Three-dimensional (3D) glass and preparation method thereof

A production method, 3D technology, applied in glass manufacturing equipment, glass production, glass molding, etc., can solve the problems of long new product development cycle, heavy mold embossing, and increased processing costs, so as to reduce the time of glass sweeping, Effect of lightening glass convex molding and reducing mold wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

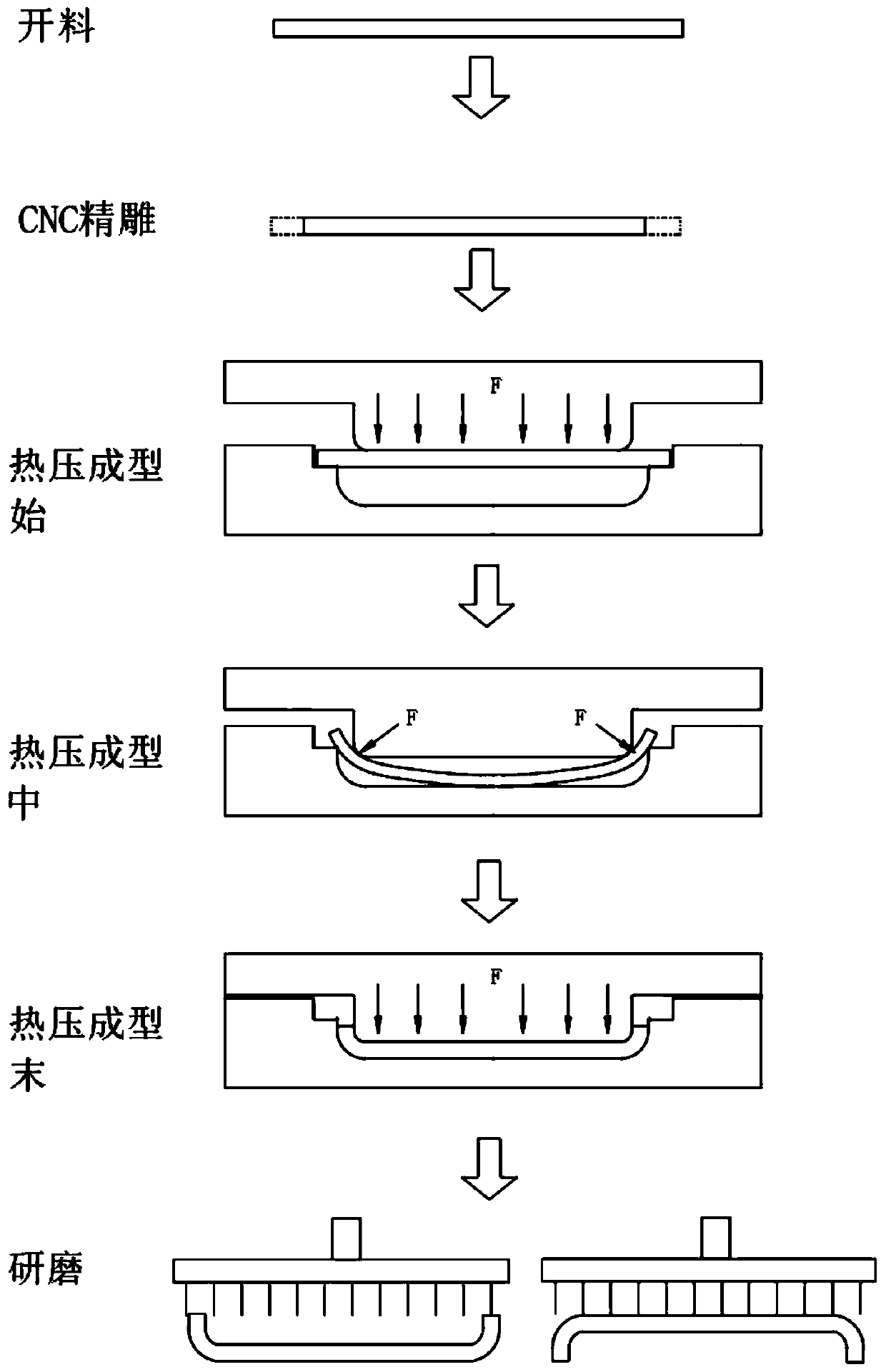

Method used

Image

Examples

Embodiment 1

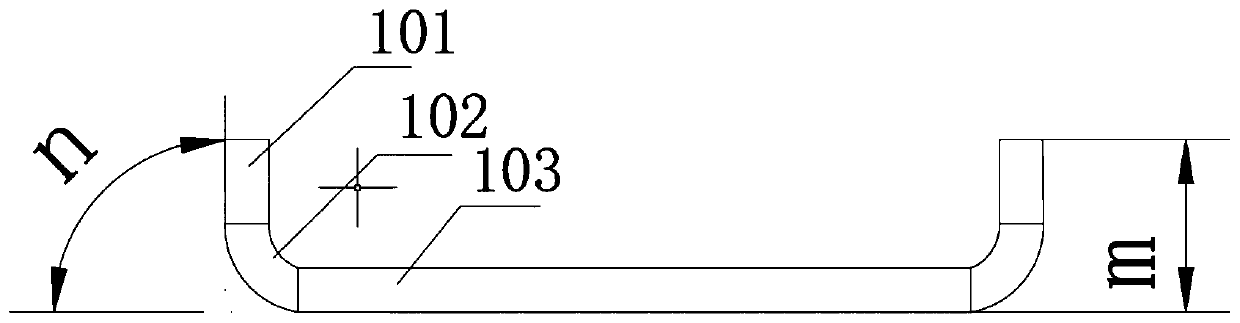

[0129] A 3D glass production method of the present invention is used to produce a 3D glass, the 3D glass includes a window portion 103, a curved portion 102 and a side wall portion 101; the window portion 103 and the side wall portion 101 are bent The portion 102 is connected; the bending angle n of the bending portion 102 is 0°<n≤10°; the sum m of the heights perpendicular to the window portion 103 of the side wall portion 101 and the bending portion 102 is 0<m≤1mm.

[0130] Step 1, place the flat glass 1 with the reserved margin in the mold. The reserved margin of the flat glass 1 is designed according to the external dimensions of the 3D glass; then high-alumina-silicate white glass with a thickness of 0.25 mm is selected as a raw material, and cut according to the reserved margin of the flat glass 1 .

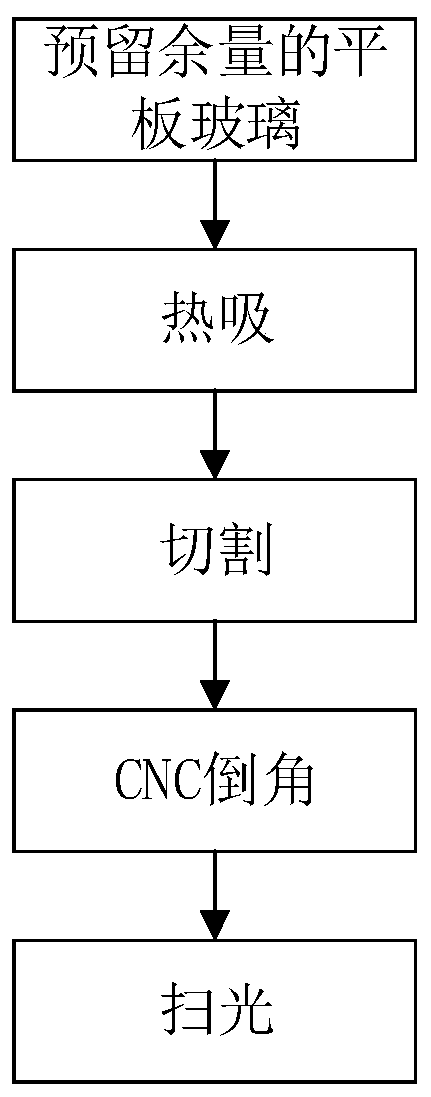

[0131] Step 2, using a set of molds to perform a heat absorption process, so that the flat glass 1 is bonded and formed on the surface of the concave mold of the mold to ob...

Embodiment 2

[0143] A 3D glass production method of the present invention is used to produce a 3D glass, the 3D glass includes a window portion 103, a curved portion 102 and a side wall portion 101; the window portion 103 and the side wall portion 101 are bent The bending angle n of the bending portion 102 is 60°; the sum m of the heights of the side wall portion 101 and the bending portion 102 perpendicular to the window portion is 5 mm.

[0144] Step 1, place the flat glass 1 with the reserved margin in the mold. The reserved margin of the flat glass 1 is designed according to the external dimensions of the 3D glass; then, Corning glass with a thickness of 0.4 mm is selected as the raw material, and cut according to the reserved margin of the flat glass 1 .

[0145] Step 2, using a set of molds to perform a heat absorption process, so that the flat glass 1 is bonded and formed on the surface of the concave mold of the mold to obtain a 3D glass blank 2, and the curvature of the upper surf...

Embodiment 3

[0157] A 3D glass production method of the present invention is used to produce a 3D glass, the 3D glass includes a window portion 103, a curved portion 102 and a side wall portion 101; the window portion 103 and the side wall portion 101 are bent The bending angle n of the bending portion 102 is 88°; the sum m of the heights of the side wall portion 101 and the bending portion 102 perpendicular to the window portion is 6≤m≤7.5mm.

[0158] Step 1, place the flat glass 1 with the reserved margin in the mold. The reserved margin of the flat glass 1 is designed according to the external dimensions of the 3D glass; then, panda glass with a thickness of 1.1 mm is selected as a raw material, and cut according to the reserved margin of the flat glass 1 .

[0159] Step 2, using two sets of molds to carry out heat absorption process, so that the flat glass 1 is bonded and formed on the surface of the concave mold of the mold to obtain a 3D glass blank 2. The two sets of molds used incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com