Patents

Literature

281results about How to "Avoid shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device and method for manufacturing the same

ActiveUS20090267225A1Reduce thicknessSmall sizeSemiconductor/solid-state device detailsSolid-state devicesShock resistanceDiffusion layer

In a semiconductor integrated circuit sandwiched between a pair of a first impact resistance layer and a second impact resistance layer, an impact diffusion layer is provided between the semiconductor integrated circuit and the second impact resistance layer. By provision of the impact resistance layer against the external stress and the impact diffusion layer for diffusing the impact, force applied to the semiconductor integrated circuit per unit area is reduced, so that the semiconductor integrated circuit is protected. The impact diffusion layer preferably has a low modulus of elasticity and high breaking modulus.

Owner:SEMICON ENERGY LAB CO LTD

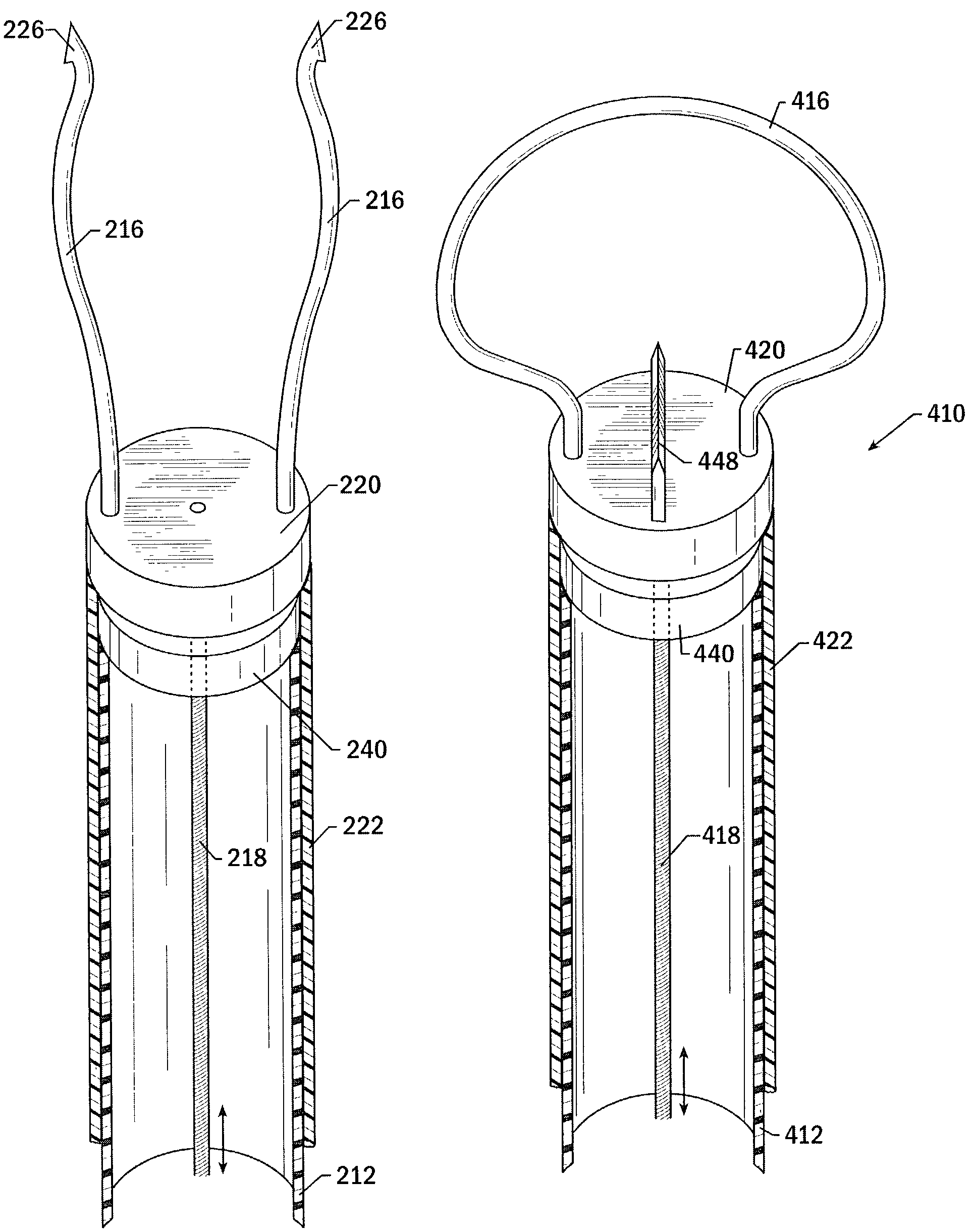

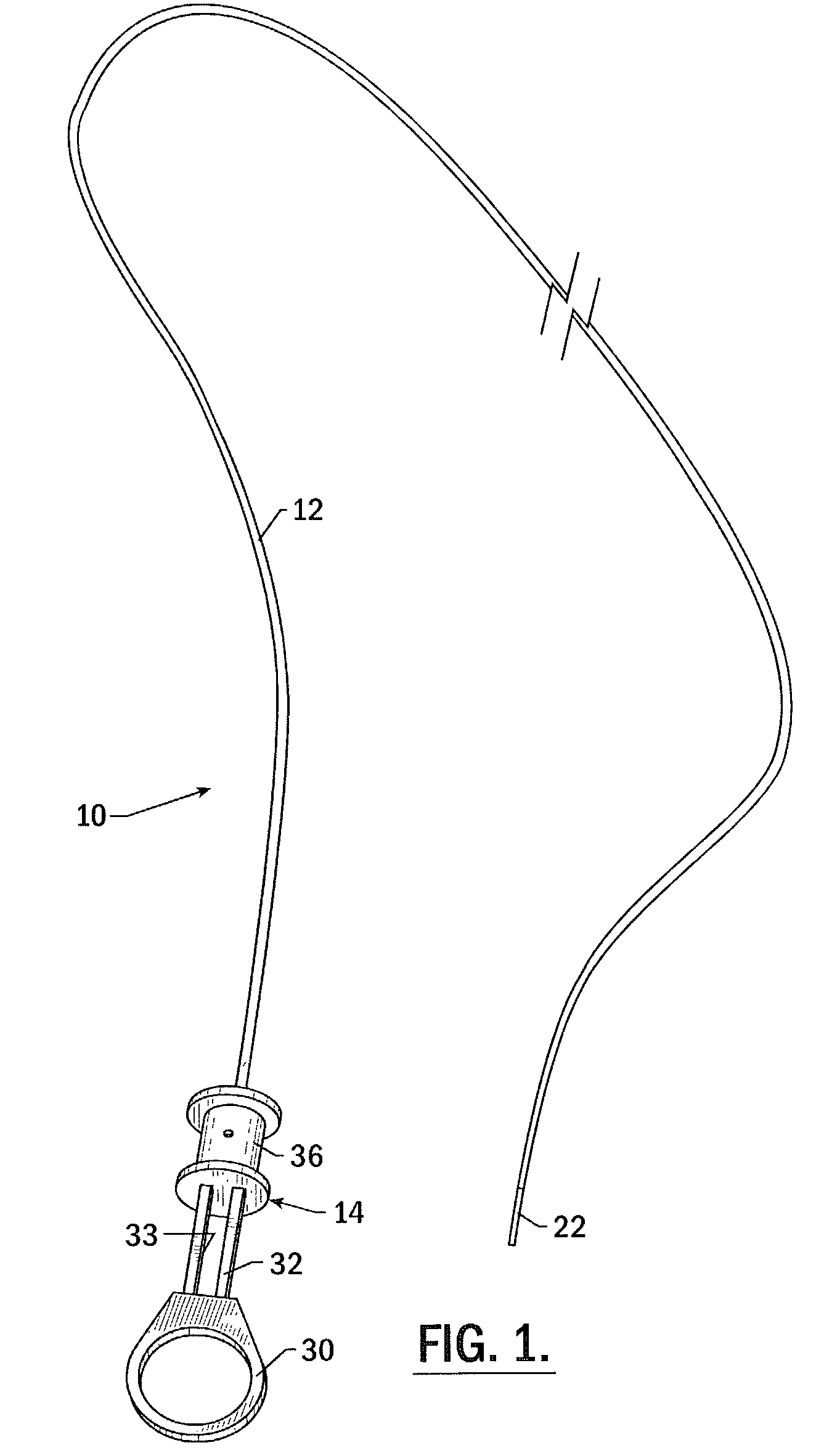

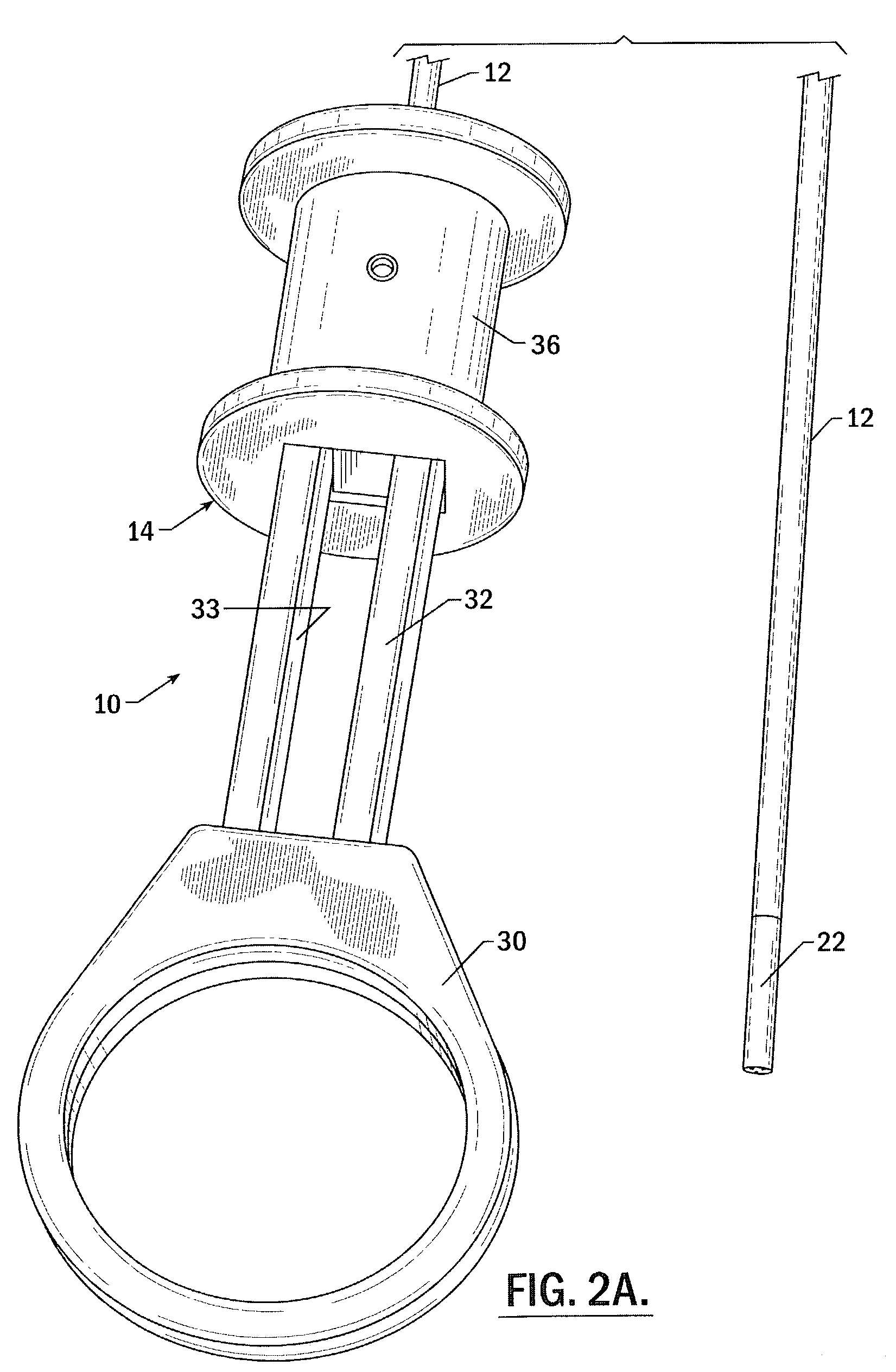

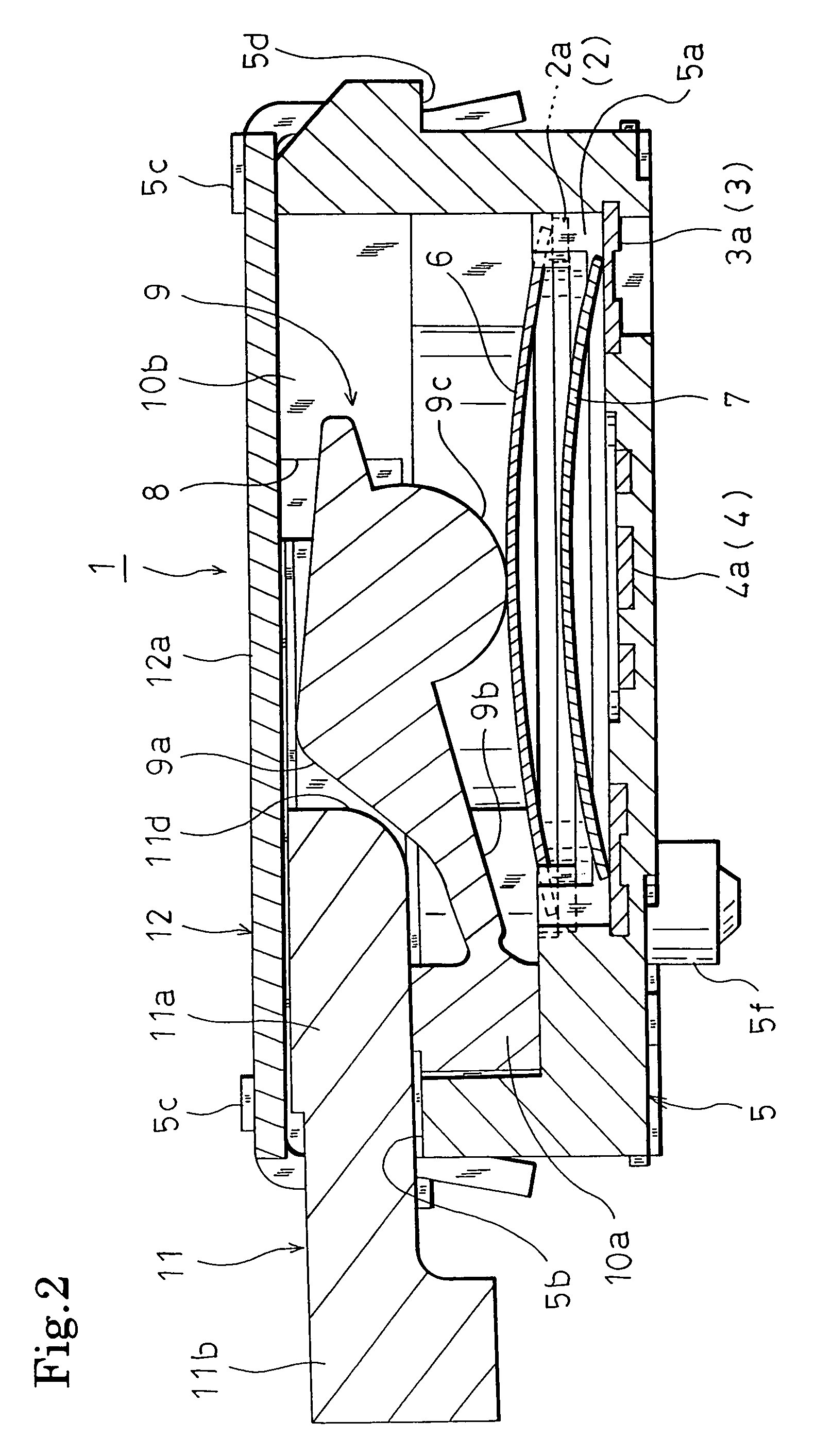

Controlled - motion endoscopic grasping instrument

InactiveUS7294139B1Complicating abilityComplicating to maneuverDiagnosticsSurgical needlesDiameter ratioEndoscopic Procedure

An improved controlled-motion instrument is provided for grasping, holding or otherwise manipulating an object in operations such as endoscopic procedures. The instrument opens and closes jaws or other manipulation members by way of a longitudinally movable cam member, but maintains the longitudinal position of the manipulation members constant relative to the instrument's body regardless of opening and closing motion. The manipulation members thus have increased length-to-diameter ratio and column strength, and the cam provides positive lateral jaw support and stability during opening and closing. The movable cam member can also include other manipulation members thereon that work in conjunction with the longitudinally fixed manipulation members.

Owner:C M WRIGHT INC

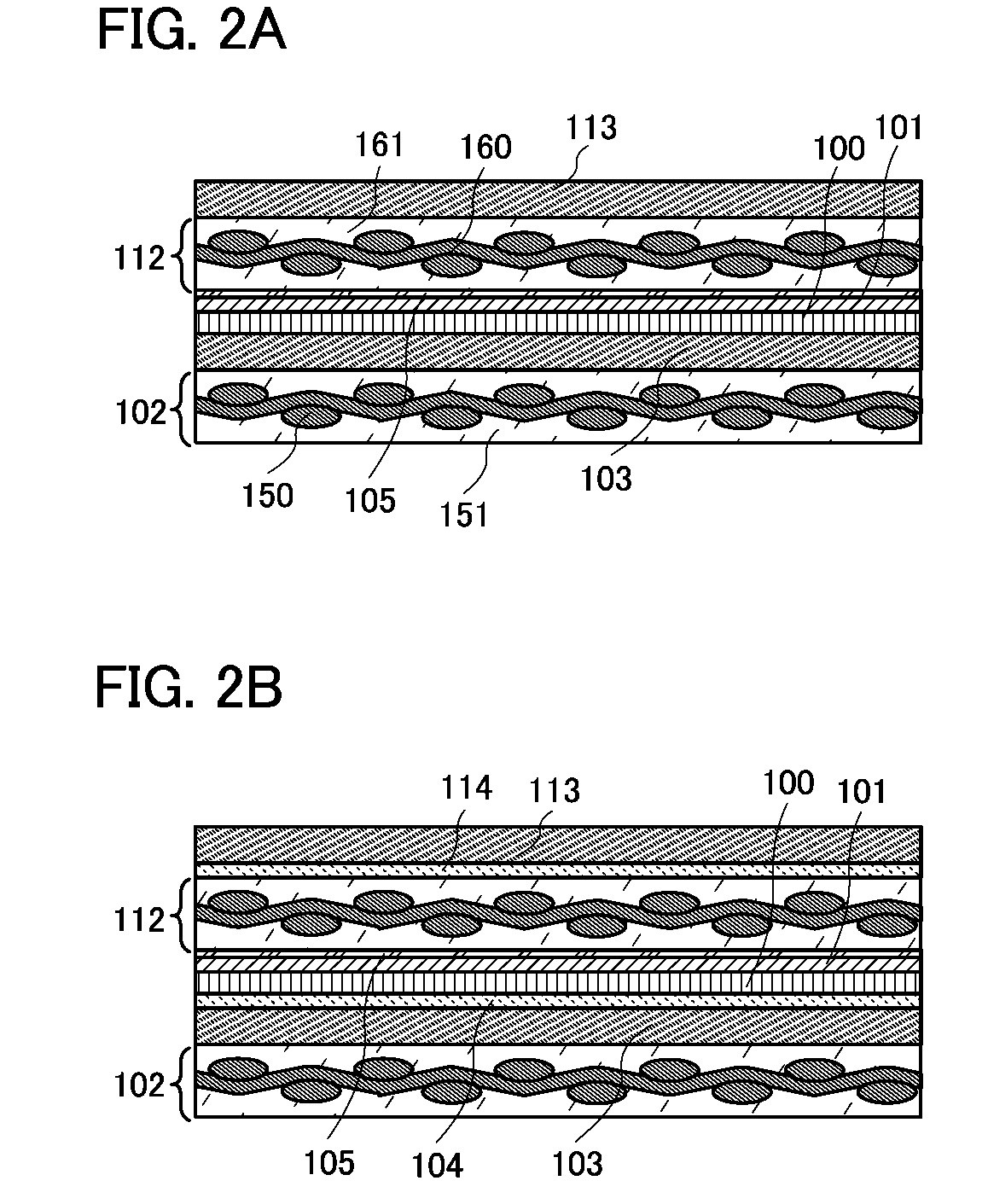

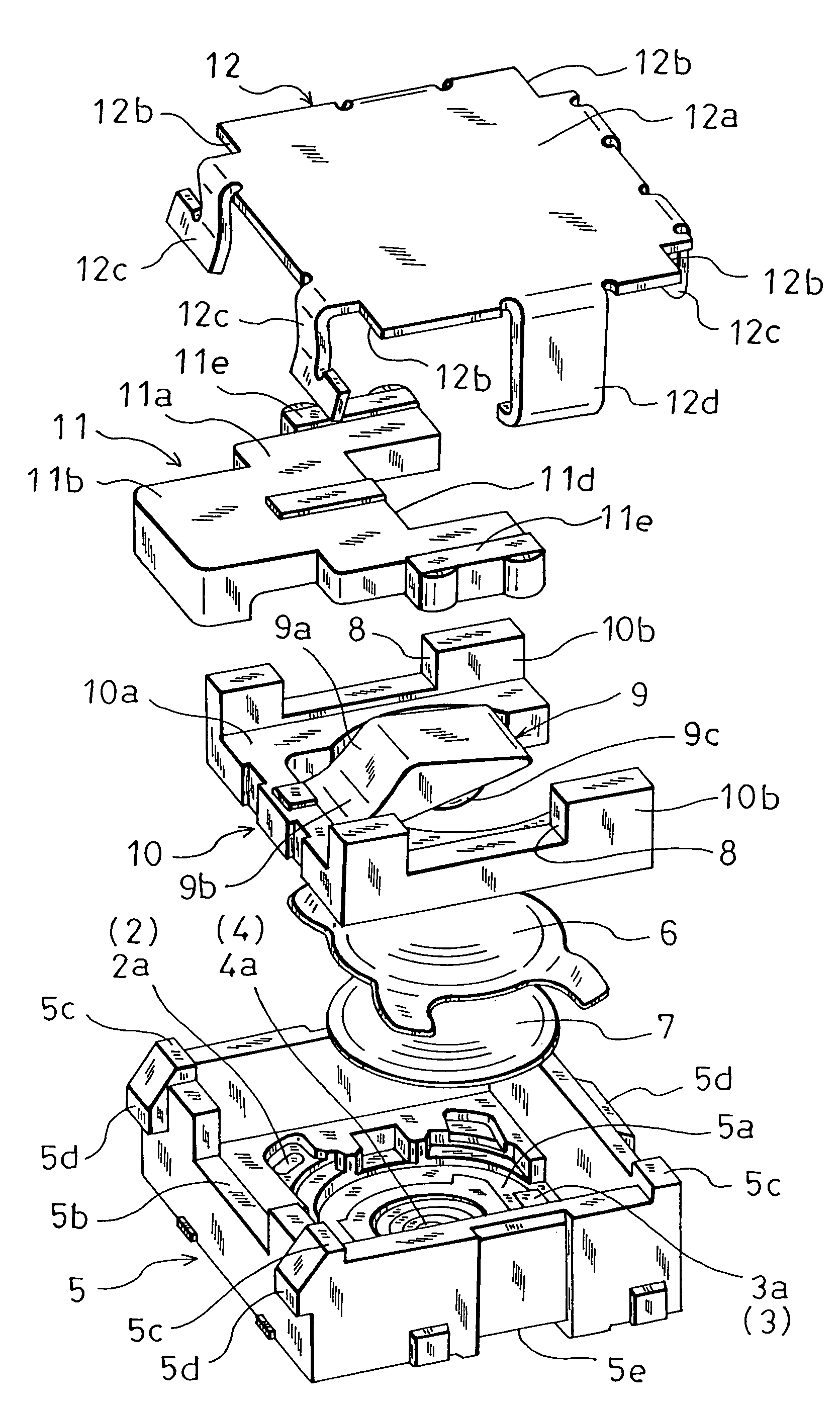

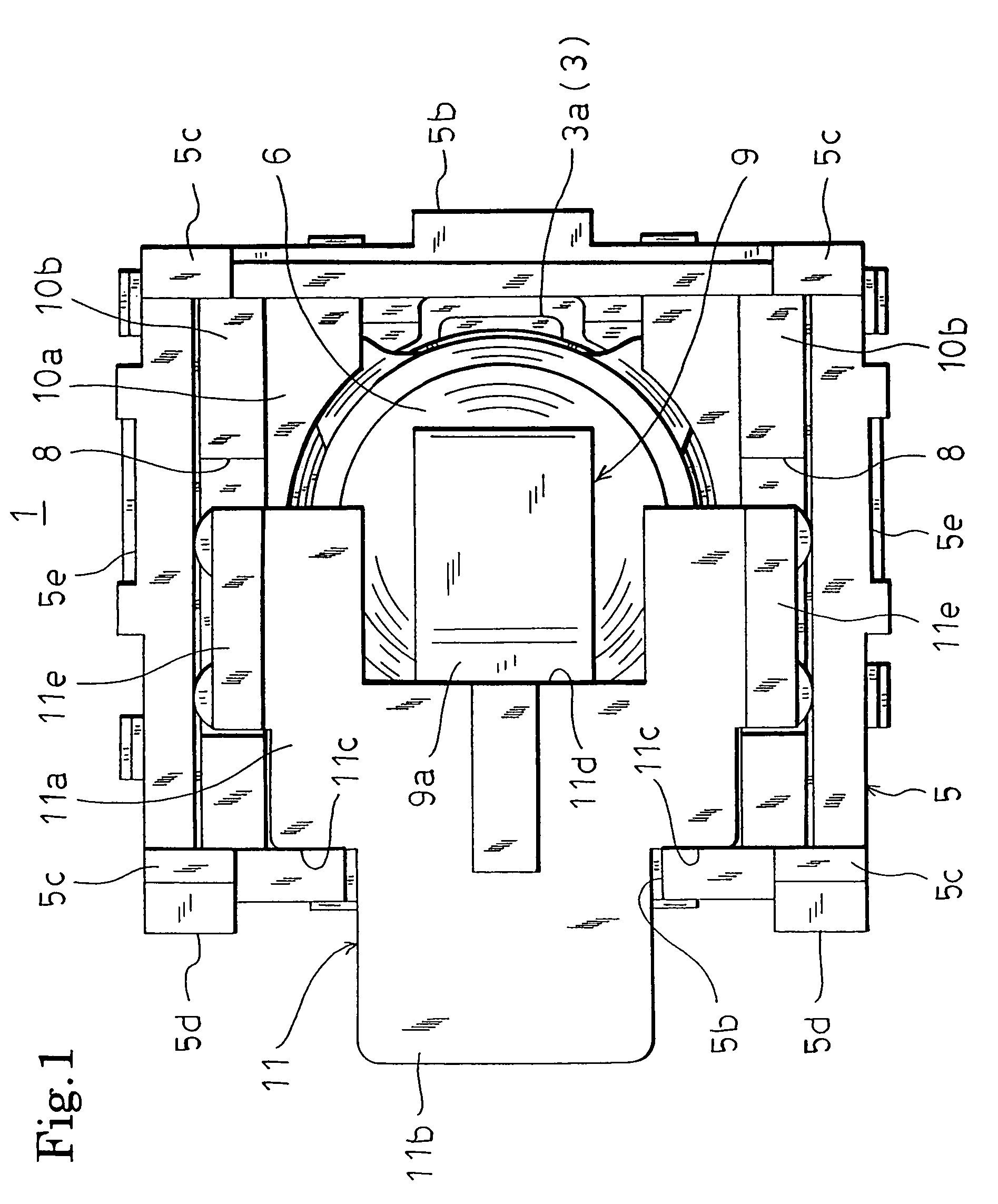

Lateral pushing type push switch

InactiveUS7449654B2Easy to operateImprove contact reliabilityContact driving mechanismsSnap-action arrangementsEngineeringPush switch

Owner:HOSIDEN CORP

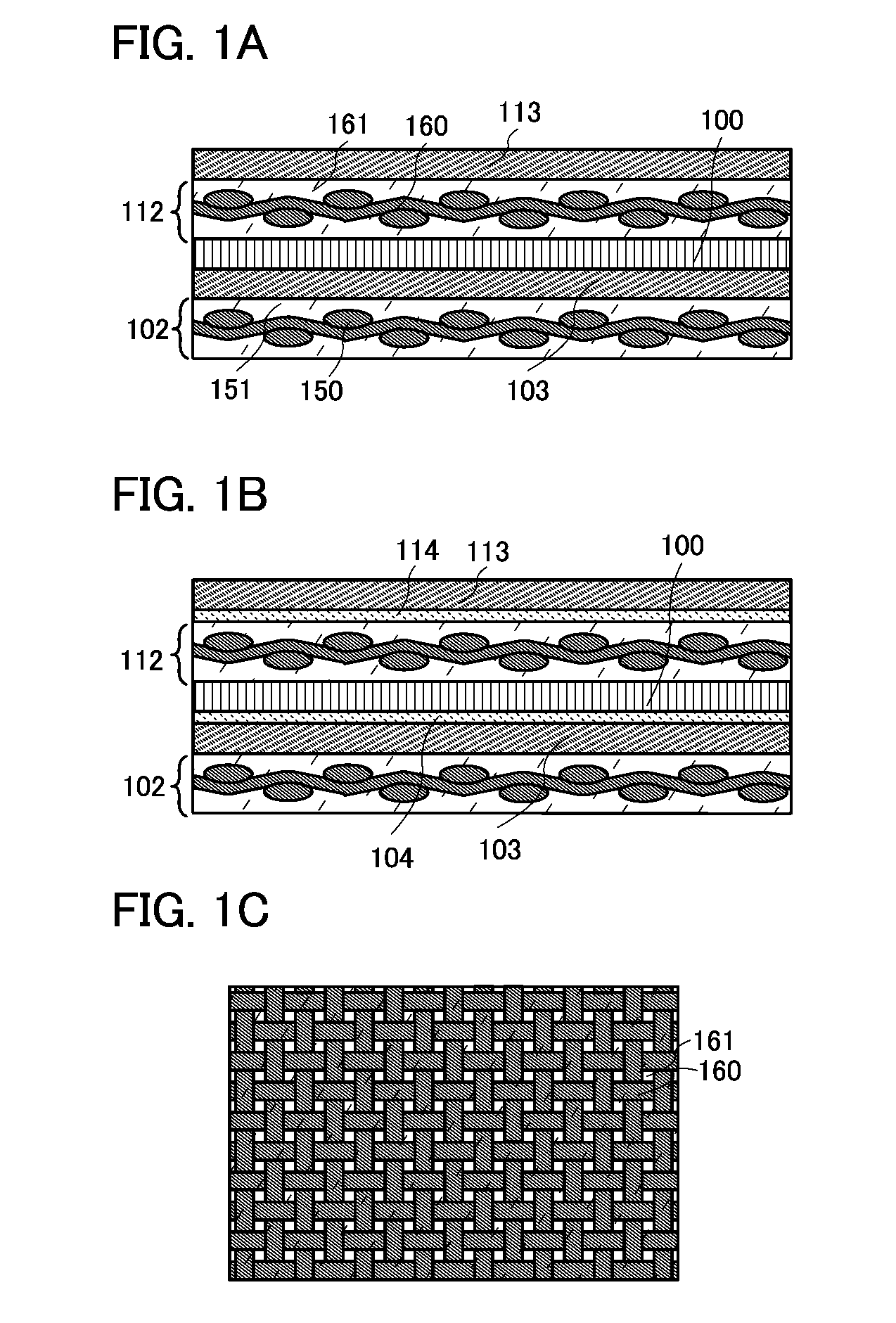

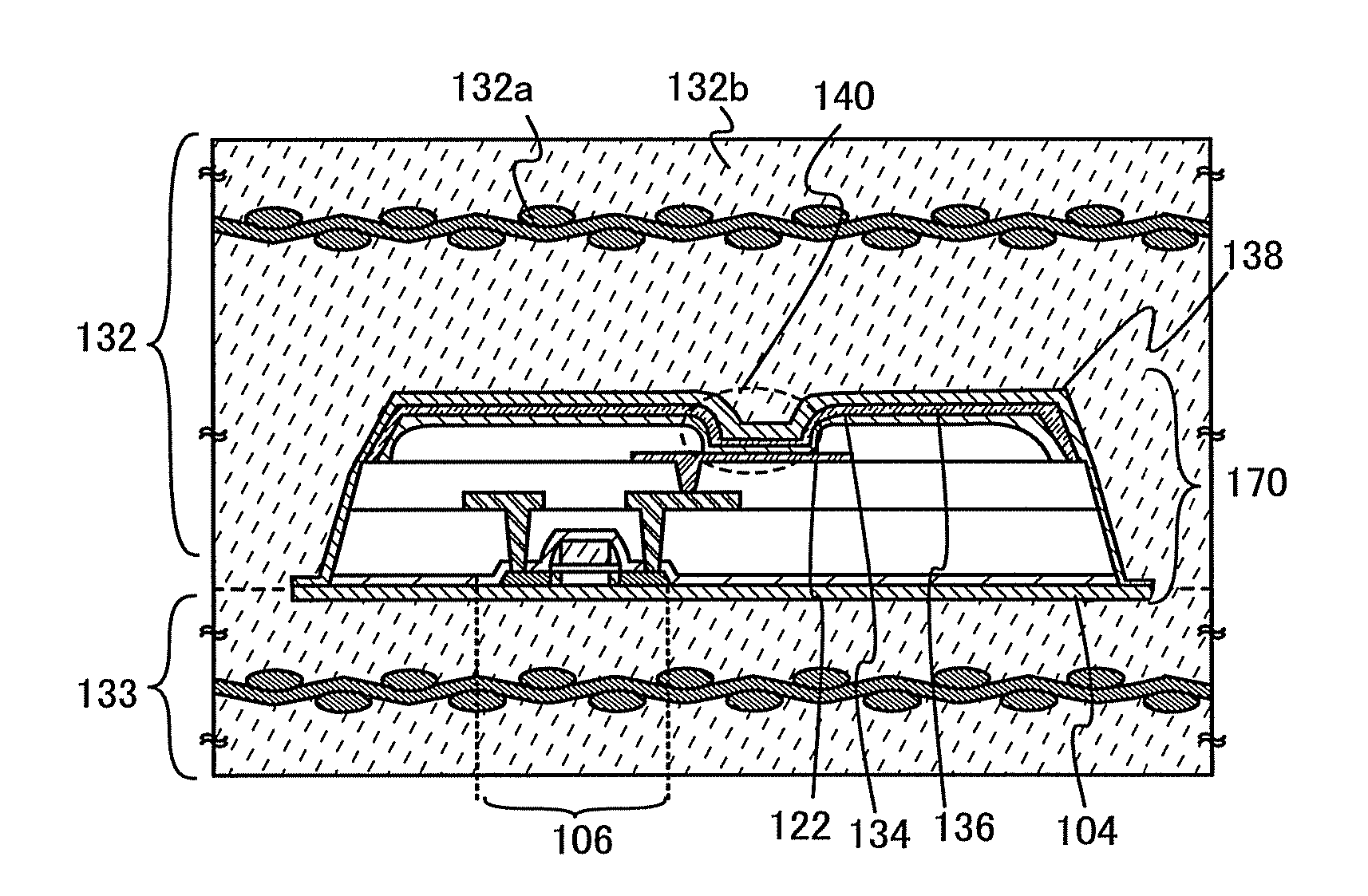

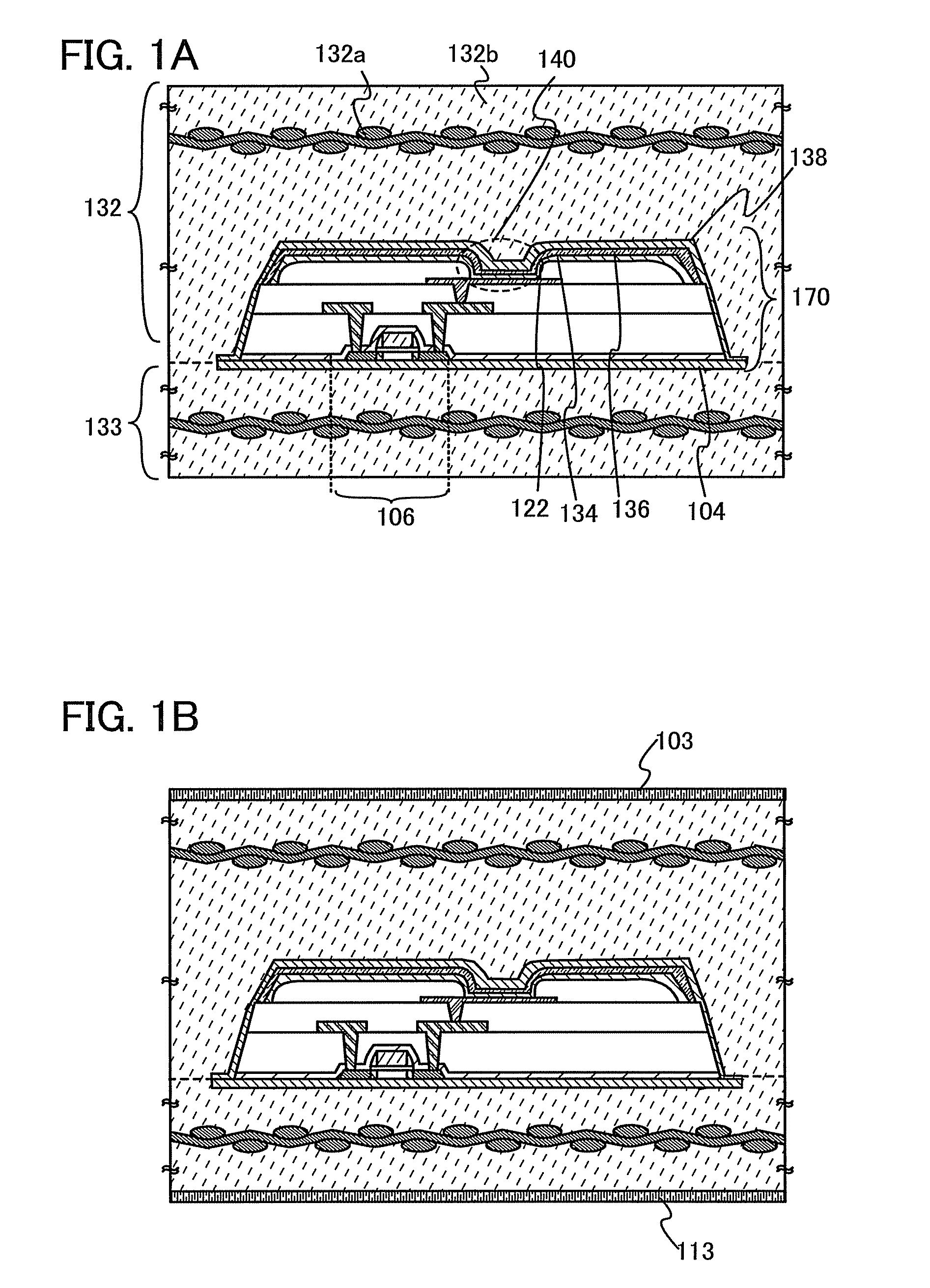

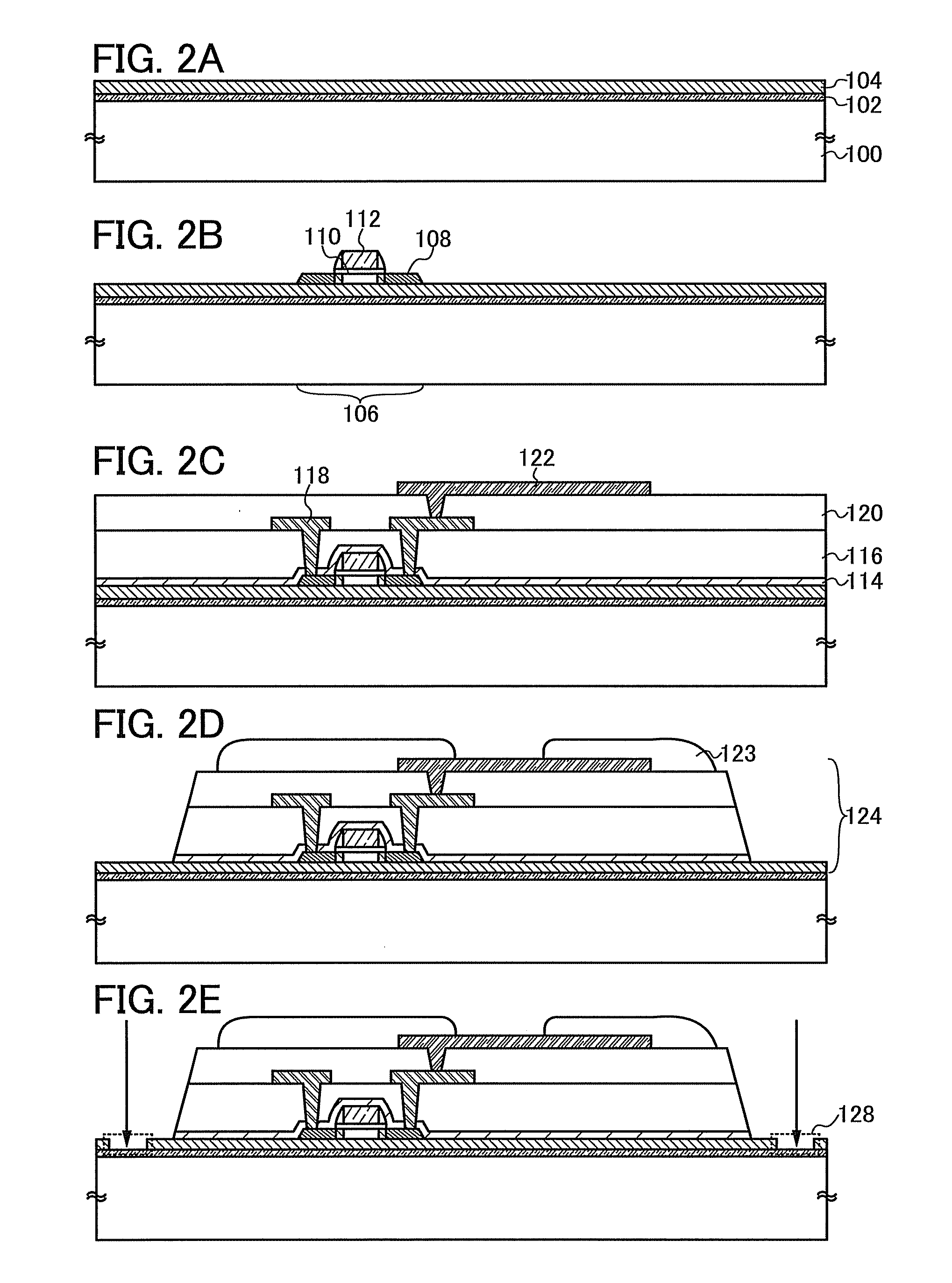

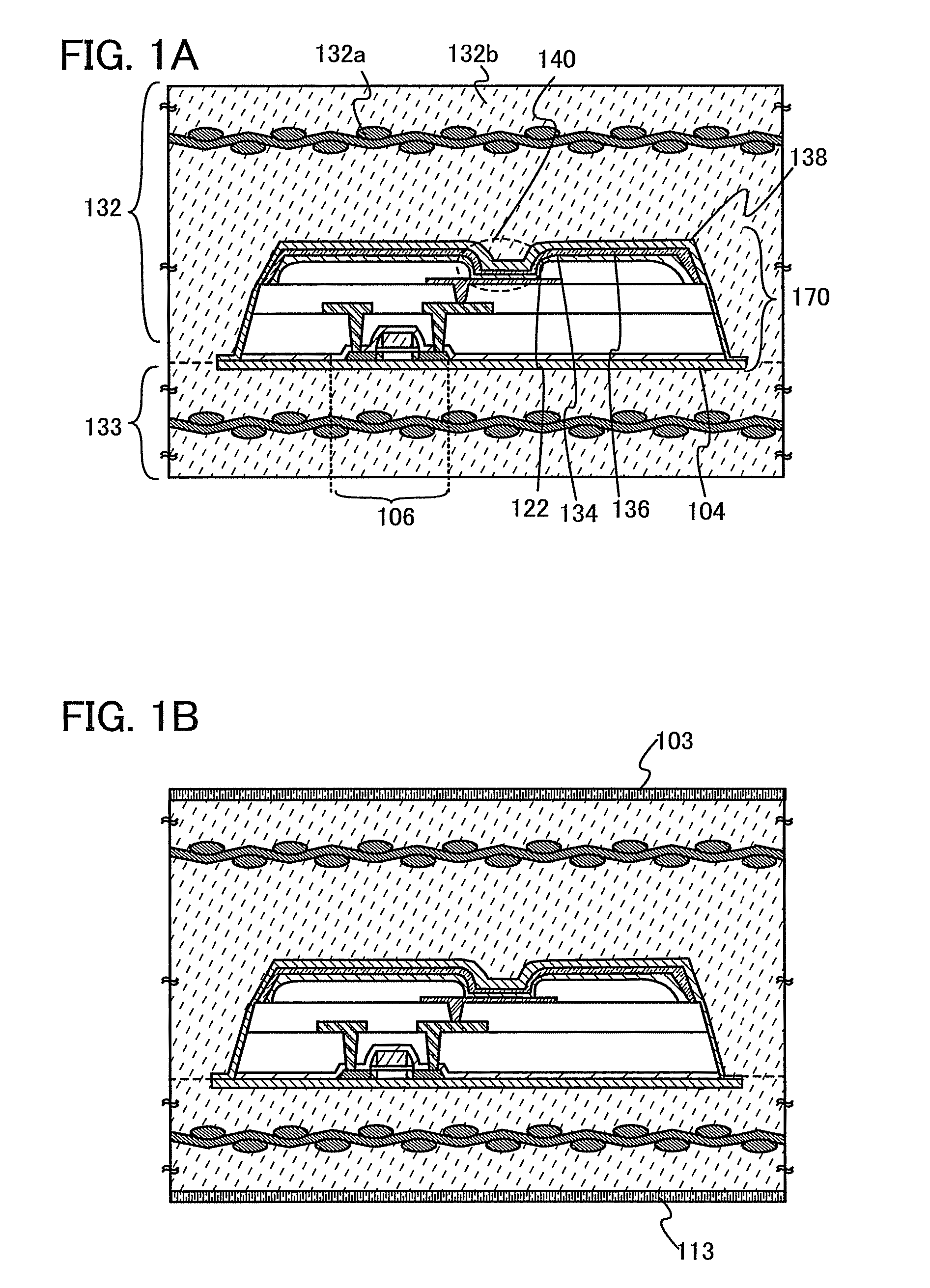

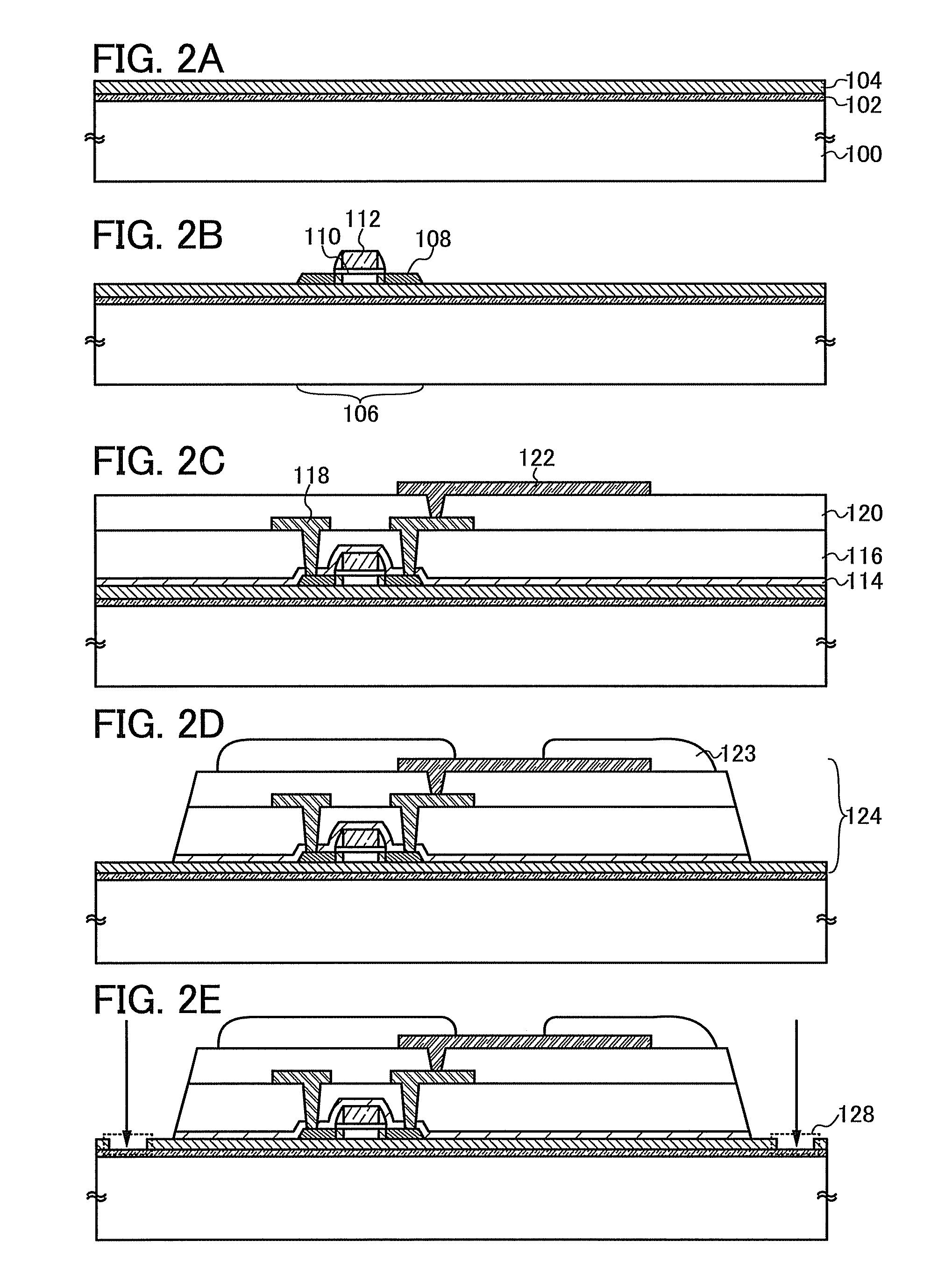

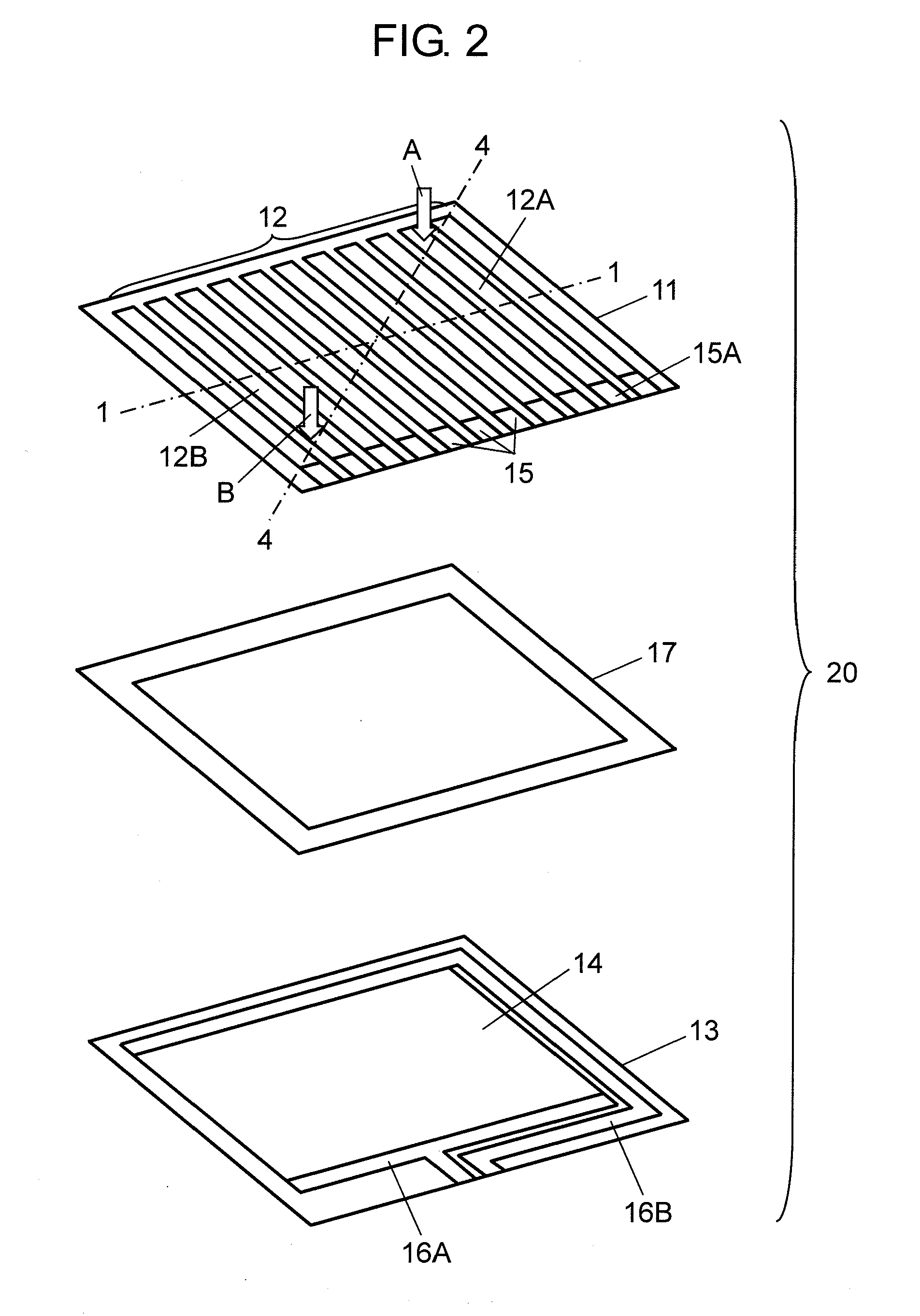

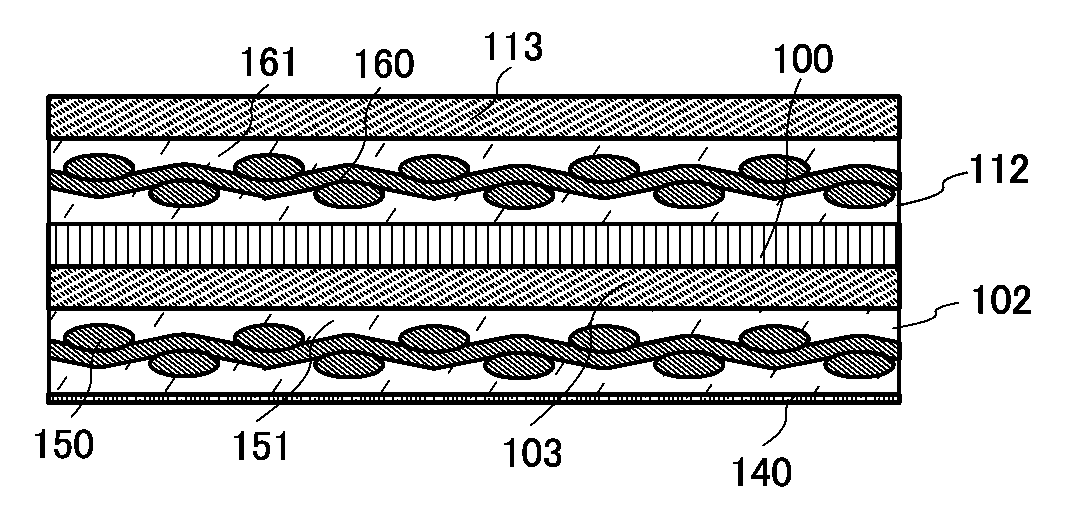

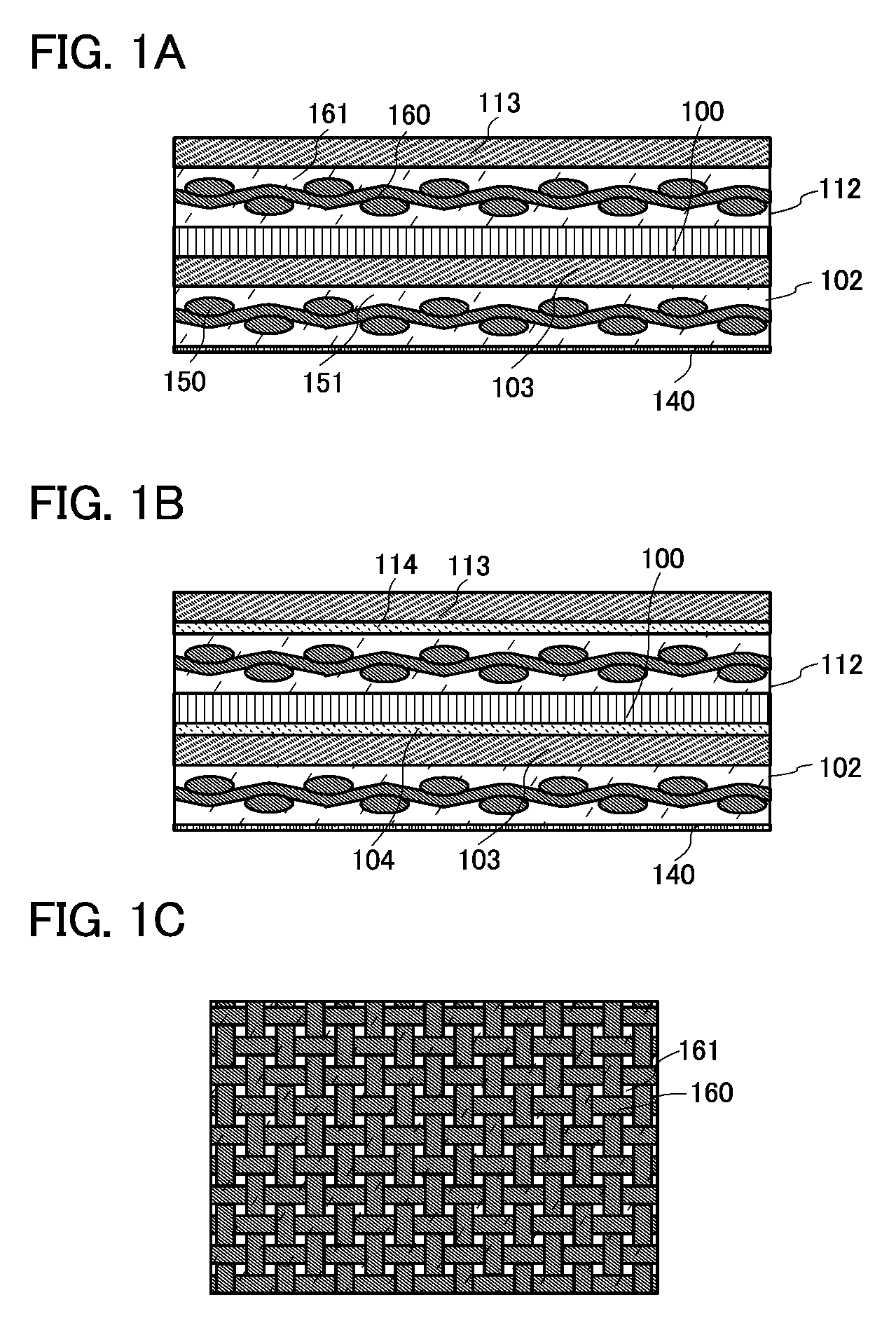

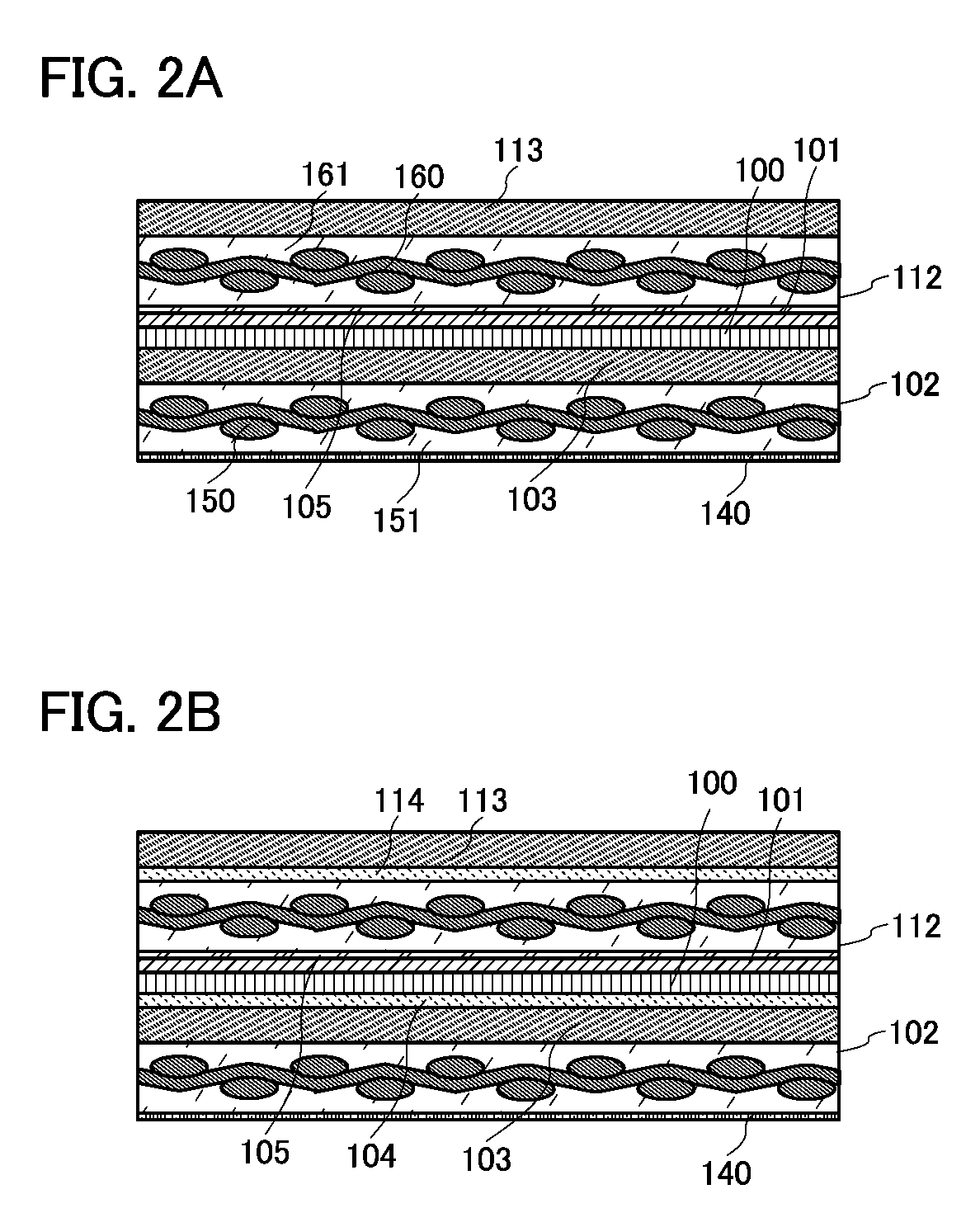

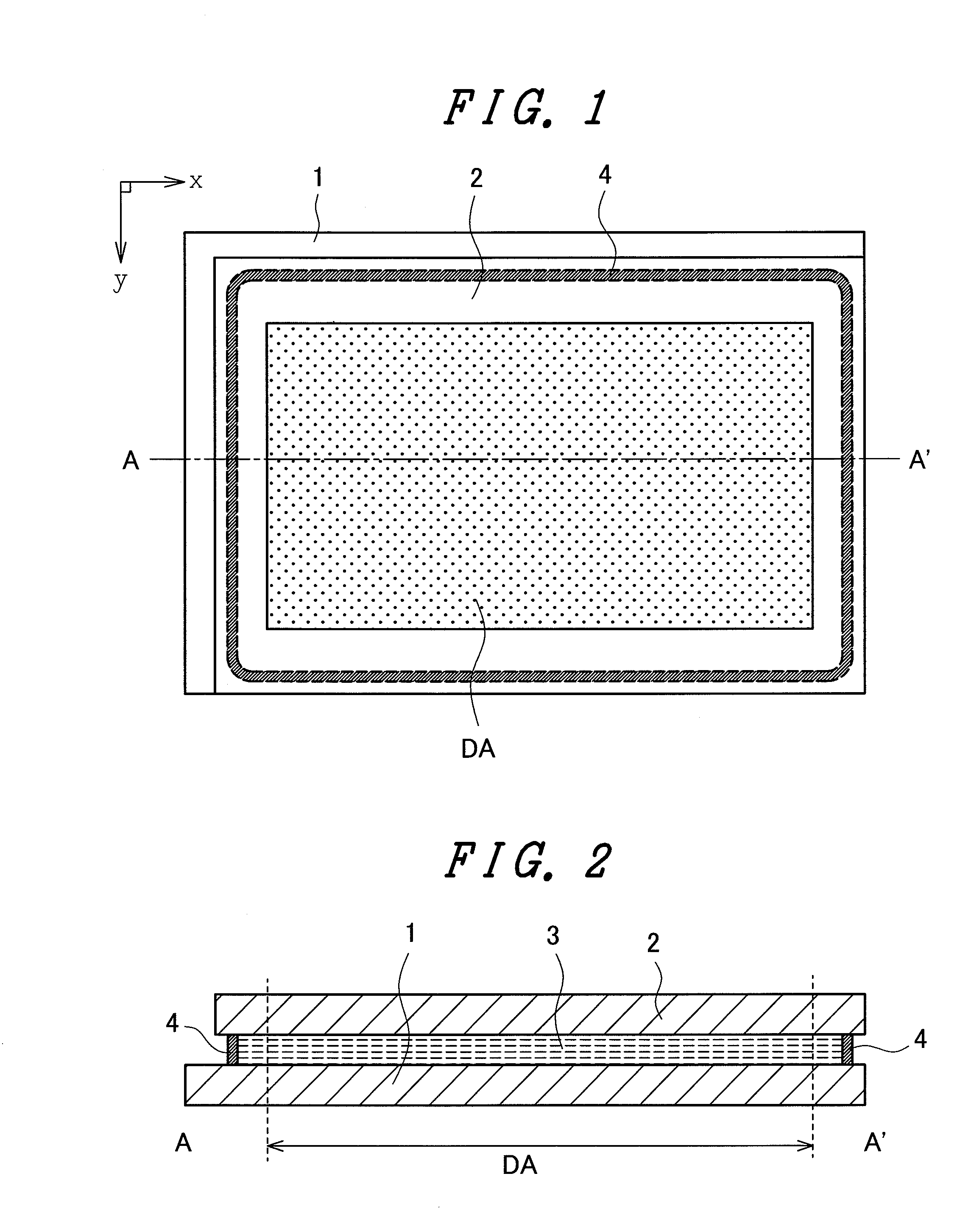

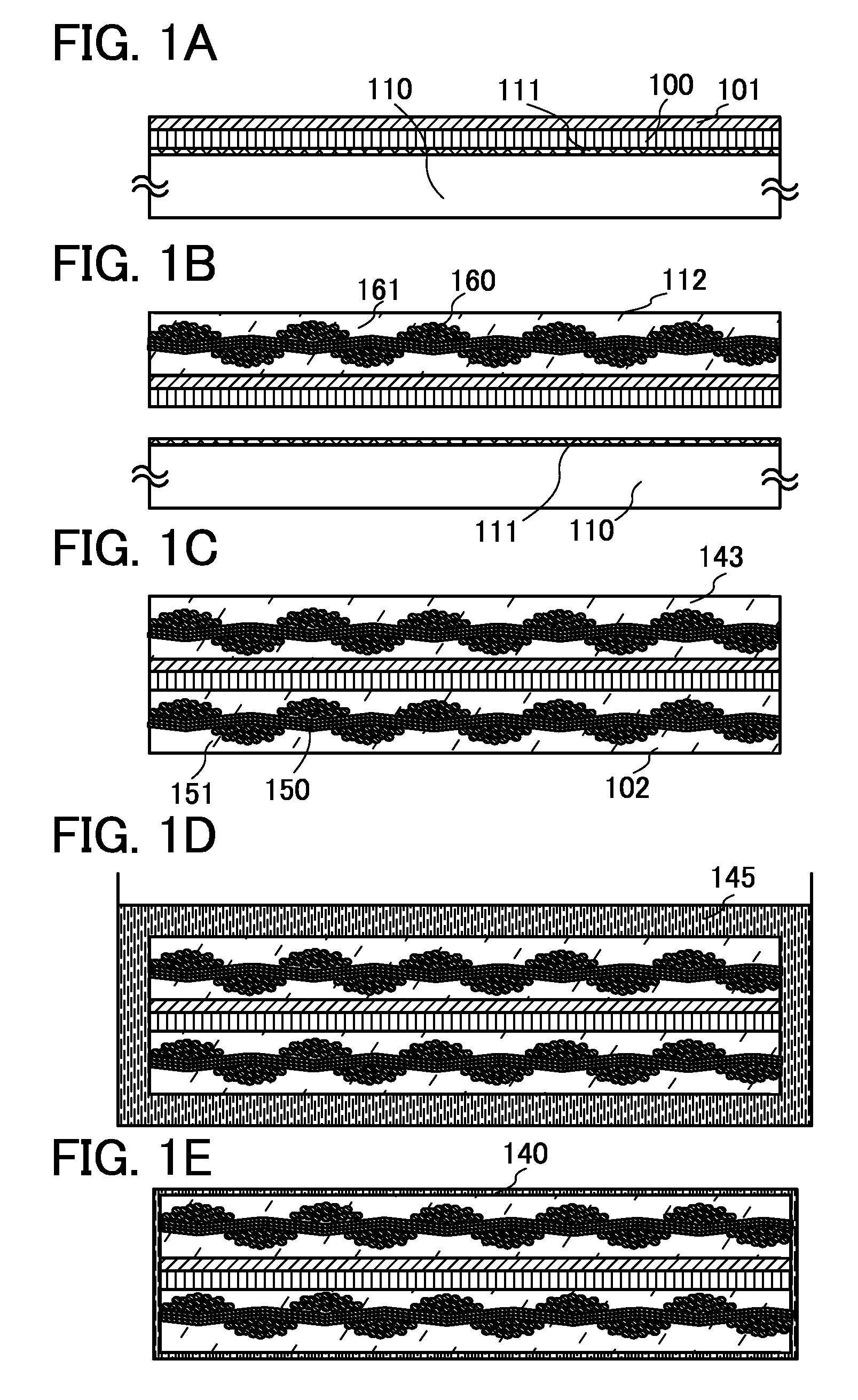

Light Emitting Device and Electronic Device

InactiveUS20100013372A1Improve reliabilityCharacteristic preventedDischarge tube luminescnet screensElectroluminescent light sourcesFibrous bodyLocal pressure

An object is to provide a highly reliable light emitting device which is thin and is not damaged by external local pressure. Further, another object is to manufacture a light emitting device with a high yield by preventing defects of a shape and characteristics due to external stress in a manufacture process. A light emitting element is sealed between a first structure body in which a fibrous body is impregnated with an organic resin and a second structure body in which a fibrous body is impregnated with an organic resin, whereby a highly reliable light emitting device which is thin and has intensity can be provided. Further, a light emitting device can be manufactured with a high yield by preventing defects of a shape and characteristics in a manufacture process.

Owner:SEMICON ENERGY LAB CO LTD

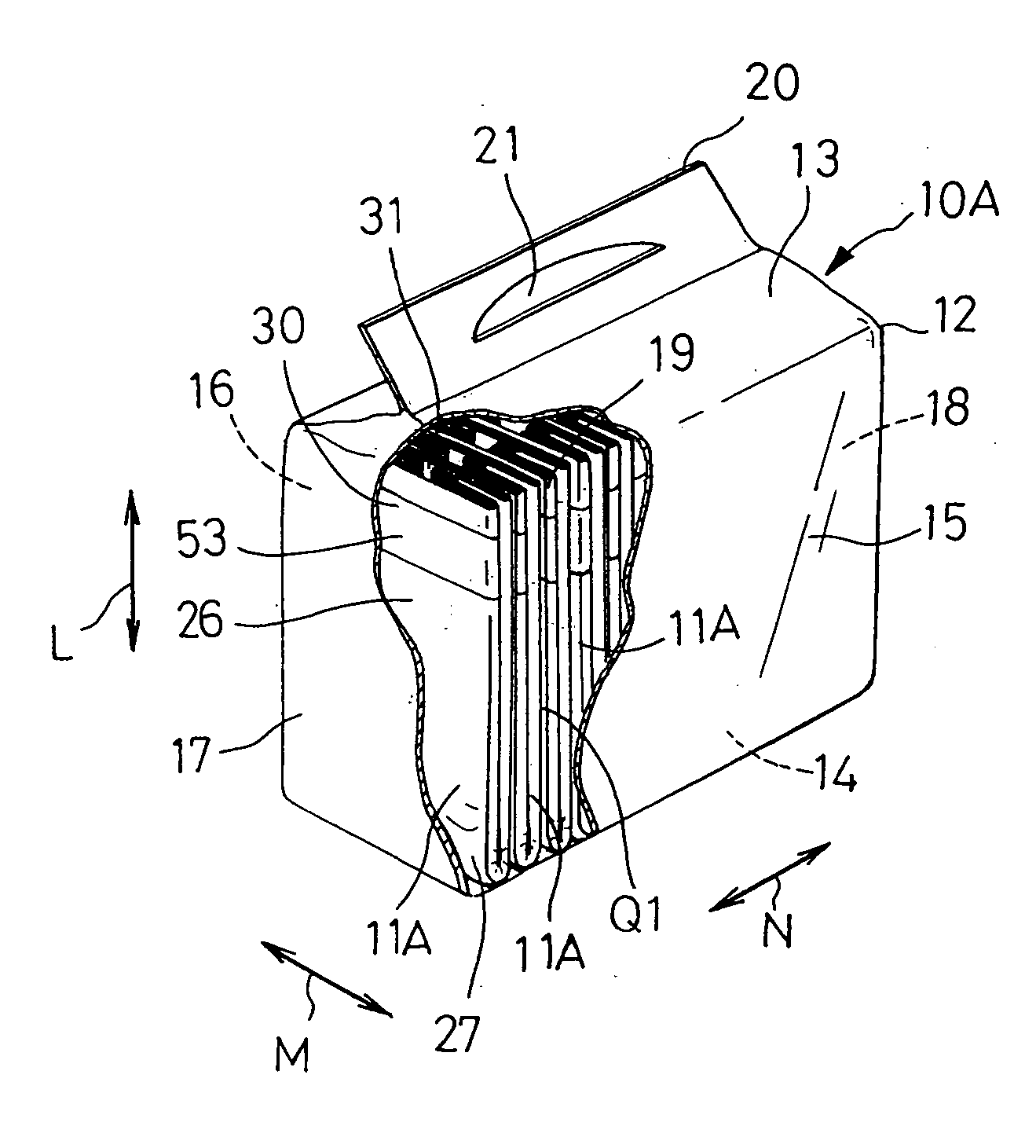

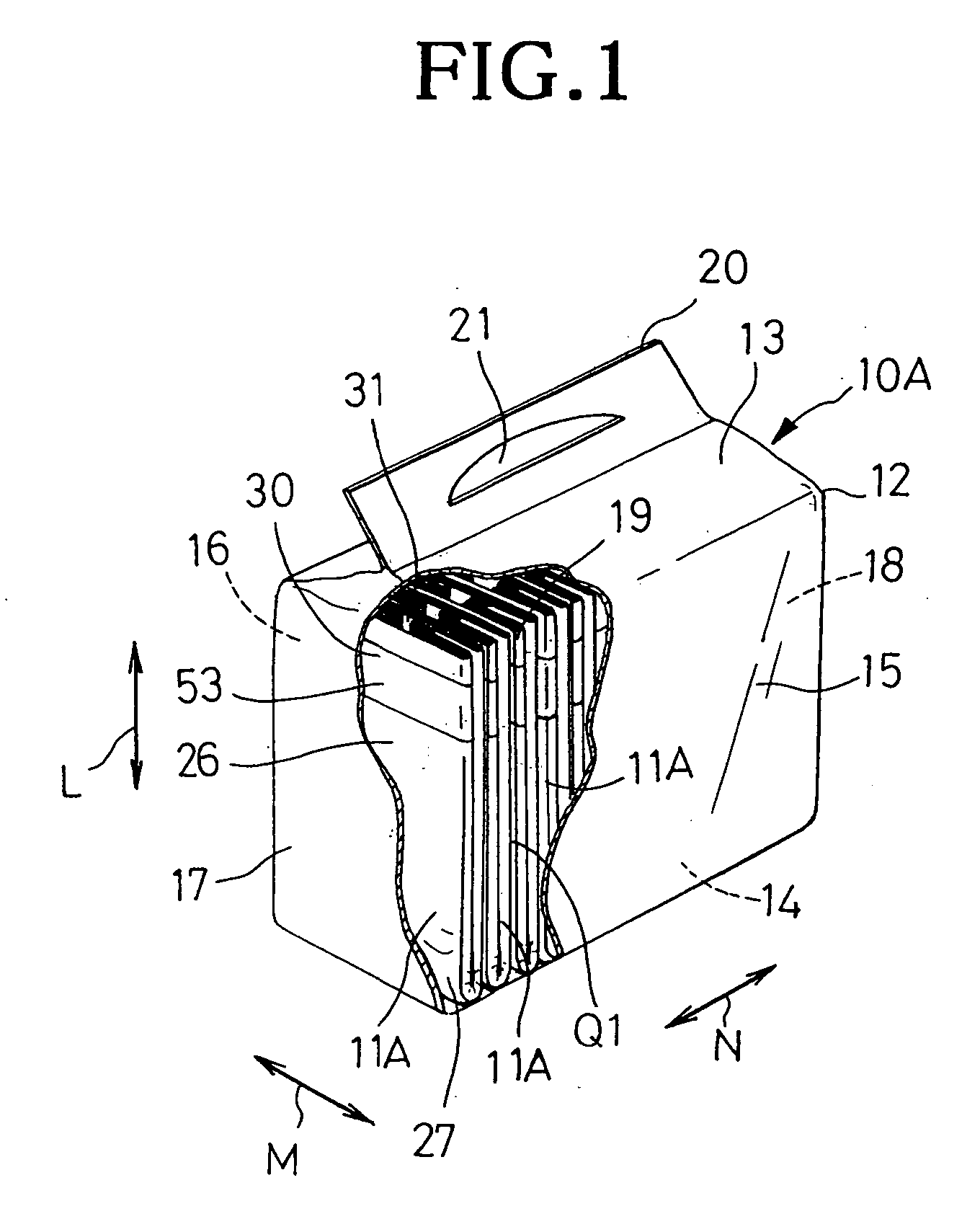

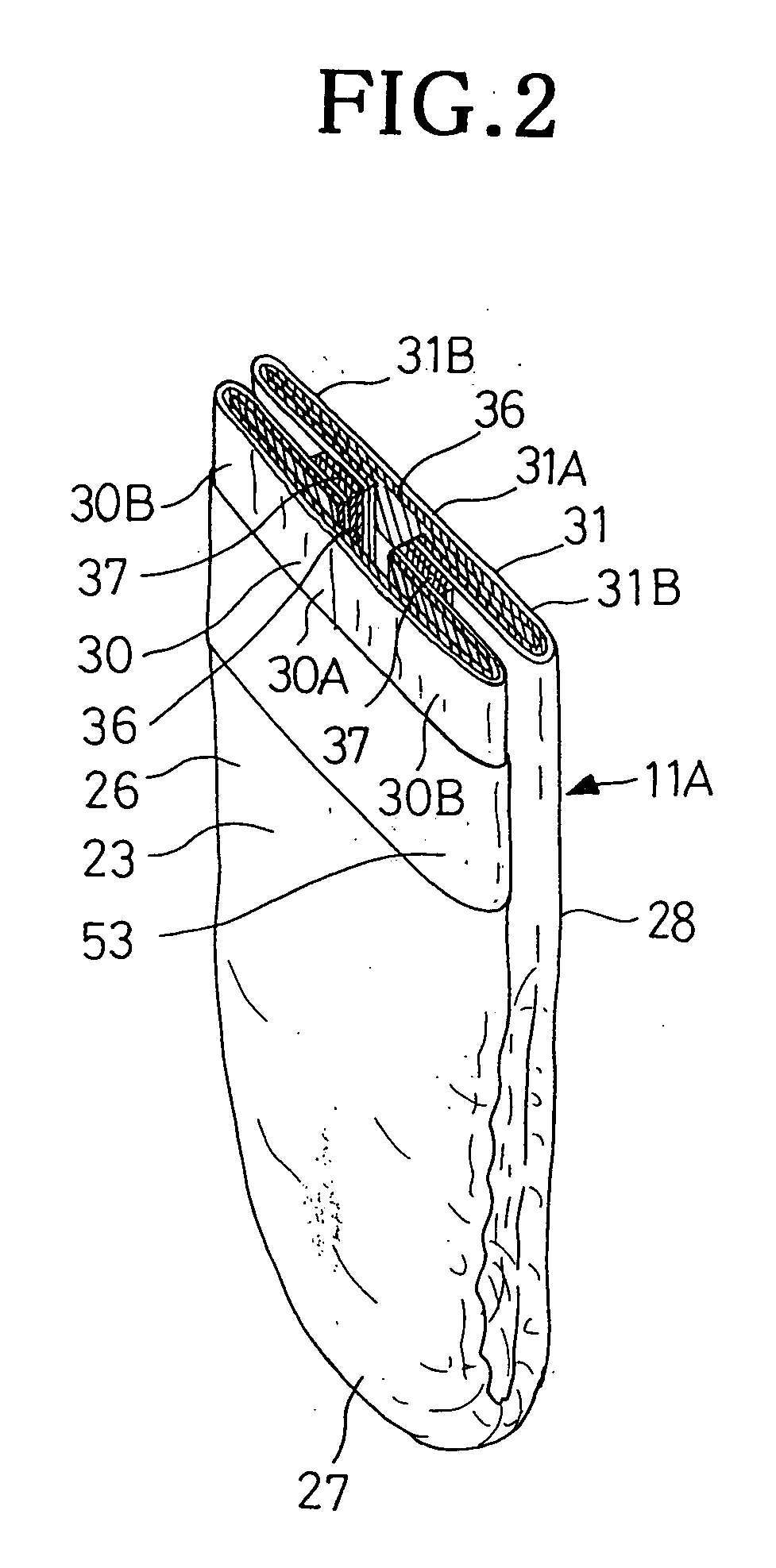

Diaper-containing package

InactiveUS20050222550A1Maintain folded shapeFree shapeDiagnosticsSurgical needlesCrotchFront and back ends

The diaper-containing package comprises a plurality of a diaper which are folded transversely inward at the opposite side portions and is folded longitudinally at the crotch region, and a bag for packaging the diapers therein. The bag forms top and bottom walls and front and back walls and opposite side walls each extending between the top and bottom walls. In the diaper, slip-resistant strips are attached to the front and back end edges and opposite side portions and these slip-resistant strips are in contact with and releasably engaged with each other. In the package, the plurality of diapers are arranged between the opposite side walls, while overlapping the waist regions each other and crotch regions each other; the front and back end edges of these diapers face to the top wall, and the crotch regions of these diapers face to the bottom wall.

Owner:UNI CHARM CORP

Aluminum target material for sputtering and method for producing same

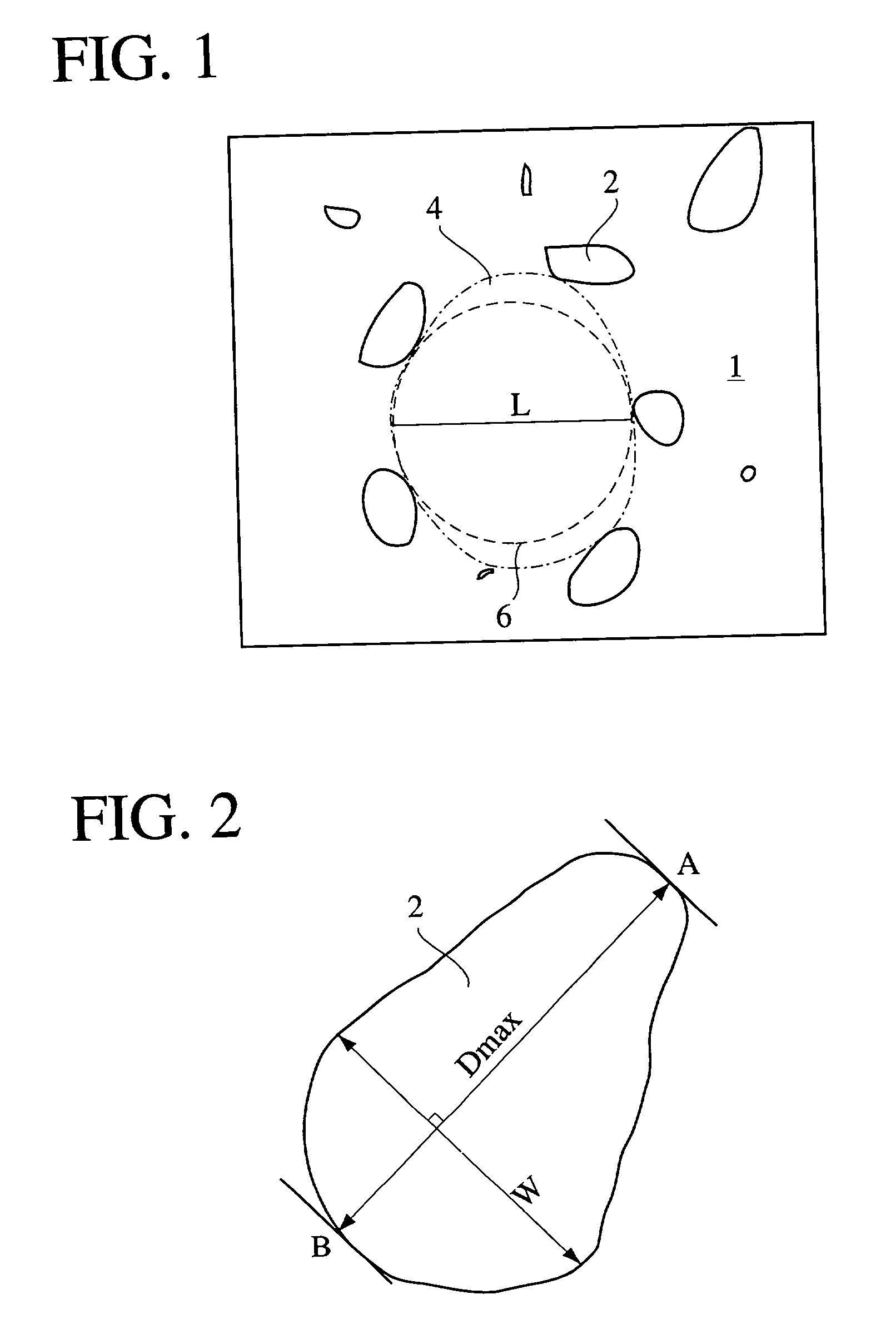

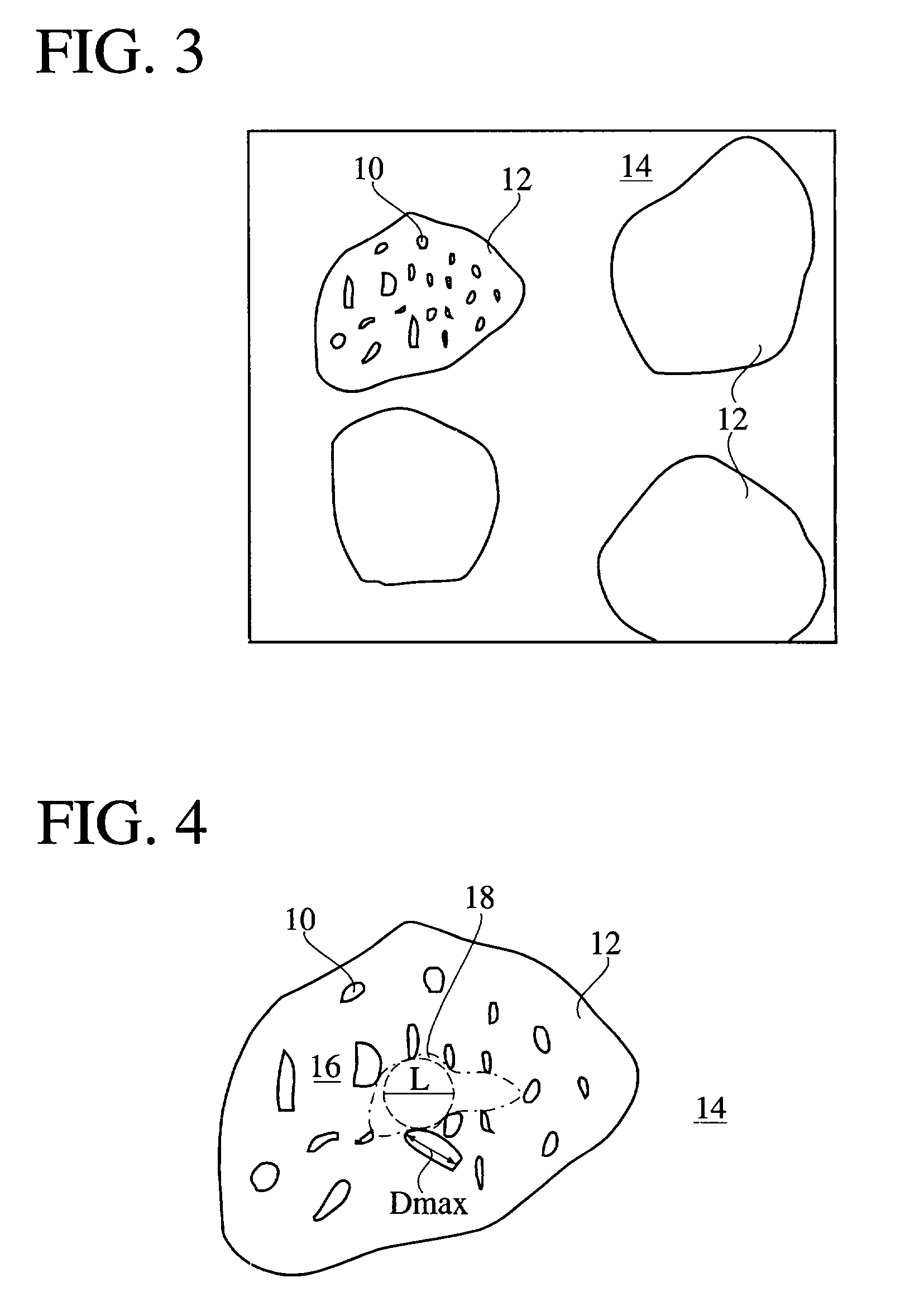

InactiveUS20020014406A1Low resistivityLittle splashingCellsVacuum evaporation coatingMaximum diameterAlloy

The first Al-based target material for sputtering contains 0.01-10 atomic % of at least one intermetallic compound-forming element, and an intermetallic compound having a maximum diameter of substantially 50 mum or less. The second Al-based target material for sputtering has a microstructure comprising an alloy phase containing 20 atomic % or less of the intermetallic compound-forming element and Al and an Al matrix phase comprising substantially pure Al, the maximum diameter of the intermetallic compound in the alloy phase being substantially 50 mum or less. The content of the intermetallic compound forming element based on the whole structure is 0.01-10 atomic %. These target materials are produced by pressure-sintering a rapid solidification powder at 400-600° C. After the pressure sintering, the target material is preferably hot-rolled at 400-600° C.

Owner:HITACHI METALS LTD

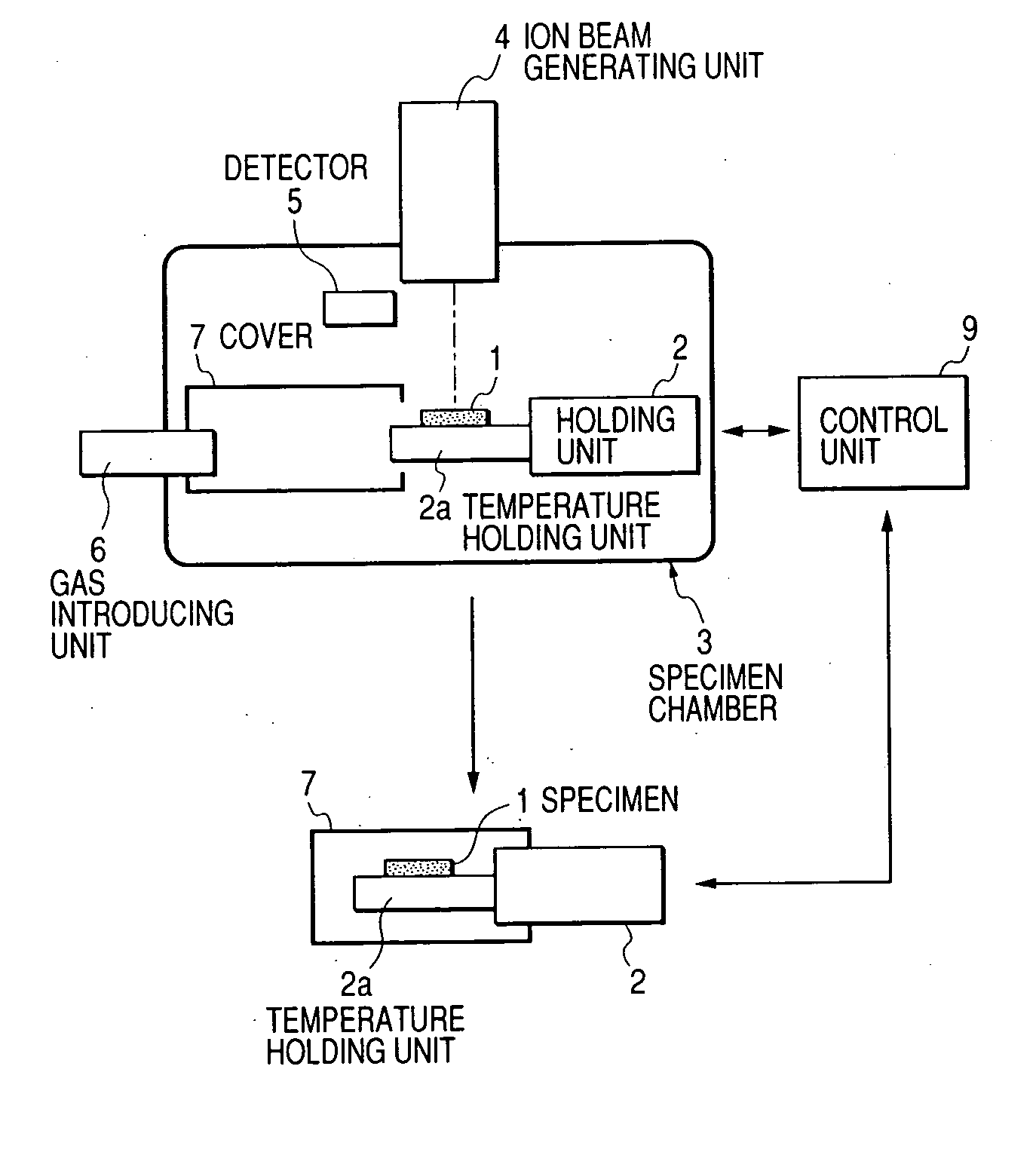

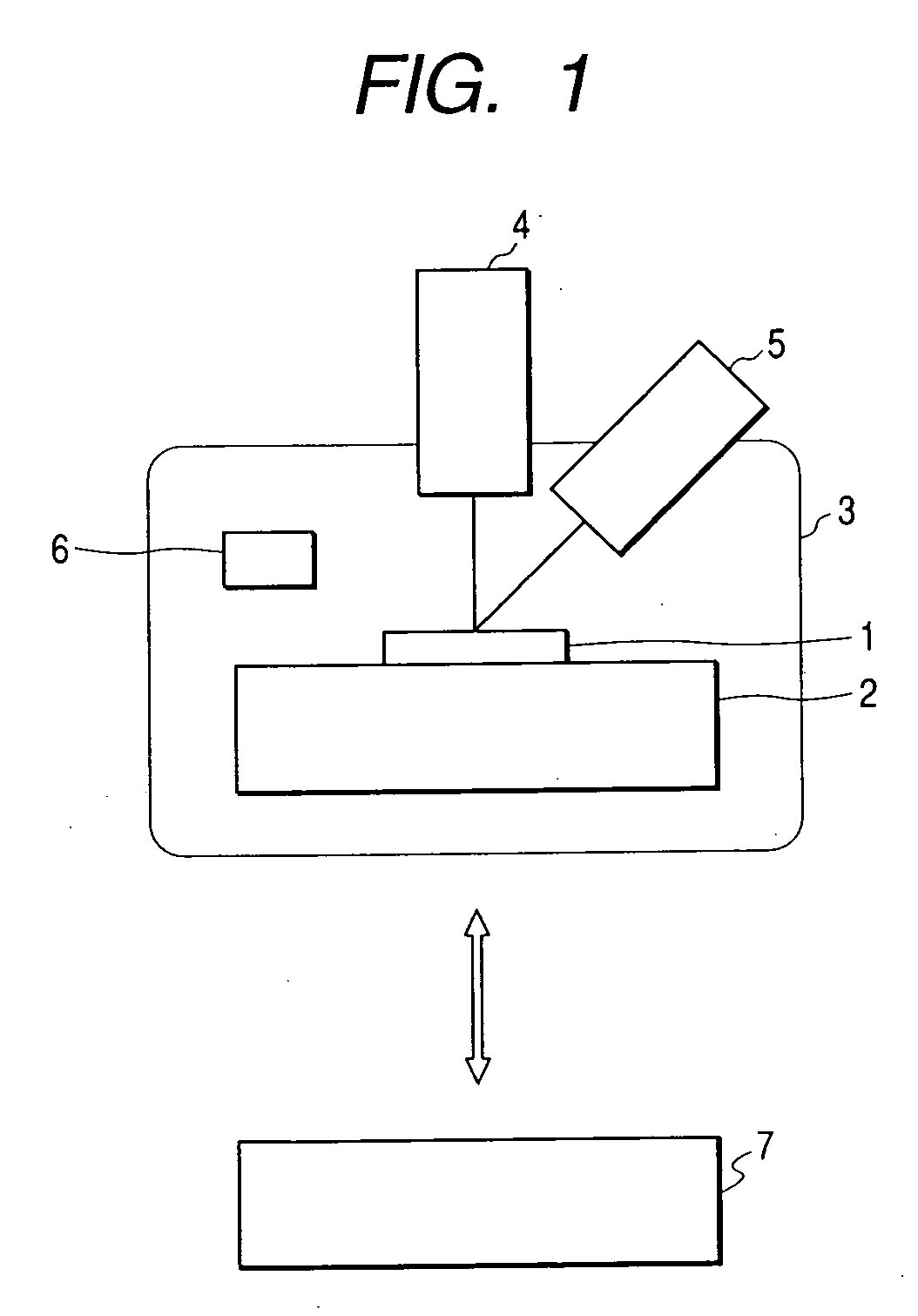

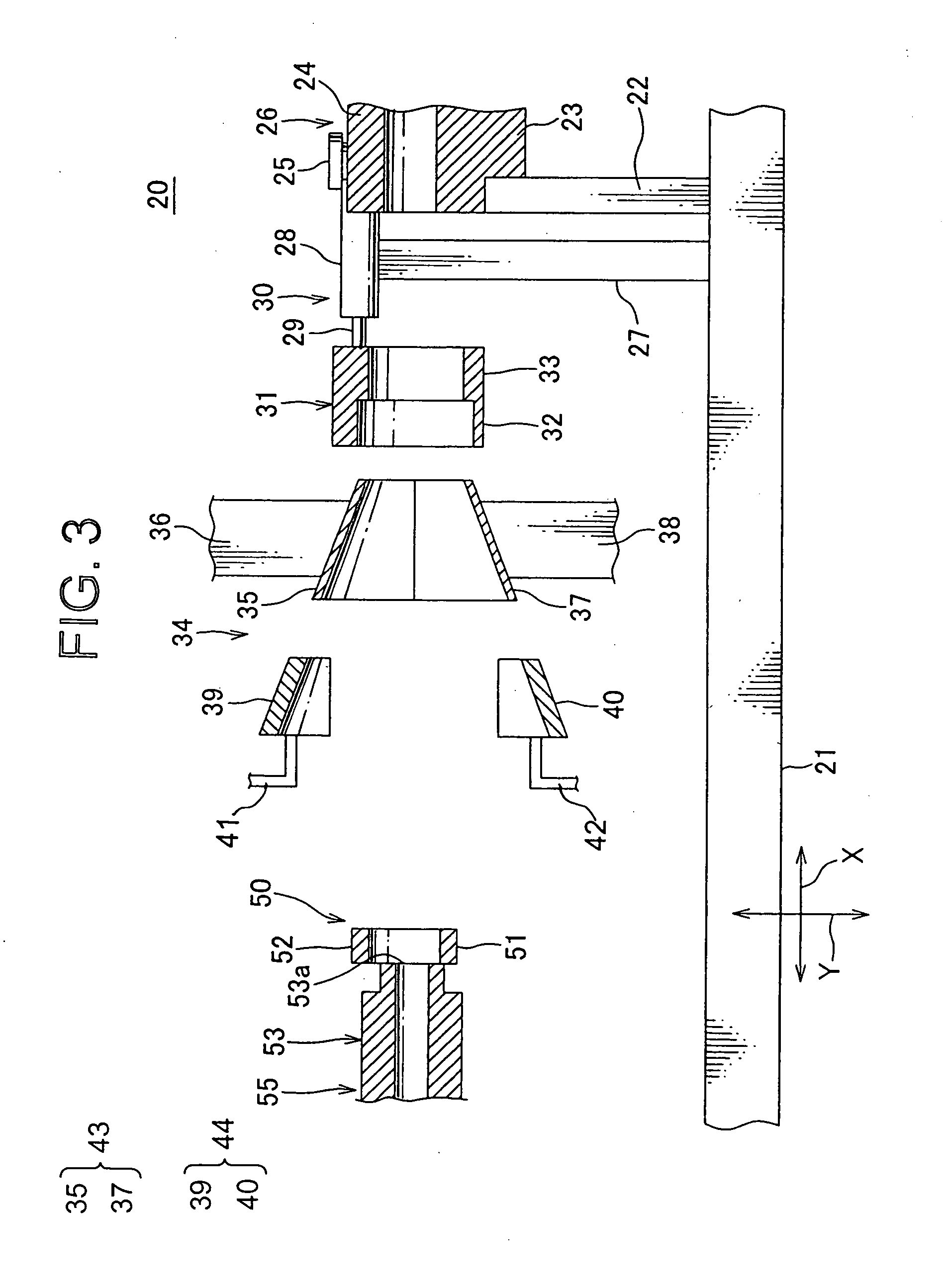

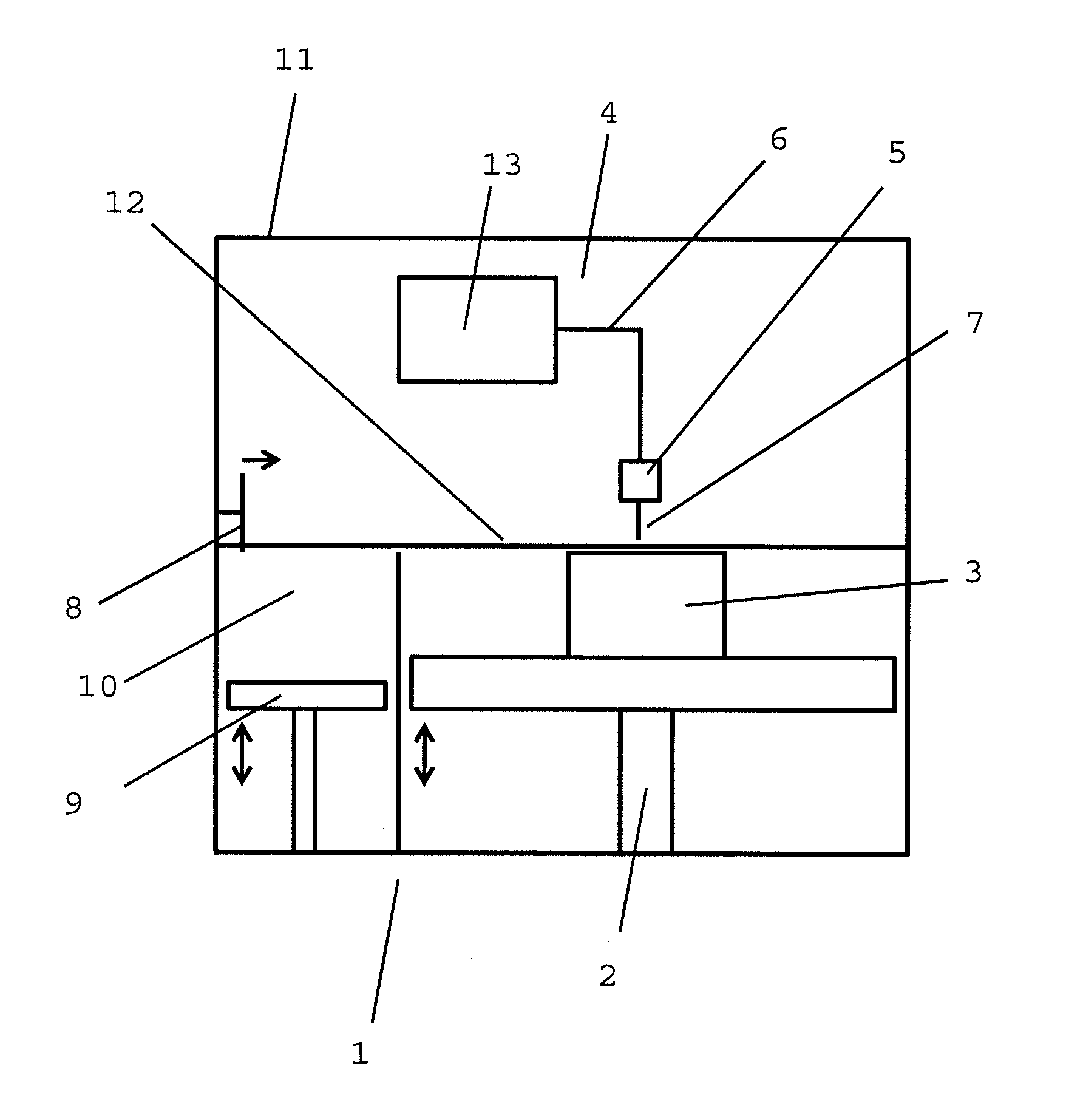

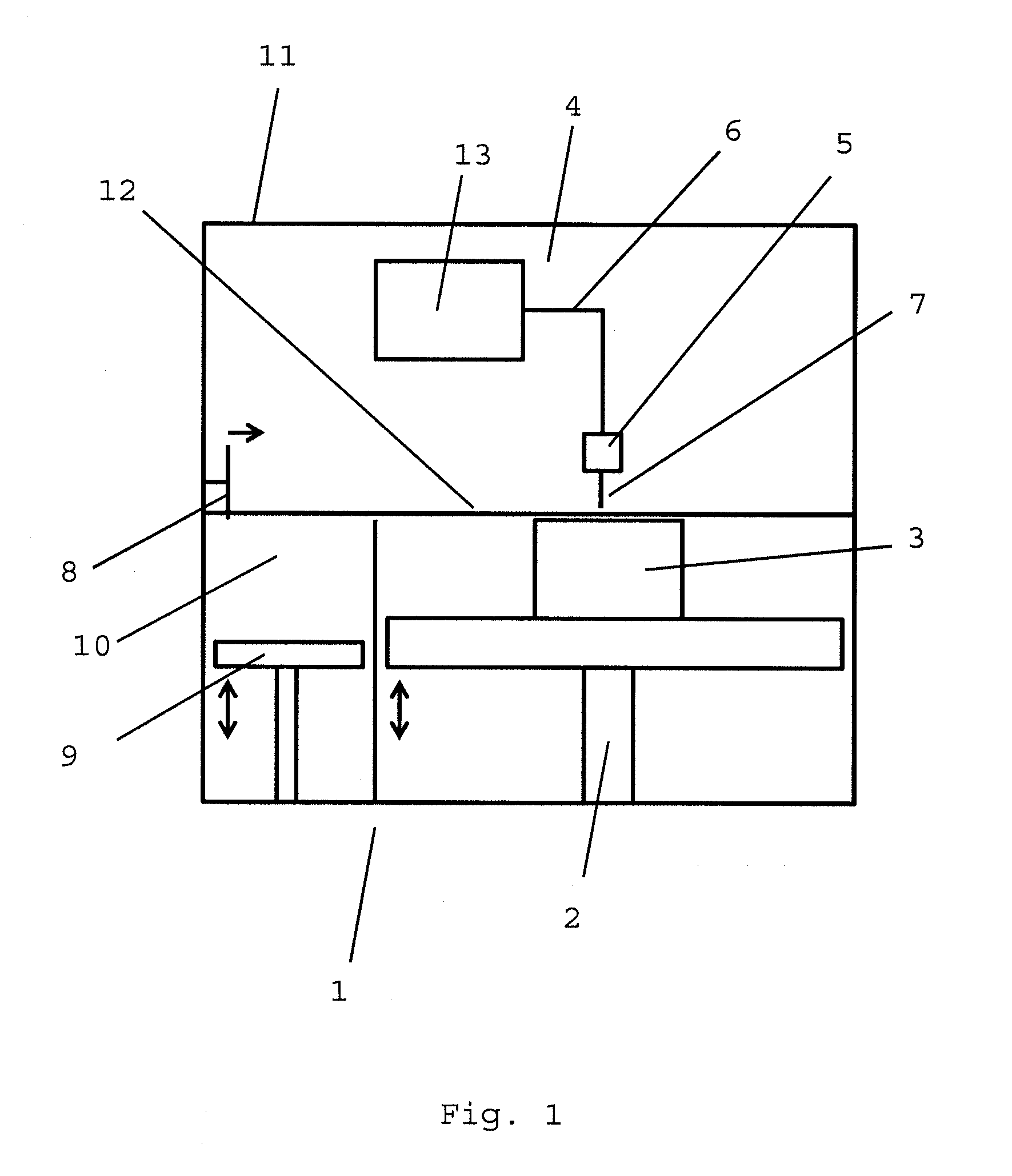

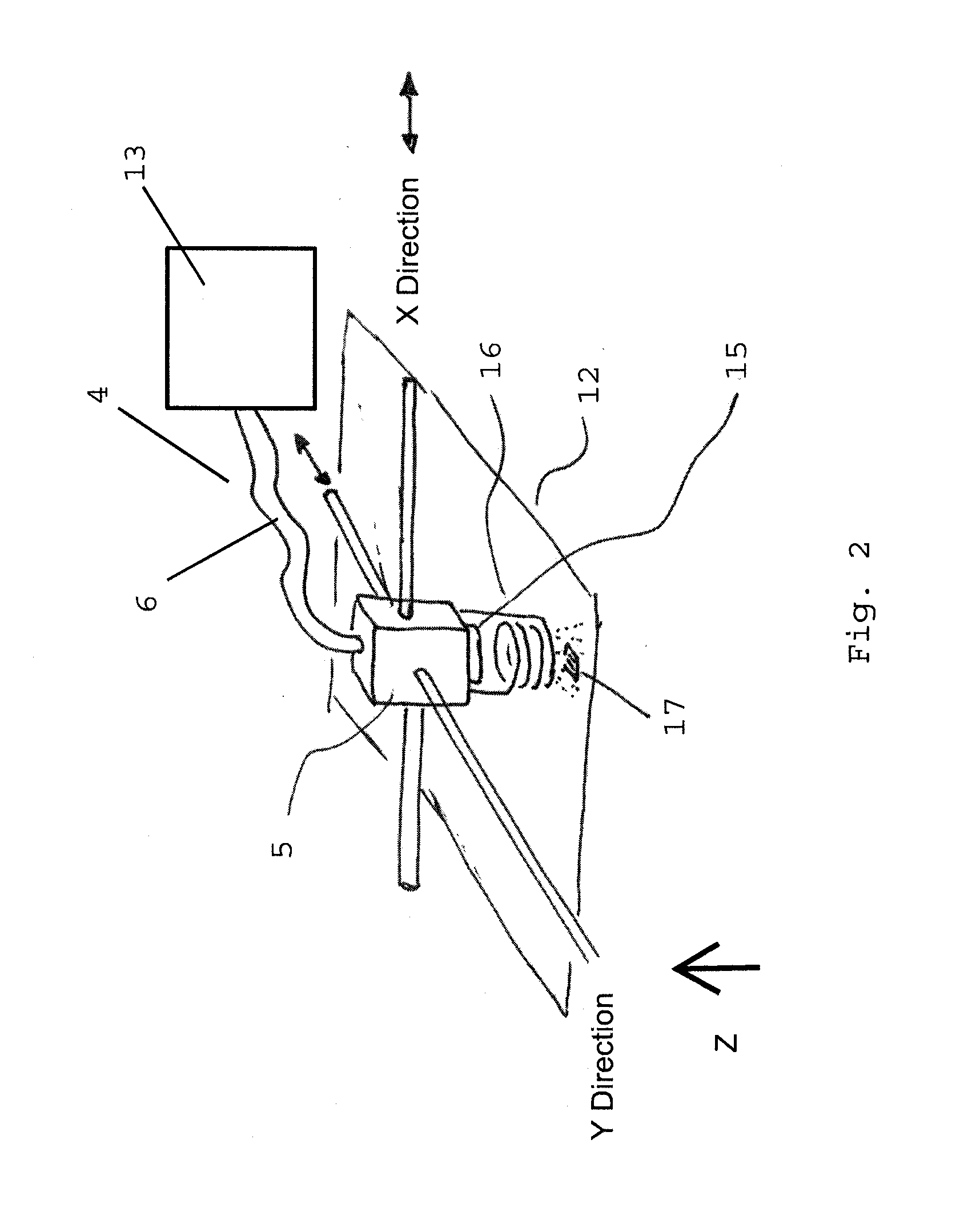

Information acquisition apparatus, cross section evaluating apparatus, cross section evaluating method, and cross section working apparatus

InactiveUS20060197017A1Avoid shapePrevented in stateElectric discharge tubesRadiation therapyBiomedical engineeringInformation acquisition

The invention provides a cross section evaluating apparatus capable of analyzing the cross sectional structure in a state where the temperature of the specimen is regulated. There is disclosed an information acquisition apparatus comprising a stage for placing the specimen, temperature regulation means for regulating the temperature of the specimen, exposure means for exposing a surface, of which information is desired, of the specimen, and information acquisition means for acquiring information relating to the surface exposed by the exposure means.

Owner:CANON KK

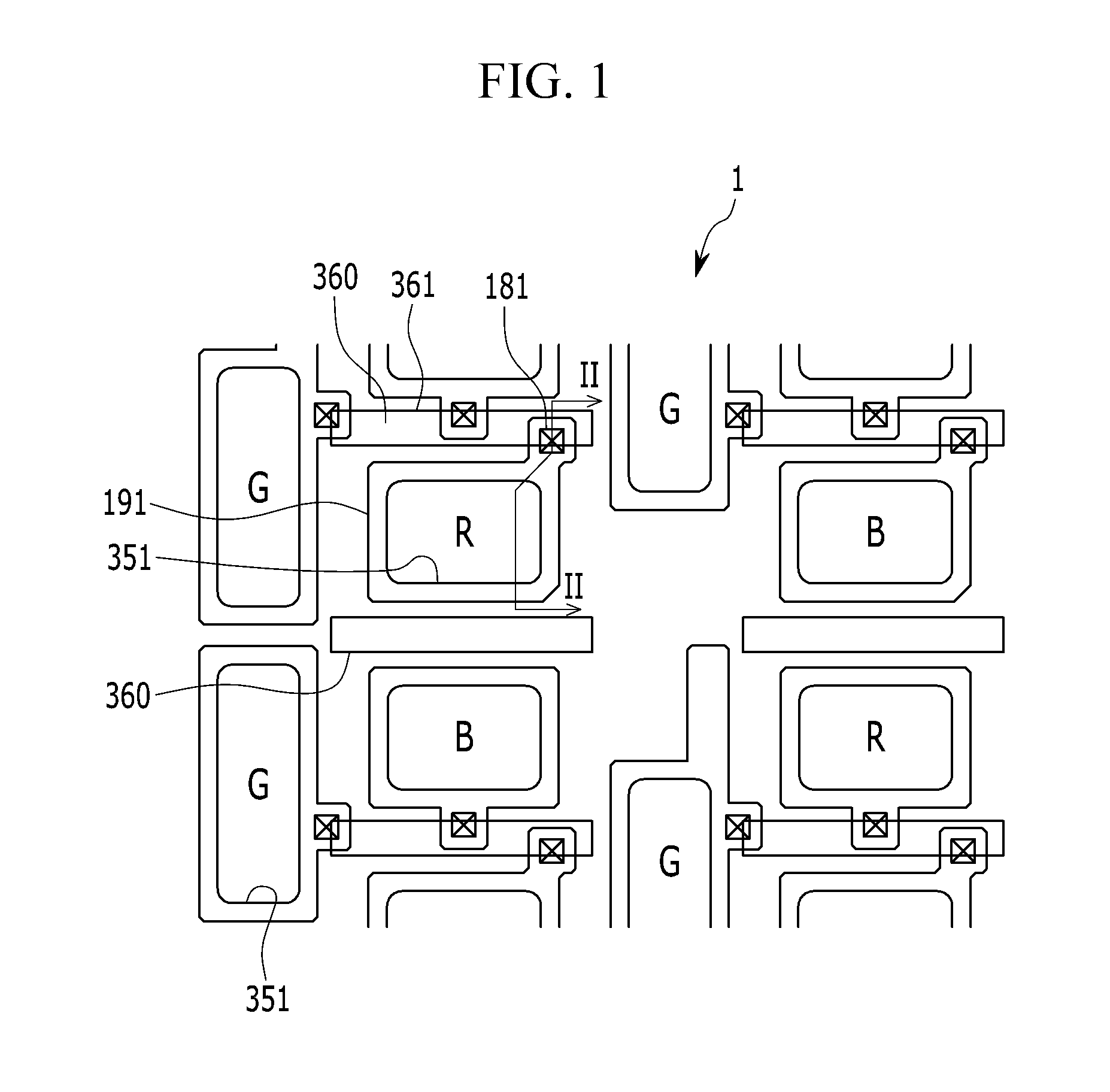

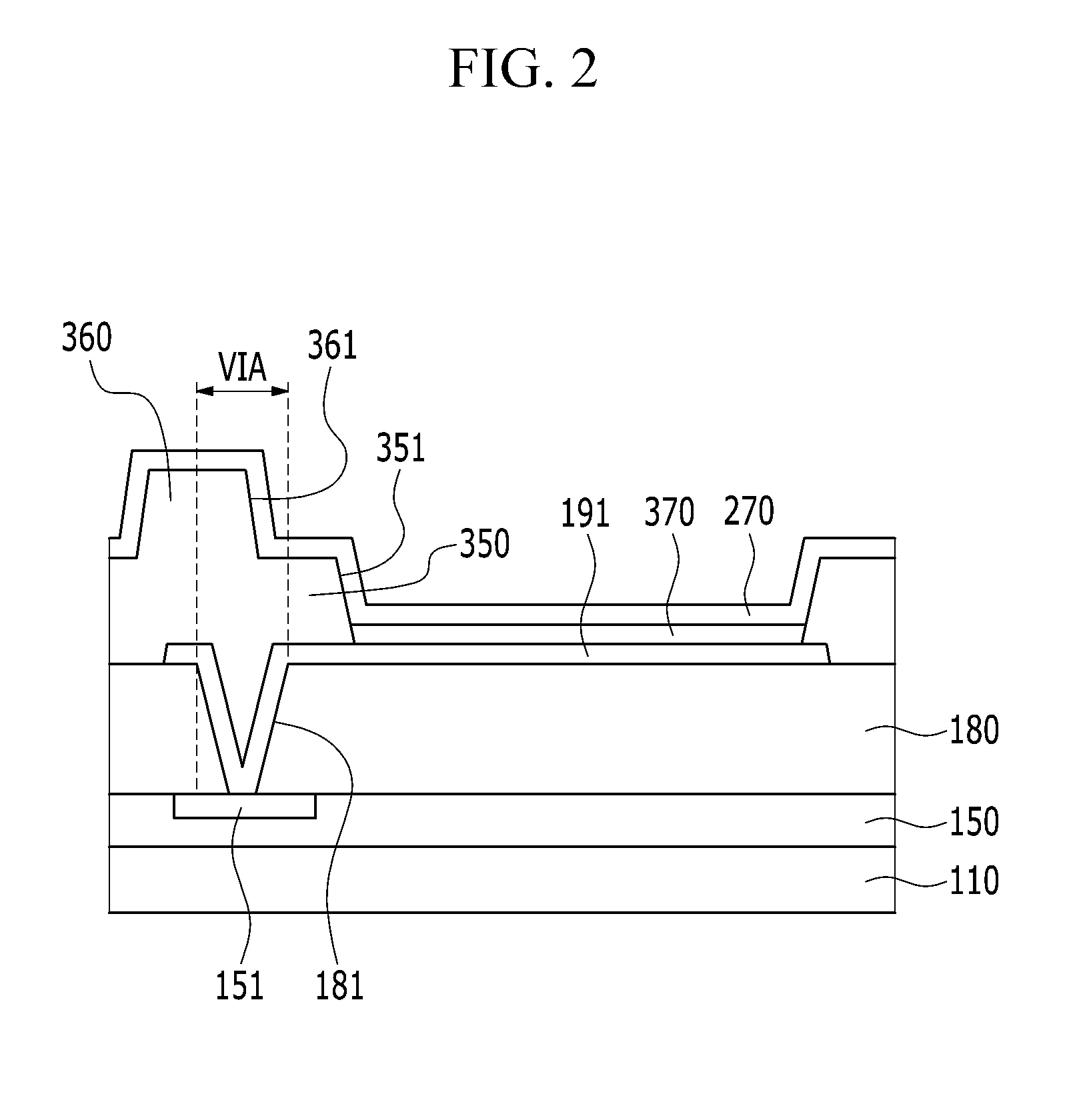

Display panel and display device

ActiveUS20150207094A1Prevent display defectsReduce reflectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSemiconductor components

A display panel and a display device, such as an organic light emitting panel that includes a spacer. The display panel and the display device include a semiconductor element including a first electrode; a passivation layer arranged on the semiconductor element and including a via hole exposing the first electrode; a second electrode arranged on the passivation layer and connected to the first electrode through the via hole; and a spacer arranged on the second electrode and adjacent to the via hole, wherein the spacer exposes at least a portion of a region where the via hole is formed.

Owner:SAMSUNG DISPLAY CO LTD

Light emitting device and electronic device utilizing fibrous barrier layers impregnated with organic resin

InactiveUS8264144B2High yieldPreventing in characteristicDischarge tube luminescnet screensElectroluminescent light sourcesFiberFibrous body

An object is to provide a highly reliable light emitting device which is thin and is not damaged by external local pressure. Further, another object is to manufacture a light emitting device with a high yield by preventing defects of a shape and characteristics due to external stress in a manufacture process. A light emitting element is sealed between a first structure body in which a fibrous body is impregnated with an organic resin and a second structure body in which a fibrous body is impregnated with an organic resin, whereby a highly reliable light emitting device which is thin and has intensity can be provided. Further, a light emitting device can be manufactured with a high yield by preventing defects of a shape and characteristics in a manufacture process.

Owner:SEMICON ENERGY LAB CO LTD

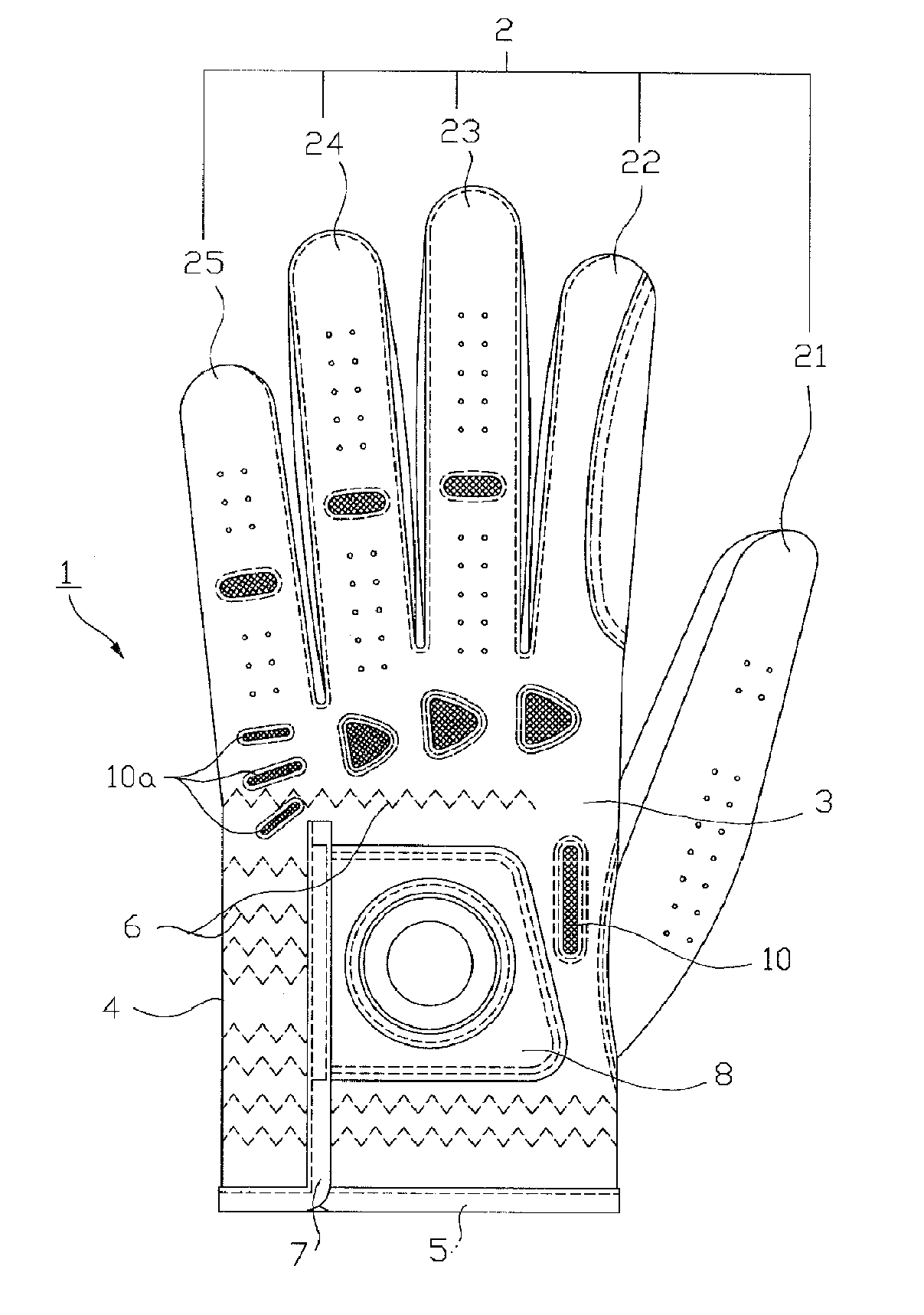

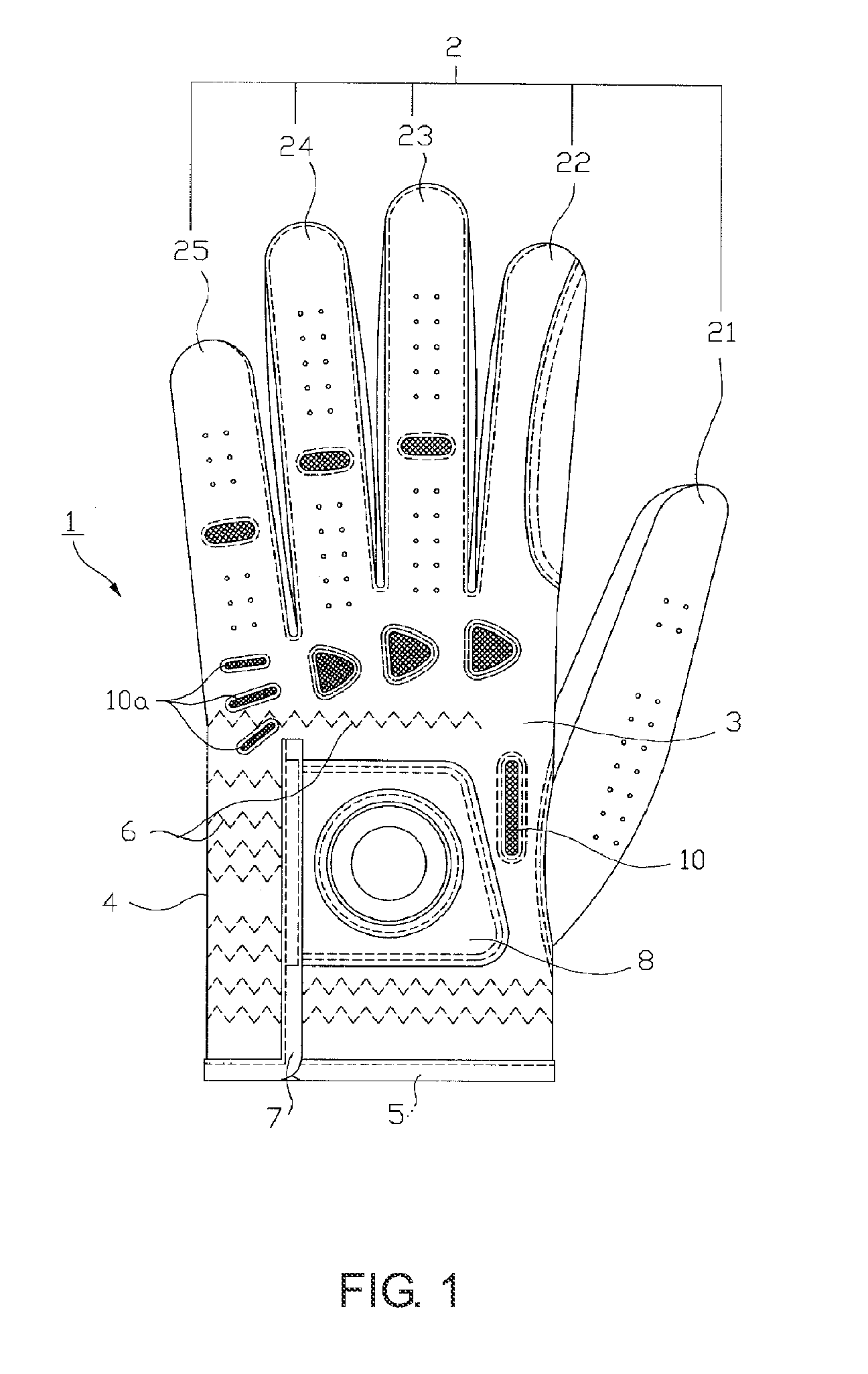

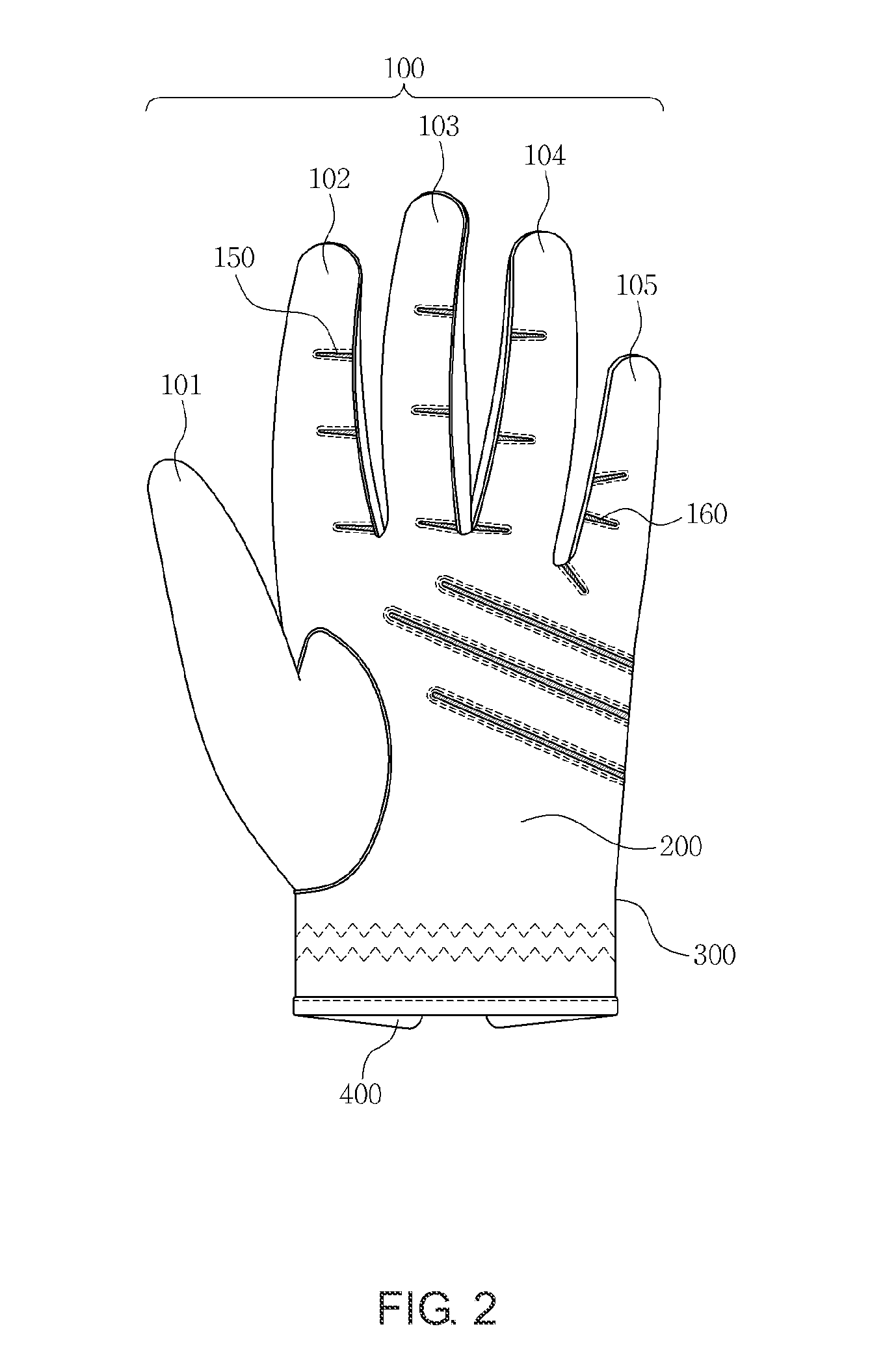

Golf glove

InactiveUS20130061369A1Avoid shapeEnhancing function of closingGlovesSport apparatusLittle fingerEngineering

Disclosed herein is a golf glove. The golf glove includes a finger part, a back hand part, a palm part and an opening. The finger part includes a thumb part, a forefinger part, a middle finger part, a ring finger part and a little finger part. The back hand part and the palm part are connected to the finger part and cover the palm and back of the hand of a user. The opening is defined by the back hand part and the palm part. The finger part has at least one cut portion formed by stitching fabric portions on opposite sides of a cut formed in a bottom of a knuckle portion of the finger part. The cut portion can have various shapes. Frictional force between the golf glove and a grip of a golf club can be enhanced by the cut portion.

Owner:LIM CHANG SEON

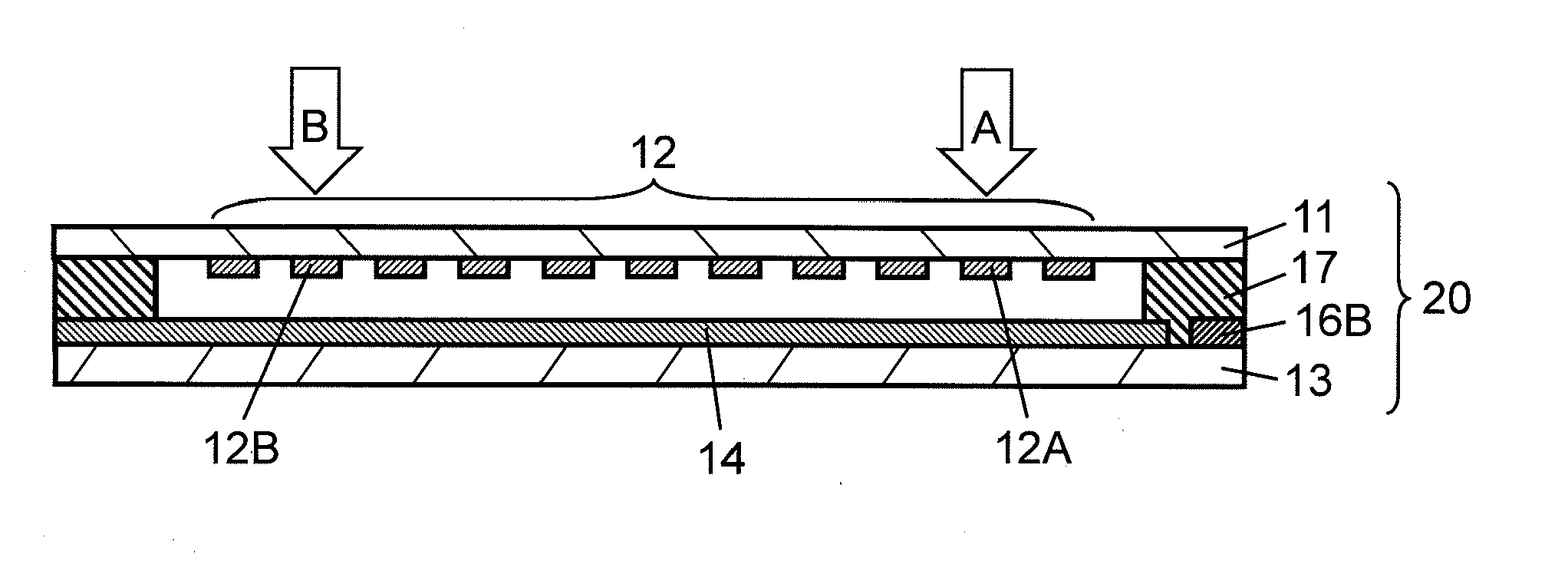

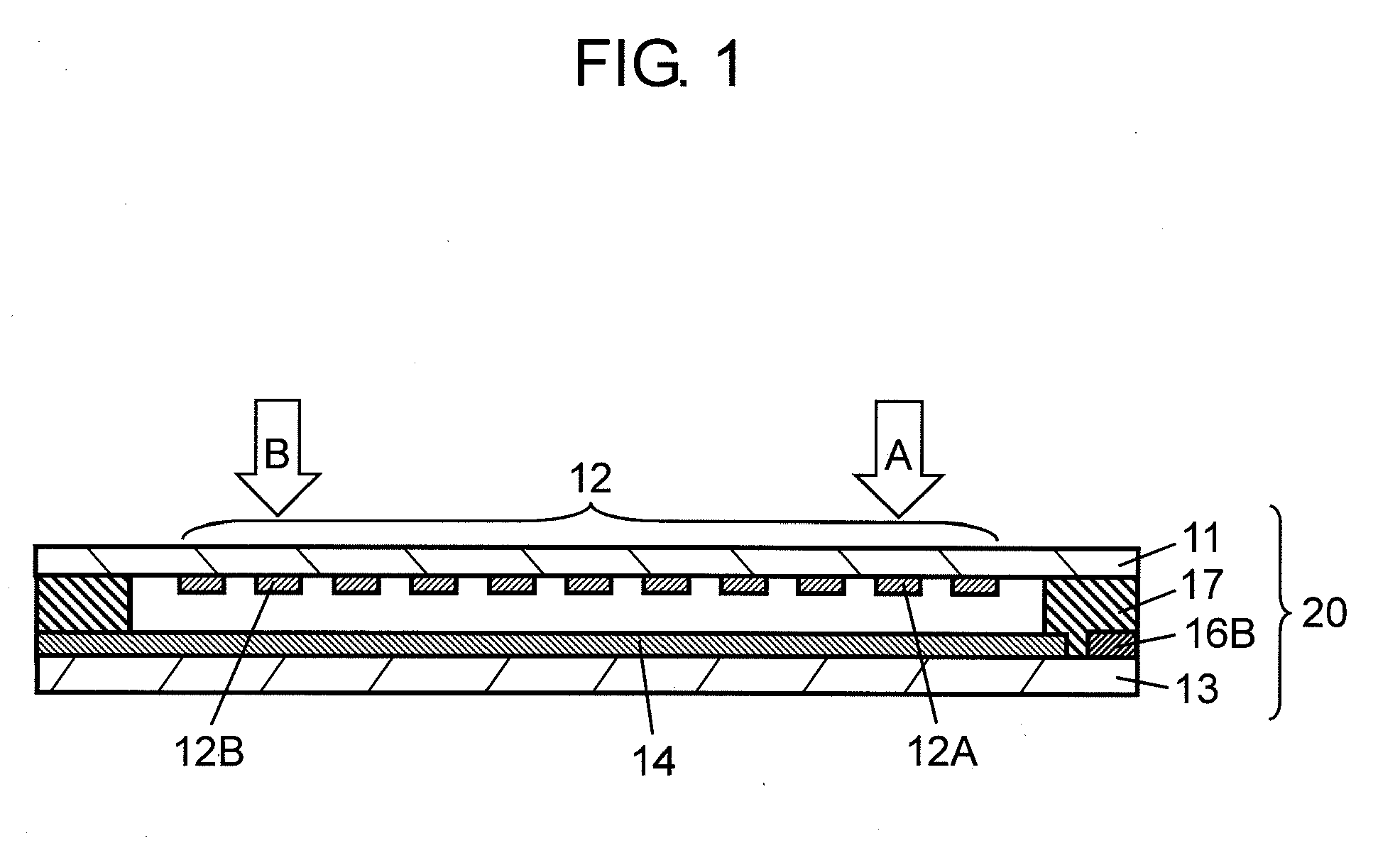

Touch panel and method of detecting press operation position thereon

InactiveUS20100207907A1Reduce in quantityAvoid shapeInput/output processes for data processingBand shapeEngineering

In a touch panel, one of conductive layers on a bottom of an upper substrate and on a top of a lower substrate is formed of belt-shaped conductive layers. The other is a single conductive layer facing the belt-shaped conductive layers. The single conductive layer is provided with a pair of electrodes in positions corresponding to both ends in a direction where the belt-shaped conductive layers extend. When the upper substrate is pressed while a voltage is applied between the pair of electrodes, the top and lower conductive layers contact with each other. Then, a voltage value corresponding to the pressed position in the direction where the belt-shaped conductive layers extend is generated from any of the belt-shaped conductive layers. From the voltage value and the position of the belt-shaped conductive layer from which the voltage value is generated, a pressed position on the upper substrate can be detected.

Owner:PANASONIC CORP

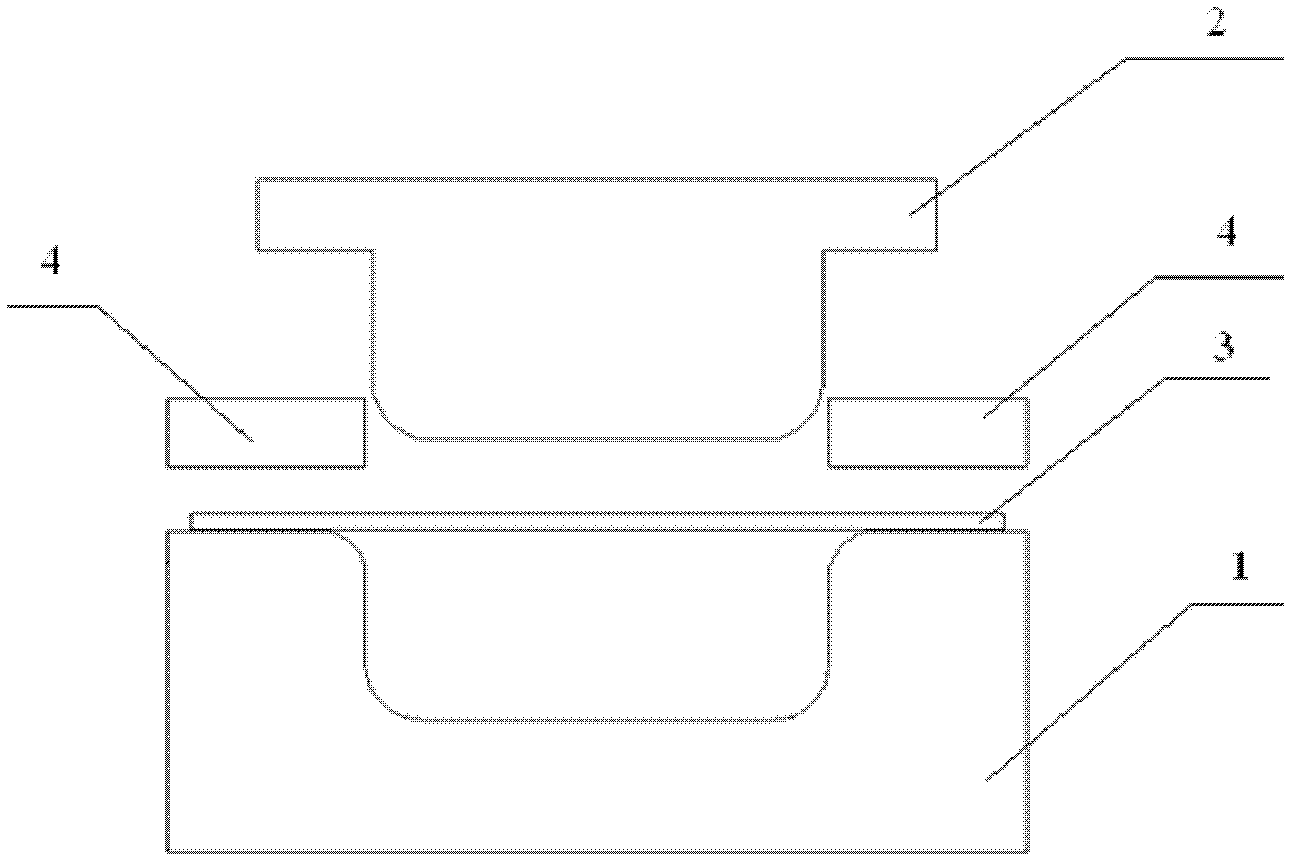

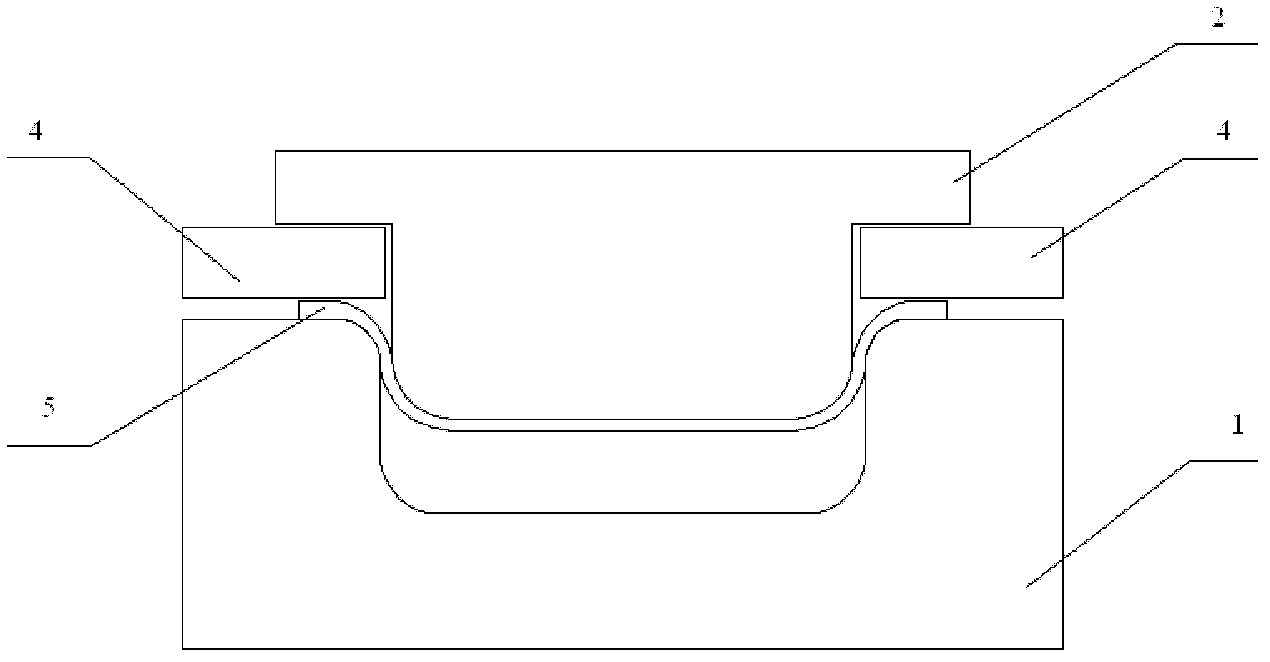

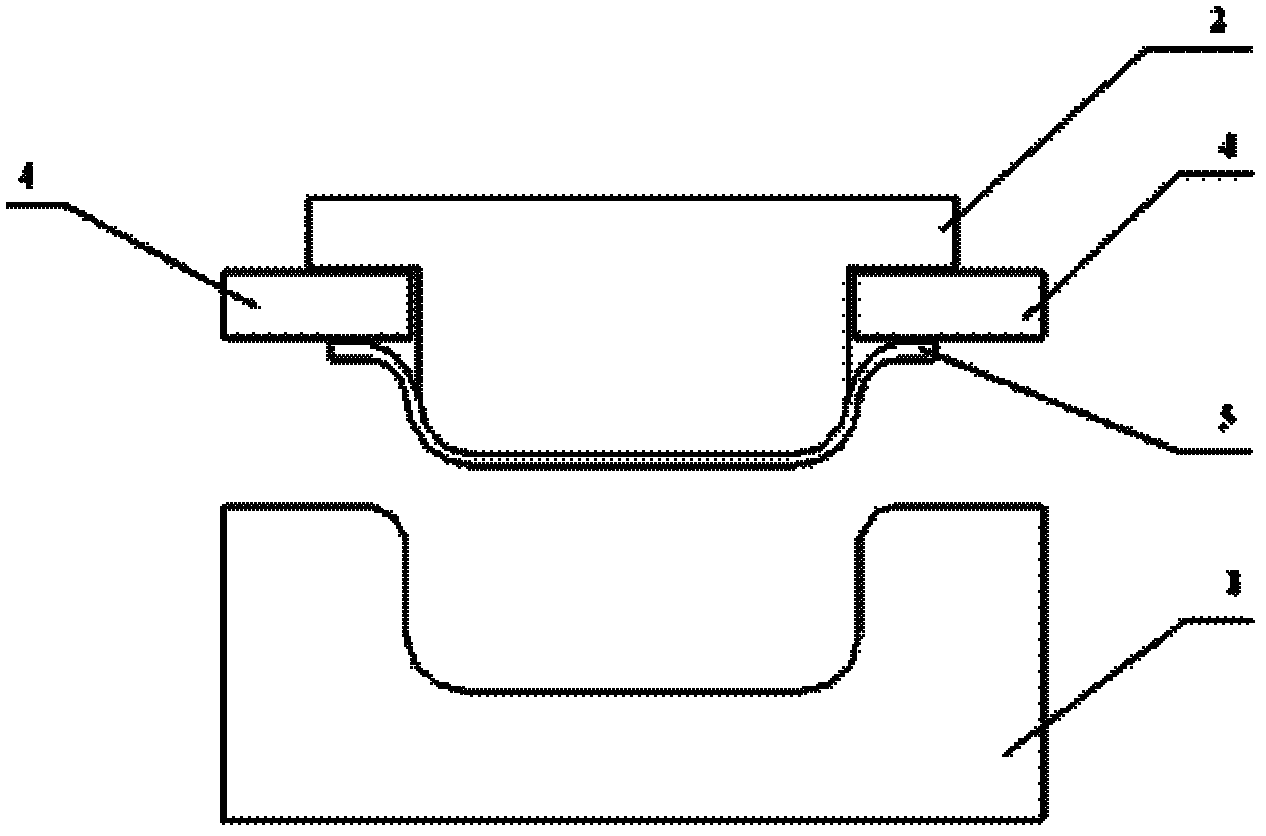

Cold-hot compound die molding method for aluminum alloy sheet metal component

ActiveCN102615201ADimensionally stableDimensional change, shape stability can be obtained directly through one-time formingShaping toolsMetalAluminium alloy

The invention discloses a cold-hot compound die molding method for an aluminum alloy sheet metal component, and relates to a molding method for a sheet metal component. The invention aims to solve the technical problems that the conventional hot-state molding method for the aluminum alloy sheet metal component is low in molding efficiency and can easily cause local crinkles and fractures, and provides the cold-hot compound die molding method for the aluminum alloy sheet metal component. The cold-hot compound die molding method comprises the following steps of: 1, heating a lower die to a temperature of between 200 and 900 DEG C; 2, placing an aluminum alloy plate blank on the lower die and heating the aluminum alloy plate blank to the deformation temperature of the aluminum alloy plate blank; 3, closing the die to press the aluminum alloy plate blank into the aluminum alloy sheet metal component; 4, separating the aluminum alloy sheet metal component, an upper die and a blank holder from the lower die; and 5, cooling the upper die and the blank holder, keeping the temperature for a certain period of time, and taking the aluminum alloy sheet metal component down to finish the cold-hot compound die molding of the aluminum alloy sheet metal component. According to the method, a cold-hot compound die in which the upper die is in a cold state and the lower die is in a hot state is adopted to mold the aluminum alloy sheet metal component. The cold-hot compound die molding method is suitable for making the aluminum alloy sheet metal component.

Owner:天津哈工永兴科技有限公司

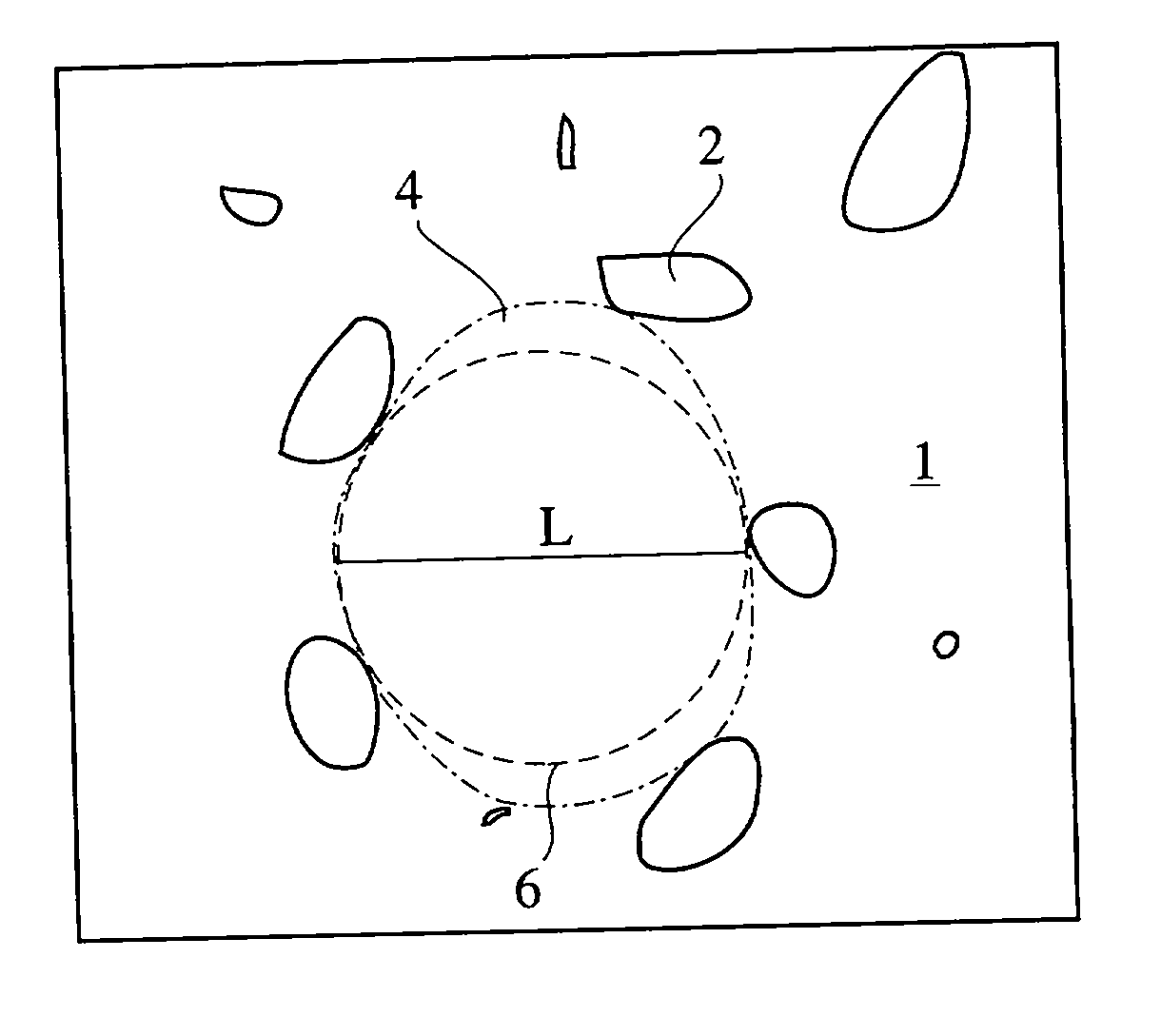

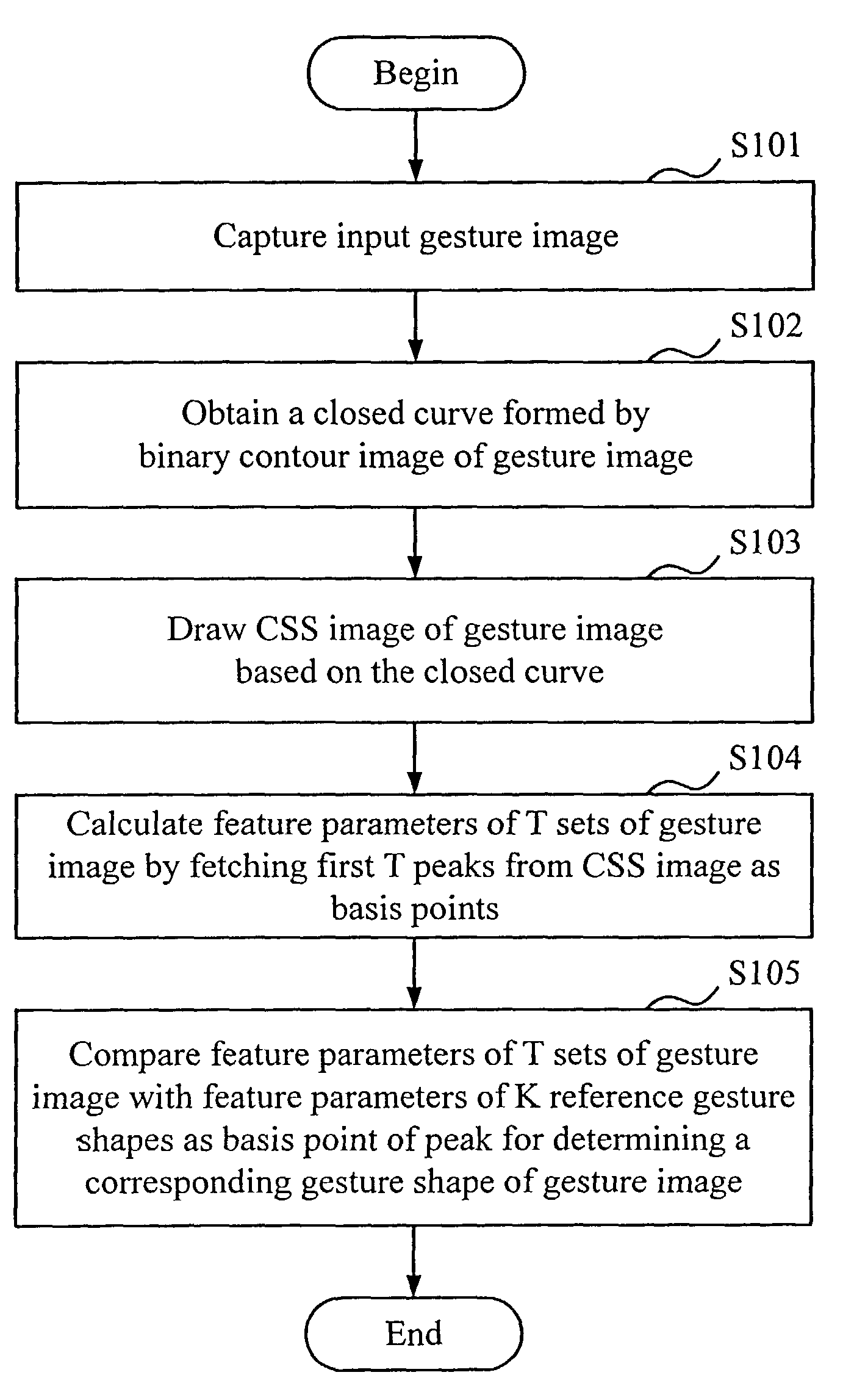

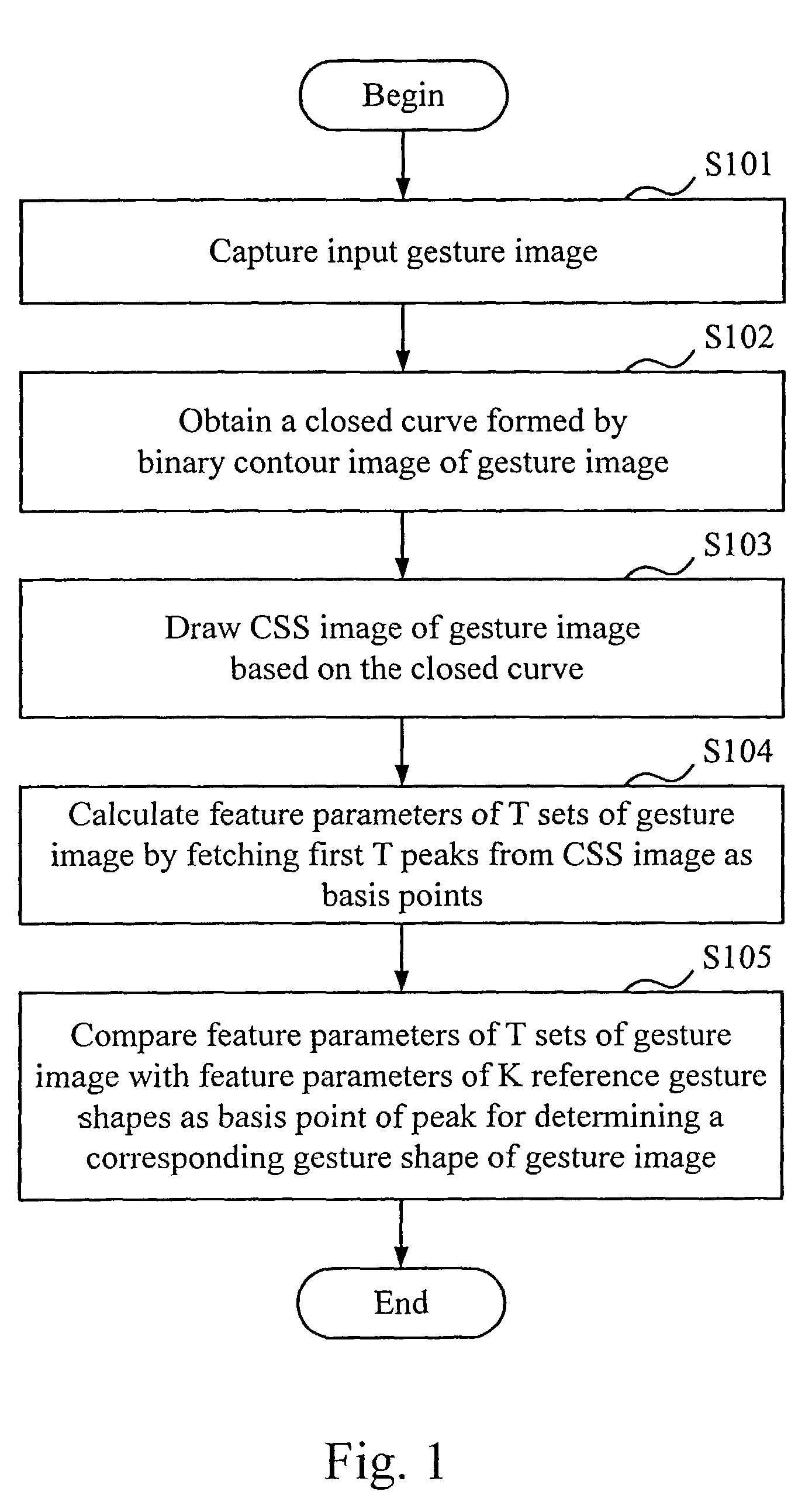

Method for extracting and matching gesture features of image

ActiveUS7068843B2Reliable feature descriptionAvoid shapeInput/output for user-computer interactionCharacter and pattern recognitionImage formationScale space

A method for extracting and matching gesture features of image is disclosed. An input gesture image is captured, and then a closed curve formed by a binary contour image of the gesture image is determined by preprocessing the gesture image. A curvature scale space (CSS) image of the gesture image is drawn based on the closed curve. Feature parameters of a plurality of sets of the gesture image are determined by extracting first plural peaks from the CSS image as basis points, and each feature parameter of the plurality of sets of the gesture image is compared with each feature parameter of a plurality of reference gesture shapes represented as a basis point of the maximal peak, thereby determining a gesture shape corresponding to the gesture image.

Owner:IND TECH RES INST

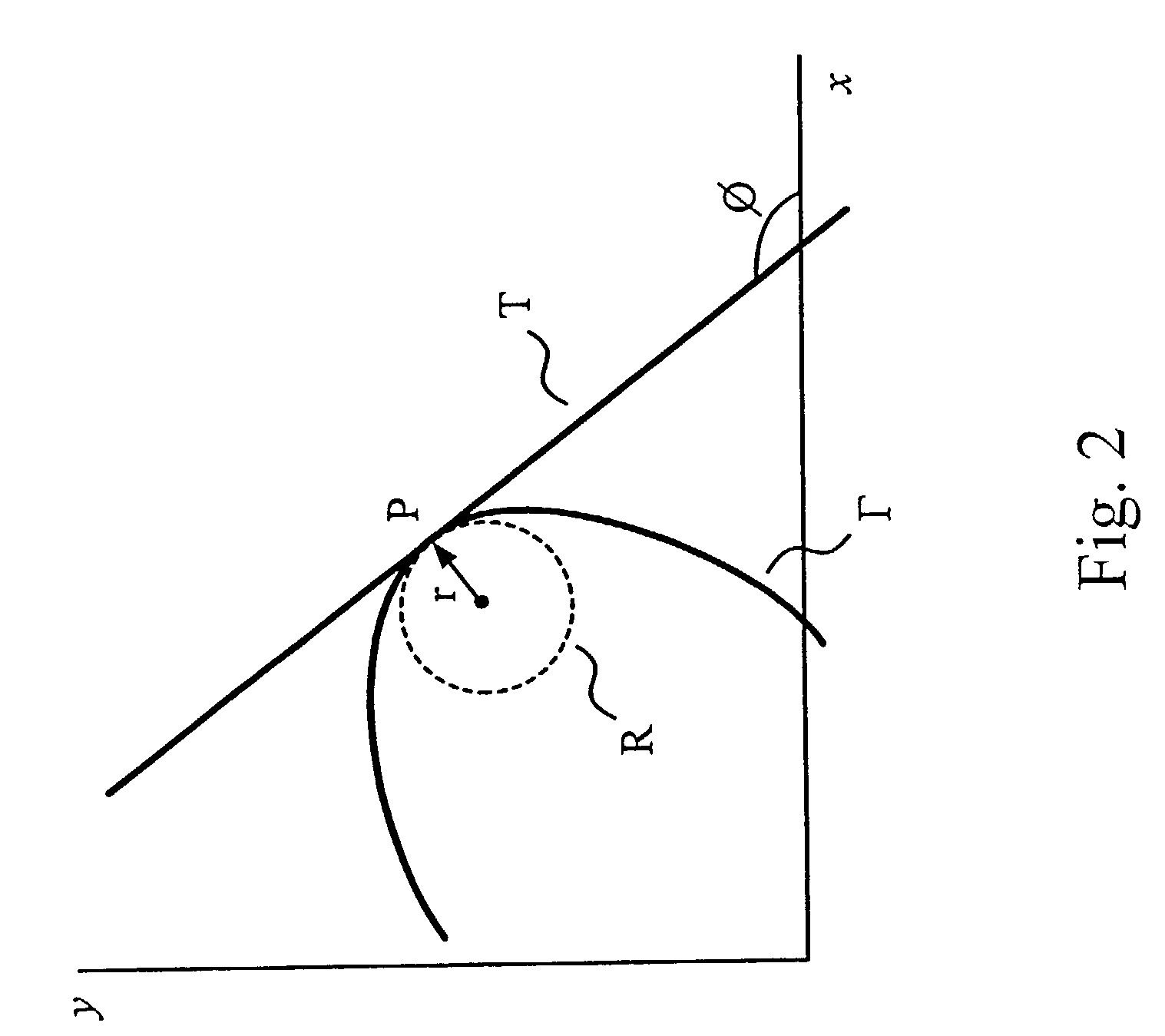

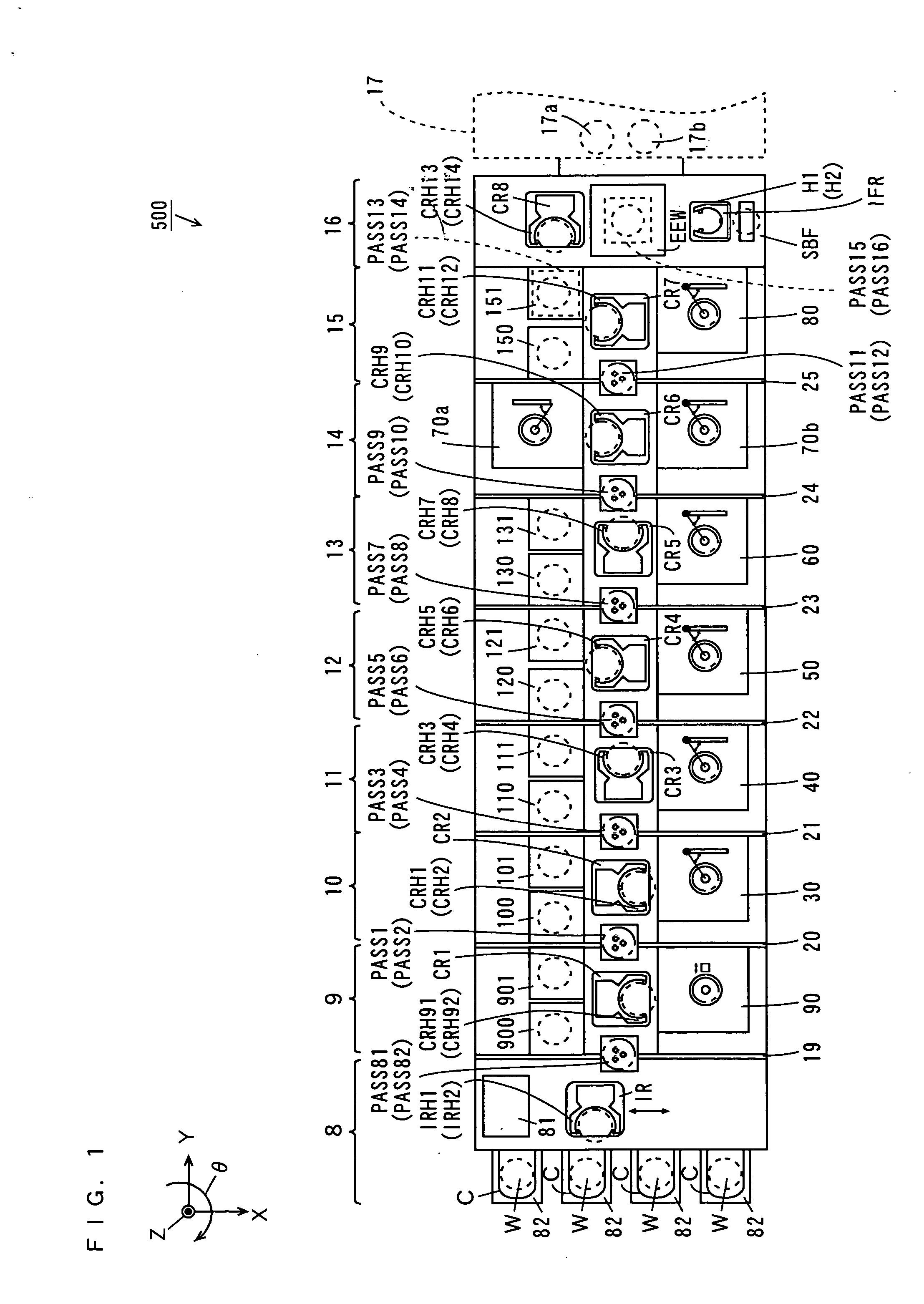

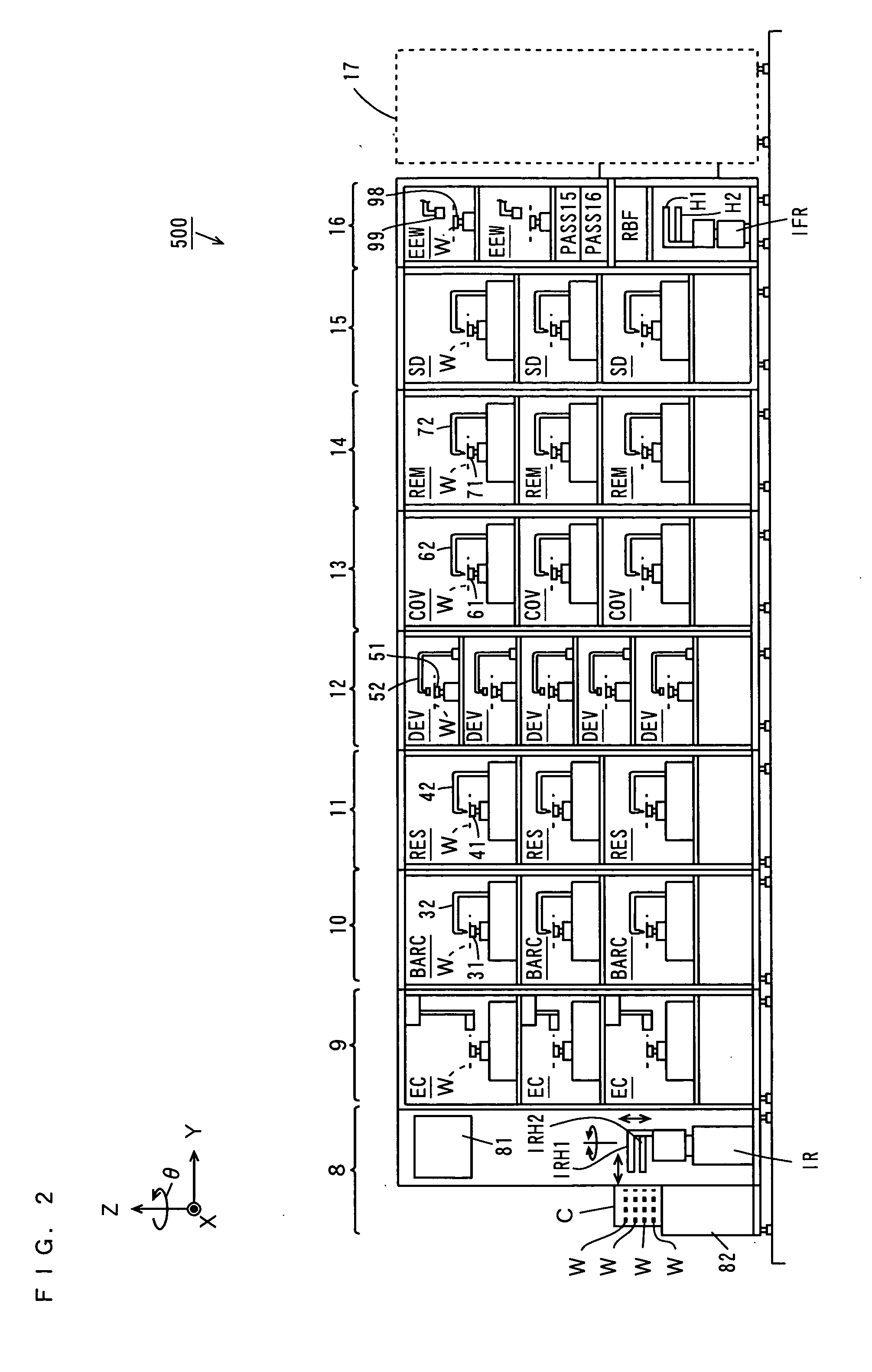

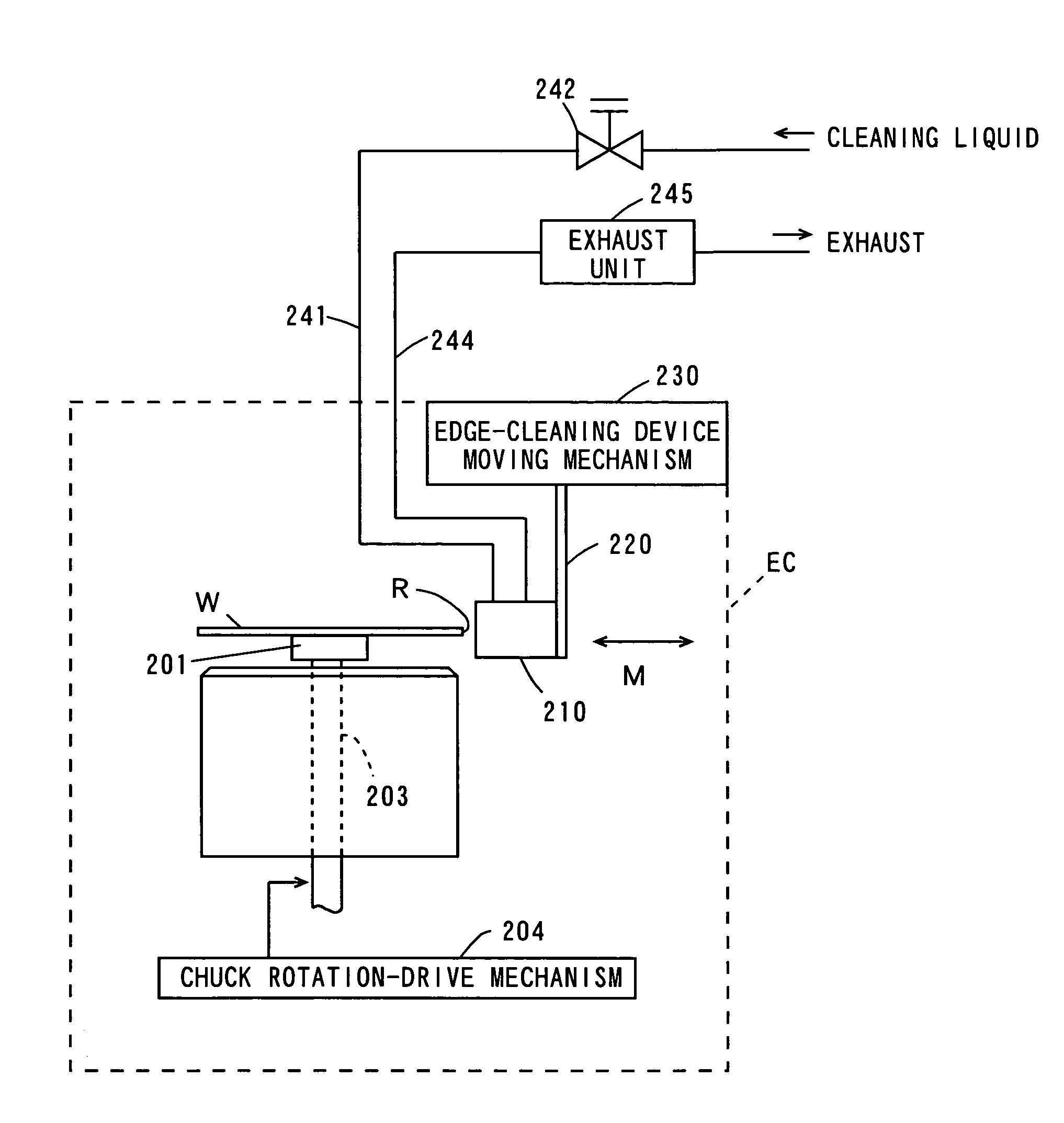

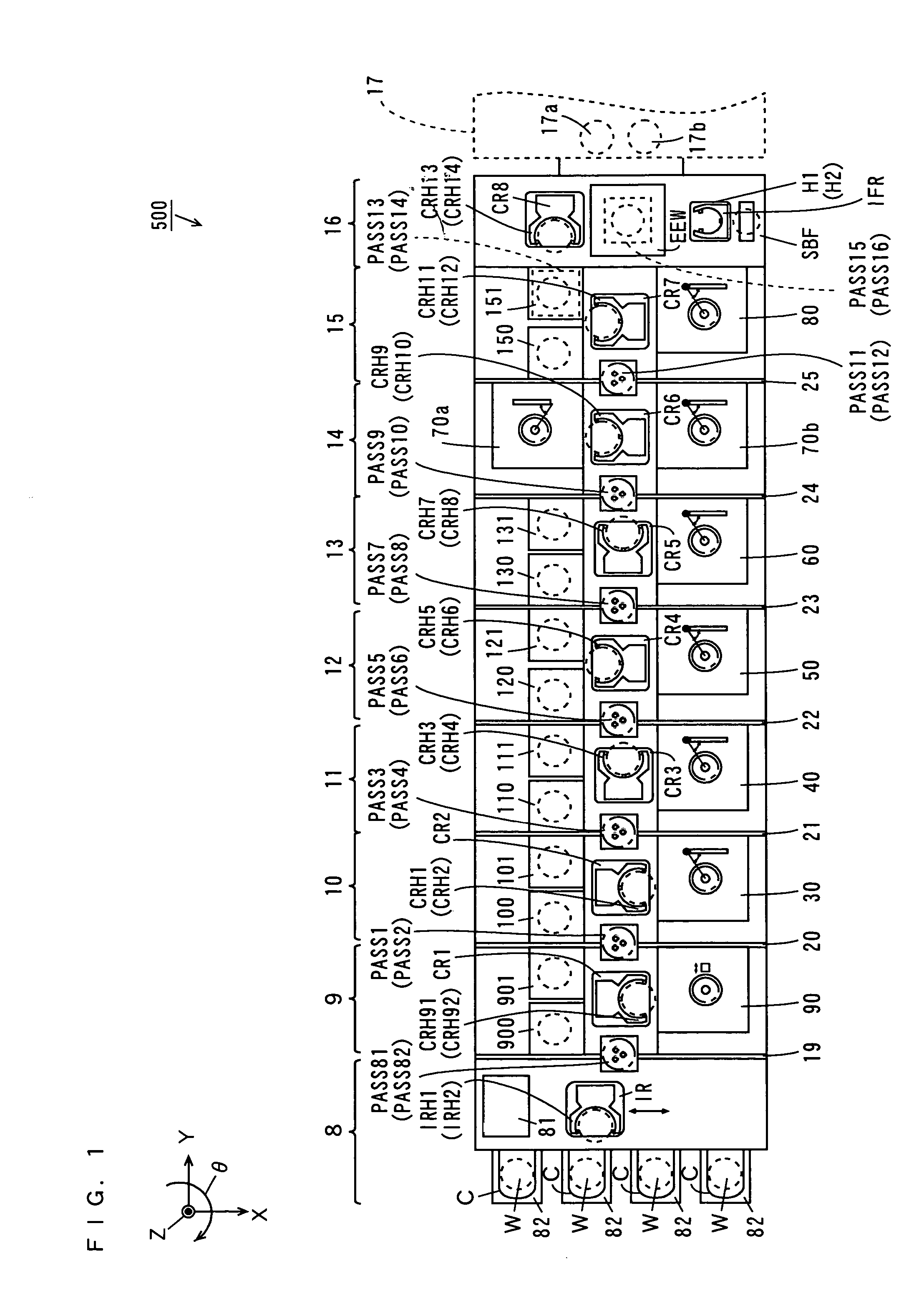

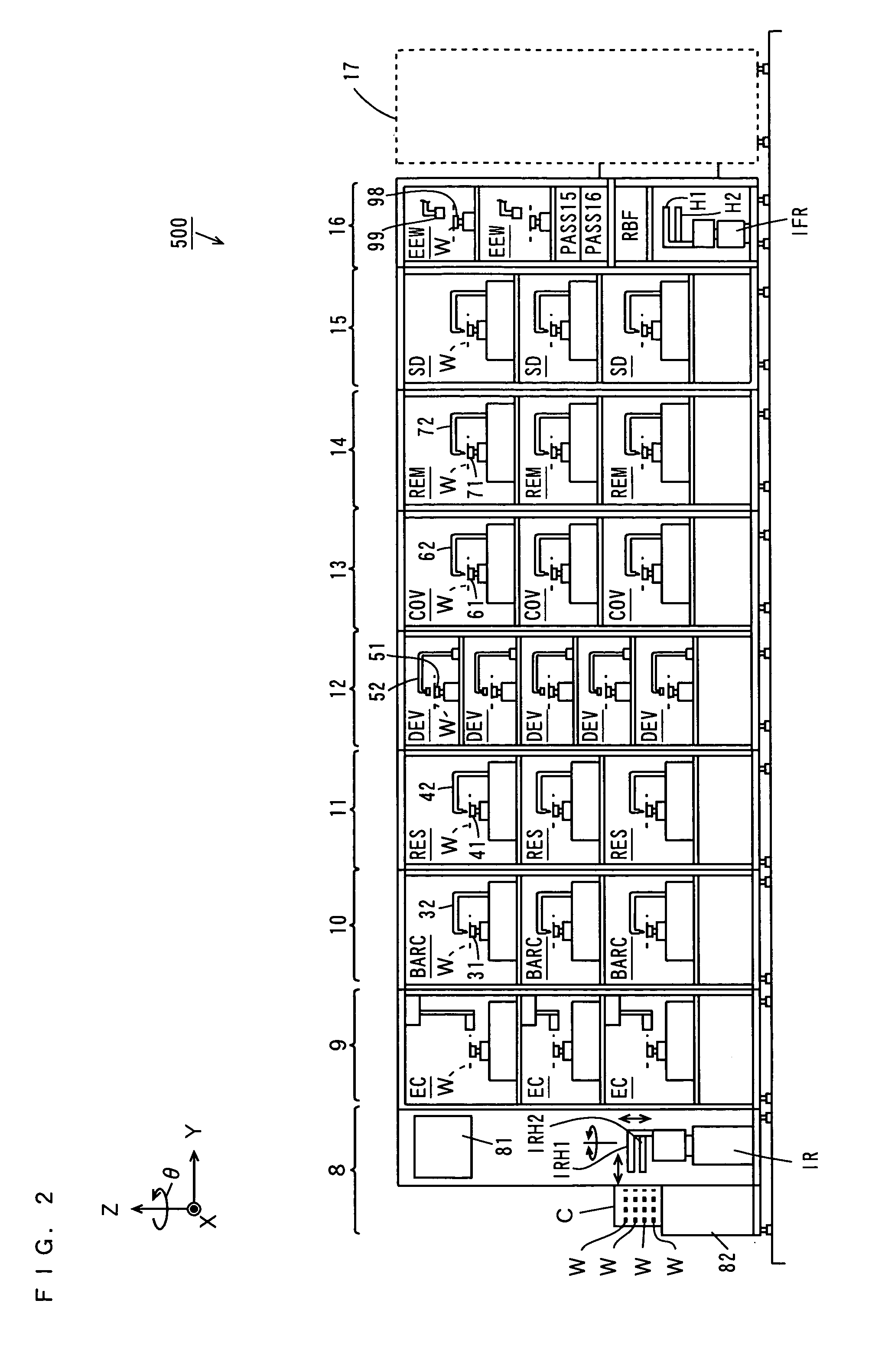

Substrate processing apparatus

ActiveUS20060291855A1Prevent contaminationAvoid defective dimension and defective shapeLiquid processingSemiconductor/solid-state device manufacturingComputer science

A substrate processing apparatus comprises an indexer block, an edge-cleaning processing block, an anti-reflection film processing block, a resist film processing block, a development processing block, a resist cover film processing block, a resist cover film removal block, a cleaning / drying processing block and an interface block. An exposure device is arranged adjacent to the interface block of the substrate processing apparatus. In the exposure device, exposure processing is applied to a substrate by a liquid immersion method. In the edge-cleaning processing group in the edge-cleaning processing block, an edge of the substrate before exposure processing is cleaned.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

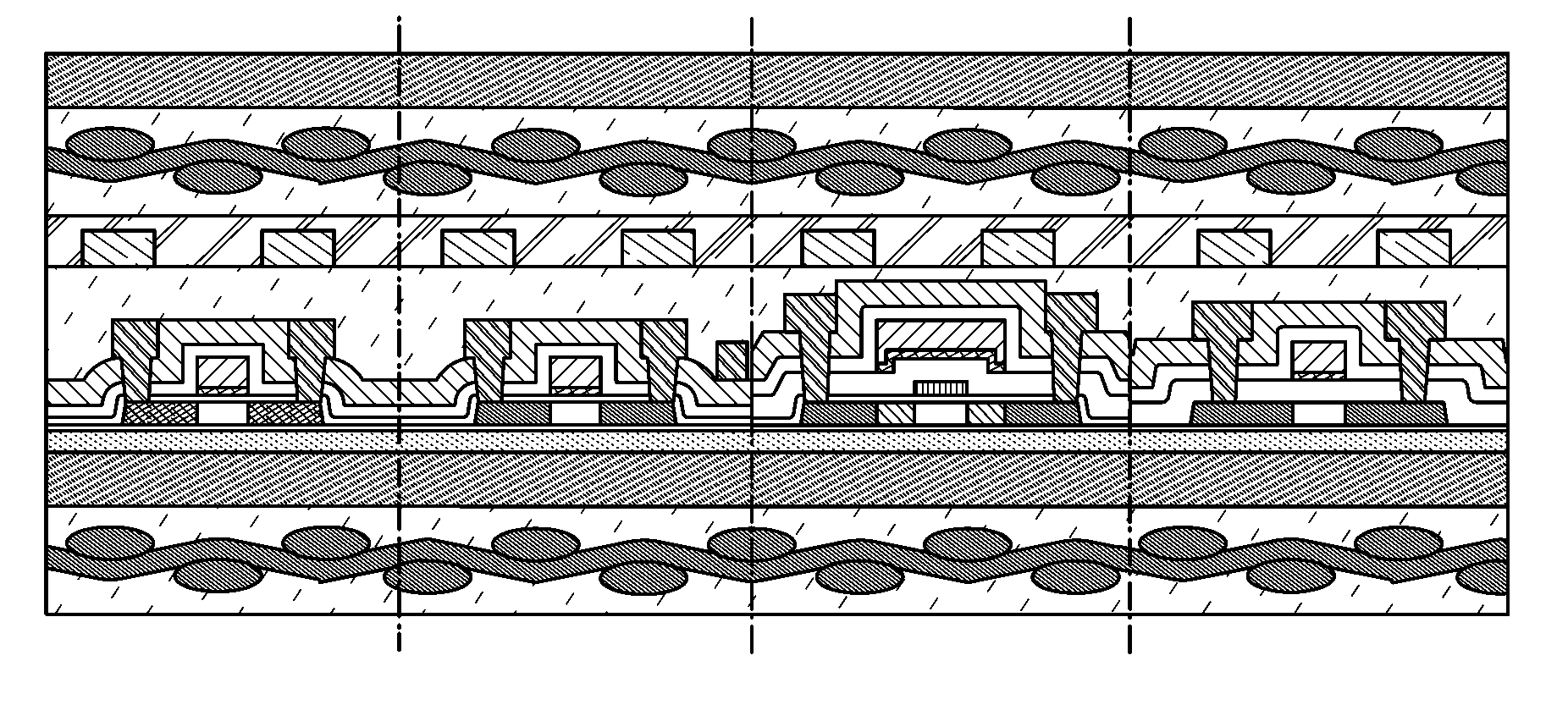

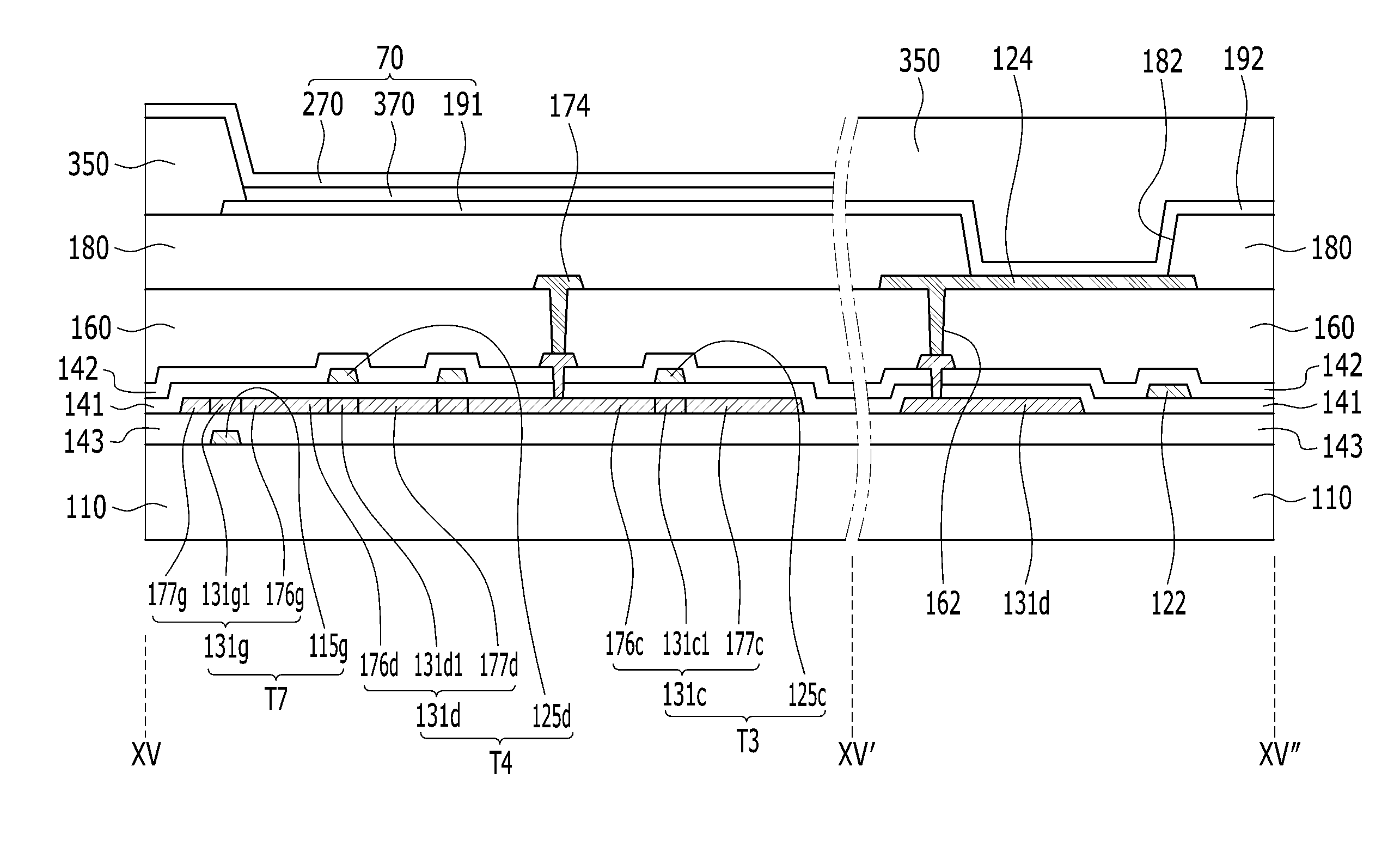

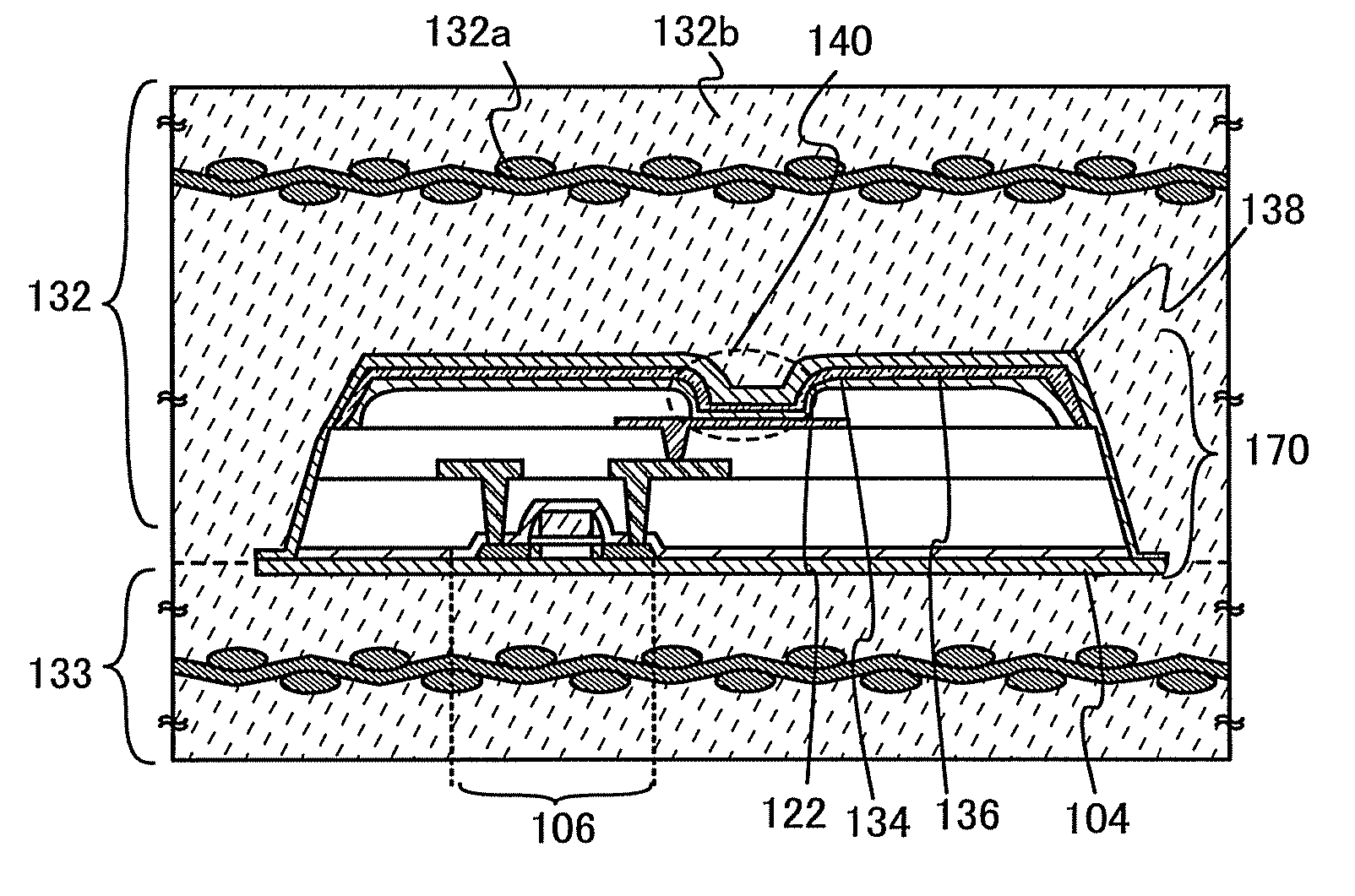

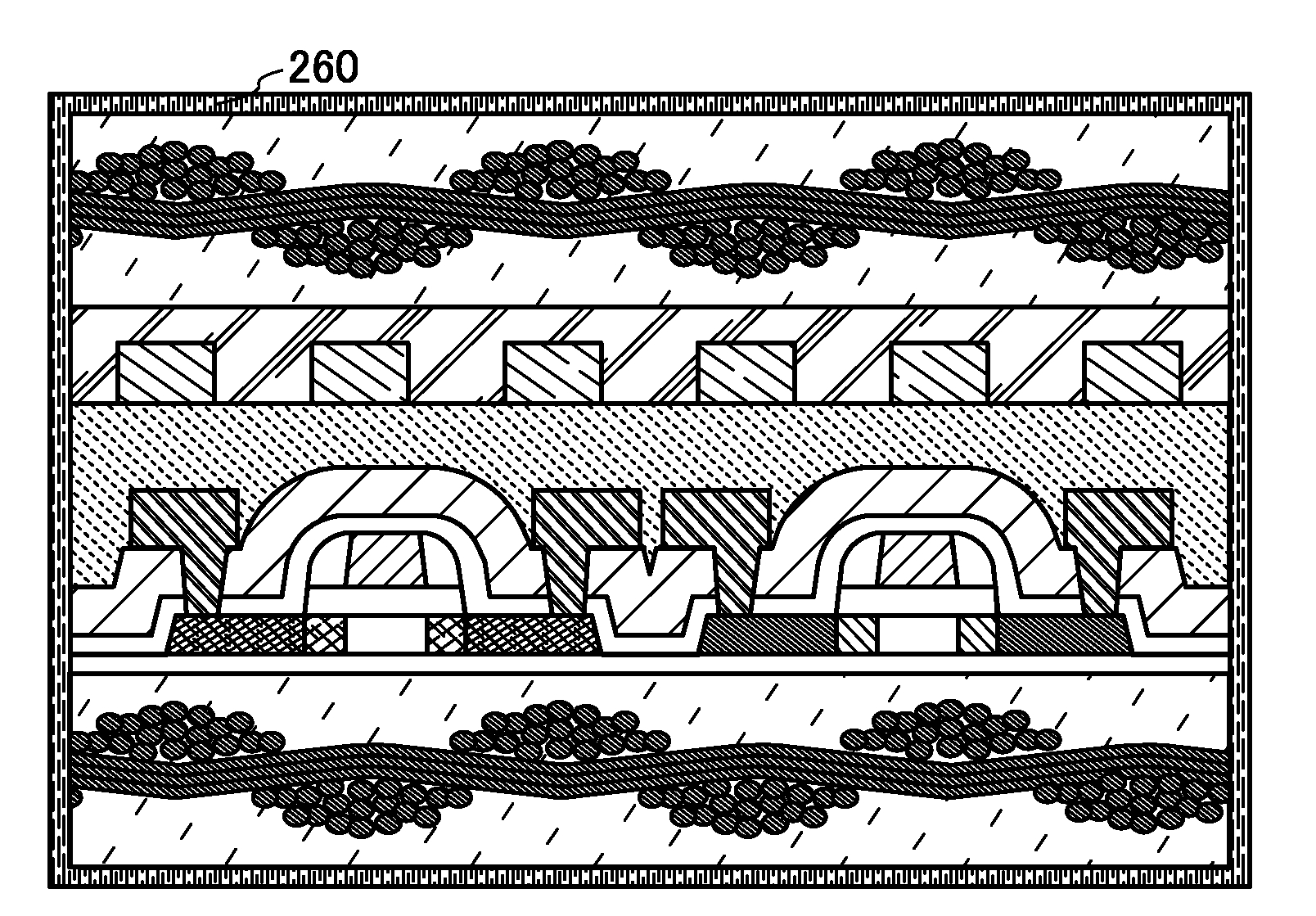

Semiconductor device and method for manufacturing semiconductor device

InactiveUS20090278252A1Reduced in thickness and sizeTolerance stressSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

To reduce defects of a semiconductor device, such as defects in shape and characteristic due to external stress and electrostatic discharge. To provide a highly reliable semiconductor device. In addition, to increase manufacturing yield of a semiconductor device by reducing the above defects in the manufacturing process. The semiconductor device includes a semiconductor integrated circuit sandwiched by impact resistance layers against external stress and an impact diffusion layer diffusing the impact and a conductive layer covering the semiconductor integrated circuit. With the use of the conductive layer covering the semiconductor integrated circuit, electrostatic breakdown (malfunctions of the circuit or damages of a semiconductor element) due to electrostatic discharge of the semiconductor integrated circuit can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

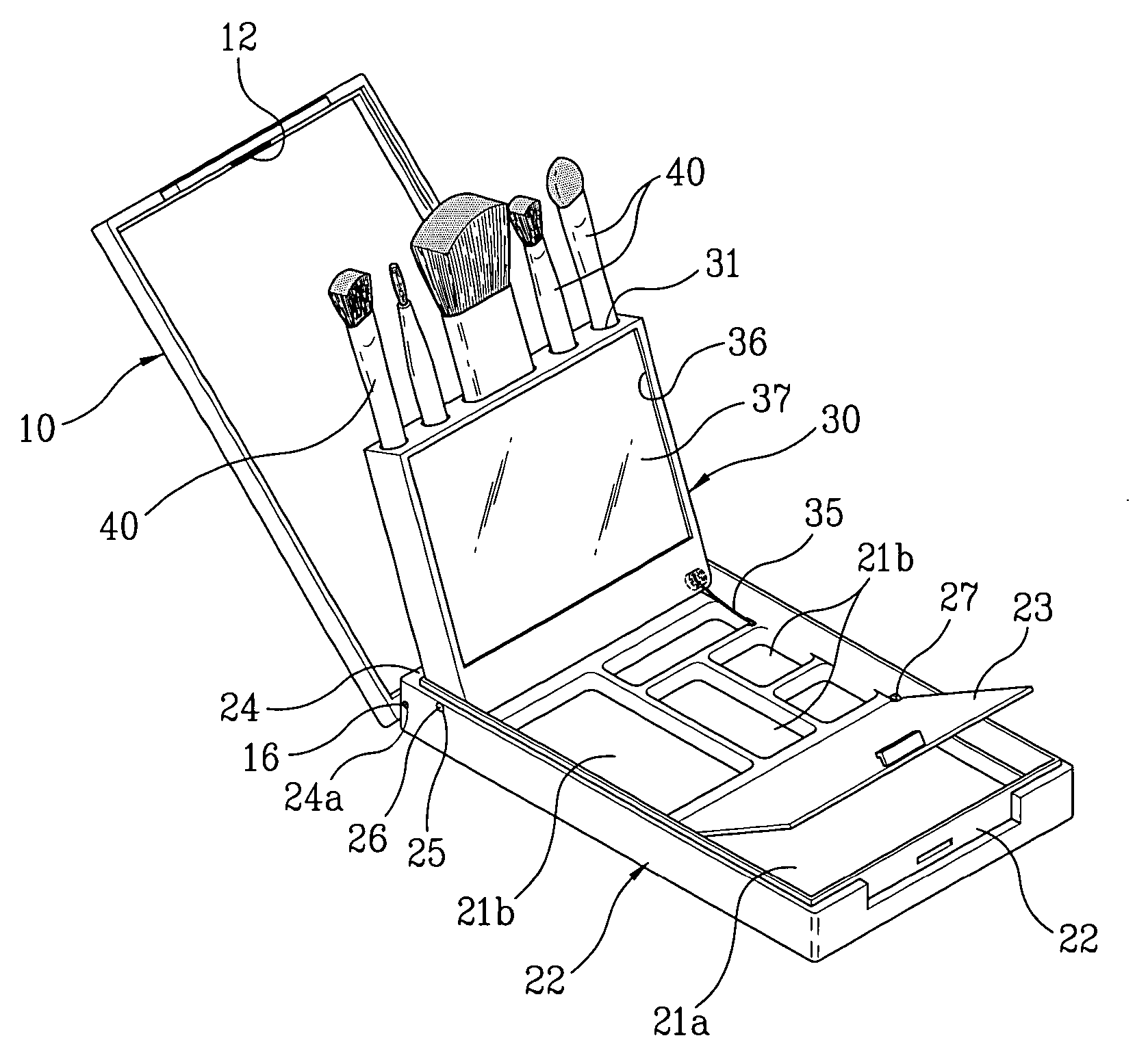

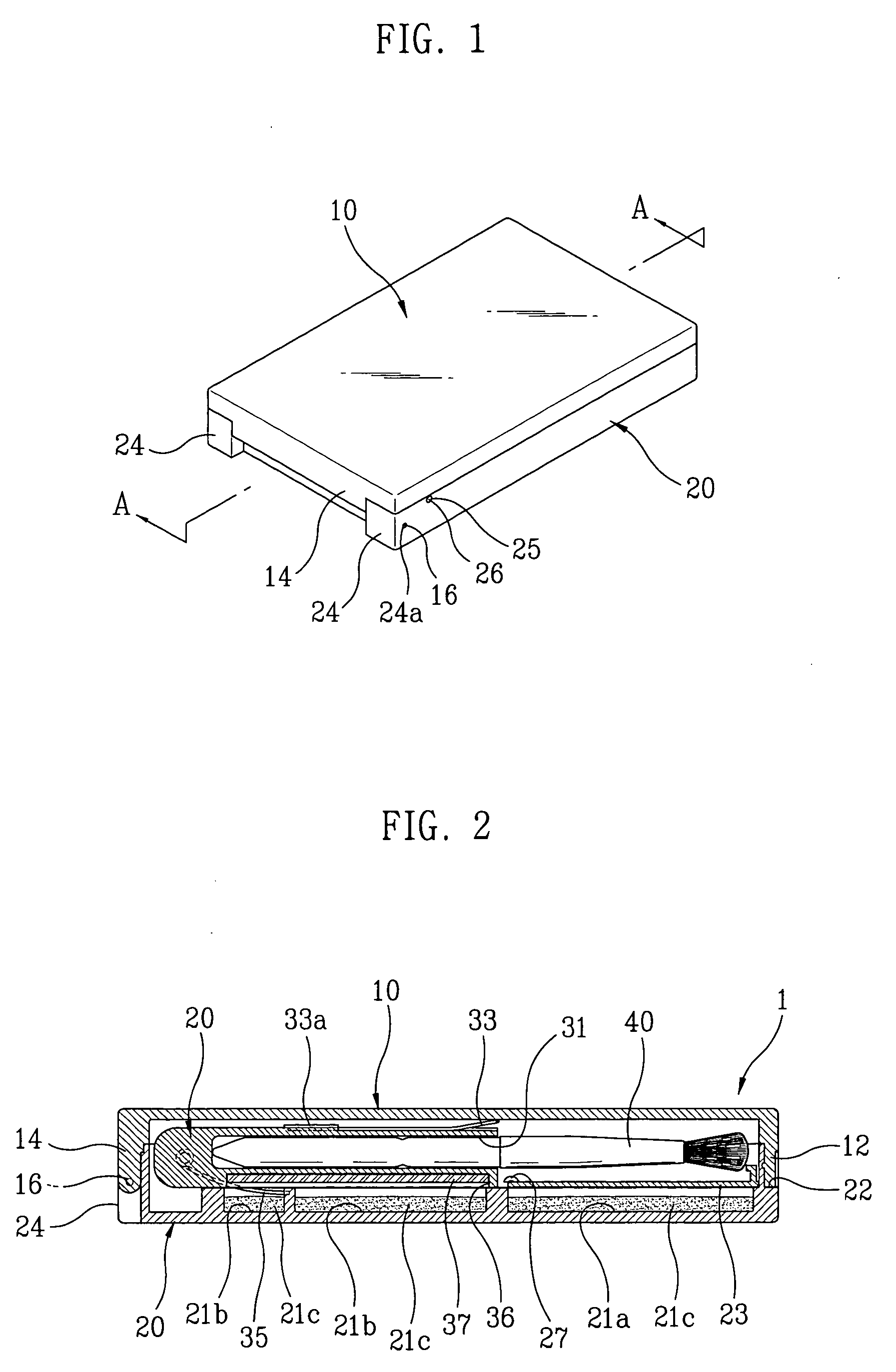

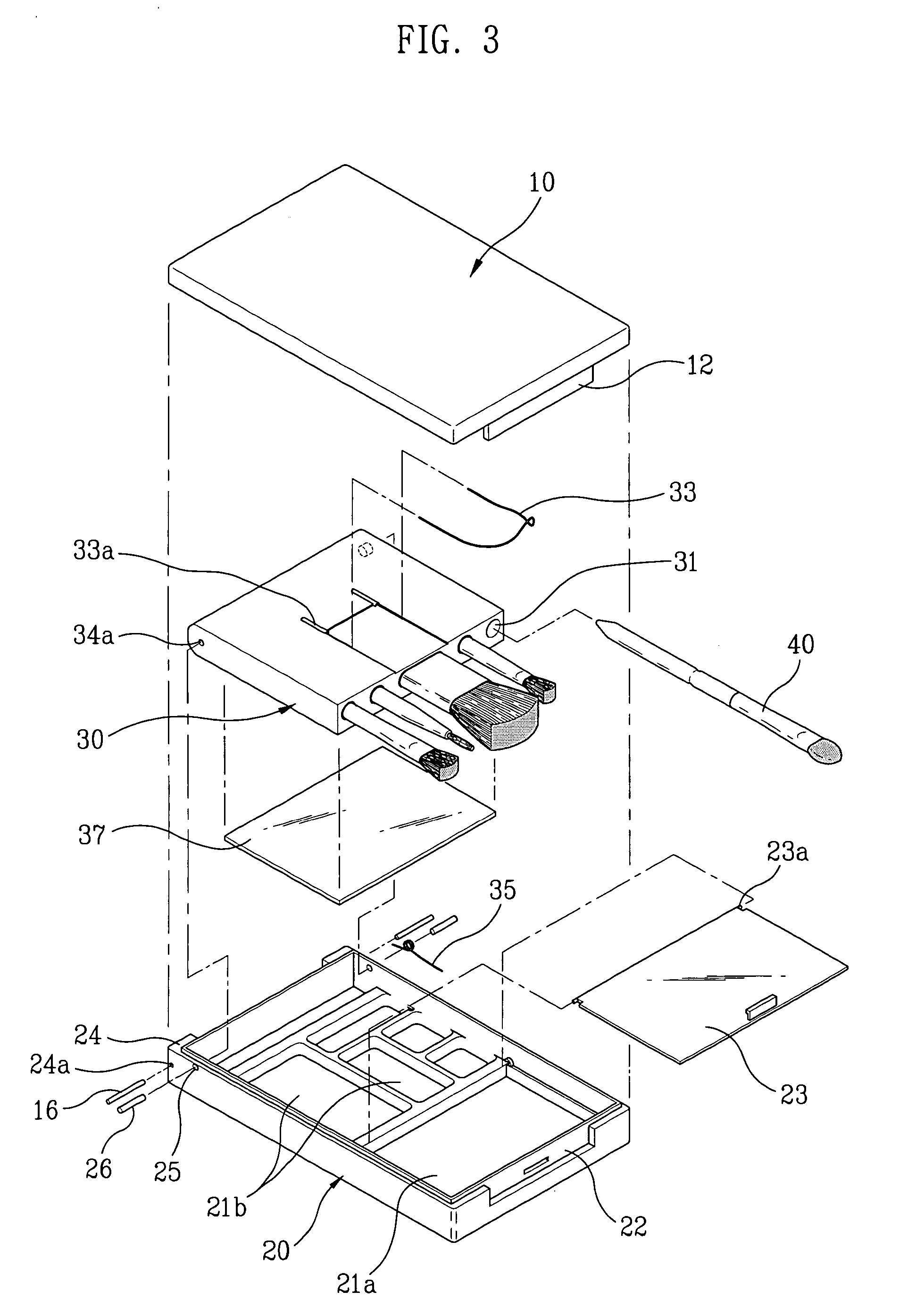

Cosmetics and cosmetic tool keeping case

InactiveUS20050194021A1Guarantee support safetyAvoid shapeOther accessoriesPackaging toiletriesEngineeringMechanical engineering

The present invention relates to a cosmetics keeping case for cosmetics and cosmetic tools, more particularly, a cosmetics case 1 for keeping cosmetics and cosmetic tools 40 which includes an upper movable body 10, a lower movable body 20, reception parts 21a and 21b for keeping a number of cosmetics 21c inside the lower movable body 20 and a tool reception part 30 for safely receiving and supporting the cosmetic tools 40 , wherein the tool reception part 30 elastically rotates by distortion spring 35 to stand up and to make the cosmetic tools 40 to be drawn out and inserted in the tool reception part when the upper movable body and, at the same time, to prevent the cosmetic tools 40 from contacting inner side of the upper movable body 10 and brush portions of the cosmetic tools 40 being pressed flat to the inner side by means of ‘U’ shaped elastic spring 33 mounted in the tool reception part 30 when the upper movable body 10 is closed and the cosmetic tools 40 are received in reception holes 31 of the tool reception part 30, so that the cosmetics keeping case can inhibit modification in shape of the brush portions of the cosmetic tools 40 and stably maintain the cosmetic tools 40.

Owner:BYUN YOUNG CHUL

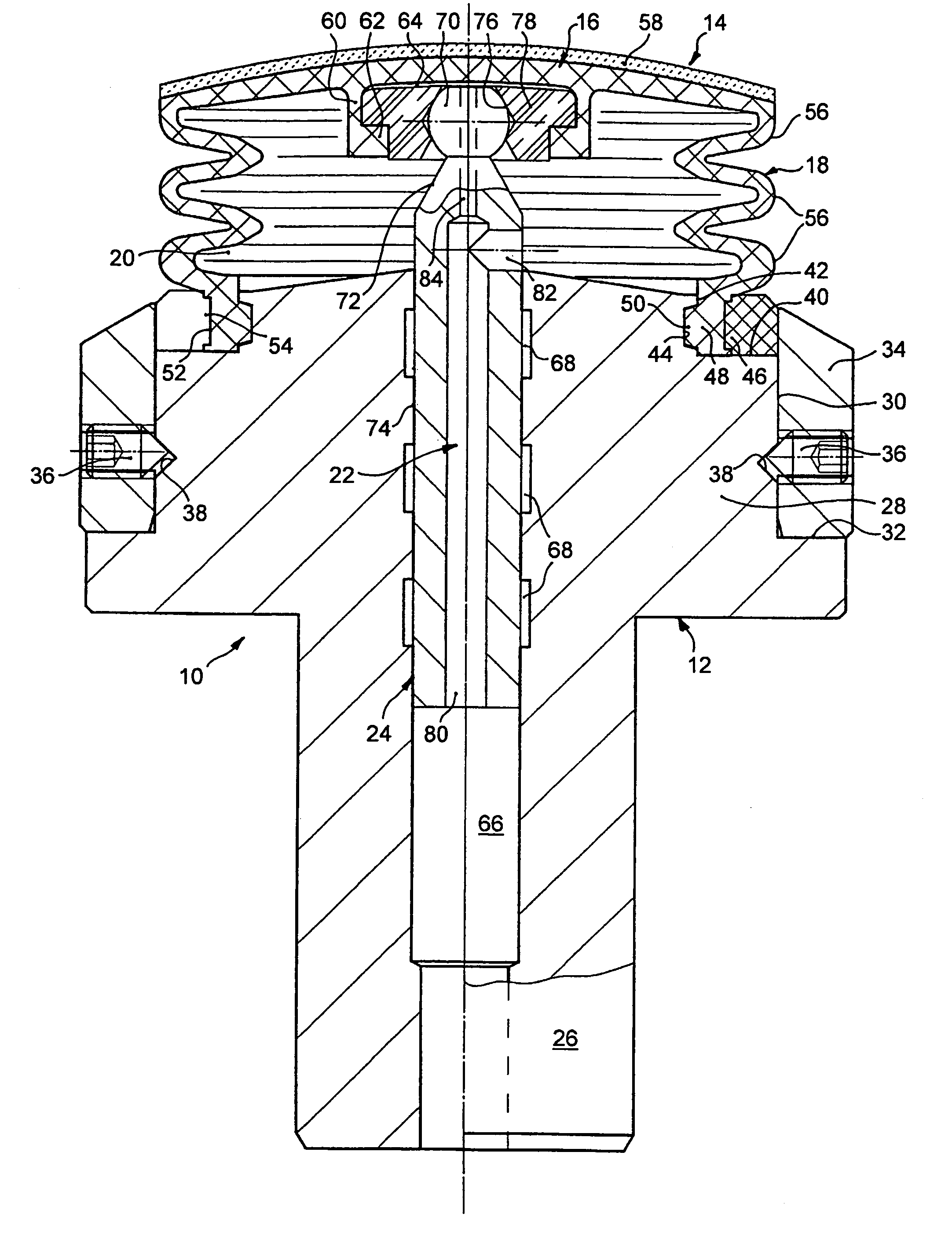

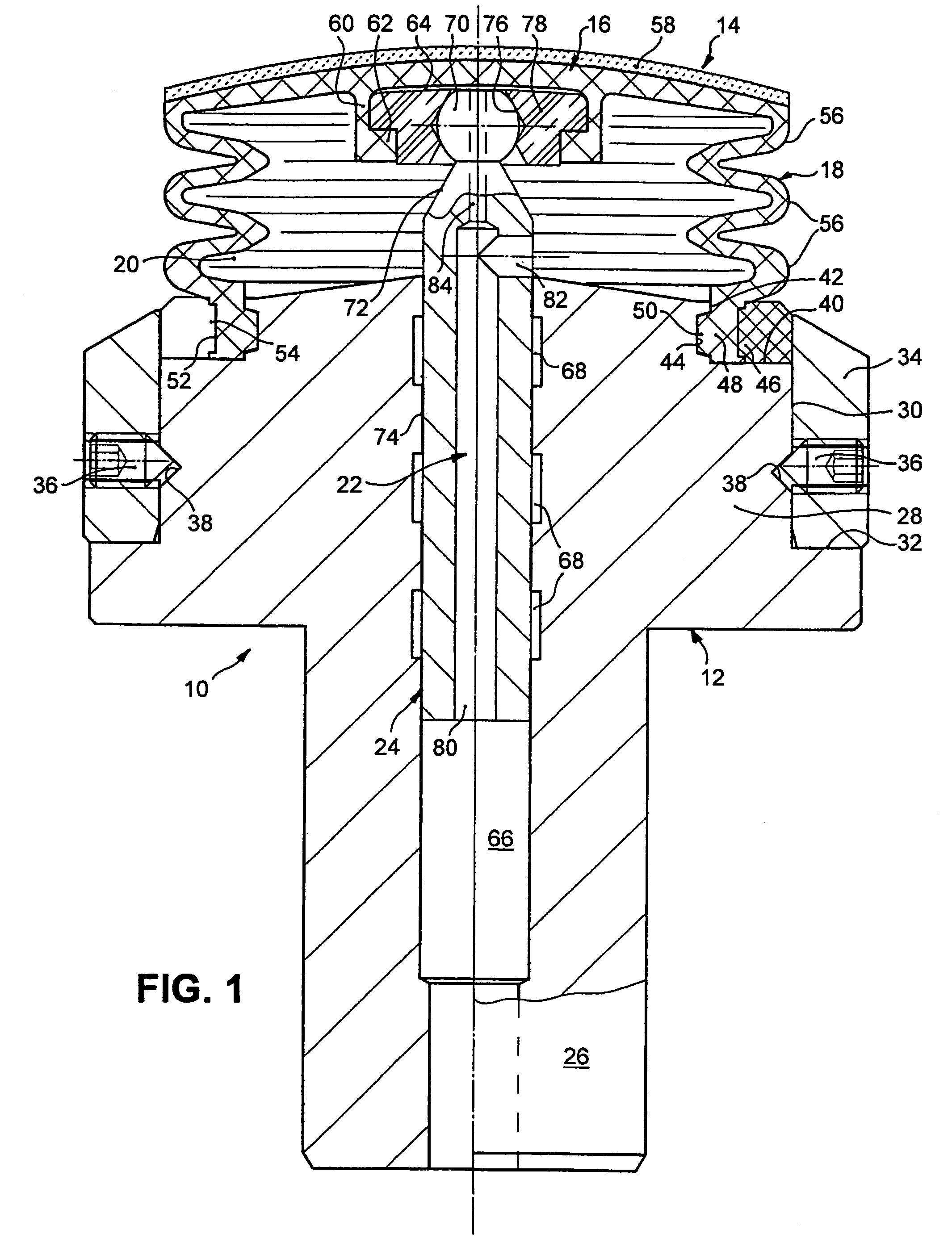

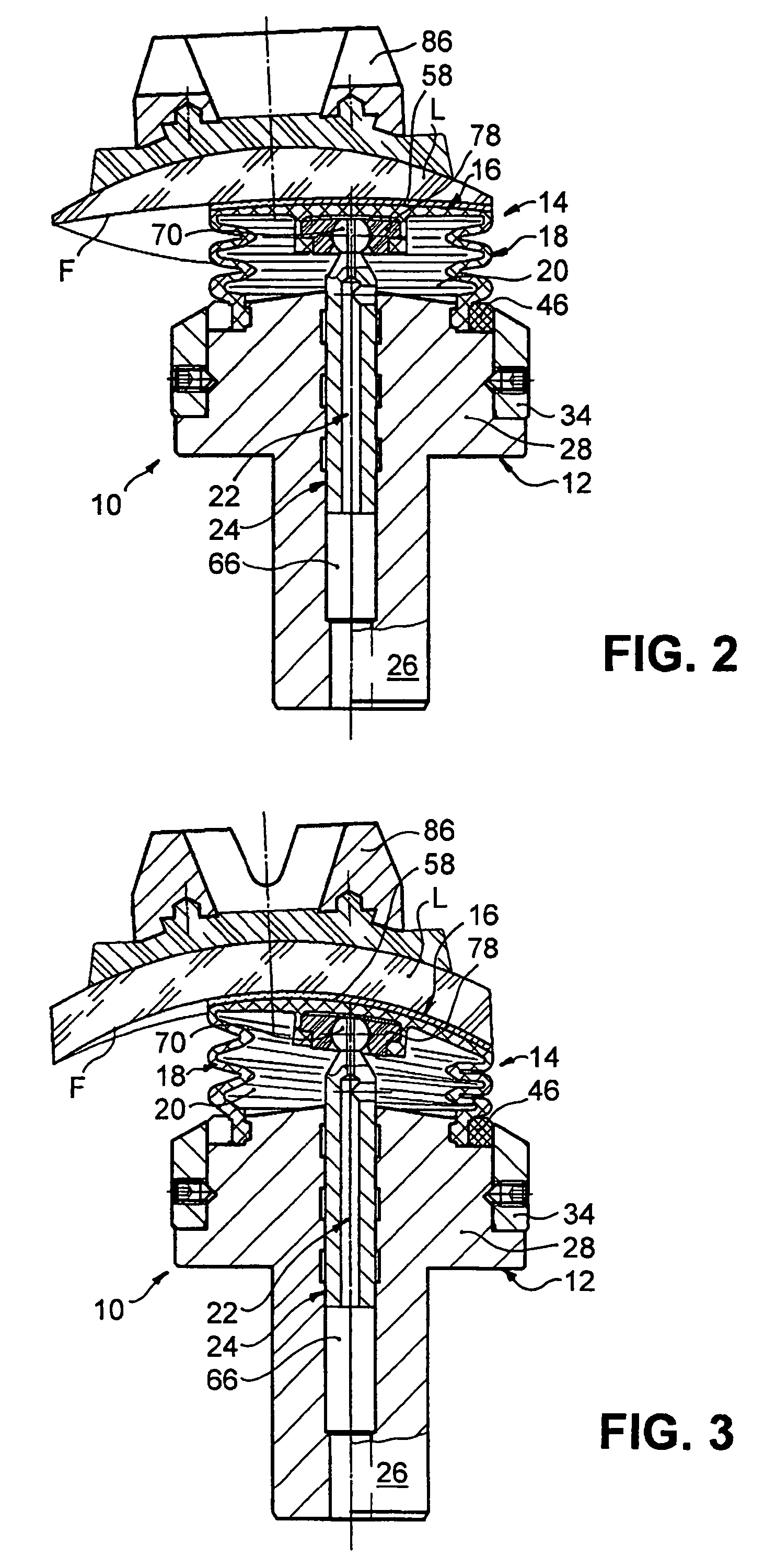

Tool for fine machining of optically active surfaces

ActiveUS7066794B2Good adaptabilityReliable functionEdge grinding machinesOptical surface grinding machinesElastic membraneMachine tool

A tool (10) is disclosed for fine machining of optically active surfaces (F), with a base body (12) that can be attached to a tool spindle of a machine tool, and an elastic membrane (14) that has a machining section (16) to which connects a gaiter section (18) by means of which the membrane is attached to the base body such that it can be rotated therewith. The base body and the membrane delimit a pressure medium chamber (20) which via a channel (22) can be optionally pressurized with a pressure medium in order to apply a machining pressure via the machining section during machining of the optically active surface. A guide element (24) guided longitudinally mobile on the base body is actively connected with the machining section so that the machining section can be moved in the longitudinal direction of the guide element and held in the transverse direction to the guide element, although under an elastic deformation of the gaiter section it is tilt-mobile in relation to the guide element. The result is a tool of simple design and reliable function which has an excellent adaptability to a wide range of geometries to be machined.

Owner:SATISLOH GMBH

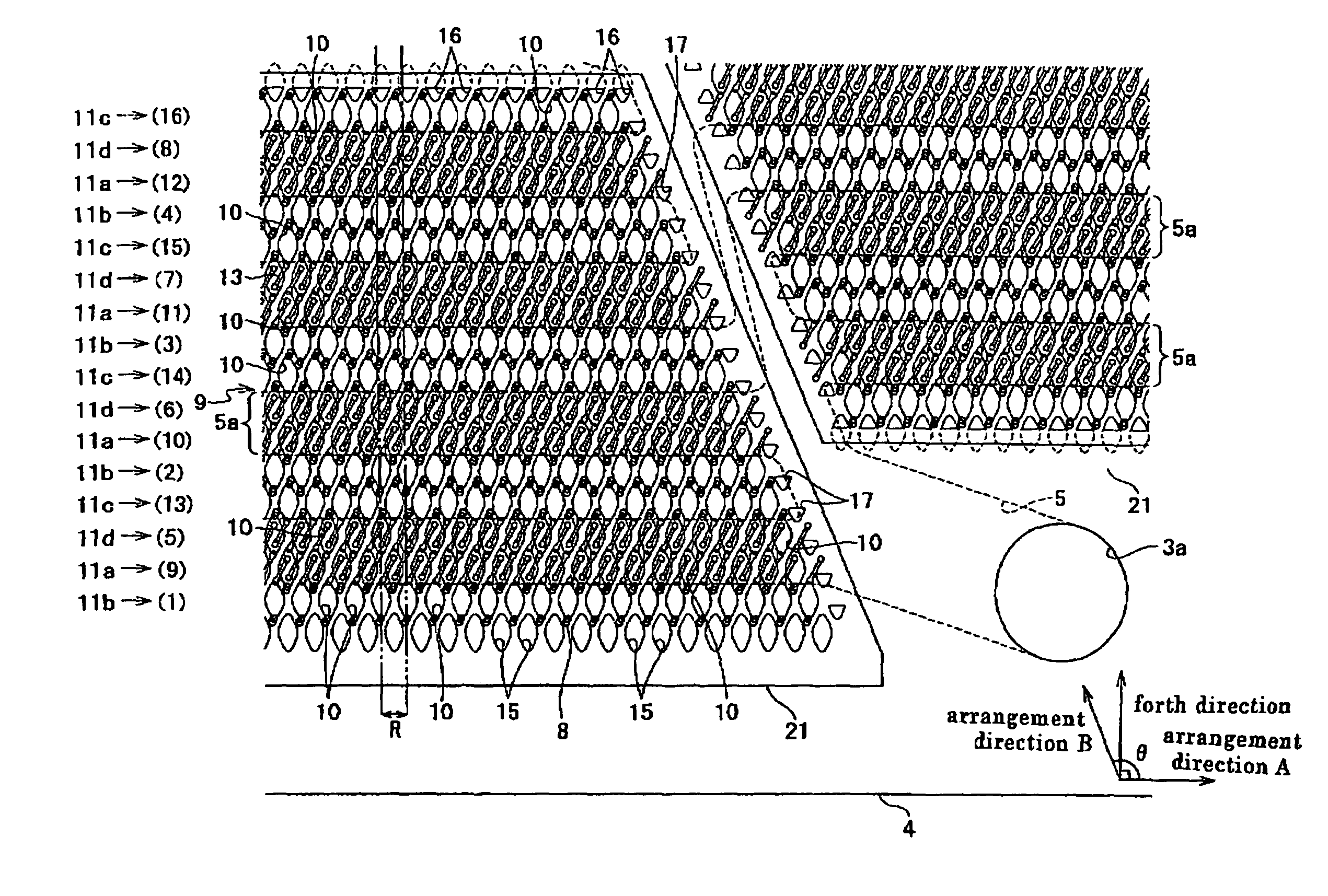

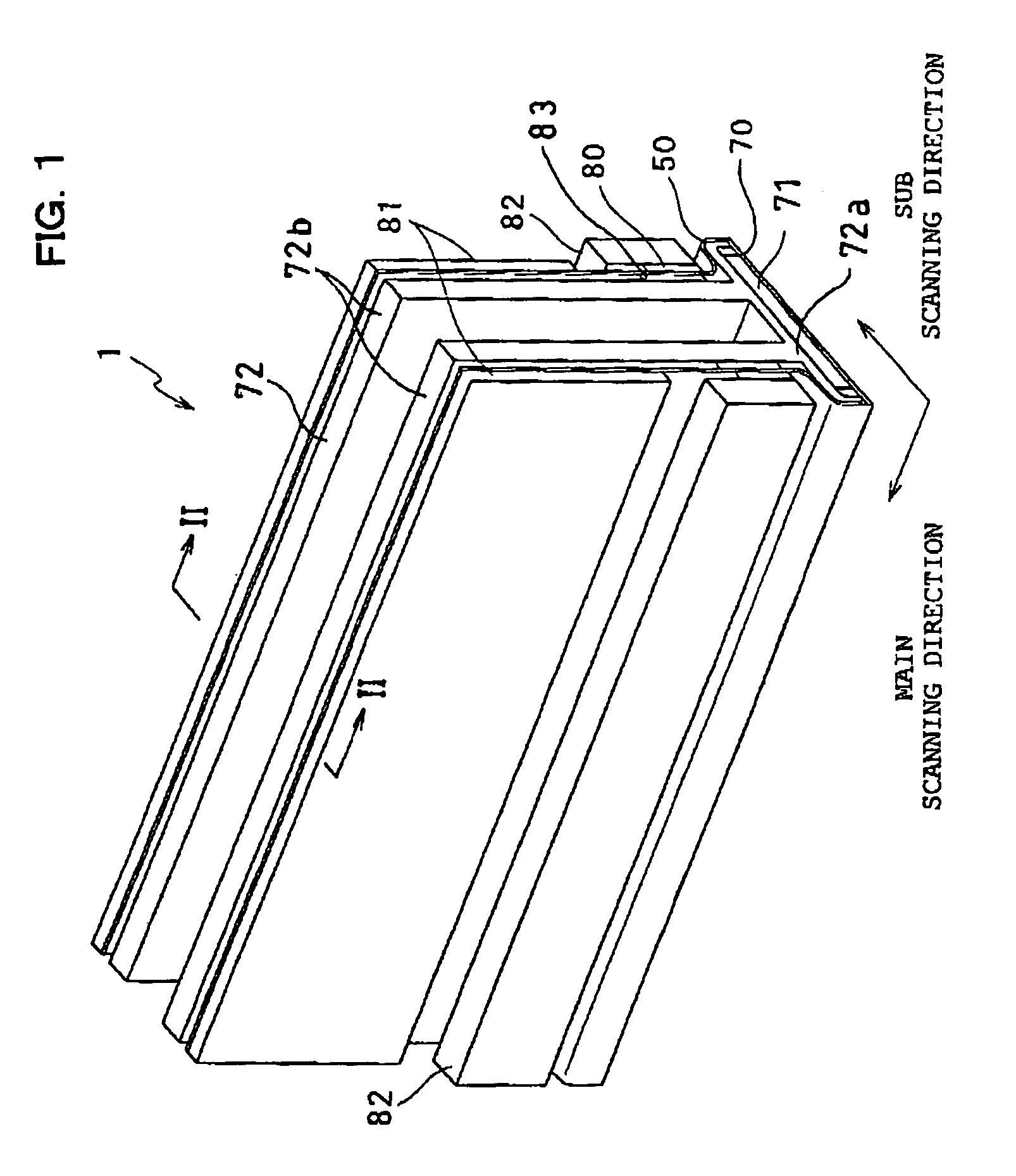

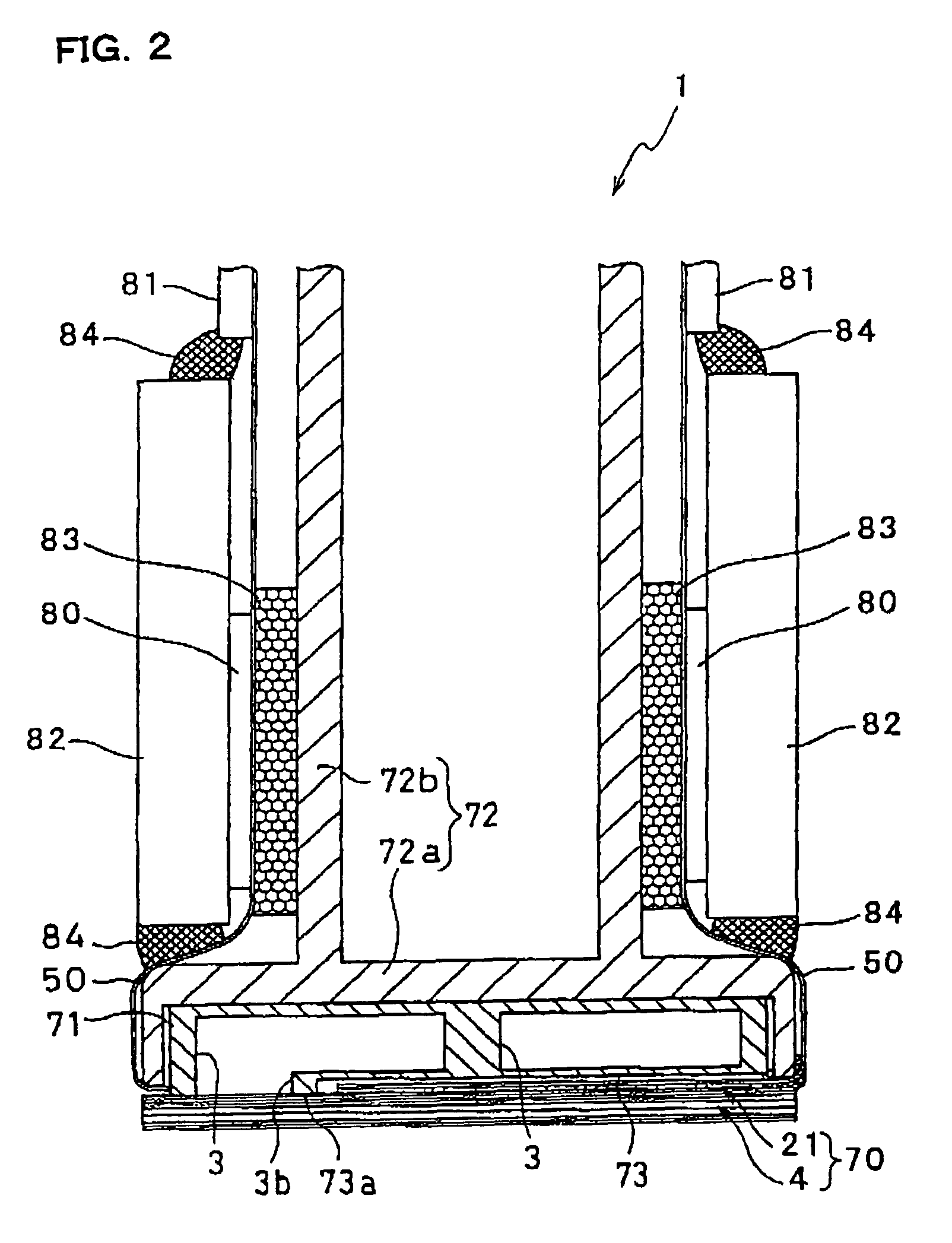

Ink-jet head

An ink-jet head comprises a passage unit with pressure chambers formed therein, and actuator units for changing the volume of each pressure chamber. In the passage unit, a plurality of cavity recesses each communicating with both a nozzle for ejecting ink and a common ink chamber and each constituting a cavity of the pressure chamber are arranged in a matrix. Further in the passage unit, formed are a plurality of peripheral recesses arranged along a whole periphery of the cavity recesses. The actuator unit closes openings of the cavity recesses to define a plurality of pressure chambers with the passage unit, and changes the volume of each pressure chamber.

Owner:BROTHER KOGYO KK

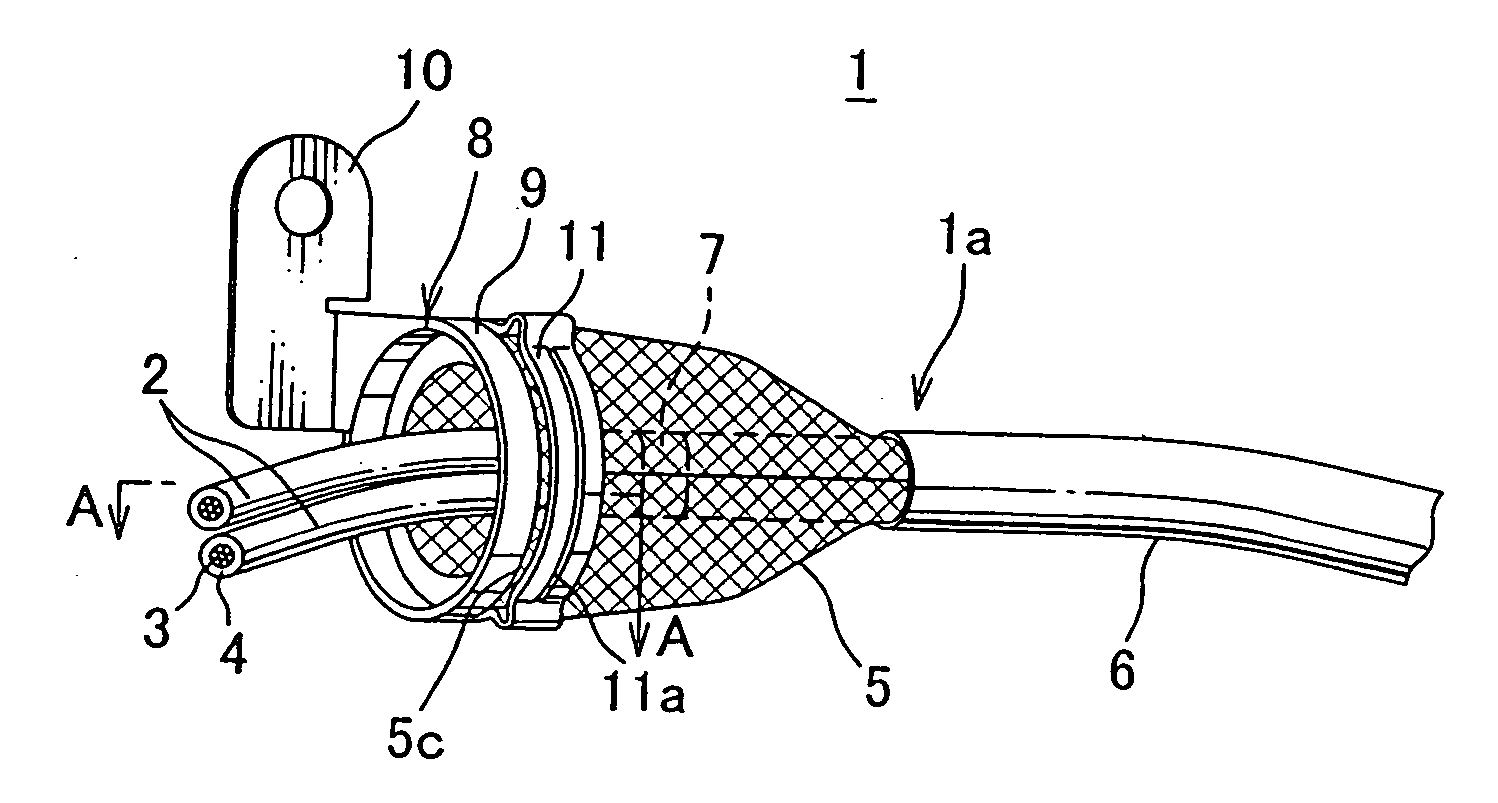

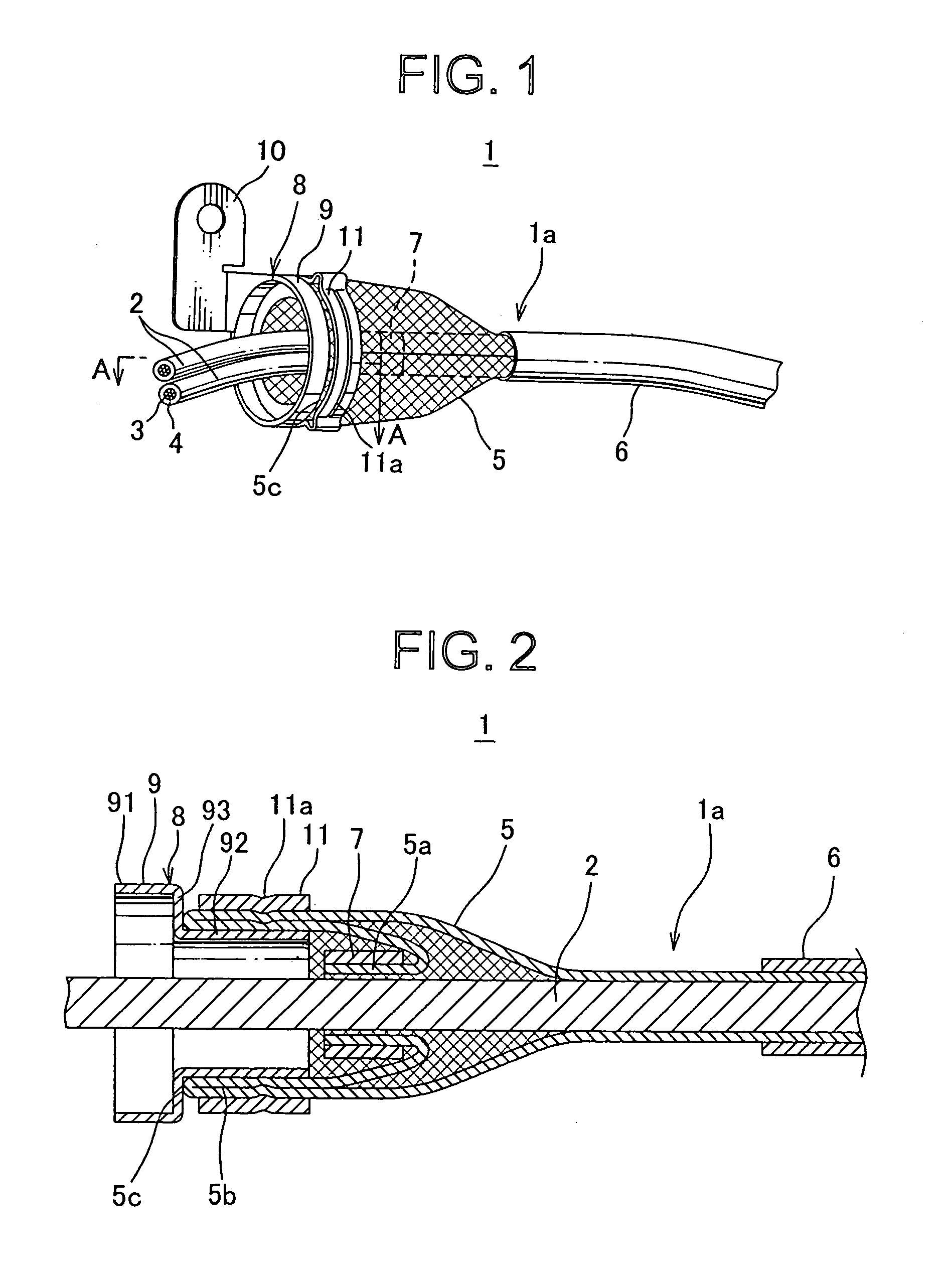

Shield wire, method for processing terminal treatment of braid of the same and apparatus for processing terminal treatment of braid of that

InactiveUS20100000788A1Processed easily and safelyImprove efficiencyElectrically conductive connectionsContact member assembly/disassemblyEngineeringElectric wire

For providing a shield wire, in which efficiency of processing terminal treatment of braid can be improved, and an apparatus for processing terminal treatment of braid, an apparatus for processing terminal treatment of braid of a shield wire includes a first hold unit holding a top of the braid covering the electric wire, a second hold unit holding a far-side of the braid, a push unit pushing the top toward the far-side so as to fold a part of braid from the top to form an overlap portion, and a forming unit forming the overlap portion into a cone shape, in which the top is located. The formed overlap portion is clamped by a set of inner and outer ring brackets.

Owner:YAZAKI CORP

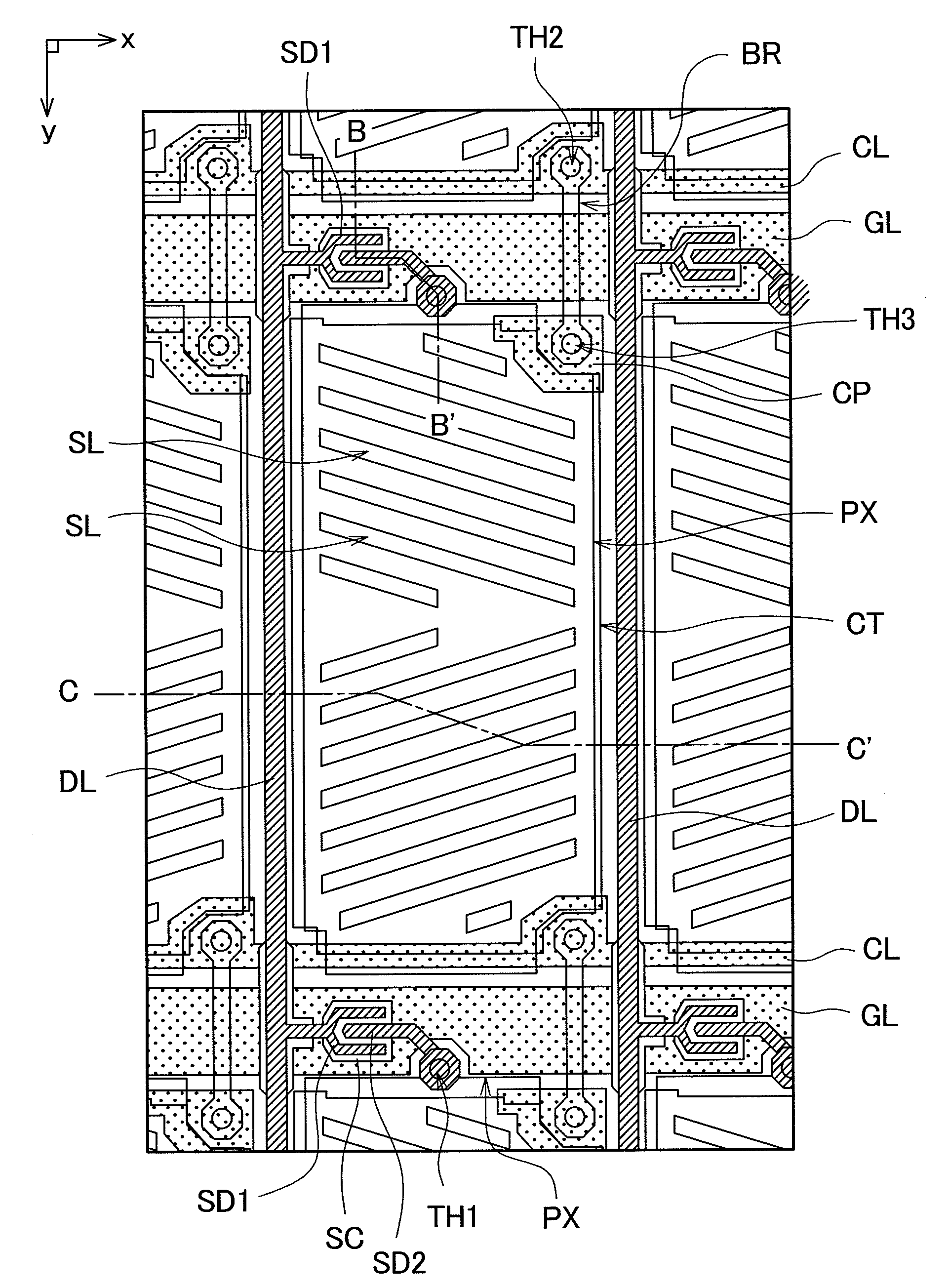

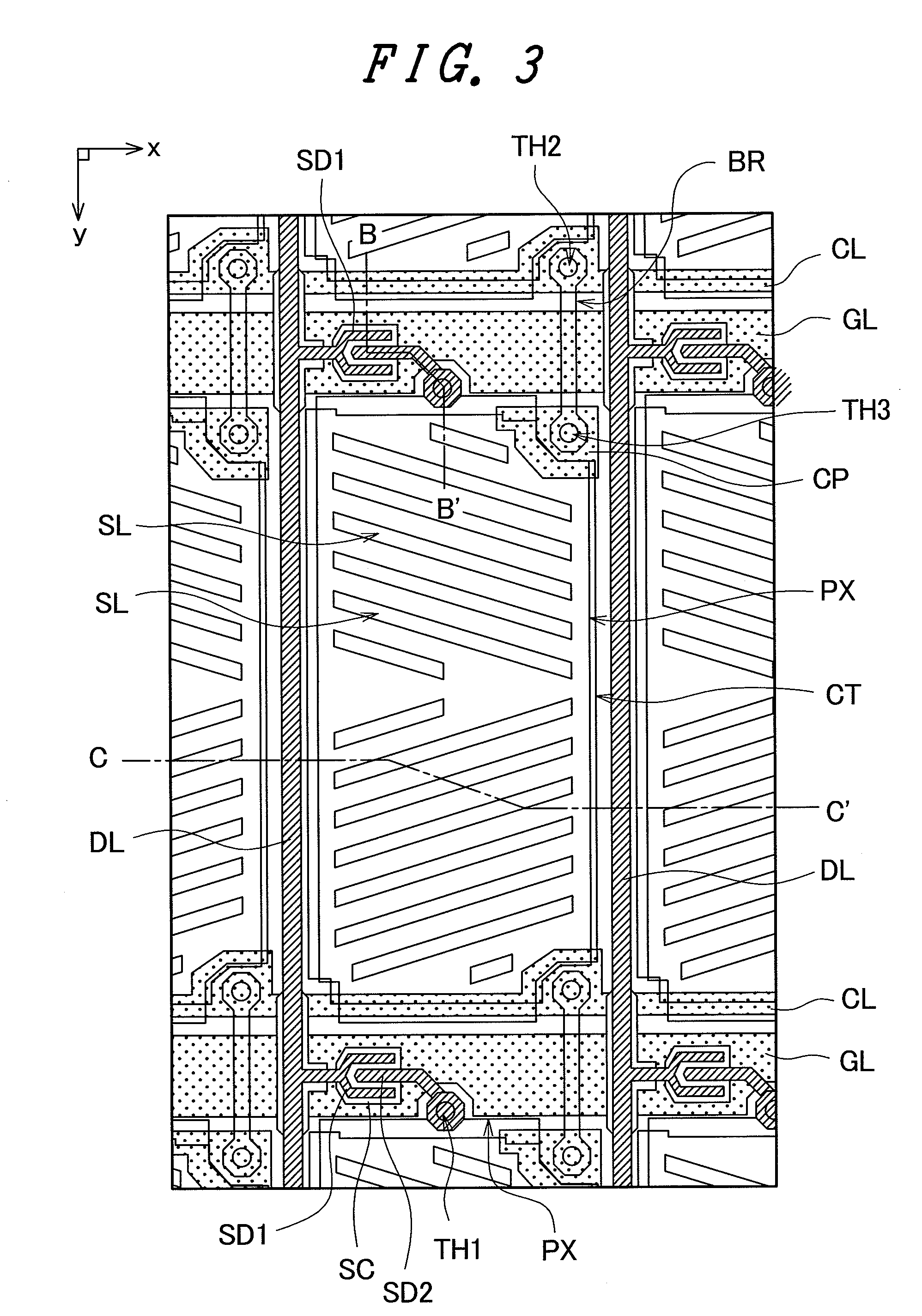

Display Device

ActiveUS20070279564A1Reduce connection failuresReduce defectsNon-linear opticsLiquid-crystal displayEngineering

The present invention reduces a connection failure between two conductive layers which are connected with each other via a through hole in a display device and reduces a defect of an orientation film formed on a TFT substrate side in a liquid crystal display device. A display device includes a display panel in which a first conductive layer formed on a surface of a substrate, and a second conductive layer which is formed over the first conductive layer as viewed from a surface of the substrate by way of a thin film layer formed of one insulation film or two or more stacked thin films including one insulation film are electrically connected with each other in an opening portion formed in the thin film layer. Out of opening ends of the opening portion of the thin film layer, an outer periphery of the opening end remote from the surface of the substrate changes a distance from the surface of the substrate one time or more during one turn of the outer periphery.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Method for manufacturing semiconductor device

InactiveUS20090305467A1Reduce thicknessSmall sizeSemiconductor/solid-state device detailsSolid-state devicesProduction rateDevice material

An object is to provide a highly reliable semiconductor device that is reduced in thickness and size and has tolerance to external stress and electrostatic discharge. Another object is to prevent defective shapes and defective characteristics due to the external stress or an electrostatic discharge in the manufacturing process, and to manufacture a semiconductor device with high yield. Still another object is to manufacture a semiconductor device at low cost and with high productivity. With the use of a conductive shield covering a semiconductor integrated circuit, electrostatic breakdown (malfunctions of the circuit or damages of a semiconductor element) due to electrostatic discharge of the semiconductor integrated circuit is prevented. The conductive shield is formed so that at least the conductive shields on the top and bottom surfaces are electrically connected by a plating method. In addition, a semiconductor device can be formed at low cost with high productivity because a plating method is used for the formation of the conductive shield.

Owner:SEMICON ENERGY LAB CO LTD

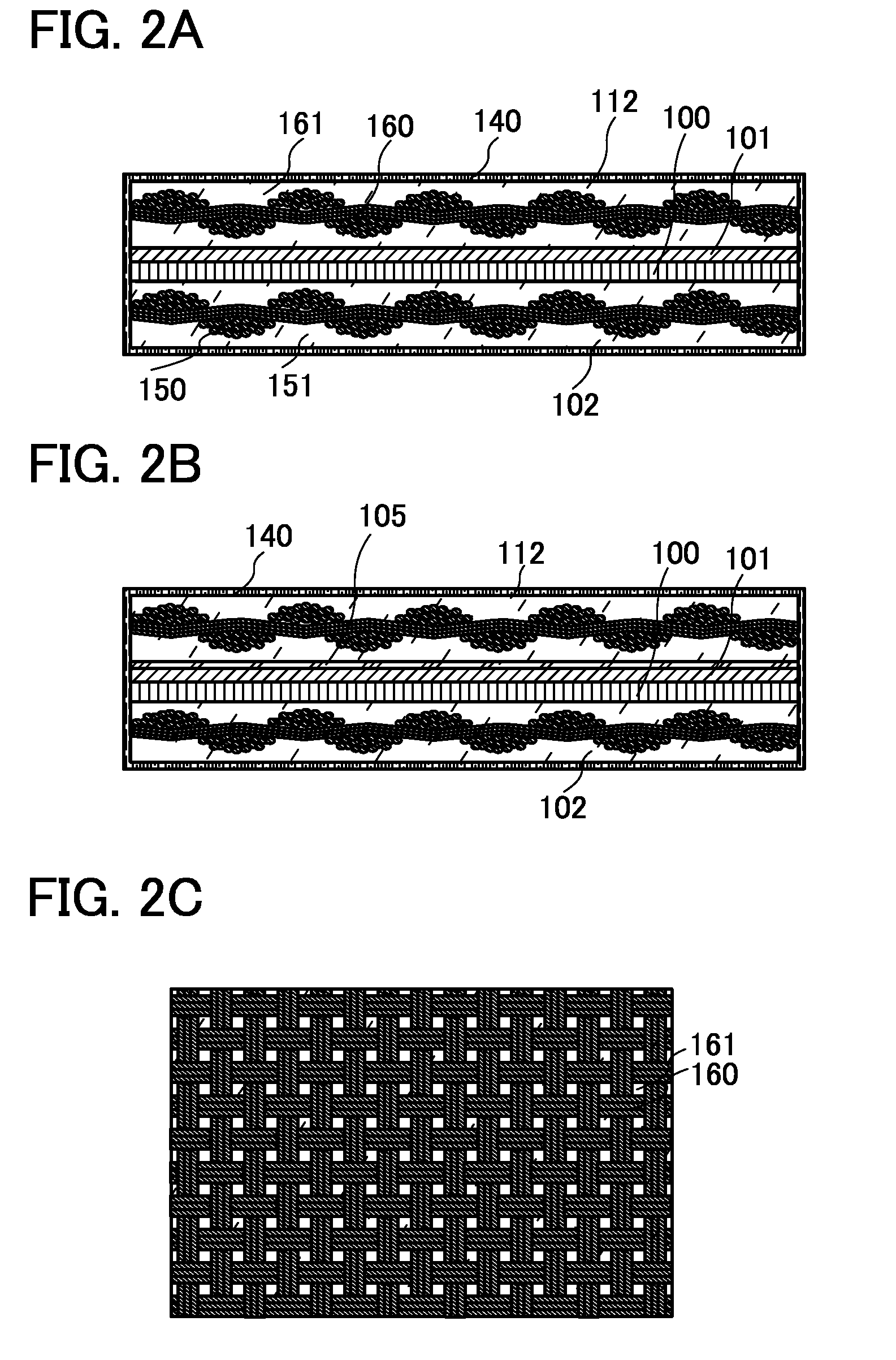

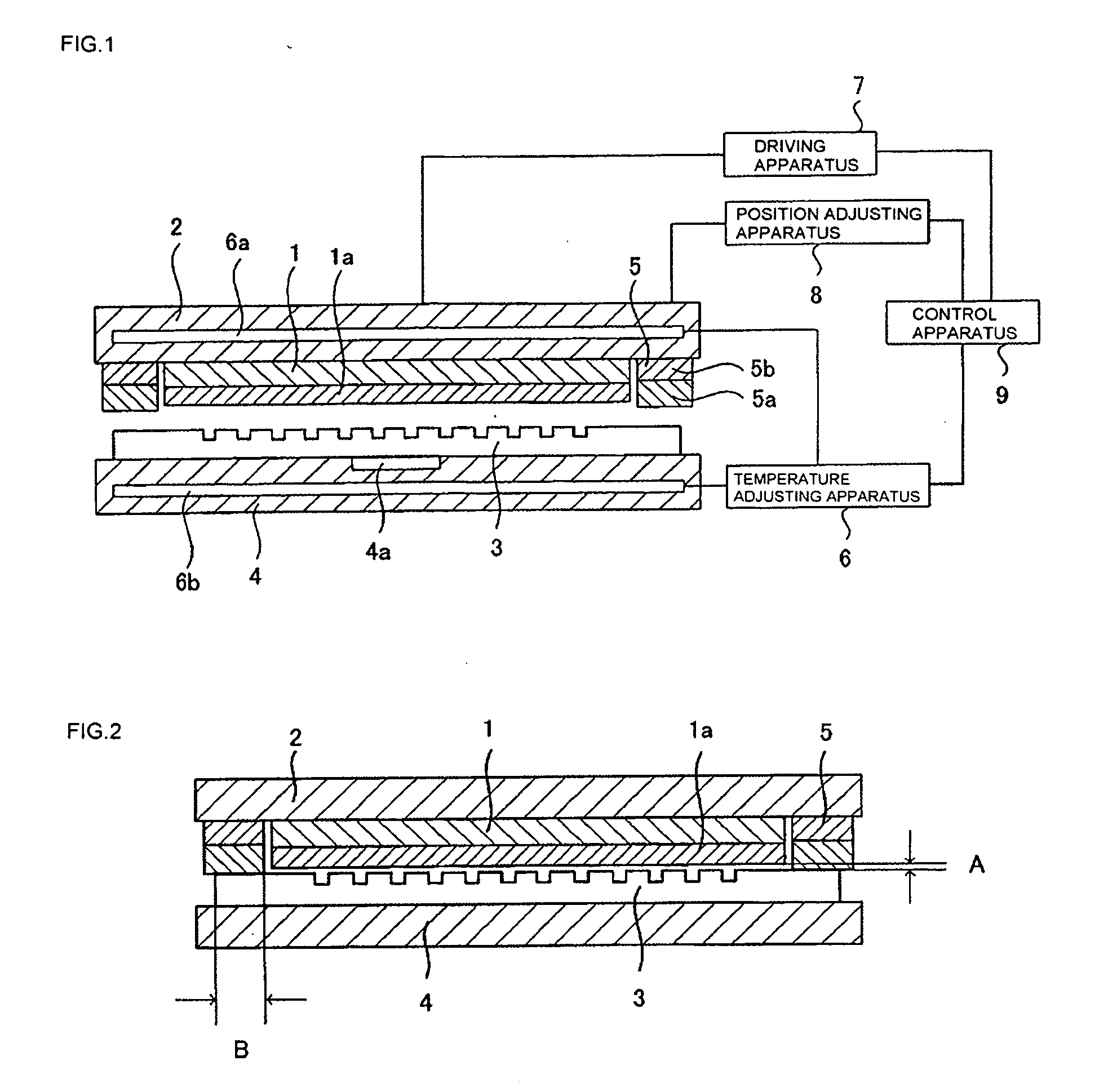

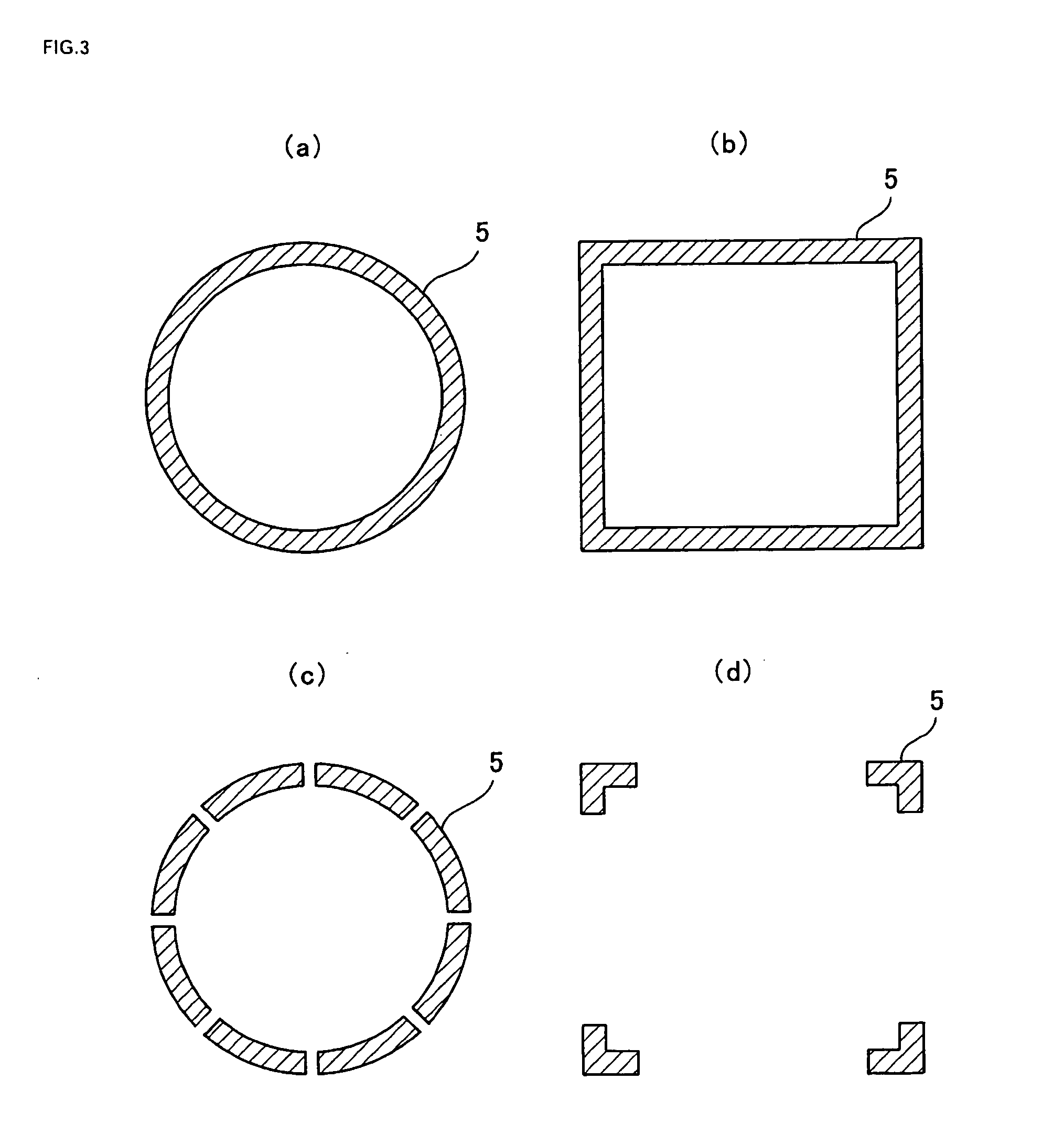

Imprint Method and Imprint Apparatus

InactiveUS20090273119A1Accurately pattern shapePrecise positioningNanoinformaticsConfectioneryThermal deformationMaterials science

[Problems] In an imprint method, any displacement of a pattern shape due to thermal deformation of a mold is prevented and the pattern shape is formed accurately on a substrate.[Solving Means] The present invention provides an imprint method for pressing a mold 3 having a pattern formed on a surface thereof against a transfer layer 1a on a substrate 1 to replicate the shape of the pattern of the mold 3 to the transfer layer 1a. A peripheral portion of the surface of the mold 3 is held by a retaining component 5 onto a mold holding component 4, and in this state, the mold 3 is pressed against the transfer layer 1a on the substrate 1.

Owner:PIONEER CORP

Substrate processing apparatus

ActiveUS7604424B2Avoid contactAvoid DimensionsLiquid processingSemiconductor/solid-state device manufacturingComputer science

A substrate processing apparatus comprises an indexer block, an edge-cleaning processing block, an anti-reflection film processing block, a resist film processing block, a development processing block, a resist cover film processing block, a resist cover film removal block, a cleaning / drying processing block and an interface block. An exposure device is arranged adjacent to the interface block of the substrate processing apparatus. In the exposure device, exposure processing is applied to a substrate by a liquid immersion method. In the edge-cleaning processing group in the edge-cleaning processing block, an edge of the substrate before exposure processing is cleaned.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

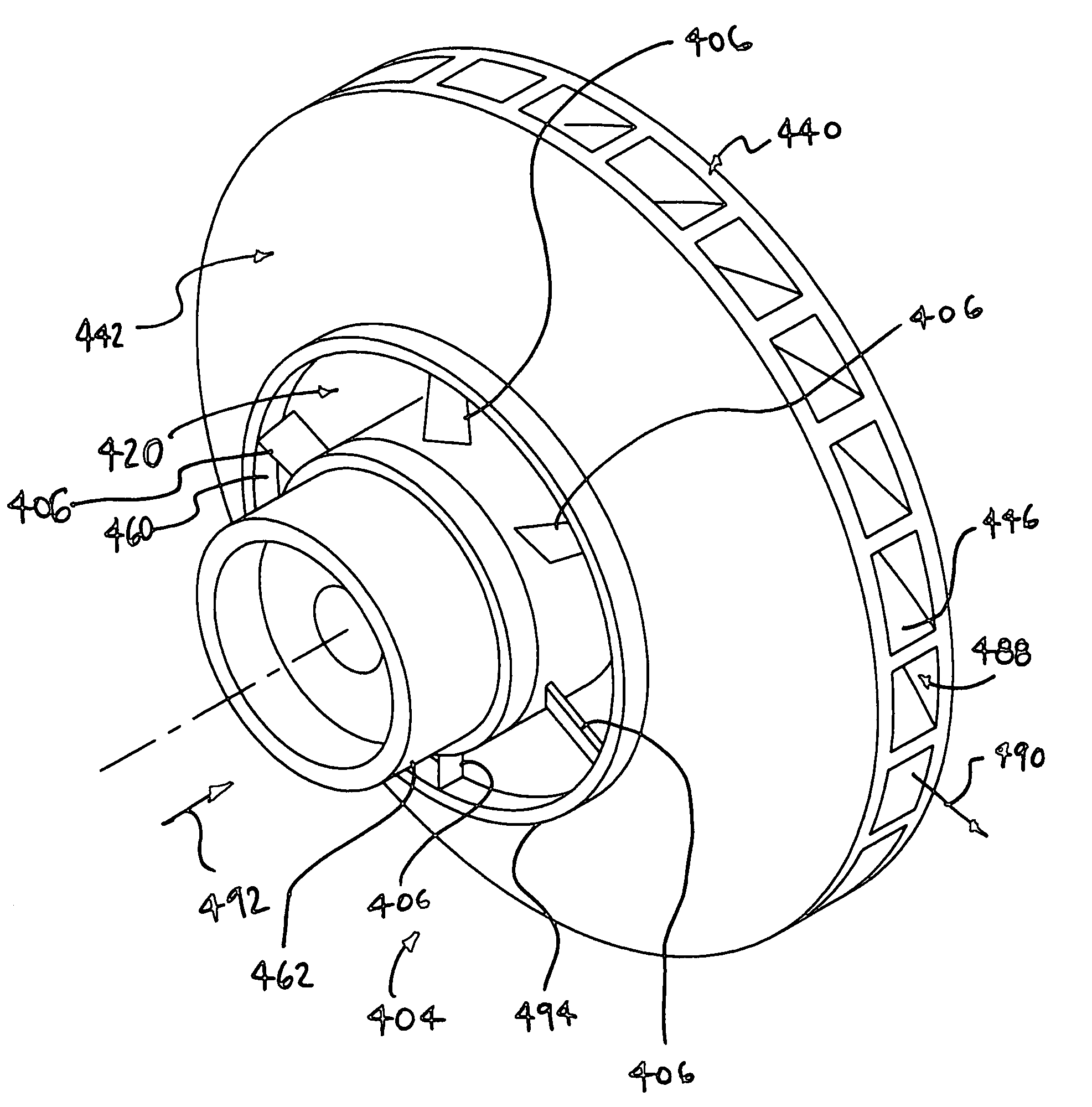

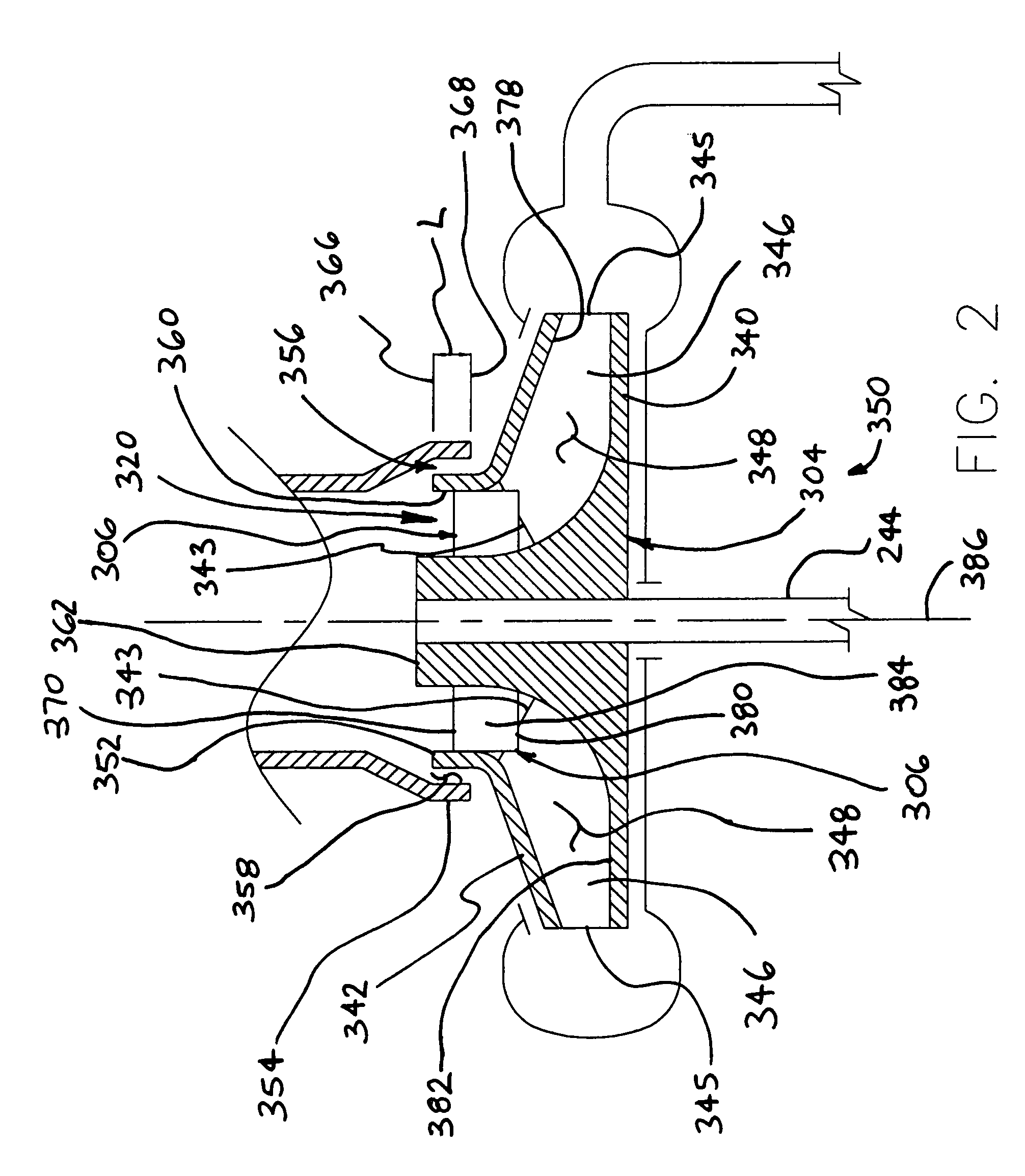

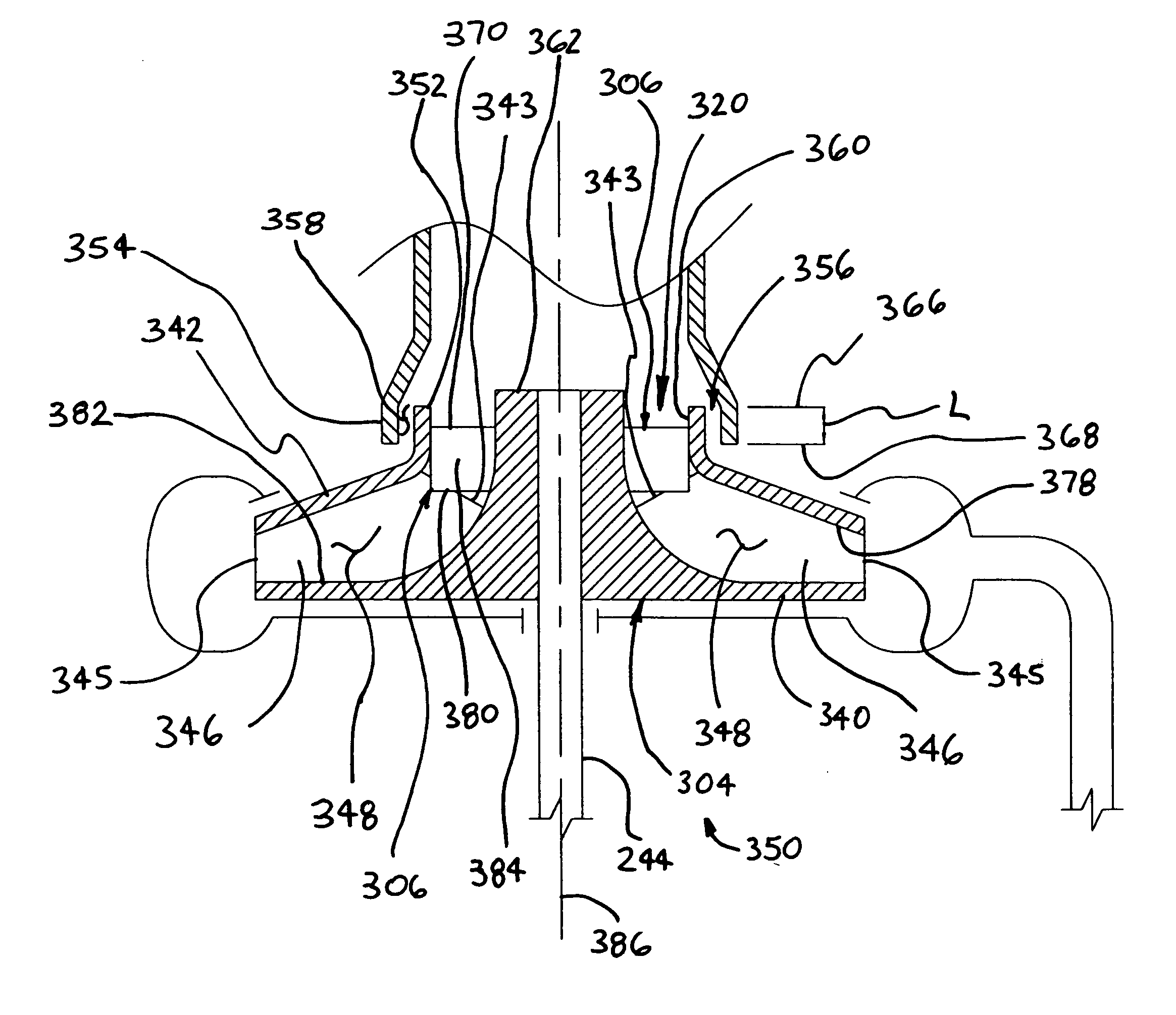

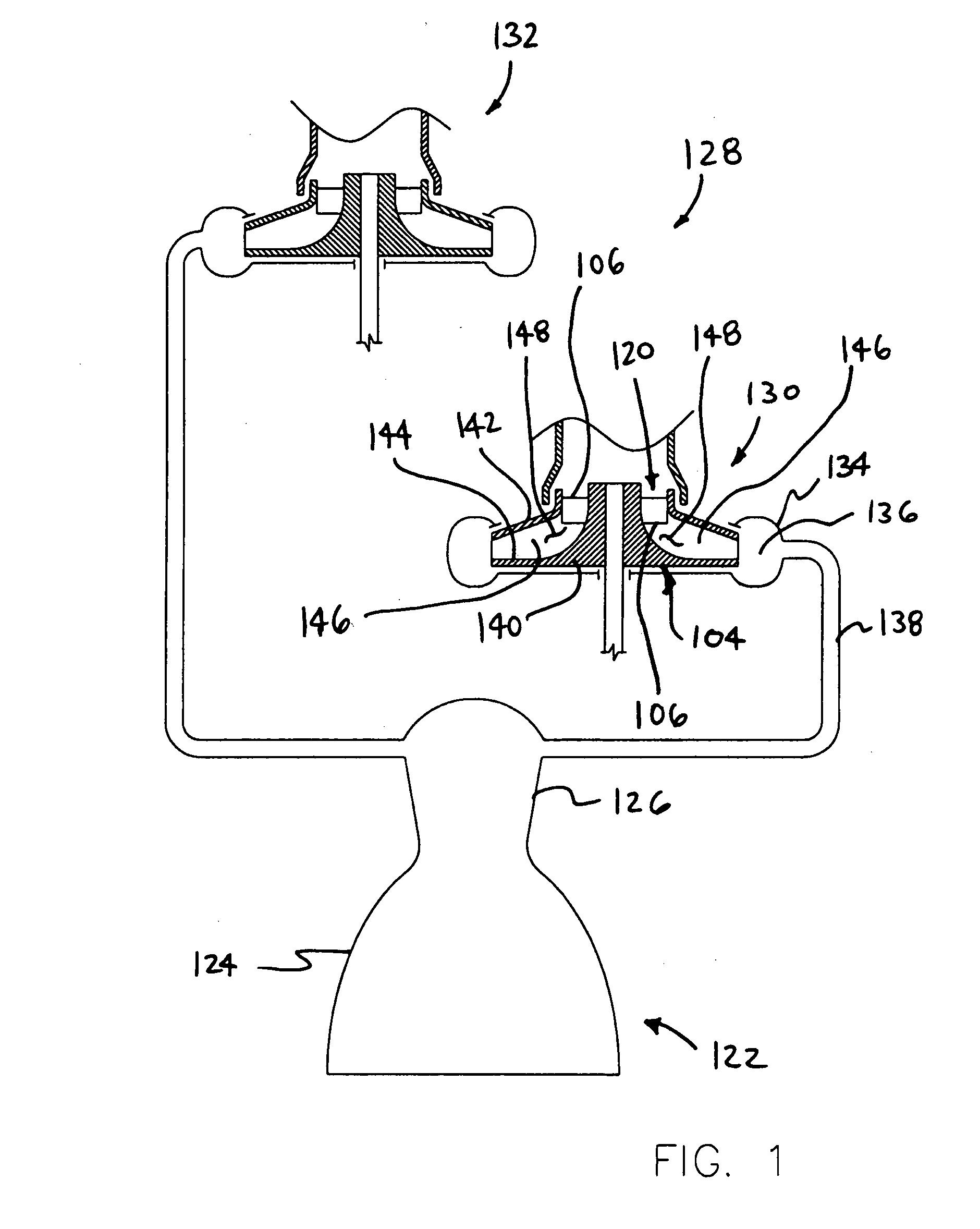

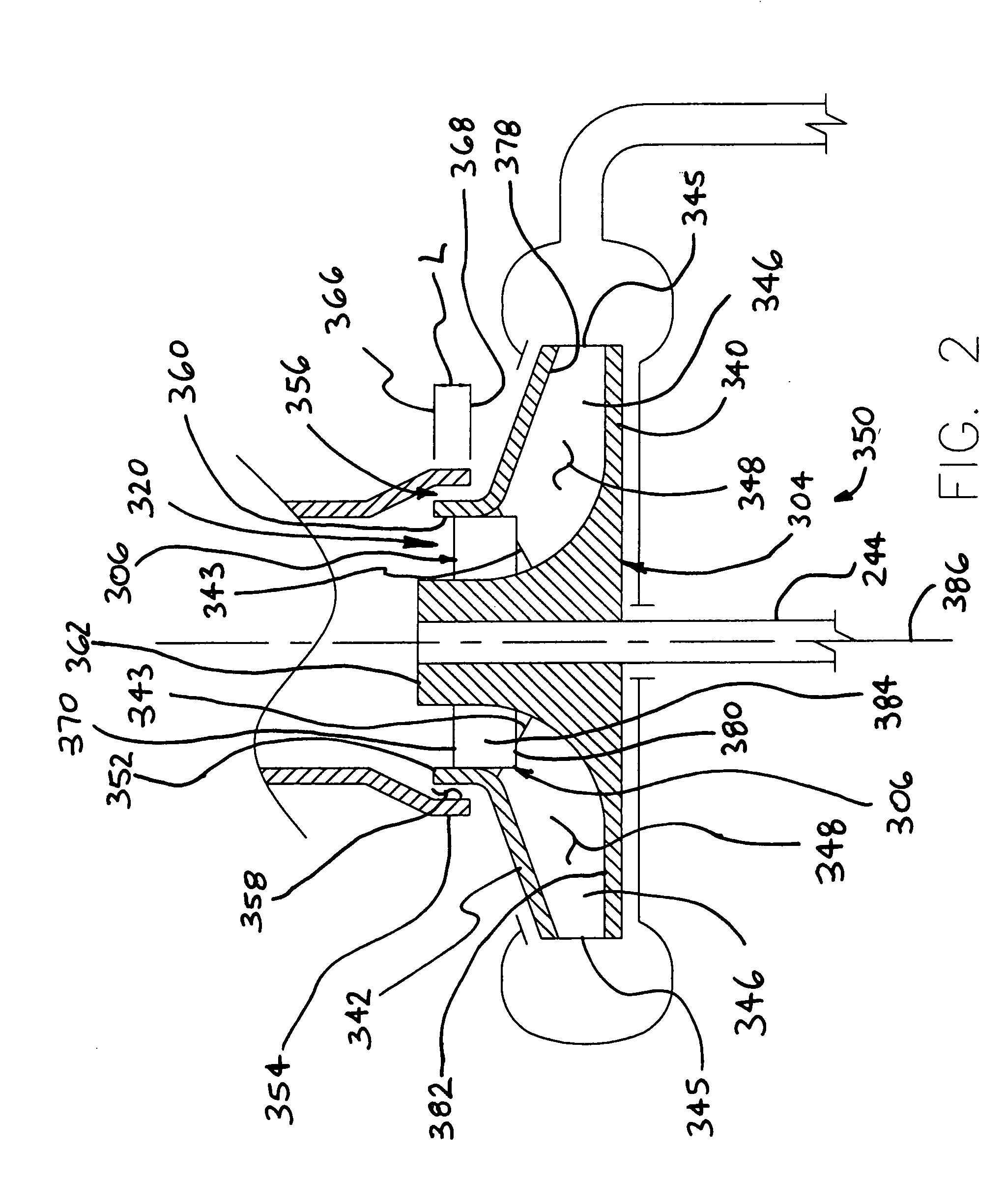

Inlet partial blades for structural integrity and performance

Methods and apparatus for conveying fluids (e.g., liquids, gases, and mixtures thereof) are disclosed. A turbopump in accordance with an exemplary implementation of the present invention comprises an impeller defining at least one flow channel and a shroud defining an opening communicating with the at least one flow channel. In certain advantageous implementations, at least one inlet partial of the impeller extends into the opening defined by the shroud. The at least one inlet partial may advantageously be capable of supporting the opening in the shroud. In some cases, the impeller may include a plurality of these inlet partials.

Owner:THE BOEING CO +1

Apparatus for laser materials processing

ActiveUS20150060422A1Prevent and reduce stressPrevent and reduce and crackAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSelective laser sintering

An apparatus for laser materials processing including a laser (4) for generating a laser beam and a laser head (5) which is movable along at least one spatial direction and is connected to the laser via a light guide, and which emits a laser beam (7) capable of processing a material. The present invention also relates to an apparatus for selective laser melting or selective laser sintering having an apparatus for laser materials processing.

Owner:MTU AERO ENGINES GMBH

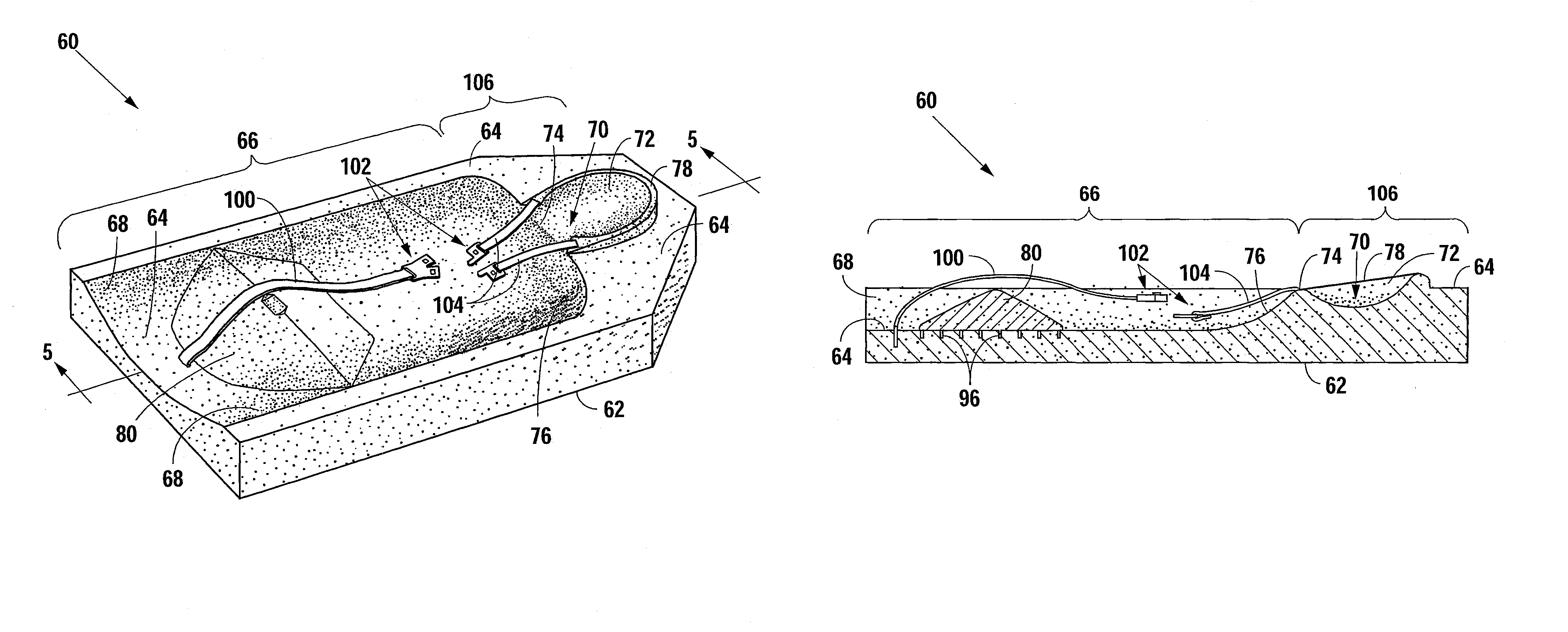

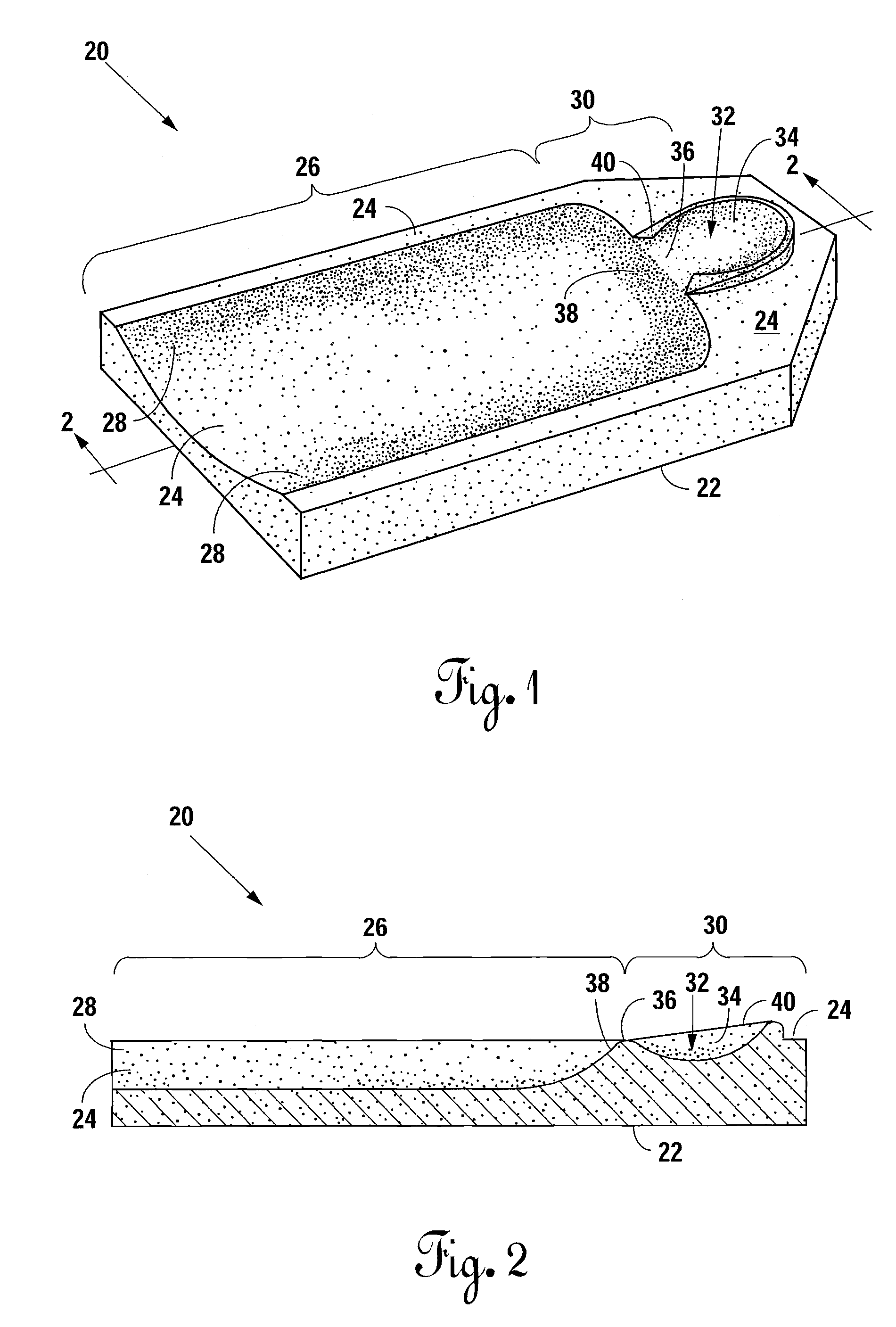

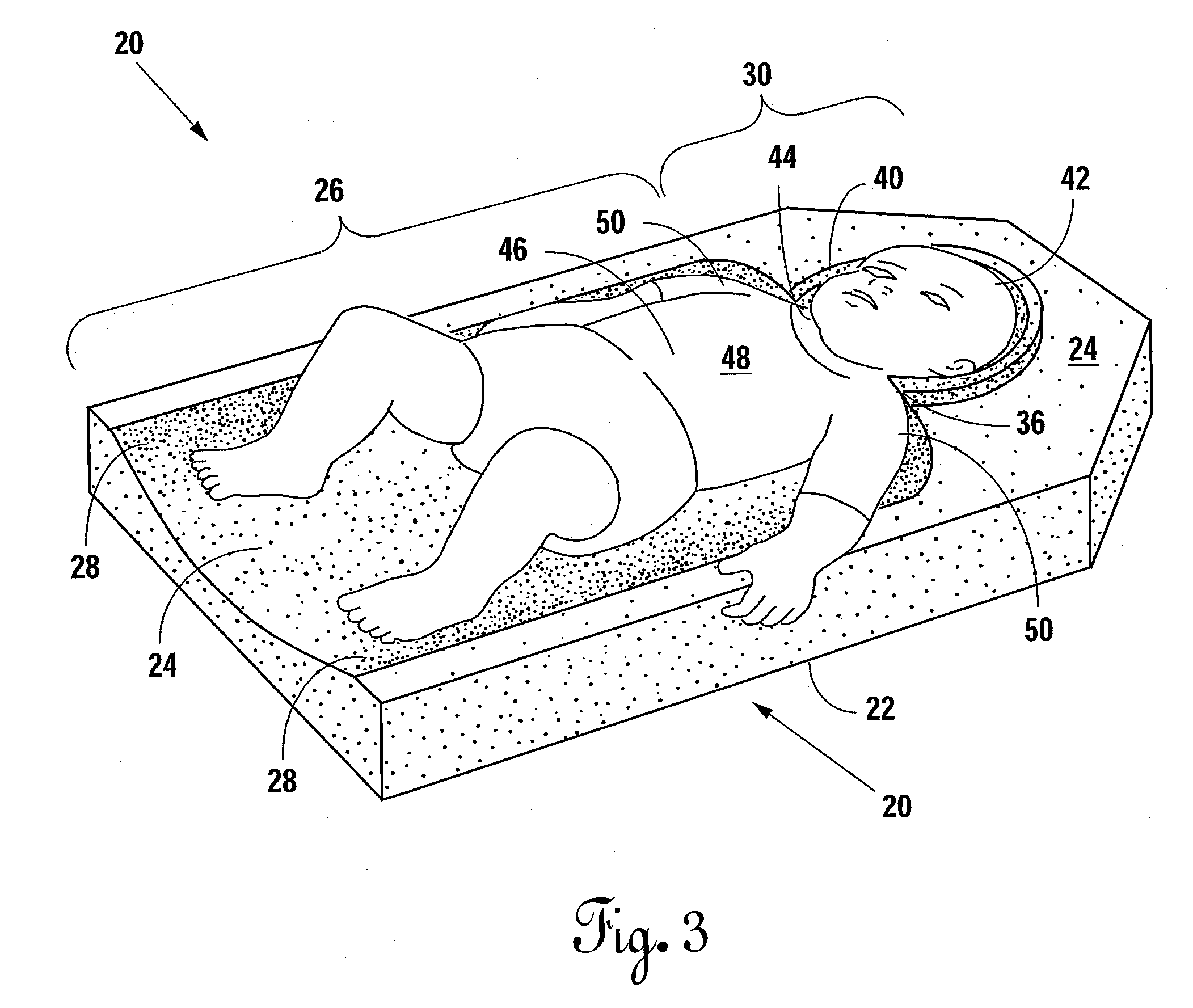

Mattress incorporating a headrest for preventing and correcting non-synostotic cranial deformities in infants

ActiveUS7647660B2Avoid shapeNormal shaping of the infantStuffed mattressesKids bedsCRANIAL DEFORMITYDeformity

Owner:TULLOUS MICAM W

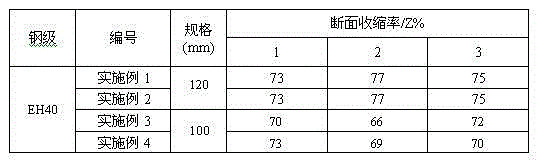

Extra-thick tempering EH40 steel for ocean engineering and preparation method thereof

The invention relates to extra-thick tempering EH40 steel for ocean engineering. A steel plate comprises the following chemical components by weight percent: 0.12 to 0.15 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.0050 percent of S, 0.020 to 0.050 percent of Nb, 0.020 to 0.050 percent of V, 0.008 to 0.020 percent of Ti, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and balance of Fe and unavoidable impurity elements. The manufacturing process of the steel plate comprises the steps of smelting, casting, reheating, rolling and tempering. The tempering process is used for substituting the normalizing process to produce a low-scaling-ratio extra-thick plate, so that the adverse effect caused by the center segregation can be avoided.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Inlet partial blades for structural integrity and performance

ActiveUS20050152779A1Reduced scallopingImprove efficiencyPropellersPump componentsImpellerEngineering

Methods and apparatus for conveying fluids (e.g., liquids, gases, and mixtures thereof) are disclosed. A turbopump in accordance with an exemplary implementation of the present invention comprises an impeller defining at least one flow channel and a shroud defining an opening communicating with the at least one flow channel. In certain advantageous implementations, at least one inlet partial of the impeller extends into the opening defined by the shroud. The at least one inlet partial may advantageously be capable of supporting the opening in the shroud. In some cases, the impeller may include a plurality of these inlet partials.

Owner:THE BOEING CO +1

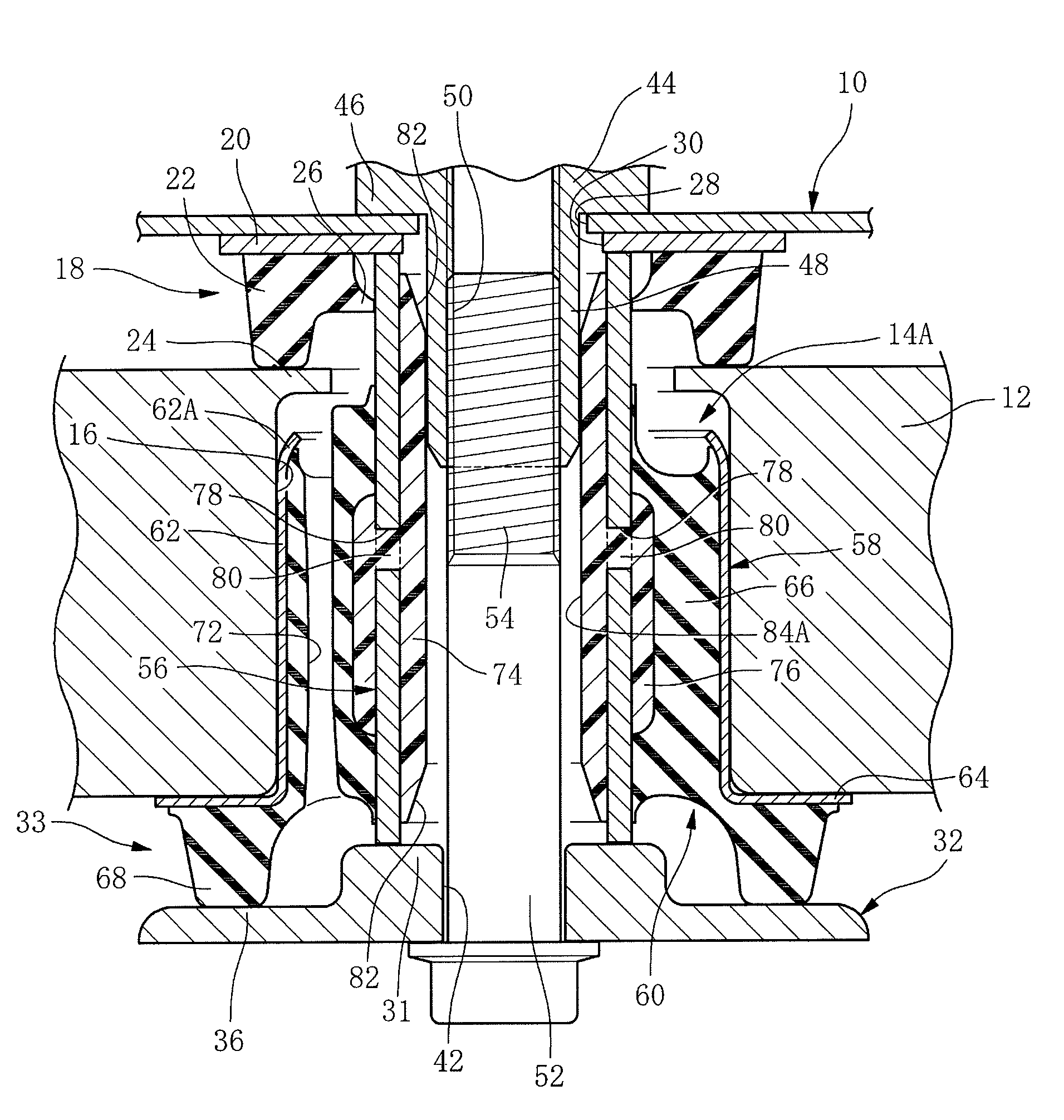

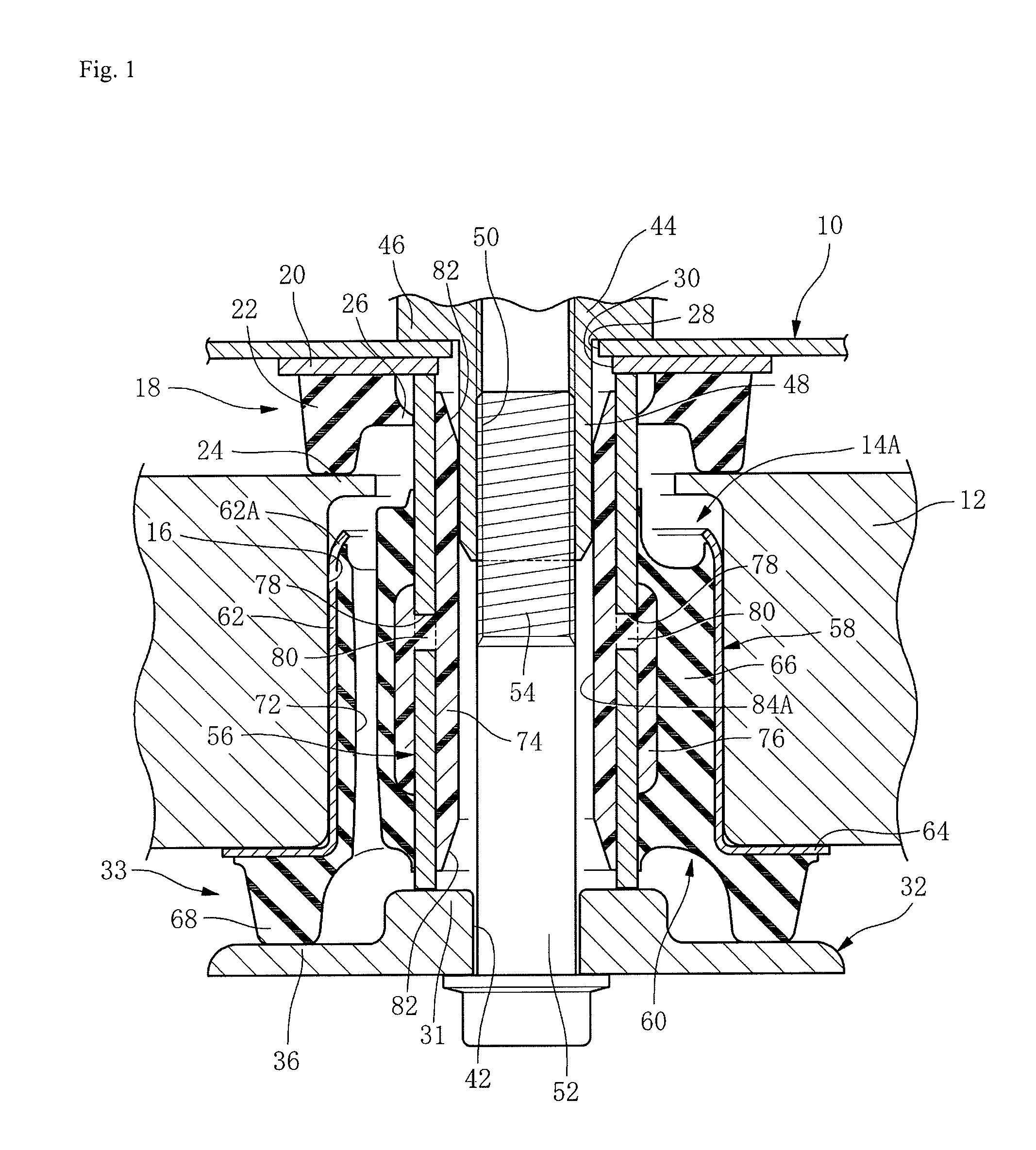

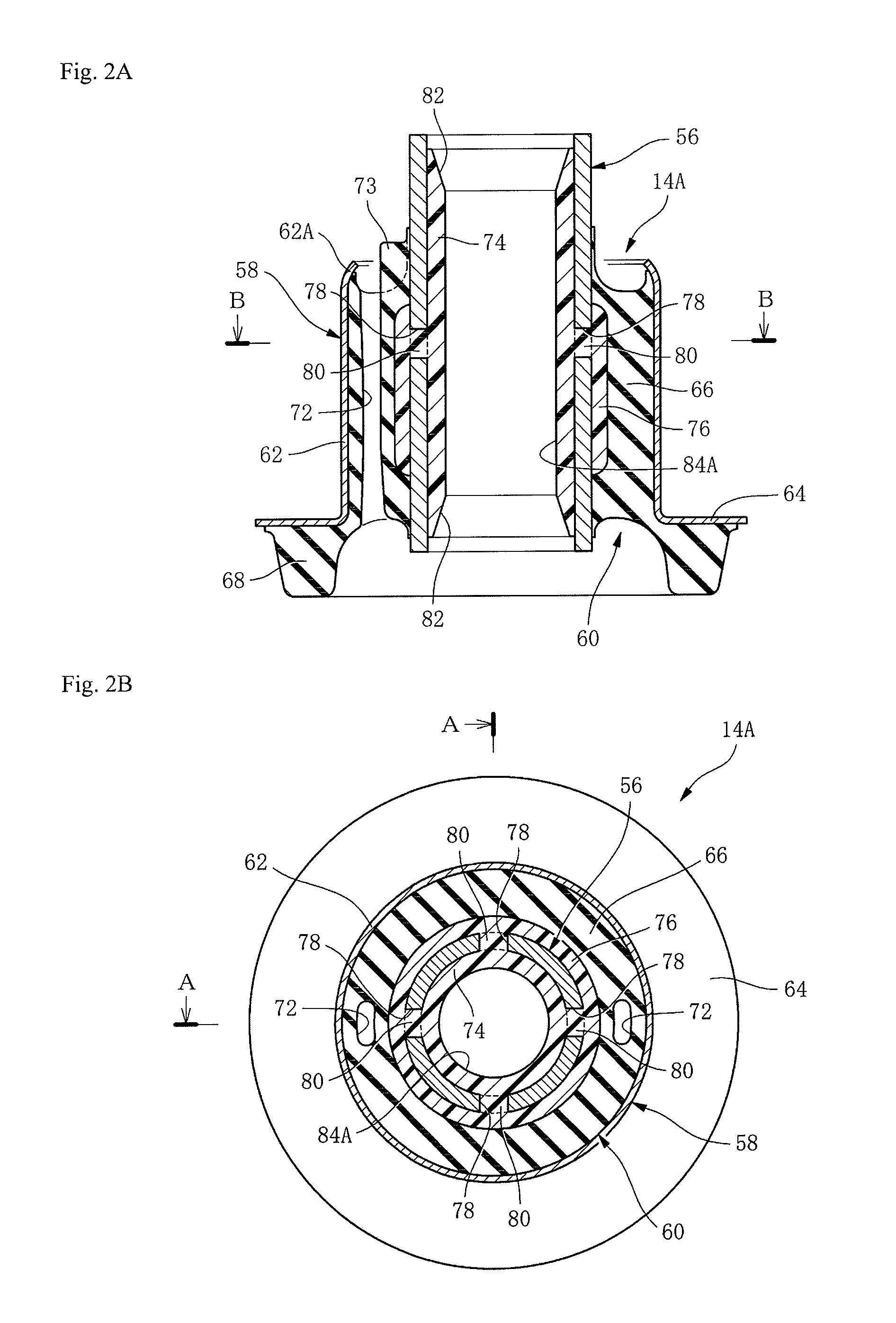

Member mount and assembly structure thereof

ActiveUS20120098178A1Avoid deformationPrevent insertionSpringsStands/trestlesElastomerBiomedical engineering

A member mount has an inner tubular member, an outer tubular member, and a rubber elastic body connecting the tubular members. An inner peripheral resin layer having an inner hole as a positional hole is layered on an internal peripheral surface of the inner tubular member and an outer peripheral resin layer is layered on an outer peripheral surface thereof. The resin layers are connected to each other in resin connection portions in connection holes passing through the inner tubular member in four positions in the circumferential direction at equal distances.

Owner:SUMITOMO RIKO CO LTD

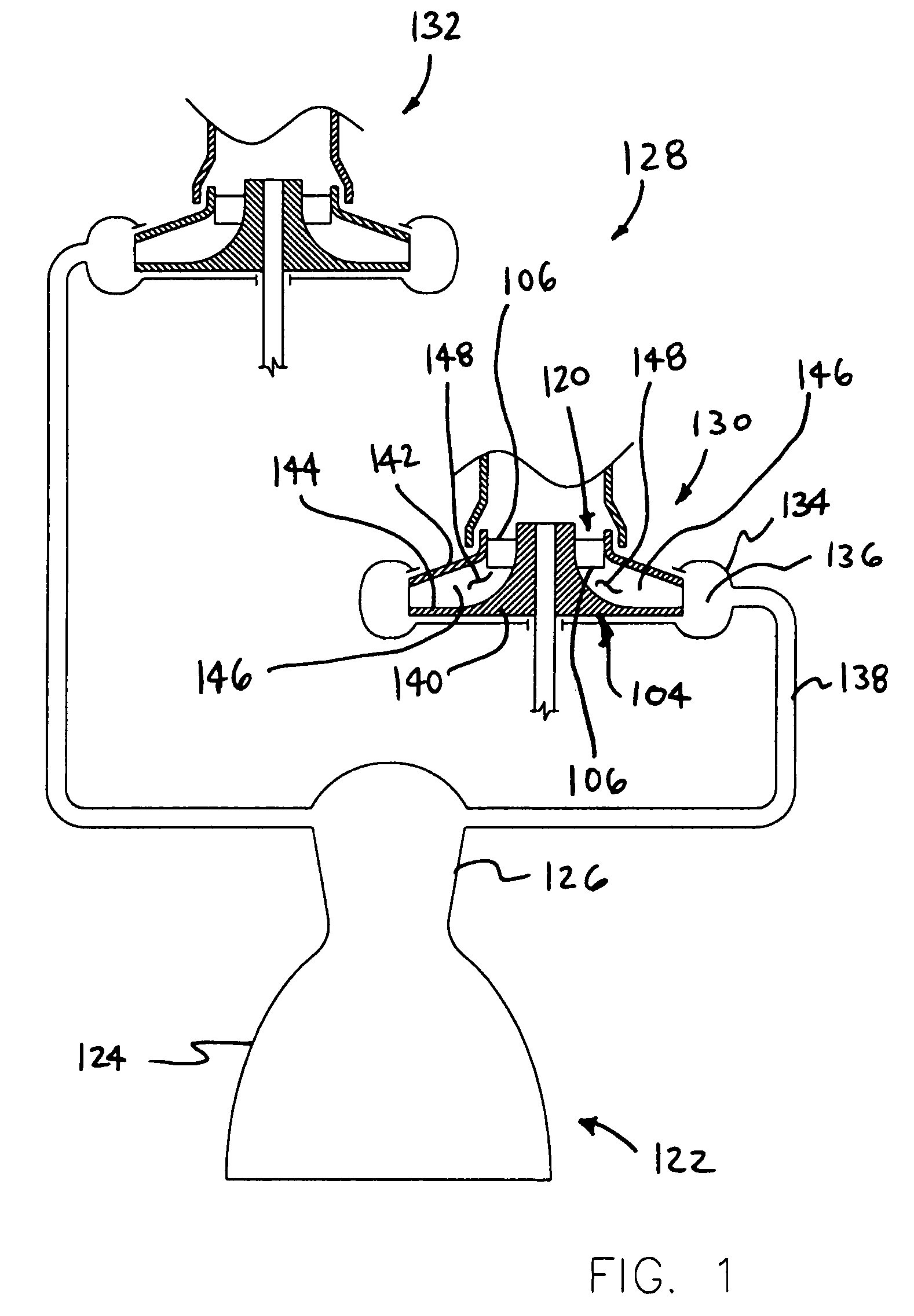

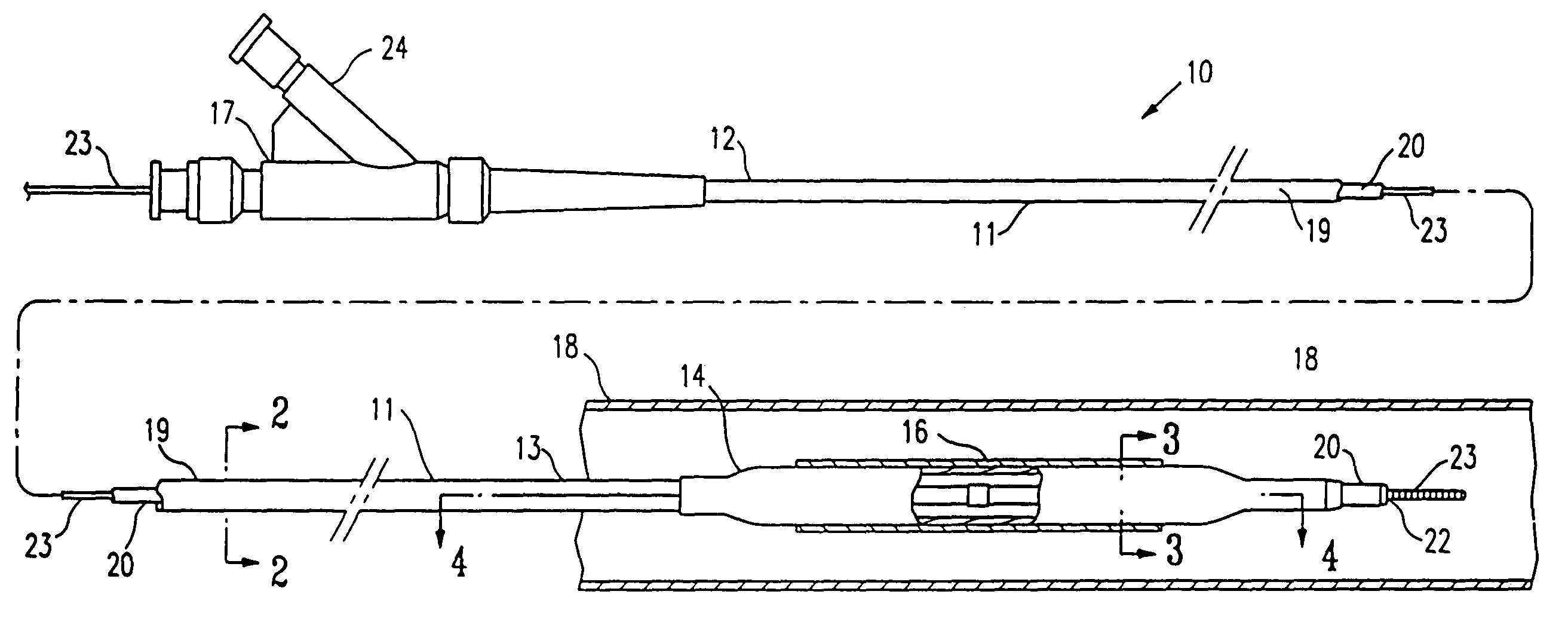

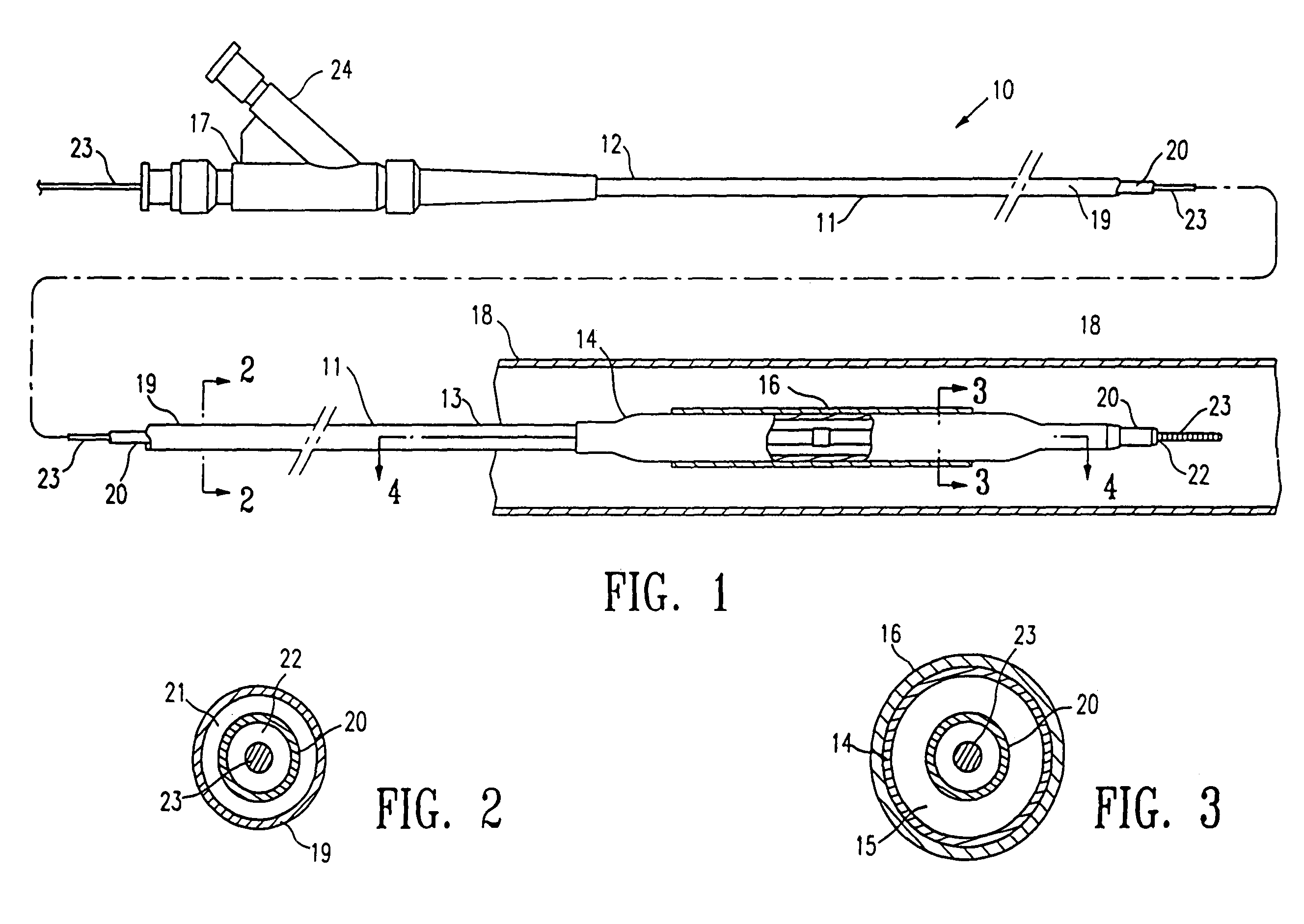

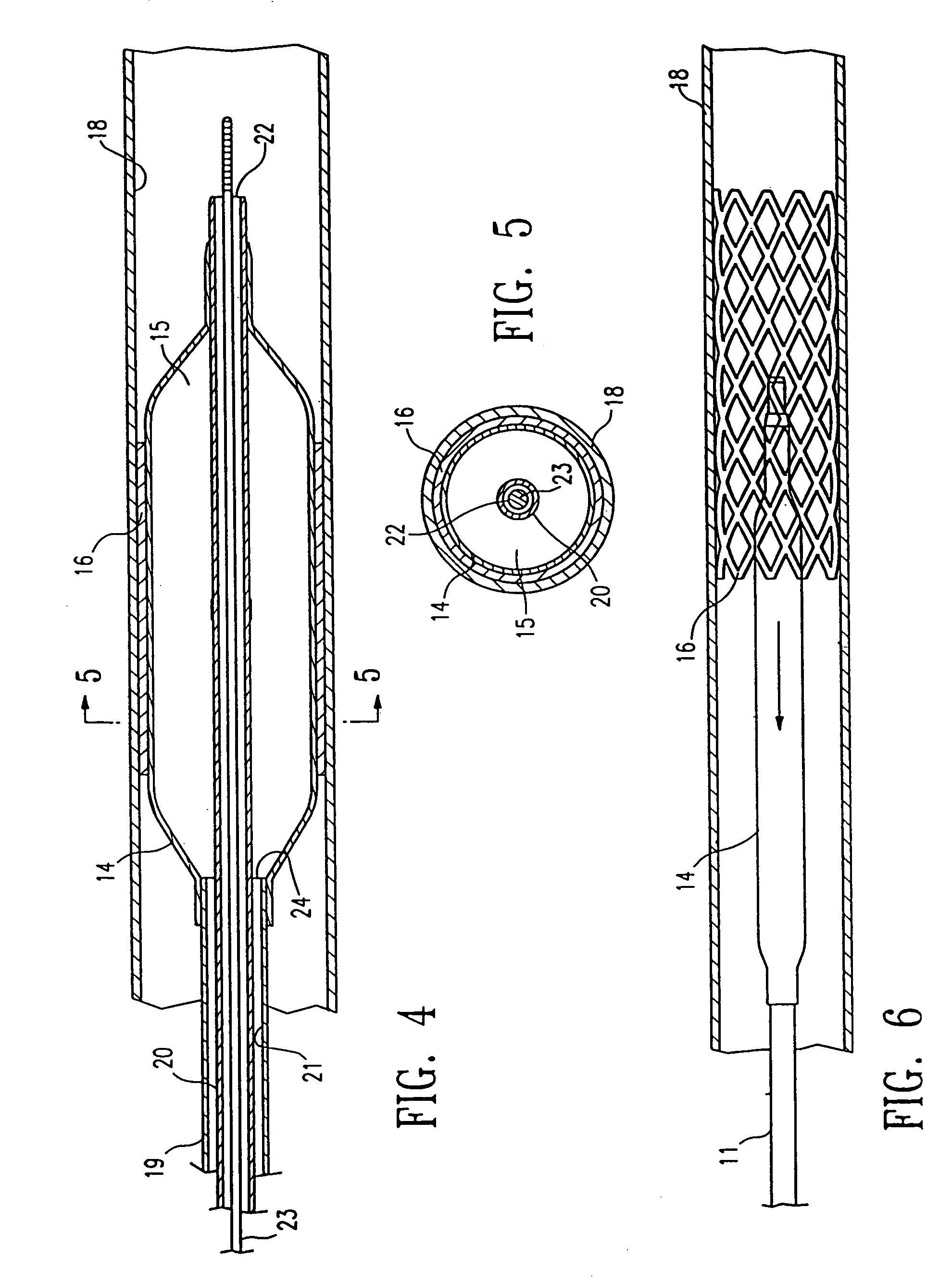

Method of making a non-compliant balloon for a catheter

InactiveUS7892469B2Improve performanceResist dilatationStentsHollow filament manufactureInsertion stentBalloon catheter

An intravascular catheter system for properly implanting a stent in a body lumen generally comprising a catheter having an elongated shaft with an inflatable balloon formed of compliant material and a stent mounted on the working length of the balloon. The balloon material is compliant within the working range of the balloon to provide substantial radial expansion. The wingless radially expansive balloon expands in a uniform manner, thereby producing uniform expansion and implantation of the stent. Another embodiment is directed to a balloon catheter, having a semi-compliant balloon or a noncompliant balloon formed at least in part of a block copolymer.

Owner:ABBOTT CARDIOVASCULAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com