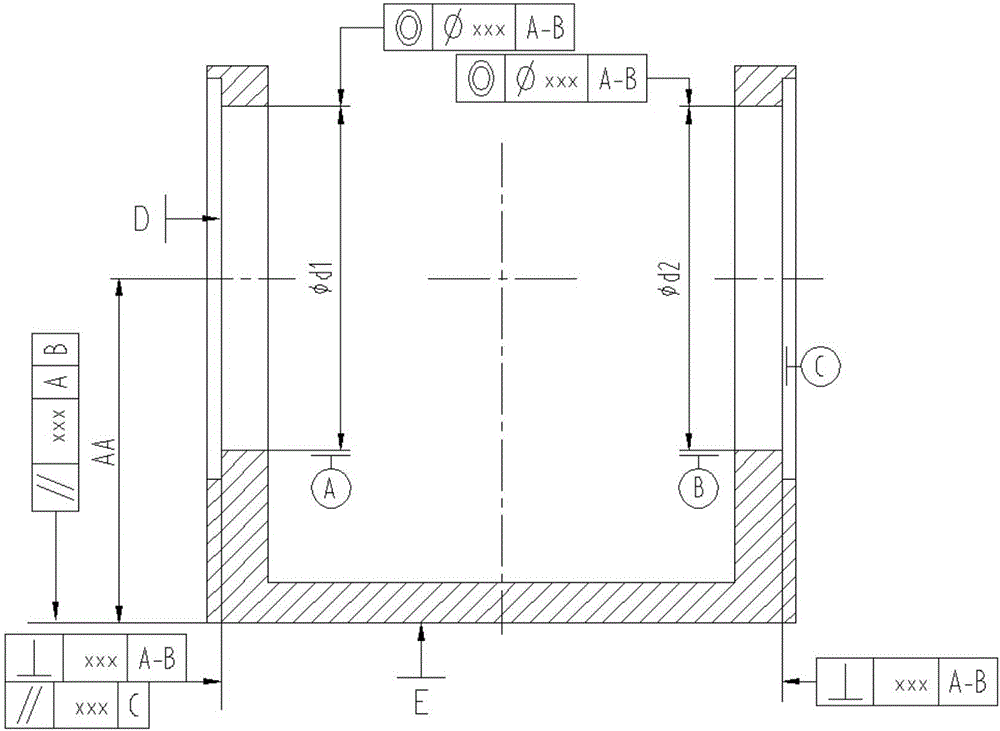

Precision machining method for high-precision U-shaped low-rigidity bearing block type parts

A precision machining and weak stiffness technology, applied in the field of precision machining, can solve problems such as uneven distribution of cutting amount, difficulty in accurately controlling cutting amount, large elastic deformation, etc., to avoid AA dimension out-of-tolerance, reduce chattering problems, The effect of increasing the rigidity of the part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

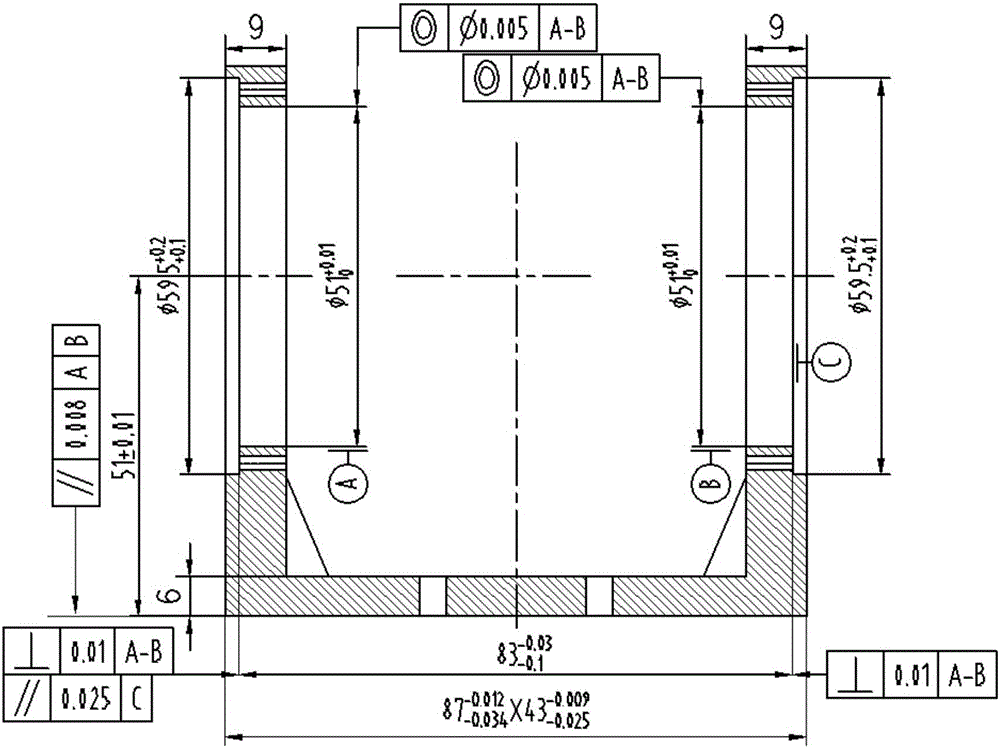

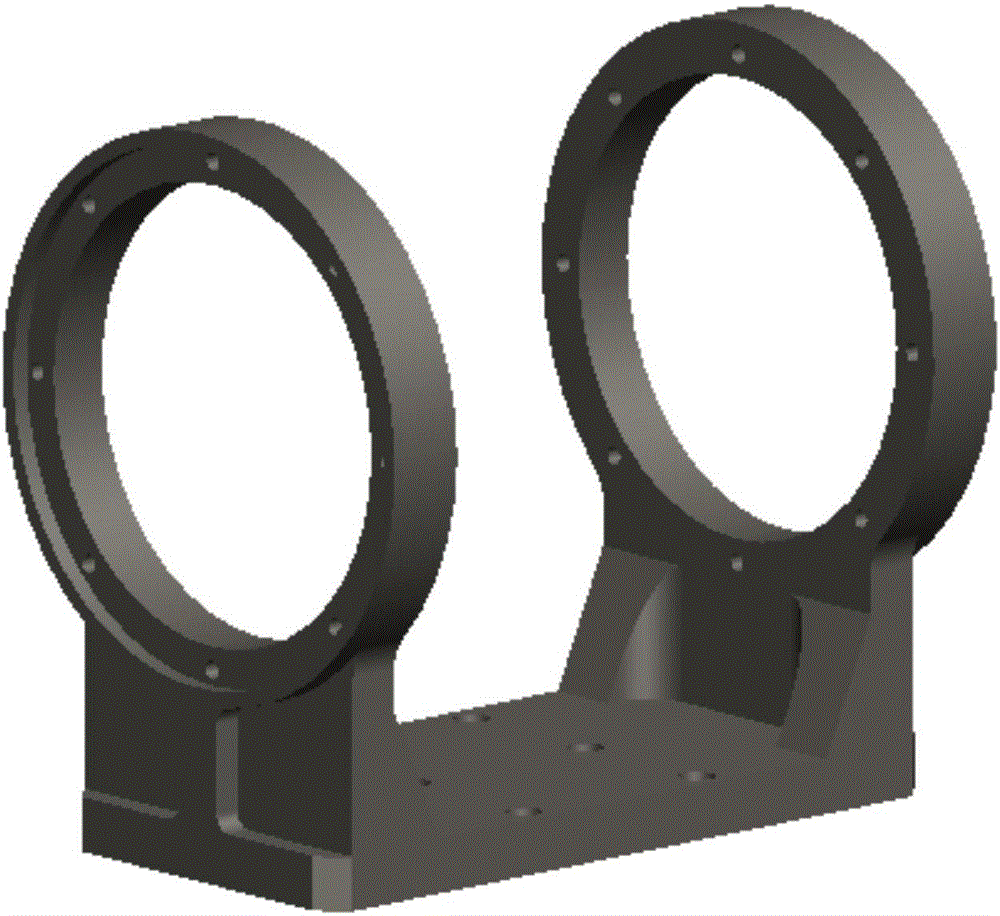

[0052] as attached figure 2 , 3 The material of the high-precision U-shaped weak rigidity bearing seat part shown is TC4R, and its precision machining method includes the following steps:

[0053] Step 1), preparing materials;

[0054] Step 2), rough machining, machining the parts into shape, leaving a margin of 2 mm for one side and radius of all shapes;

[0055] Step 3), vacuum stress relief aging;

[0056] Step 4), semi-finishing, processing each feature of the part, including 51±0.01 lower end surface, two places hole, both ends, A margin of 0.4mm is left on one side of the four sides and the radius, two 8-M2-7H are not processed, and the rest of the features are processed to meet the size requirements of the drawing;

[0057] Step 5), vacuum stress relief aging;

[0058] Step 6), process 1: fine boring 51±0.01 lower end face, The size requirements of the four-sided map, guarantee: 51±0.01 lower end surface flatness ≤0.01mm; if attached Figure 4 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com