Cold-hot compound die molding method for aluminum alloy sheet metal component

A technology of aluminum alloy and sheet metal parts, applied in the field of sheet metal forming, can solve problems such as cracking, low forming efficiency, and wrinkling, and achieve the effects of improving production efficiency, shortening forming time, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

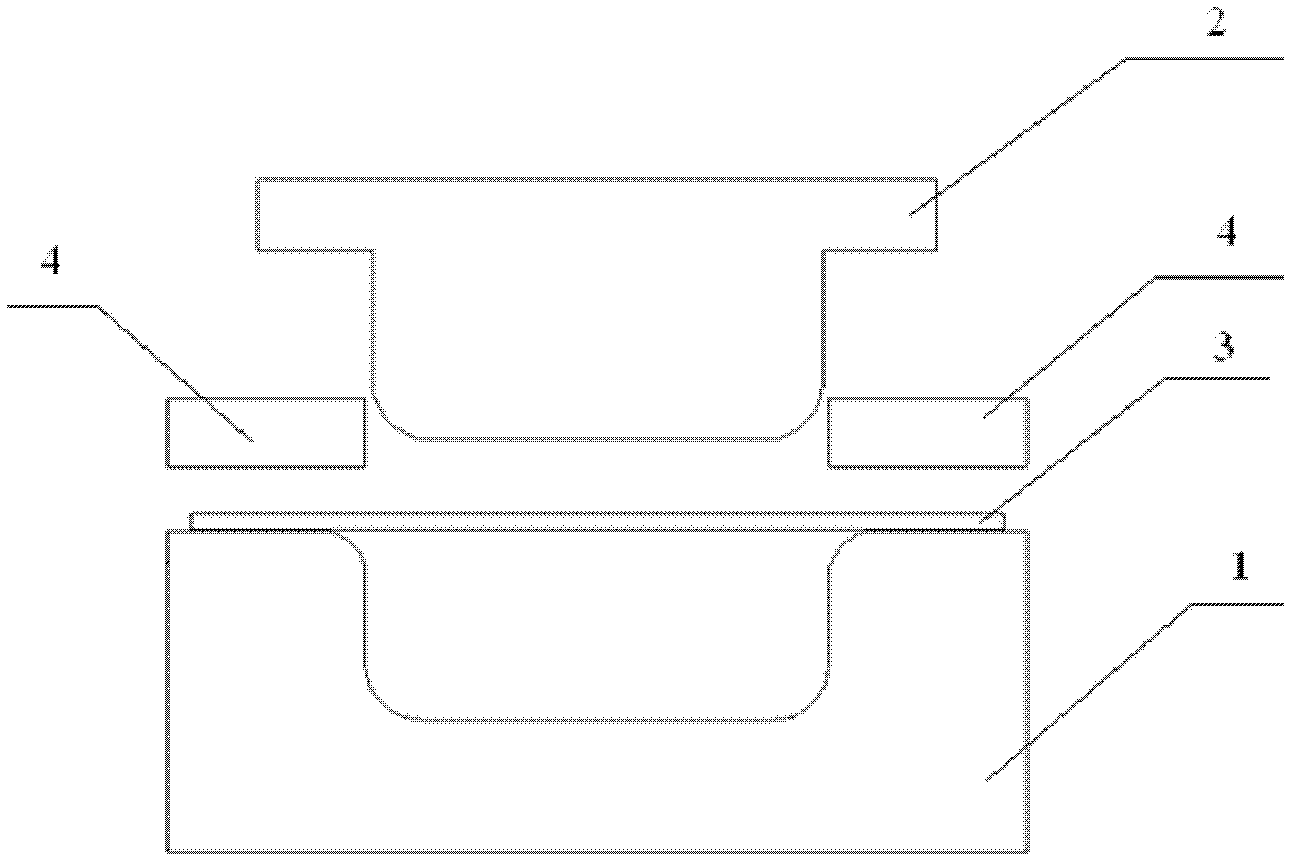

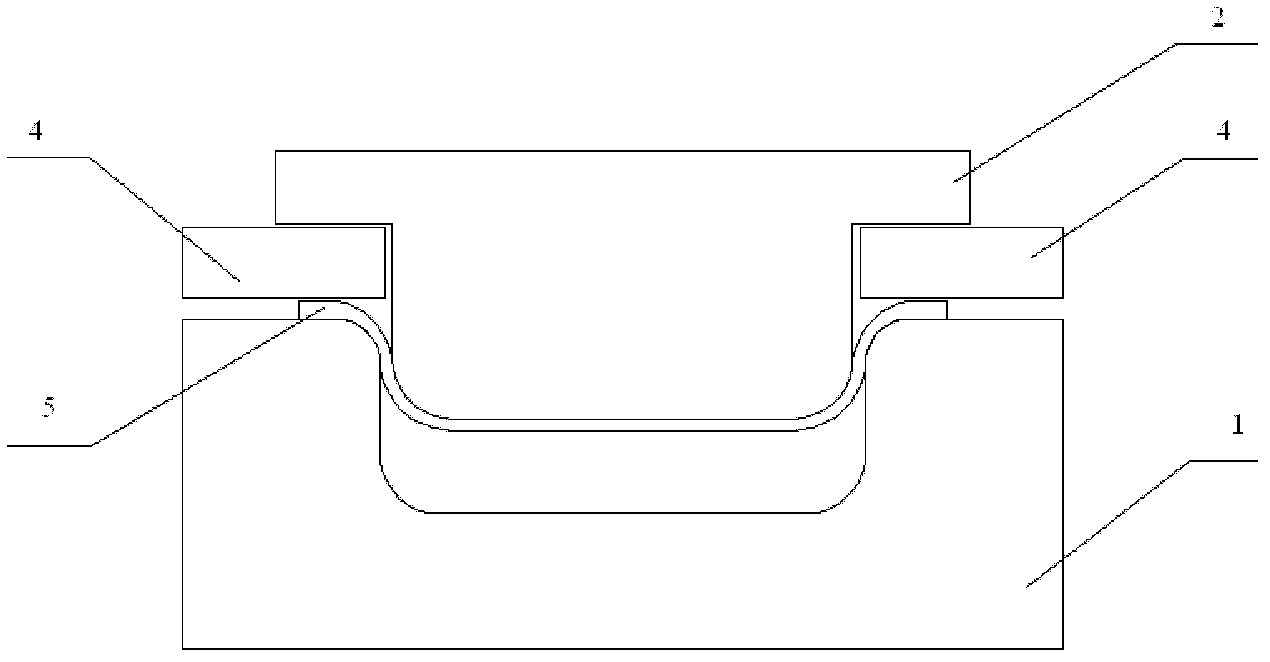

[0023] Specific implementation mode one: (see attached figure 1 , 2 And 3) the cold and hot composite mold forming method of the aluminum alloy sheet metal part of the present embodiment is carried out according to the following steps:

[0024] 1. Heat the lower mold 1 to 200-900°C;

[0025] 2. Place the aluminum alloy slab 3 on the lower mold 1, so that the aluminum alloy slab 3 is heated to its deformation temperature;

[0026] 3. Clamp the upper mold 2 and the blank holder 4 with the lower mold 1 within 2 to 10 seconds, and press the aluminum alloy slab 3 into an aluminum alloy sheet metal part 5;

[0027] 4. Move up the aluminum alloy sheet metal part 5, the upper mold 2 and the blank holder 4 together to disengage them from the lower mold 1;

[0028] 5. Lower the temperature of the upper mold 2 and blank holder 4 to 20-150° C. and keep it there for 2-10 seconds, then remove the aluminum alloy sheet metal part 5 to complete the forming of the cold and hot compound mold ...

specific Embodiment approach 2

[0029] Specific implementation mode two: (see attached figure 1 , 2 And 3) the cold and hot composite mold forming method of the aluminum alloy sheet metal part of the present embodiment is carried out according to the following steps:

[0030] 1. Perform solid solution treatment on the aluminum alloy slab 3; heat the lower mold 1 to 200-900°C;

[0031] 2. Place the aluminum alloy slab 3 processed in step 1 on the lower mold 1, so that the aluminum alloy slab 3 is heated to its deformation temperature;

[0032] 3. Clamp the upper mold 2 and the blank holder 4 with the lower mold 1 within 2 to 10 seconds, and press the aluminum alloy slab 3 into an aluminum alloy sheet metal part 5;

[0033] 4. Move up the aluminum alloy sheet metal part 5, the upper mold 2 and the blank holder 4 together to disengage them from the lower mold 1;

[0034] 5. Cool the upper mold 2 and blank holder 4 to 20-150°C and keep it for 2-10 seconds, then remove the aluminum alloy sheet metal part 5; pe...

specific Embodiment approach 3

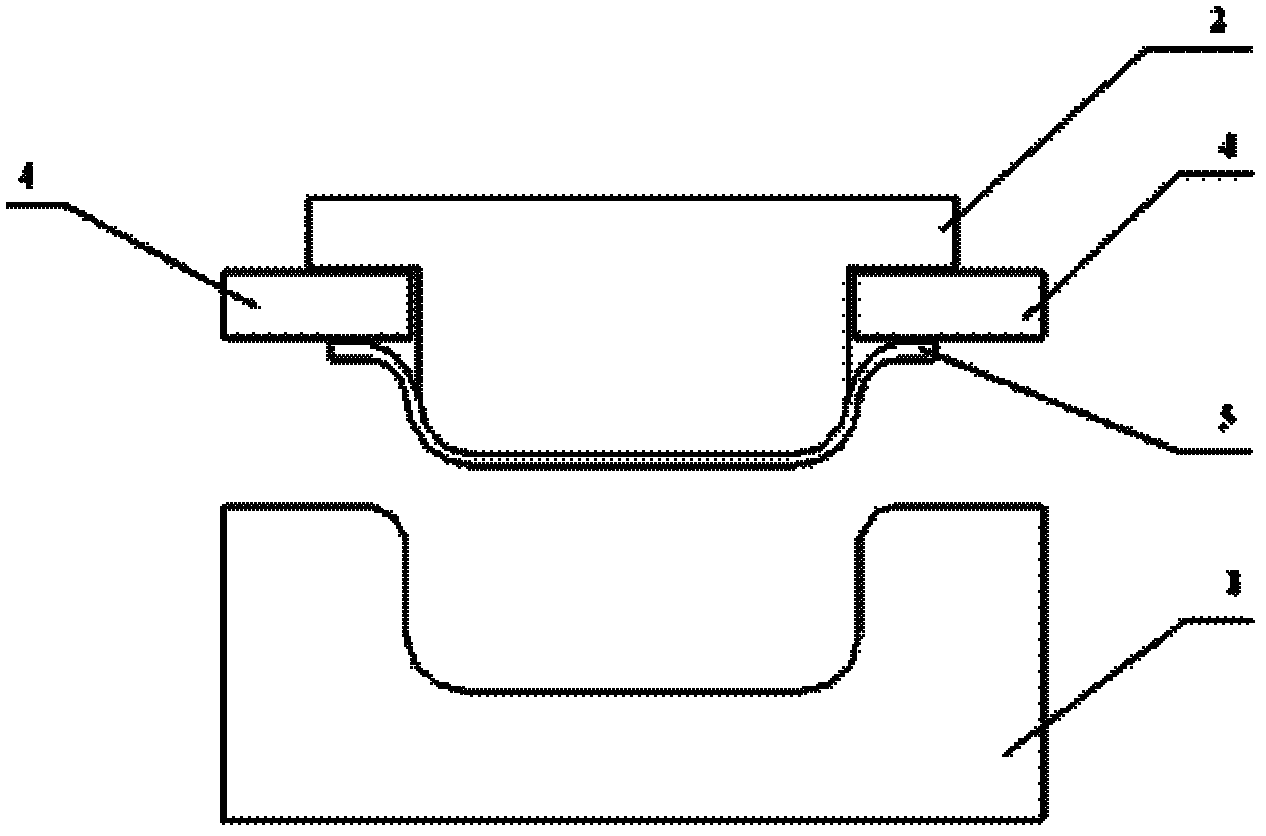

[0036] Specific implementation mode three: (see Figure 4 ) The difference between this embodiment and the specific embodiment 1 or 2 is that the heating method of the lower mold 1 in step 1 is to use the heating rod 6 built in the lower mold 1 for heating, and the others are the same as the specific embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com