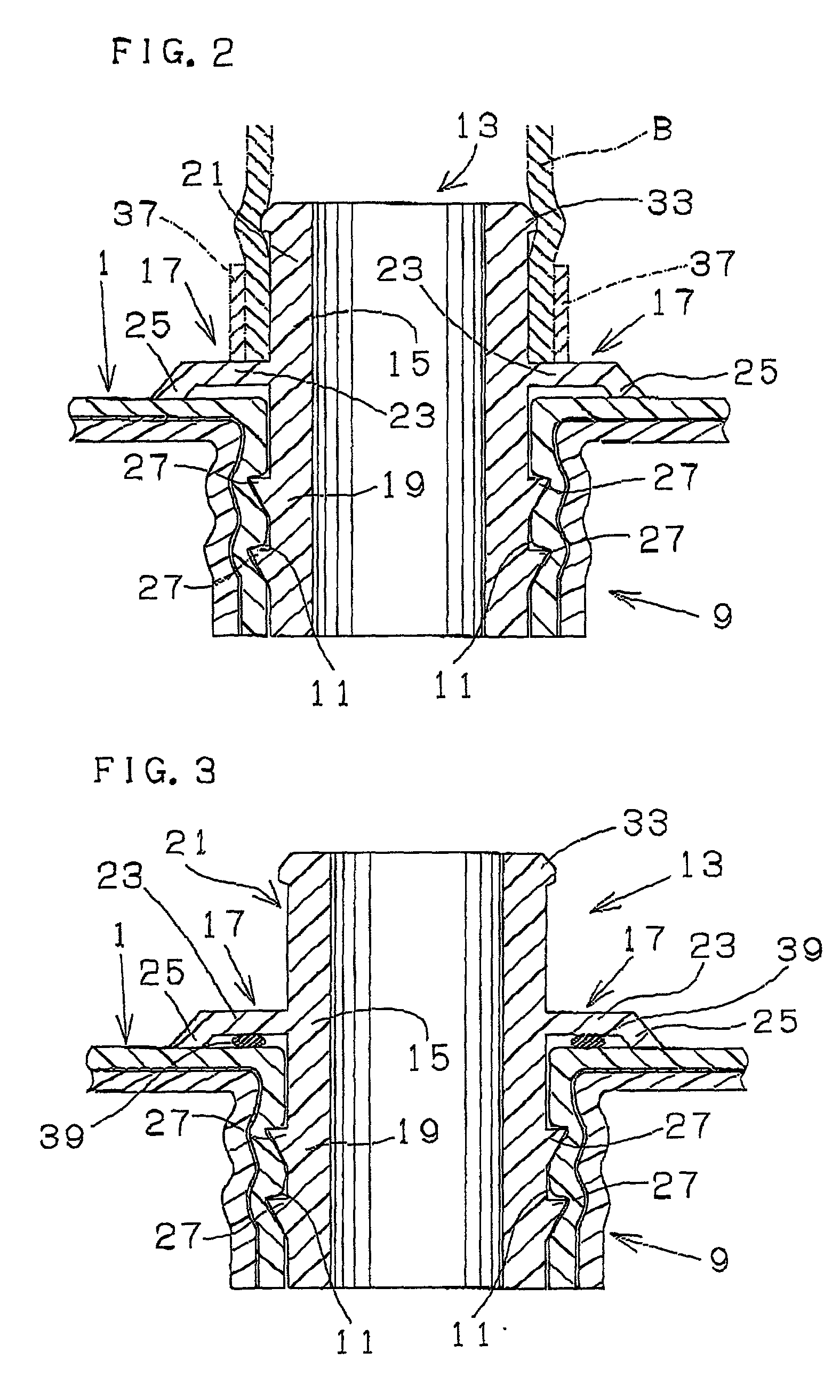

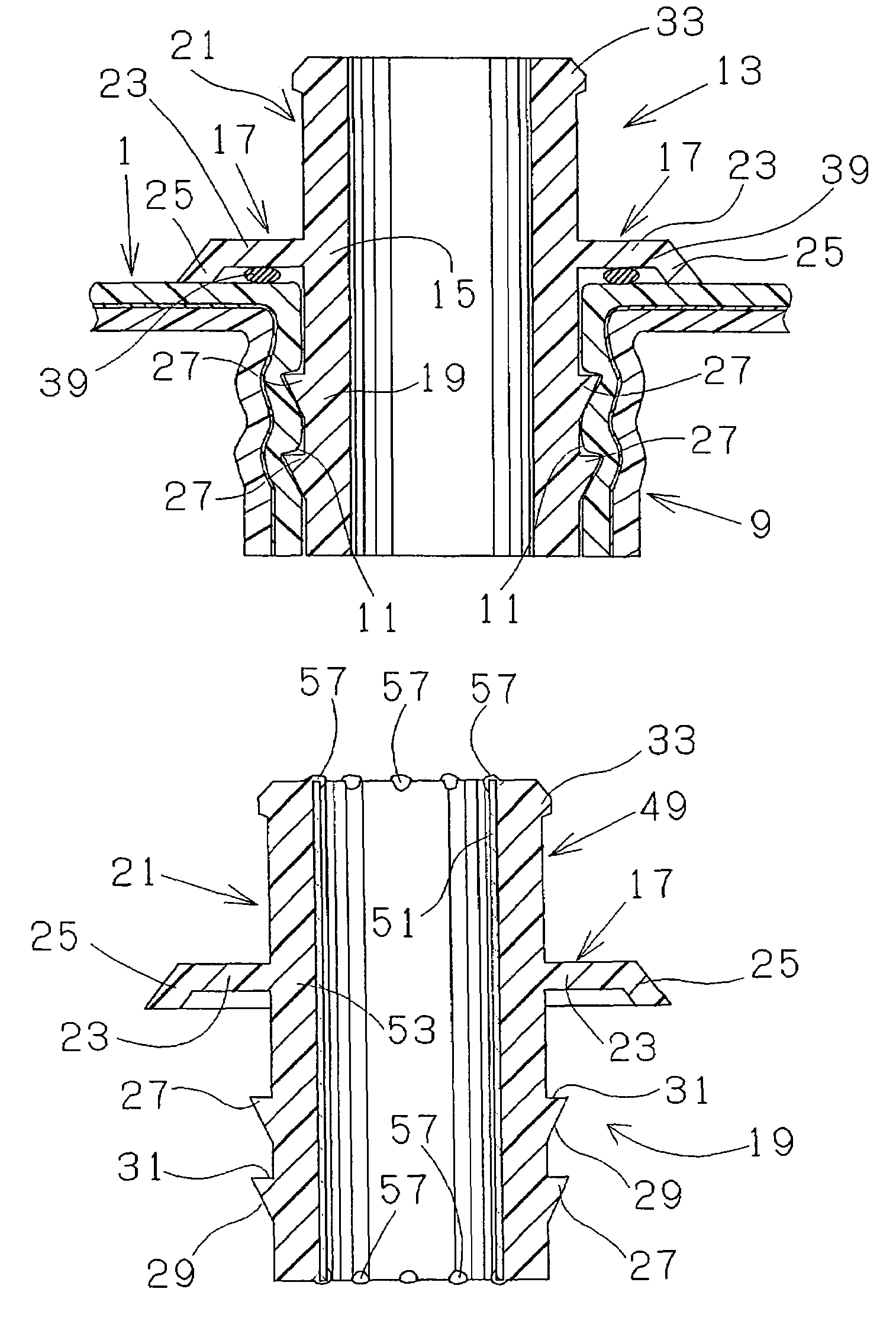

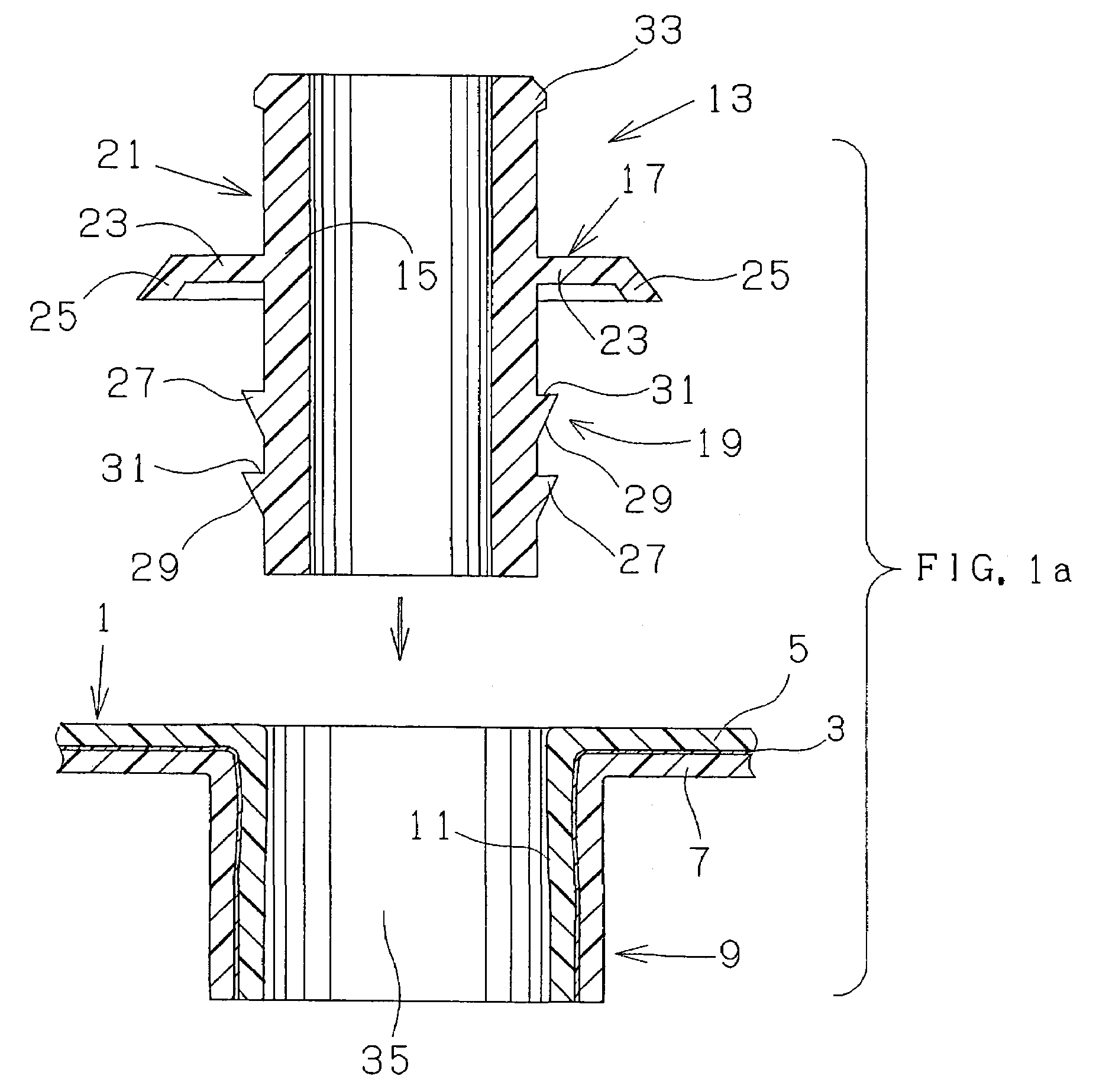

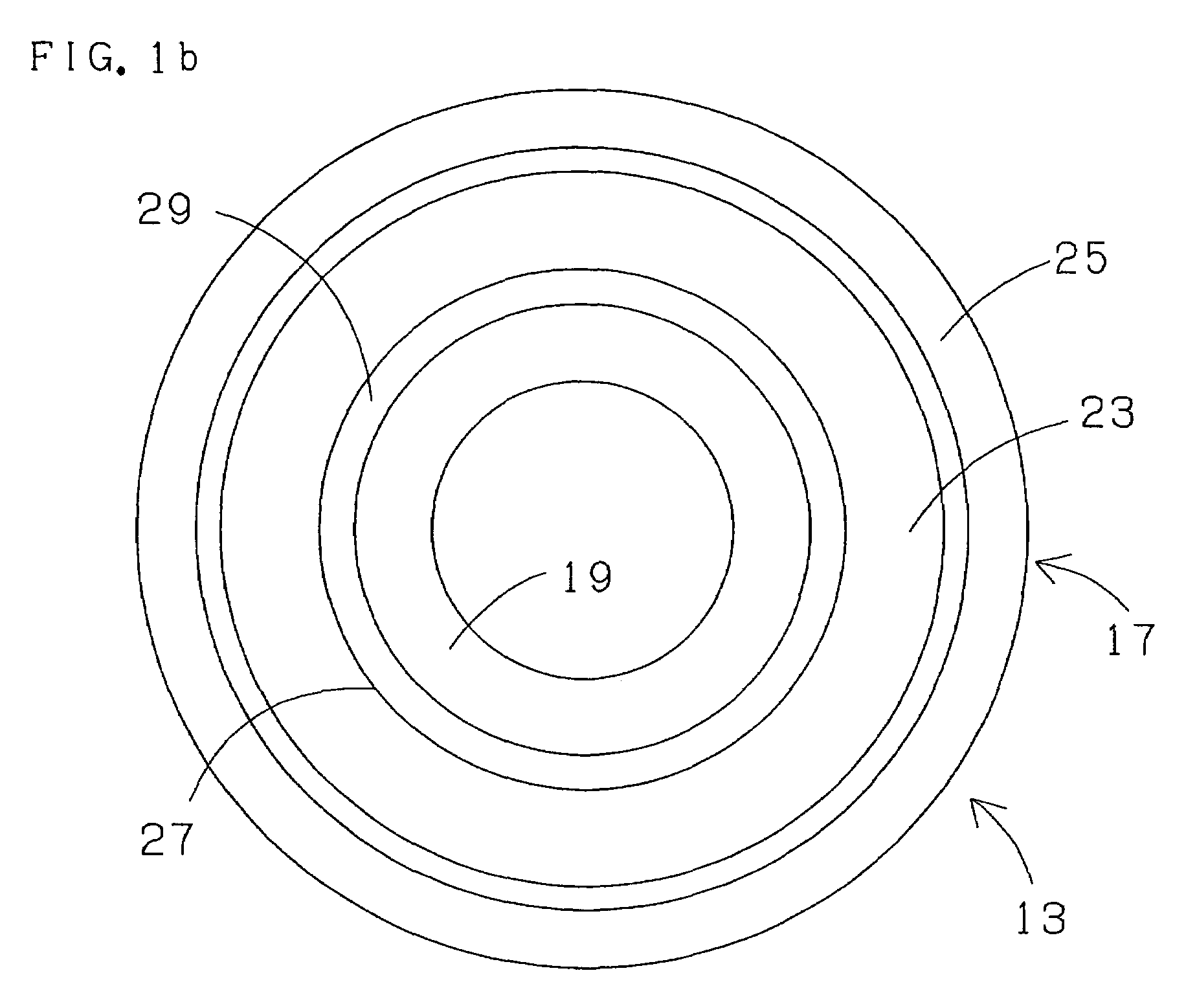

Structure for connecting tubular member to fuel tank

InactiveUS20020130515A1Improve penetration resistanceAvoid DimensionsLarge containersUnderstructuresFuel tank

An cylindrical convex portion of which opposite ends are open is integrally formed onto a fuel tank made of RDPE therewith so as to inwardly extend in the fuel tank, to provide an opening thereon. A press-fit portion of a filler hose connecting pipe made of PA as a tubular member is press-fitted in the cylindrical convex portion to connecting the tubular member to the fuel tank. At least one annular projection is provided on the outer peripheral surface of the press-fit portion of the tubular member so as to bite in the inner peripheral surface of the cylindrical connvex portion. A face of the annular projection in direction axially of one end of tubular member is formed so as to extend outwardly and inclinedly with respect to the axial direction of the tubular member form one end toward the other end thereof.

Owner:SUMITOMO RIKO CO LTD

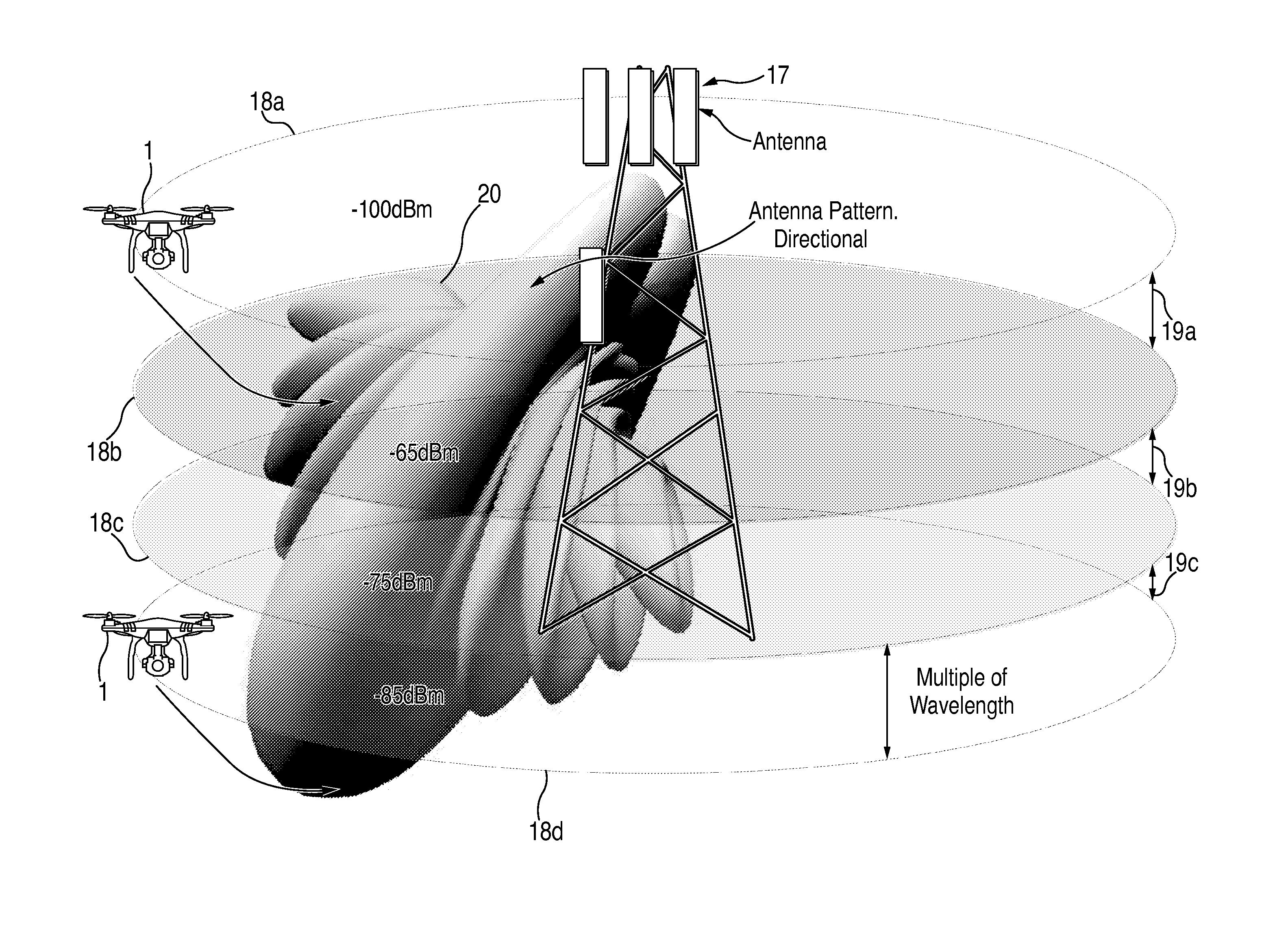

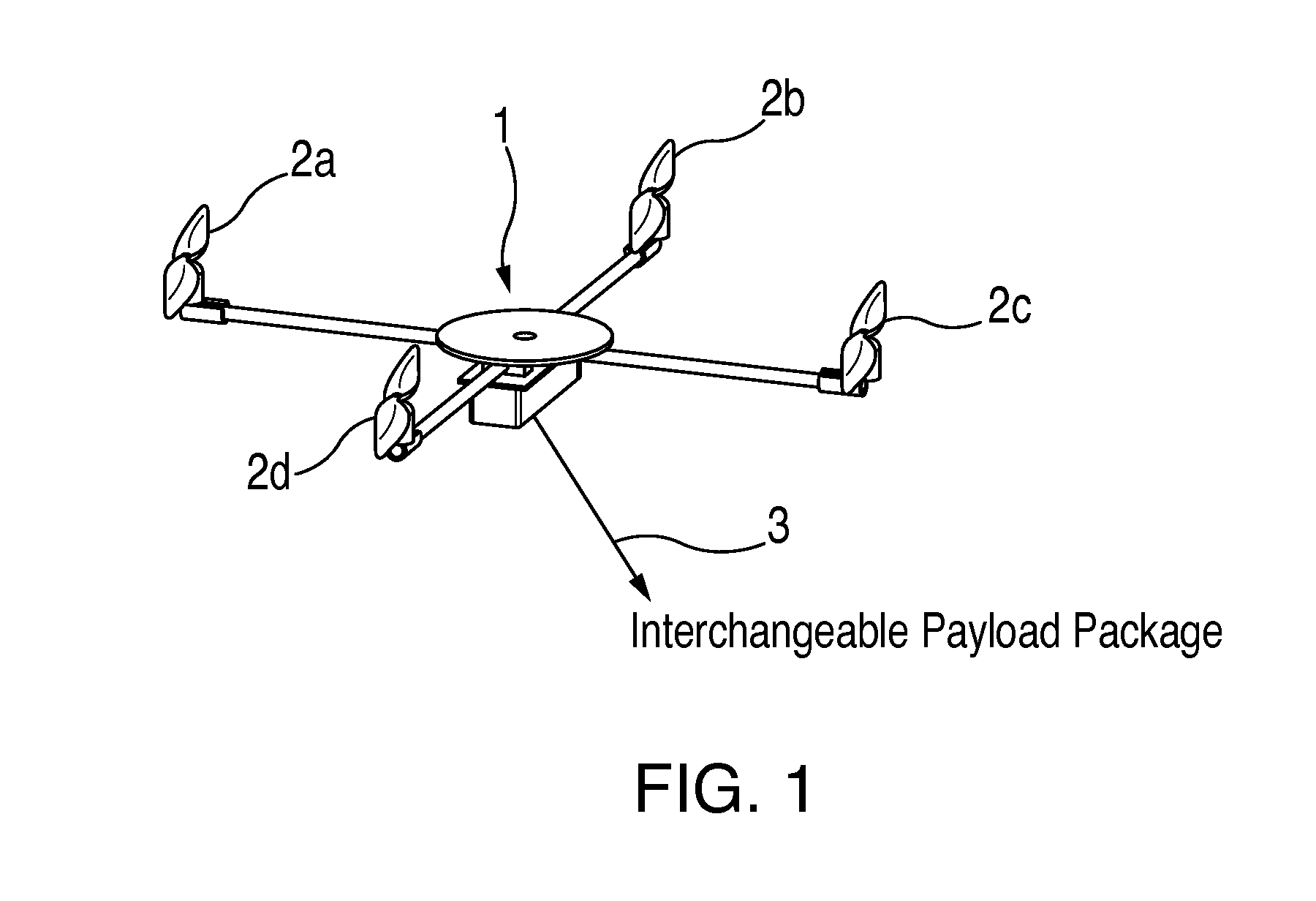

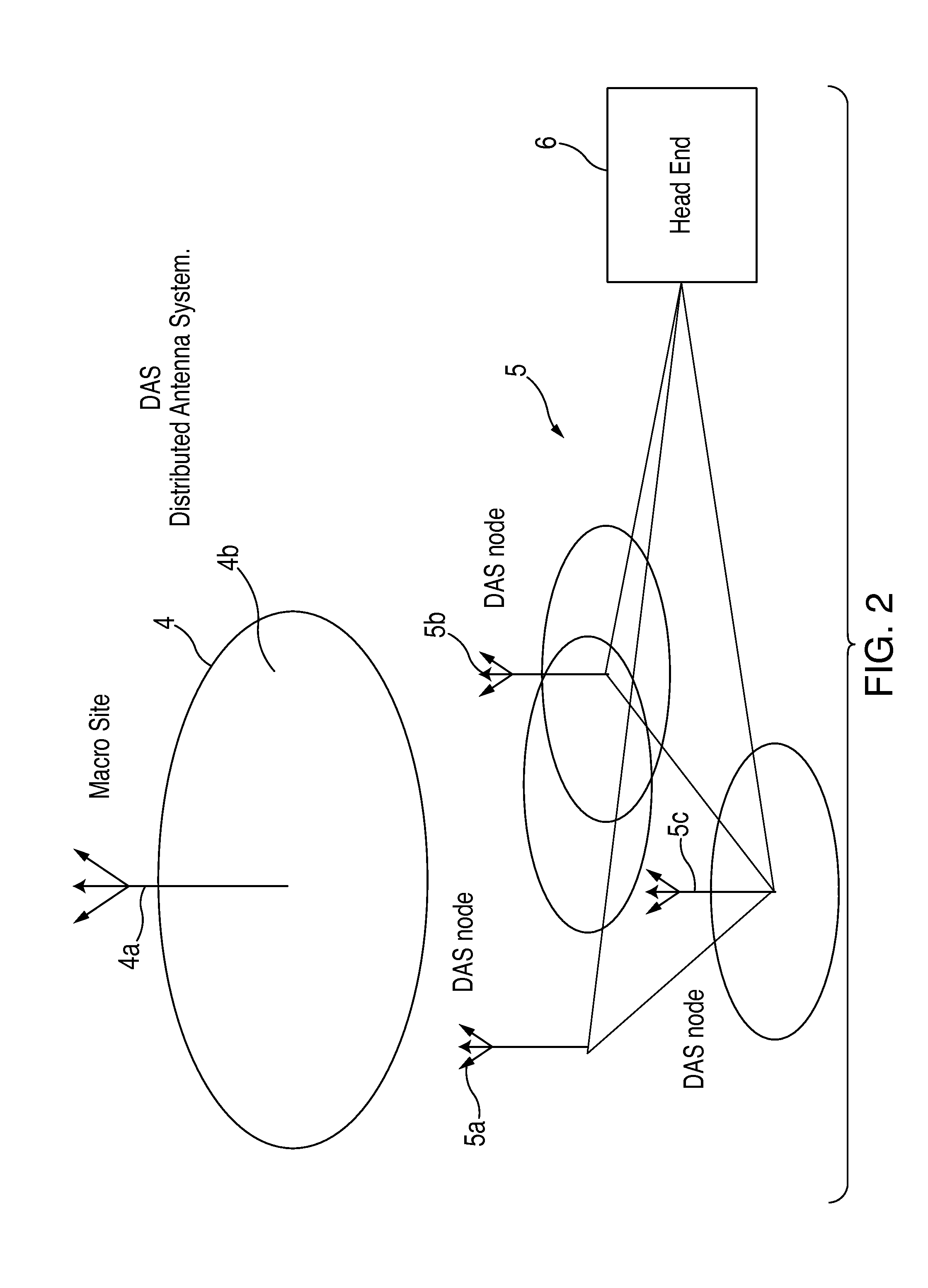

Method of Acquiring, Auditing and Interpreting Radiation Data for Wireless Network Optimization

InactiveUS20160269917A1Enhance and tune D modelingEffectively monitor network performanceTransmitters monitoringWireless communicationRadio frequencyTerrain

The present invention is a method for surveying, monitoring and auditing cell towers and antennas emitting radiation such as radio frequency and infra-red radiation using unmanned aerial vehicles. The method employs vertical measurements of signal strength, interference and radiation with a mobile platform for evaluating test data and optimizing network performance and safety. The invention is particularly suited for monitoring and auditing RF antennas situated in a variety of terrains.

Owner:ONTEGRITY INC

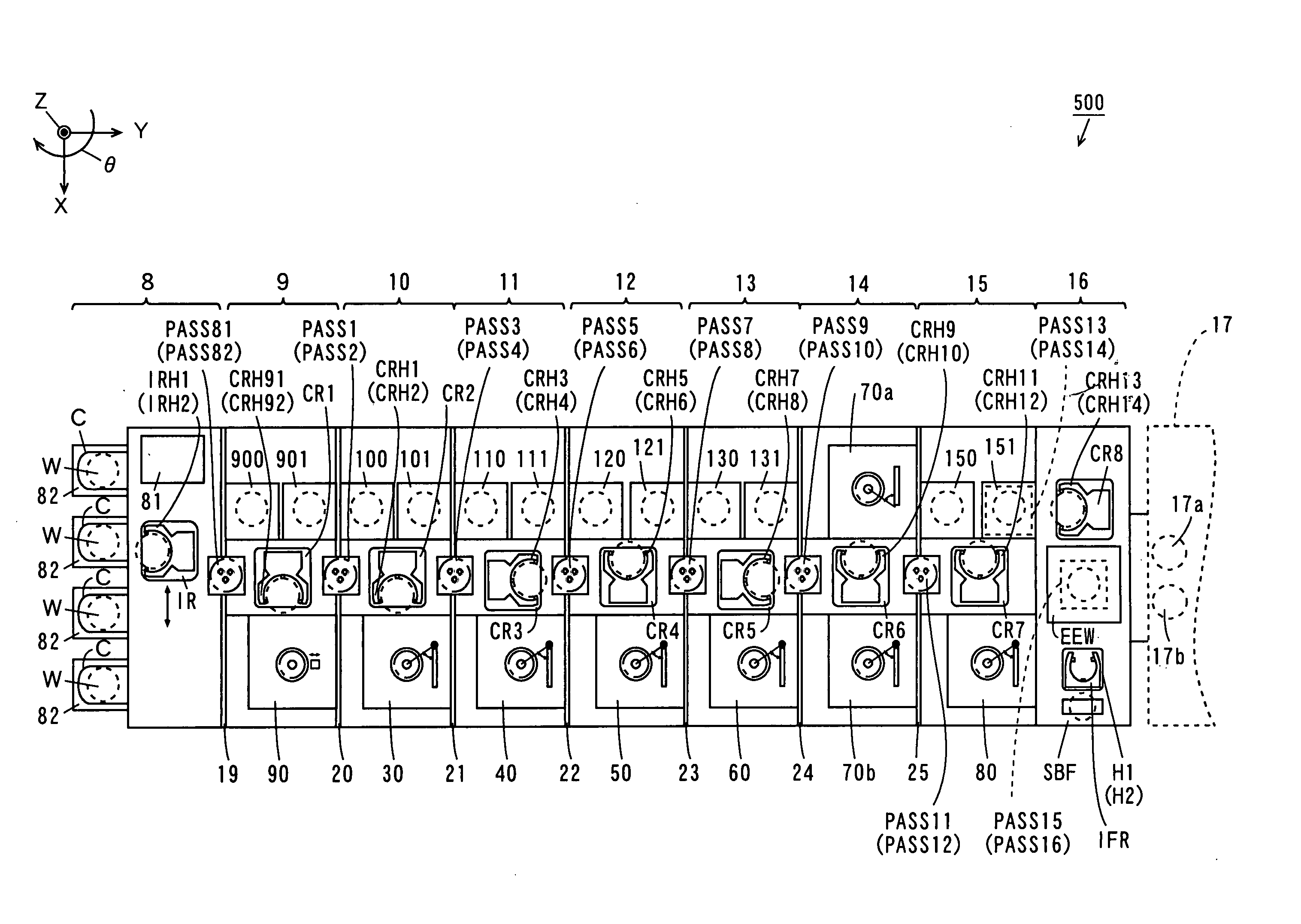

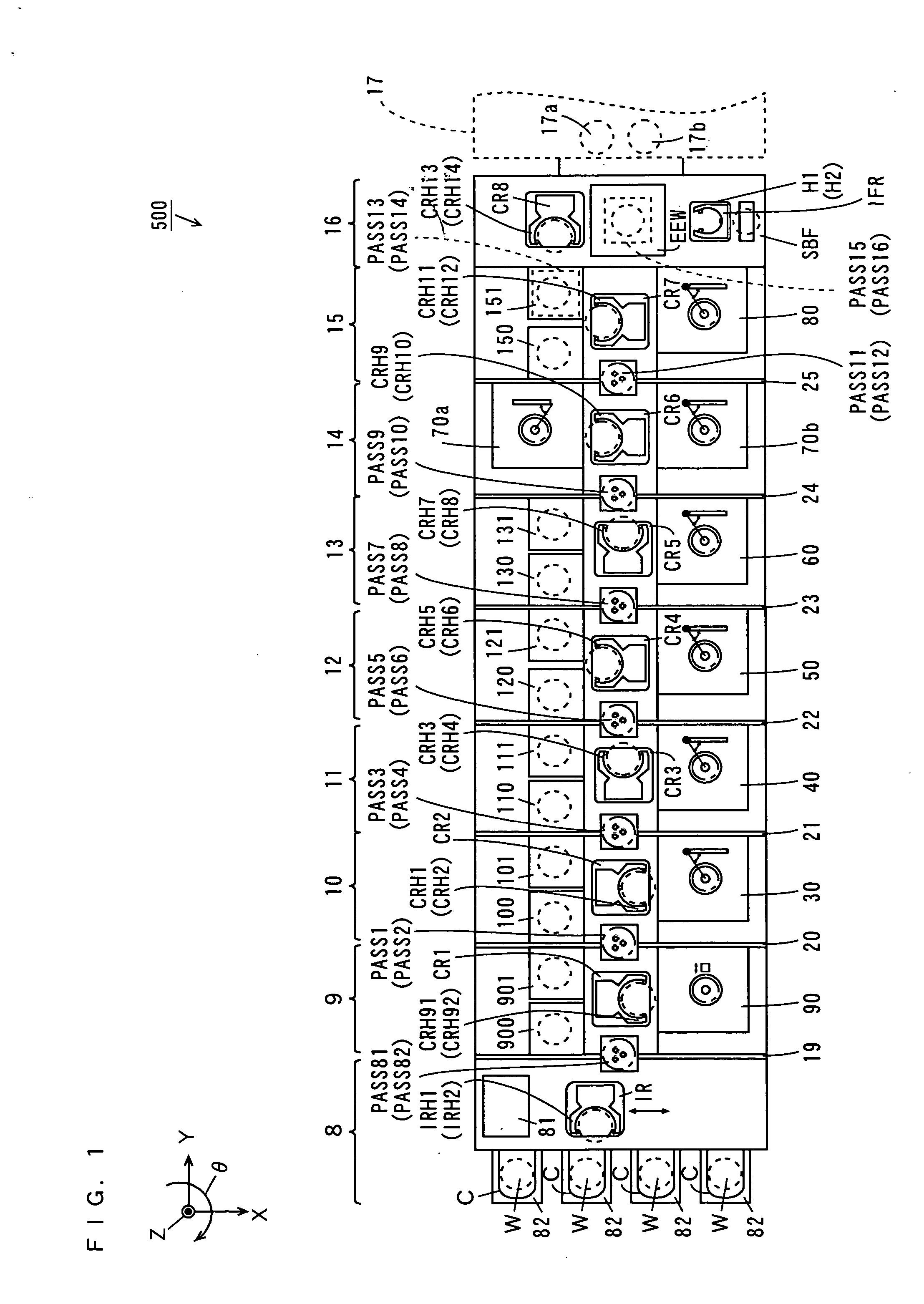

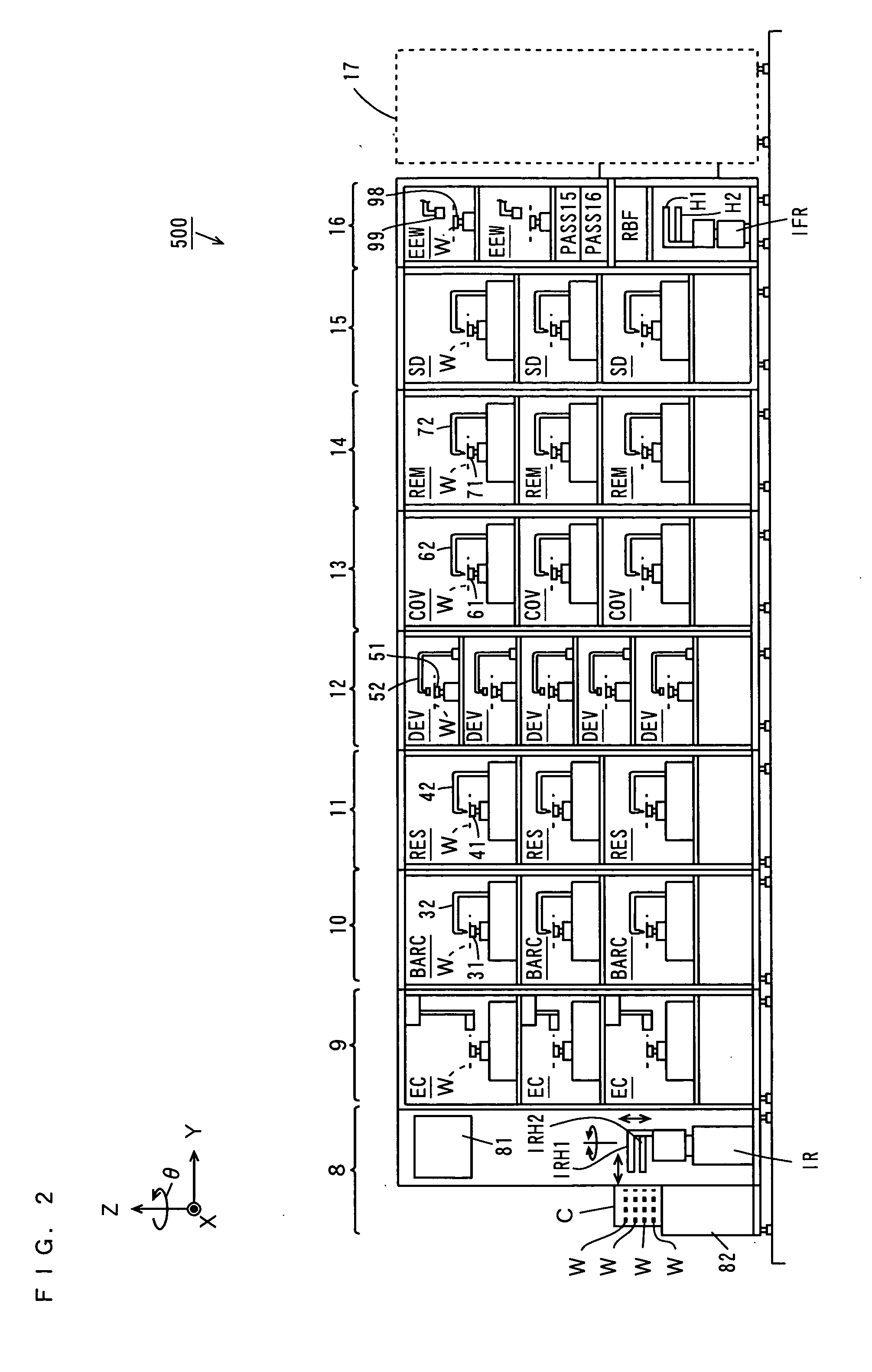

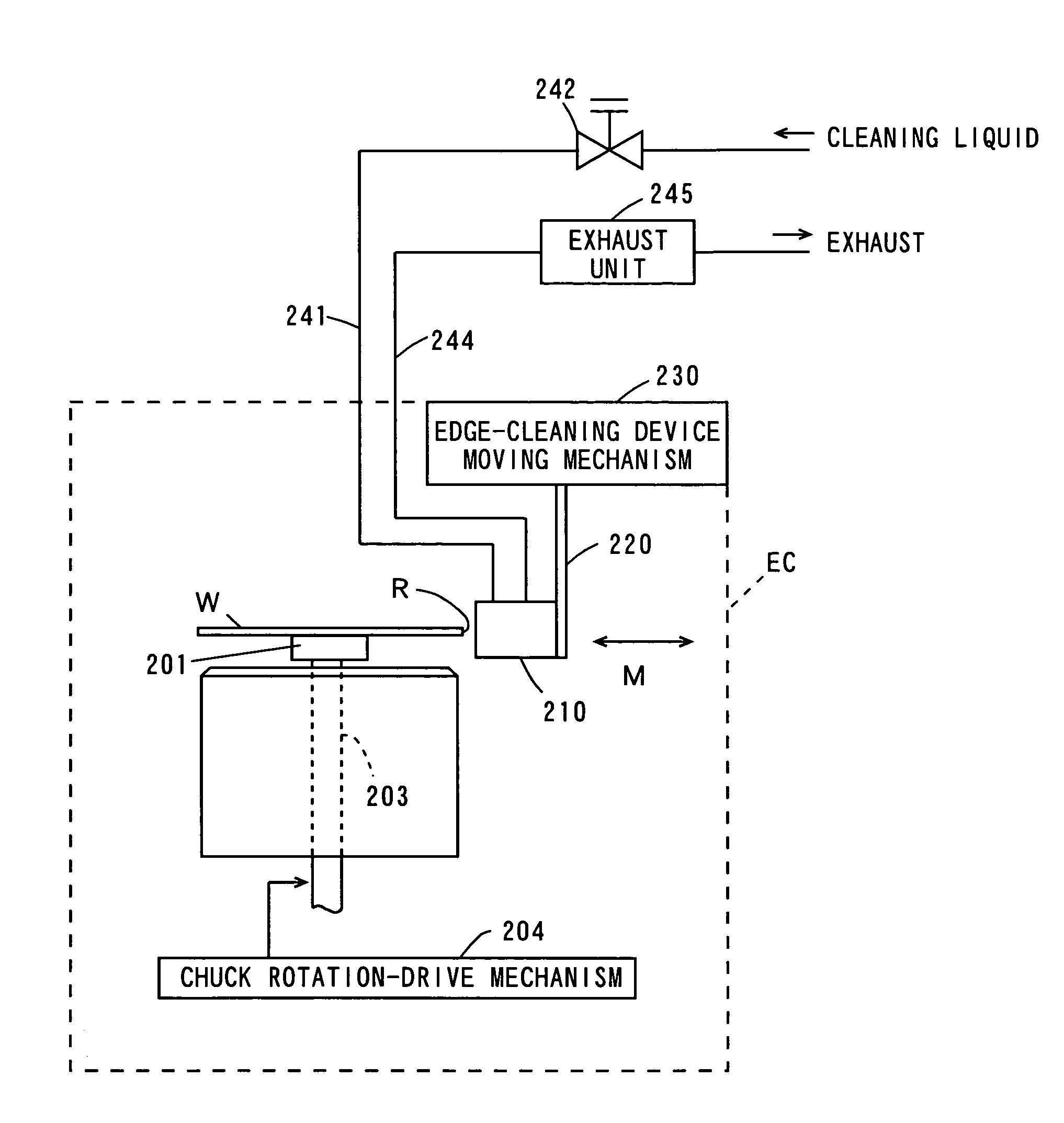

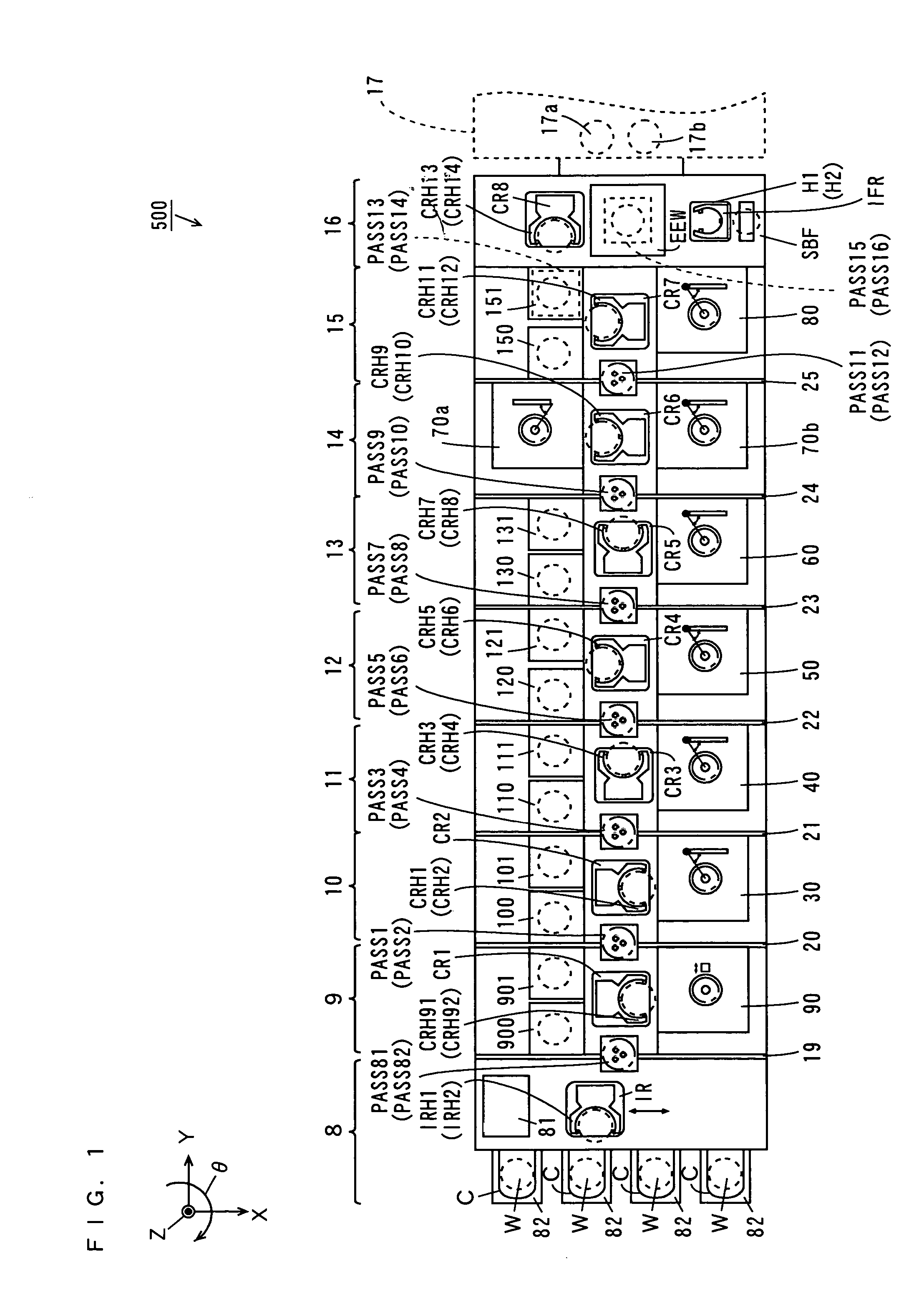

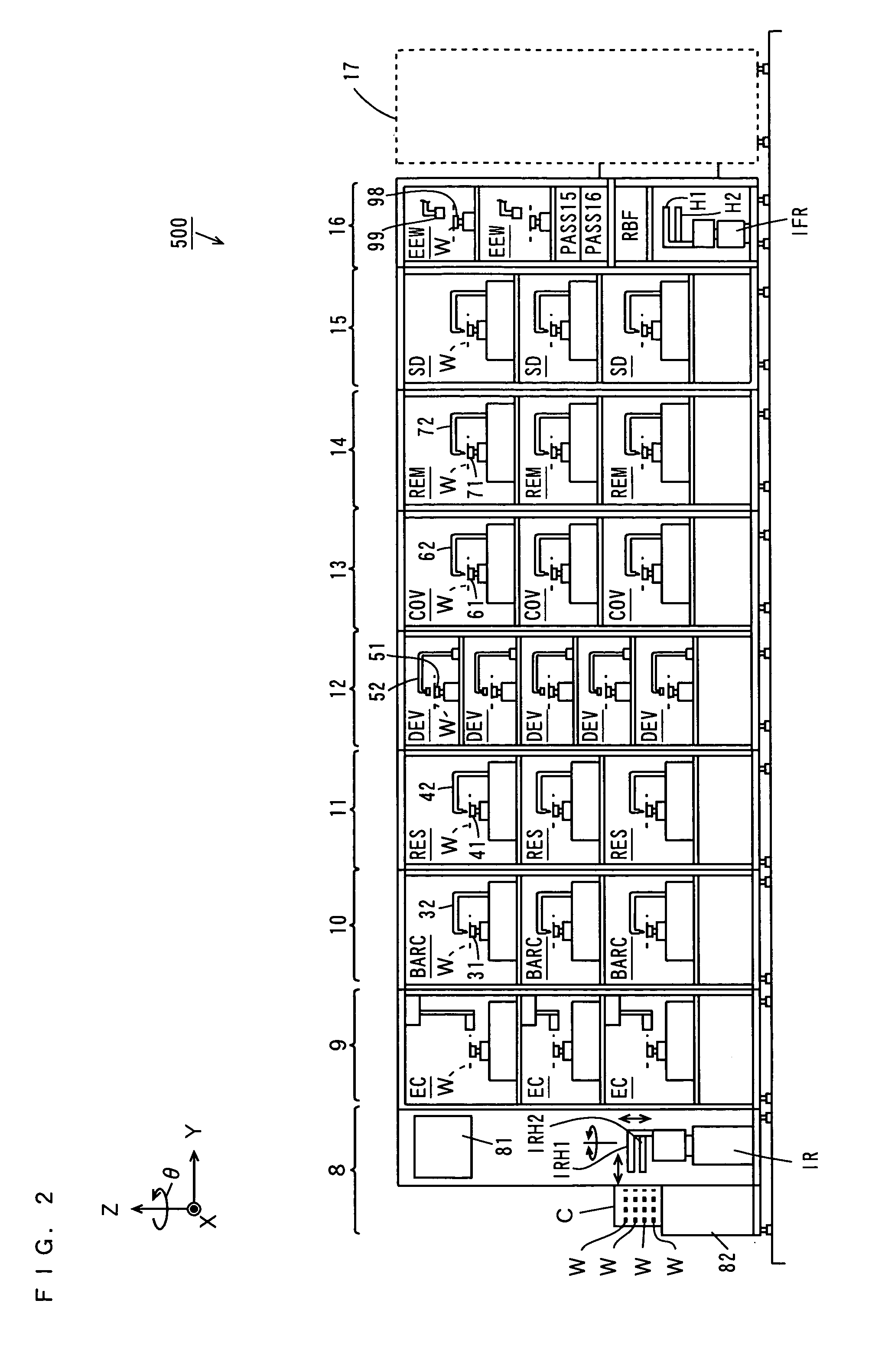

Substrate processing apparatus

ActiveUS20060291855A1Prevent contaminationAvoid defective dimension and defective shapeLiquid processingSemiconductor/solid-state device manufacturingComputer science

A substrate processing apparatus comprises an indexer block, an edge-cleaning processing block, an anti-reflection film processing block, a resist film processing block, a development processing block, a resist cover film processing block, a resist cover film removal block, a cleaning / drying processing block and an interface block. An exposure device is arranged adjacent to the interface block of the substrate processing apparatus. In the exposure device, exposure processing is applied to a substrate by a liquid immersion method. In the edge-cleaning processing group in the edge-cleaning processing block, an edge of the substrate before exposure processing is cleaned.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

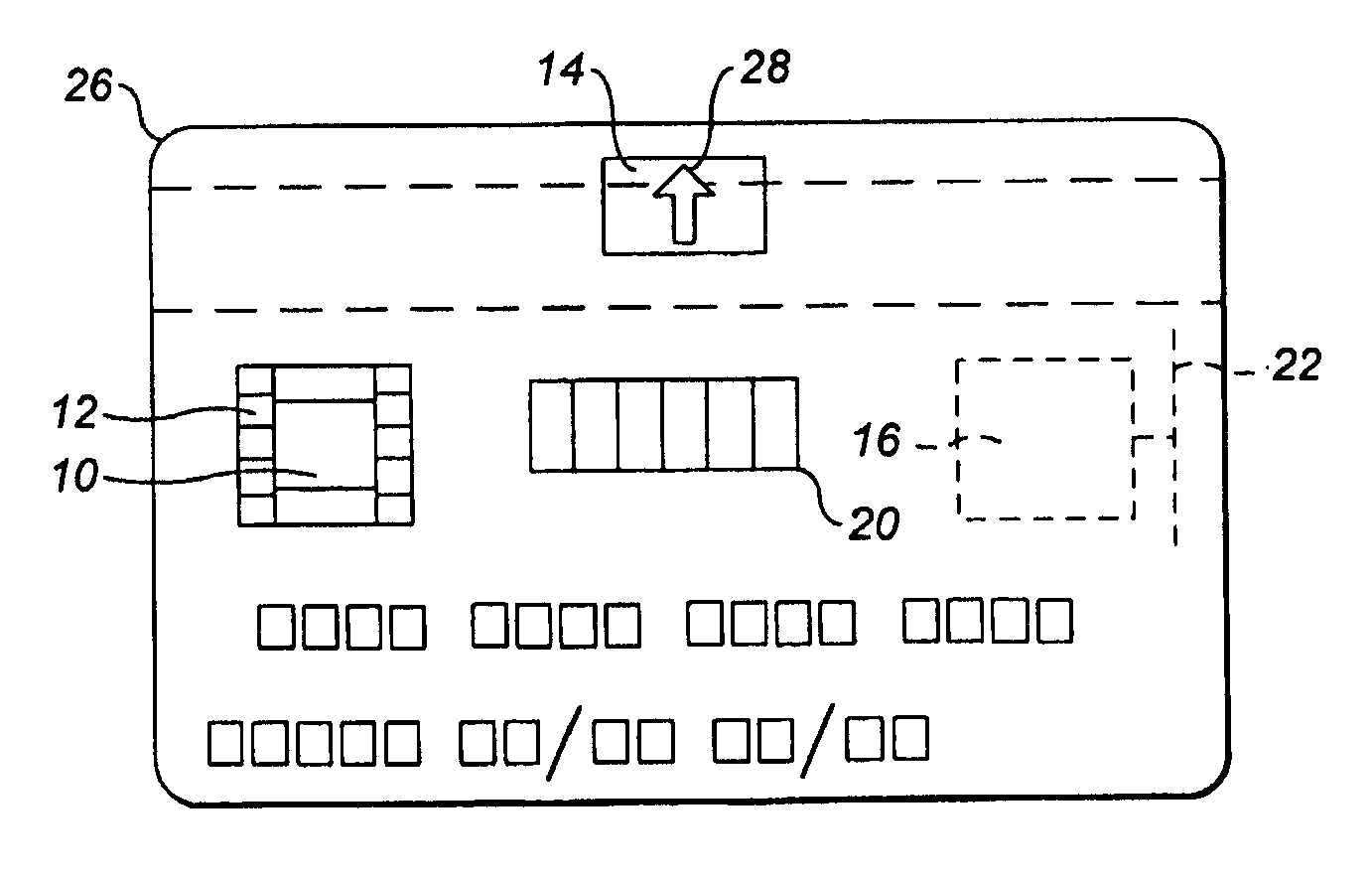

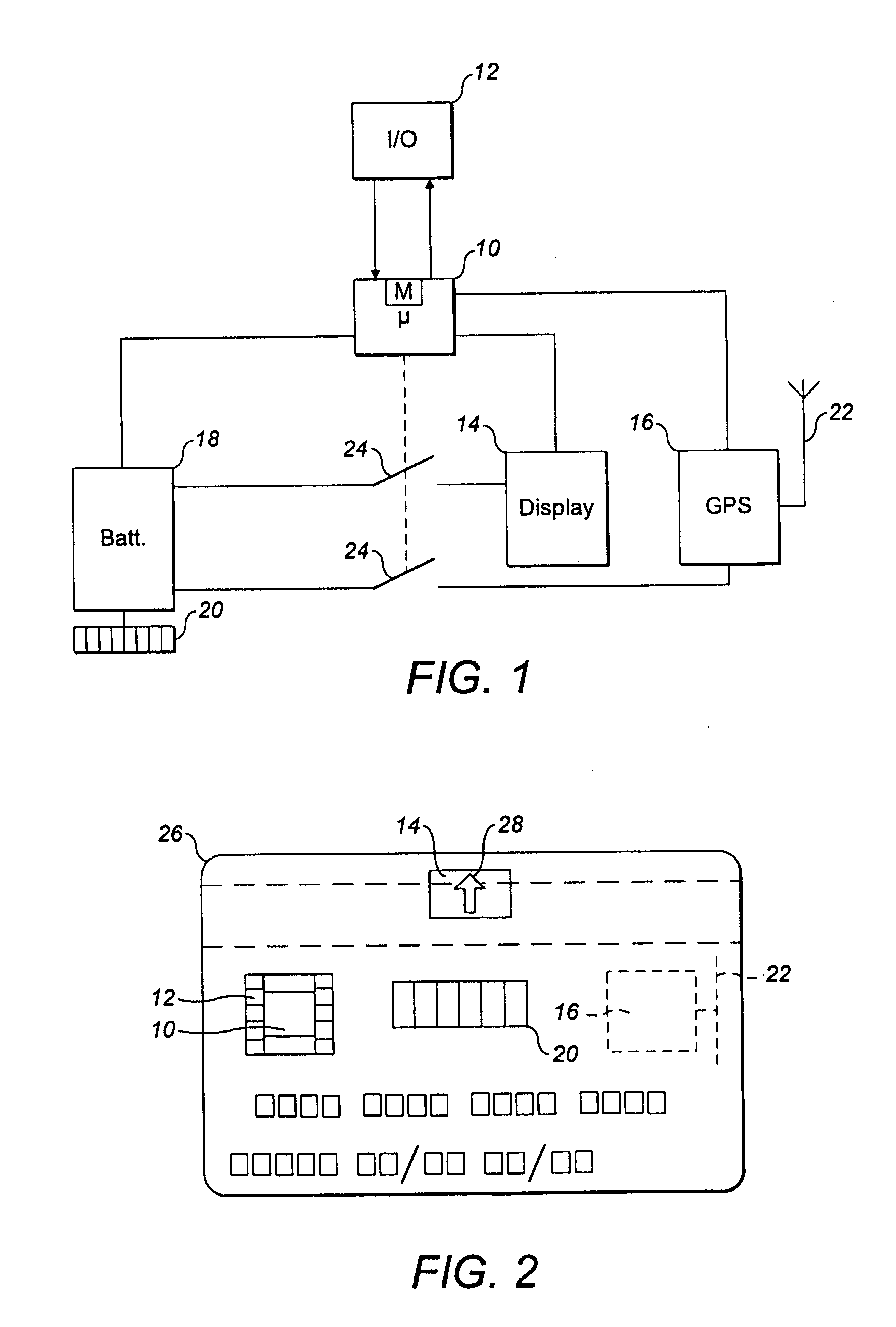

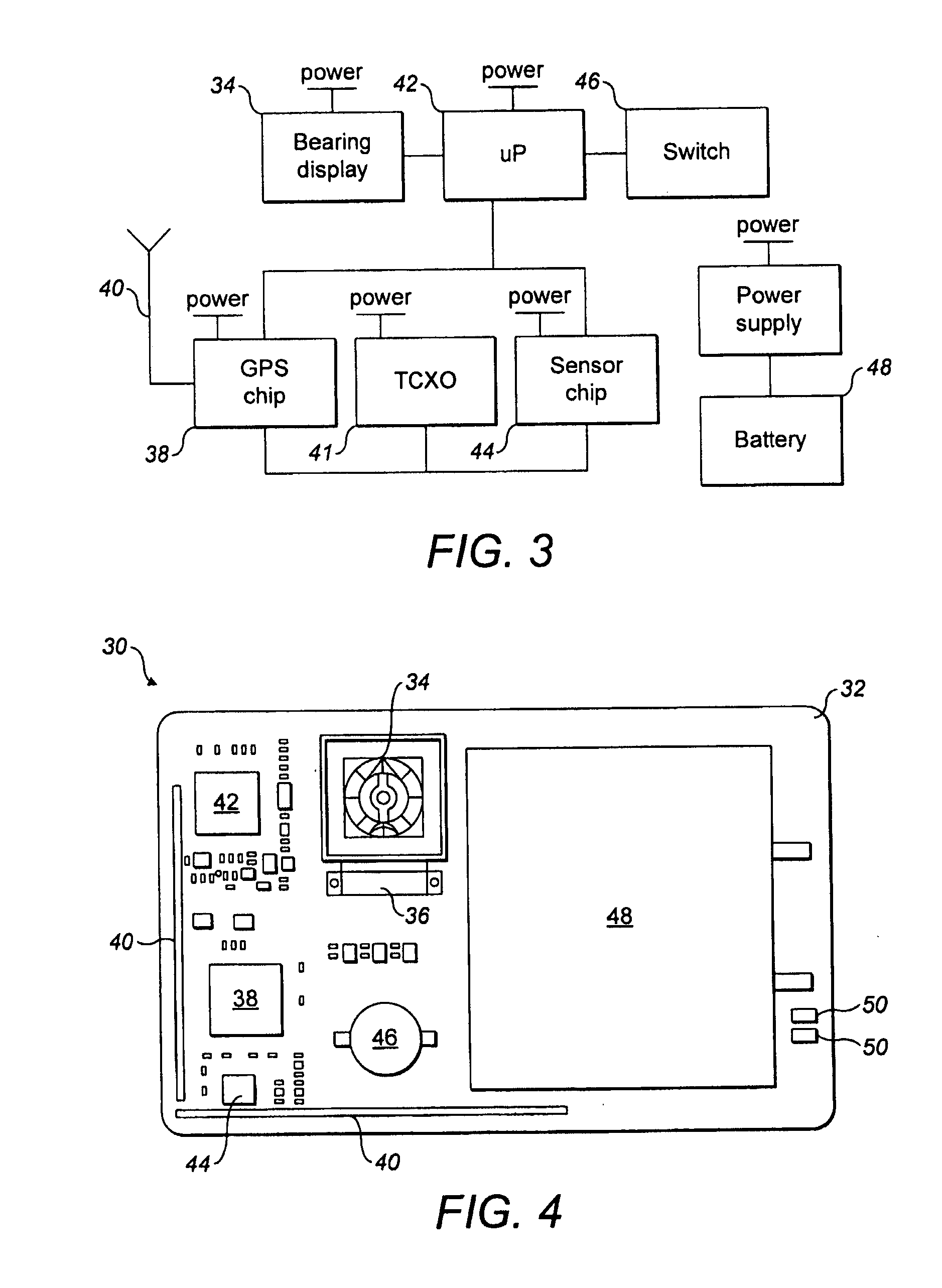

Bearing information on a card

InactiveUS20110208648A1Save energySave powerNavigational calculation instrumentsFinanceComputer hardwareDisplay device

A financial transaction card is supplemented by position determining means which determines position coordinates for the card. The determined position is compared with a predetermined position stored in the memory to provide bearing data on the predetermined position from the position of the card. The card also includes a display for indicating the bearing. The card is particularly useful for indicating the bearing of the Kaaba from the position of the card.

Owner:SAMBA FINANCIAL GROUP

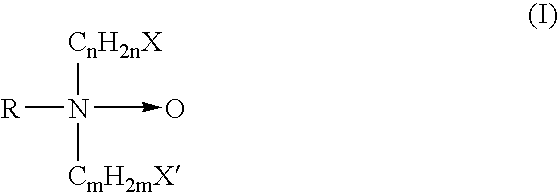

Detergent For Lithography And Method Of Forming Resist Pattern With The Same

InactiveUS20090004608A1Easy to optimizeReduce surface tensionAnionic surface-active compoundsNon-surface-active detergent compositionsResistLithographic artist

Conventional detergents for lithography which contain a surfactant as an active ingredient should have a reduced surfactant concentration because heightened surfactant concentrations result in dissolution of the resin component of a photoresist composition and hence in a dimensional change of a resist pattern. However, the conventional detergents have had a drawback that such a low concentration unavoidably reduces the ability to inhibit pattern falling and defect occurrence. A detergent for lithography is provided which is an aqueous solution containing (A) at least one member selected among nitrogenous cationic surfactants and nitrogenous ampholytic surfactants and (B) an anionic surfactant. This detergent retains a low surface tension even when it has a low concentration. It is effective in inhibiting pattern falling and defect occurrence. It can also inhibit resist patterns from fluctuating in dimension.

Owner:TOKYO OHKA KOGYO CO LTD

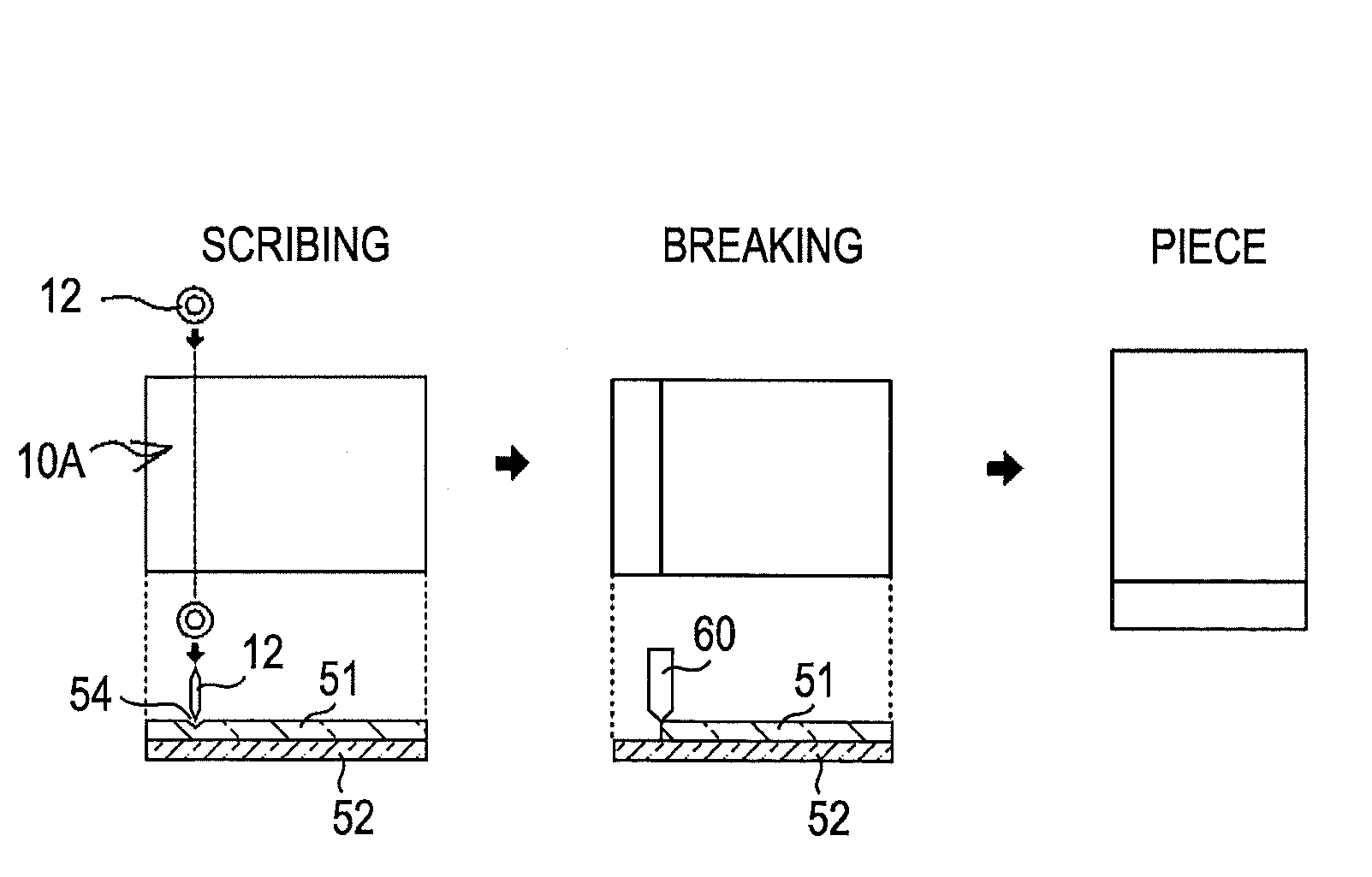

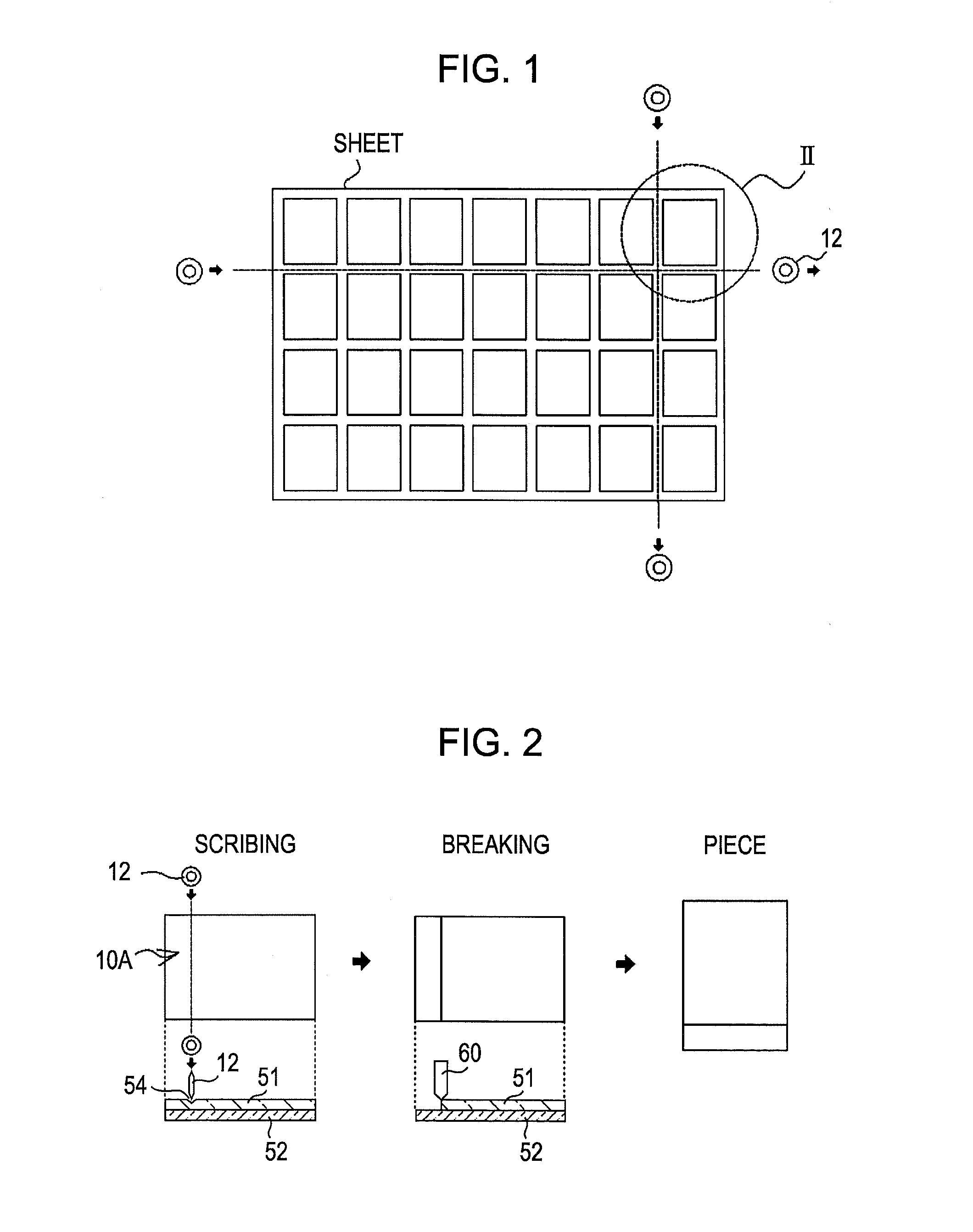

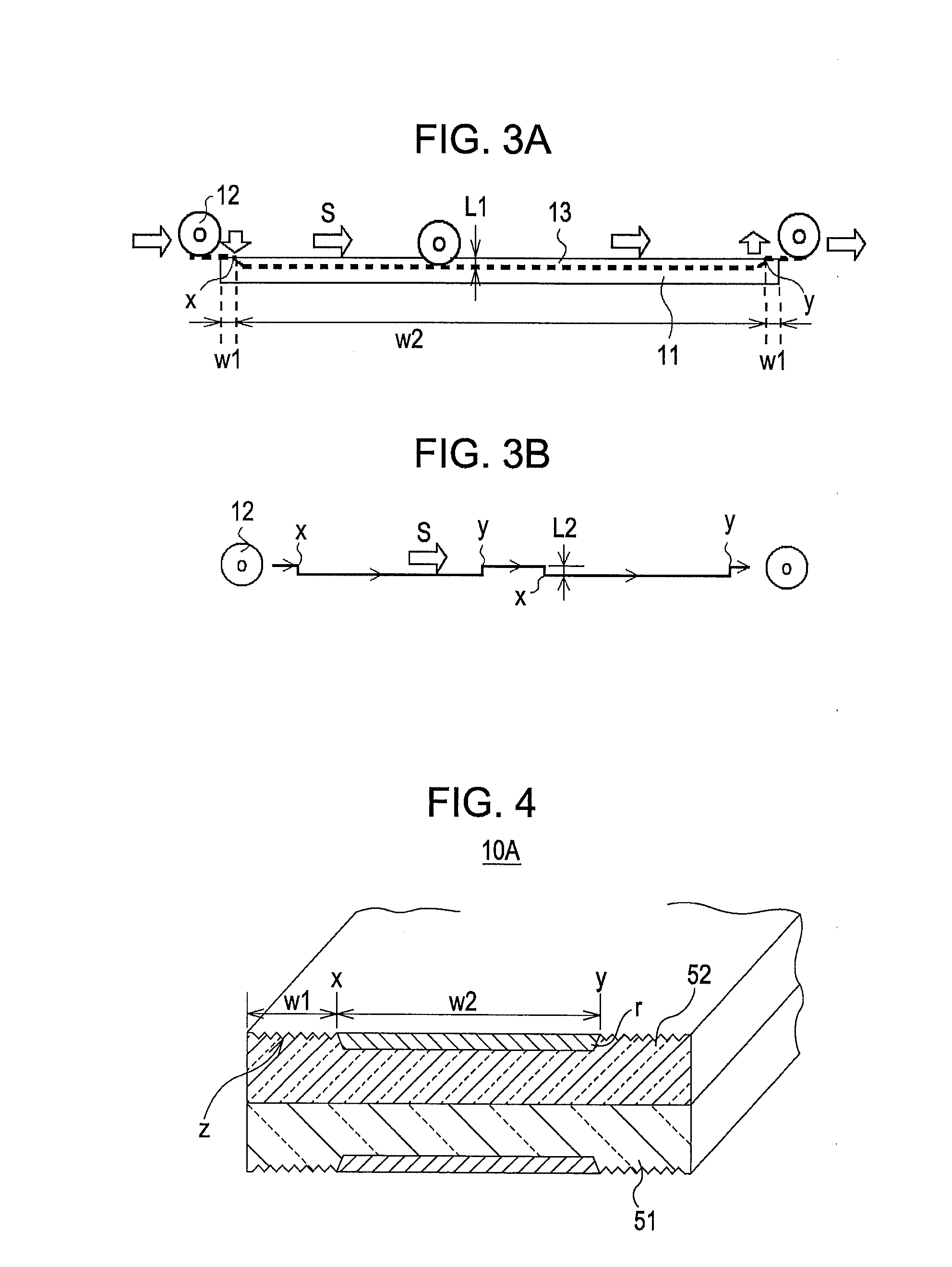

Display device having pair of glass substrates and method for cutting it

InactiveUS20080311817A1Out dimension of accurateOuter dimension can be preventedStampsWrappersDisplay deviceEngineering

Owner:JAPAN DISPLAY WEST

Substrate processing apparatus

ActiveUS7604424B2Avoid contactAvoid DimensionsLiquid processingSemiconductor/solid-state device manufacturingComputer science

A substrate processing apparatus comprises an indexer block, an edge-cleaning processing block, an anti-reflection film processing block, a resist film processing block, a development processing block, a resist cover film processing block, a resist cover film removal block, a cleaning / drying processing block and an interface block. An exposure device is arranged adjacent to the interface block of the substrate processing apparatus. In the exposure device, exposure processing is applied to a substrate by a liquid immersion method. In the edge-cleaning processing group in the edge-cleaning processing block, an edge of the substrate before exposure processing is cleaned.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

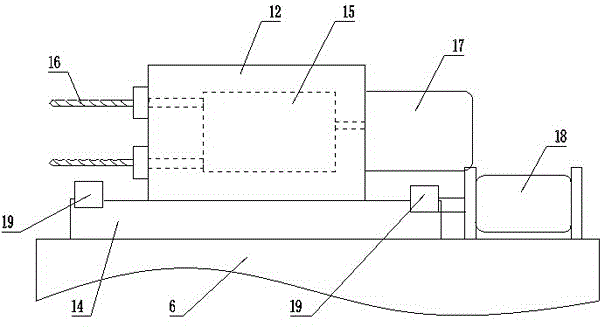

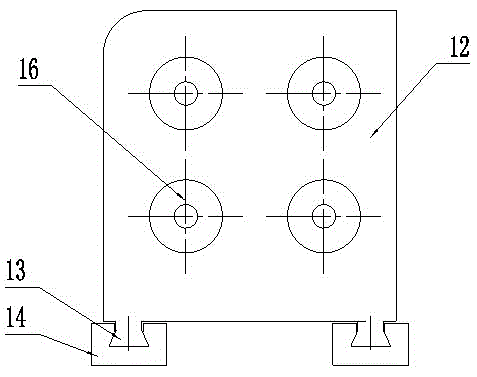

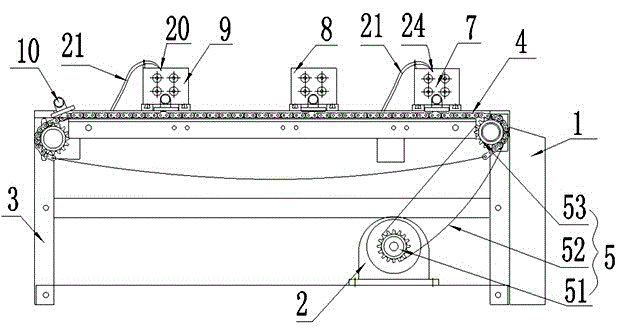

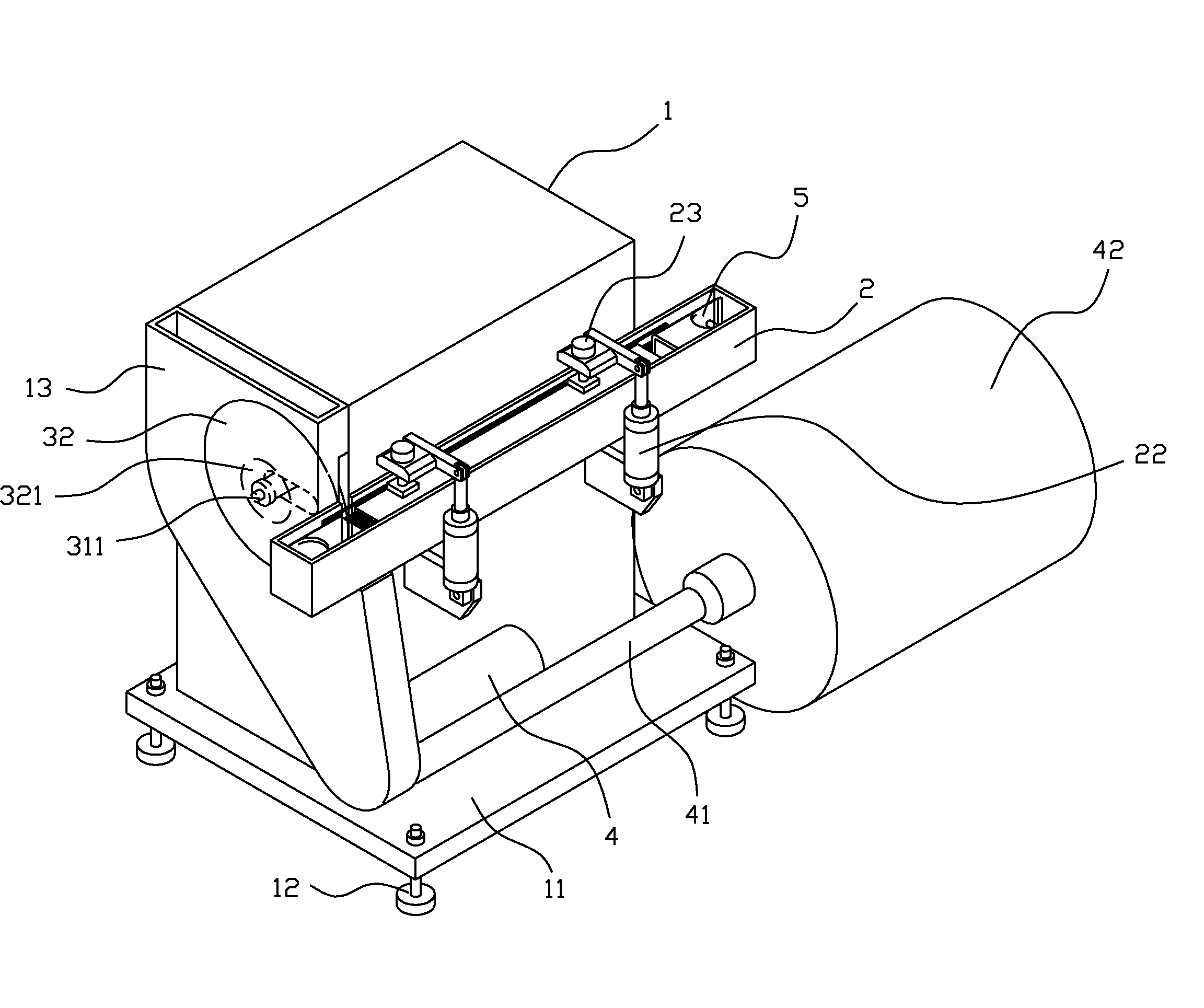

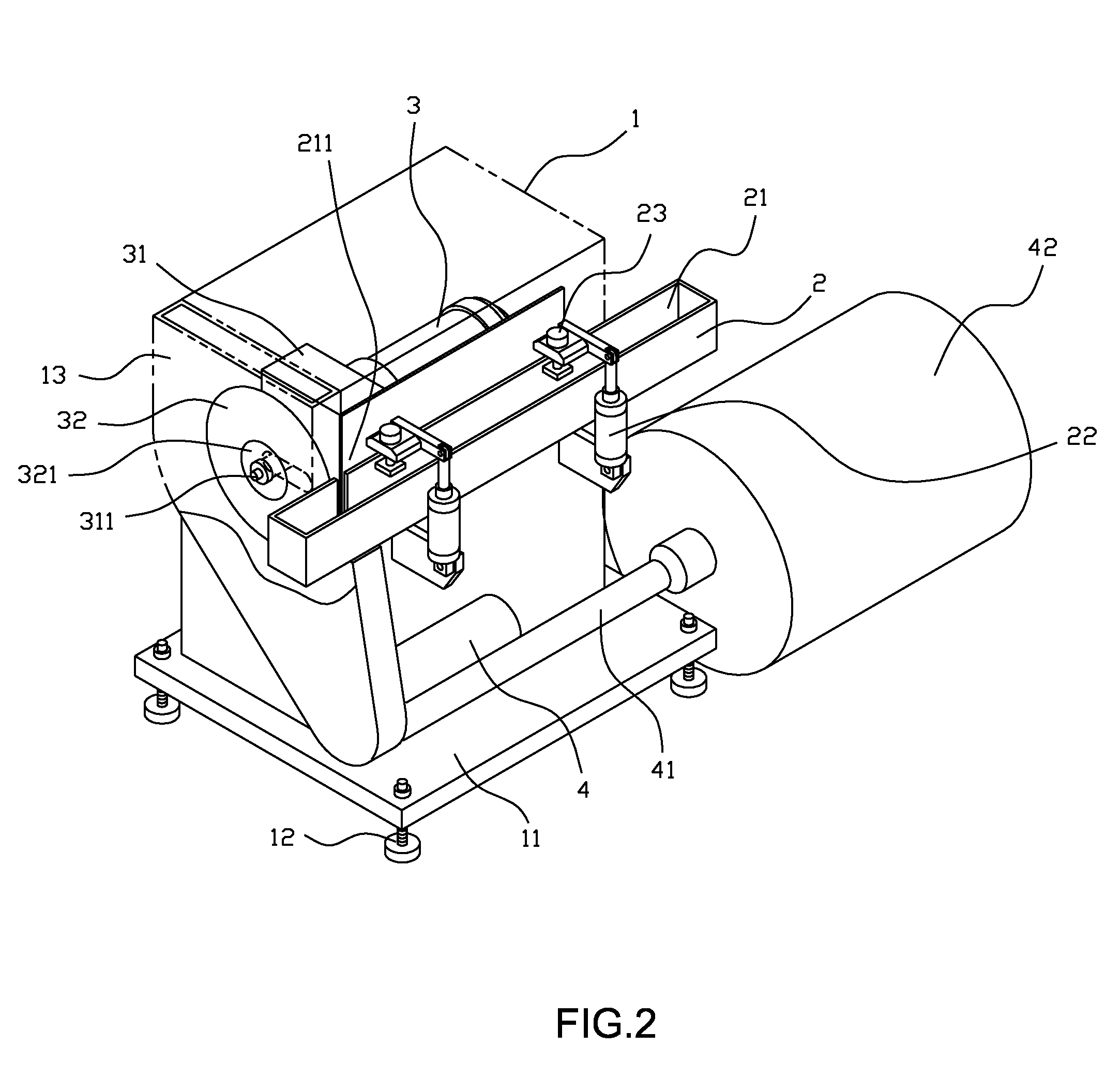

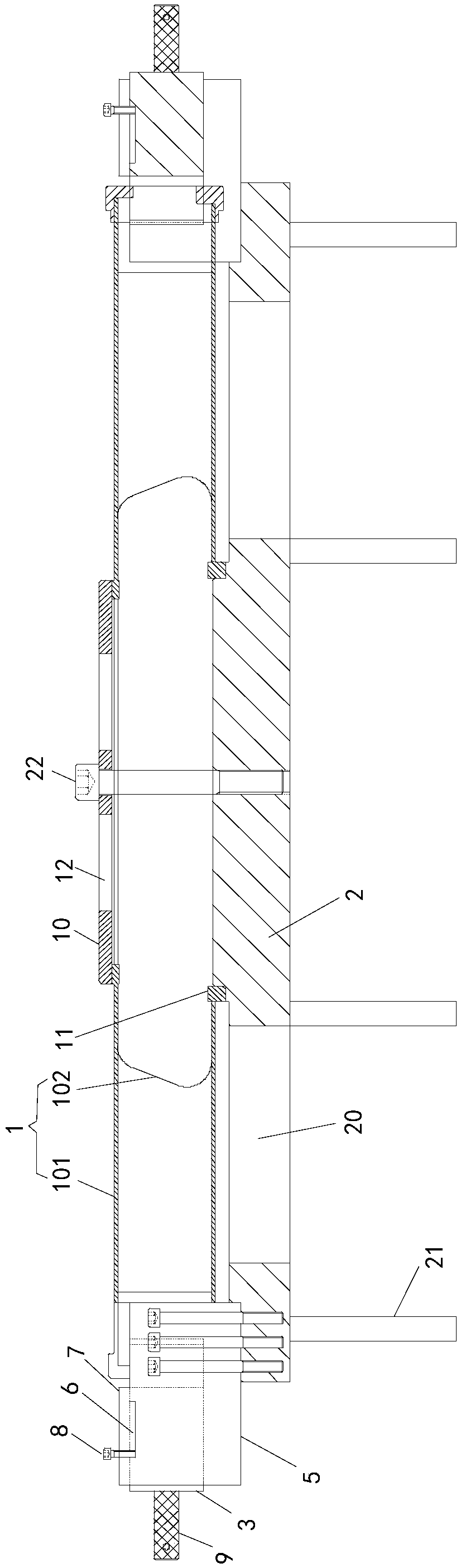

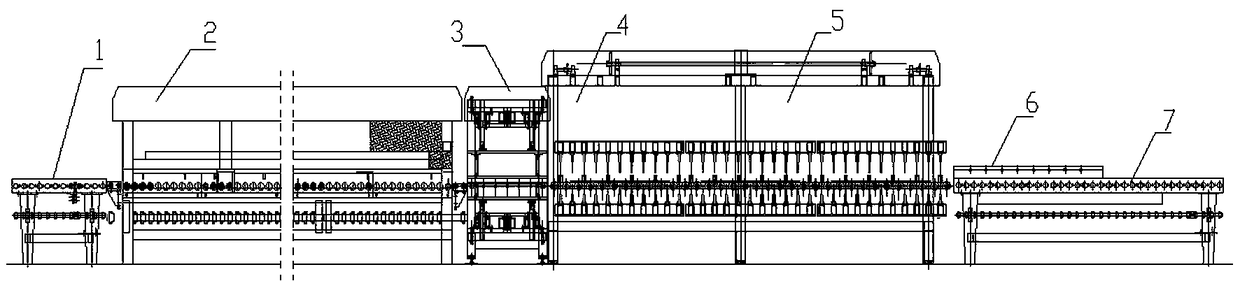

Two-sided drilling combined machine tool

InactiveCN105058059AGuaranteed accuracyReduce labor intensityOther manufacturing equipments/toolsMetal working apparatusMotor driveMaterial consumption

The invention discloses a two-sided drilling combined machine tool and relates to the technical field of cold machining machine tools. The two-sided drilling combined machine tool comprises a control box, a main motor and a rack, wherein a conveying belt is arranged in the middle of the rack; the control box is arranged on one side of the feed side beside the rack; the main motor is connected with the conveying belt by a transmission mechanism; workbenches are arranged on the top of the rack; the workbenches are arranged at two sides of the conveying belt; bottom hole processing devices, orifice chamfering devices and tapping devices are symmetrically arranged at two sides of the conveying belt; the main motor, the bottom hole processing devices, the orifice chamfering devices and the tapping devices are connected with the control box; clamp bodies are arranged on the conveying belt at intervals; the clamp bodies are used for clamping to-be-processed box bodies; and two ends of the clamp bodies are matched with the workbenches at two sides by pin rollers. The main motor drives the conveying belt to drive the to-be-processed box bodies clamped on the clamp bodies to pass bottom hole processing work stations, orifice chamfering work stations and tapping work stations in sequence, so that drilling and tapping are finished, the labor and material consumption is reduced, and the processing efficiency is improved.

Owner:孙立民

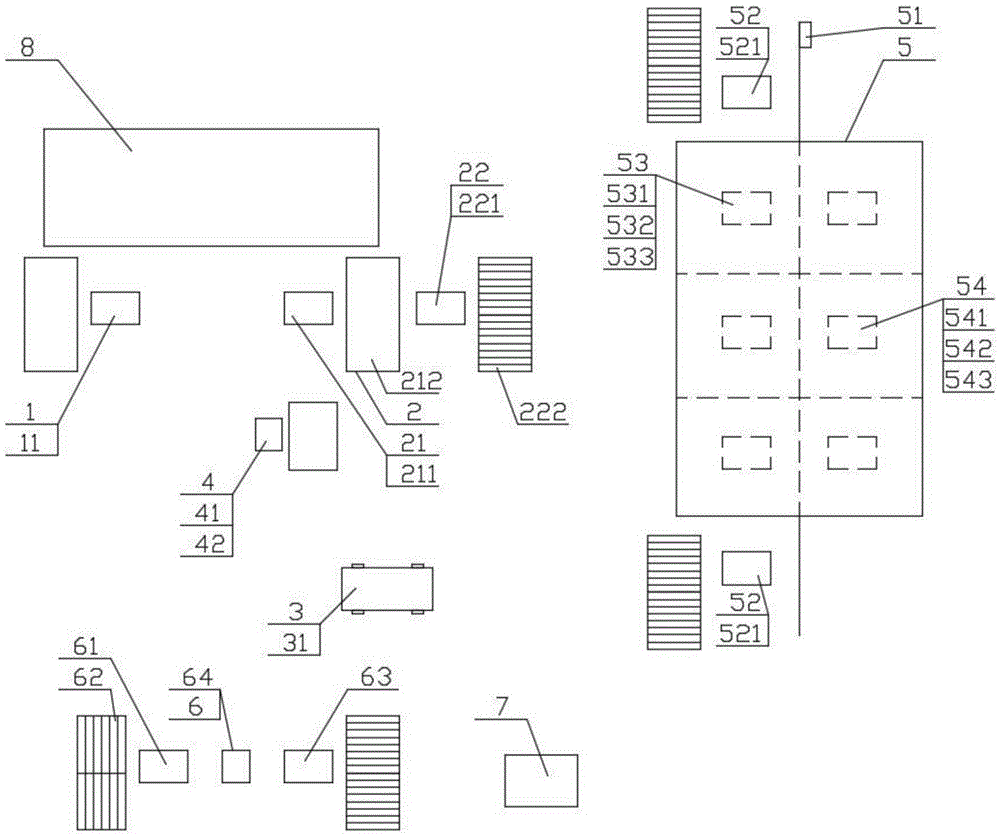

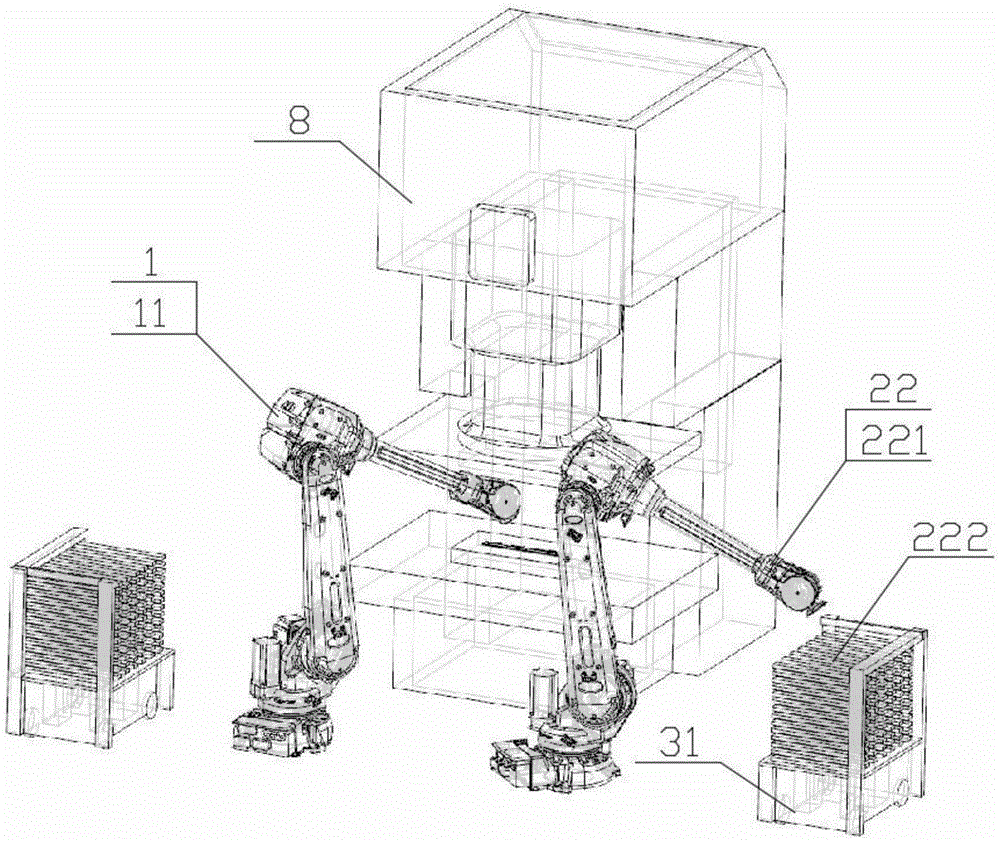

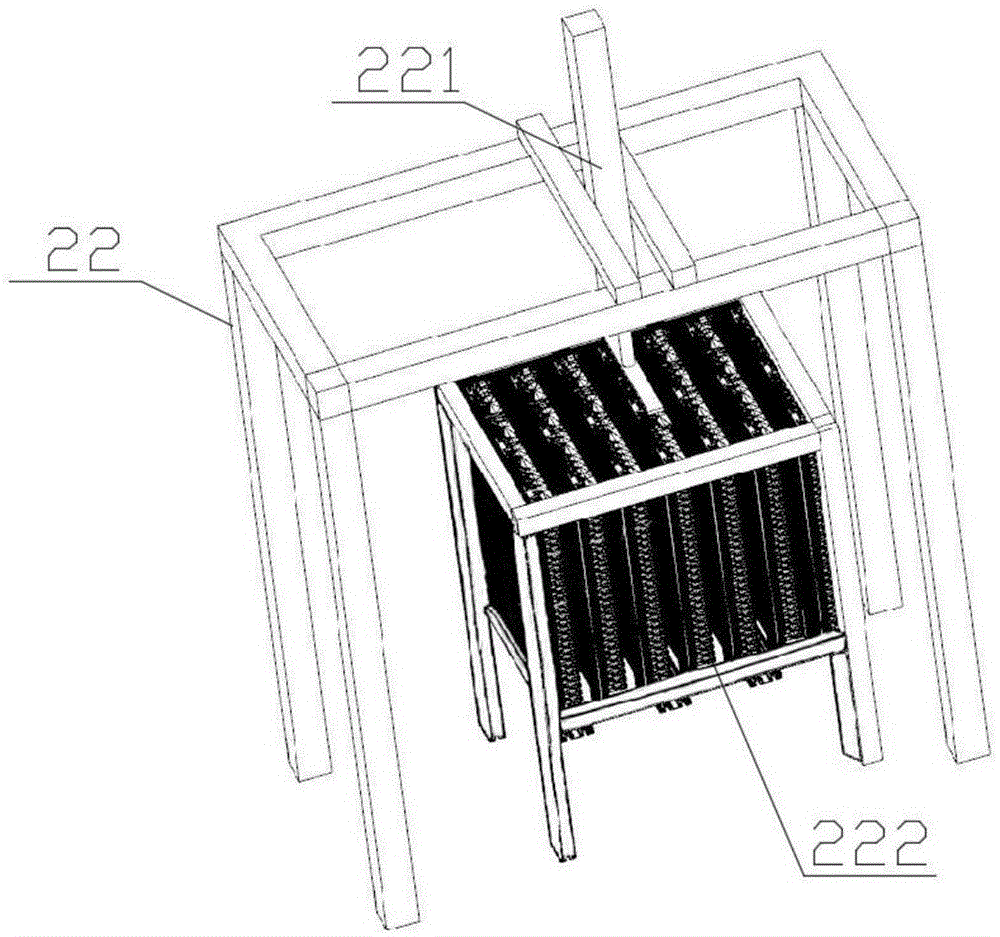

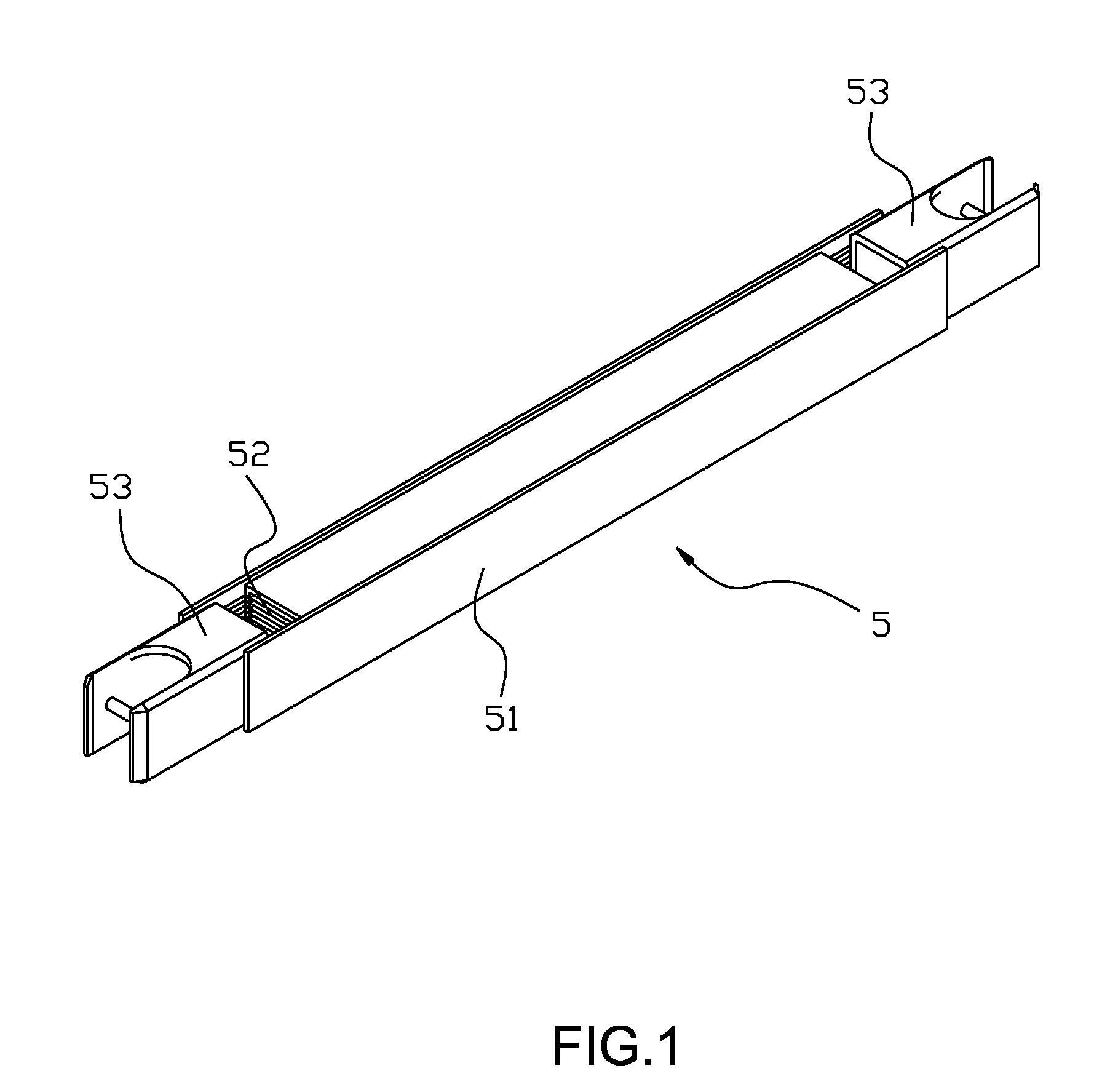

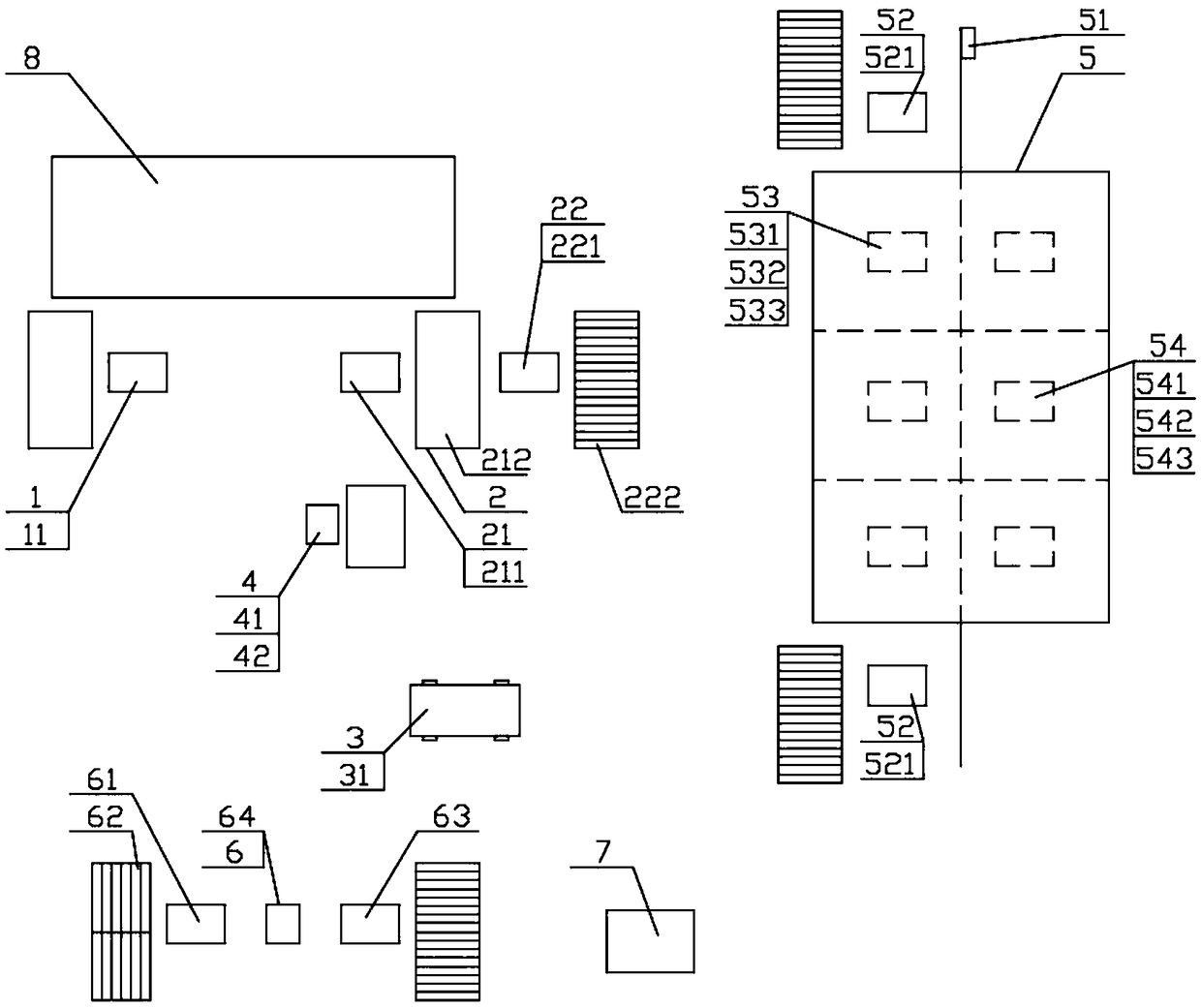

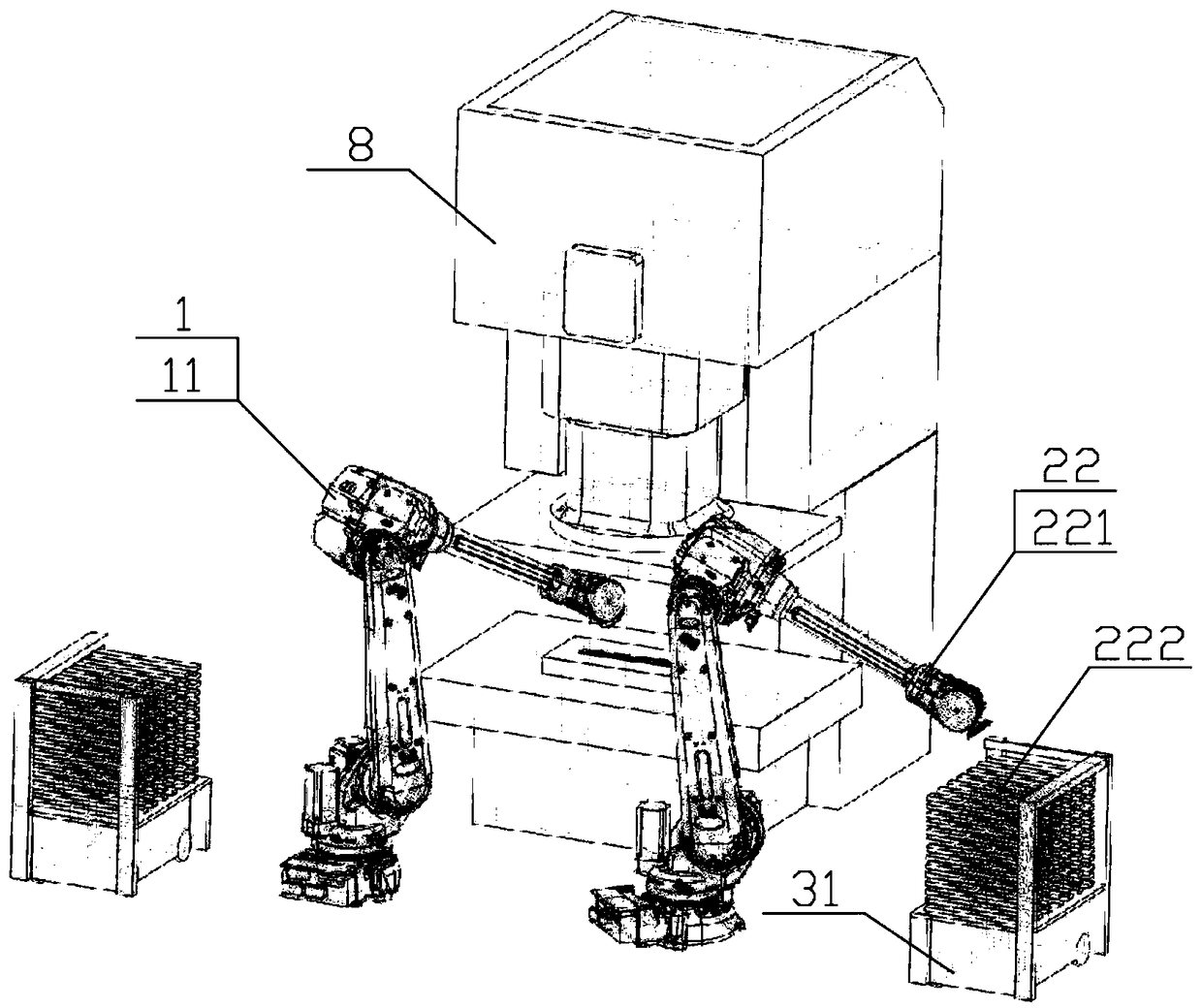

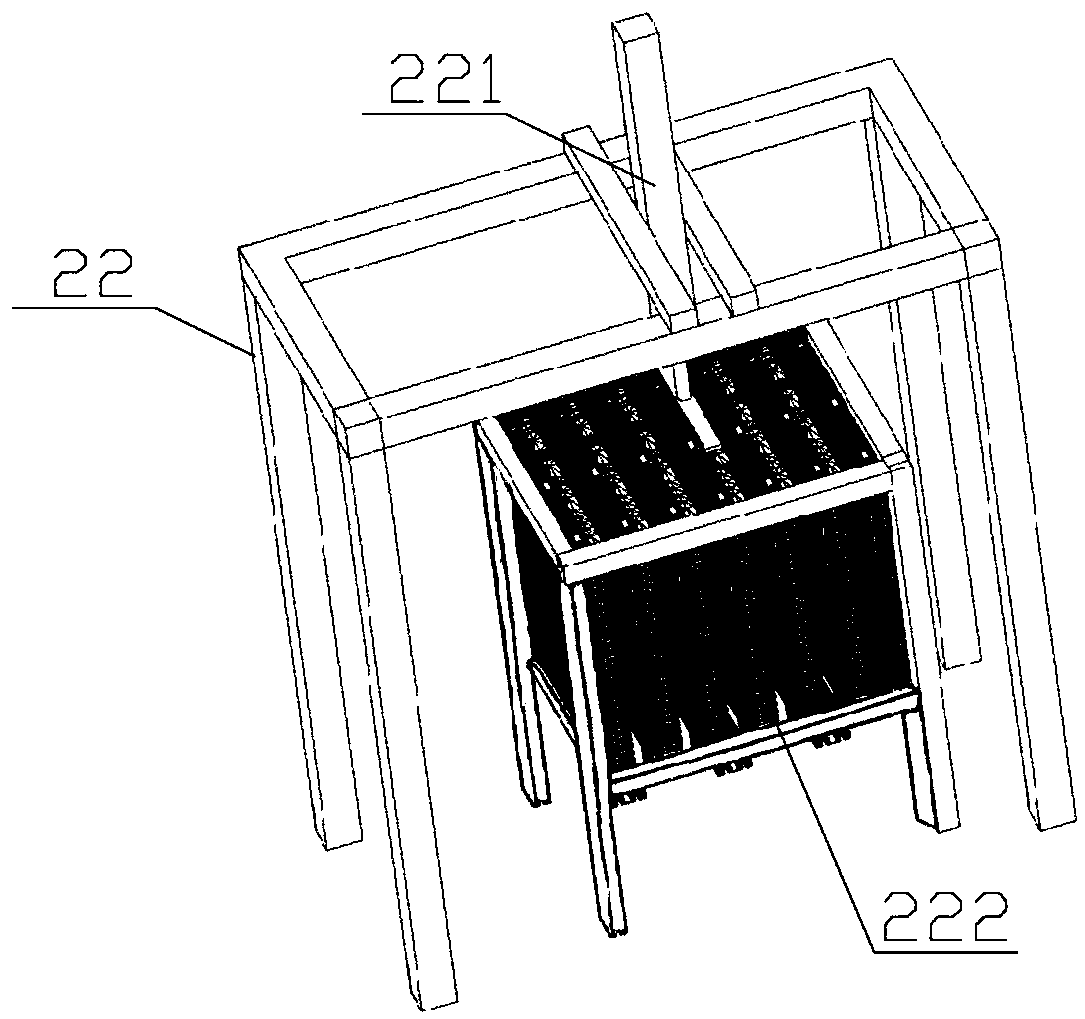

Artificial intelligence sheet metal part producing system

ActiveCN105642781AGuarantee product qualityAvoid DimensionsMetal-working feeding devicesMaterial gluingElectronic control unitMaterial supply

The invention discloses an artificial intelligence sheet metal part producing system. The system comprises a material supply unit (1), a formed sheet metal part automatic taking and stacking unit (2), an intelligent logistics carrying and transporting unit (3) and a centralized electronic control unit (7). The formed sheet metal part automatic taking and stacking unit comprises a plurality of counting and stacking devices (22) arranged nearby the discharging end of a sheet metal machining device (8); each counting and stacking device comprises a grabbing and stacking part II(221), a stacking bracket (222) and an electronic control part; and each stacking bracket comprises a plurality of containing spaces (2221) evenly arranged in the horizontal and vertical direction and an electronic control mechanism. According to the artificial intelligence sheet metal part producing system, the grabbing and stacking parts II controlled by a microcomputer stretch into the sheet metal machining device and are used for grabbing punched and formed sheet metal parts from the discharging end and sequentially stacking the sheet metal parts in the containing spaces of the stacking brackets, and the artificial intelligence sheet metal part producing system is a digital control system and can be seamlessly connected with a digital bus in a factory to achieve centralized digital management.

Owner:XUZHOU DKEC ELECTRICAL TECH

Structure for connecting tubular member to fuel tank

InactiveUS7128346B2Enhance air tightnessImprove penetration resistanceLarge containersPipe elementsEngineeringFuel tank

An cylindrical convex portion of which opposite ends are open is integrally formed onto a fuel tank made of HDPE therewith so as to inwardly extend in the fuel tank to provide an opening thereon. A press-fit portion of a filler hose connecting pipe made of PA as a tubular member is press-fitted in the cylindrical convex portion to connecting the tubular member to the fuel tank. At least one continuous annular projection is provided on the outer peripheral surface of the press-fit portion of the tubular member so as to bite into the inner peripheral surface of the cylindrical convex portion to provide continuous circumferential contact. A face of the annular projection in direction axially of one end of tubular member is formed so as to extend outwardly and inclinedly with respect to the axial direction of the tubular member form one end toward the other end thereof.

Owner:TOKAI RUBBER IND LTD

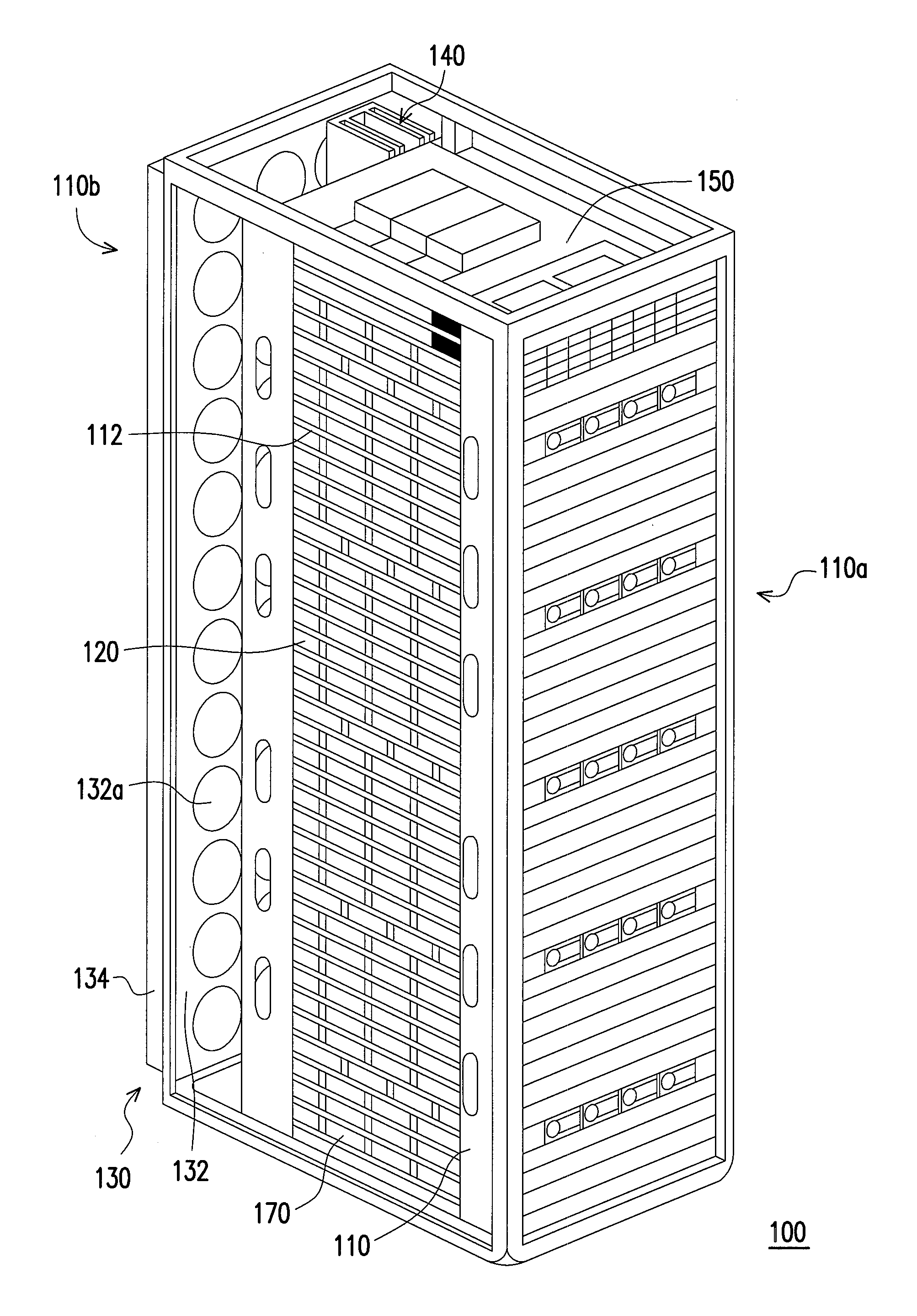

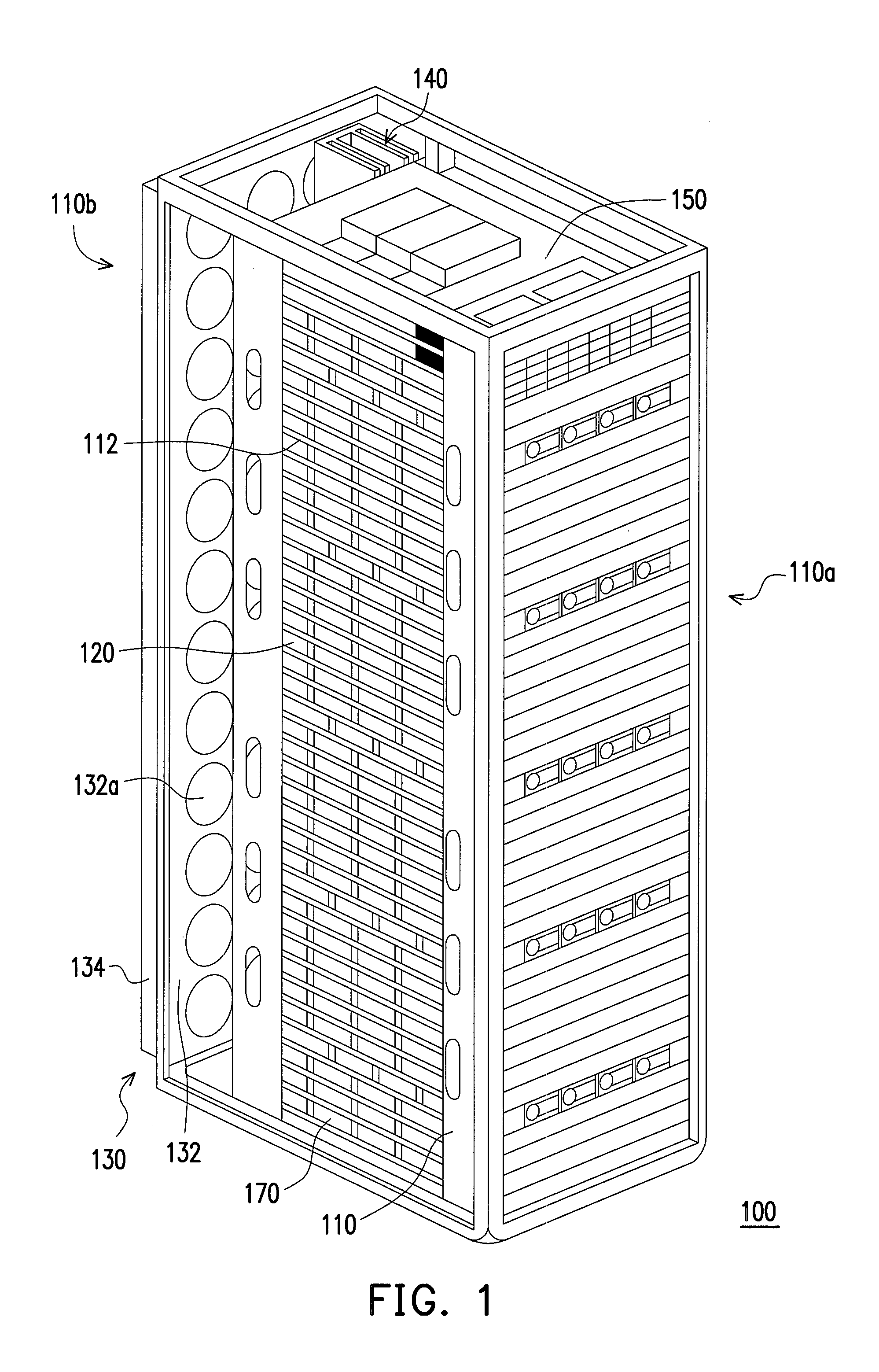

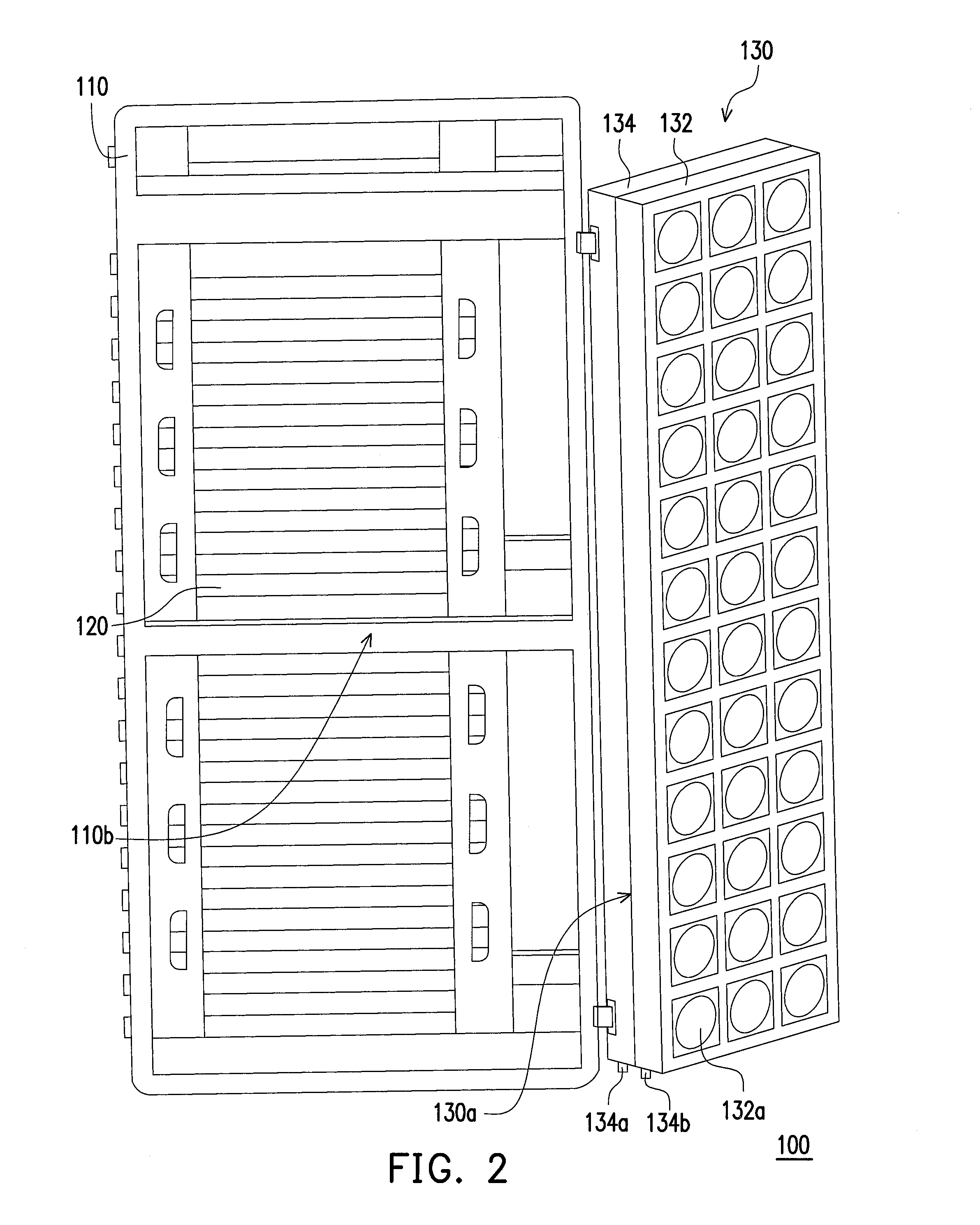

Server rack system

ActiveUS20120262864A1Improve cooling efficiencyLow costDigital data processing detailsElectrical apparatus contructional detailsEngineeringMechanical engineering

A server rack system includes a rack, servers, and a heat-dissipating wall. The rack has guiding rails, a front end, and a rear end opposite to the front end. The servers slidably configured on the guiding rails and in the rack are adapted for being moved into or out of the rack from the front end. The heat-dissipating wall is pivoted to the rear end and adapted for being folded against or unfolded away from the rear end. The heat-dissipating wall includes a fan wall. Fans lie on the fan wall. The fans are adapted for sucking cool air, such that the cool air enters the rack from the front end and passes through the servers. Heat exchange between the cool air and the servers is carried out to generate hot air that flows out of the rack through the heat-dissipating wall to dissipate heat of the servers.

Owner:INVENTEC CORP

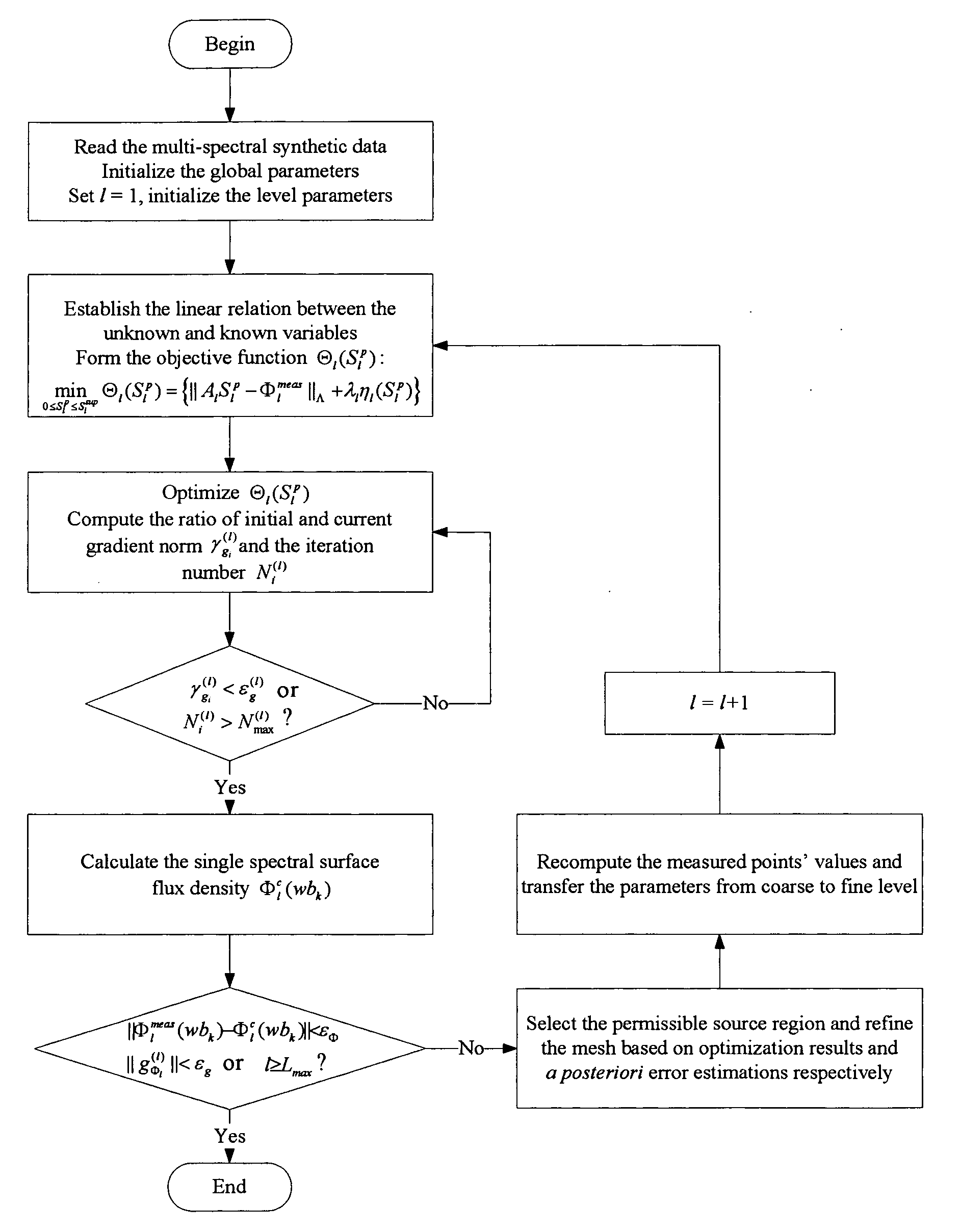

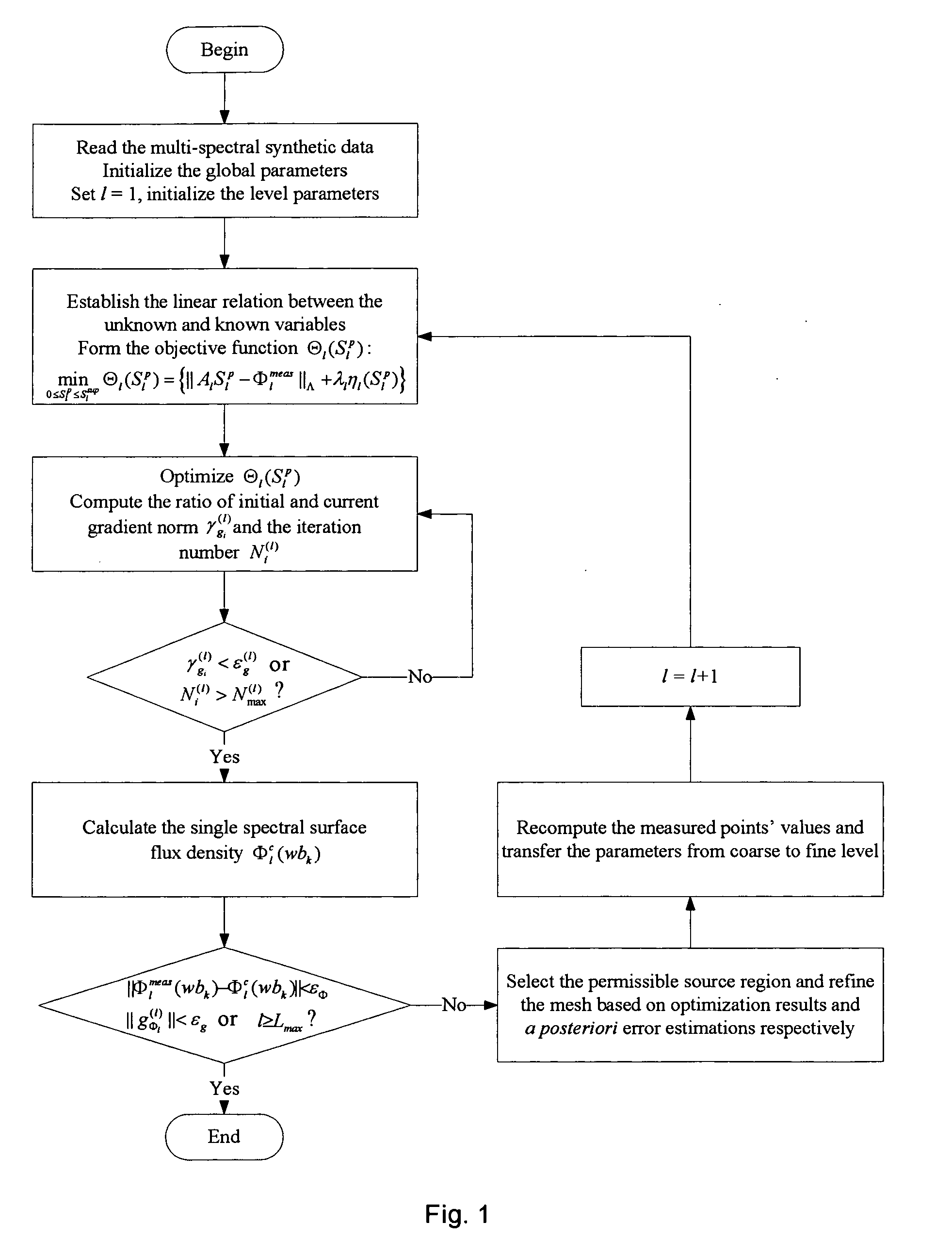

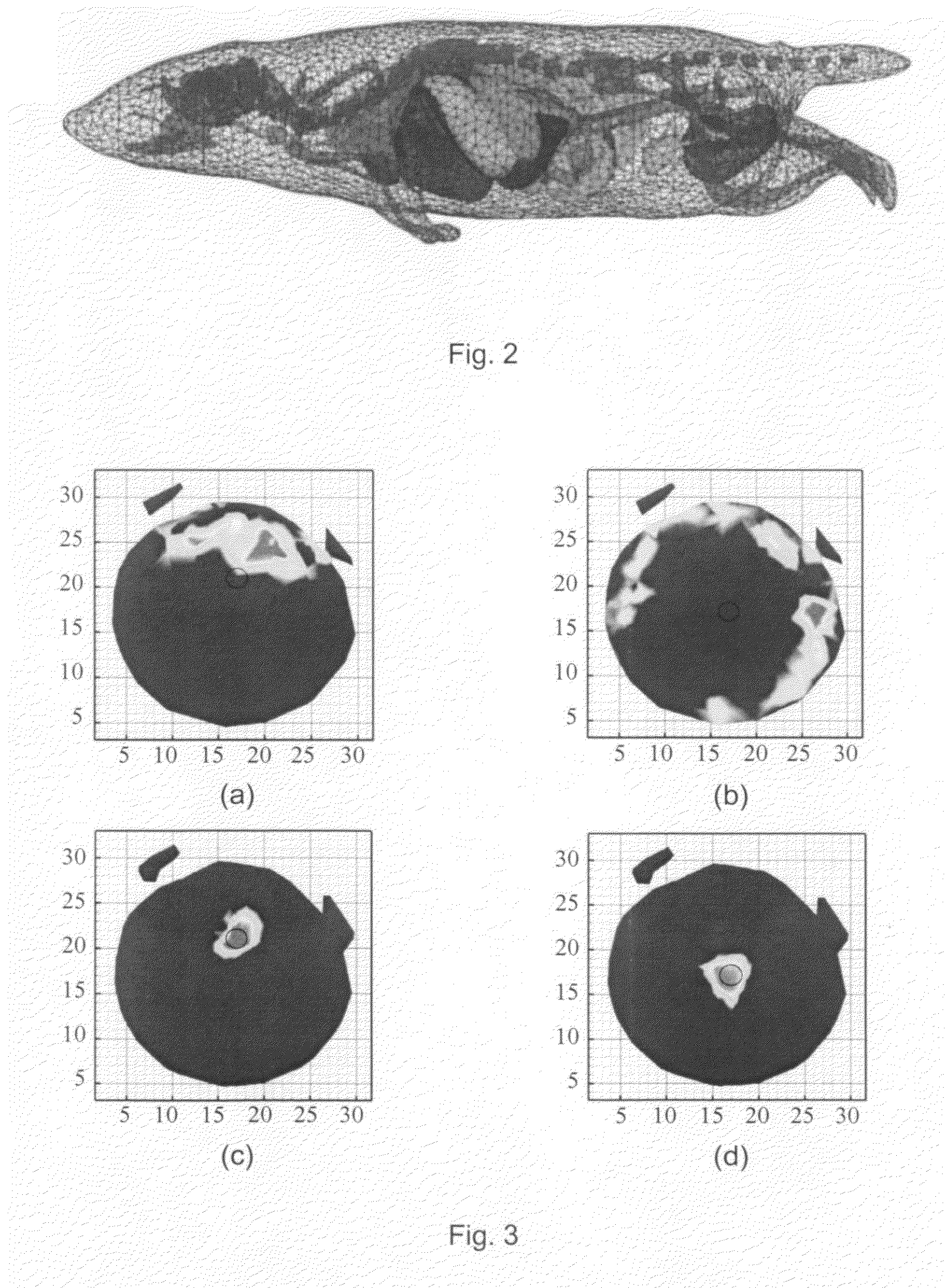

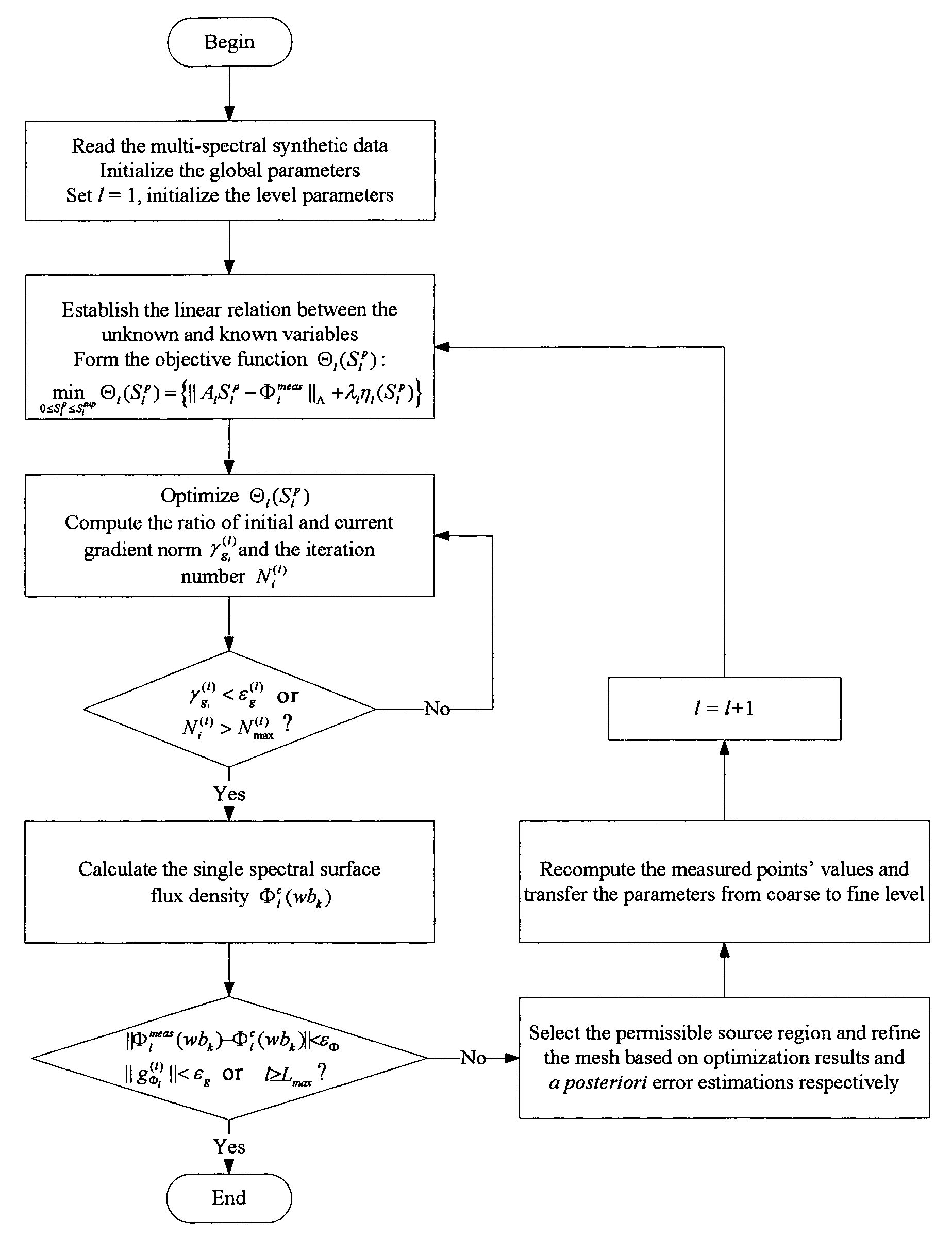

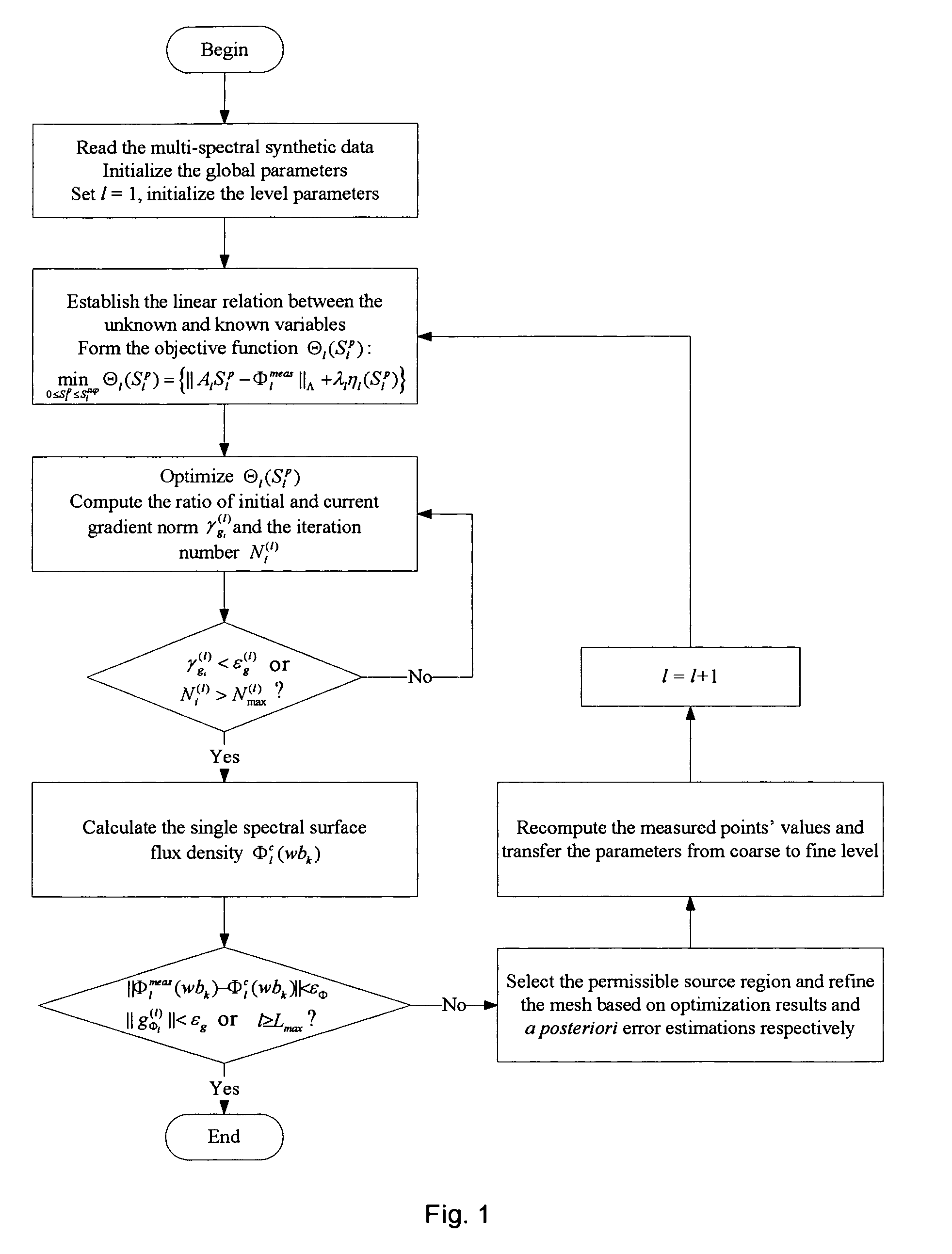

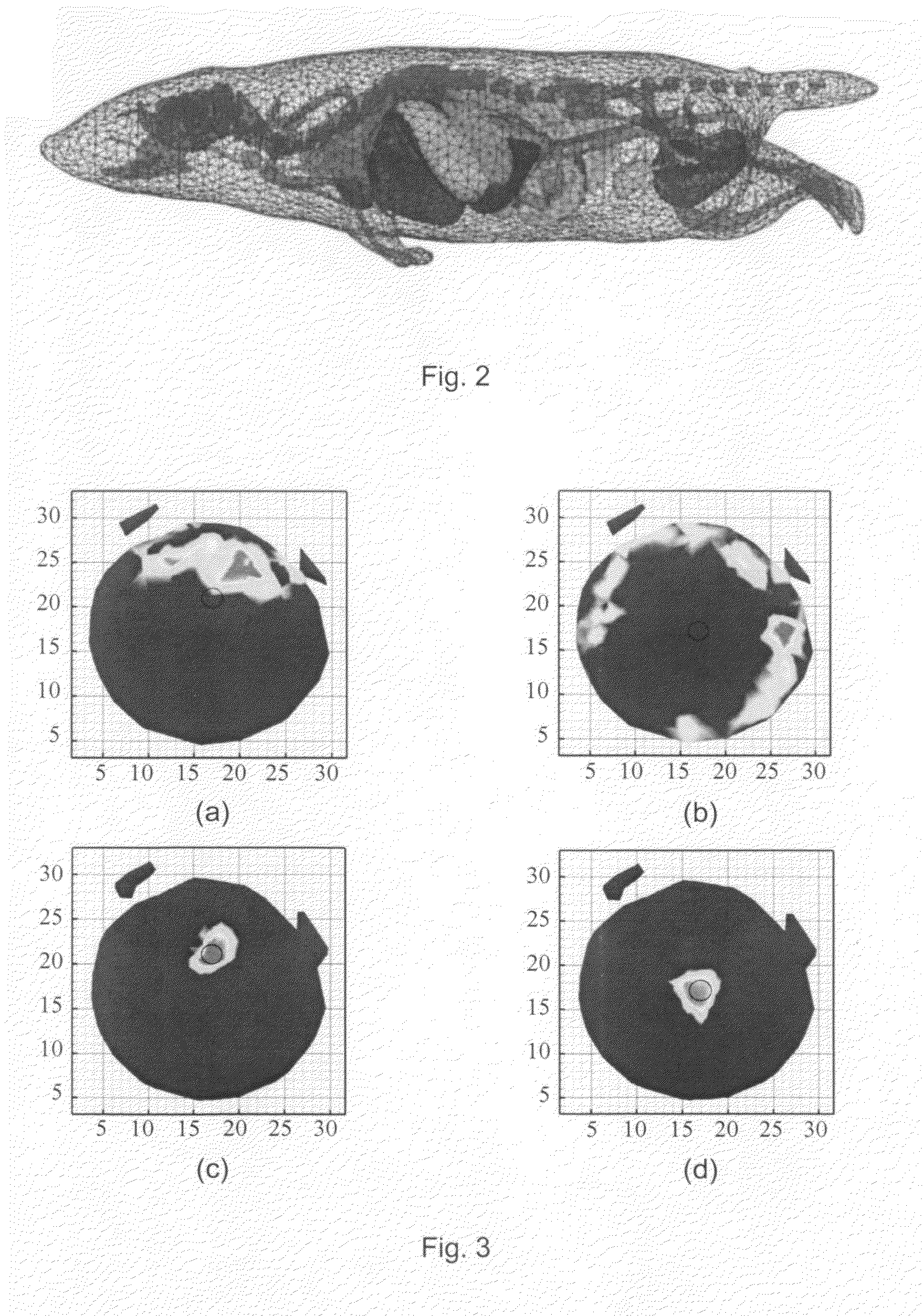

Multi-spectral reconstruction method based on adaptive finite element

ActiveUS20080259074A1Less discomfortQuality improvementCharacter and pattern recognitionDiagnostics using tomographyRegion selectionPrior information

A multi-spectral reconstruction method based on adaptive finite element comprising the following steps: discretizing the diffusion equation in the object domain on the single spectral; establishing the relationship between the boundary measurement data and the unknown source variables on single spectral based on a posteriori permissible source region selection method, and forming the objective function based on the multi-spectral characteristics and the regularization method; optimizing the objective function and determining if the reconstruction shall be stopped or not; and if the reconstruction shall not be stopped, refining the mesh adaptively by using a posteriori measure method, and then returning to the first step to continue the reconstruction process. This method uses kinds of a priori information and the multi-spectral information, combined with the adaptive finite element method, proposes a posteriori permissible source region strategy, improves the reconstruction quality and speed of BLT availably, and reduces the ill-posedness of this imaging modality.

Owner:ZHUHAI DI PU MEDICAL TECH CO LTD

Underwater cutting device for the handle of MTR plate-type feul

InactiveUS20110000081A1Effectively simplify cutting processImprove efficiencyMetal sawing devicesMetal working apparatusUnderwaterFiltration

An underwater cutting device for the handle of MTR plate-type fuel has a housing that has an accommodation space for a feed pneumatic cylinder to drive a slidable base for lateral movement. And in front of the accommodation space there is a cutting chamber. A primary motor is located on the slidable base to drive the saw blade inside the cutting chamber to move and cut laterally with the slidable base that is driven by the feed pneumatic cylinder. A positioning block is located on the side with the housing and in the moving path of the saw blade. In the positioning block there is an accommodation space to hold the MTR plate-type fuel. Above the positioning block there is at least a pressing pneumatic cylinder to immobilize the MTR plate-type fuel and facilitate the saw blade to cut and remove the handle of MTR plate-type fuel. On the side of the bottom of the cutting chamber there is a filtration motor to absorb the metal cutting debris and deliver the debris through a conduit to the filter frame that contains filter for filtration.

Owner:INST NUCLEAR ENERGY RES ROCAEC

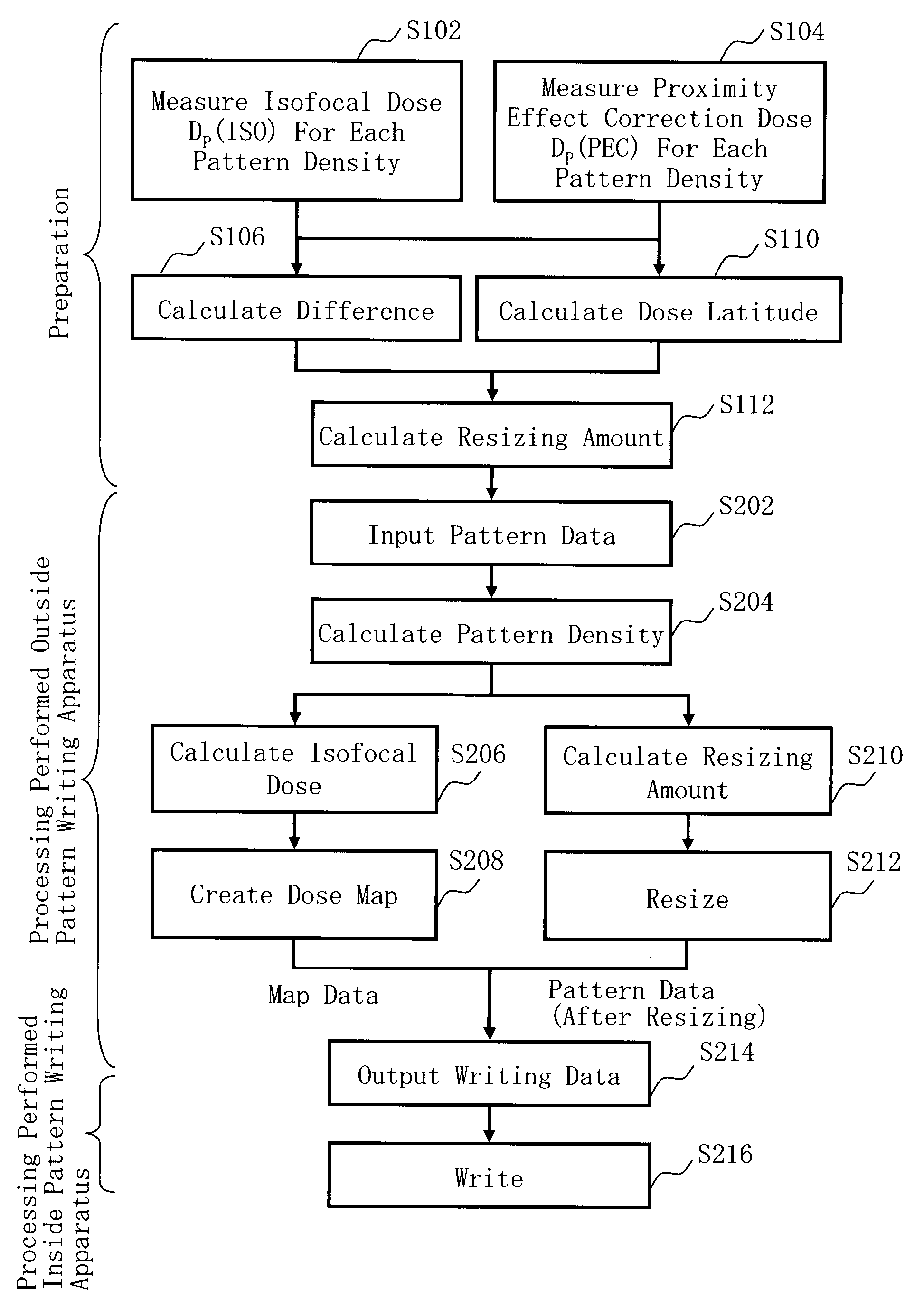

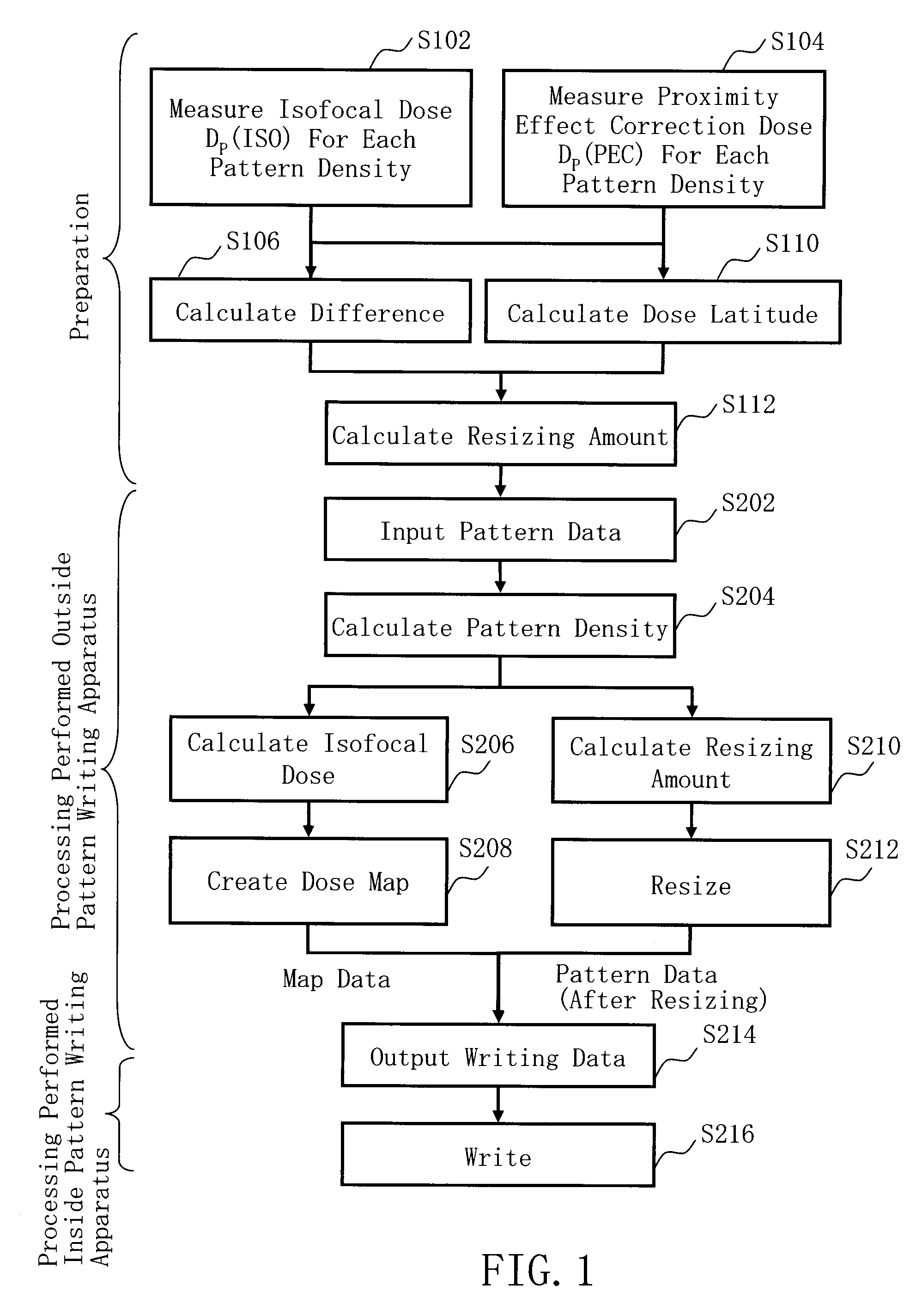

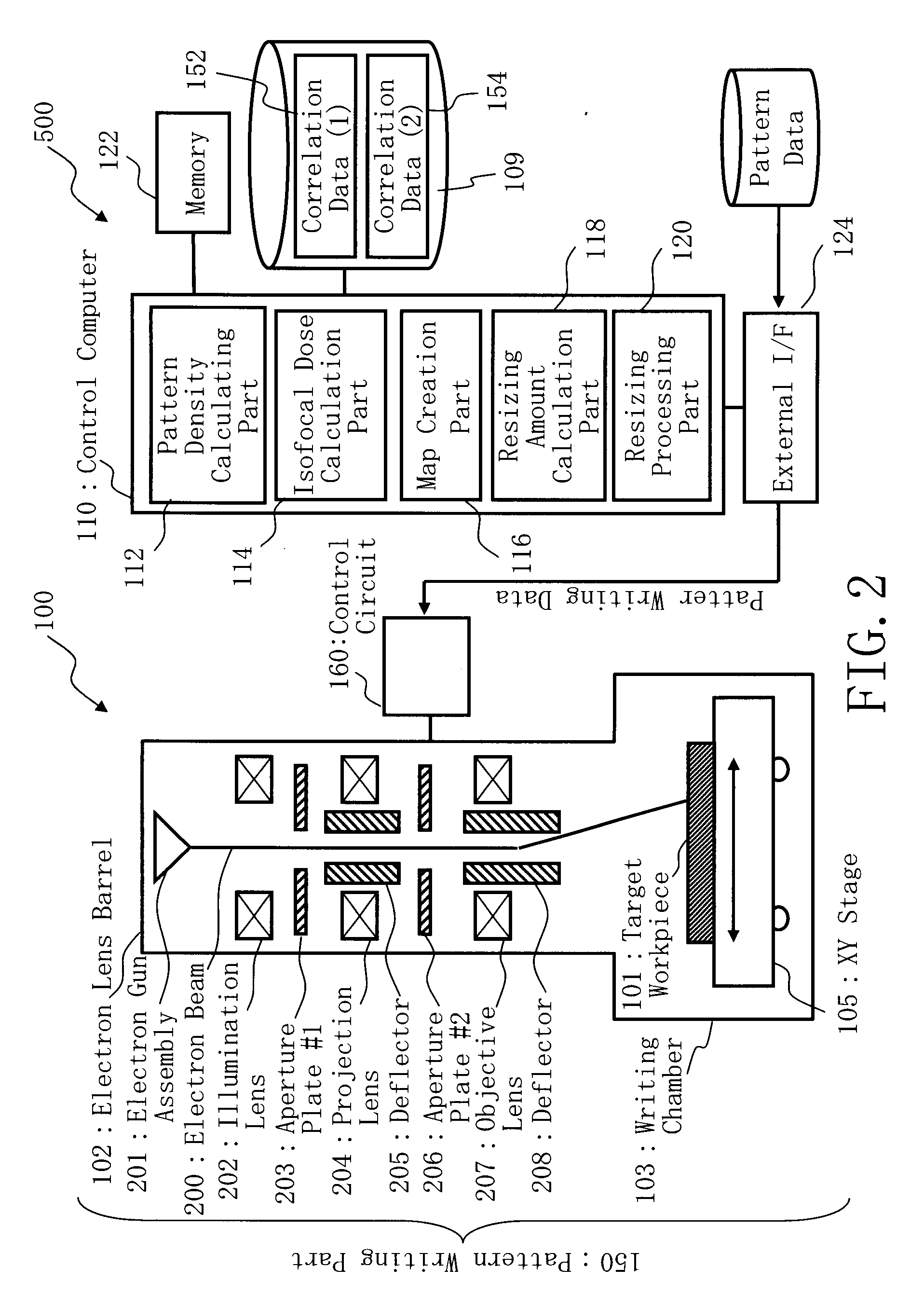

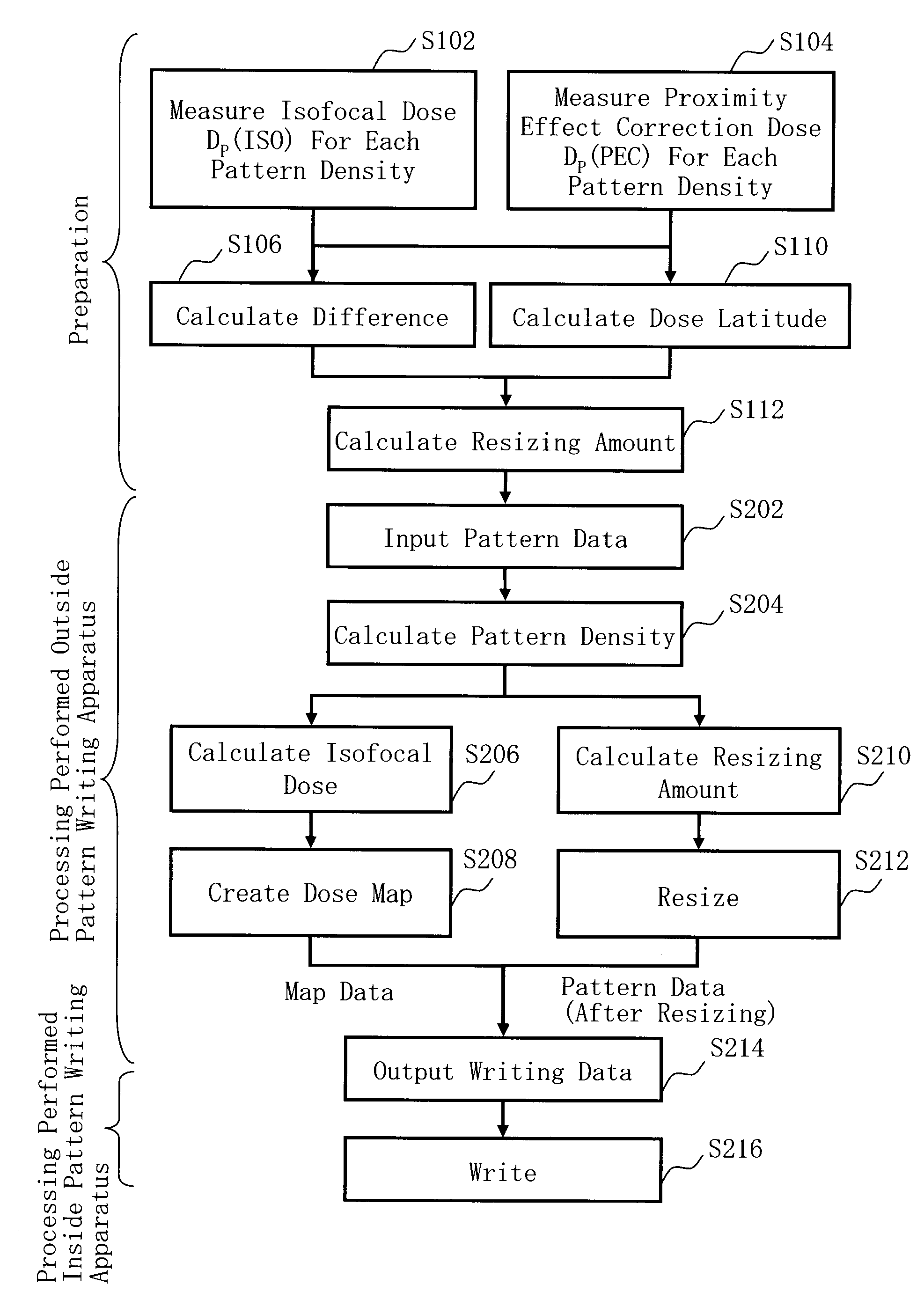

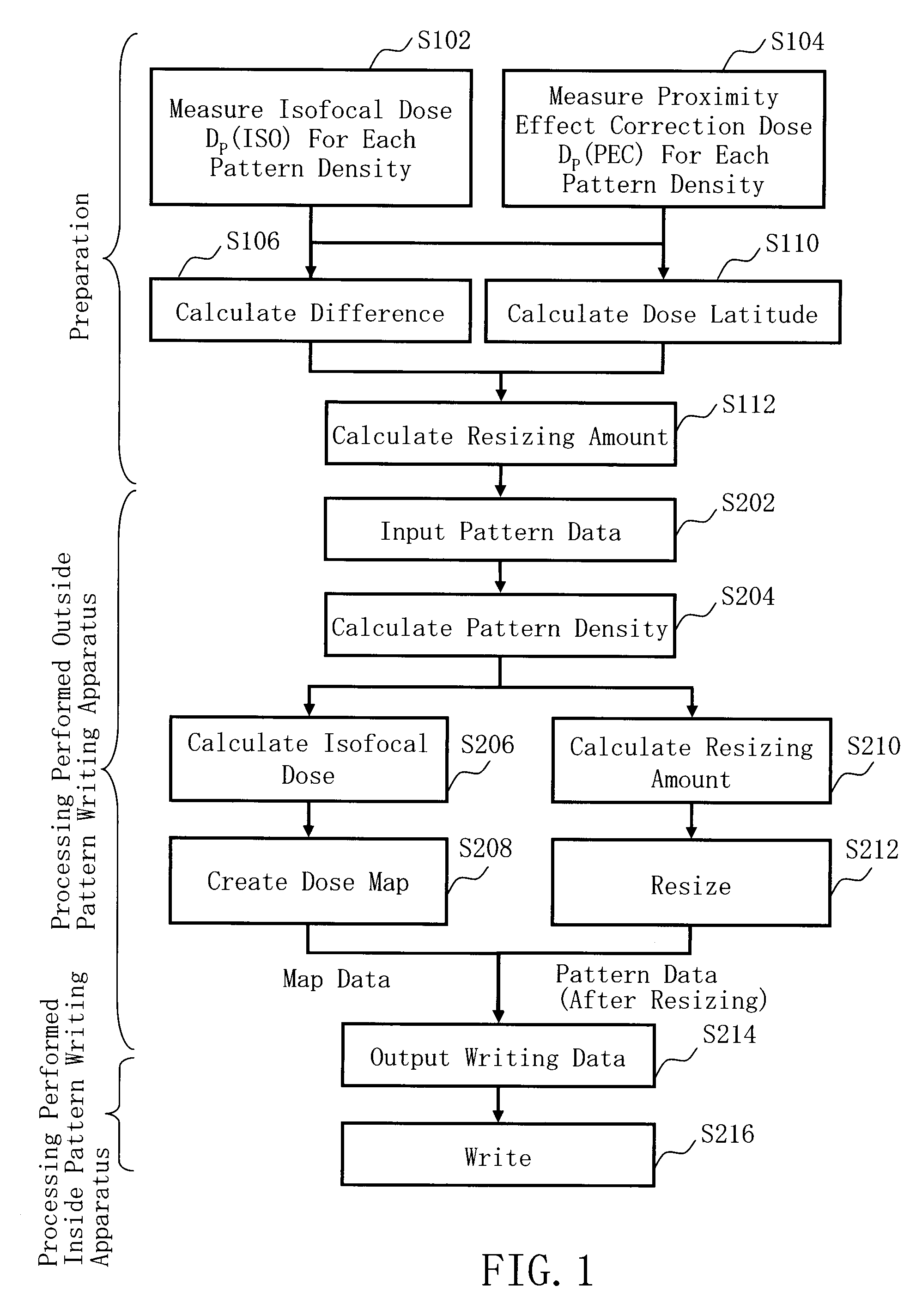

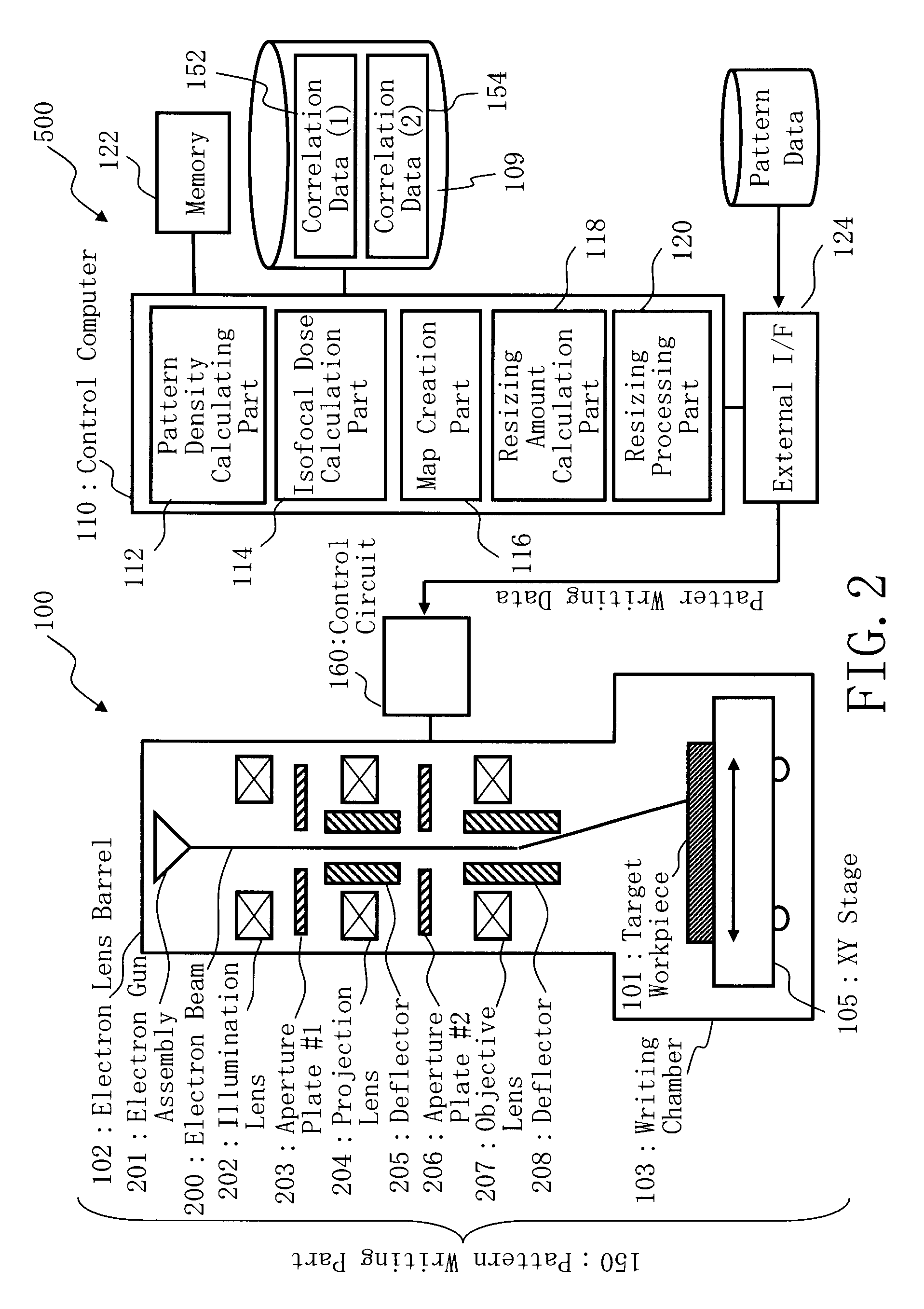

Writing method of charged particle beam, support apparatus of charged particle beam writing apparatus, writing data generating method and program-recorded readable recording medium

ActiveUS20080073574A1Preventing pattern dimensionAvoid DimensionsMaterial analysis using wave/particle radiationElectric discharge tubesComputer scienceDesign pattern

A charged particle beam writing method includes inputting design pattern data, virtually dividing a writing area to be written with the design pattern data into a plurality of small areas in a mesh-like manner, calculating a pattern density in each of the plurality of small areas based on the design pattern data, calculating a resizing amount for each pattern density in a case of irradiating a charged particle beam at an isofocal dose, resizing a dimension of the design pattern data in each of the plurality of small areas, based on the resizing amount in each of the plurality of small areas, and writing a resized design pattern on a target workpiece with the isofocal dose corresponding to the pattern density which was calculated before the resizing in each of the plurality of small areas.

Owner:NUFLARE TECH INC

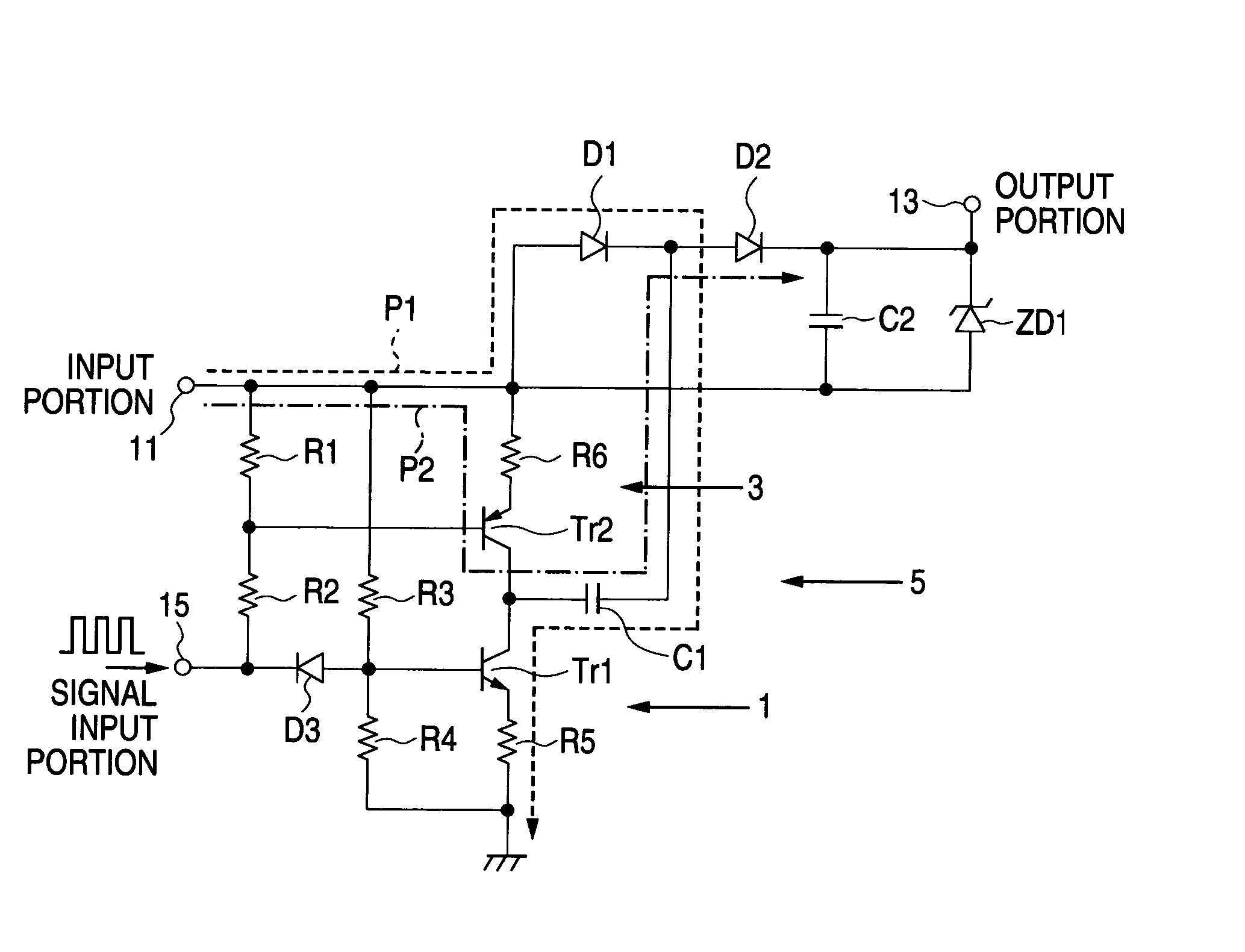

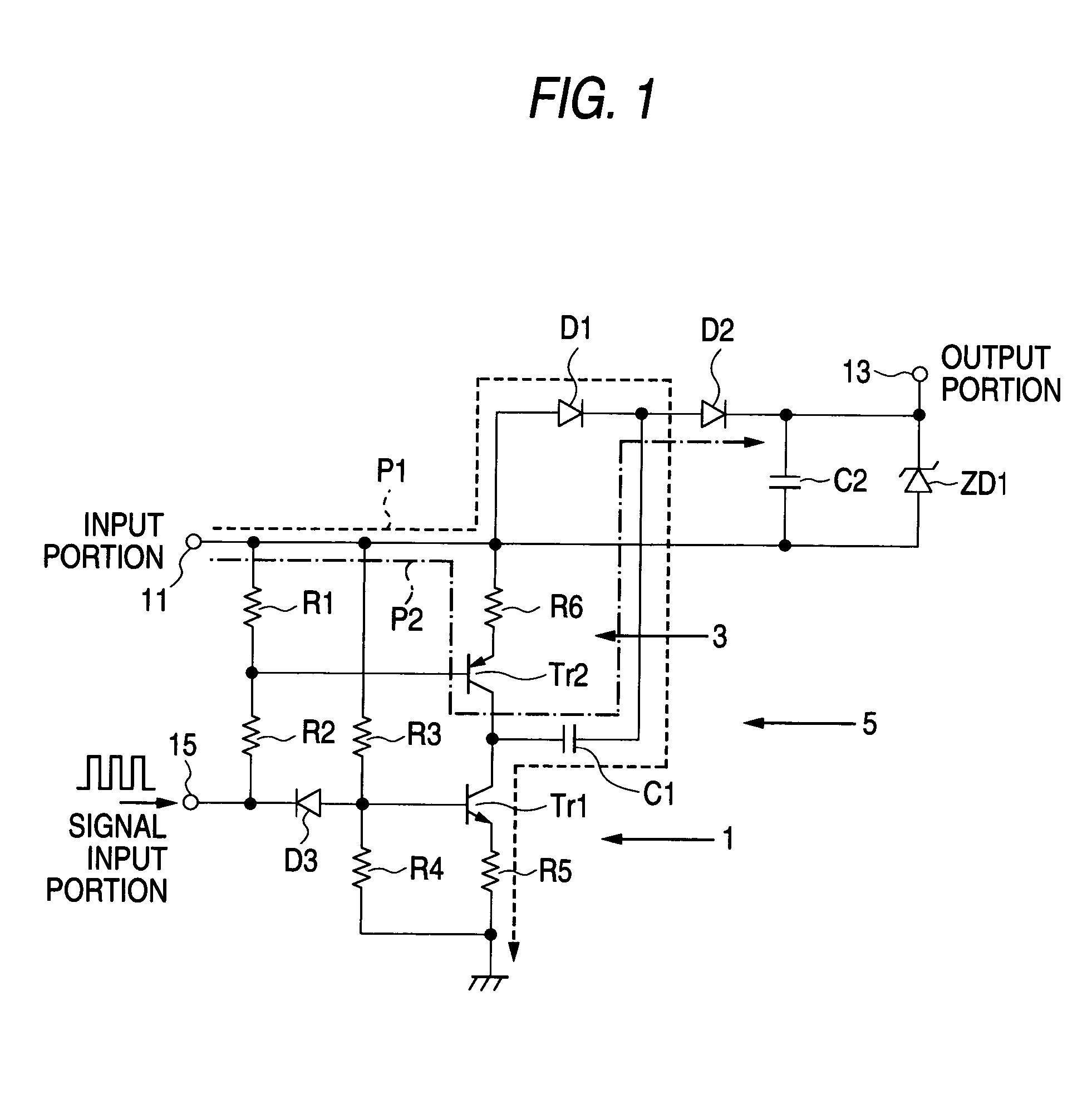

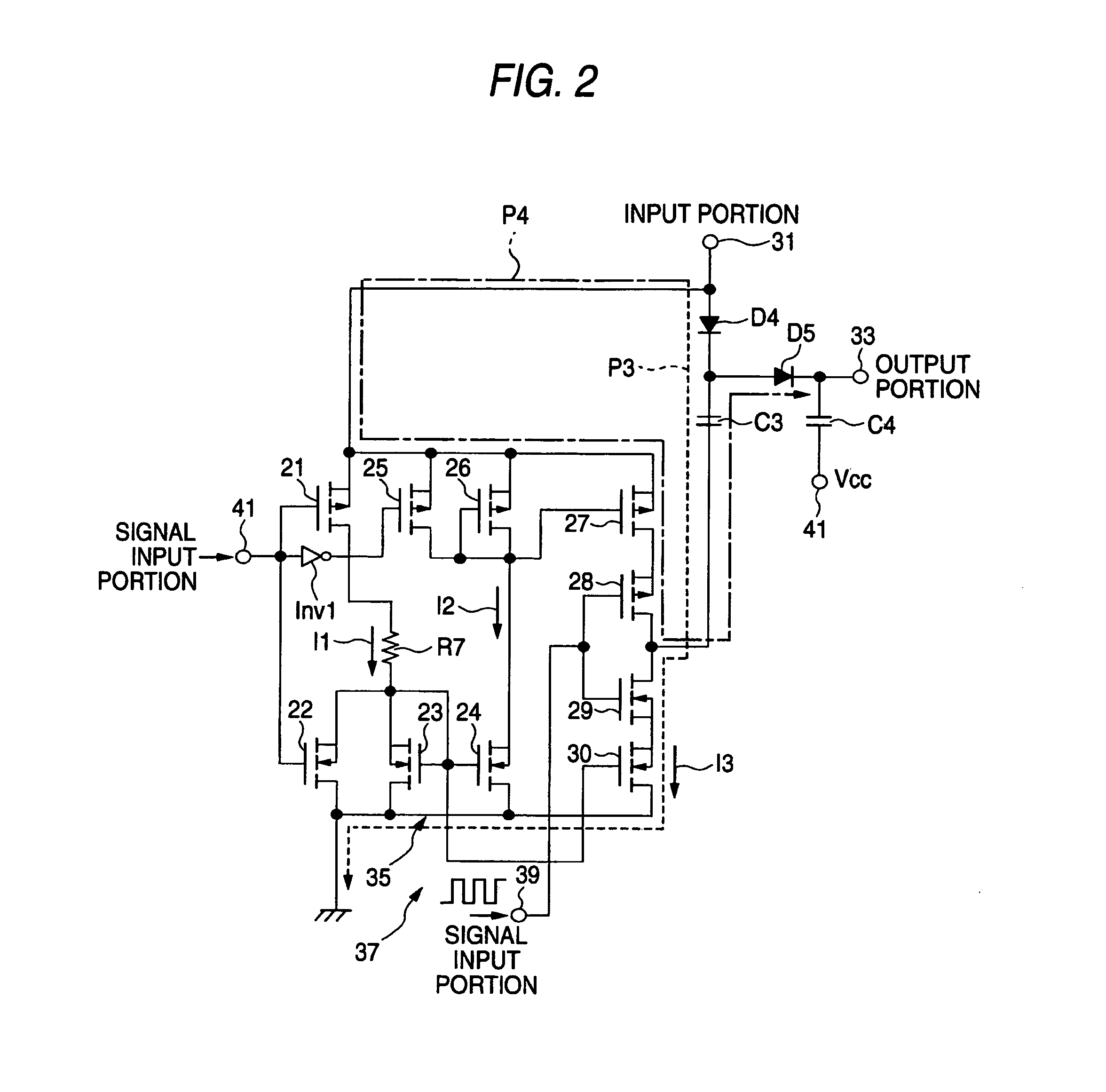

Charge pump circuit

ActiveUS7075356B2Considerable noiseShort timeAc-dc conversionApparatus without intermediate ac conversionEngineeringCapacitor

According to the charge pump circuit, a constant current charging and discharging circuit using follower circuits is interposed at current paths in charging and discharging a capacitor for stepping up. Transistors of the follower circuits are alternately made ON in accordance with a clock signal inputted from a signal input portion for switching to connect the capacitor for stepping up and restricting a current in cooperation with resistors or the like.

Owner:AUTONETWORKS TECH LTD +2

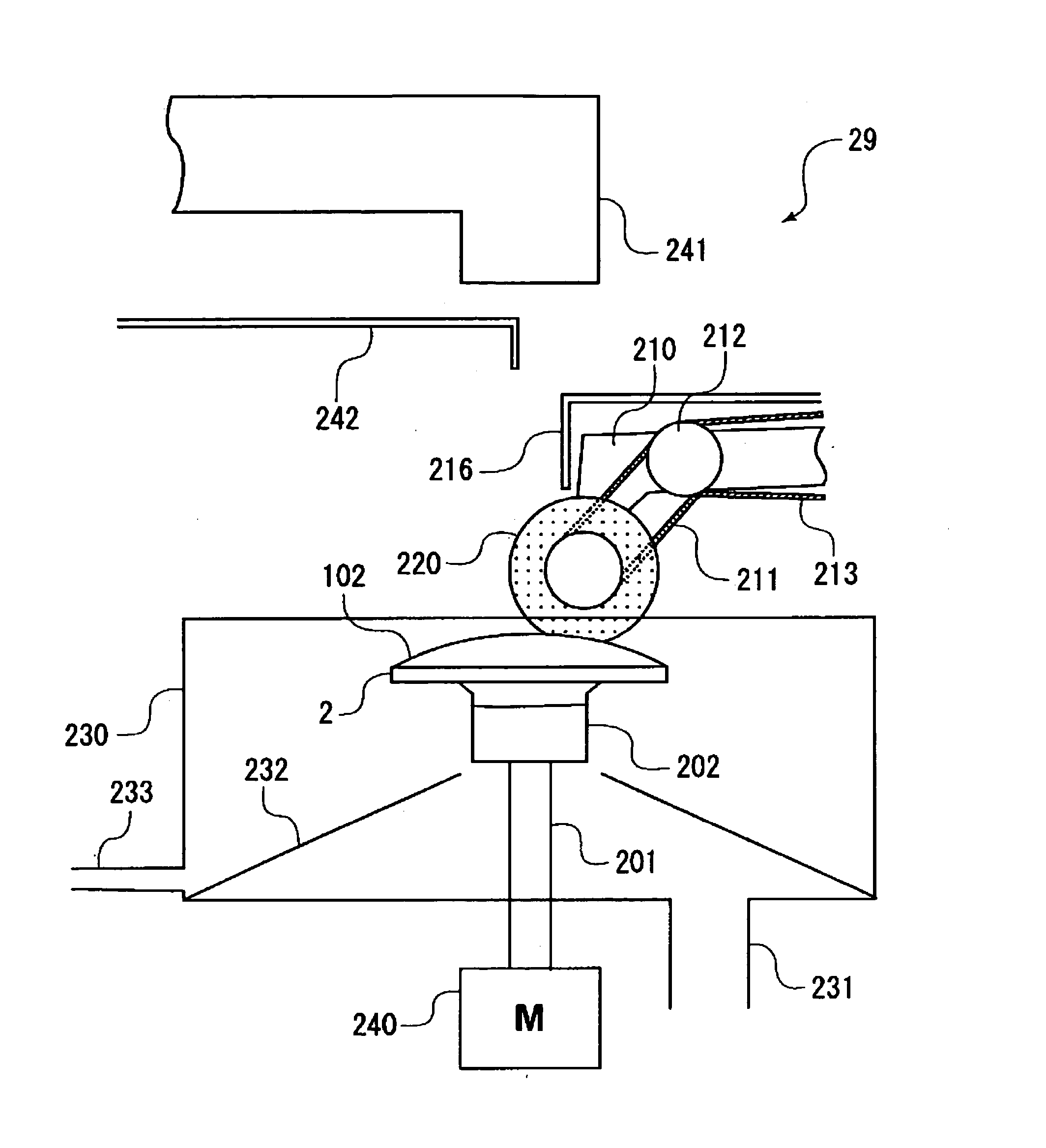

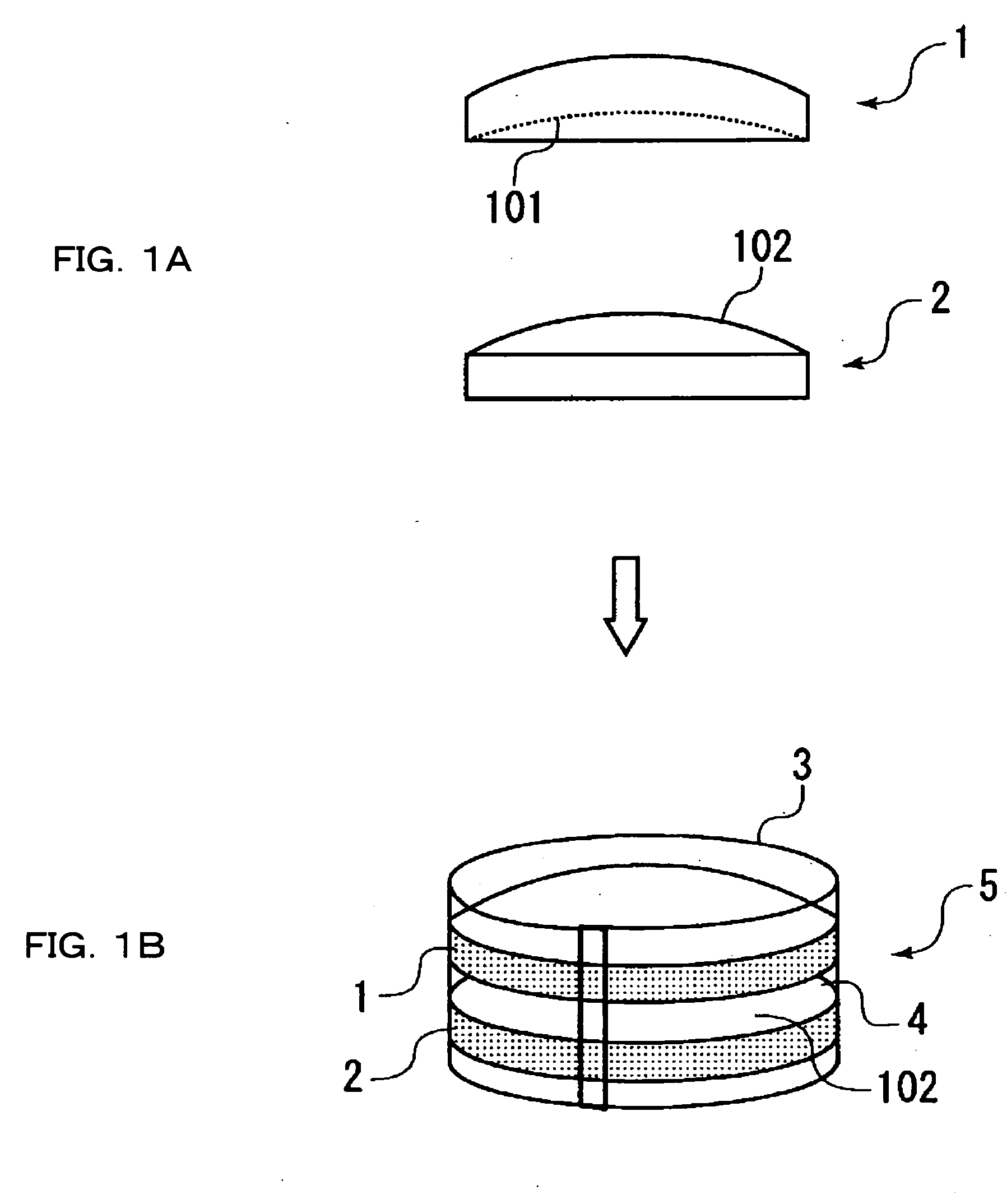

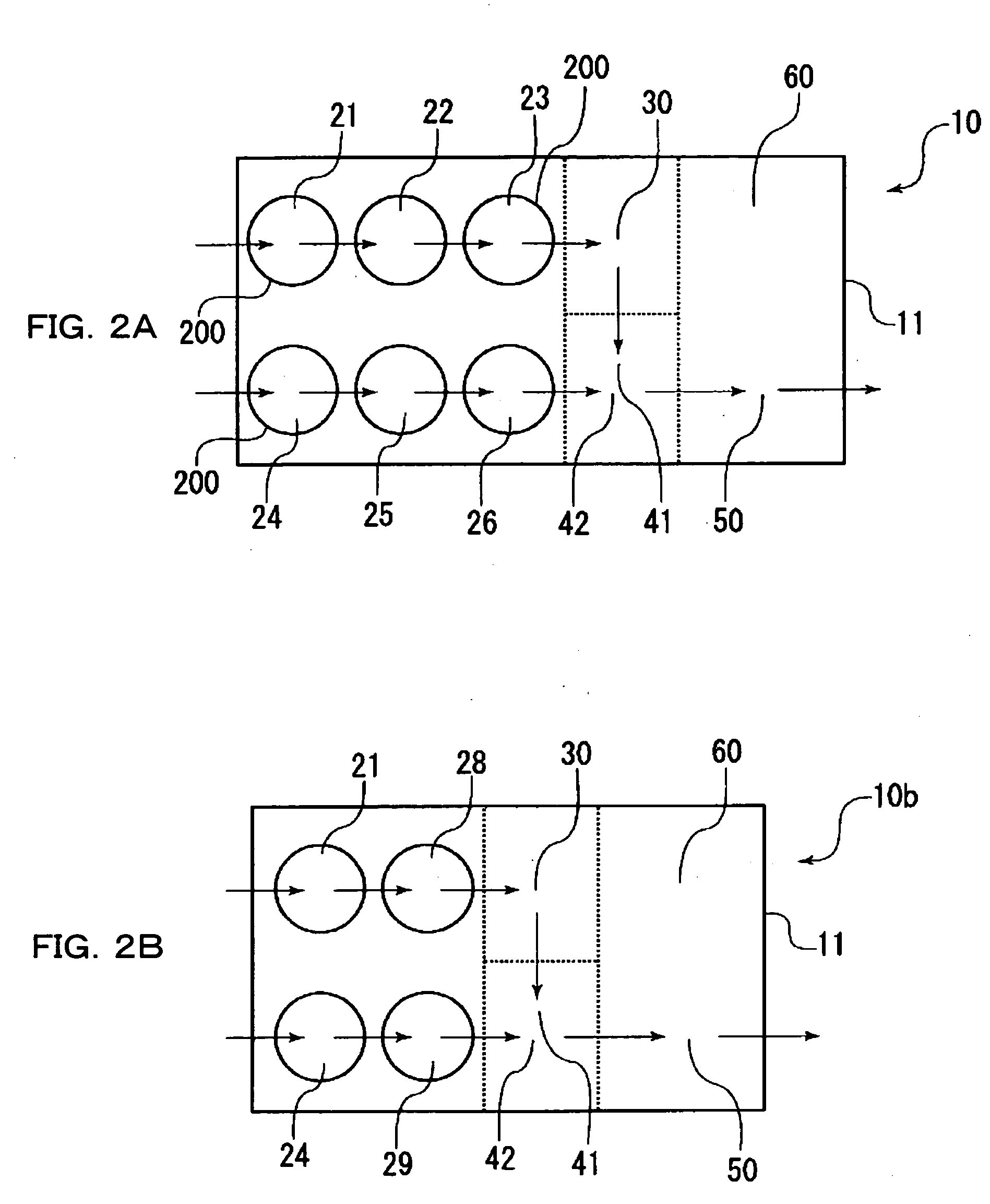

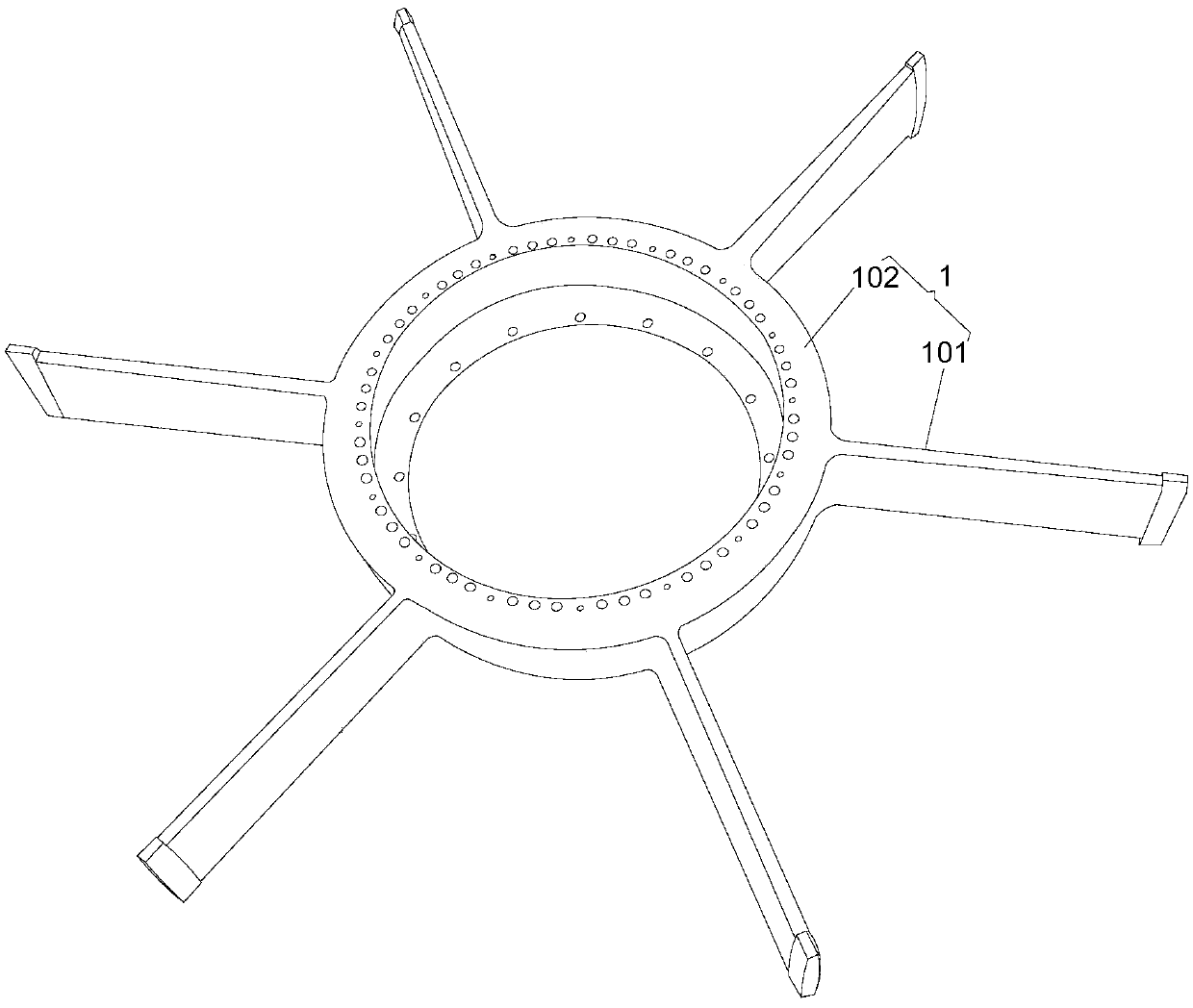

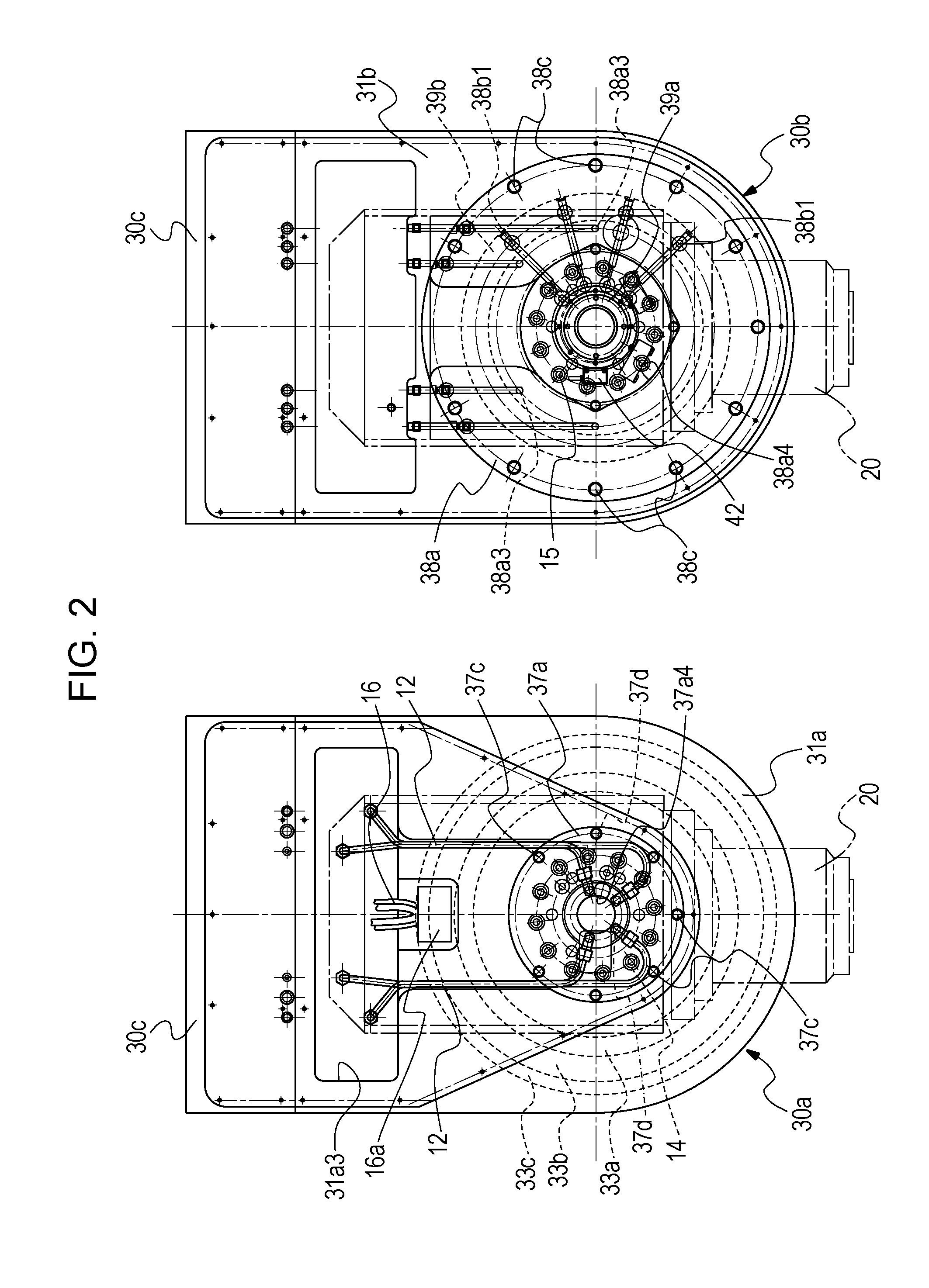

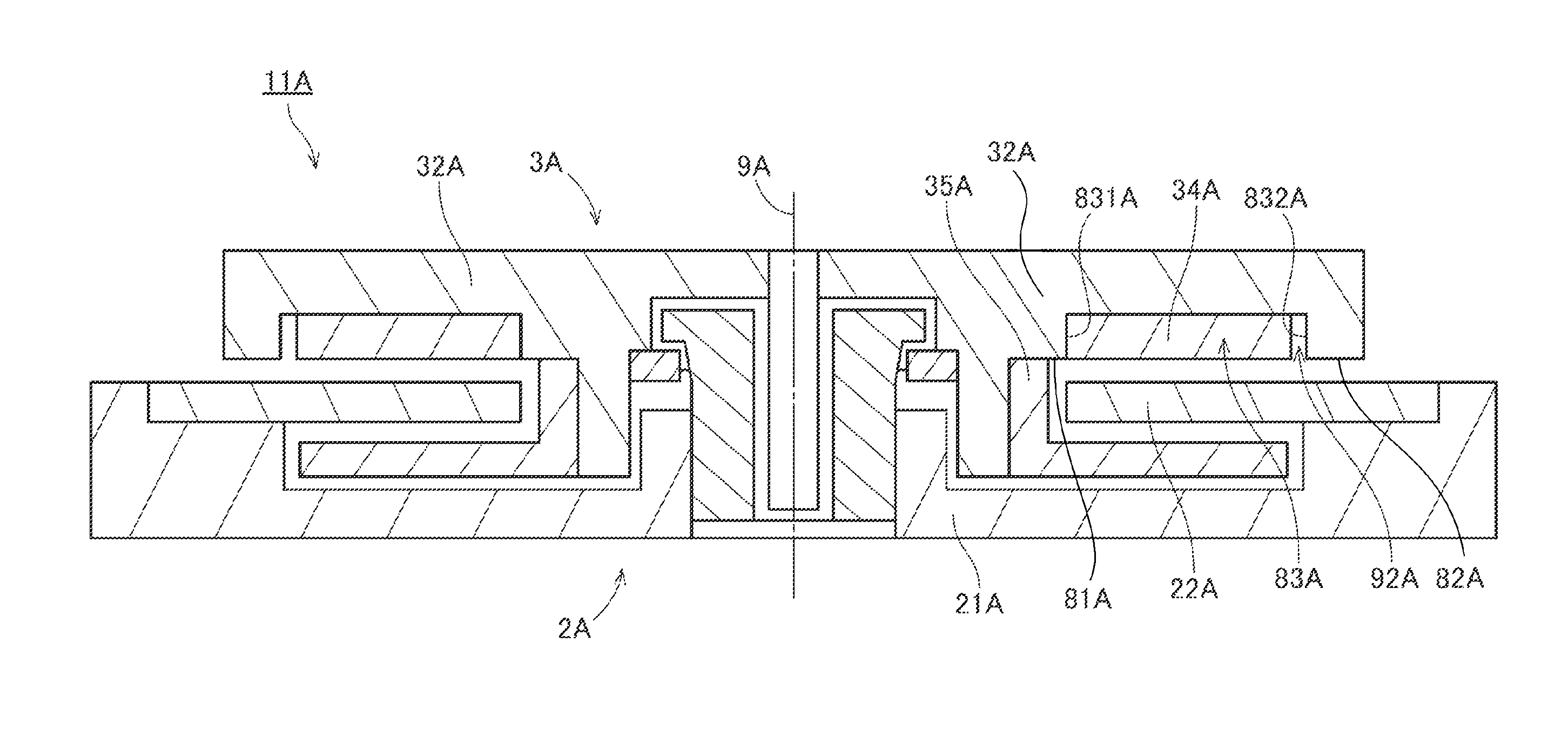

Lens molding die assembling device, lens molding die washing method, and lens molding die assembling method

InactiveUS20050167862A1Efficiently assembleSmall installation areaOptical articlesOptical partsConcave surfaceMechanical engineering

An apparatus is constructed by accommodating in one dust-proof room 11, a concave-mold first cleaning device 21 which abrades the convex-surface forming surface 101 of a concave mold 1, a concave-mold second cleaning device 22, a concave-mold drying device 23, a convex-mold first cleaning device 24 which abrades a concave-surface forming surface for a lens, a convex-mold second cleaning device 25, a convex-mold drying device 26, an inversion device 30 which inverts the concave mold 1 or a convex mold 2 up or down, a positioning device 50 which brings the geometric centers of the concave mold 1 and the convex mold 2 into coincidence and then arranges them in opposition, and a tape winding device 60 which winds an adhesive tape onto the peripheral surfaces of the concave mold 1 and convex mold 2 so as to seal the gap between these molds, thereby to provide the lens-casting-mold assembling apparatus which can efficiently assemble a lens-casting-mold assembly, and which saves space.

Owner:SEIKO EPSON CORP

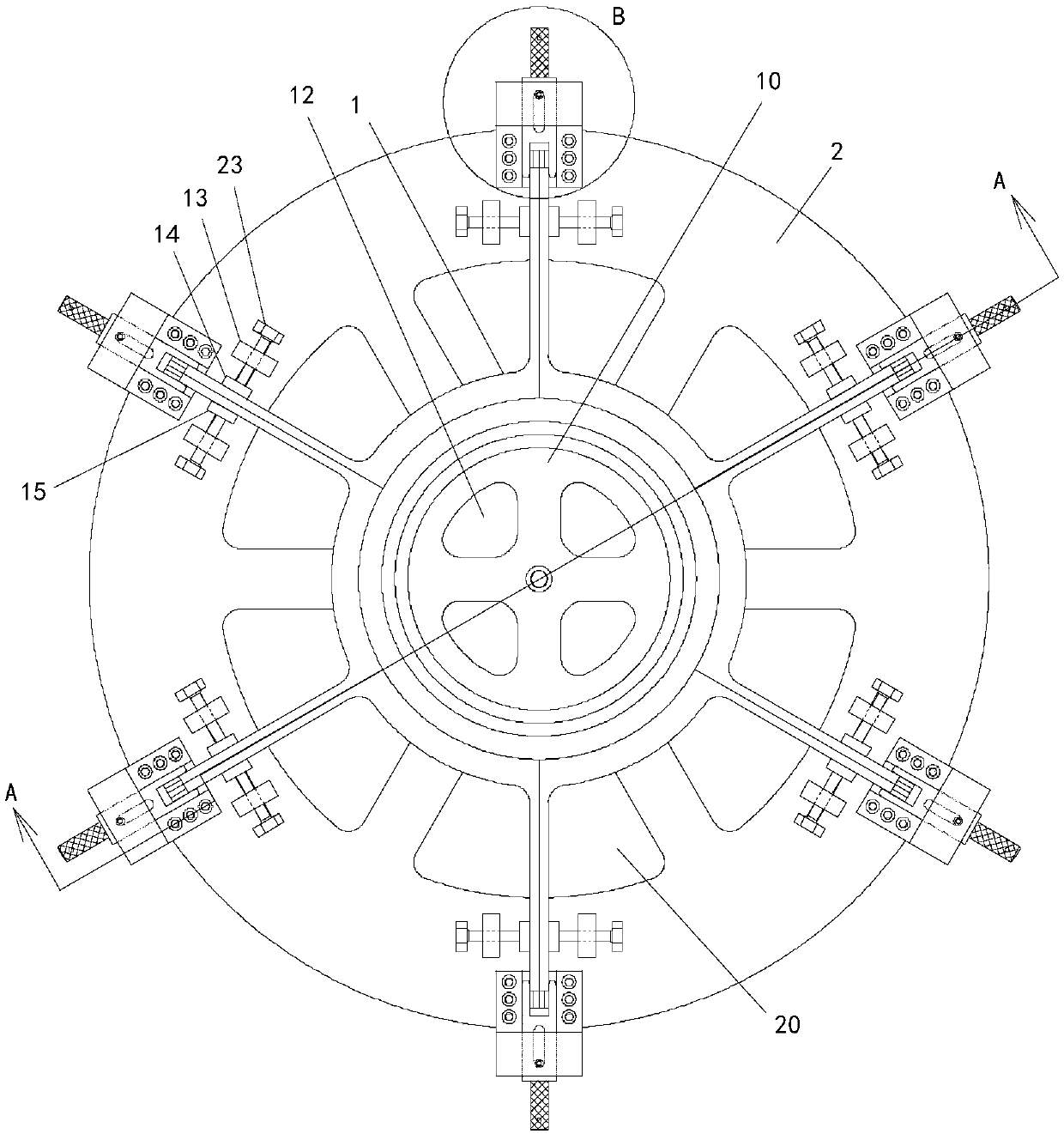

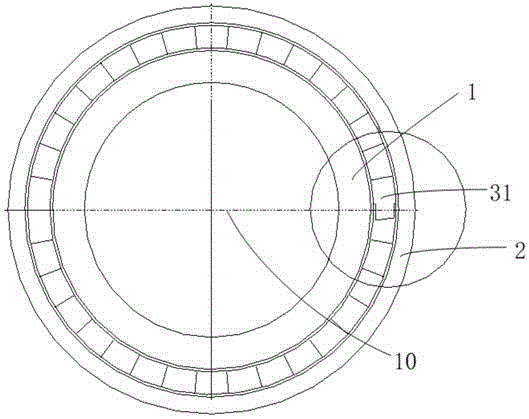

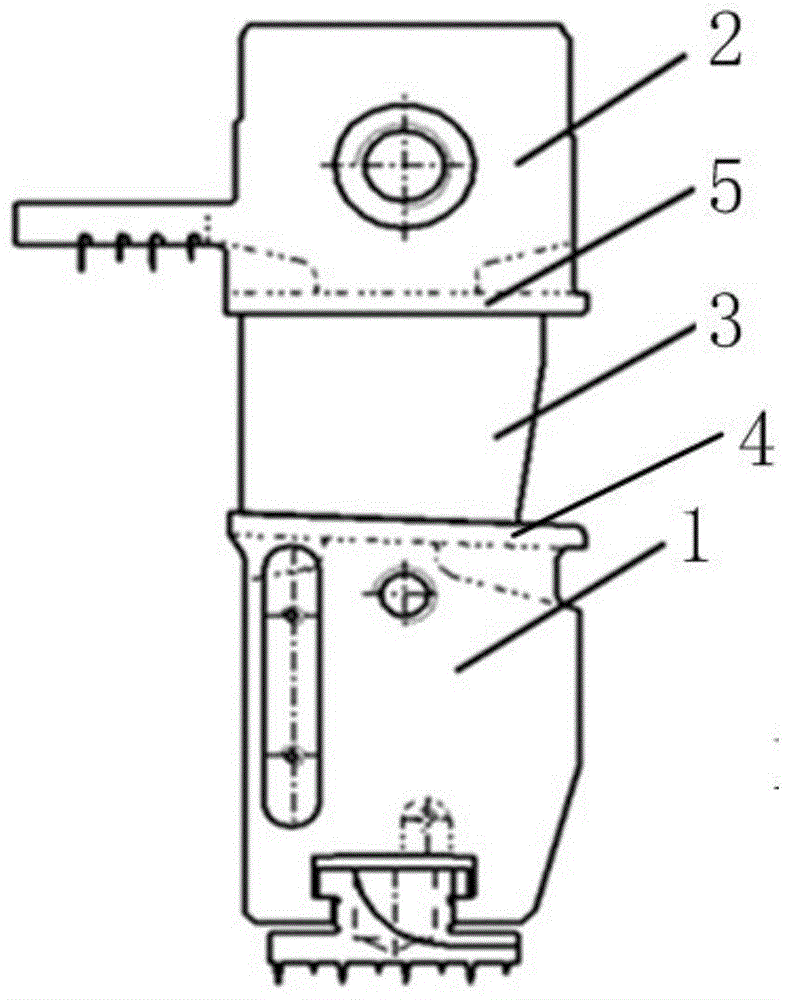

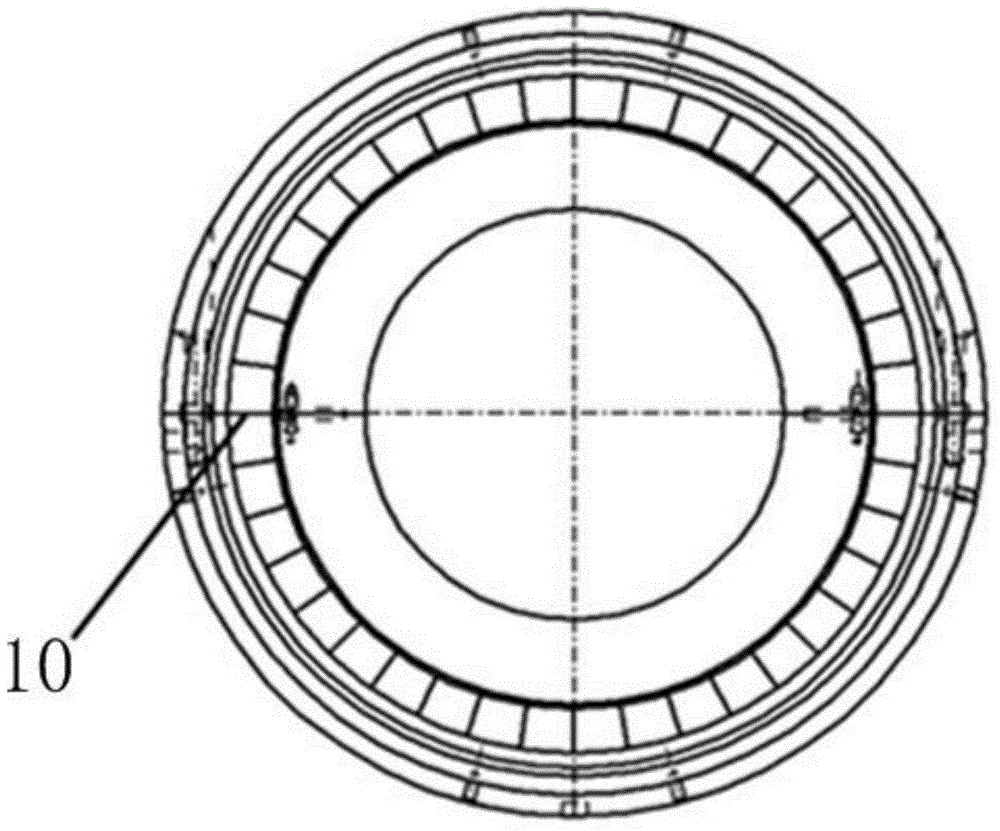

Integrated device for angular alignment and detection of turbine supporting casing support plates

ActiveCN109520400AImprove stabilityImprove pass rateMechanical solid deformation measurementsManufacturing technologyEngineering

The invention provides an integrated device for angular alignment and detection of turbine supporting casing support plates, and relates to the technical field of manufacturing of aeroengine turbine supporting casing assemblies. The technical problems of difficult angular size control, size tolerance, unstable part processing and low qualification rate of six support plates of a turbine supportingcasing rear housing support in the prior art are solved. The problem that product delivery is seriously restricted is solved. The problem that the progress of model development is affected is solved.The device comprises a base, support plate correction devices, support plate detection devices, and a fixing device which is used for fixing the turbine supporting casing rear housing support on thebase. The support plate correction devices and the support plate detection devices are arranged on the base. A set of support plate correction device and support plate detection device are correspondingly arranged on each end, which is corresponding to the turbine supporting casing rear housing support, of six support plates. The device provided by the invention is used for angular alignment and detection of the turbine supporting casing support plates.

Owner:AECC AERO SCI & TECH CO LTD

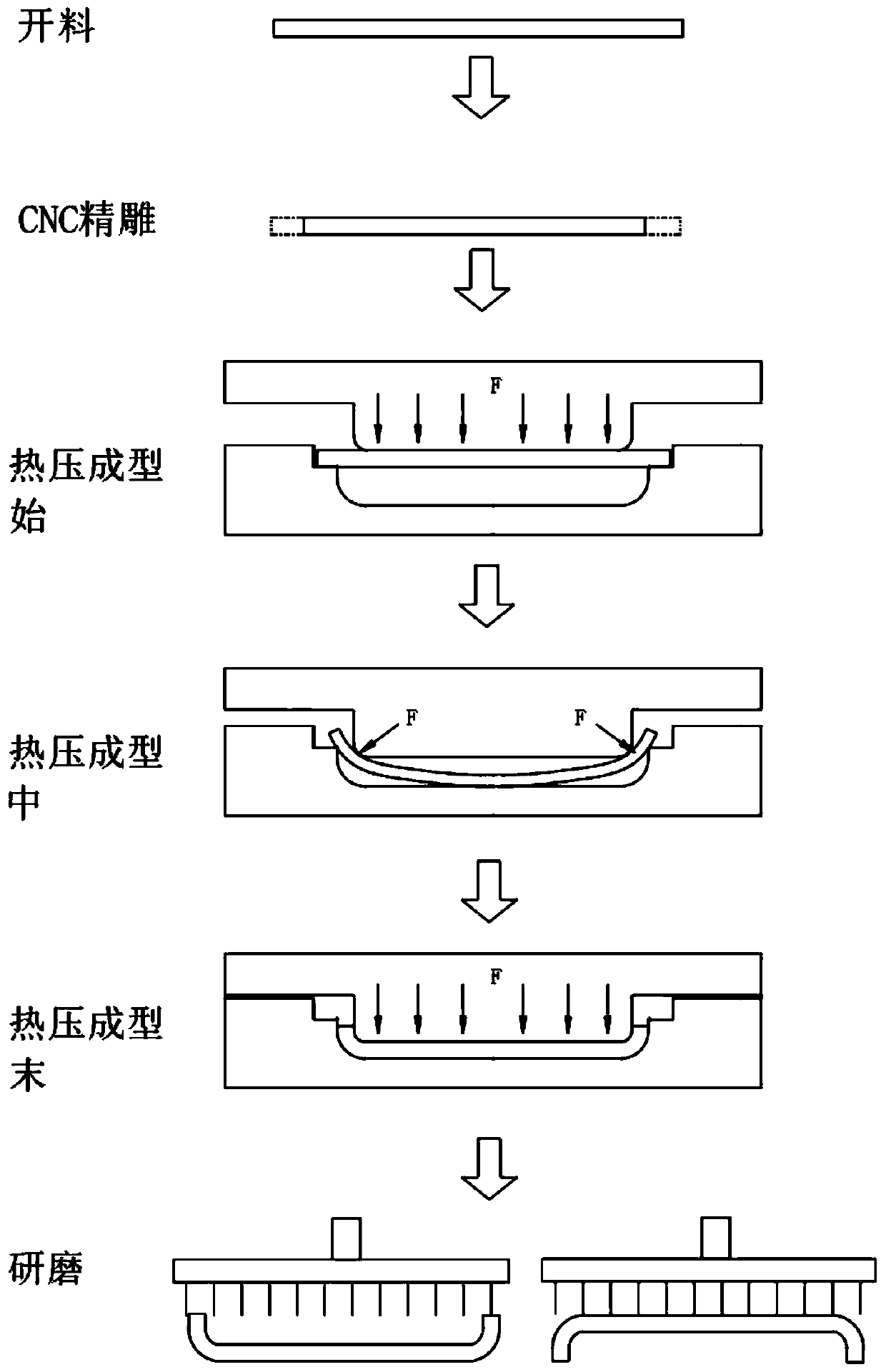

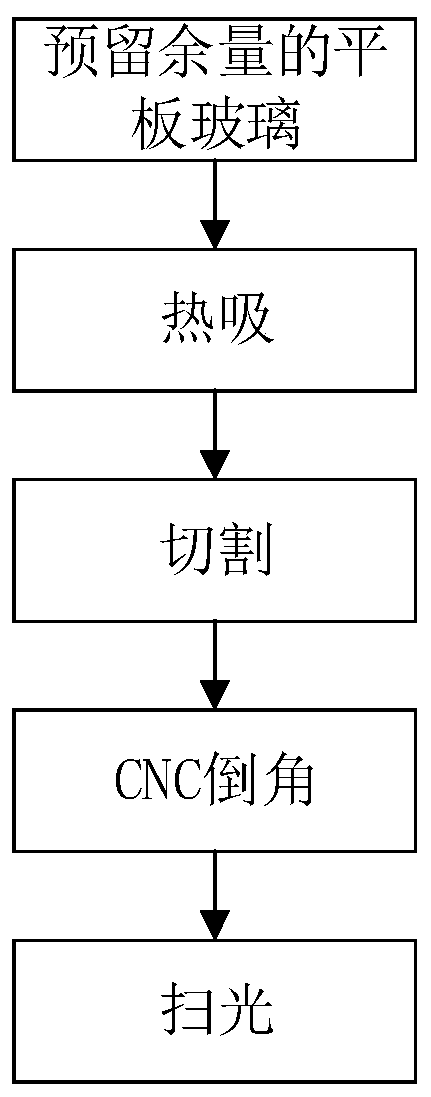

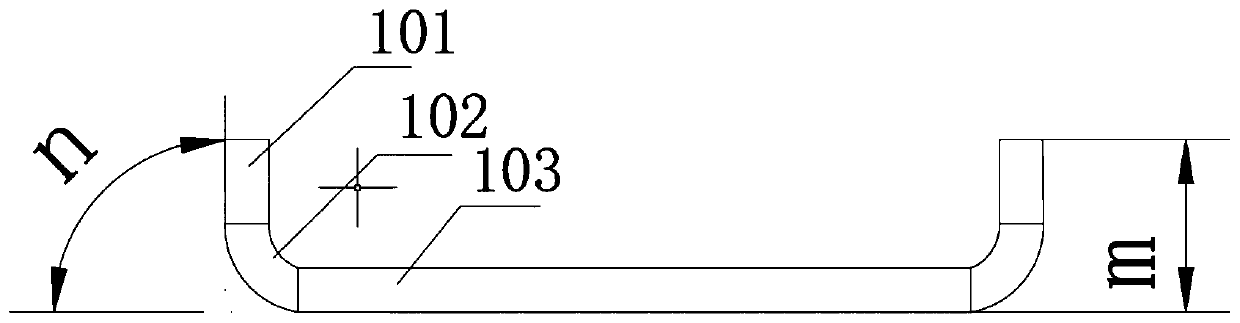

Three-dimensional (3D) glass and preparation method thereof

ActiveCN110272187AImprove yield rateAvoid DimensionsGlass reforming apparatusGlass severing apparatusFlat glassNumerical control

The invention discloses three-dimensional (3D) glass and a preparation method thereof. The method comprises the following steps: step 1, placing flat glass with a reserved allowance into a die; step 2, attaching and forming the flat glass on the upper surface of a female die of the die by adopting a heat adsorption process to obtain a 3D glass blank; step 3, cutting the 3D glass blank to obtain a 3D glass semi-finished product; step 4, carrying out computer-numerical-control (CNC) carving, grinding and chamfering on the 3D glass semi-finished product to obtain a 3D glass raw material; and step 5, carrying out shining treatment on the surface of the 3D glass raw material to obtain the 3D glass with a side wall part, a bending part and a window part. According to the invention, the yield of 3D glass production can be improved to be close to 100%, and the problem that in a process that the size of flat glass is pre-designed and then hot press forming and carving are carried out in a conventional 3D glass manufacturing method, the size of formed 3D glass is unqualified due to the fact that a placement position is deviated or the forming pressure is not uniform during hot-pressing molding is solved.

Owner:CHENGDU TOMI SHUANG DU OPTOELECTRONICS CO LTD

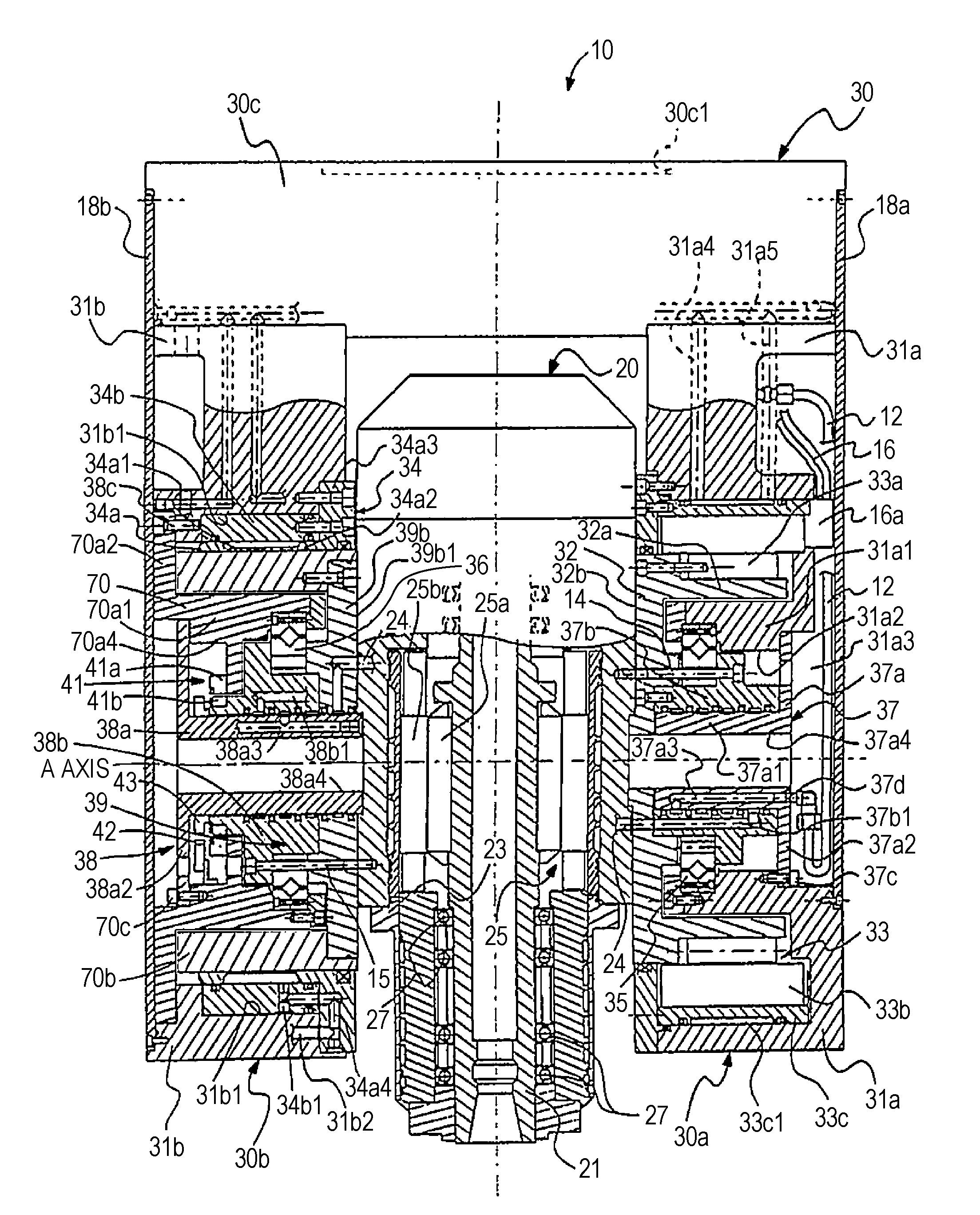

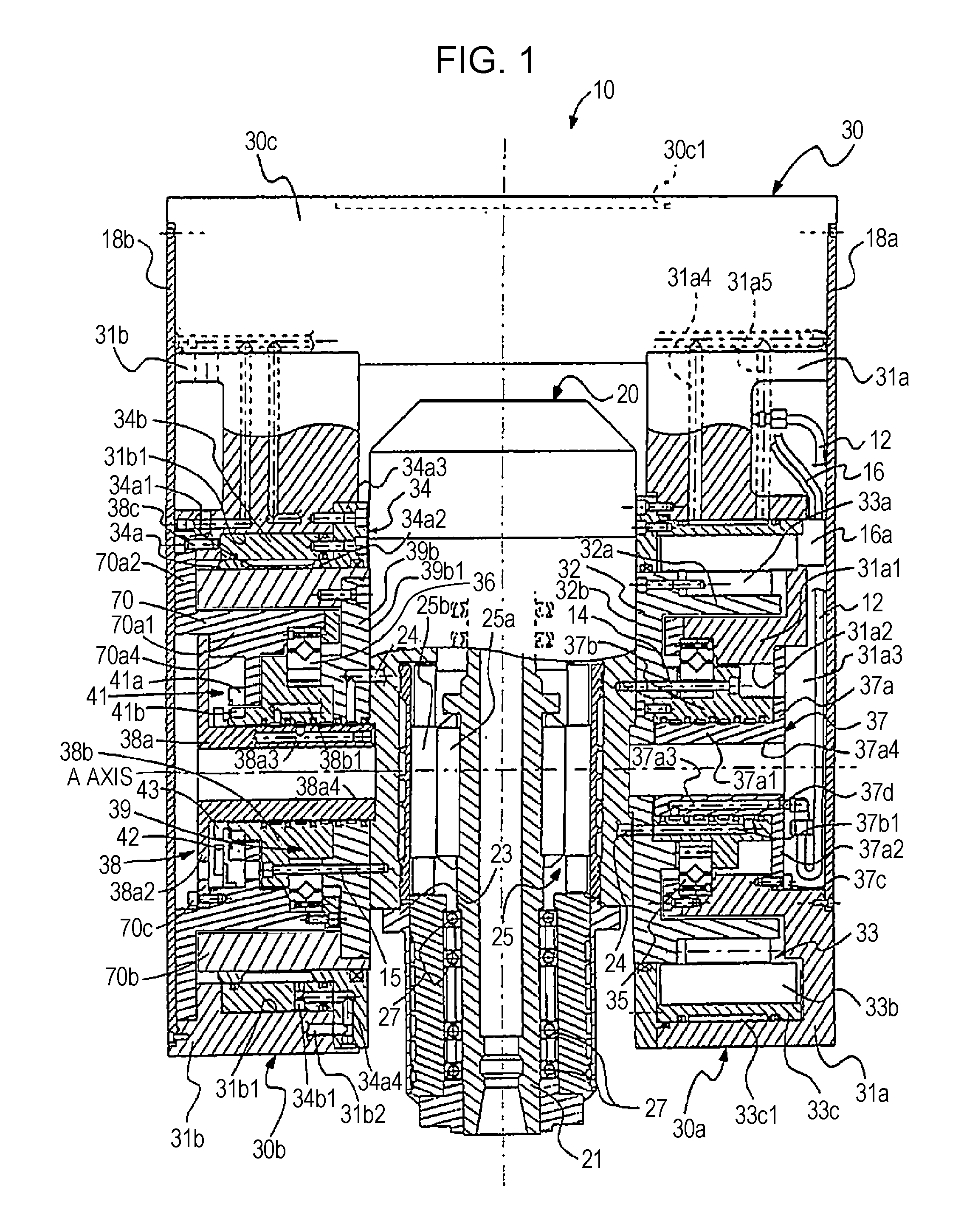

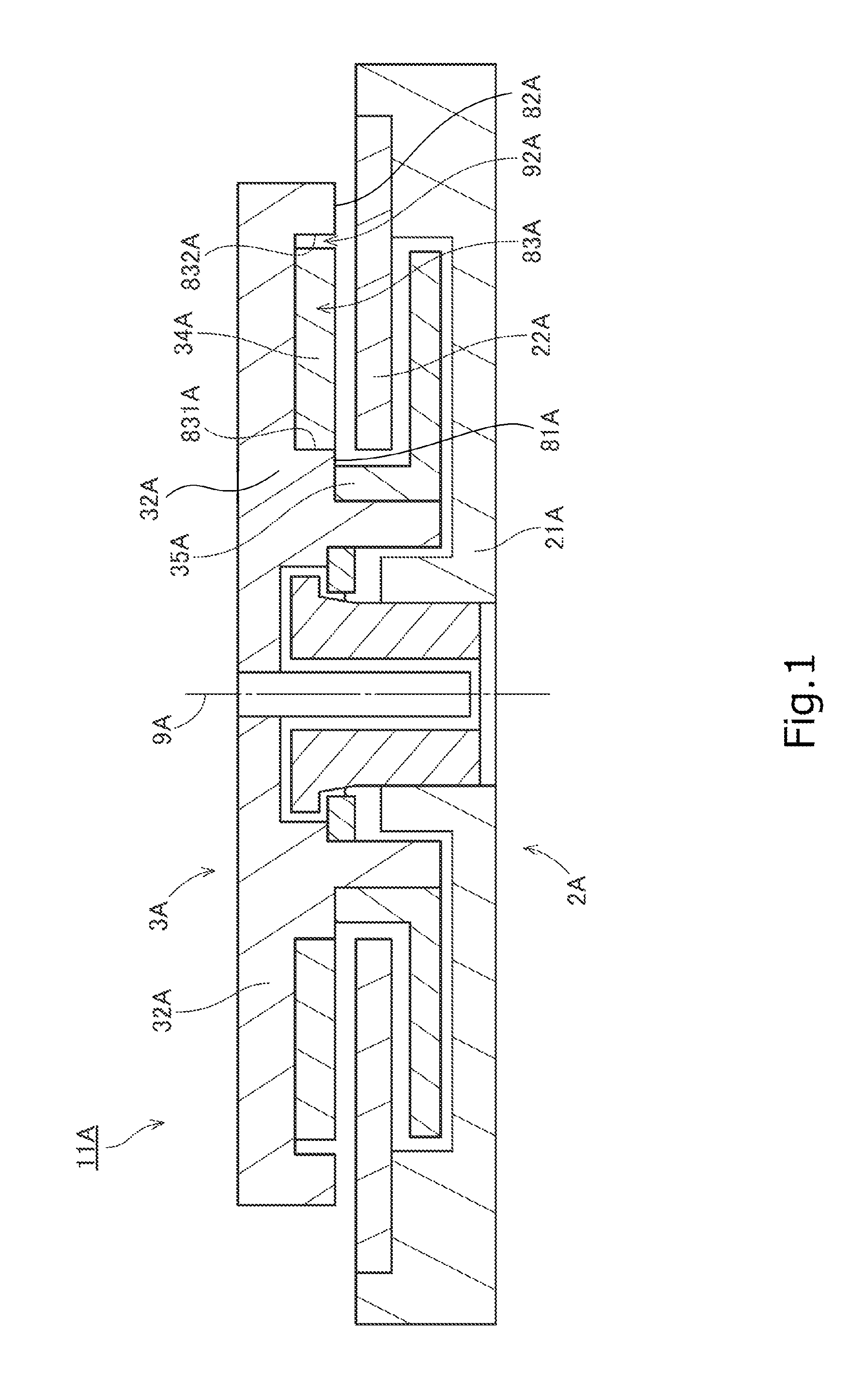

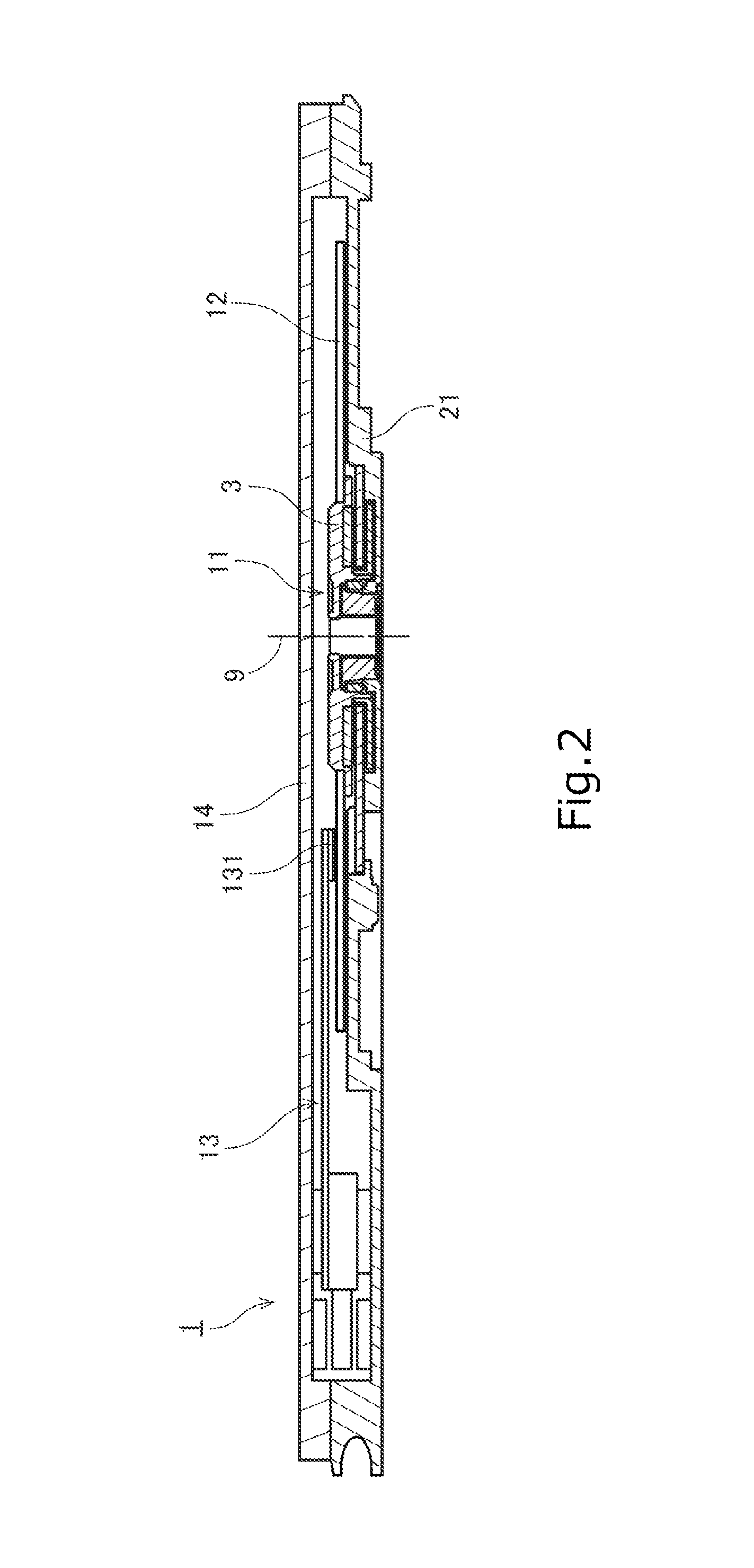

Machining head for machine tool

InactiveUS20120121356A1Increase in sizeImprove accuracyMachine tool componentsMilling machinesEngineeringMechanical engineering

A machining head (10) for a machine tool includes a spindle unit (20) to which a tool is attachable and a support head component (30, 60) that includes an index mechanism for indexing an angular position of a spindle (21). The index mechanism includes a drive motor (33, 63) supported by a bearing (35, 65) within the housing (31a, 61) of the support head component (30, 60) and a rotary joint (37, 67) disposed concentrically with the bearing (35, 65) and the drive motor (33, 63). The bearing (35, 65) is disposed within a range occupied by the drive motor (33, 63) in an axial direction of a support shaft (32, 37b, 62, 67c), and the rotary joint (37, 67) is disposed within the drive motor (33, 63) in a radial direction thereof.

Owner:TSUDAKOMA KOGYO KK

Partition of steam turbine and processing technology thereof

ActiveCN106150570AOvercome the difficult separation problemSolve these problems of wear and tearMachines/enginesEngine componentsStructural engineeringProcess engineering

The invention discloses a partition of a steam turbine and a processing technology thereof, and belongs to the field of manufacturing of partitions of steam turbines. The partition of the steam turbine comprises semicircular partitions, wherein the two sides of blades of the semicircular partitions are inner shrouds and outer shrouds respectively; the height of the single blade positioned on a midsplit surface is larger than the height of the midsplit surface; U-shaped notches are formed in the connection parts of the single blade and the corresponding inner shroud and the single blade and the corresponding outer shroud; and the height of the U-shaped notches exceeds the height of the midsplit surface. According to the processing technology of the partition of the steam turbine, full circle processing and full circle welding methods are adopted, and the U-shaped notches are cut in to-be-cut positions of the single blade on the midsplit surface in advance, so that the problem that during full circle processing of the partition, the midsplit surface is not liable to separate is overcome, the welding deformation is reduced, and the processing accuracy is improved.

Owner:北京北重汽轮电机有限责任公司

Multi-spectral reconstruction method based on adaptive finite element

ActiveUS8094149B2Less discomfortQuality improvementCharacter and pattern recognitionDiagnostics using tomographyRegion selectionPrior information

A multi-spectral reconstruction method based on adaptive finite element comprising the following steps: discretizing the diffusion equation in the object domain on the single spectral; establishing the relationship between the boundary measurement data and the unknown source variables on single spectral based on a posteriori permissible source region selection method, and forming the objective function based on the multi-spectral characteristics and the regularization method; optimizing the objective function and determining if the reconstruction shall be stopped or not; and if the reconstruction shall not be stopped, refining the mesh adaptively by using a posteriori measure method, and then returning to the first step to continue the reconstruction process. This method uses kinds of a priori information and the multi-spectral information, combined with the adaptive finite element method, proposes a posteriori permissible source region strategy, improves the reconstruction quality and speed of BLT availably, and reduces the ill-posedness of this imaging modality.

Owner:ZHUHAI DI PU MEDICAL TECH CO LTD

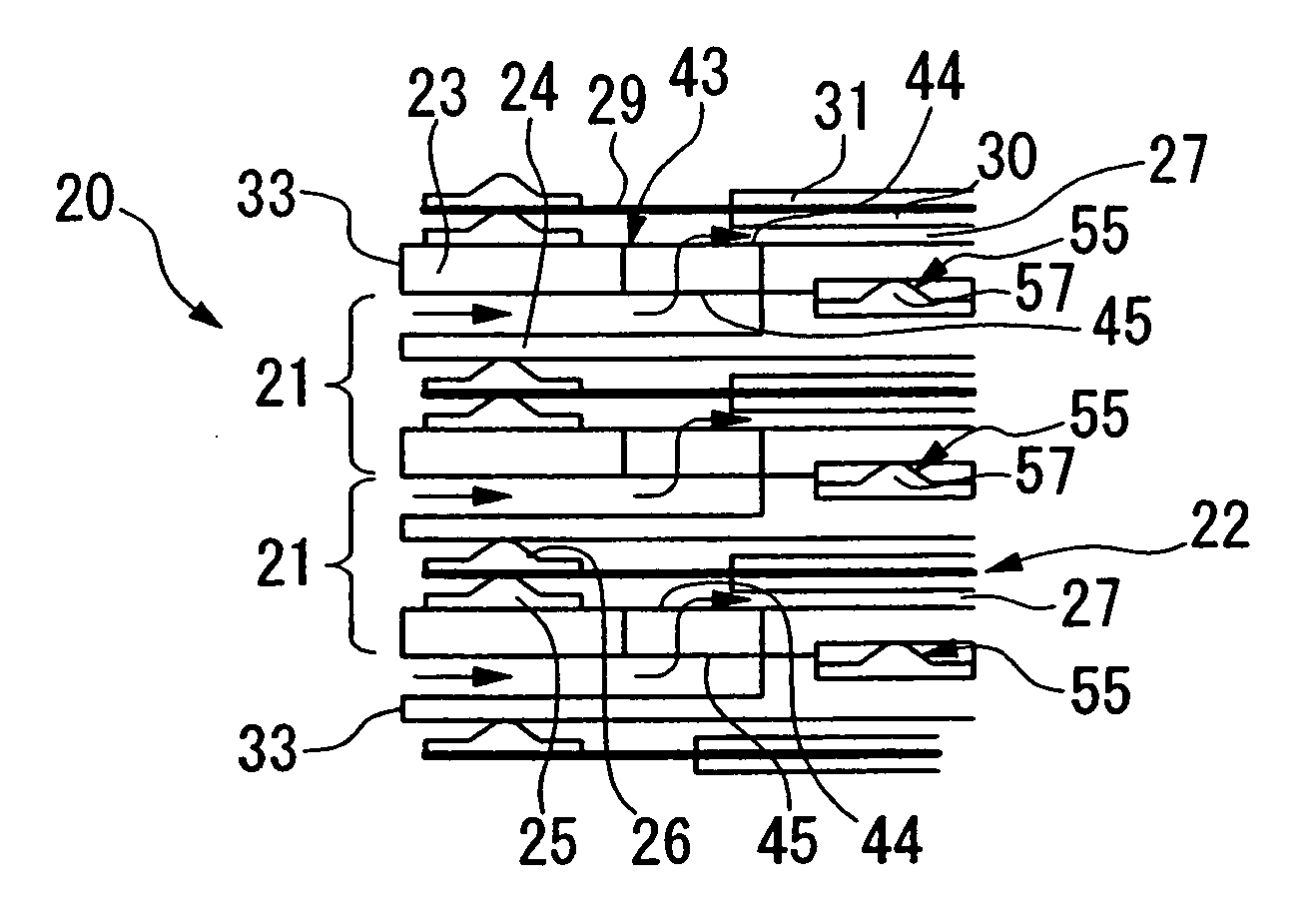

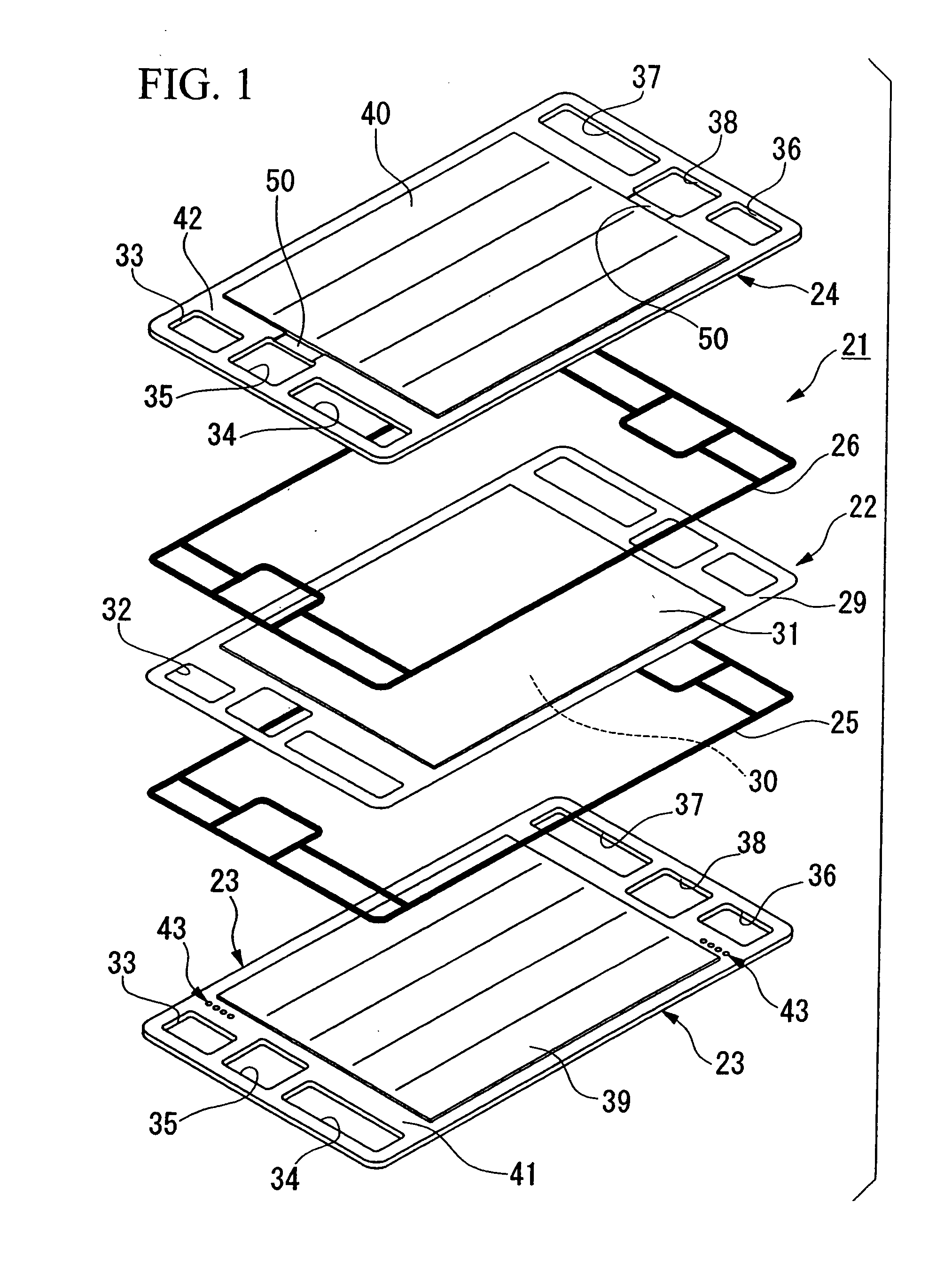

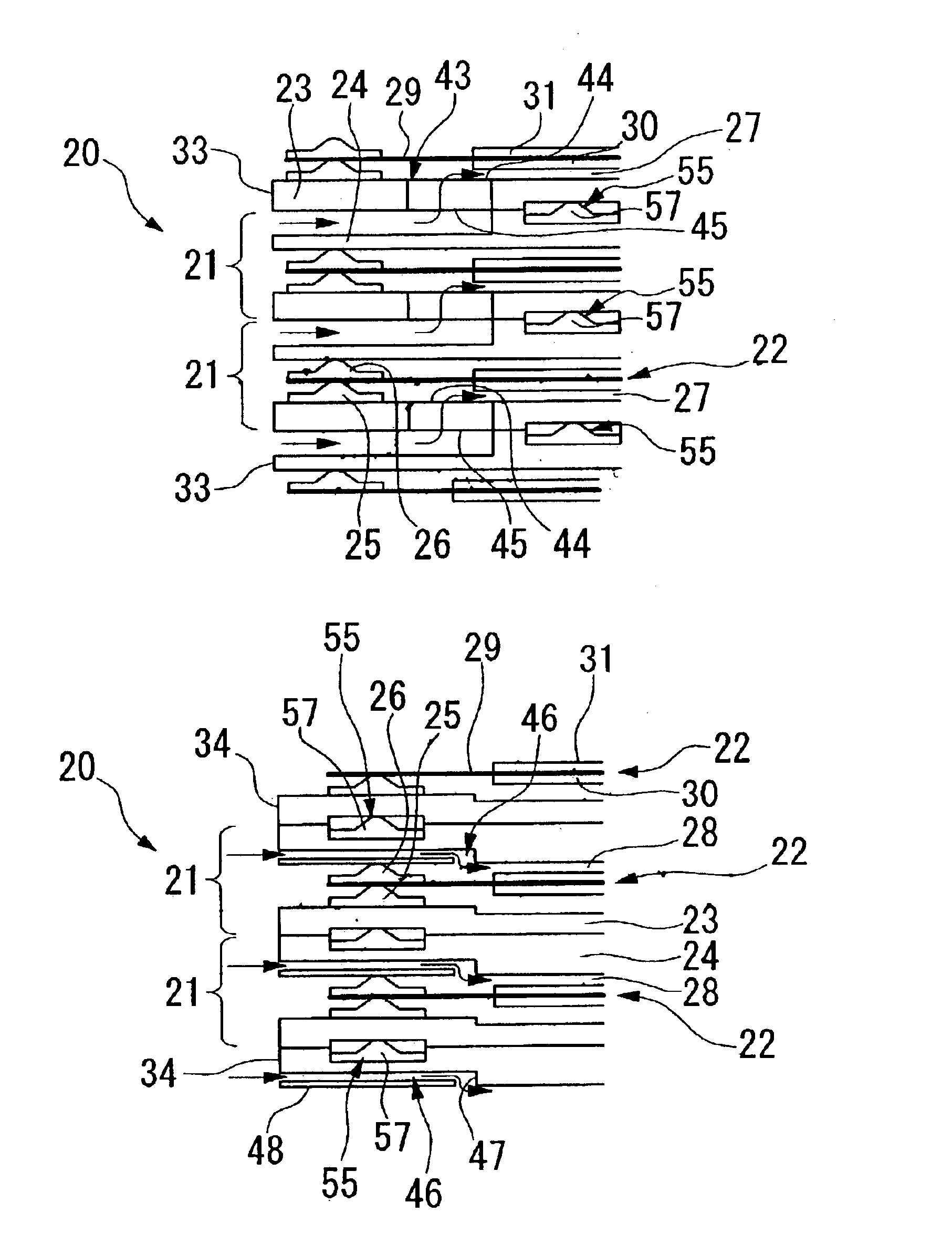

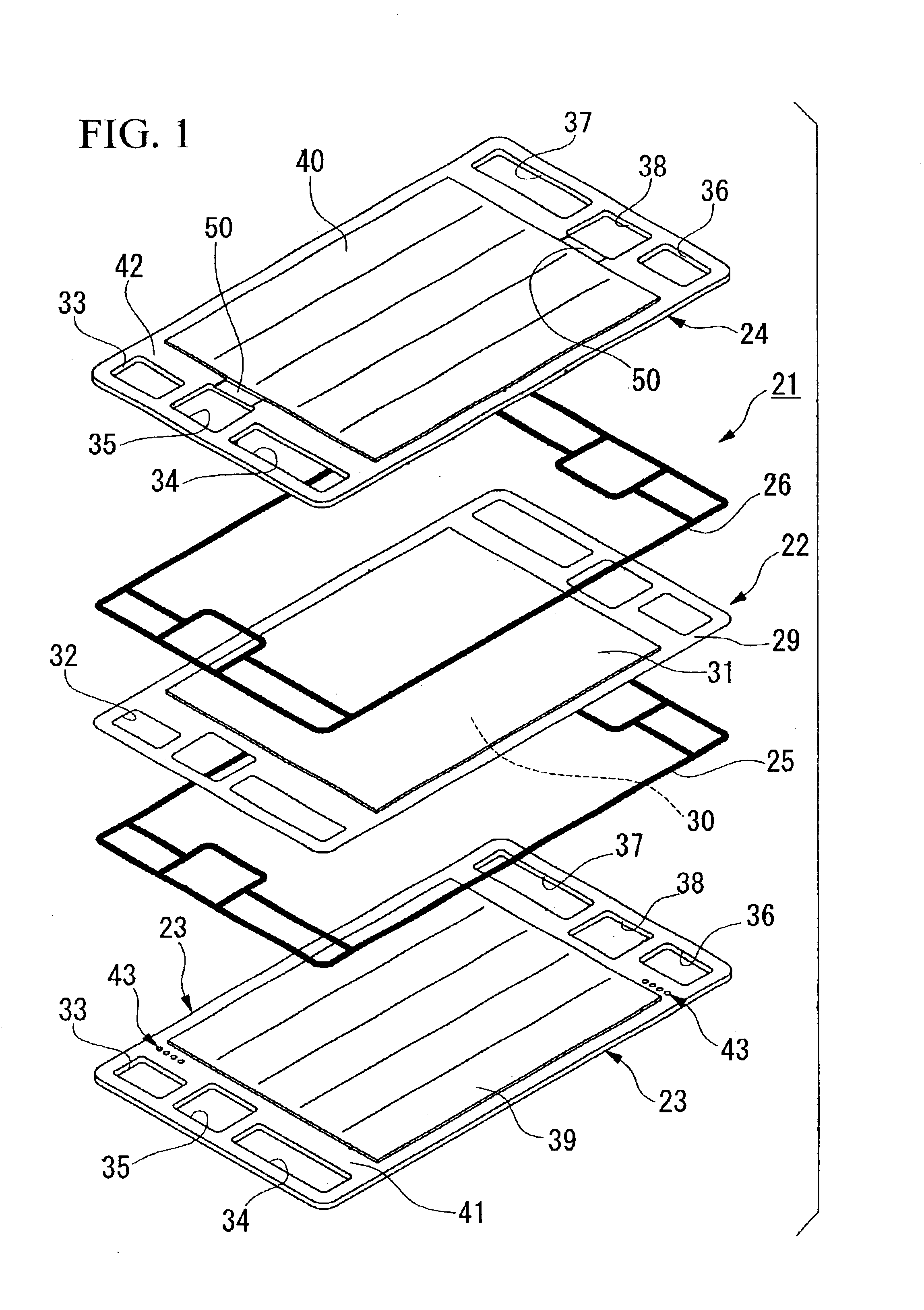

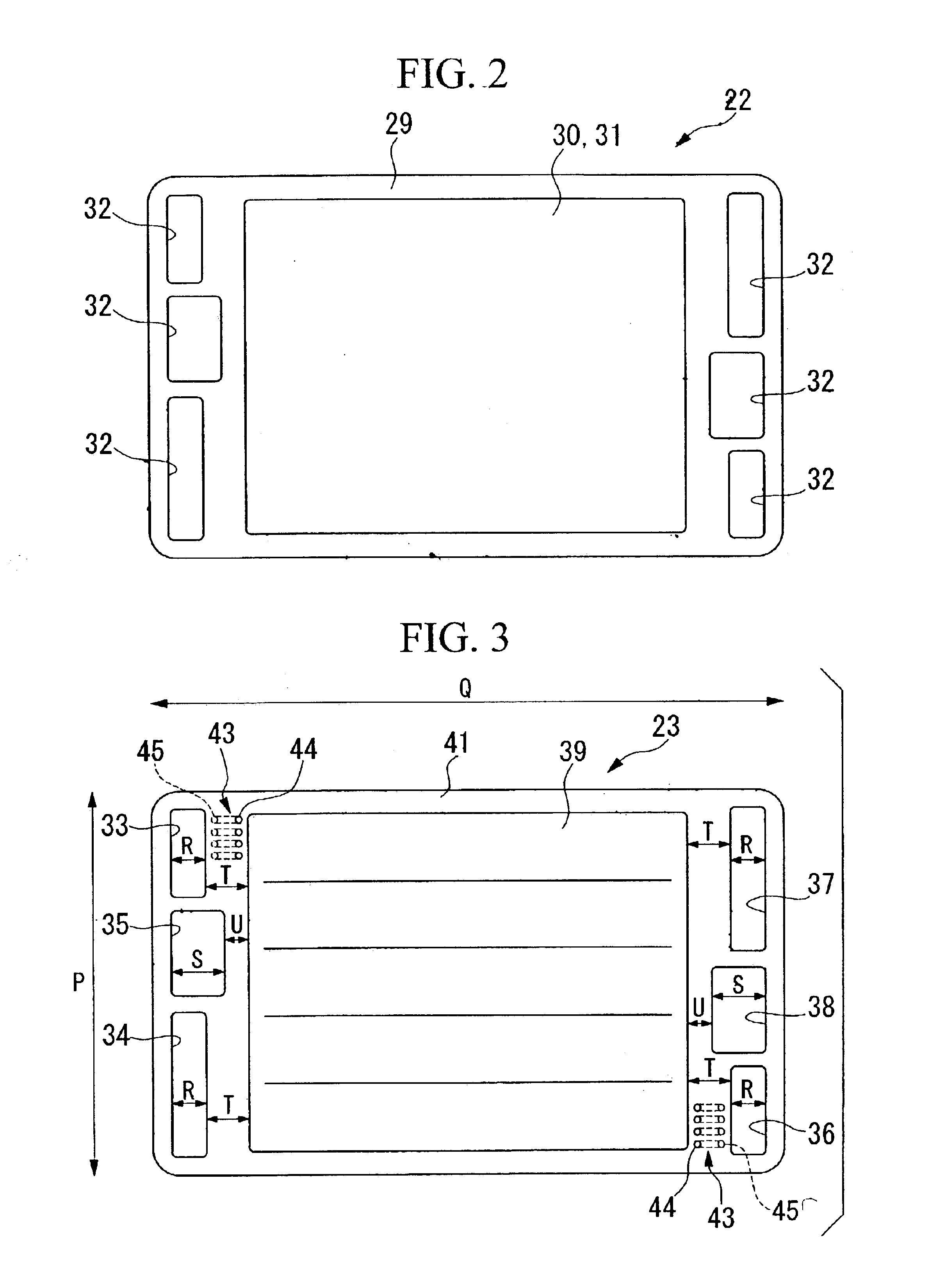

Fuel cell and separator thereof

InactiveUS20050238942A1Improve sealingAvoid DimensionsFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell includes a plurality of fuel cell units. Each fuel cell unit includes an electrode assembly having electrodes and an electrolyte, a pair of separators, and gas sealing members. At least two of the fuel cell units include at least two electrode assemblies and at least three separators. In each of the separators, reaction gas communication ports are provided. In one of the separators of one of the stacked fuel cell units that is located at the end in a direction of stacking, through paths are formed. In one of the separators of one of the stacked fuel cell units that is located at the other end in the direction of stacking, reaction gas communication paths are formed. Both the through paths and the reaction gas communication paths are formed in all separators that are located between two fuel cell units that are located at the ends.

Owner:HONDA MOTOR CO LTD

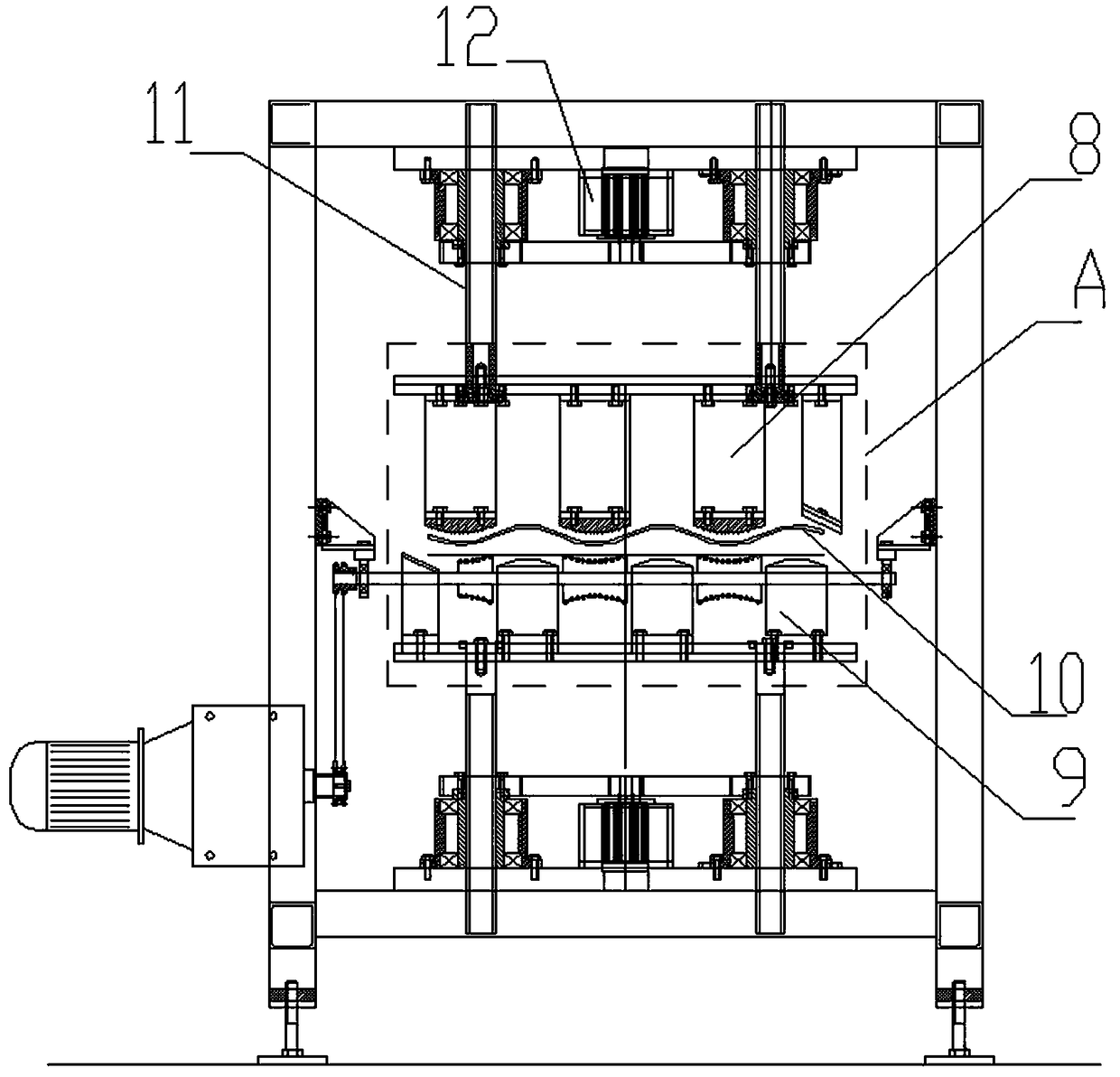

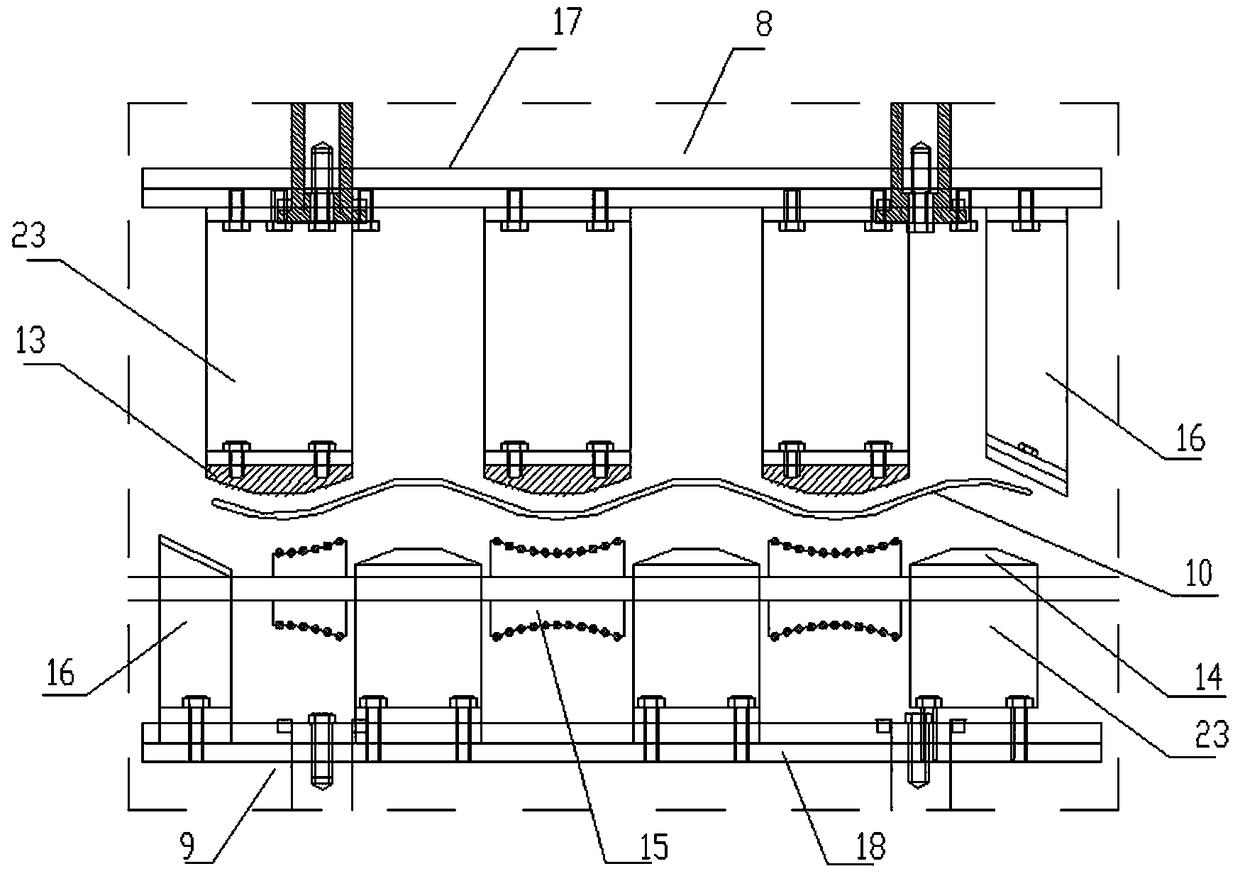

Production equipment of wave-shaped tempered glass

ActiveCN108328911ASolve bottlenecksIncrease power generation capacityGlass reforming apparatusGlass tempering apparatusWave shapeFusiform shape

The invention relates to production equipment of wave-shaped tempered glass. The production equipment comprises a sheet charging table, a heating furnace, a primary shaping section, a rolling pressingcorrection section, a tempering section and a sheet discharging table in sequential arrangement along the process progress direction, wherein the primary shaping section comprises an upper module, alower module and a plurality of rows of shaping rollers; the upper module and the lower module are in vertical arrangement; the shaping rollers are arranged in the glass conveying direction; a plurality of upper molds used for wave-shaped concave surface part shaping are arranged in the upper module; the upper molds and the shaping rollers are in vertical correspondence; a plurality of lower moldsused for wave-shaped glass convex surface part shaping are arranged in the lower module; the bus lines of the shaping rollers are anastomotic with the lower surface sectional line of the concave surface part after the glass shaping; the rolling pressing correction section is mainly formed by a roller way which are ranged in the glass conveying direction and is provided with a plurality of fusiform rollers; the bus lines of the fusiform rollers are anastomotic with the interface sectional lines of the wave-shaped glass in contact with the fusiform rollers. The equipment has the advantages thatthe production of the wave-shaped tempered glass becomes possible; the bottleneck problem of the wave-shaped curve surface photovoltaic solar panel production is solved.

Owner:洛阳格莱斯机械设备有限公司

Brushless motor and disk drive apparatus

InactiveUS20130313935A1Efficiently flowLarge flowMagnetic circuit rotating partsRecord information storageMagnetEngineering

A brushless motor includes a stationary unit and a rotary unit rotatably supported with respect to the stationary unit. The stationary unit includes an armature and a base member arranged to support the armature. The rotary unit includes a magnet, a hub made of a magnetic material and a rotor yoke made of a magnetic material. The armature includes a plurality of coil patterns arranged along a circumferential direction. The hub includes an inner lower surface, an outer lower surface and a recess portion. The recess portion is arranged between the inner lower surface and the outer lower surface and depressed upward. At least a portion of the magnet is accommodated within the recess portion. At least one of the inner lower surface and the outer lower surface is positioned above a lower surface of the magnet.

Owner:NIDEC CORP

Writing method of charged particle beam, support apparatus of charged particle beam writing apparatus, writing data generating method and program-recorded readable recording medium

ActiveUS7495243B2Avoid DimensionsMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsComputer scienceDesign pattern

A charged particle beam writing method includes inputting design pattern data, virtually dividing a writing area to be written with the design pattern data into a plurality of small areas in a mesh-like manner, calculating a pattern density in each of the plurality of small areas based on the design pattern data, calculating a resizing amount for each pattern density in a case of irradiating a charged particle beam at an isofocal dose, resizing a dimension of the design pattern data in each of the plurality of small areas, based on the resizing amount in each of the plurality of small areas, and writing a resized design pattern on a target workpiece with the isofocal dose corresponding to the pattern density which was calculated before the resizing in each of the plurality of small areas.

Owner:NUFLARE TECH INC

Fuel cell

InactiveUS6866959B2Improve sealingAvoid DimensionsFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell is provided that has a sufficient sealing performance while having a restrained dimension in the stacking direction thereof. The fuel cell is formed by stacking a plurality of fuel cell units, each fuel cell unit comprising: an electrode assembly formed by disposing electrodes on both sides of an electrolyte; a pair of separators that sandwich the electrode assembly in the thickness direction thereof; and gas sealing members that are disposed at an outer peripheral portion of the electrode assembly, and that seal respective reaction gas flow passages that are formed between each separator and the electrode assembly and are bounded by the separators and electrode assembly. In each of the separators, there are provided reaction gas communication ports that are provided outward from the gas sealing members, in one separator, through paths are formed that penetrate the separator in the thickness direction thereof and connect the reaction gas communication ports with the reaction gas flow passages, and in the other separator, reaction gas communication paths are formed that detour around the gas sealing member in the thickness direction of the separator and connect the reaction gas communication ports with the reaction gas flow passages.

Owner:HONDA MOTOR CO LTD

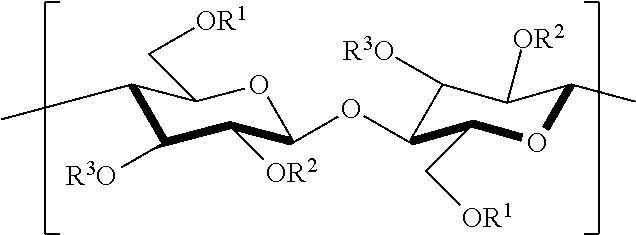

Polymer-based resin compositions derived from cellulose and articles made using these compositions

A shaped article comprising a polymer-based resin derived from cellulose, wherein the polymer-based resin has an HDT of at least 95° C., a bio-derived content of at least 20 wt %, a notched izod impact strength of greater than 80 J / m and at least one of the following properties chosen from: flexural modulus of greater than 1900 MPa; a spiral flow length or at least 3.0 cm; a flex creep deflection of less than 12 mm; a transmission of at least 70%; a ΔE value of less than 25; or an L* color of at least 85.

Owner:EASTMAN CHEM CO

Intelligent sheet metal part production system capable of adhering sponge automatically

ActiveCN108790193AGuarantee product qualityAvoid DimensionsMetal-working feeding devicesMaterial gluingMicrocomputerControl system

Owner:XUZHOU DKEC ELECTRICAL TECH

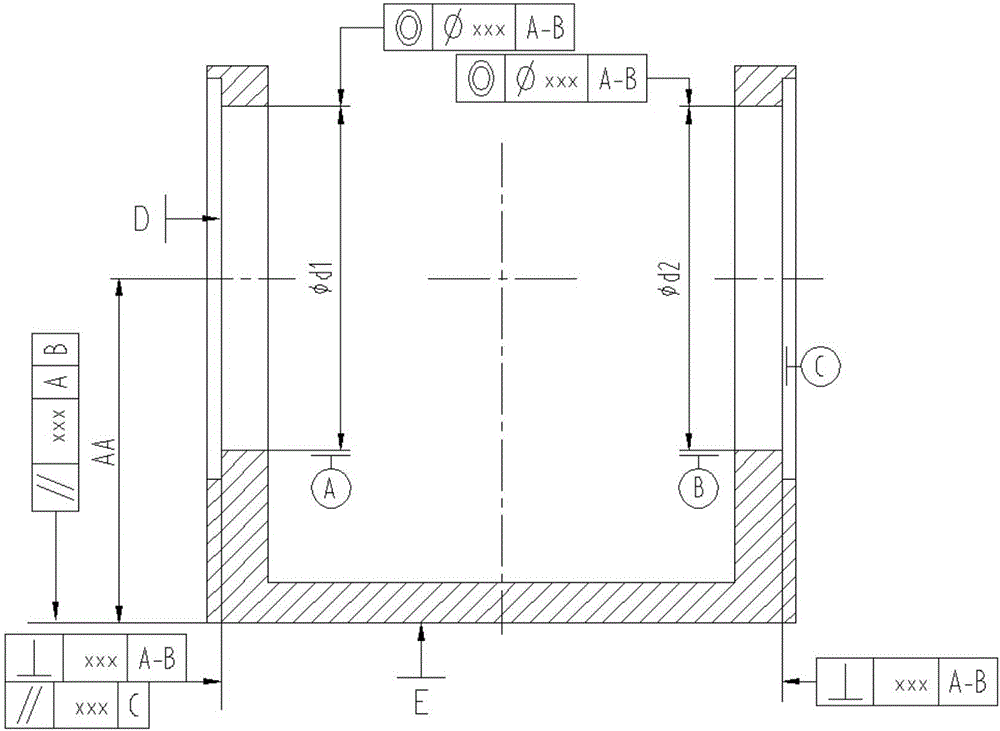

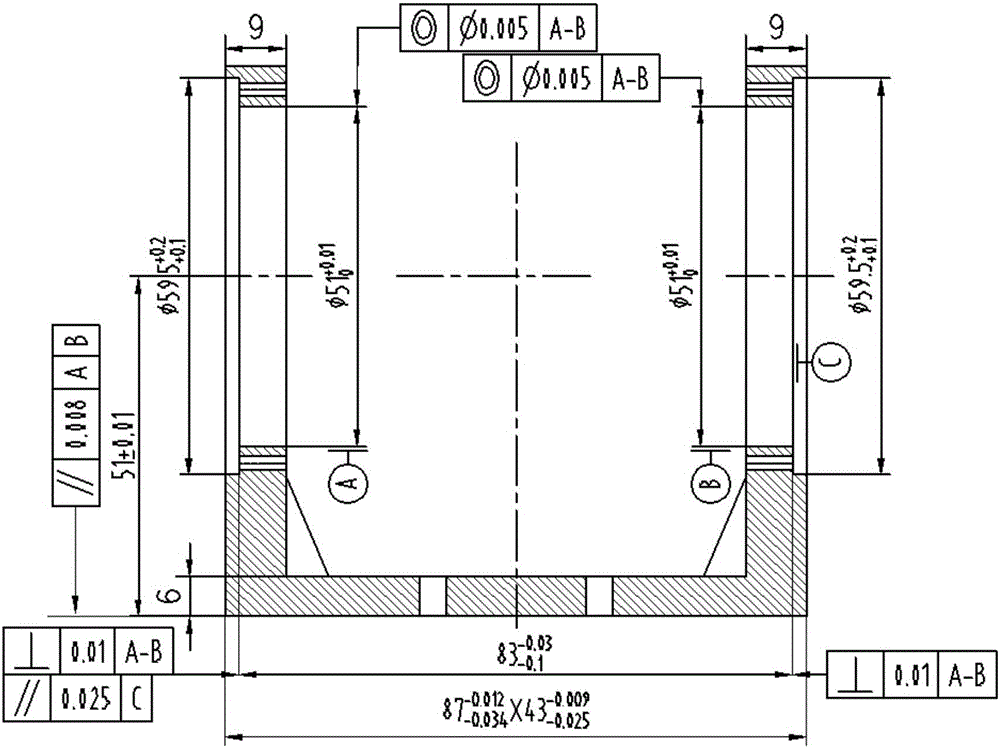

Precision machining method for high-precision U-shaped low-rigidity bearing block type parts

The invention discloses a precision machining method for high-precision U-shaped low-rigidity bearing block type parts. The method comprises steps as follows: 1, materials are prepared; 2, rough machining is performed, the parts are machined and shaped, and all outlines reserve the machining allowance; 3, stress ageing is eliminated, and the residual stress produced by rough machining is eliminated; 4, semi-finish machining is performed, and except that assembling datum surfaces, mounting holes of bearings, end surfaces of the bearings and important mounting connecting holes reserve the machining allowance, other machining characteristics meet size requirements; 5, stress ageing is eliminated again, and the residual stress produced by semi-finish machining is eliminated; 6, finish machining is performed on the assembling datum surfaces, the mounting holes of the bearings, the end surfaces of the bearings and the important mounting connecting holes. The datum-uniform and datum-first principles are adopted in the process, auxiliary tools are designed to reduce trembling and improve the rigidity of the parts, meanwhile, the influence of machining elastic deformation is considered in control on central high sizes, and certain correction margins are reserved. With the method, the percent of pass of the high-precision U-shaped low-rigidity bearing block type parts is guaranteed.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

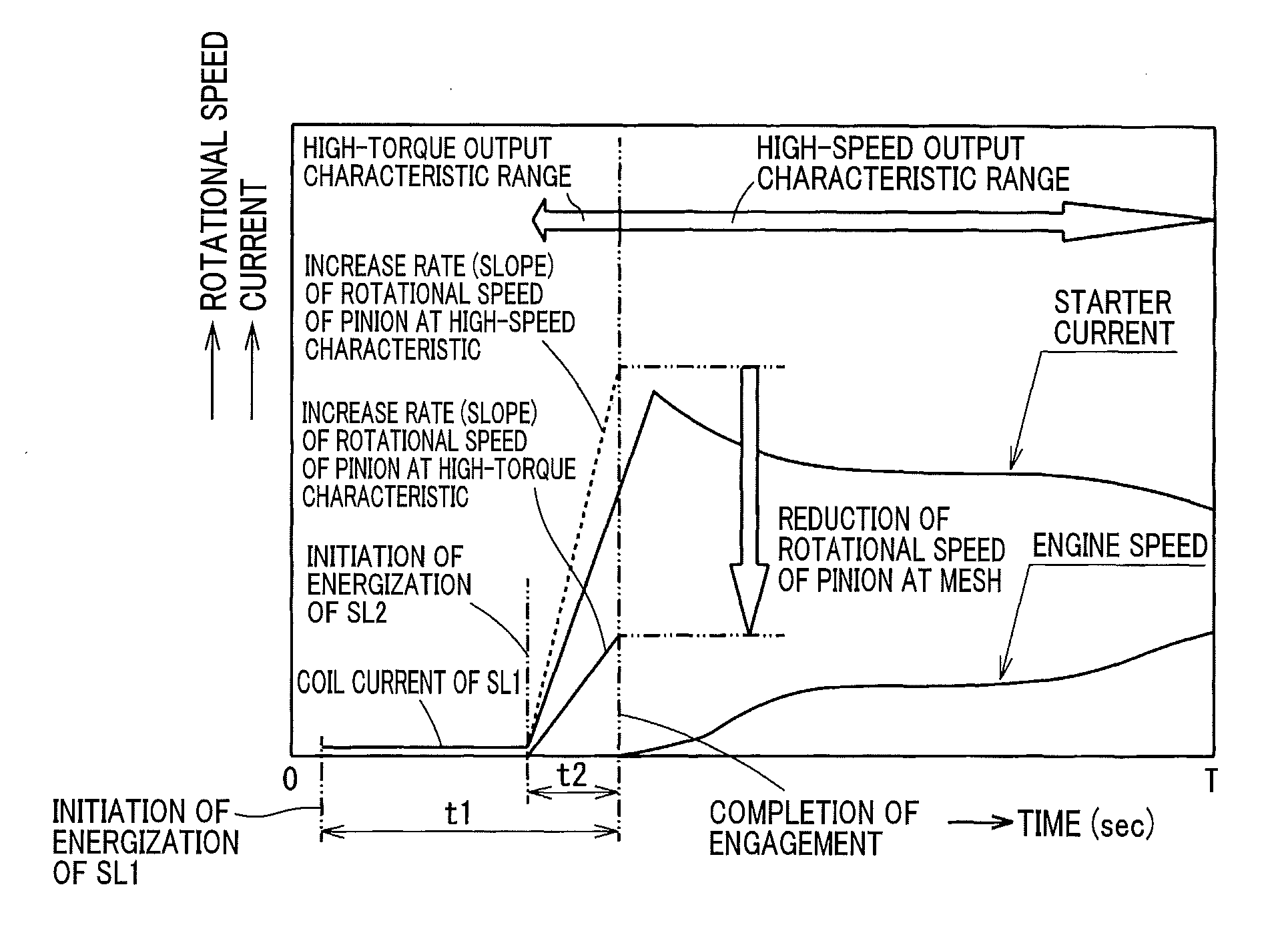

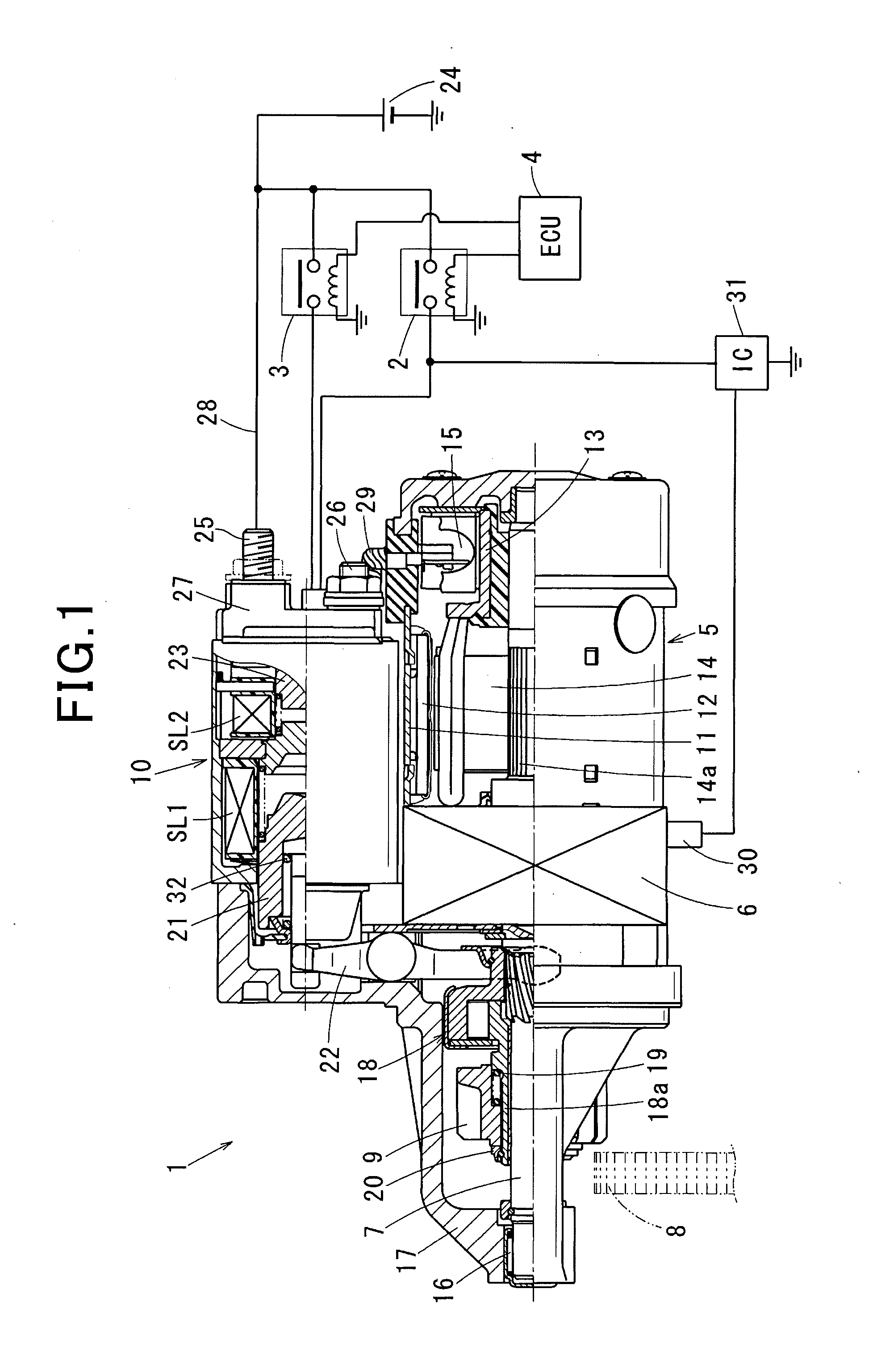

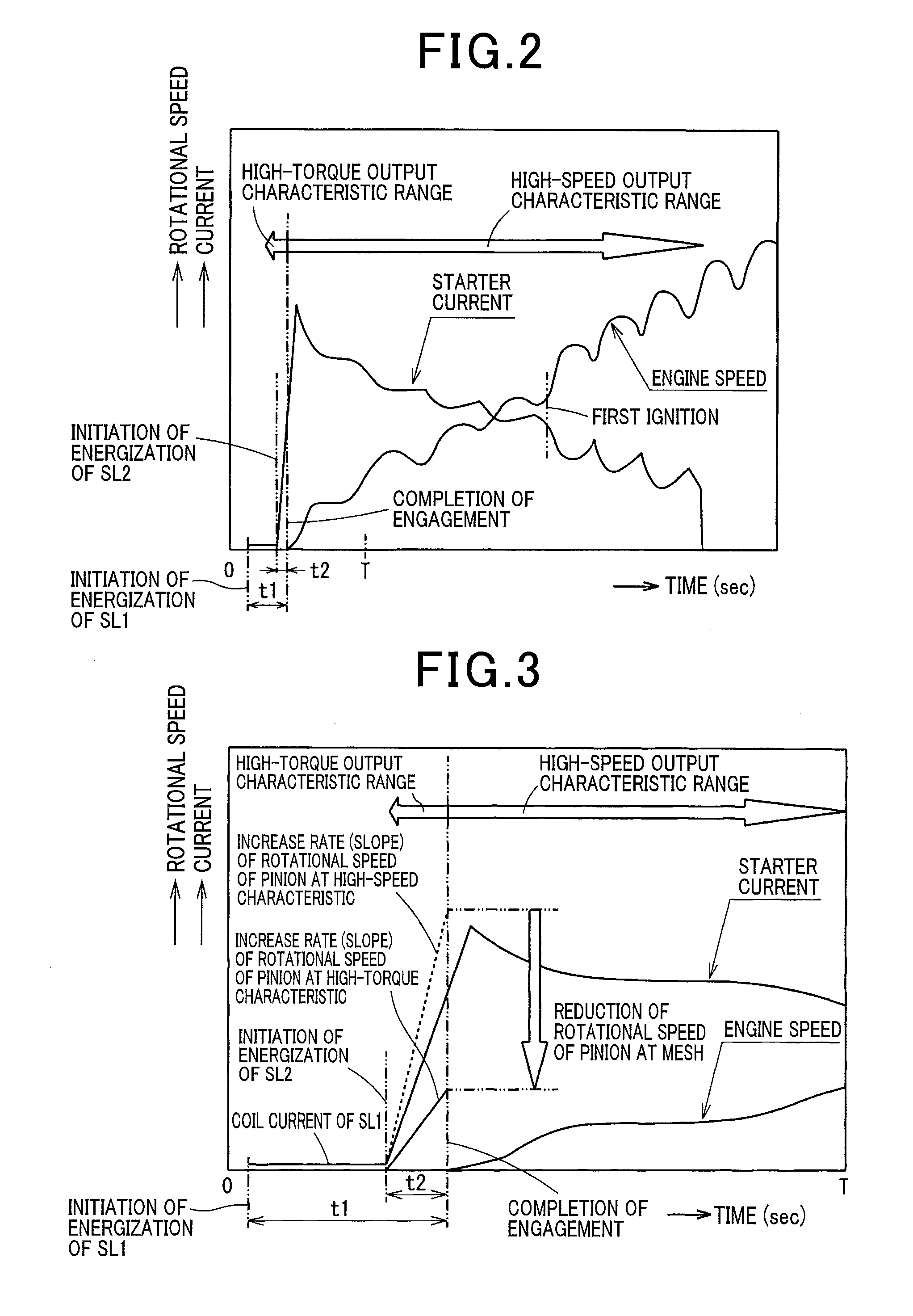

Engine starting apparatus

InactiveUS20150354524A1Reduce speedEnhance engagement reliabilityPower operated startersElectric motor startersLow speedHigh torque

An apparatus for starting an engine, including an inertia-engagement-type starter. In the apparatus, a starter-characteristic switching mechanism is configured to switch an output characteristic of the starter between a plurality of output characteristics including at least a low-torque high-speed characteristic and a high-torque low-speed characteristic, where the output characteristic of the starter is hereinafter referred to a starter characteristic. A timing controller is configured to control when the starter-characteristic switching mechanism switches the starter characteristic such that the starter characteristic is set to the high-torque low-speed characteristic from initiation of actuation of the starter at least until a pinion successfully meshes with a ring gear, and after the pinion has successfully meshed with the ring gear, the starter characteristic is switched from the high-torque low-speed characteristic to the low-torque high-speed characteristic at which the engine is cranked by the starter.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com