Patents

Literature

69results about How to "Avoid frictional contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

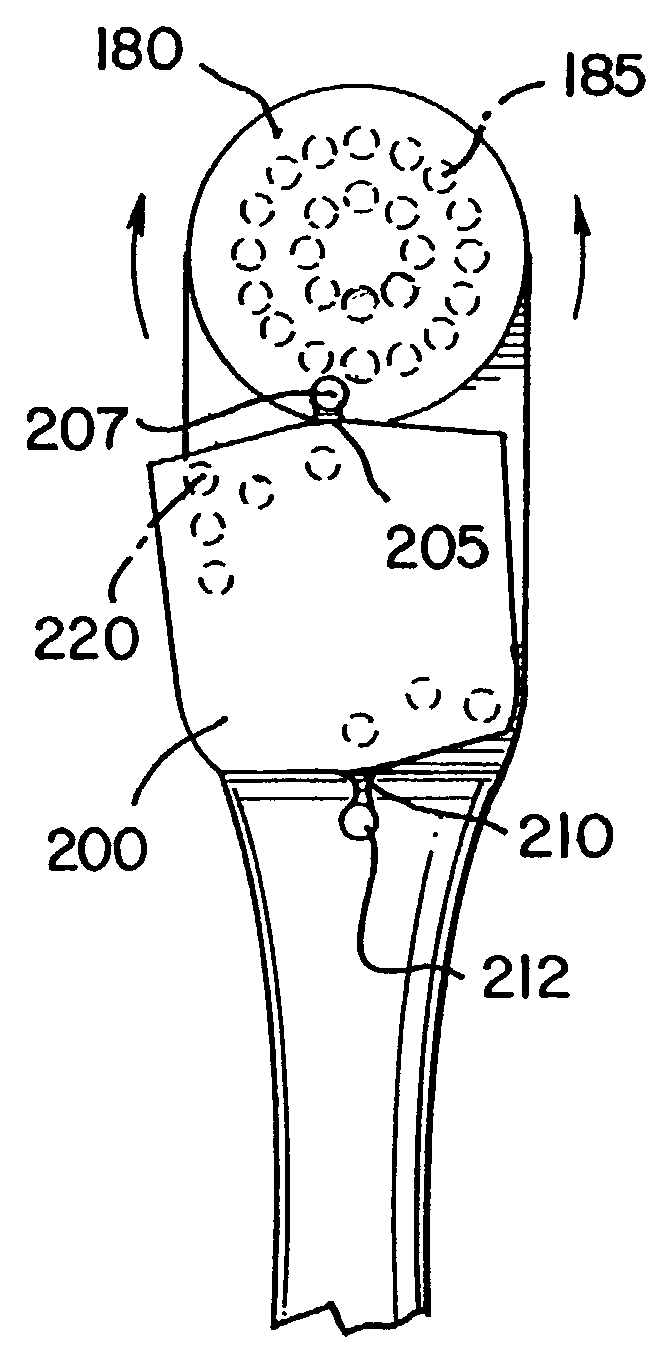

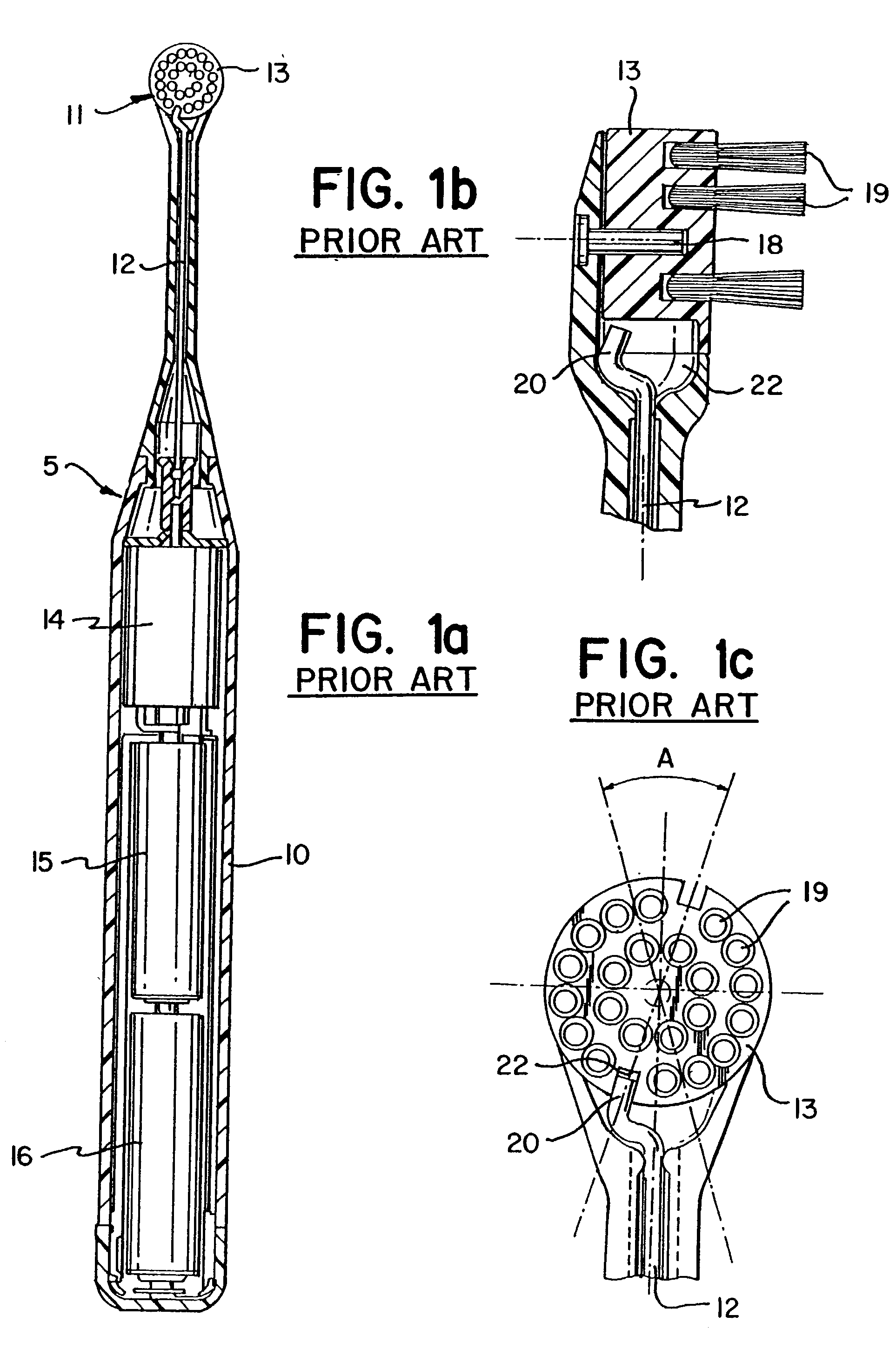

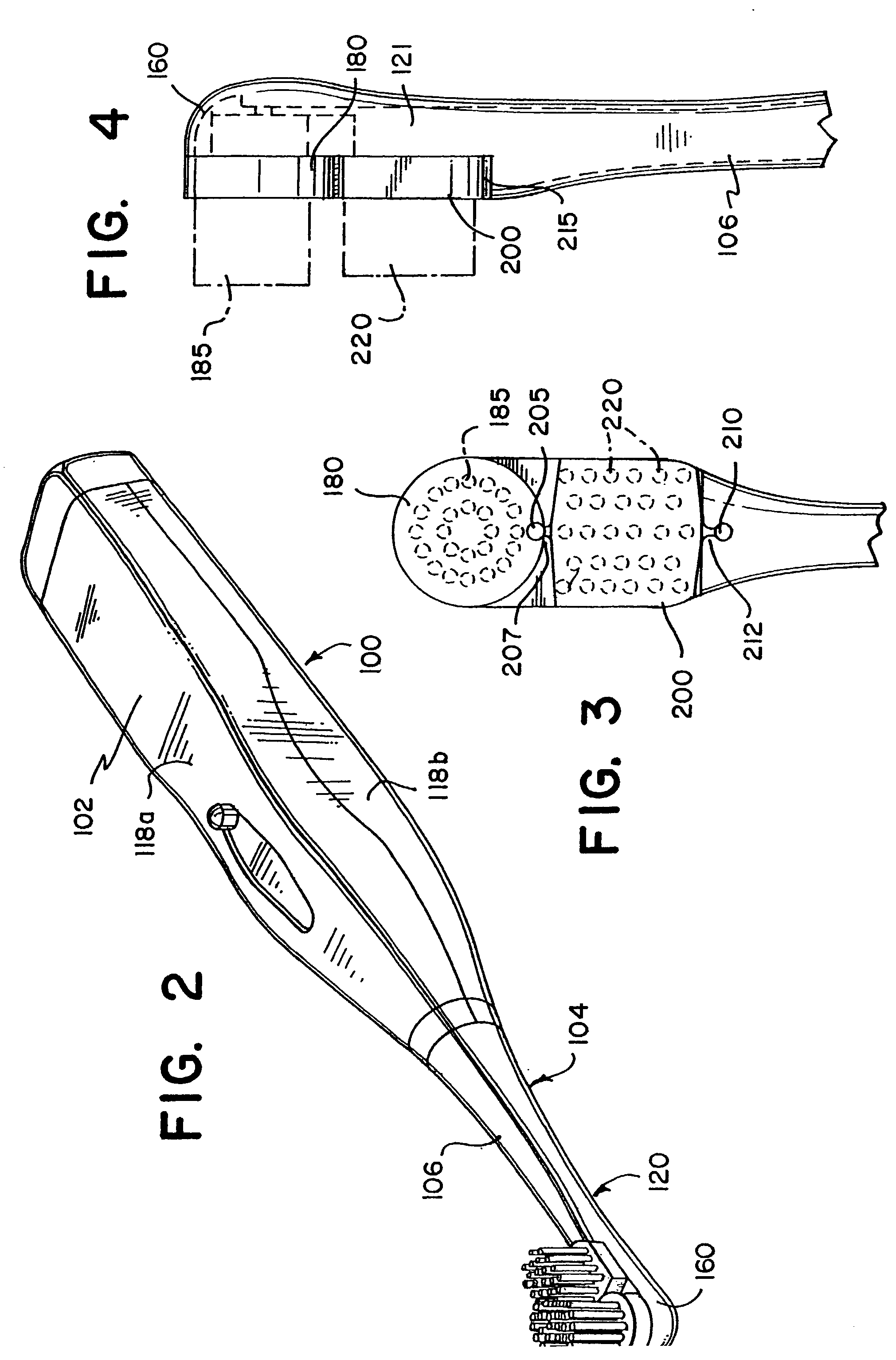

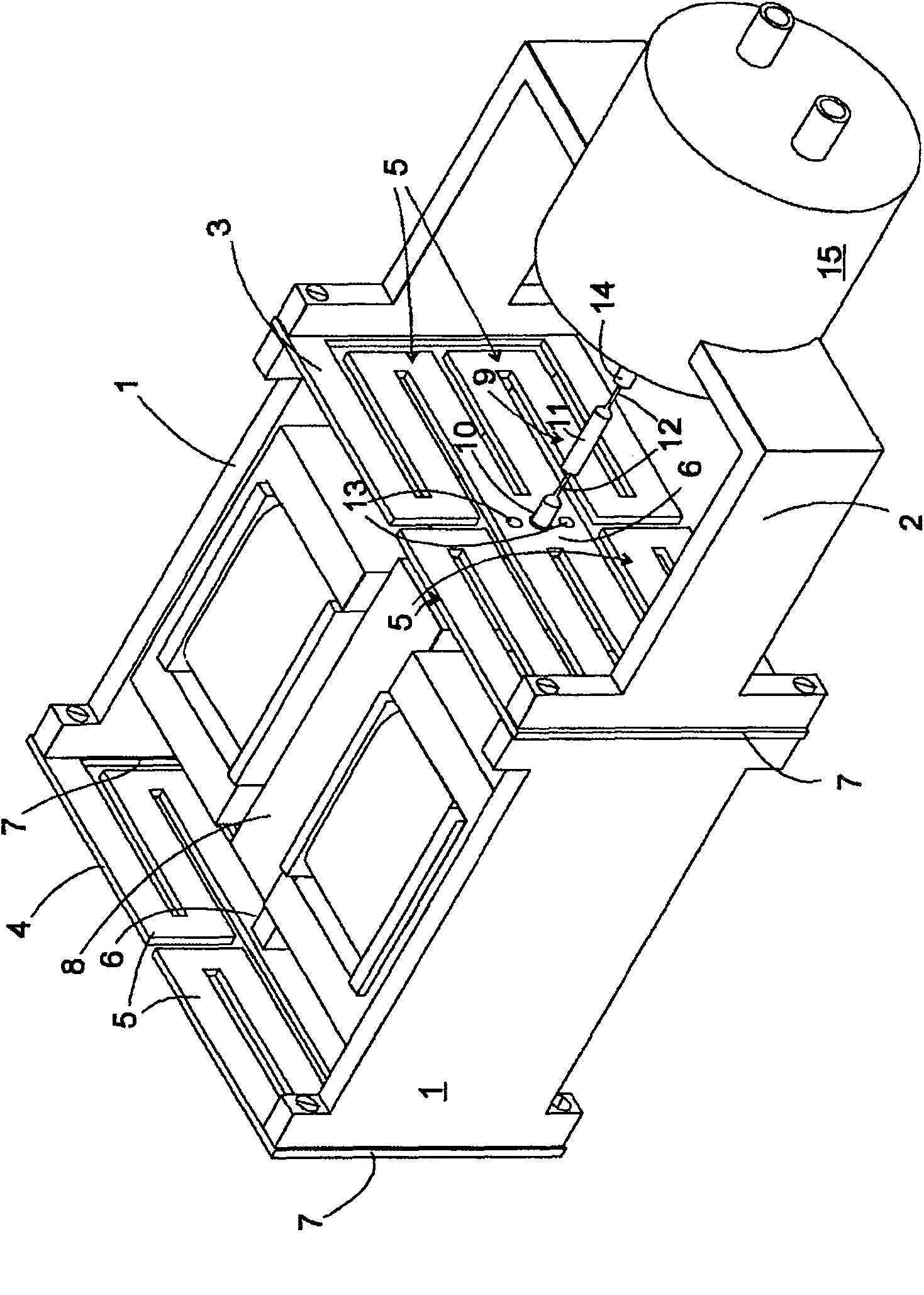

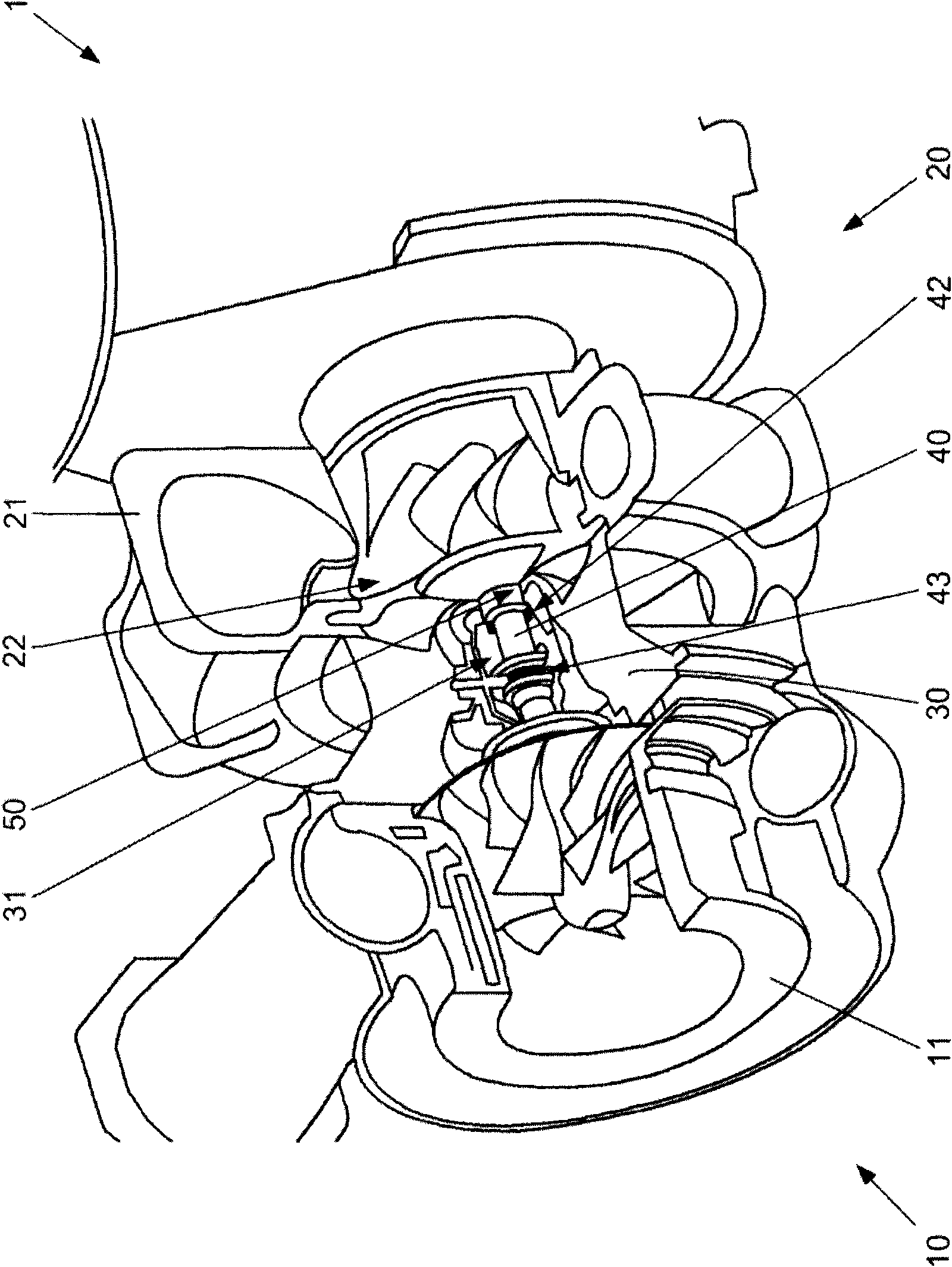

Toothbrush with sectorial motion

InactiveUS20040060137A1Increased moving bristle areaImprove cleanlinessCarpet cleanersKitchenware cleanersBristleEngineering

A powered toothbrush to provide oral hygiene having a brush section with a first bristle carrier that is powered and driven to rotate in an oscillating manner through a prescribed angle. A second bristle carrier is pivotally connected to the first bristle carrier and also pivotally connected to the brush section. The second bristle carrier oscillates in accordance with the oscillation of the first bristle carrier in a sectorial manner. The bristle carriers may include a variety of elastomeric and non-elastomeric bristles or combinations thereof to provide cleaning, polishing, whitening and stimulating to the teeth and gums.

Owner:COLGATE PALMOLIVE CO

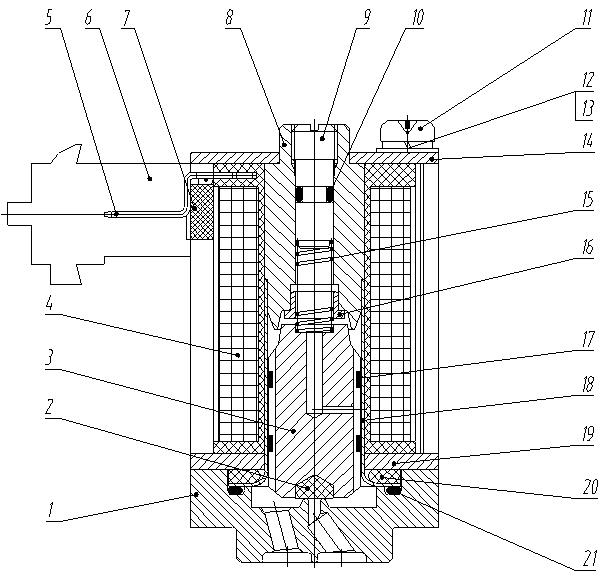

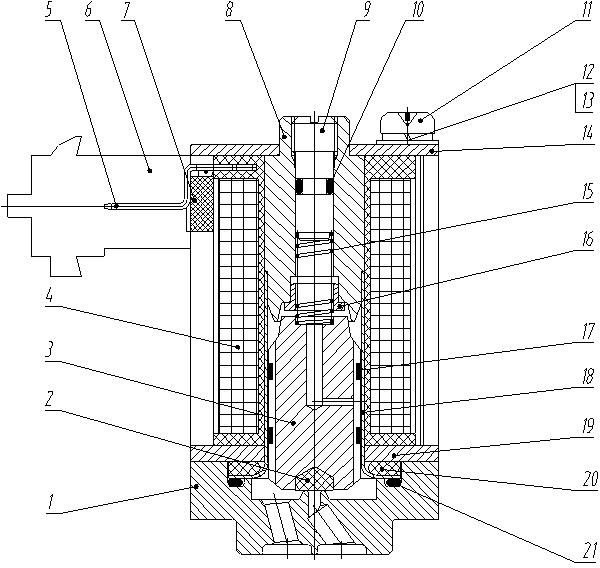

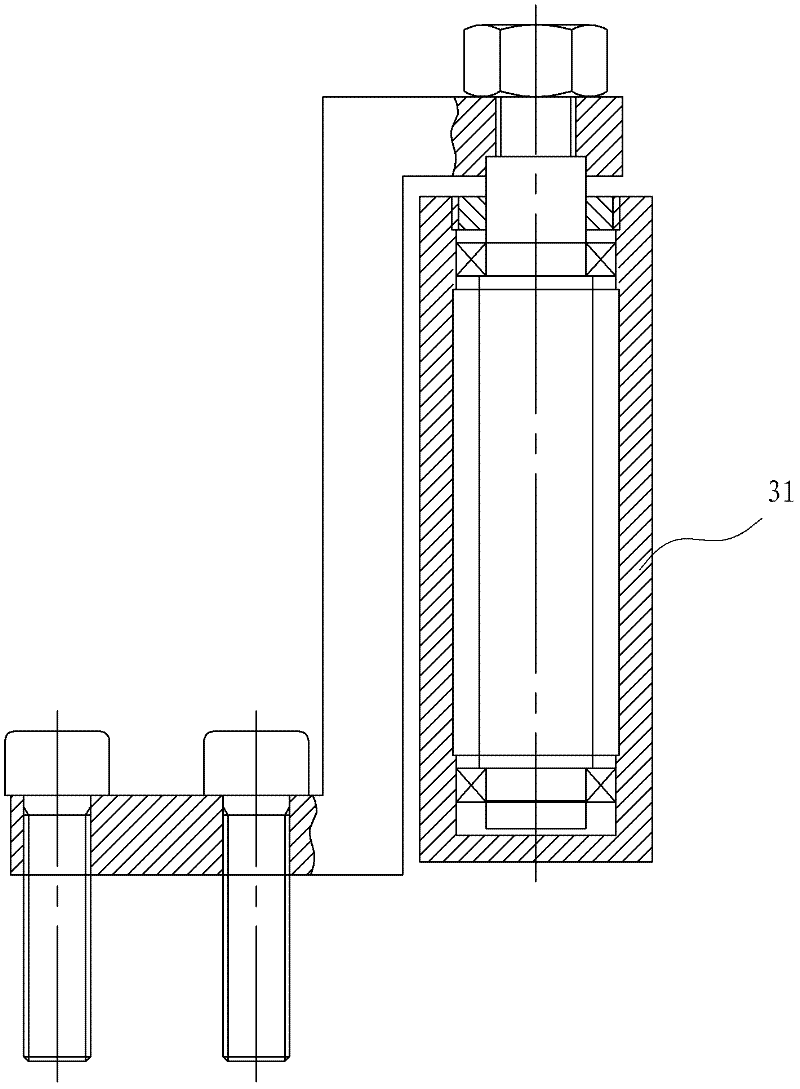

Proportional electromagnetic valve for electrically controlled high-pressure common-rail fuel injection system of diesel engine

InactiveCN102506217AMeet the use requirementsControl on and offOperating means/releasing devices for valvesFuel injection apparatusDriving currentCommon rail

The invention discloses a proportional electromagnetic valve for an electrically controlled high-pressure common-rail fuel injection system of a diesel engine and relates to an electromagnetic valve. A position at which a fixed iron core (8) and a movable iron core (3) of the electromagnetic valve attract each other is a conical polar plane. The fixed iron core (8), the movable iron core (3), a guide pipe (18), a spiral spring (15), an electromagnetic coil (4), a square iron core (19), a shell (14) and a valve body (1) jointly form the electromagnetic valve in an assembling way. When driving current is input into the electromagnetic coil, a magnetic field is generated through a magnetic path in the valve, electromagnetic force with magnitude which is in proportion with the magnitude of the driving current and is not related to a stroke is generated relative to the movable iron core, the movable iron core is enabled to overcome spring force to move, the movable iron core stops moving at a balance point of the two kinds of force and therefore is kept at a stable position, and the movable iron core can proportionally and continuously move according to the magnitude of the driving current to control the opening of the valve. Under complex working conditions under which the diesel engine works, the electromagnetic valve not only can stably control the on / off of a fuel path, but also can accurately and proportionally control the flow of the fuel path according to the driving current.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

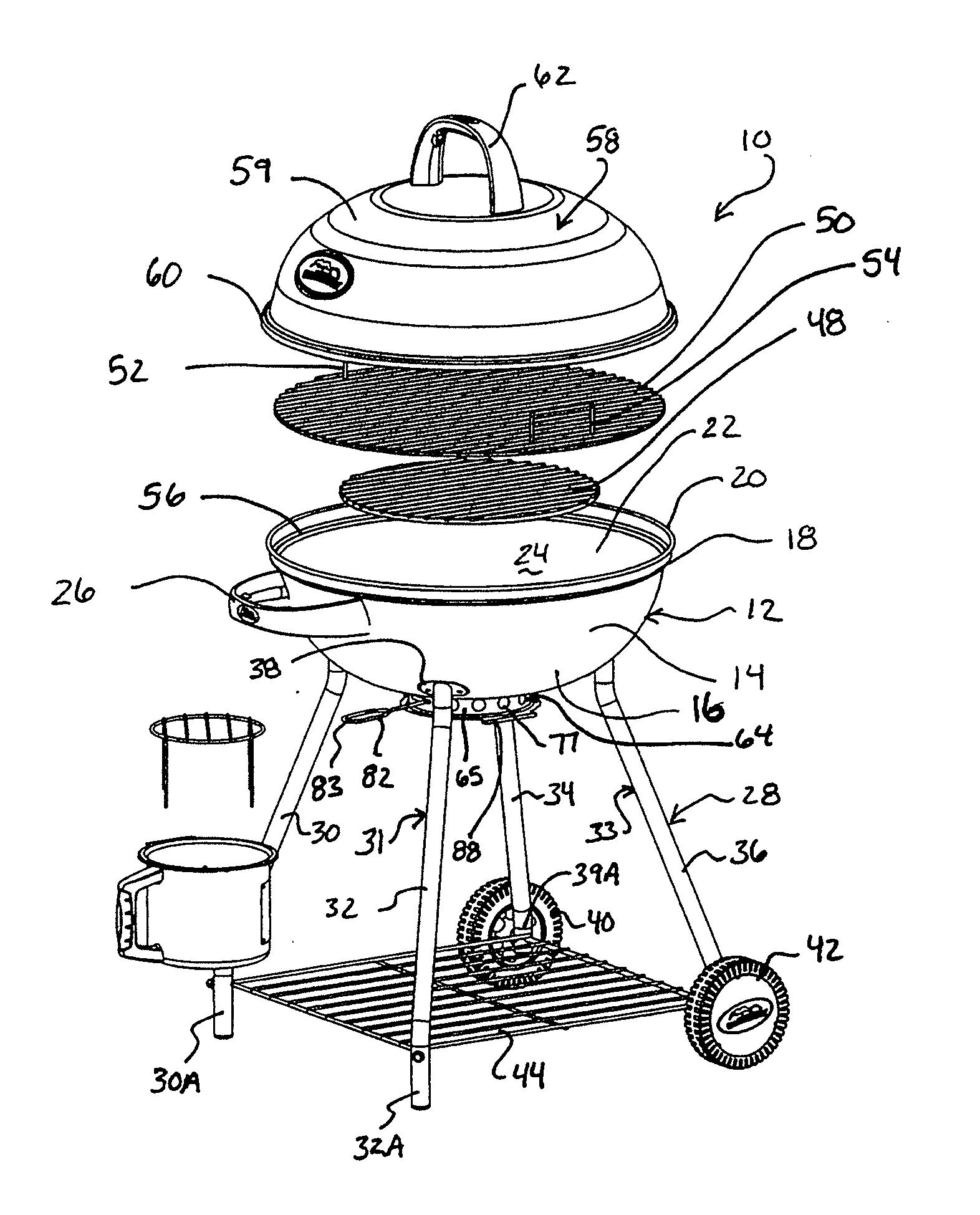

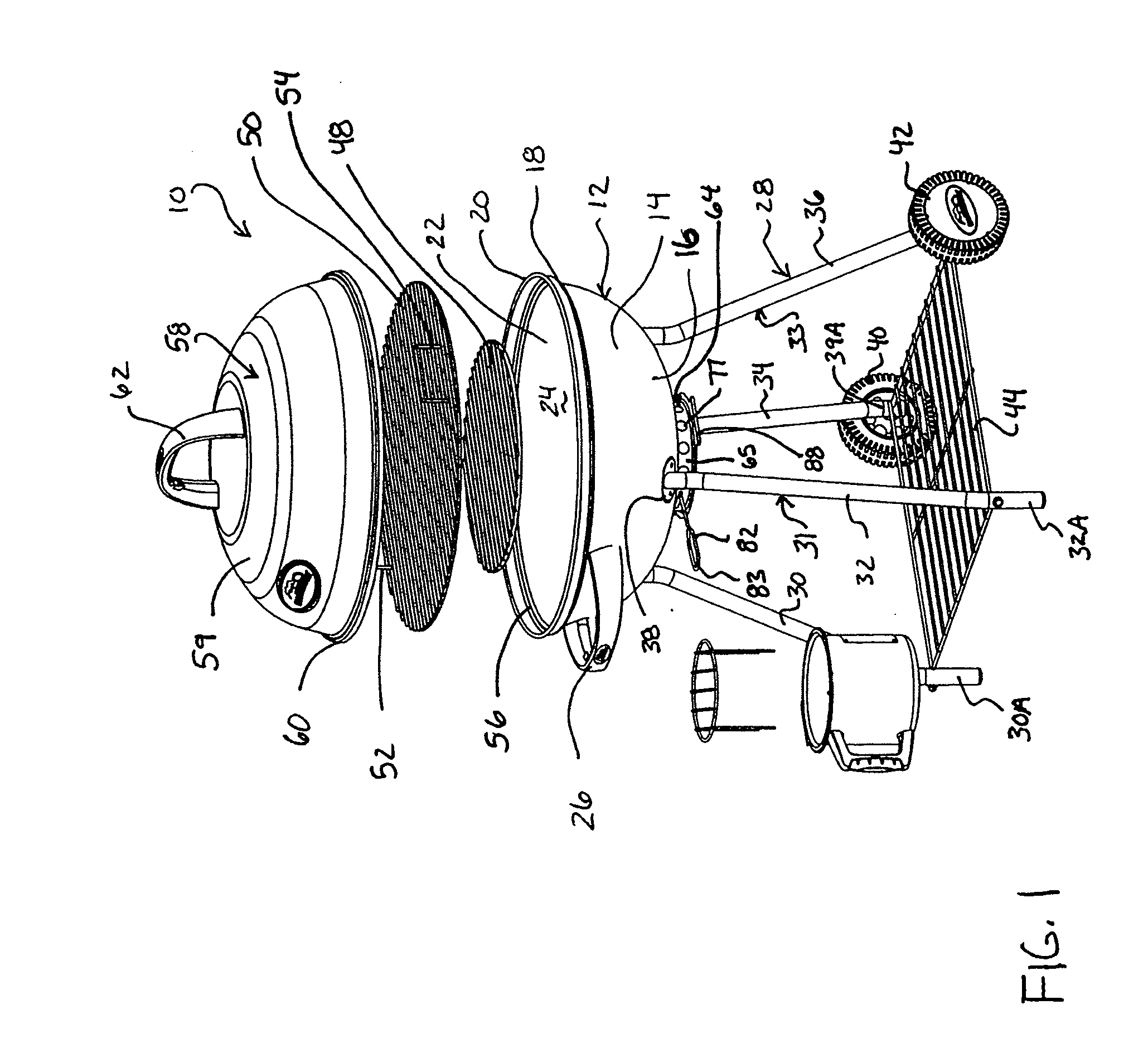

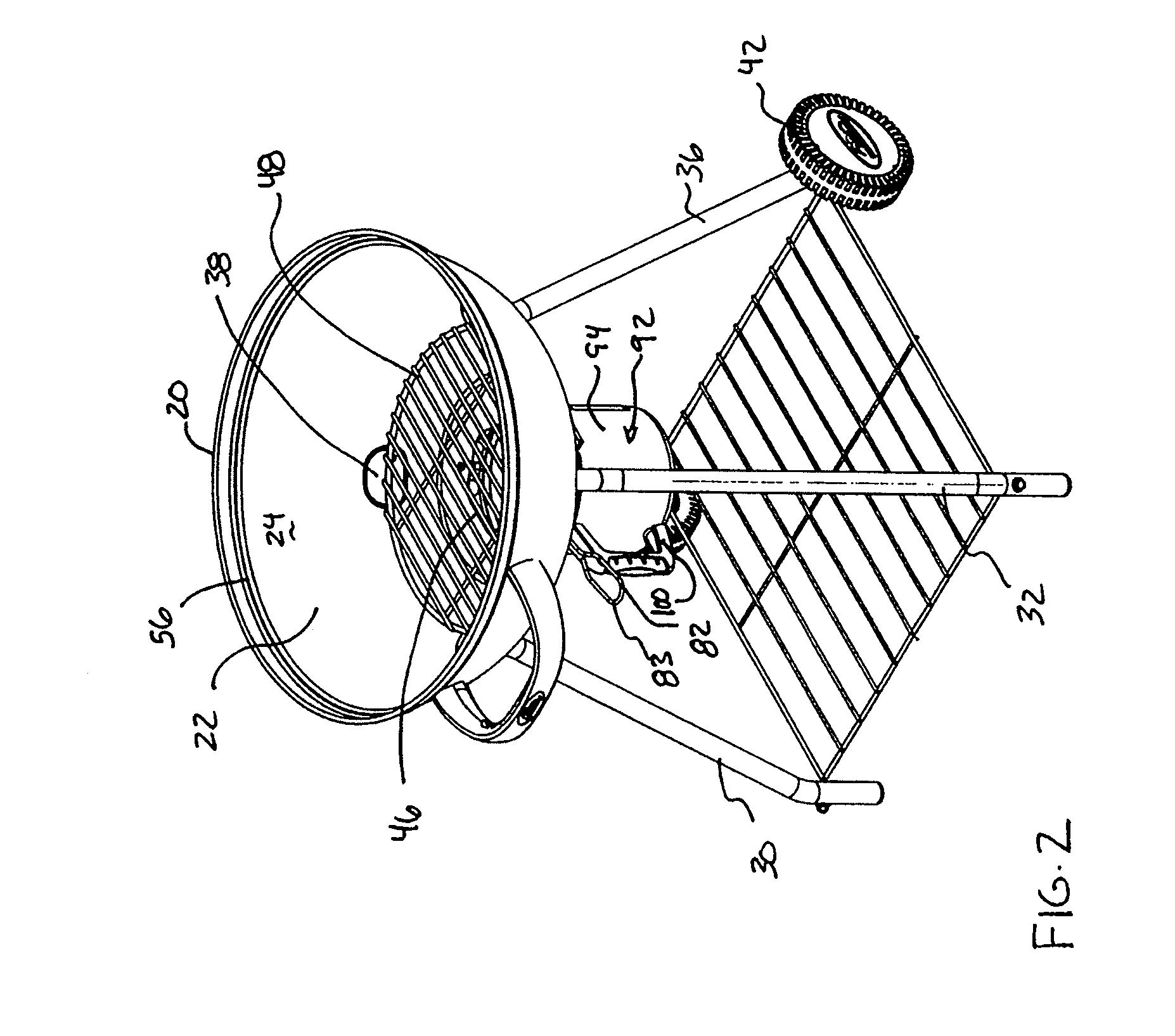

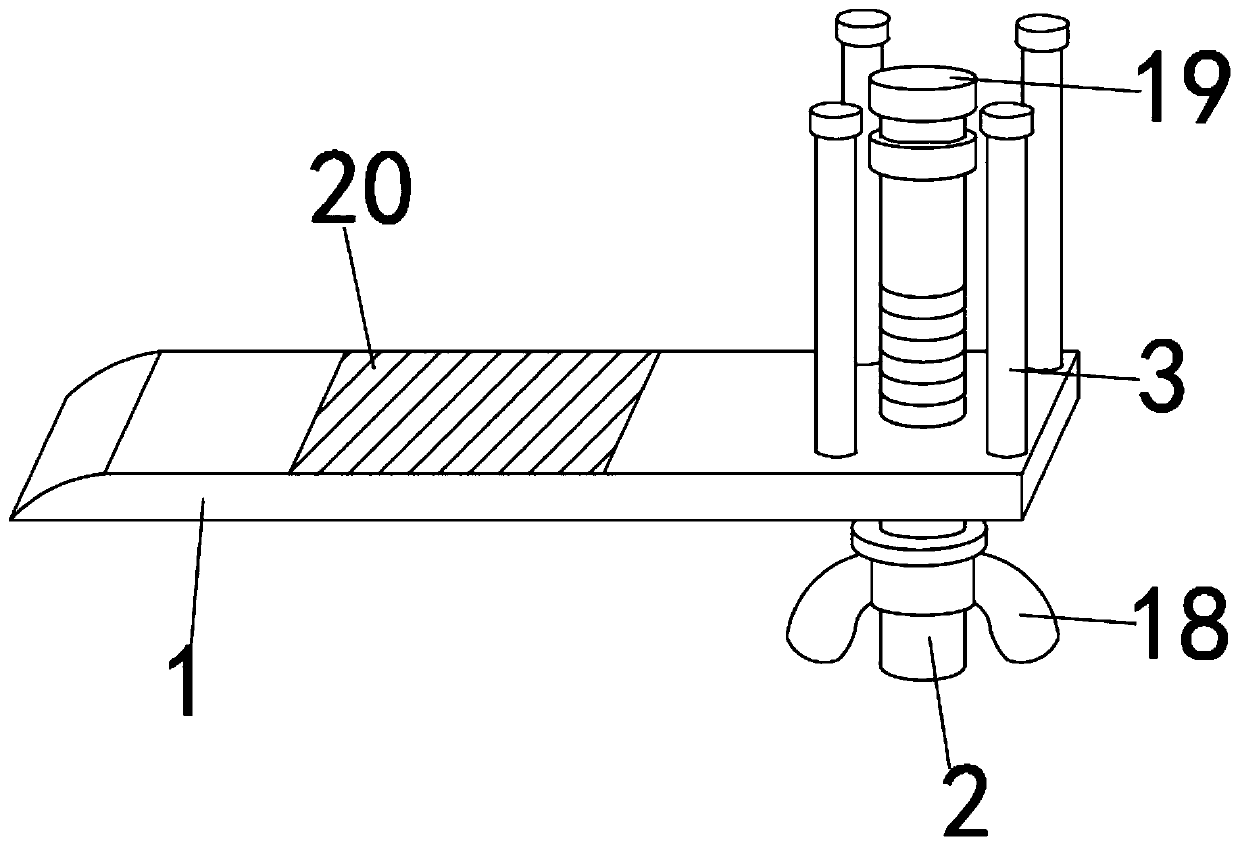

Cooking apparatus with a cooking fuel ignition facilitator and method of assembling and using same

InactiveUS20120090593A1Rapid and highly ensured ignition maintenanceEasy to igniteStoves/ranges foundationsCombustion-air/flue-gas circulation for stovesEngineeringTinder

A cooking fuel ignition assembly for an outdoor cooking apparatus as in a barbeque grill. The ignition assembly includes a tinder support combination of an ash can and tinder support stand. An operator inserts the tinder support stand within the ash can such that its lower spacer structure makes contact with the base of the ash can receptacle and the upper tinder platform is in the upper region of the ash can. The operator places tinder T on the upper surface of the tinder platform. The tinder combination with tinder is mounted in suspended fashion below an aperture in the grill base such that upon ignition of the tinder a flame extends up through, for example, an interface slide catch collar assembly and into an ignition relationship with supported cooking fuel above.

Owner:MASTERBUILT MFG LLC

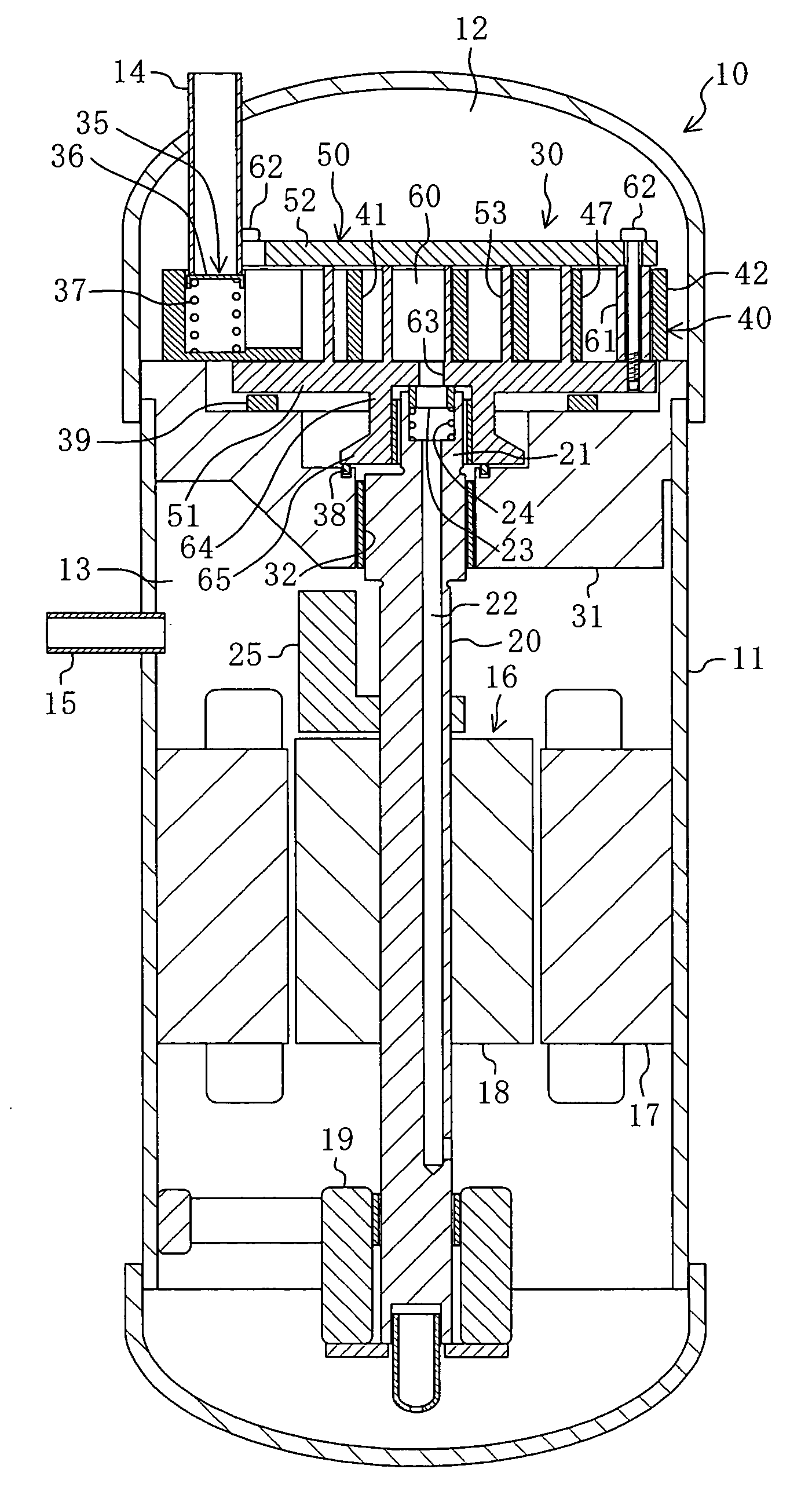

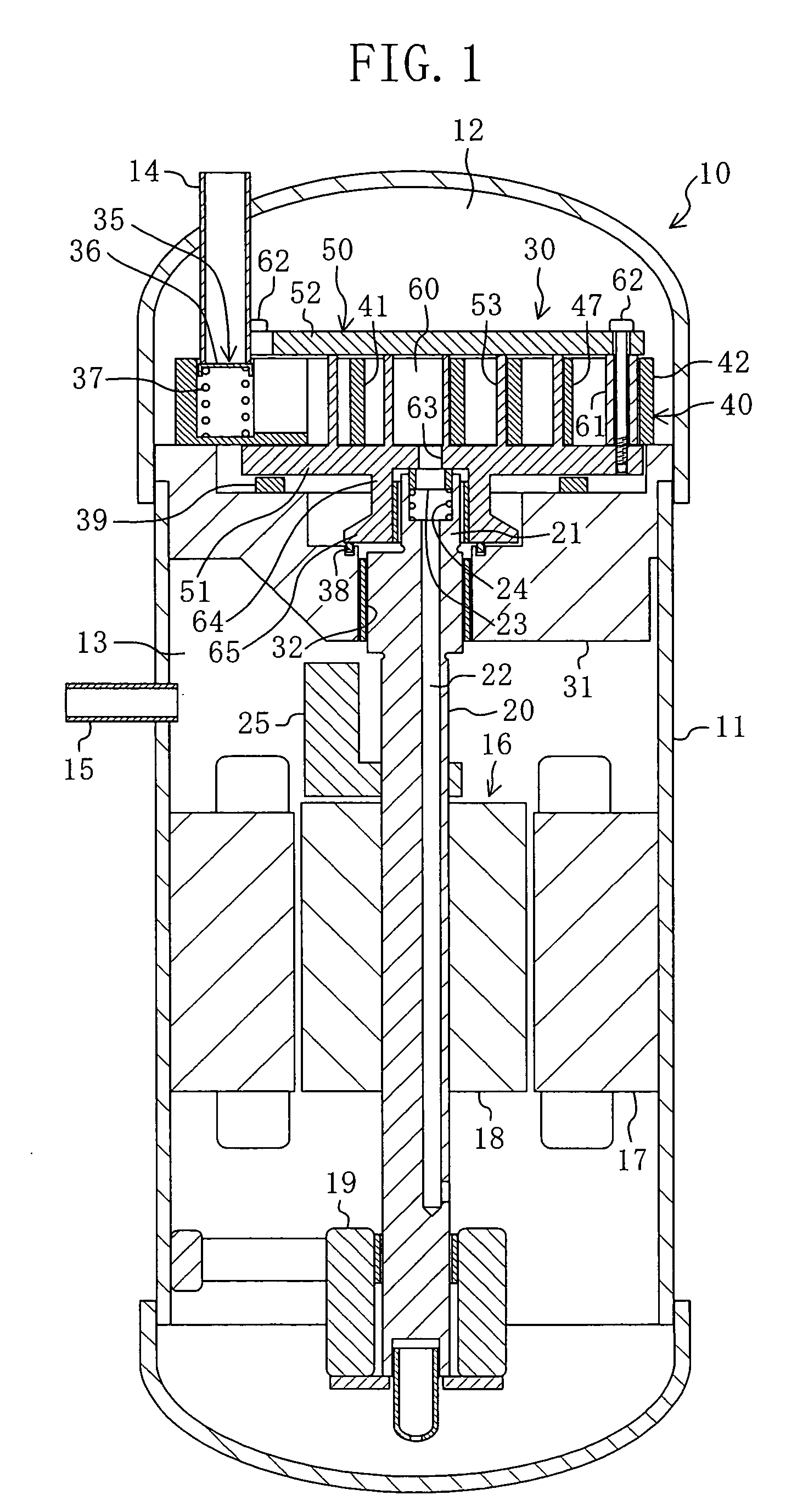

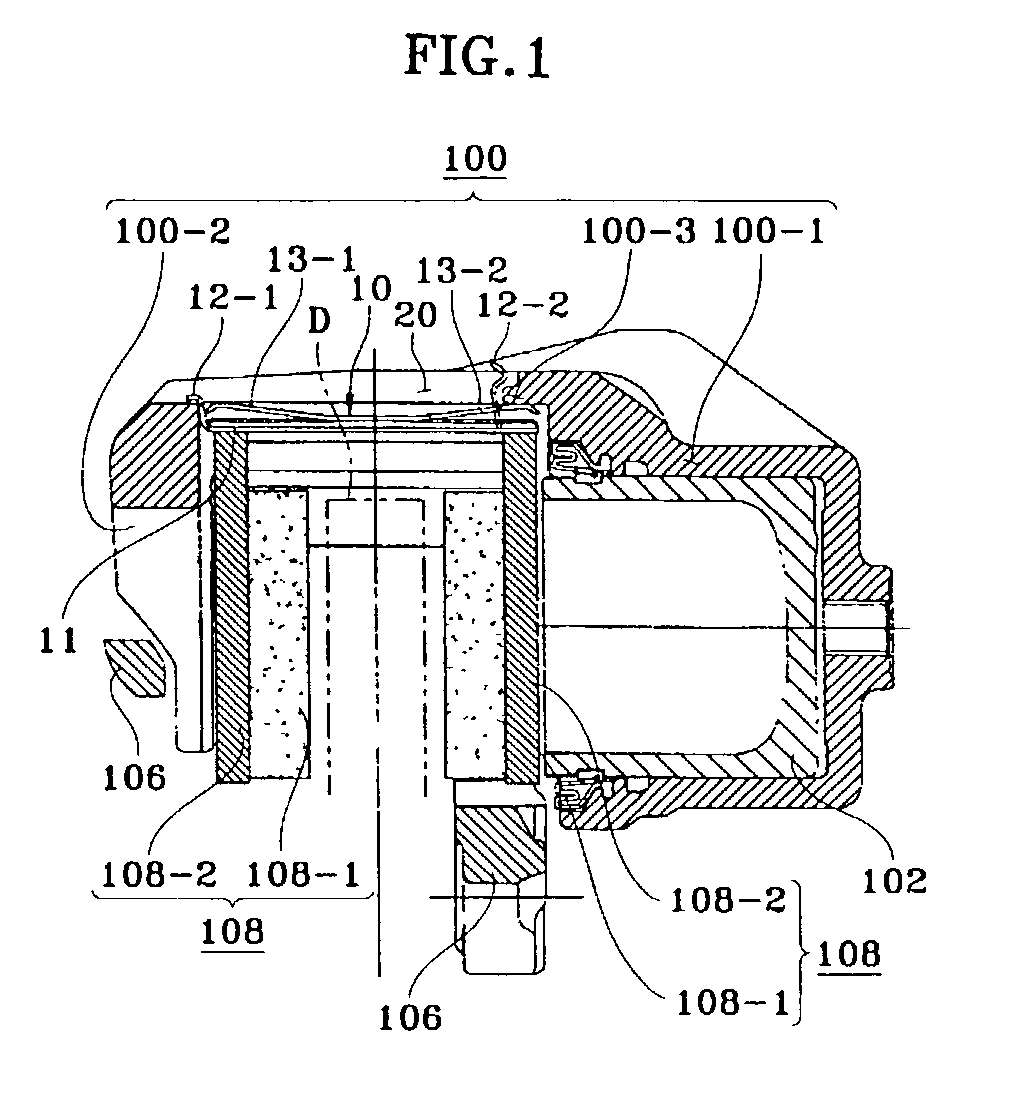

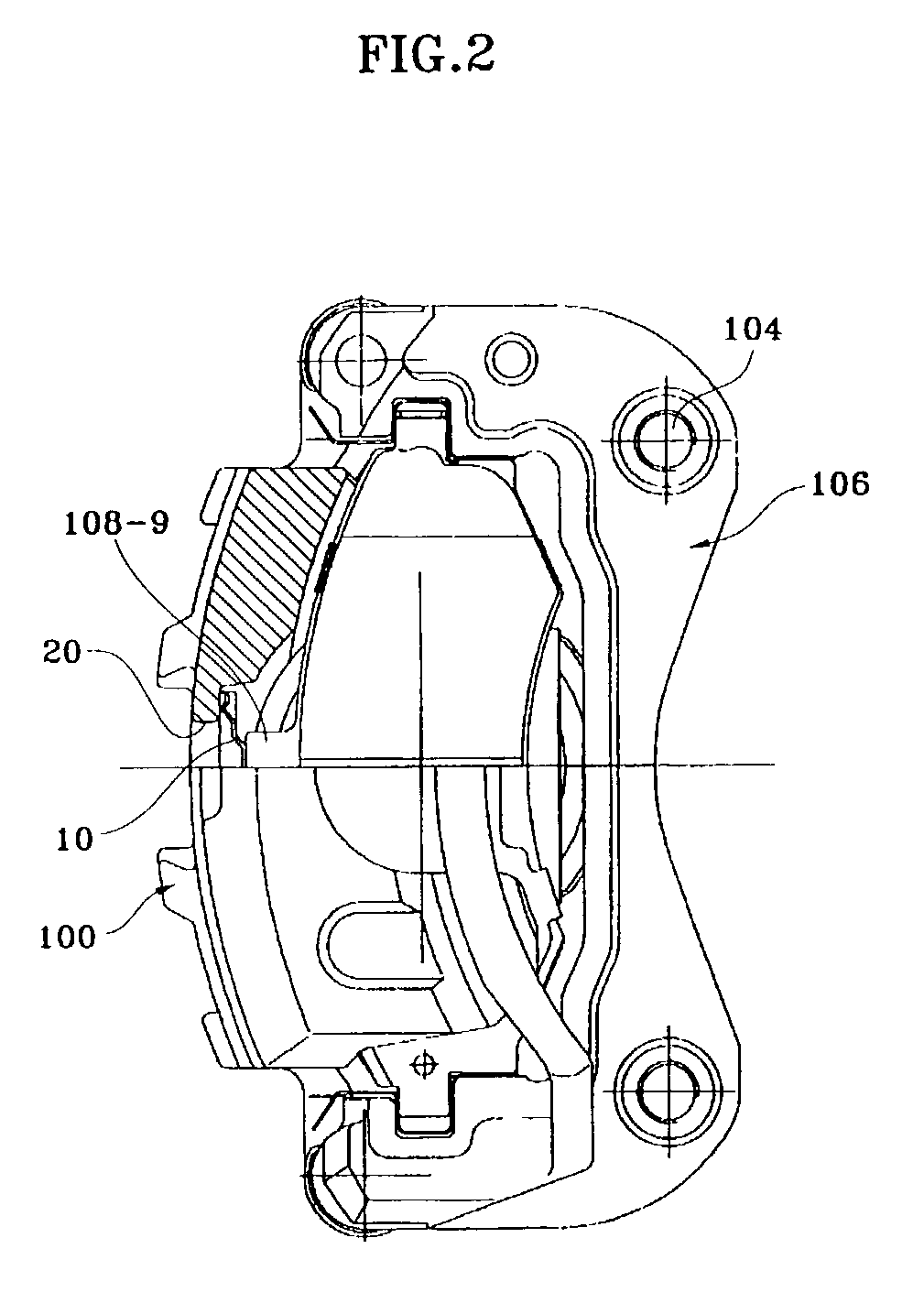

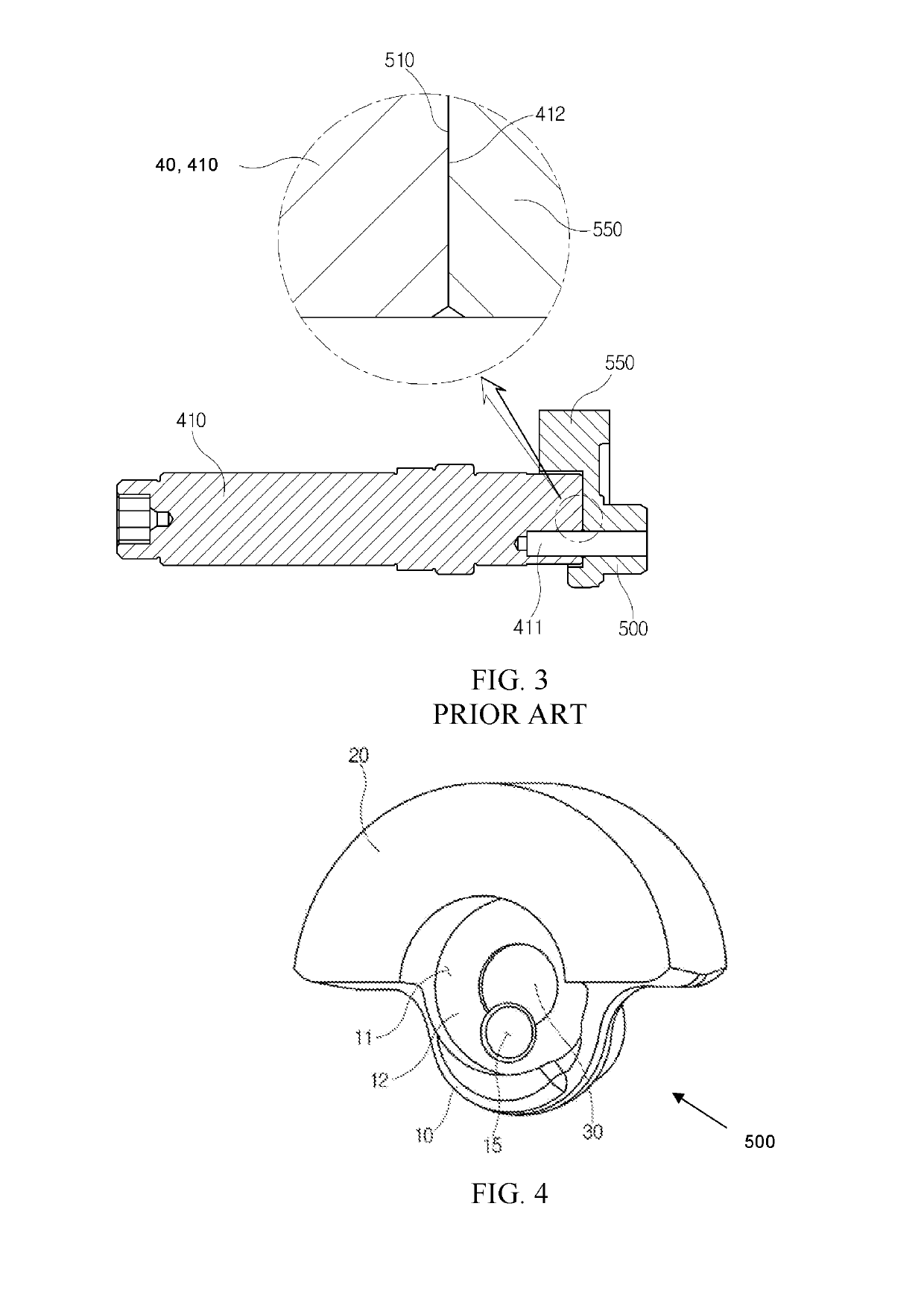

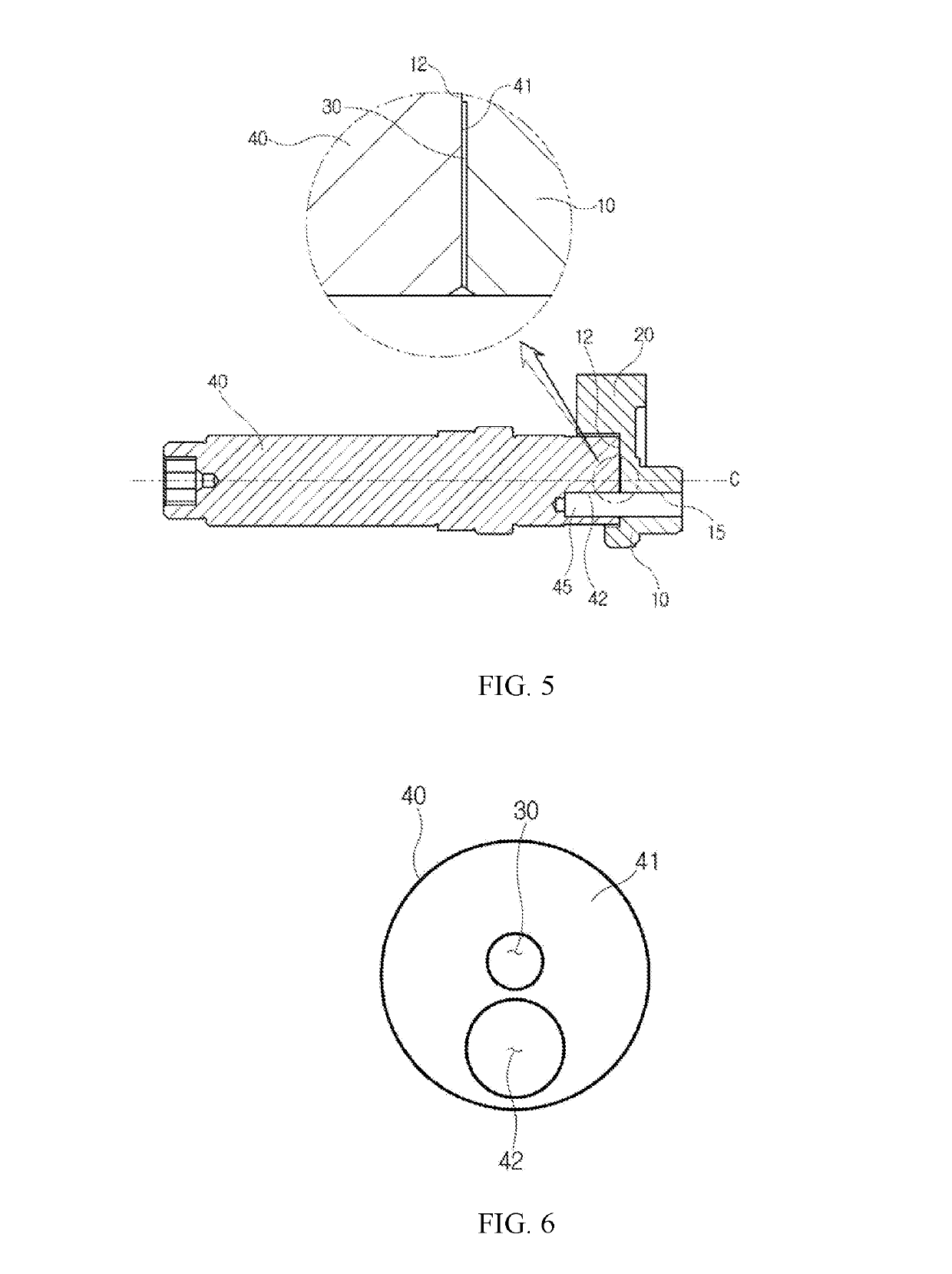

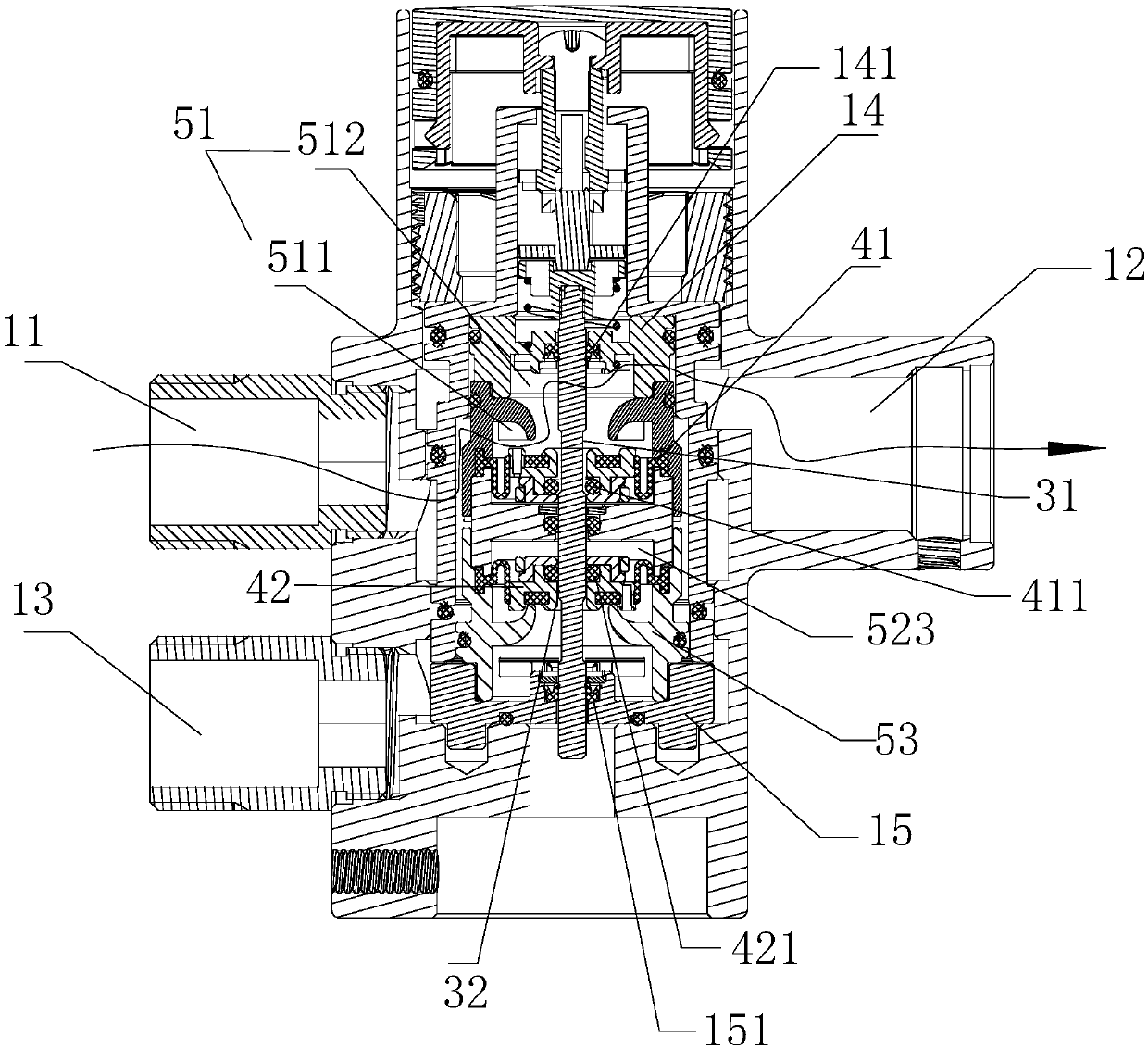

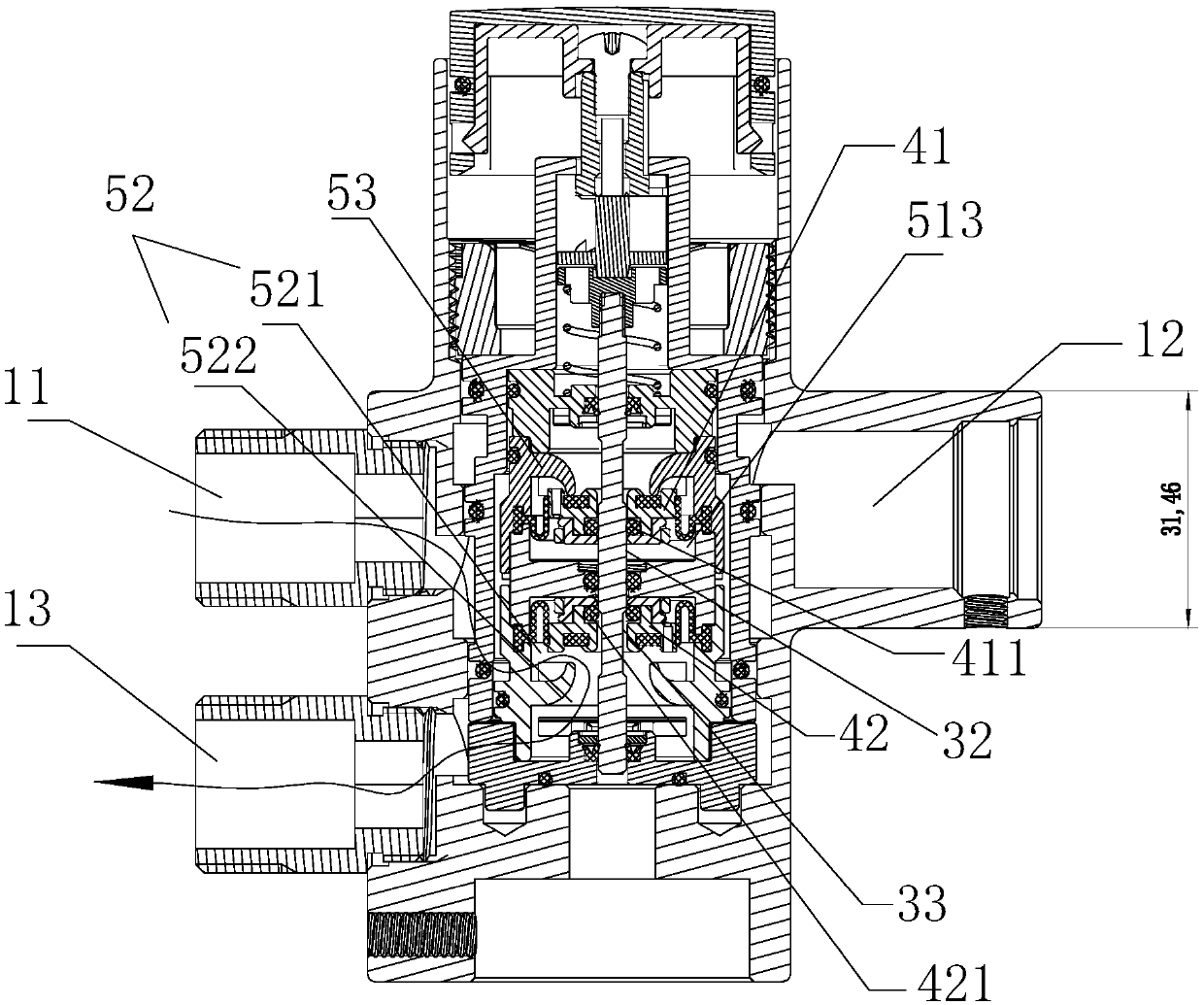

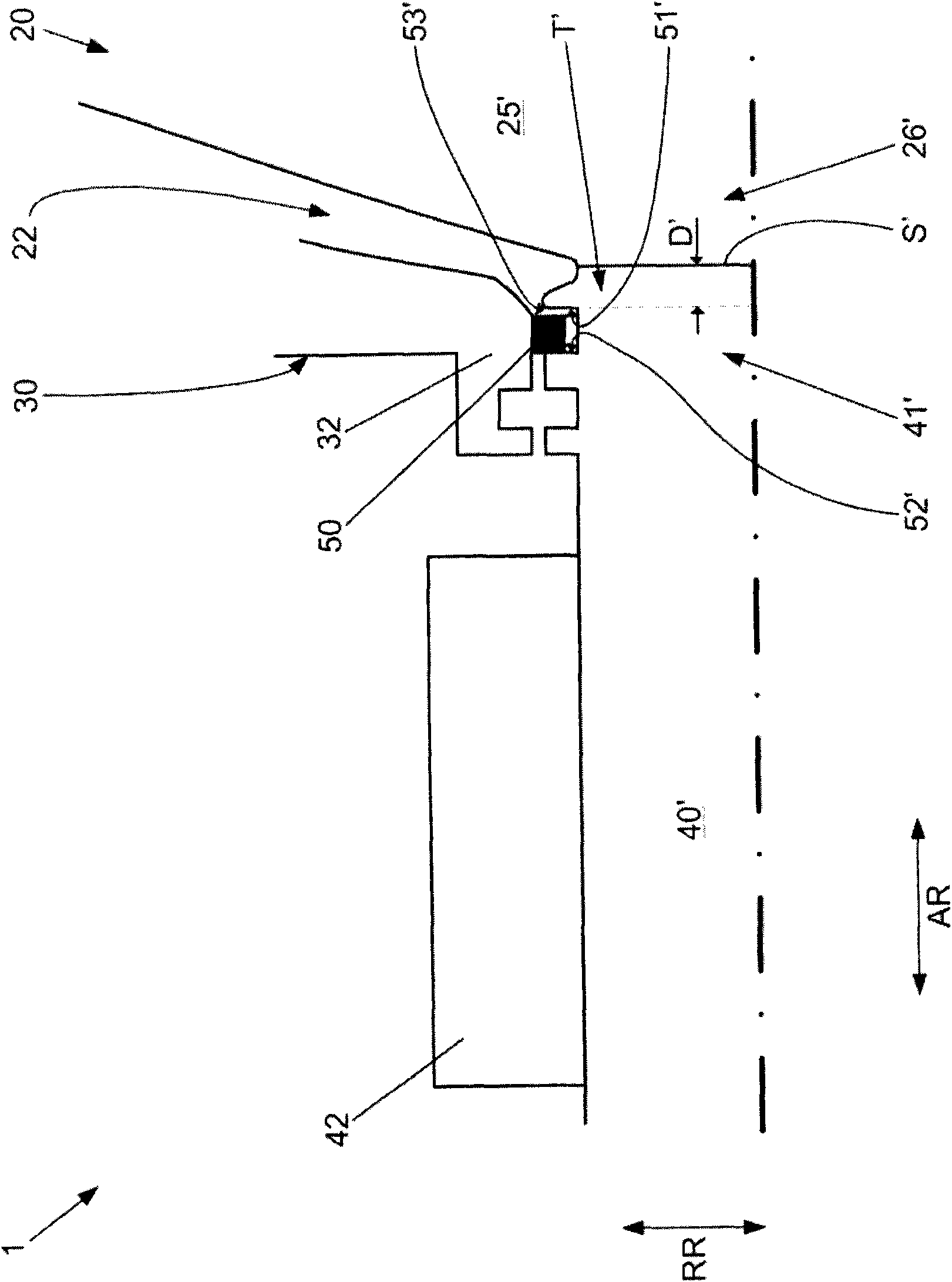

Scroll type fluid machine

InactiveUS20040101428A1Improve reliabilityIncrease frictional resistanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

A stationary scroll (40) is provided with a stationary side wrap (41) and an outer peripheral portion (42). The stationary side wrap (41) is formed into a spiral wall shape. The outer peripheral portion (42) is formed into a ring-like shape enclosing the periphery of the stationary side wrap (41). The movable scroll (50) is provided with a first flat plate (51), a movable side wrap (53), and a second flat plate (52). The movable side wrap (53) is formed into a spiral wall shape. Additionally, the movable side wrap (53) is caught between the first flat plate (51) and the second flat plate (52), with the movable side wrap (53) in mating engagement with the stationary side wrap (41). In the movable side wrap (53), the first flat plate (51) is formed integrally with the movable side wrap (53). Additionally, the second flat plate portion (52) is formed as a separate body from the first flat plate (51) and the movable side wrap (53) and is coupled to the first flat plate (51) with a bolt (62).

Owner:DAIKIN IND LTD

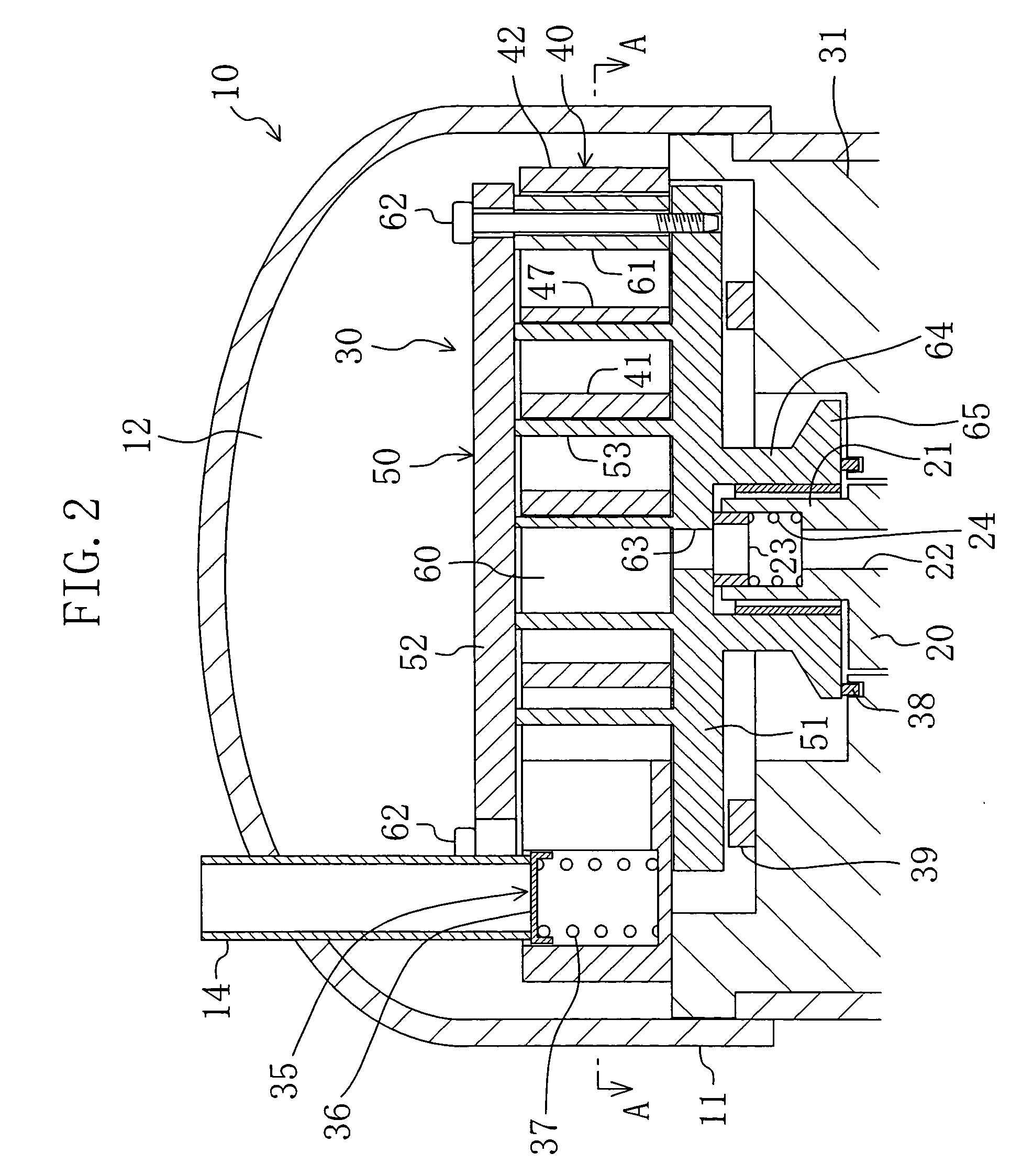

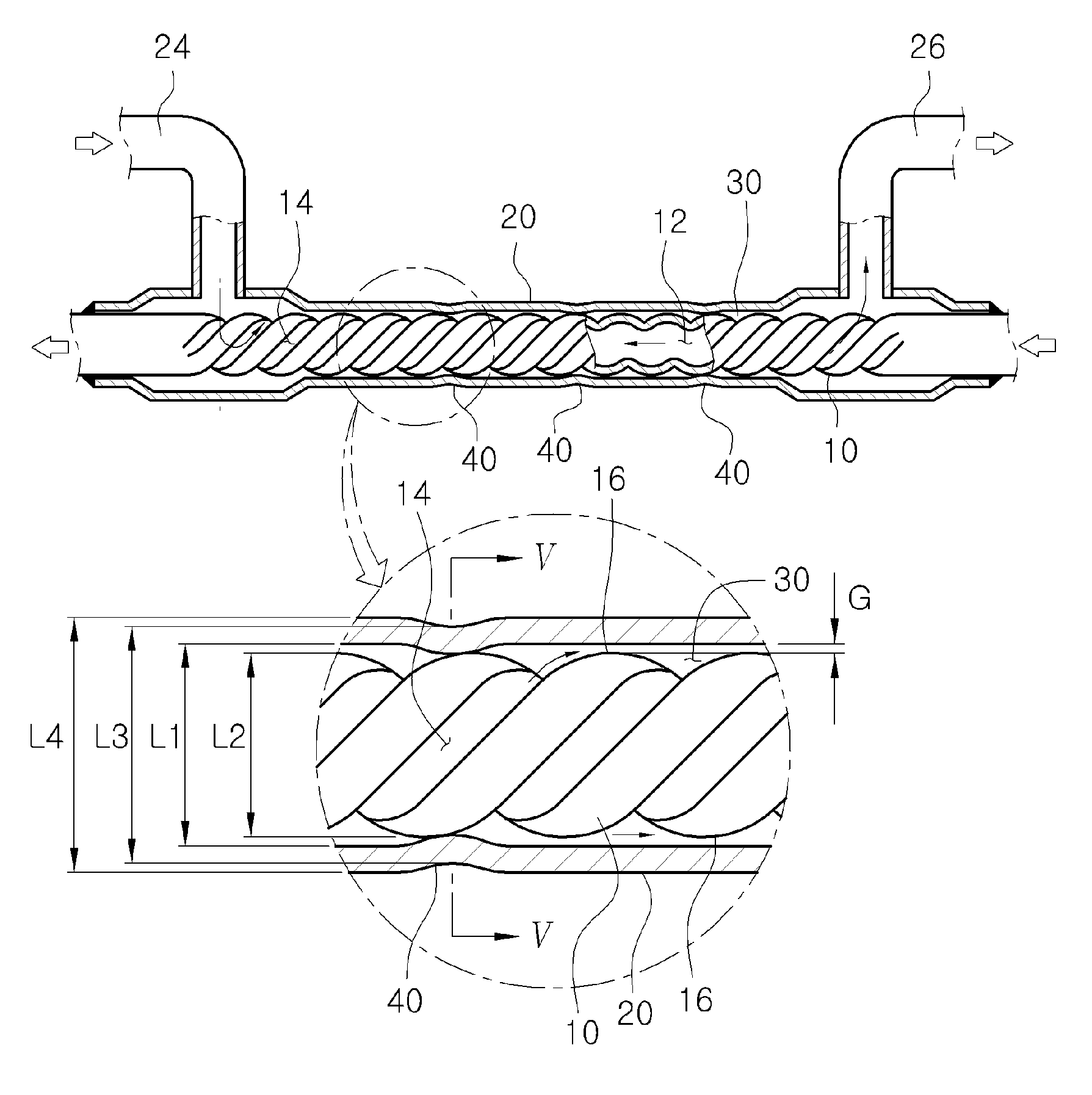

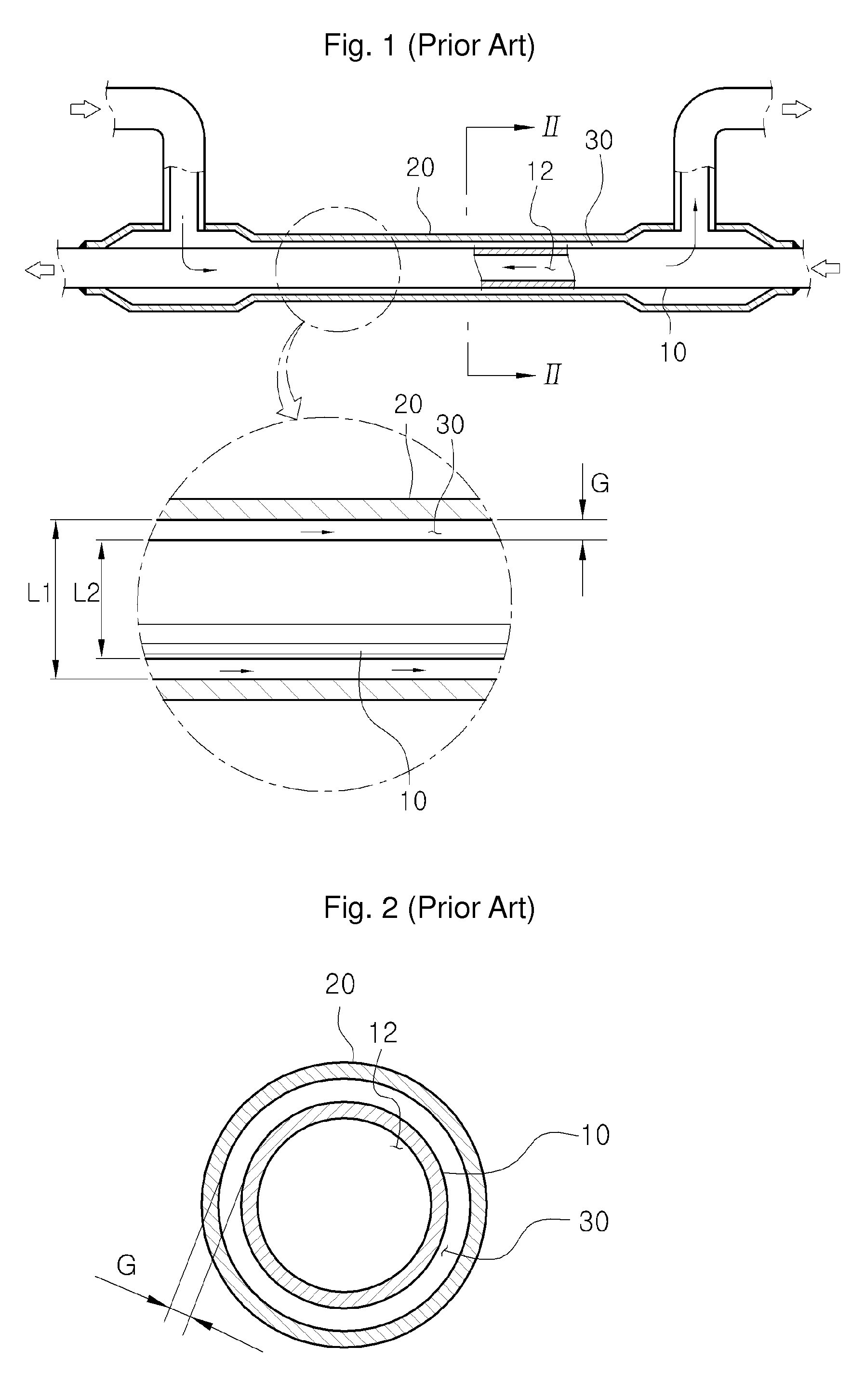

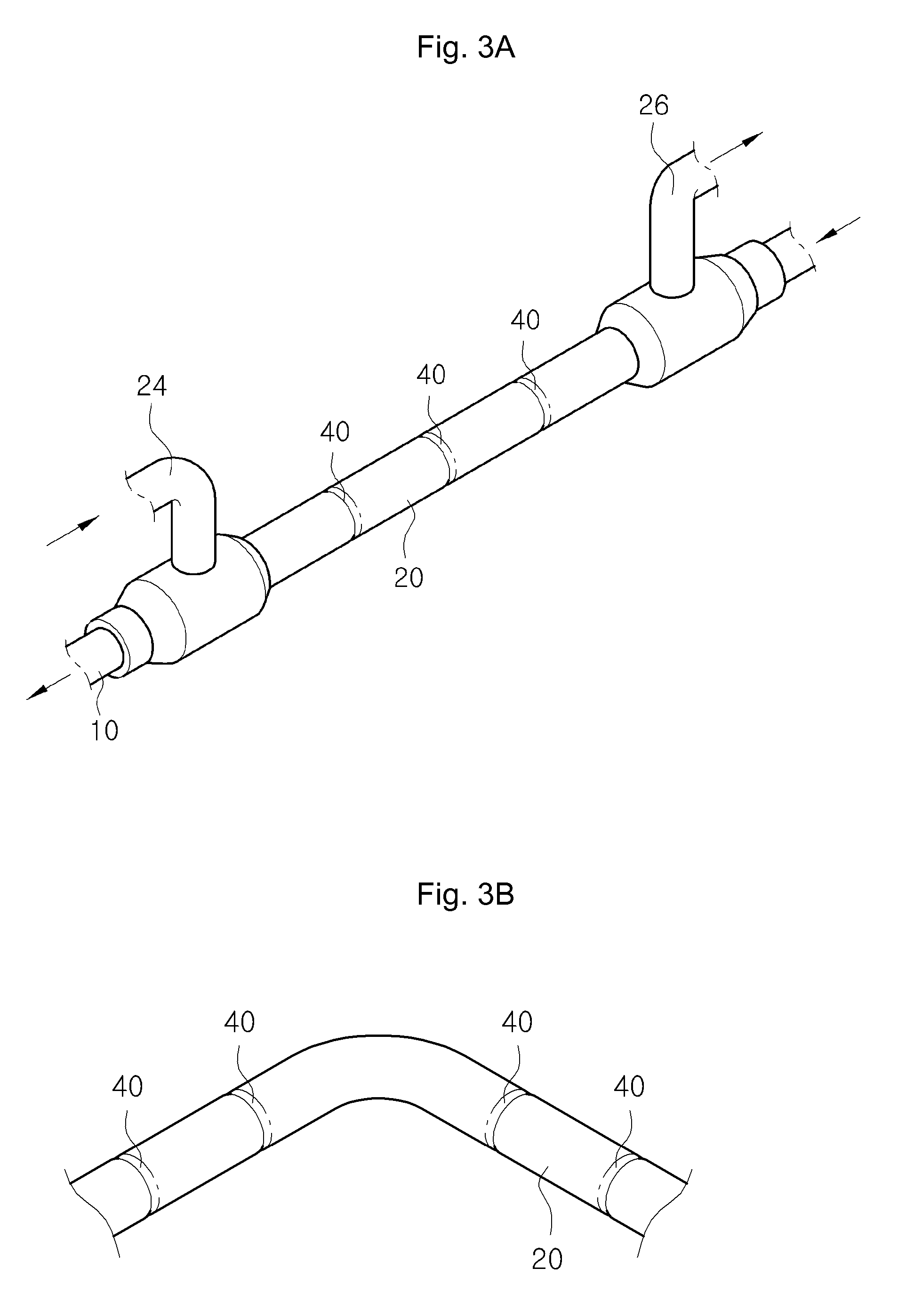

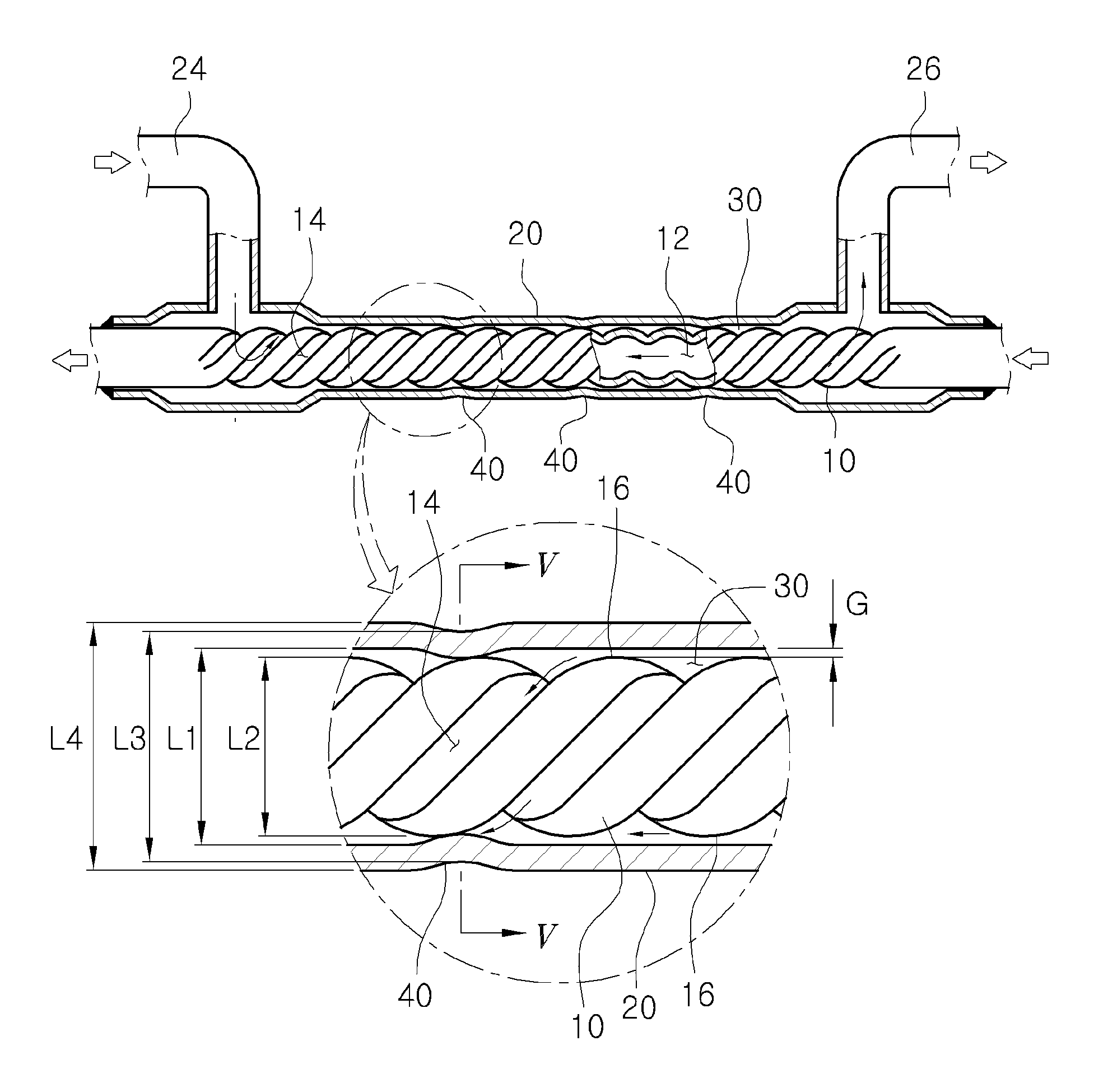

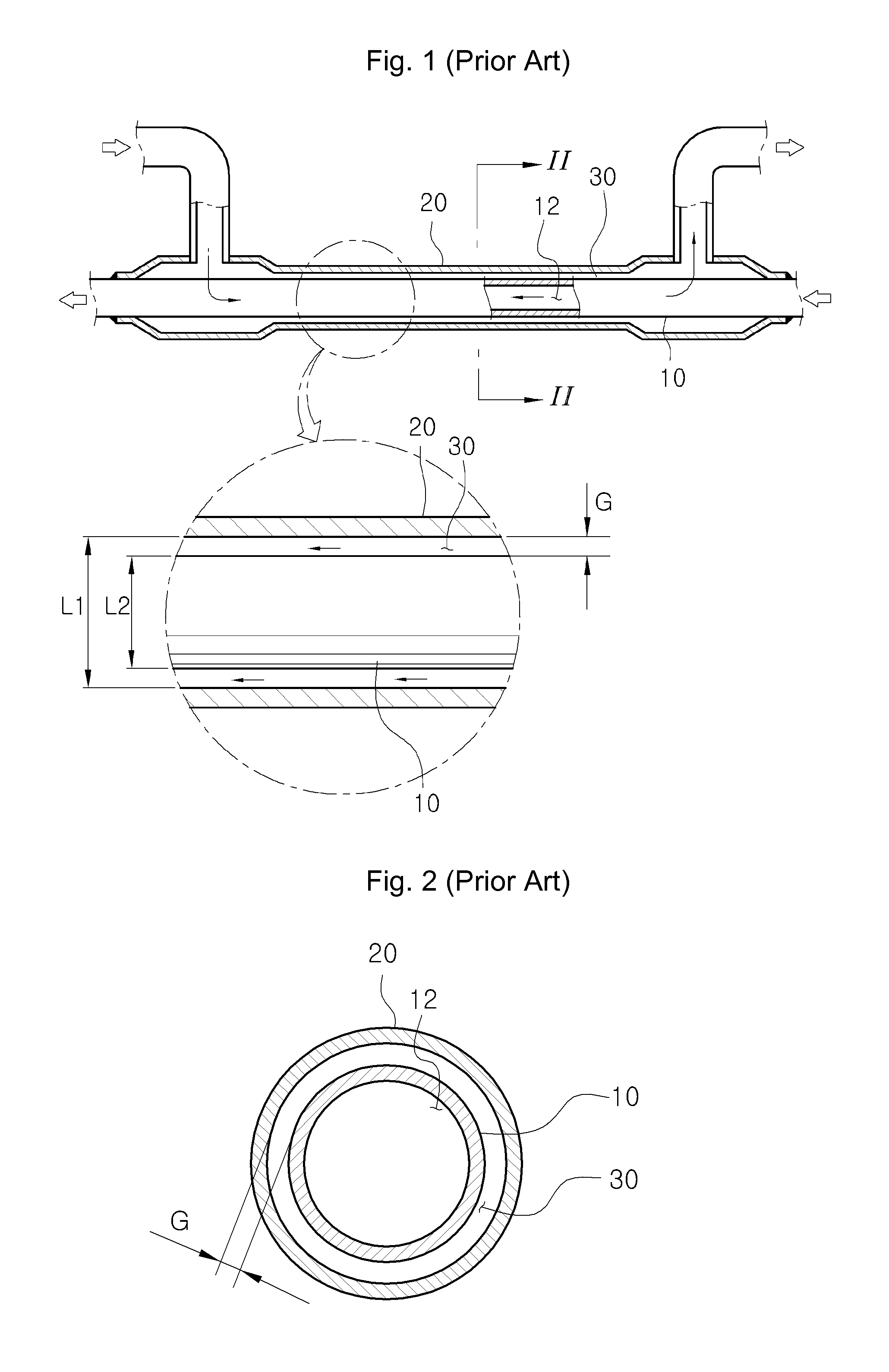

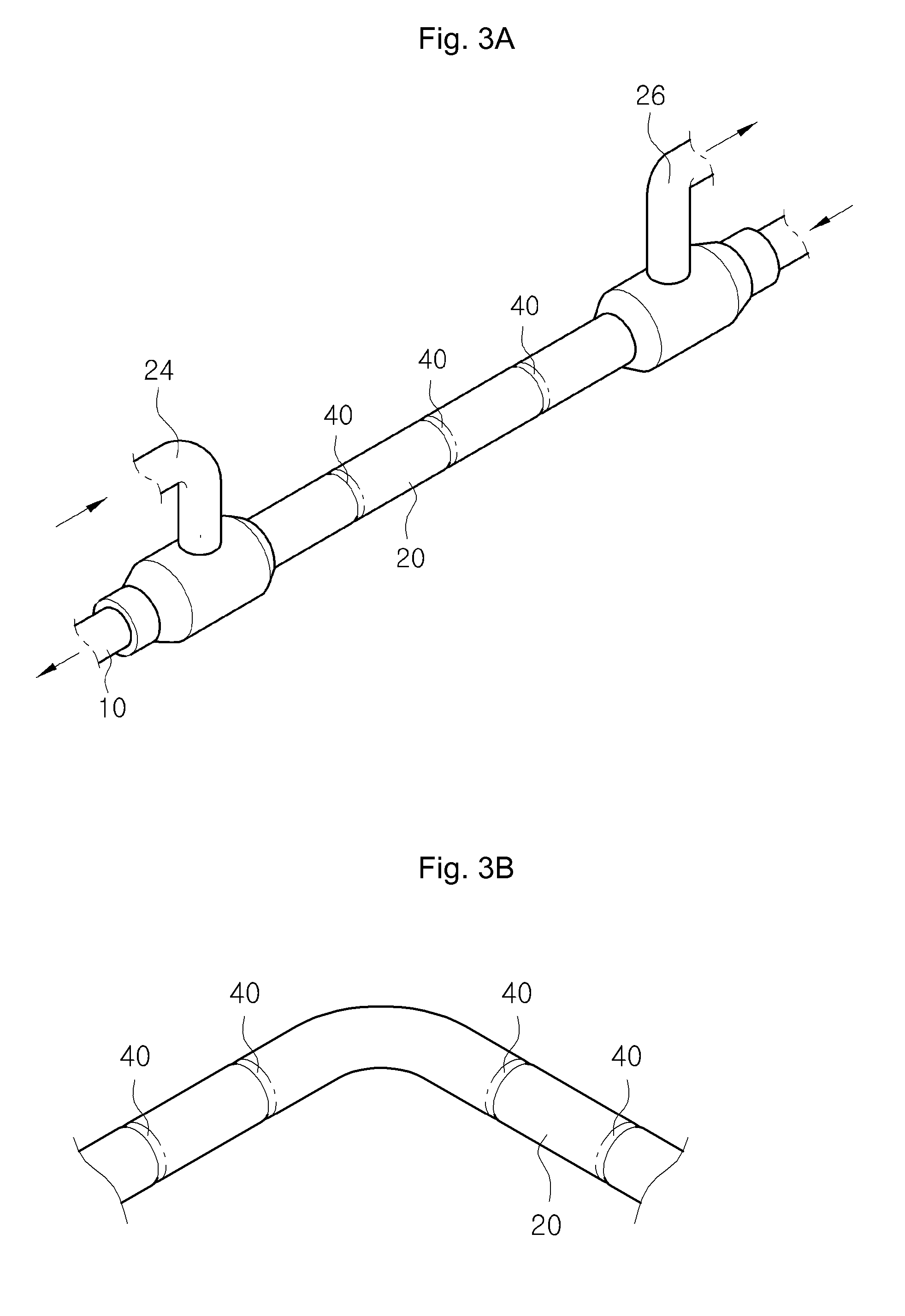

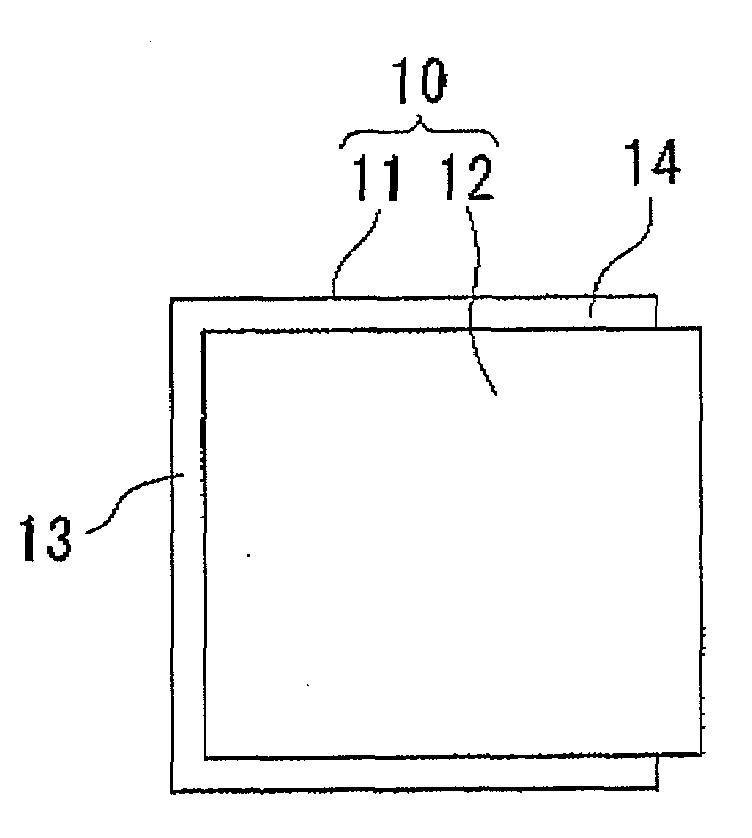

Double pipe type heat exchanger and method for manufacturing the same

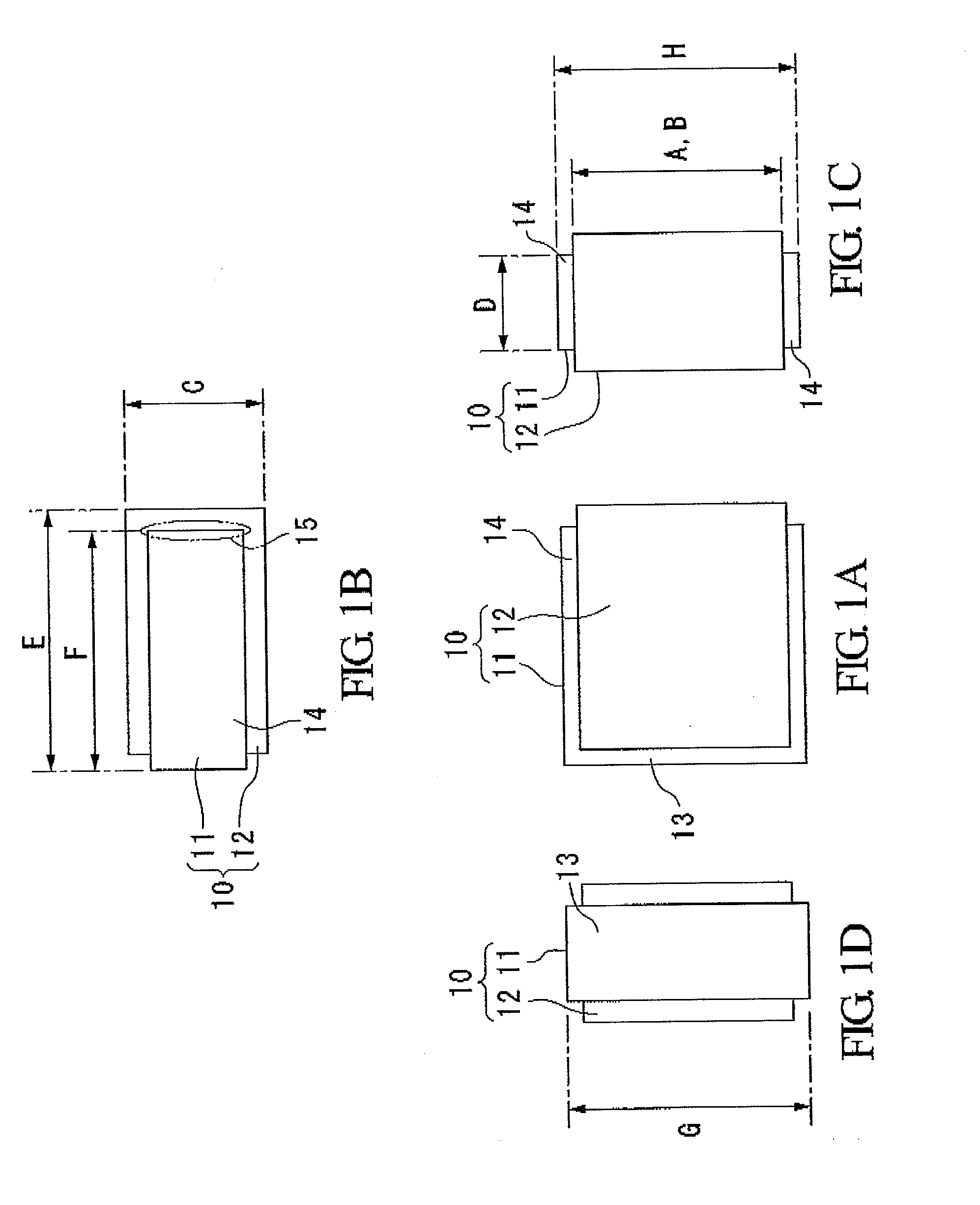

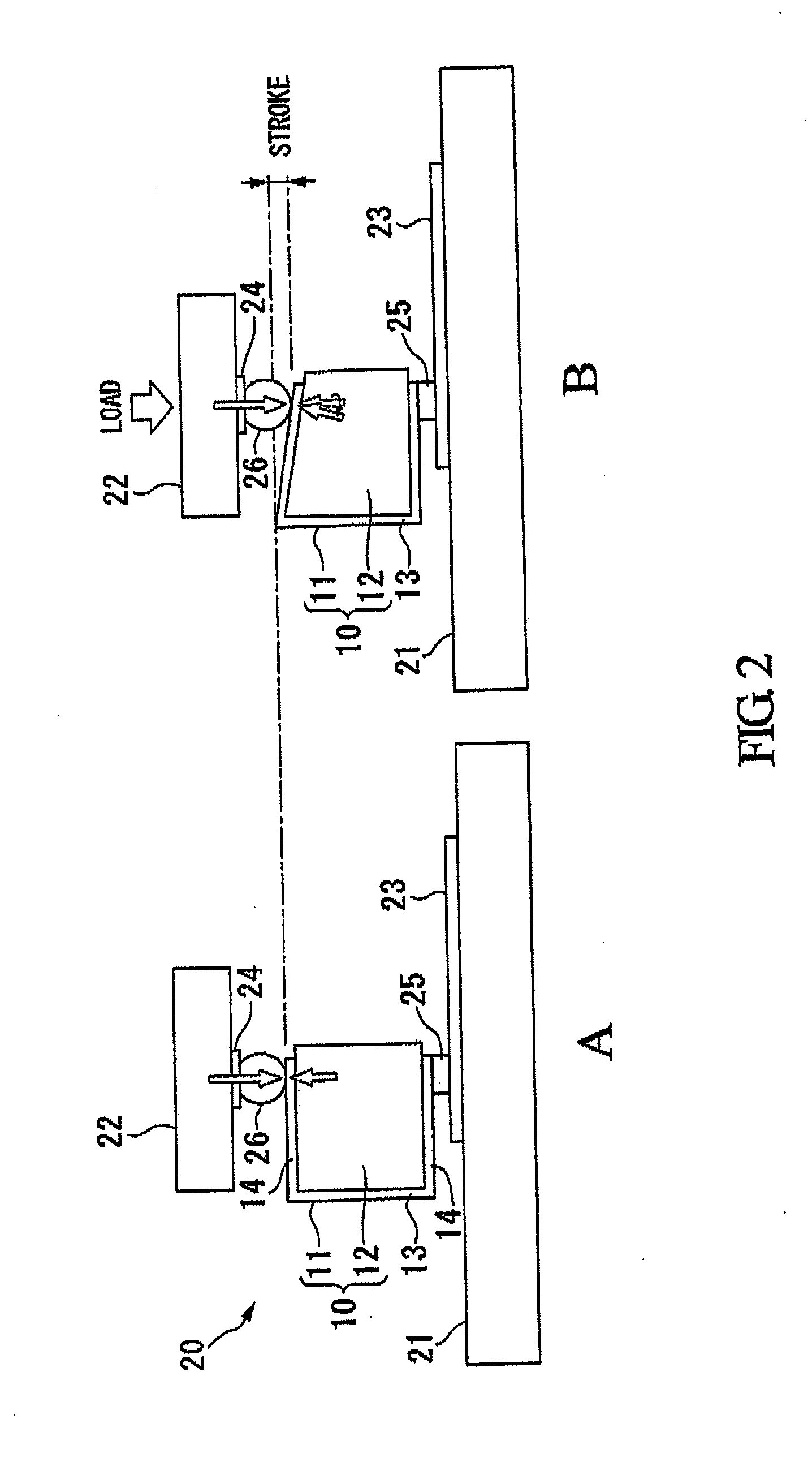

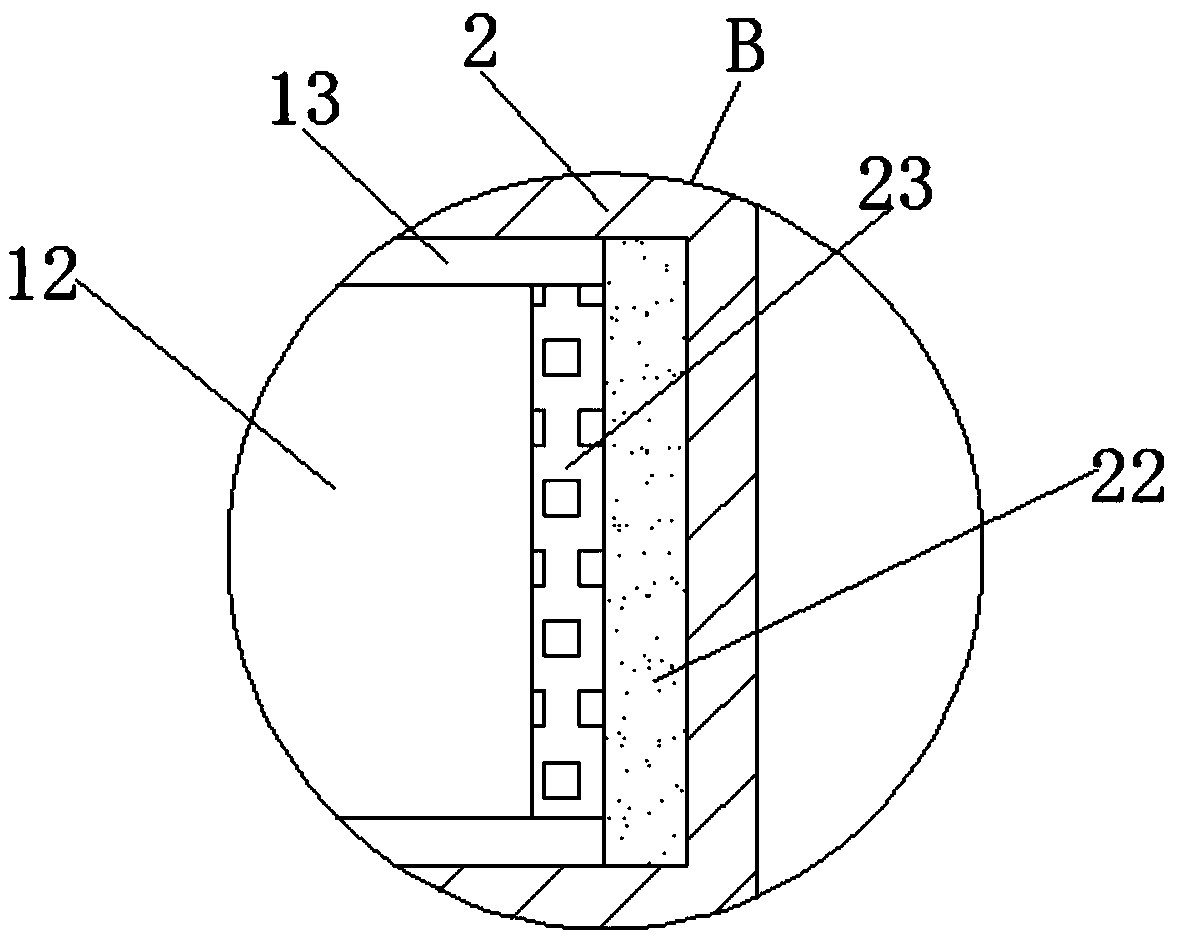

ActiveUS9091487B2Extend heat exchange timeAvoid frictional contactSafety devices for heat exchange apparatusHeat exhanger conduitsEngineeringHeat exchanger

A double pipe type heat exchanger includes an inner pipe having a first flow path defined therein and an outer pipe arranged around the inner pipe to define a second flow path between the inner pipe and the outer pipe. The inner pipe includes a spiral groove formed on an outer circumferential surface of the inner pipe to extend along a longitudinal direction of the inner pipe. The outer pipe includes a reduced diameter portion protruding inwardly so that the inner surface of the outer pipe is intermittently contacted with the outer circumferential surface of the inner pipe.

Owner:HANON SYST

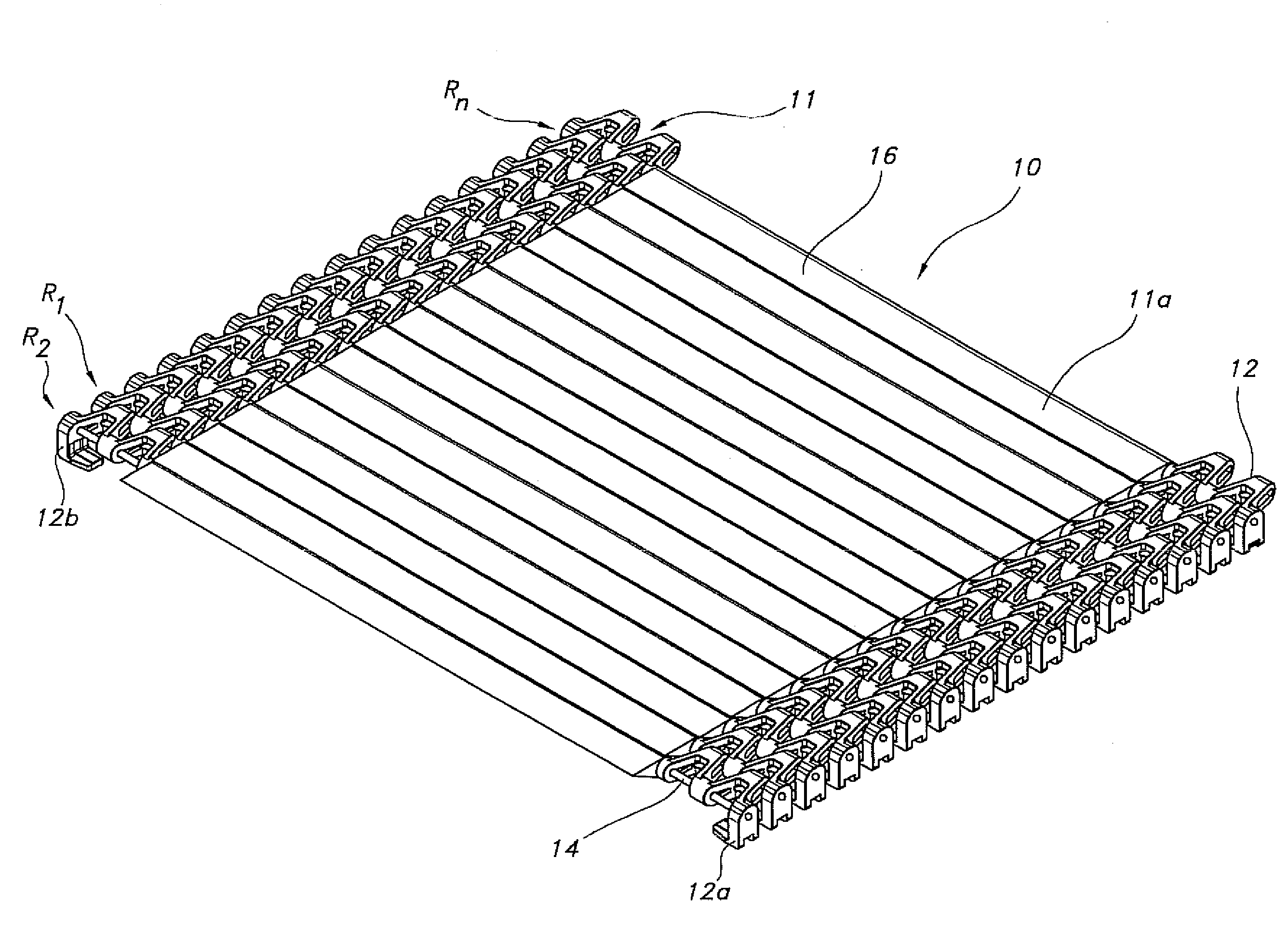

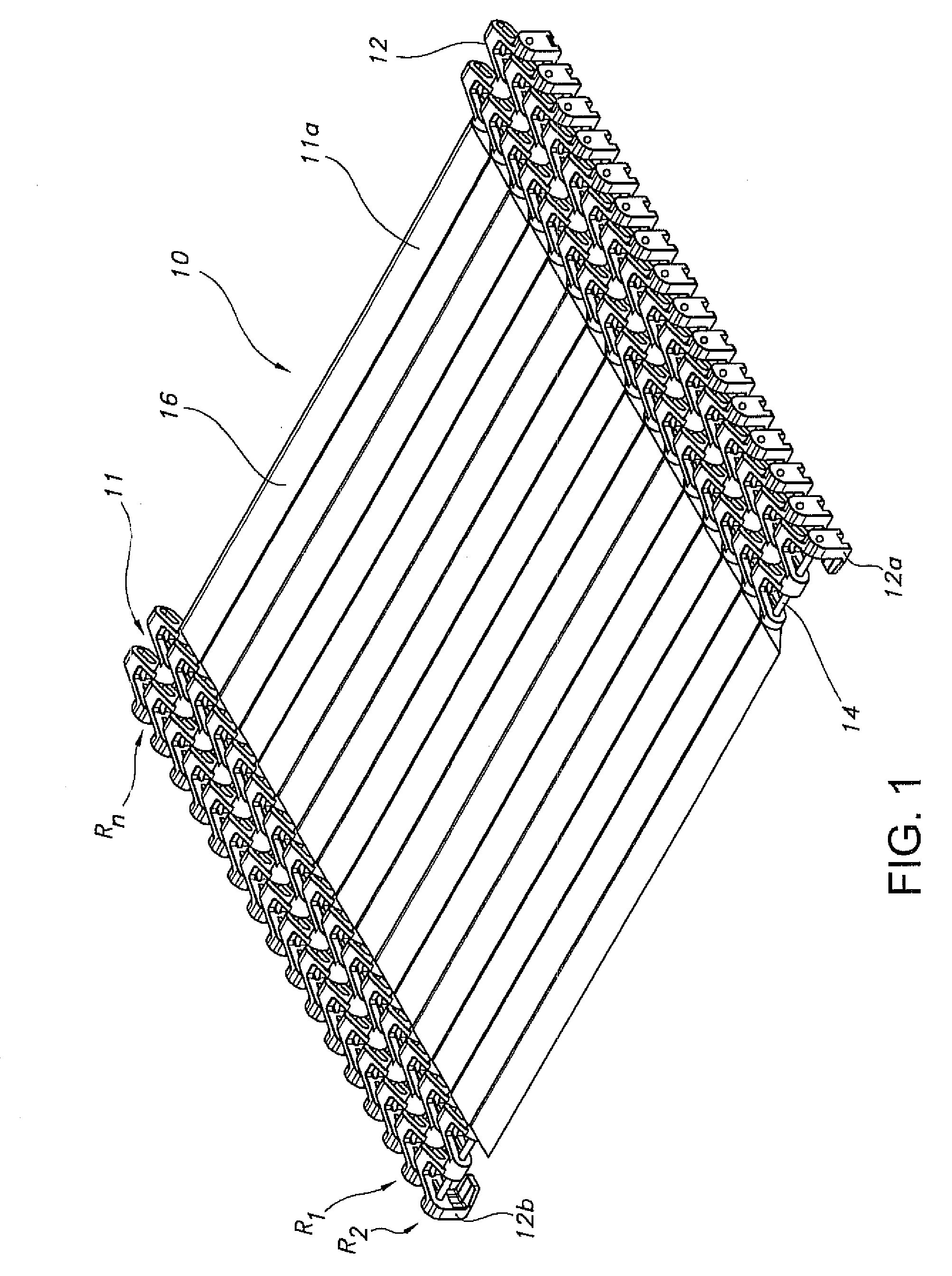

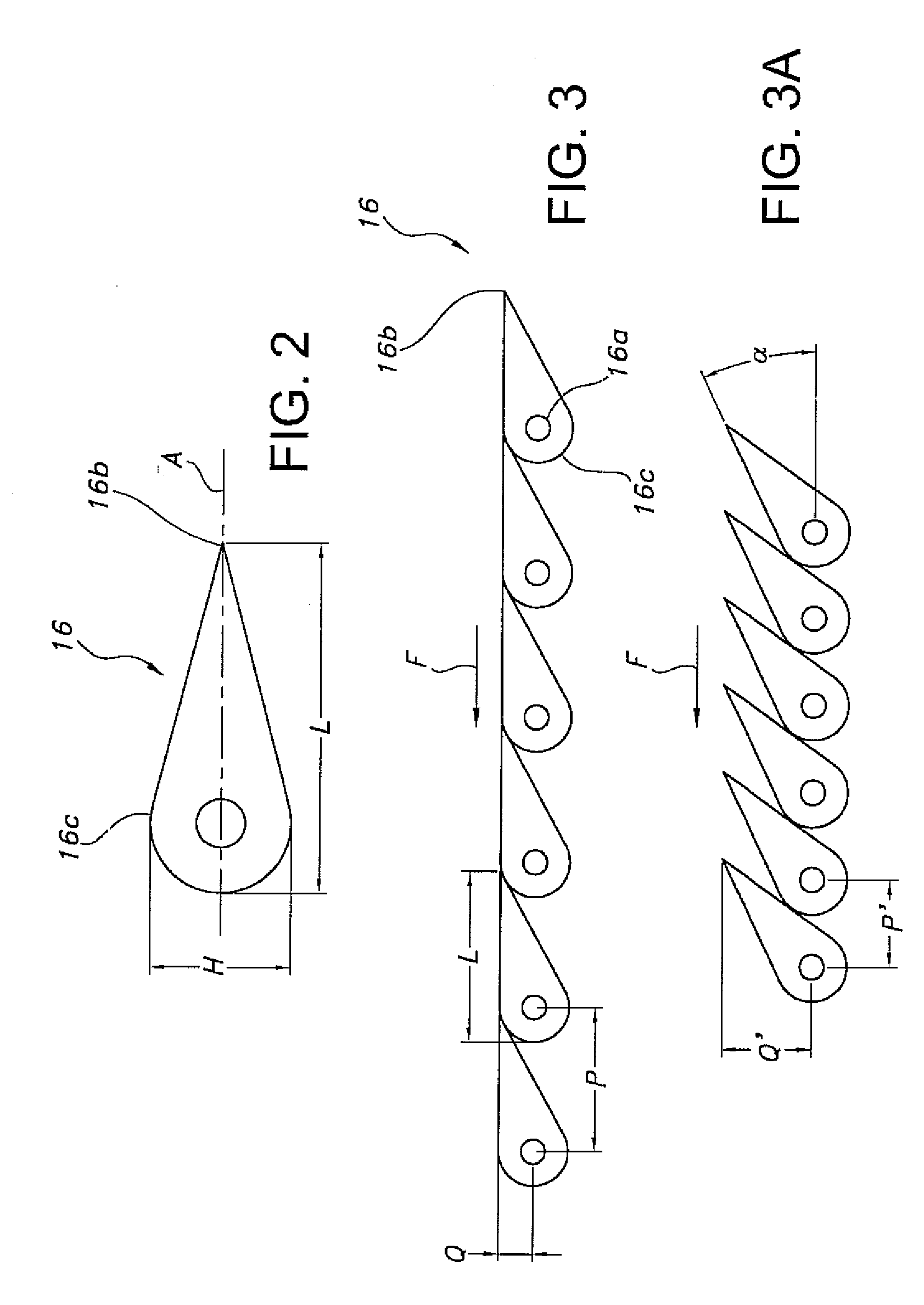

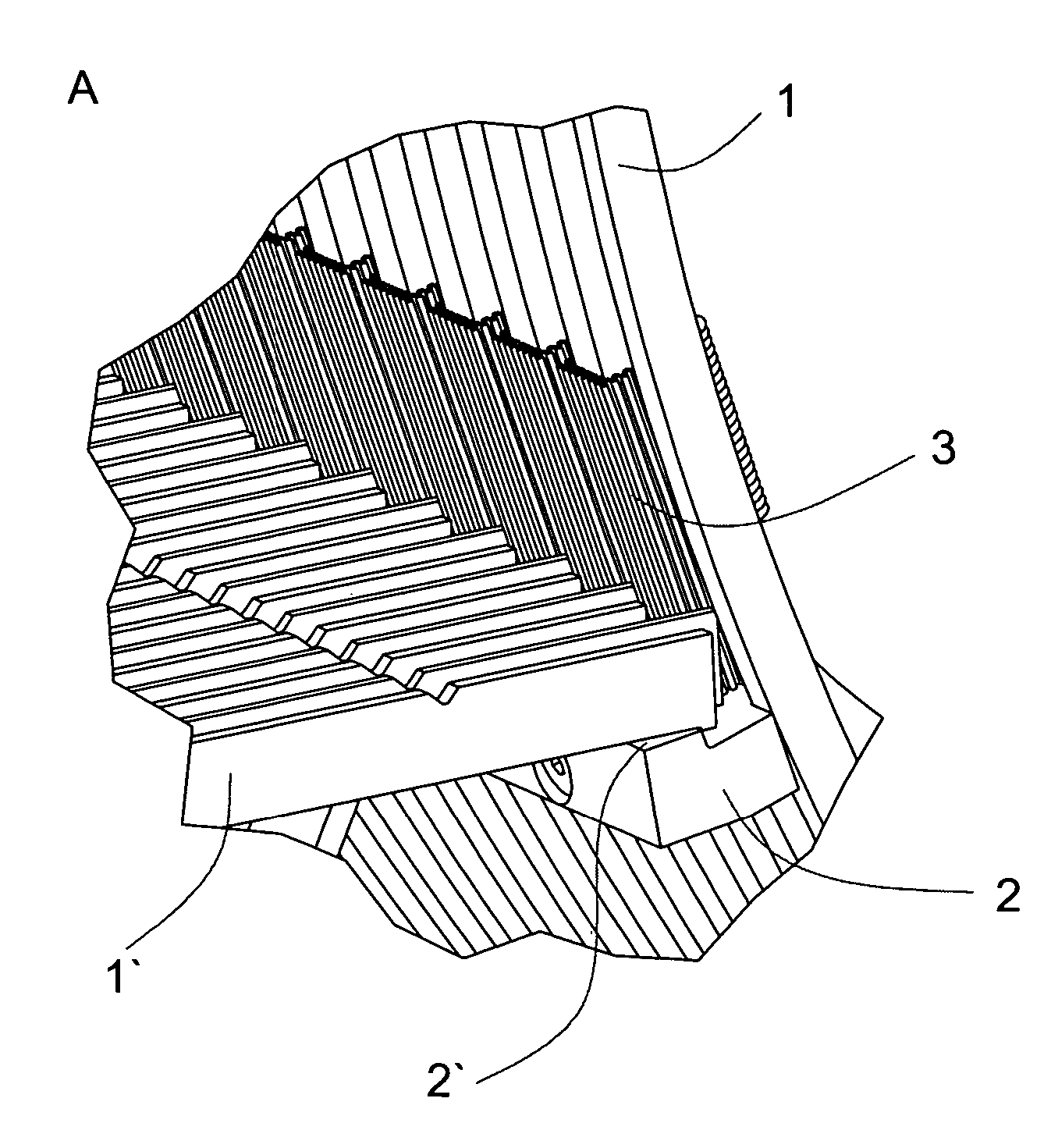

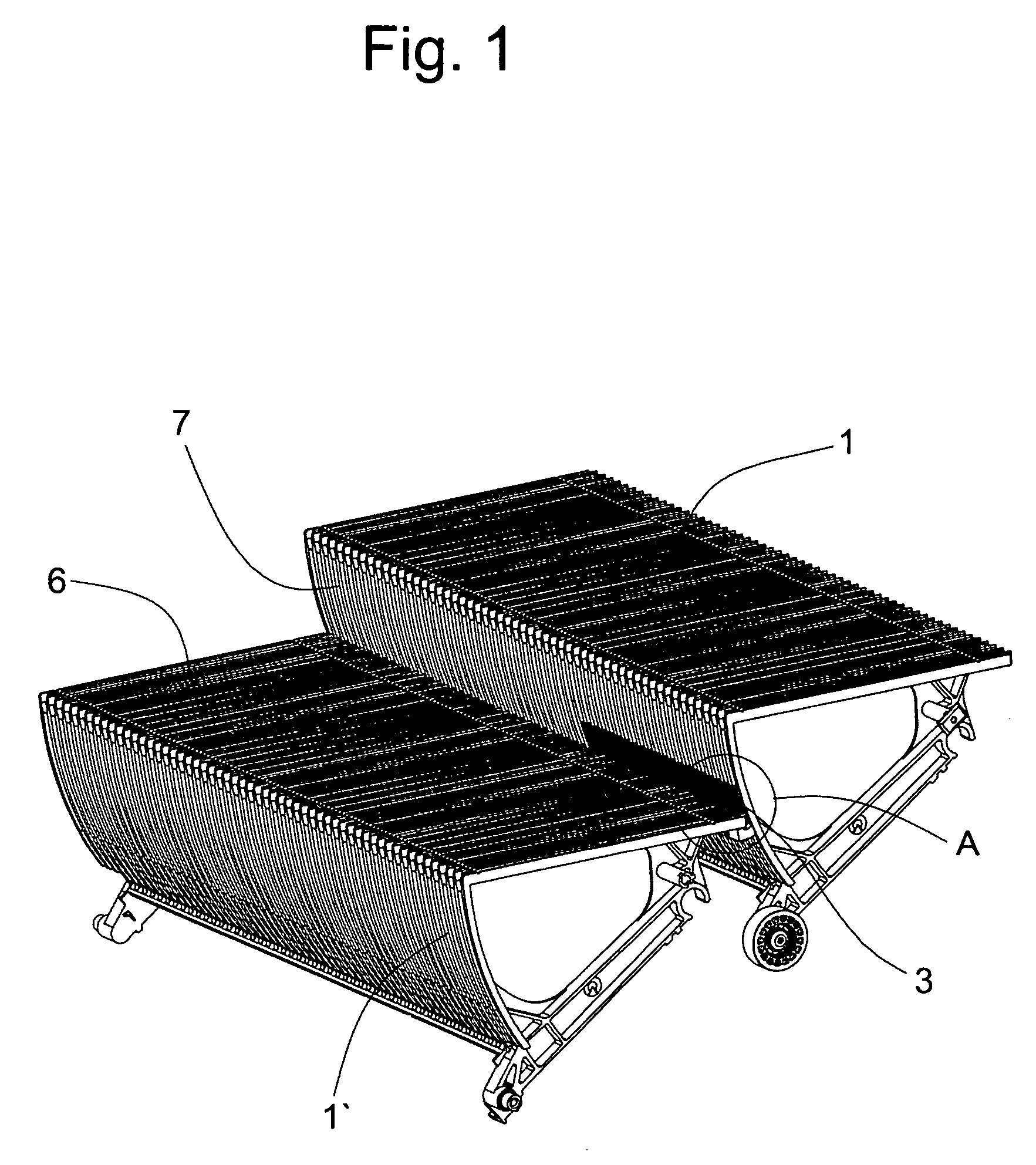

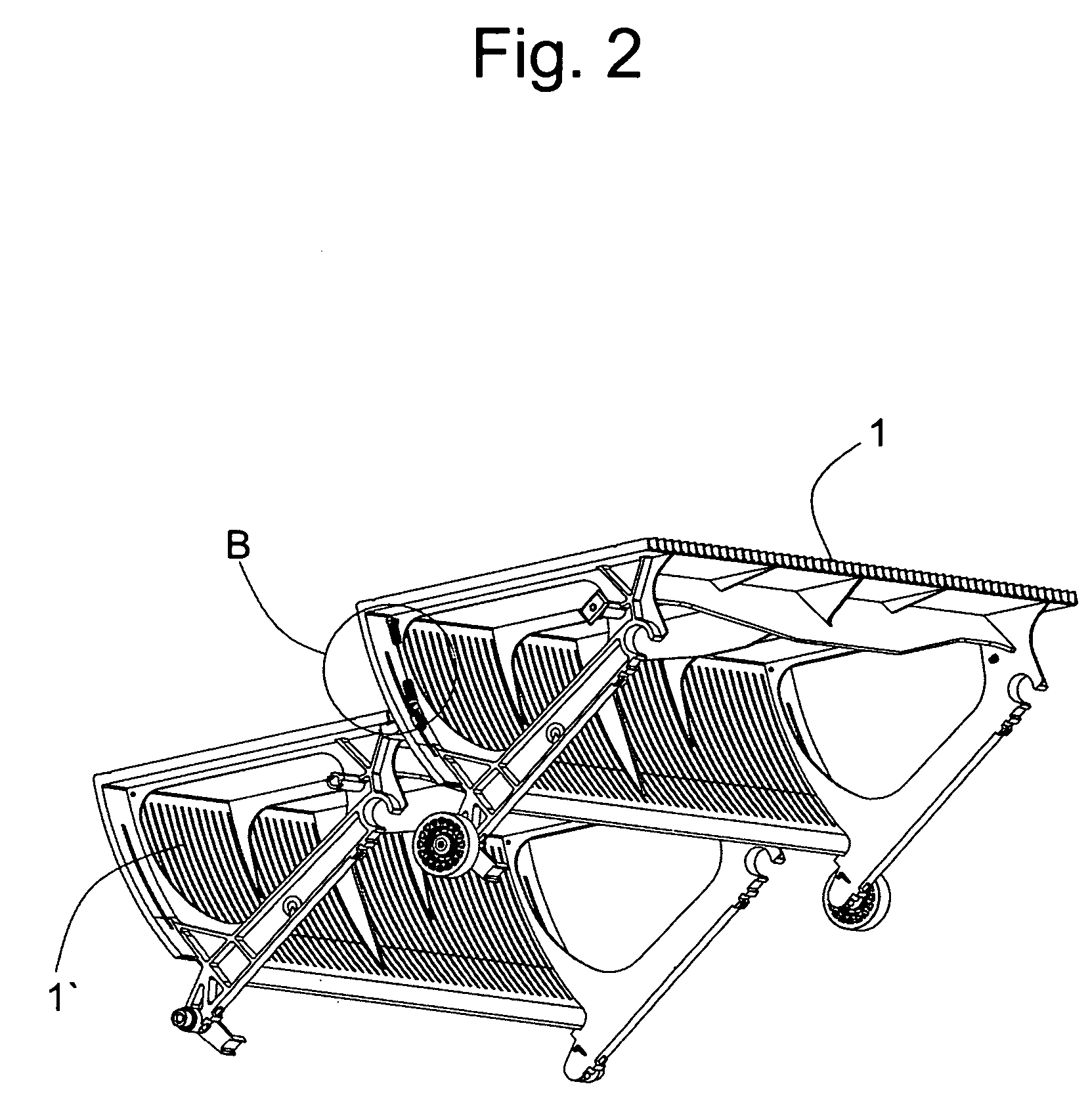

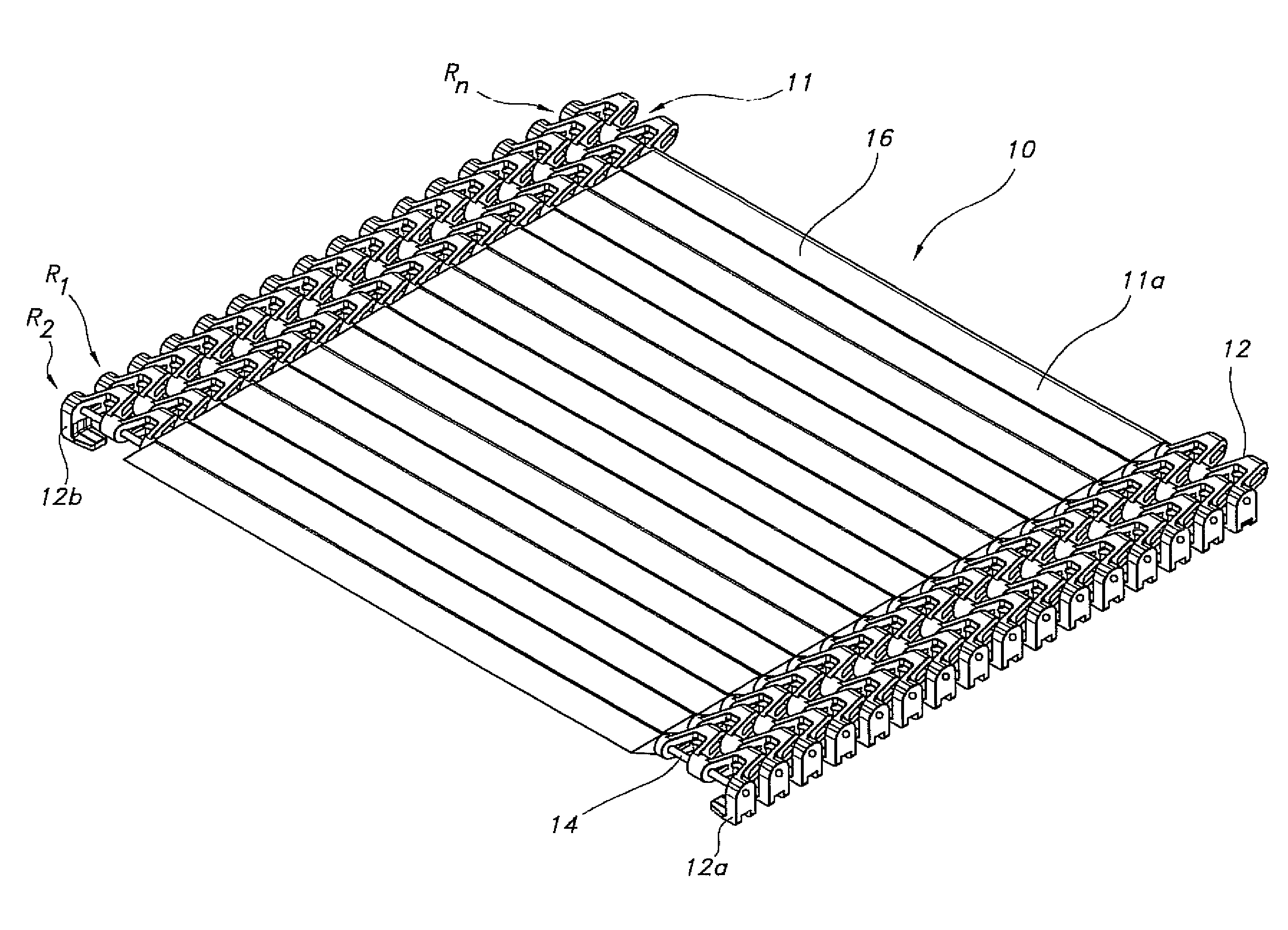

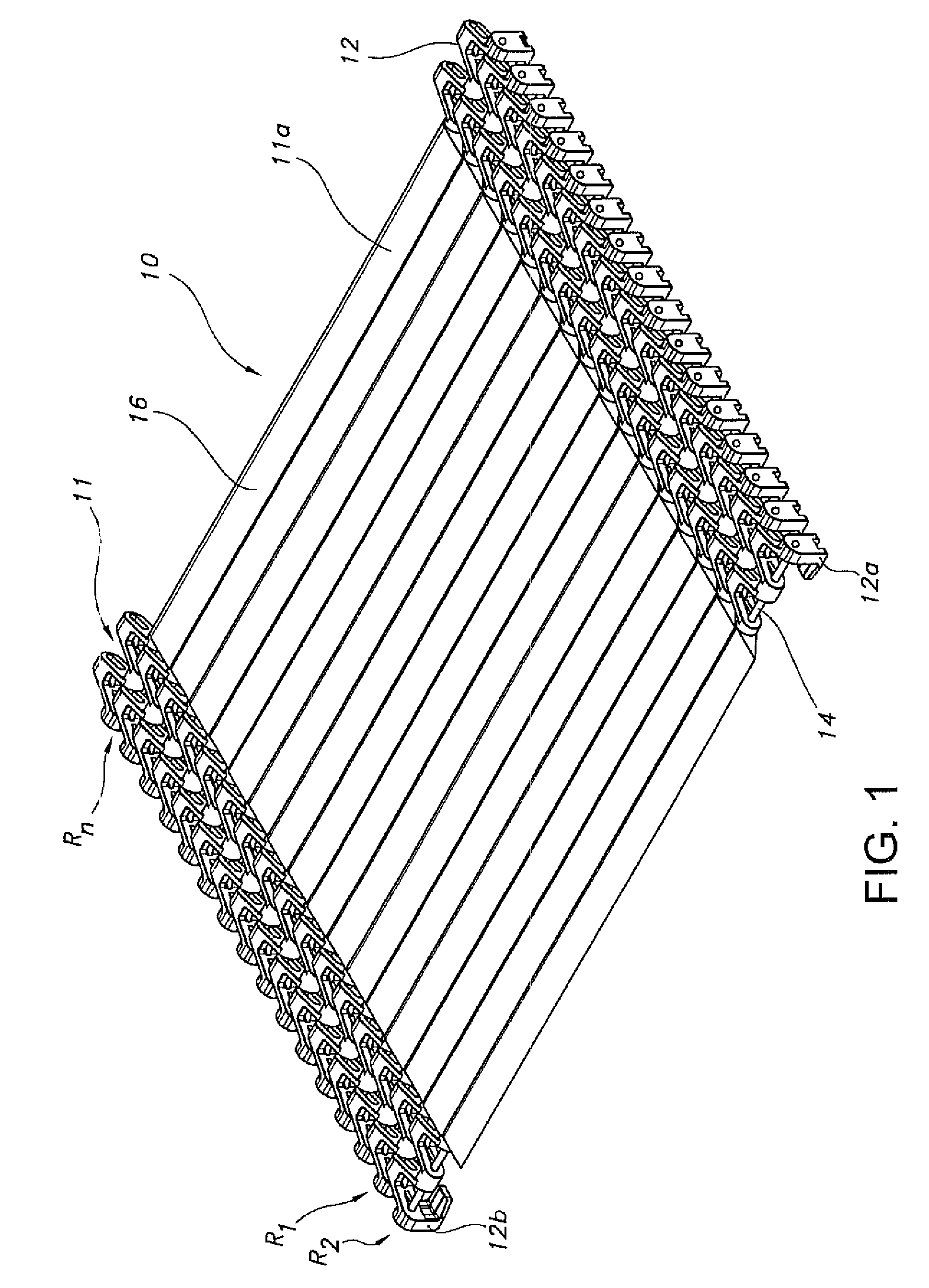

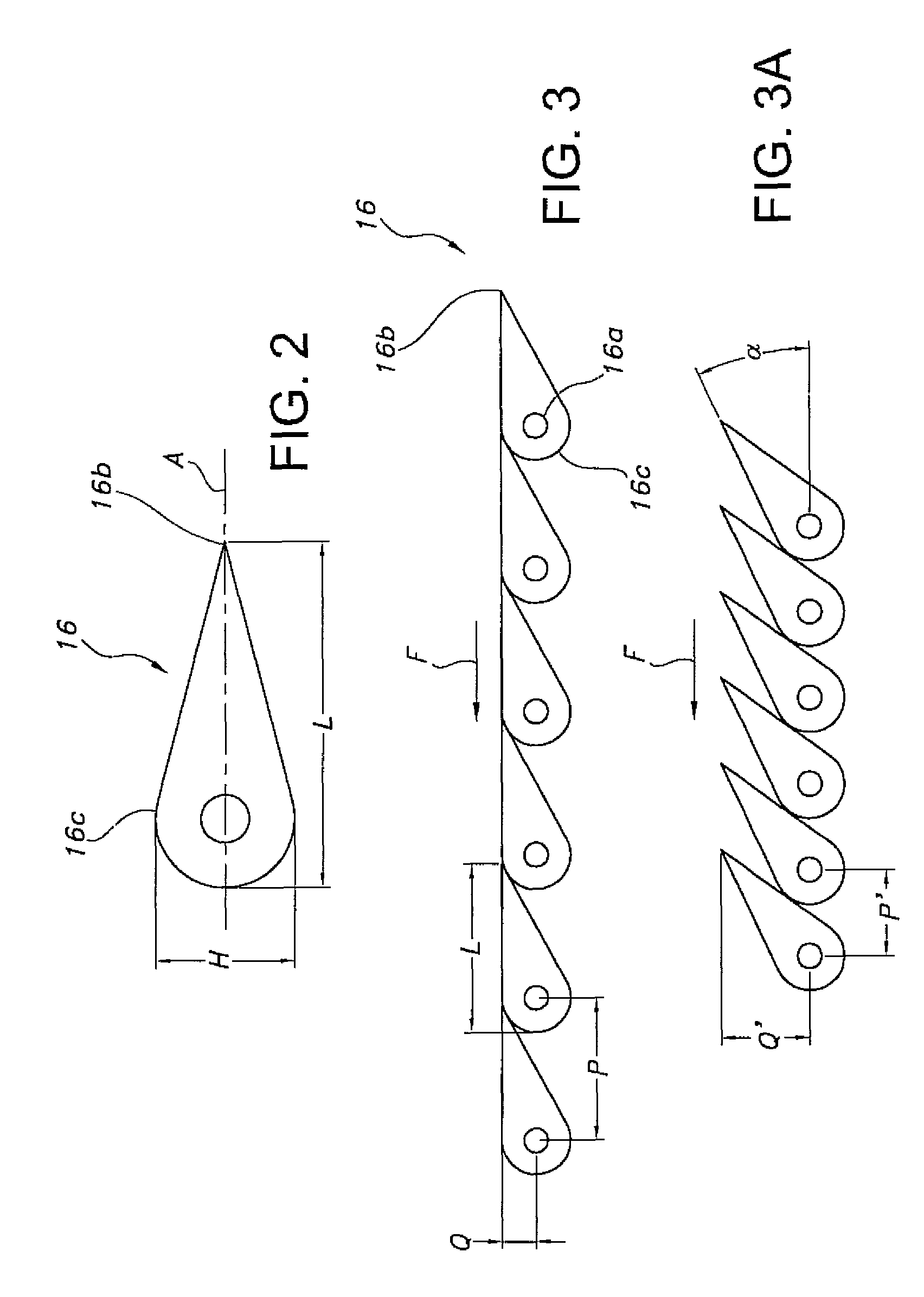

Side-flexing conveyor chain with pivoting slats and related methods

InactiveUS20090107805A1Avoid direct frictional contactReduce wearConveyorsPackagingEngineeringMechanical engineering

Owner:SPAN TECH

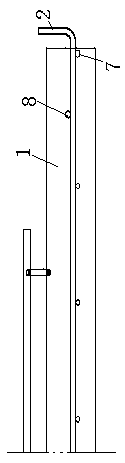

Double Pipe Type Heat Exchanger and Method for Manufacturing the Same

ActiveUS20120043055A1Efficiently exchange heatImprove performanceSafety devices for heat exchange apparatusHeat exhanger conduitsEngineeringHeat exchanger

A double pipe type heat exchanger includes an inner pipe having a first flow path defined therein and an outer pipe arranged around the inner pipe to define a second flow path between the inner pipe and the outer pipe. The inner pipe includes a spiral groove formed on an outer circumferential surface of the inner pipe to extend along a longitudinal direction of the inner pipe. The outer pipe includes a reduced diameter portion protruding inwardly so that the inner surface of the outer pipe is intermittently contacted with the outer circumferential surface of the inner pipe.

Owner:HANON SYST

Escalator with riser brushes, step of such an escalator and method of modernizing an escalator

ActiveUS7204361B2Pinching or wedging of objects is avoided or greatly minimizedEasy to useMine liftsEscalatorsClassical mechanicsEngineering

An escalator with steps having a tread surface and riser surface has riser brushes arranged at the riser surface. The riser brushes provide a barrier for the gap which is normally present between the tread surface of a first step and the riser surface of an adjacent step. The riser brushes may be mounted to a brush strip which is guided along the riser as the steps transfer between vertical and horizontal travel.

Owner:INVENTIO AG

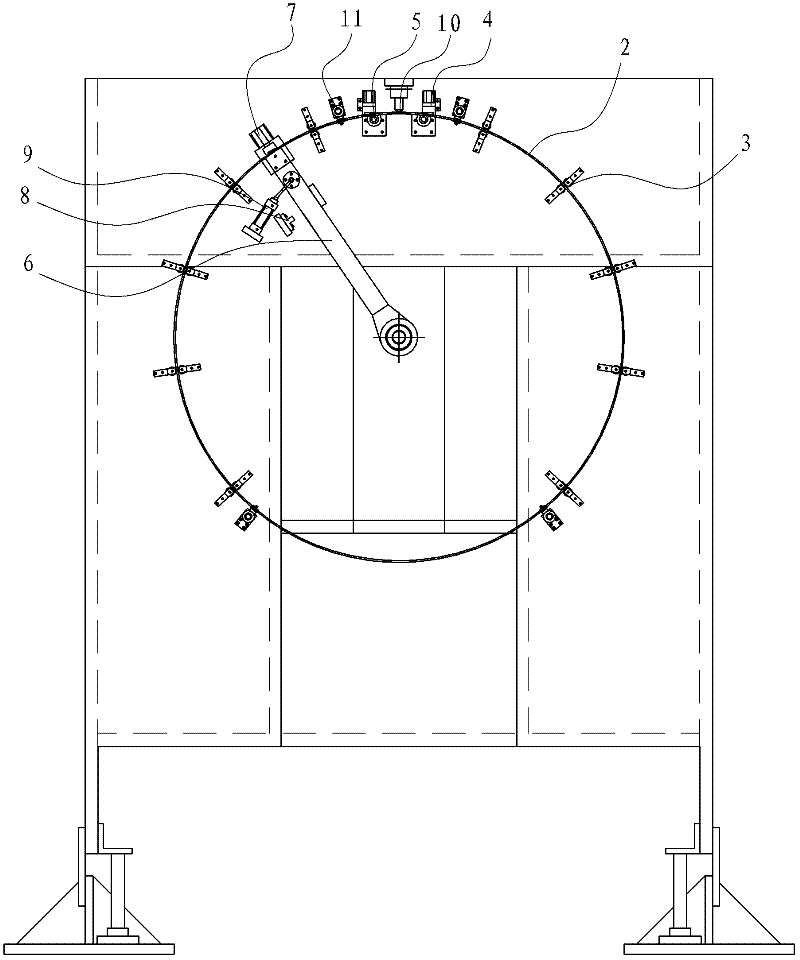

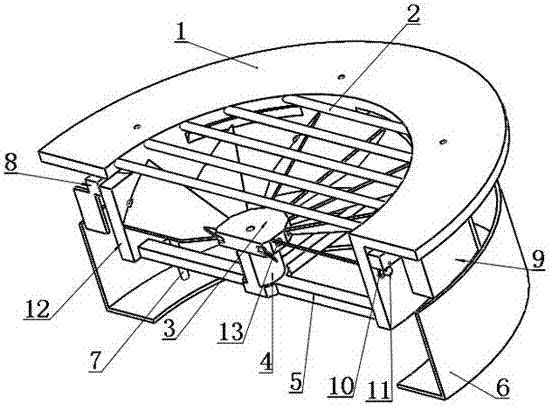

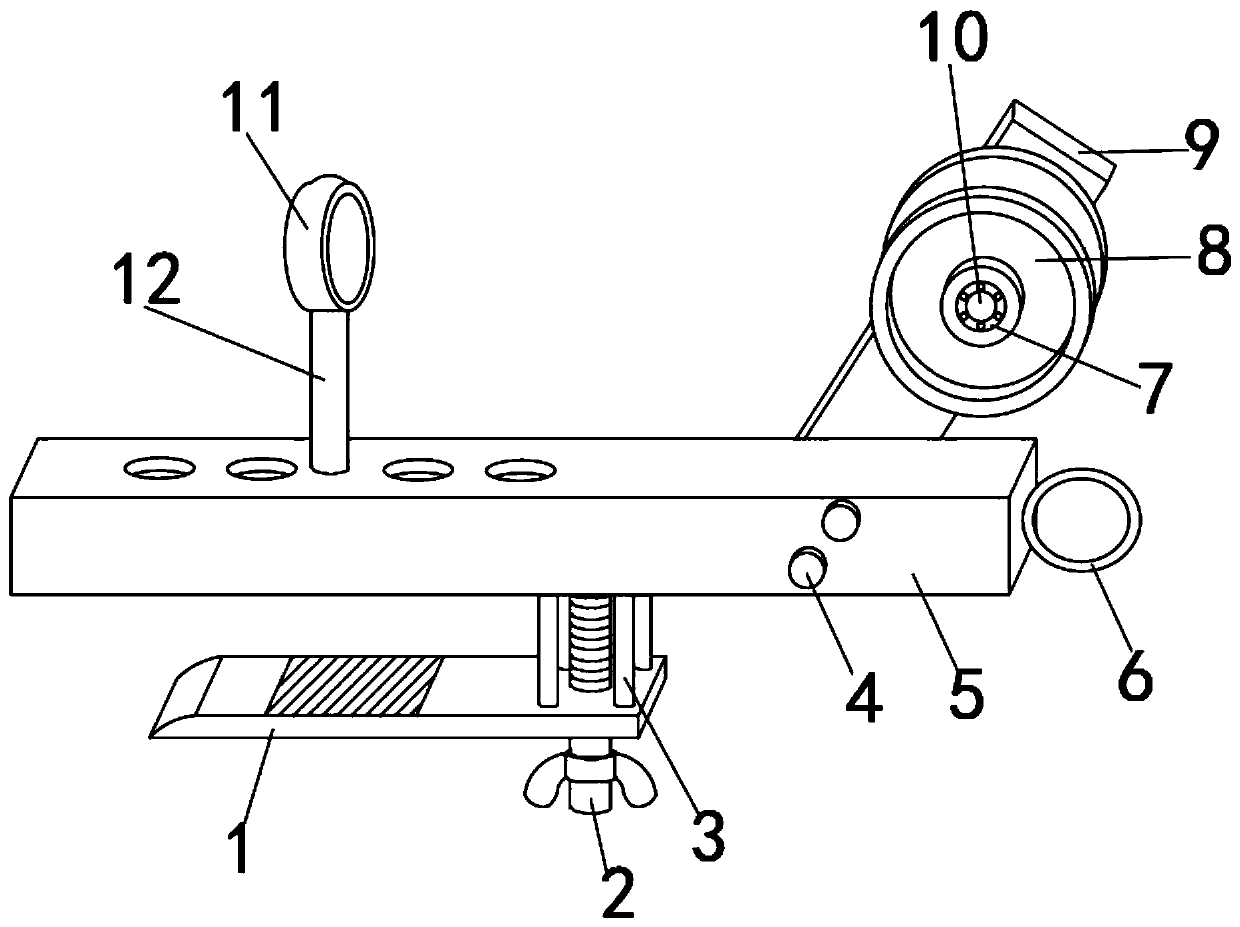

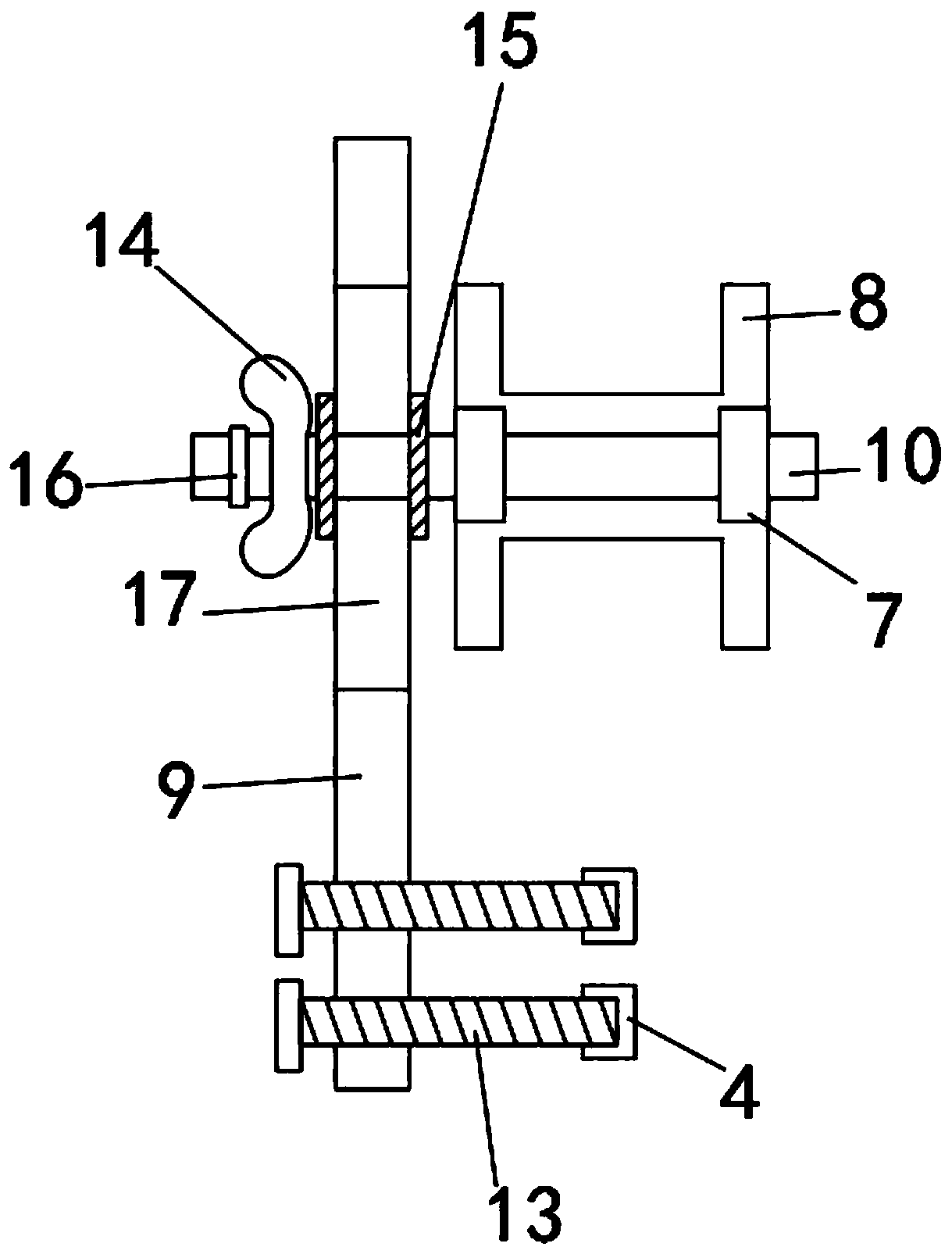

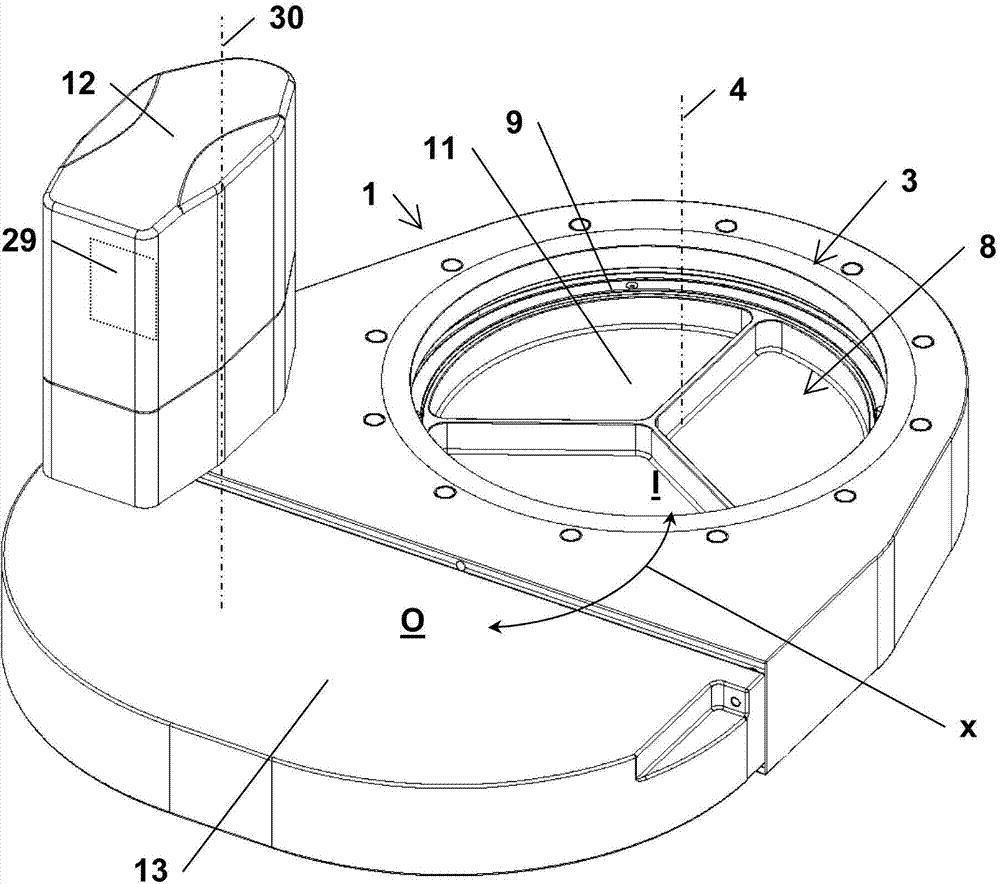

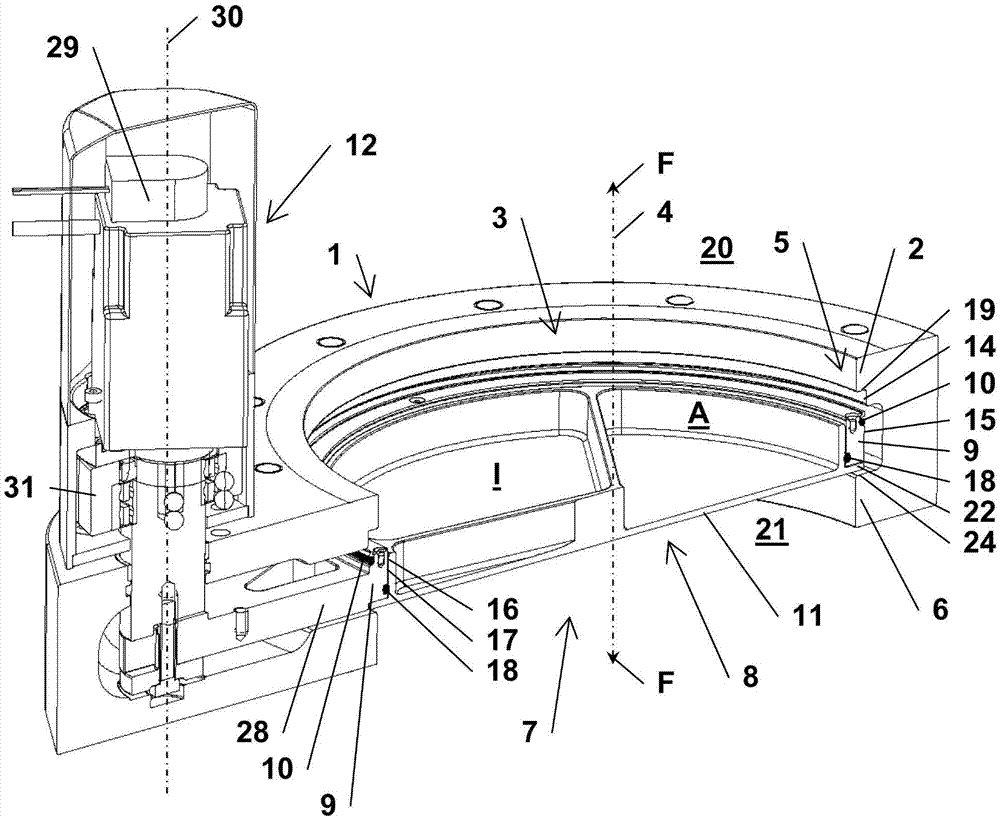

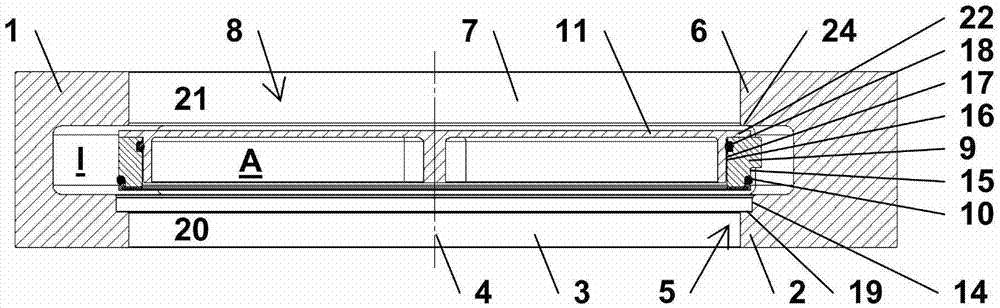

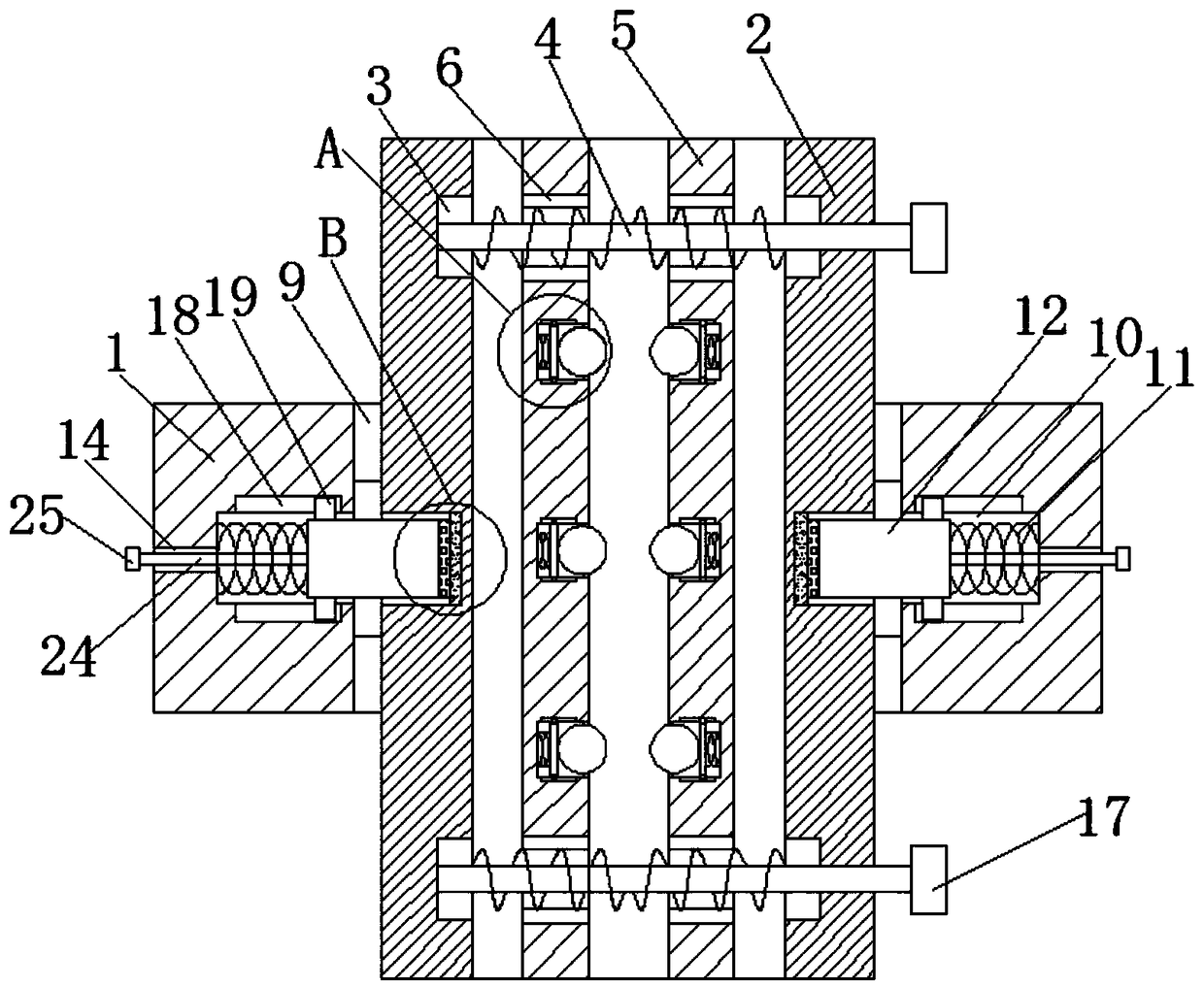

A processing method and a pocket hole processing device for an integral cage of a wind power equipment bearing

InactiveCN102267042AGuaranteed accuracyAvoid early wearPositioning apparatusMetal-working holdersElectricityRounding

The invention relates to a pocket machining device and a method for machining an integral bearing retainer of wind power equipment. The machining method comprises the steps of material feeding, rough rounding, welding, fine rounding and shaping in sequence, as well as pocket machining; the machining method is characterized in that: in the material feeding step, a cold-rolled plate is cut into a straight-strip-shaped pocket-free plate; the pocket machining step is performed after the fine rounding step and before the shaping step; and the roundness of pockets on the retainer can be ensured, the pockets can be prevented from deforming and generating multi-edge round, and the precision of the pockets on the retainer can be guaranteed. The pocket machining device comprises a supporting mechanism, a radial positioning mechanism, an axial positioning mechanism, a retainer driving and moving mechanism and a movable arm limiting mechanism, as well as a hydraulic control system which is used for controlling a first cylinder, a second cylinder, a movable arm cylinder and a third cylinder. The functions of clamping, positioning, equal-distance feeding, compressing and discharging and the like of the retainer after being welded into a whole can be realized during pocket laser cutting and machining.

Owner:田天红

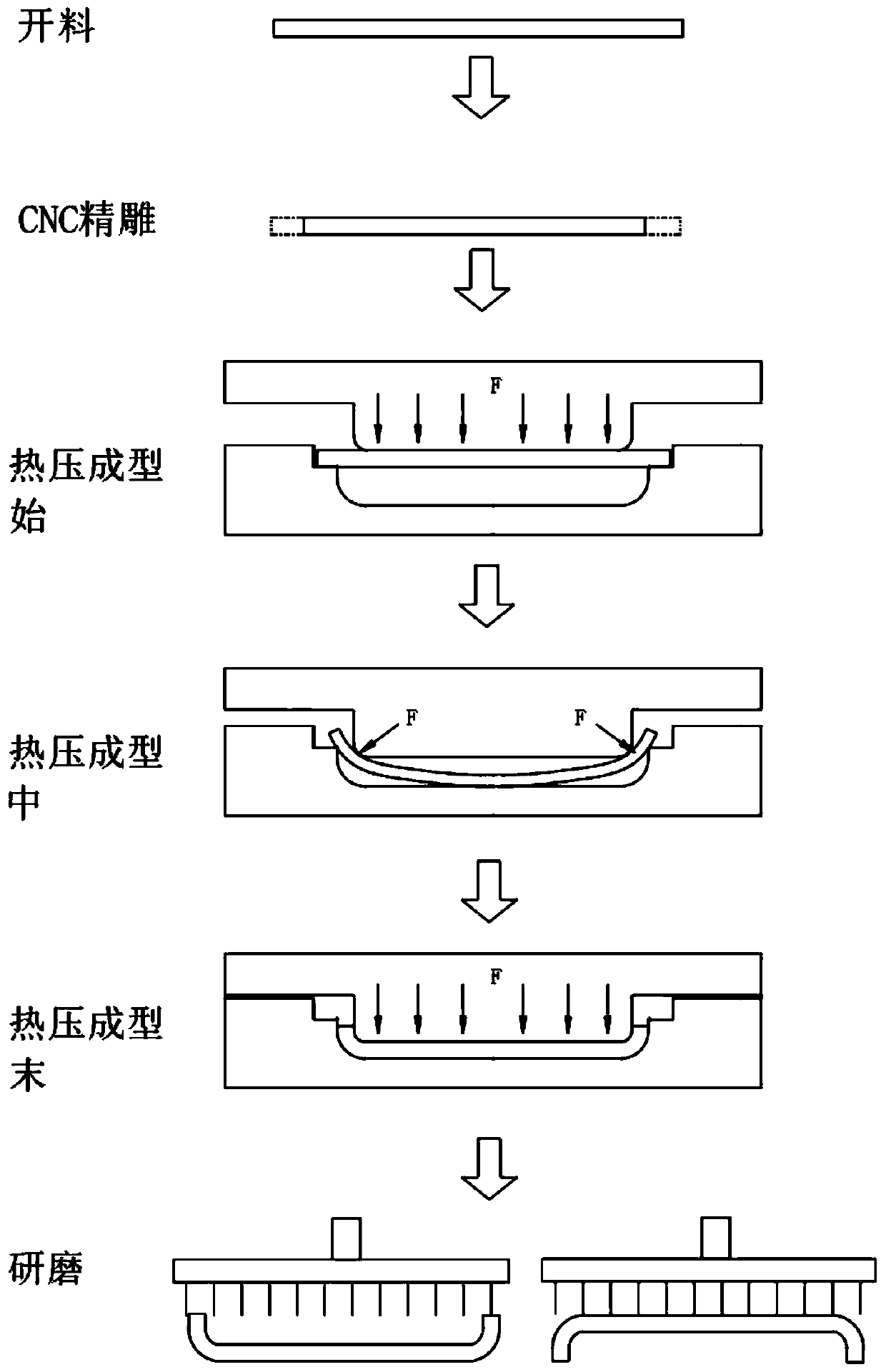

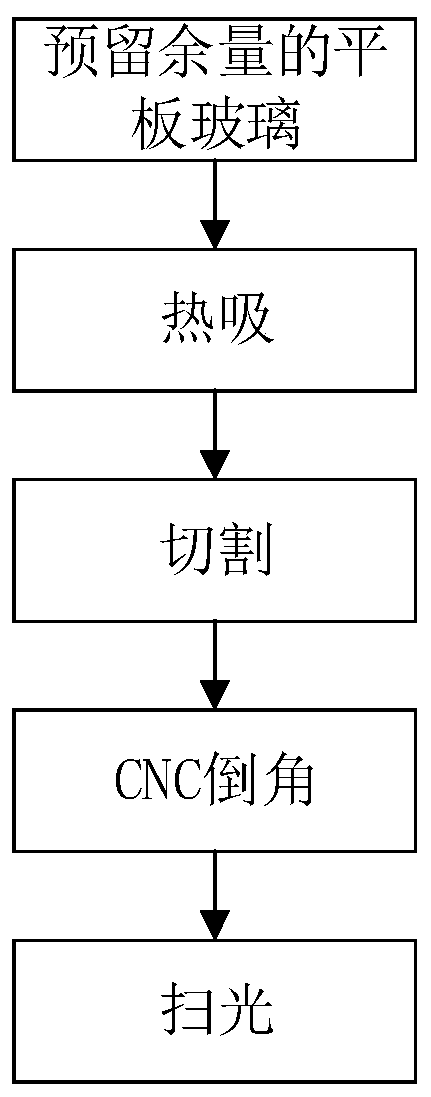

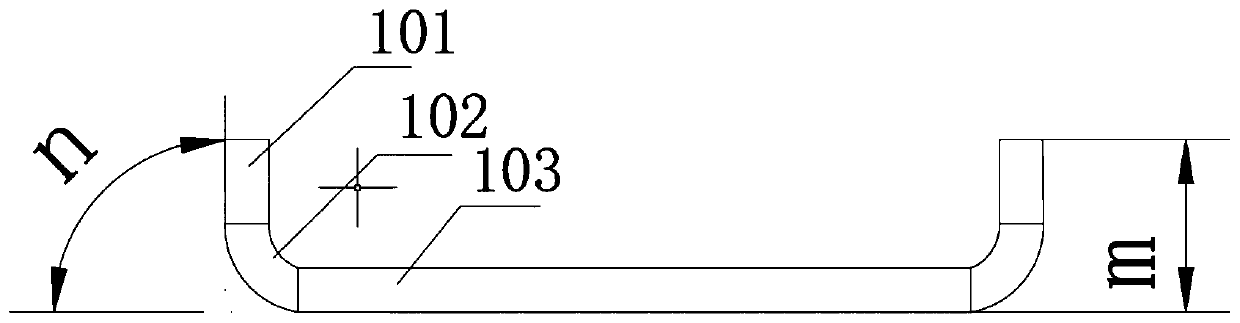

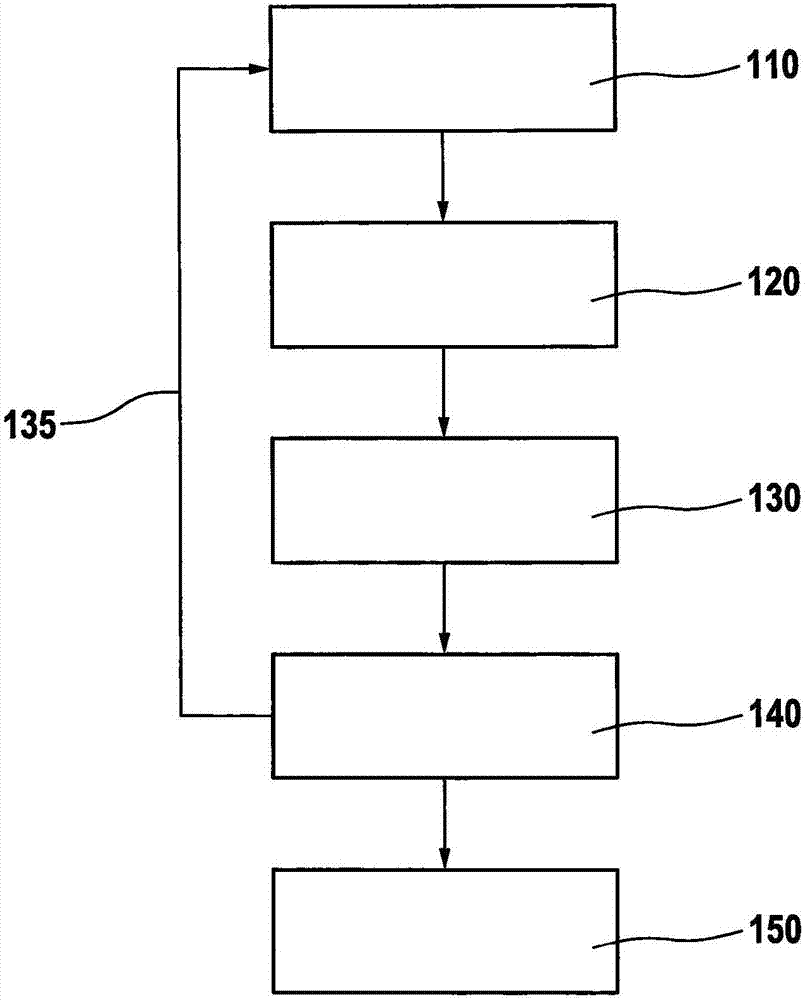

Three-dimensional (3D) glass and preparation method thereof

ActiveCN110272187AImprove yield rateAvoid DimensionsGlass reforming apparatusGlass severing apparatusFlat glassNumerical control

The invention discloses three-dimensional (3D) glass and a preparation method thereof. The method comprises the following steps: step 1, placing flat glass with a reserved allowance into a die; step 2, attaching and forming the flat glass on the upper surface of a female die of the die by adopting a heat adsorption process to obtain a 3D glass blank; step 3, cutting the 3D glass blank to obtain a 3D glass semi-finished product; step 4, carrying out computer-numerical-control (CNC) carving, grinding and chamfering on the 3D glass semi-finished product to obtain a 3D glass raw material; and step 5, carrying out shining treatment on the surface of the 3D glass raw material to obtain the 3D glass with a side wall part, a bending part and a window part. According to the invention, the yield of 3D glass production can be improved to be close to 100%, and the problem that in a process that the size of flat glass is pre-designed and then hot press forming and carving are carried out in a conventional 3D glass manufacturing method, the size of formed 3D glass is unqualified due to the fact that a placement position is deviated or the forming pressure is not uniform during hot-pressing molding is solved.

Owner:CHENGDU TOMI SHUANG DU OPTOELECTRONICS CO LTD

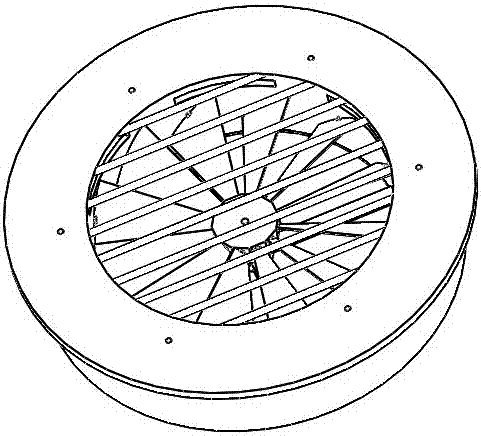

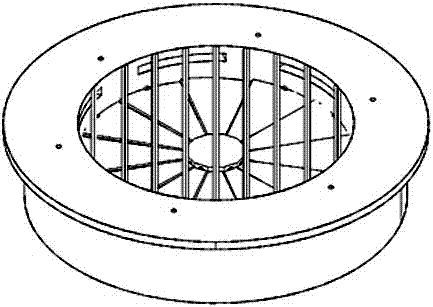

Wellhead drainage device with blade type closing valve

InactiveCN107366345AConsider water permeabilityTaking into account environmental protectionSewerage structuresWellheadRocker arm

The invention discloses a wellhead drainage device with a vane type closed valve, which comprises an upper casing and a lower casing fixedly connected, an annular cavity is formed between the inner cylinder of the upper casing and the lower casing , the outer wall of the inner cylinder is sleeved with a push ring, and a plurality of plastic blocks are fixed on the push ring; a hub is installed in the middle of the inner cylinder, and a plurality of rotatable blades are installed on the hub, and the blades The wide end of the blade is hinged on the inner cylinder through a mounting column, the end of the mounting column at the wide end of the blade is fixed with a rocker arm, the end of the rocker arm is fixedly connected with a push-pull rod, and the other end of the push-pull rod is hinged on the On the push ring, the top of the inner cylinder is provided with a strip-shaped water inlet, and the bottom of the lower shell is provided with a circular hole-shaped water outlet, and the water inlet of the water inlet is more than ten times the water outlet of the water outlet . The invention utilizes the closed valve which can be opened and closed automatically, and takes water permeability and environmental protection into account.

Owner:成都兆丰斯诺科技有限公司

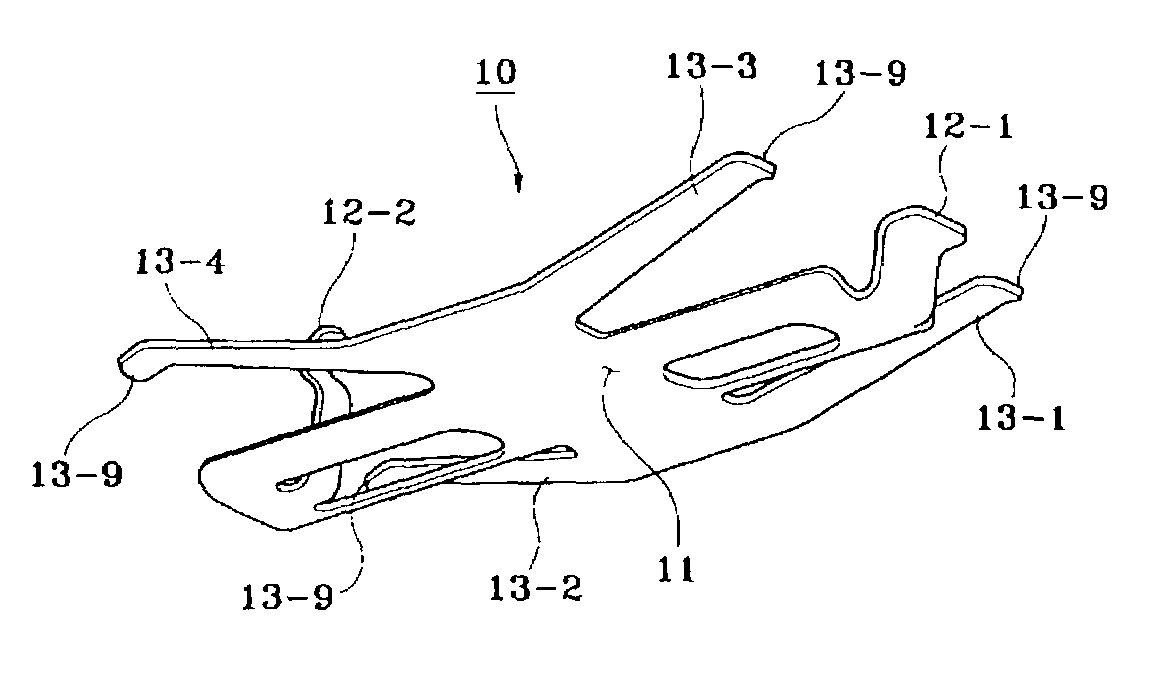

Socket contact terminal and semiconductor device

InactiveUS20090250256A1Avoid frictional contactMaintenance characteristicEngagement/disengagement of coupling partsContact member assembly/disassemblyElectrical conductorElectrical connection

A socket contact terminal for electrical connection between a connection portion formed of a metal conductor on a printed circuit board and a connection terminal of an IC package. The contact terminal comprises a metal terminal composed of a main columnar portion and arm portions on both sides and having an angular U shape and an elastomeric member attached to the metal terminal. A metal surface is exposed from the outer surface of each arm portion. The elastomeric member is firmly held between the arm portions of the metal terminal and exhibits a repulsive force when the arm portions are pressed in the direction that the arm portions approach each other.

Owner:THE FUJIKURA CABLE WORKS LTD

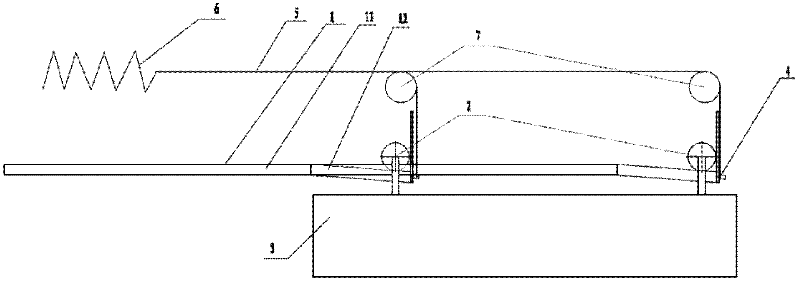

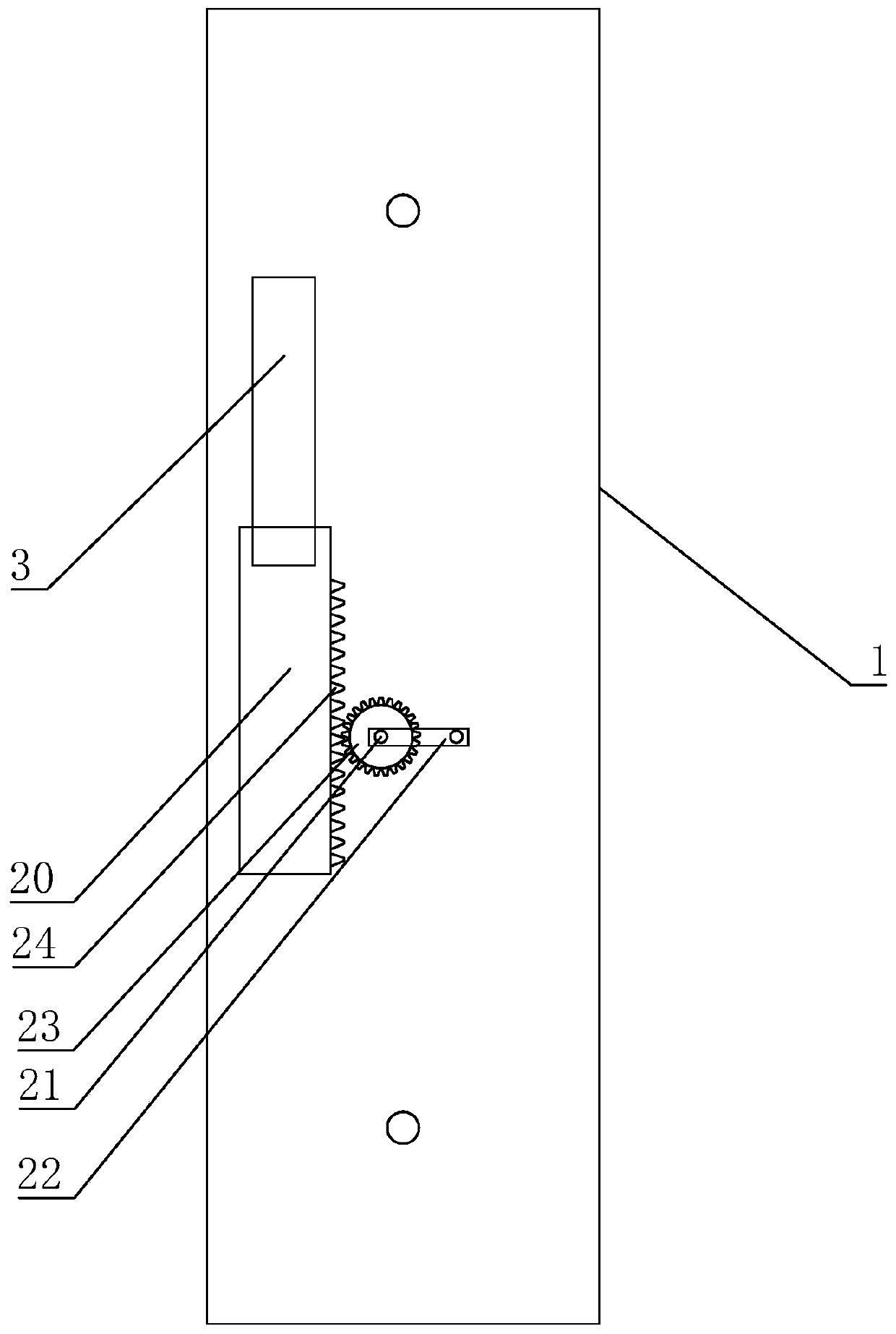

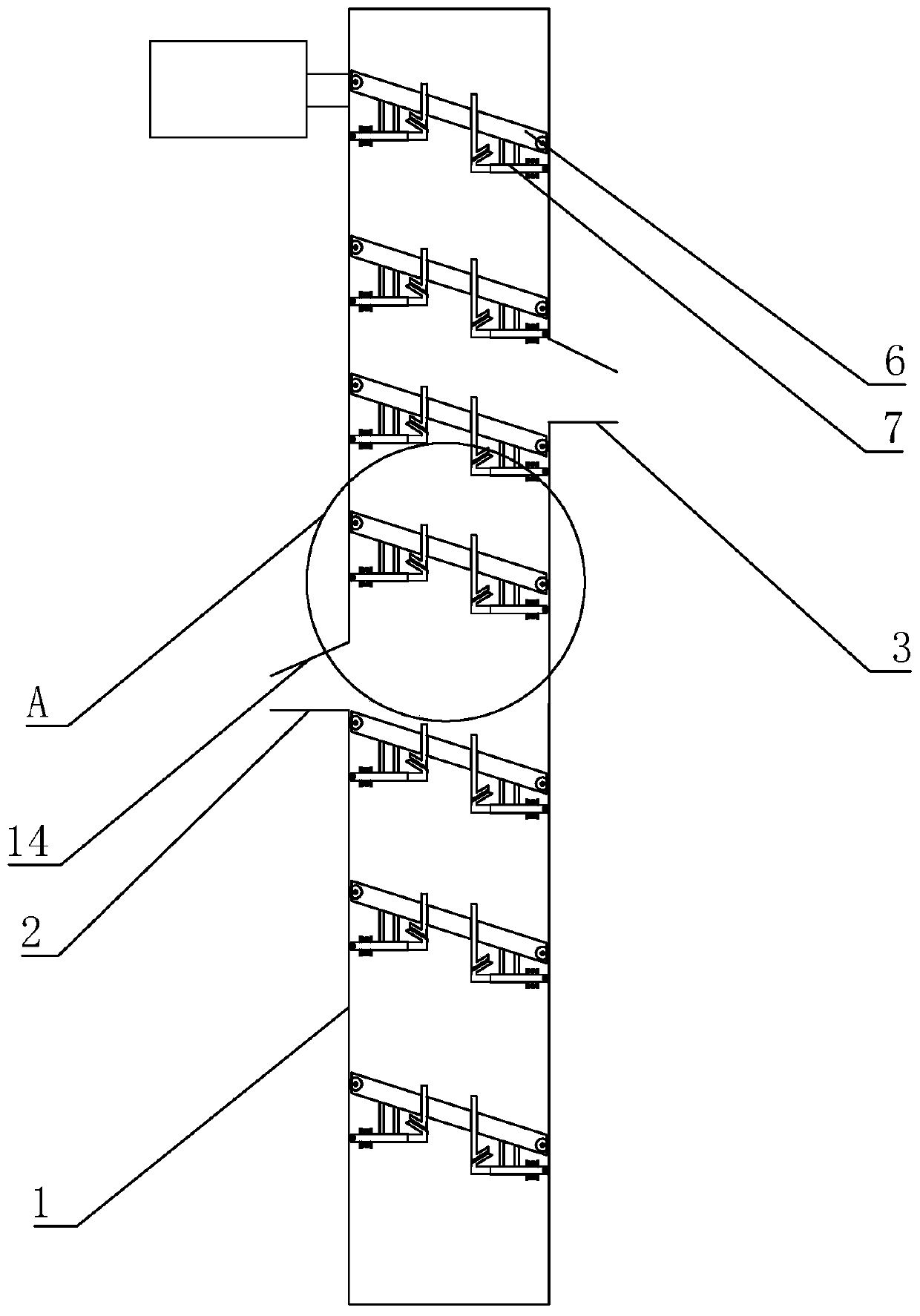

Guide wire feeding device for computer wire-stripping machine

PendingCN110790085AAvoid contactExtend equipment lifeLine/current collector detailsFilament handlingEquipment useButt joint

The invention discloses a guide wire feeding device for a computer wire-stripping machine. The guide wire feeding device comprises a fixed base, a butt joint clamping plate and a guide wheel. The guide wheel is movably mounted on the upper portion of the fixed base. A fixed side plate is fixedly mounted on the outer surface of the rear end of the fixed base. The fixed base is in butt joint with the guide wheel and is fixed to the guide wheel through the fixed side plate. The middle of the inner side of the guide wheel is connected with a connecting rod in a sleeving manner, and the outer surface of the connecting rod is movably sleeved with two sets of bearings. The guide wheel and the connecting rod are movably connected through the bearings. The guide wheel and the fixed side plate are in butt joint and are fixed through the connecting rod. A fixed clamping ring is fixedly mounted on the side, close to the fixed side plate, of the outer surface of the connecting rod. According to theguide wire feeding device for the computer wire-stripping machine, sliding motion replaces traditional friction motion, contact of a guide wire and a guide hole can be effectively avoided, and the service life of equipment is prolonged; and wire raw material waste is avoided, the guide wire feeding device is provided with an adjusting structure, and the use flexibility of the guide wire feeding device is improved.

Owner:芜湖瑞昌电气系统有限公司

Automobile brake caliper for reducing noise

InactiveUS7178641B2Eliminate rattling noiseEliminate vibrationNoise/vibration controlBraking membersEngineeringCalipers

An automobile brake caliper for reducing noise is disclosed. An elastic member is installed so that elastic forces can act between the respective components. Thus, when the automobile generates vibrations while running over a rough terrain, the adjacent components avoid frictional contact, thereby eliminating any impact noise.

Owner:HYUNDAI MOTOR CO LTD

Valve for mostly gas-proof interruption of a flow path

ActiveCN102900861AAvoid formingAvoid frictional contactSlide valveLift valveEngineeringPressure difference

Owner:VAT HLDG AG

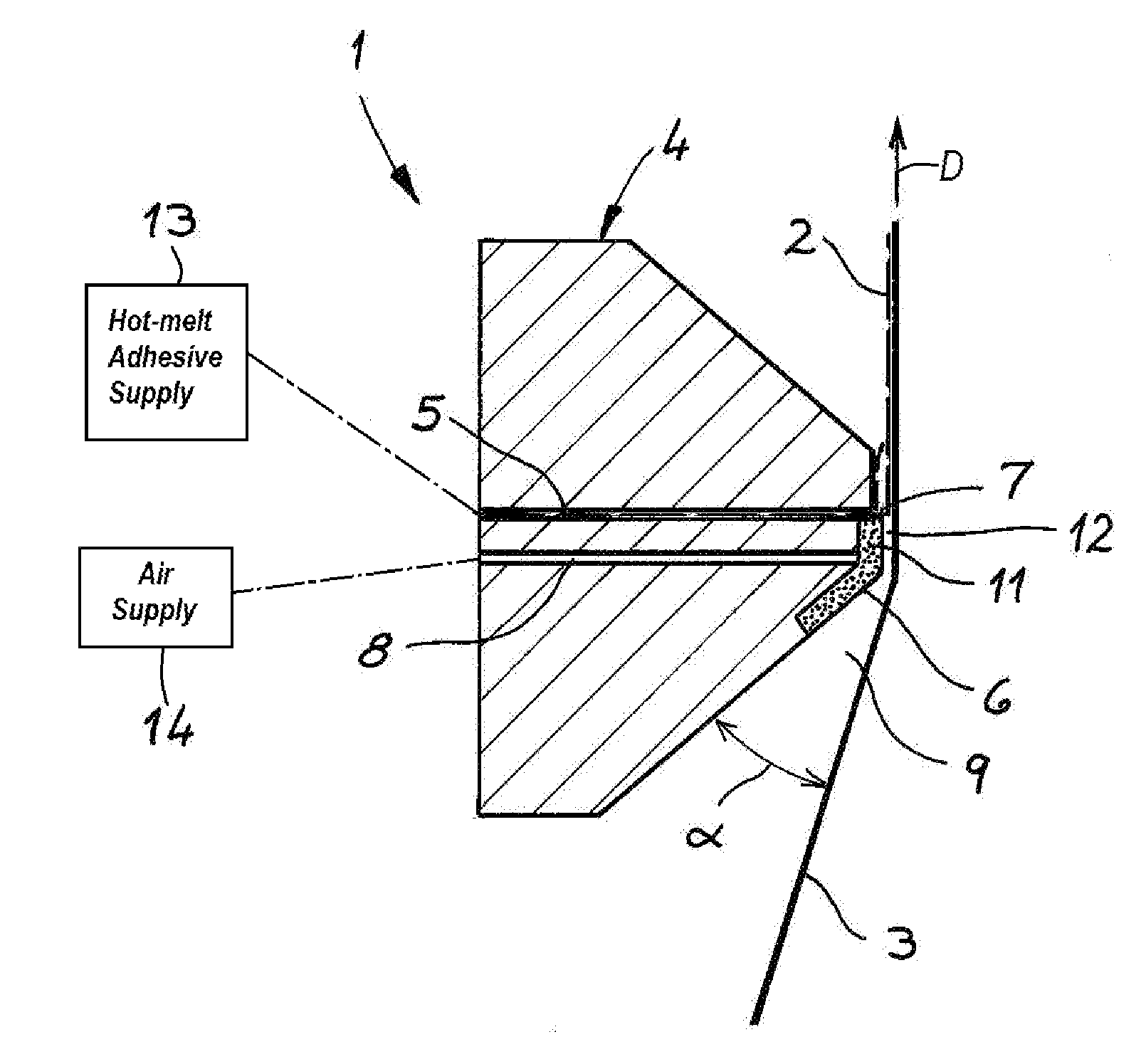

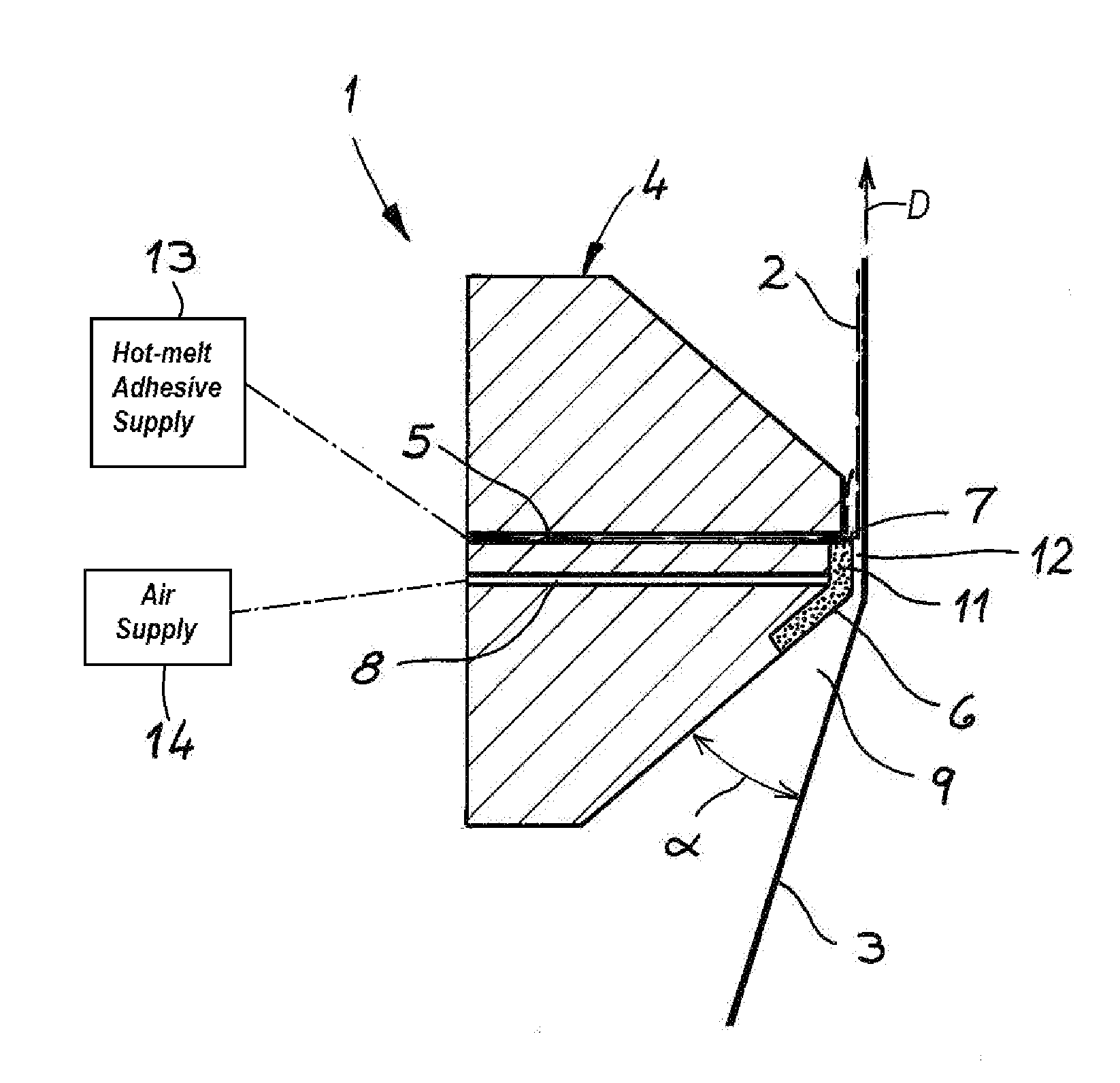

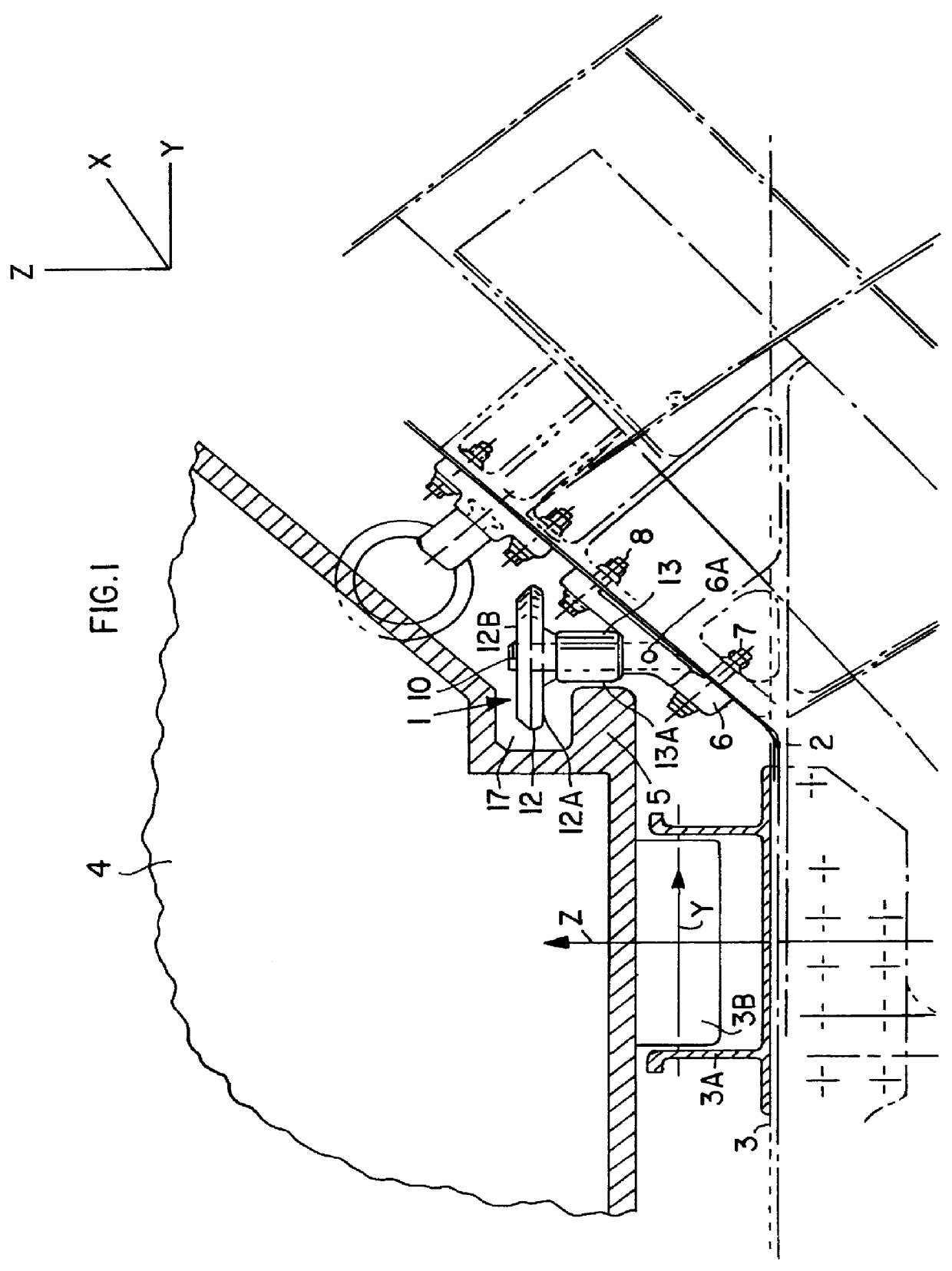

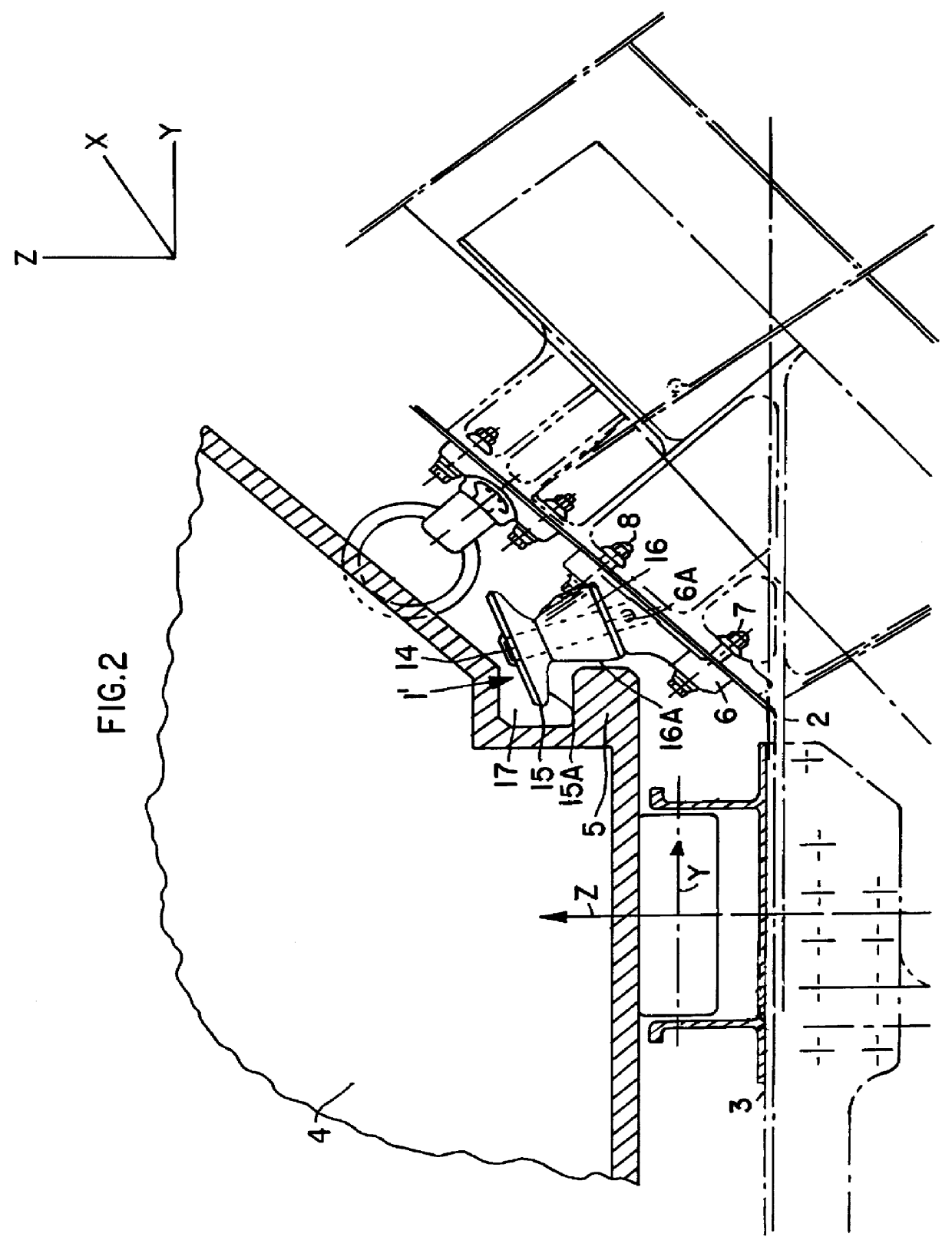

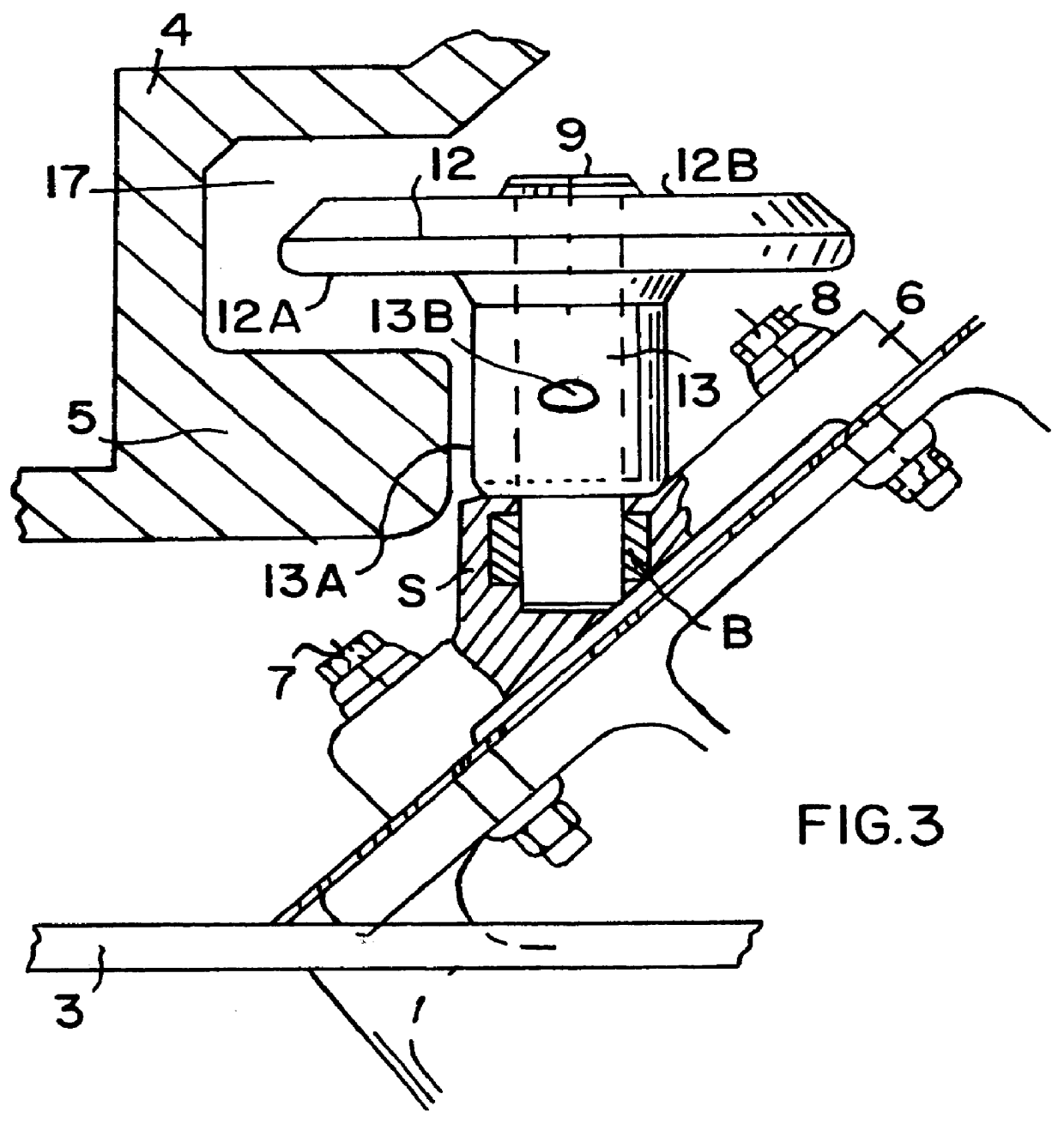

Self-cleaning nozzle for applying adhesive to a moving web

InactiveUS20120263873A1Avoid scratchesAvoid frictional contactLiquid spraying apparatusSpecial surfacesAdhesiveEngineering

A nozzle for applying a liquid adhesive to a web moving continuously in a travel direction has a body having a passage forming an outlet opening generally transversely to the direction immediately adjacent the moving web at a face of the body so that the liquid adhesive flows through the passage and out the outlet end onto the moving web. Structure on the face of the body forms immediately upstream of the outlet a porous region. Air is fed through the structure and out of the face to form between the region and the web an air cushion.

Owner:MONDI GRONAU

YZ- latch for tying freight to a loading floor

InactiveUS6139232AMinimal frictionLocking is safe and reliableVehicle with removable loadingLoad accommodationEngineeringVertical displacement

A YZ-latch for holding down a piece of freight on a loading floor in an aircraft which has a base holding an axle stub which in turn has mounted thereon two rollers for rolling contact with the freight piece. One roller holds against lateral displacement in the Y-direction. The other roller holds against vertical displacement in the Z-direction. Free movement is permitted in the X-direction. Either the axle stub with fixed rollers is rotatable, or the rollers are rotatable on the fixed axle stub, or at least one roller or both rollers are rotatable on a rotatable axle stub.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

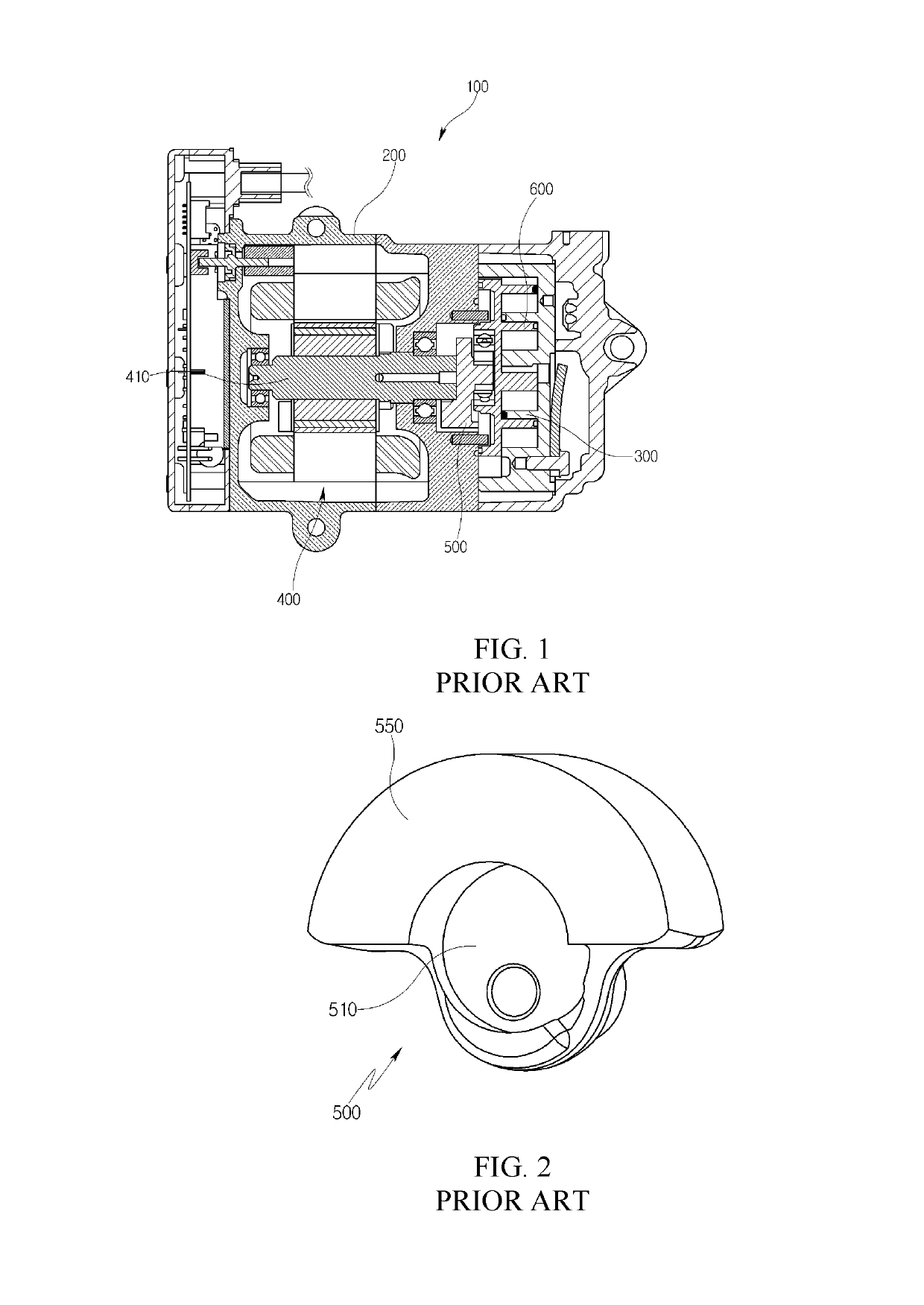

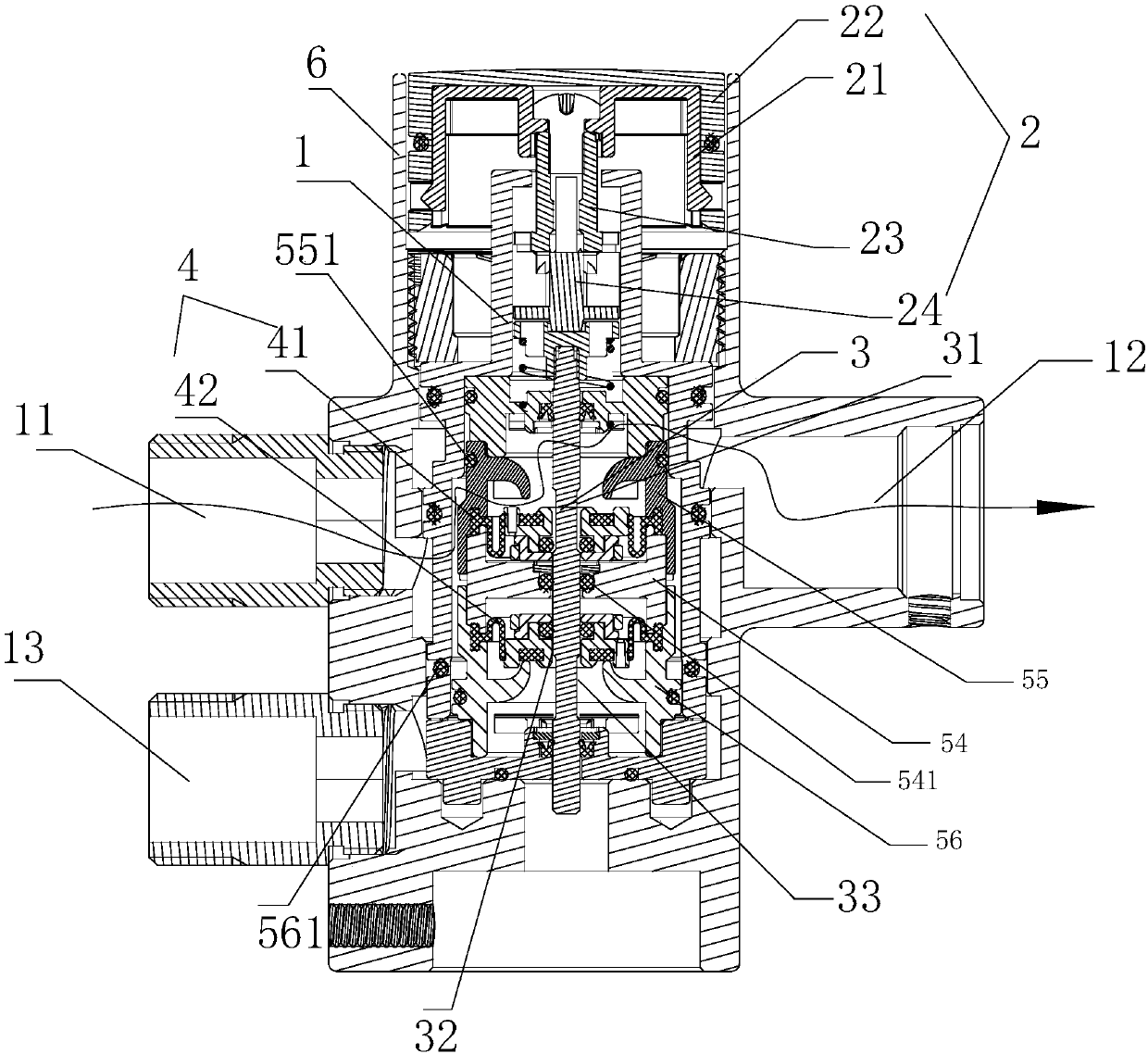

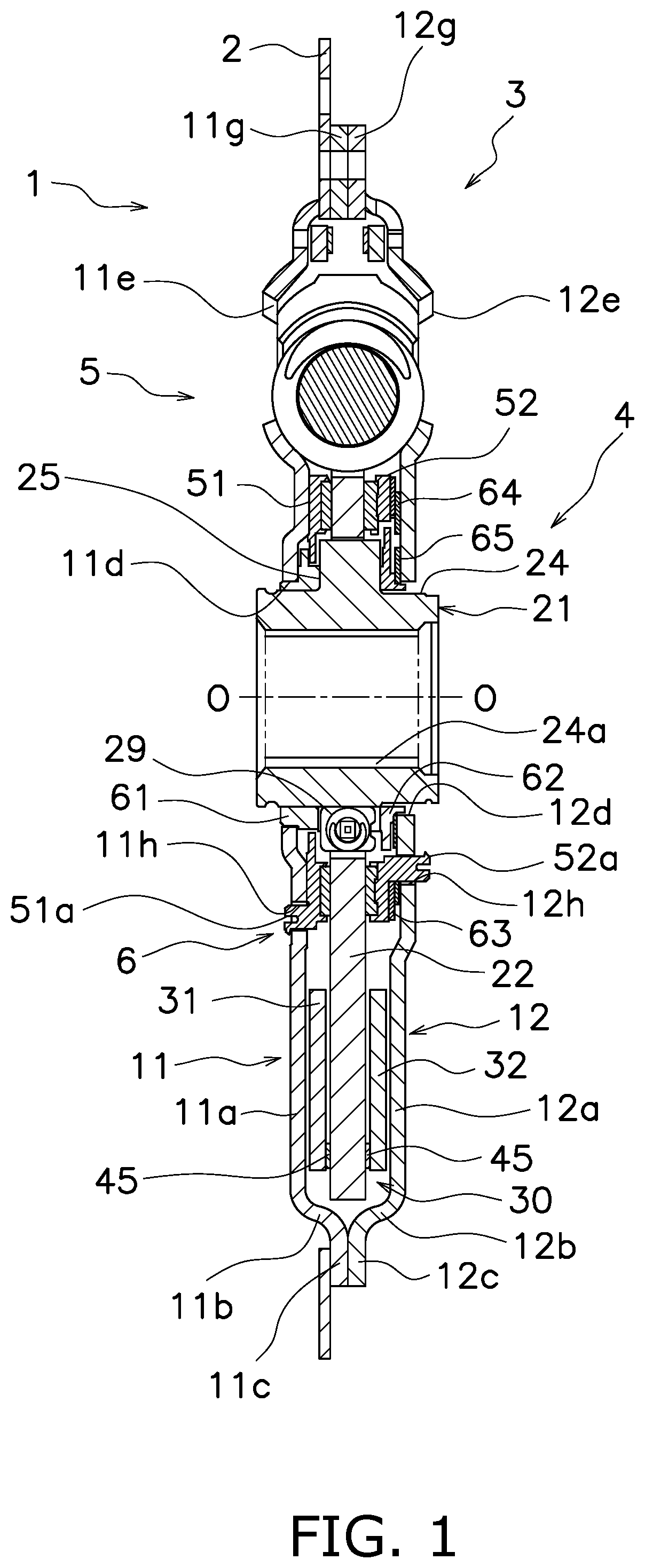

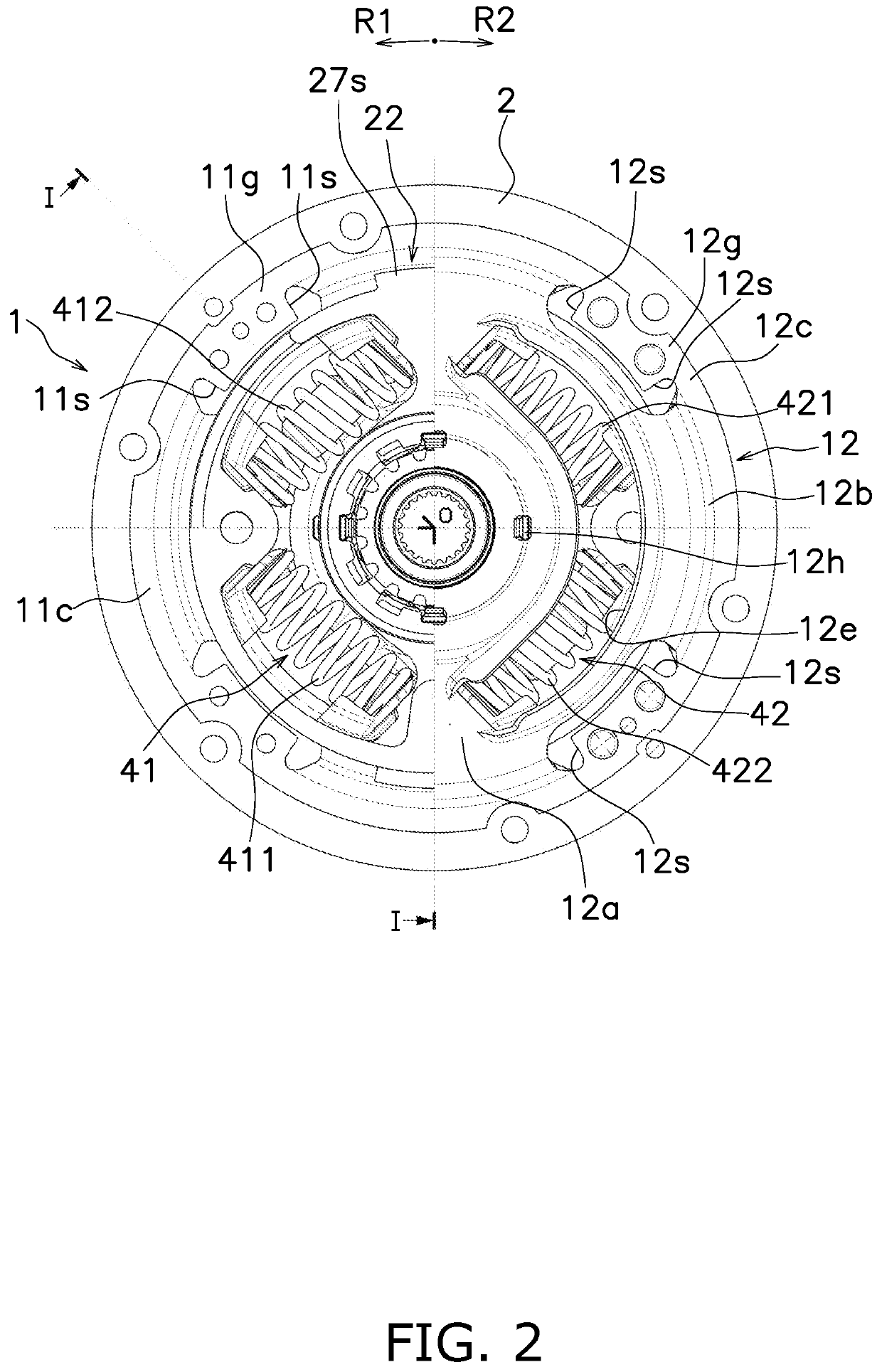

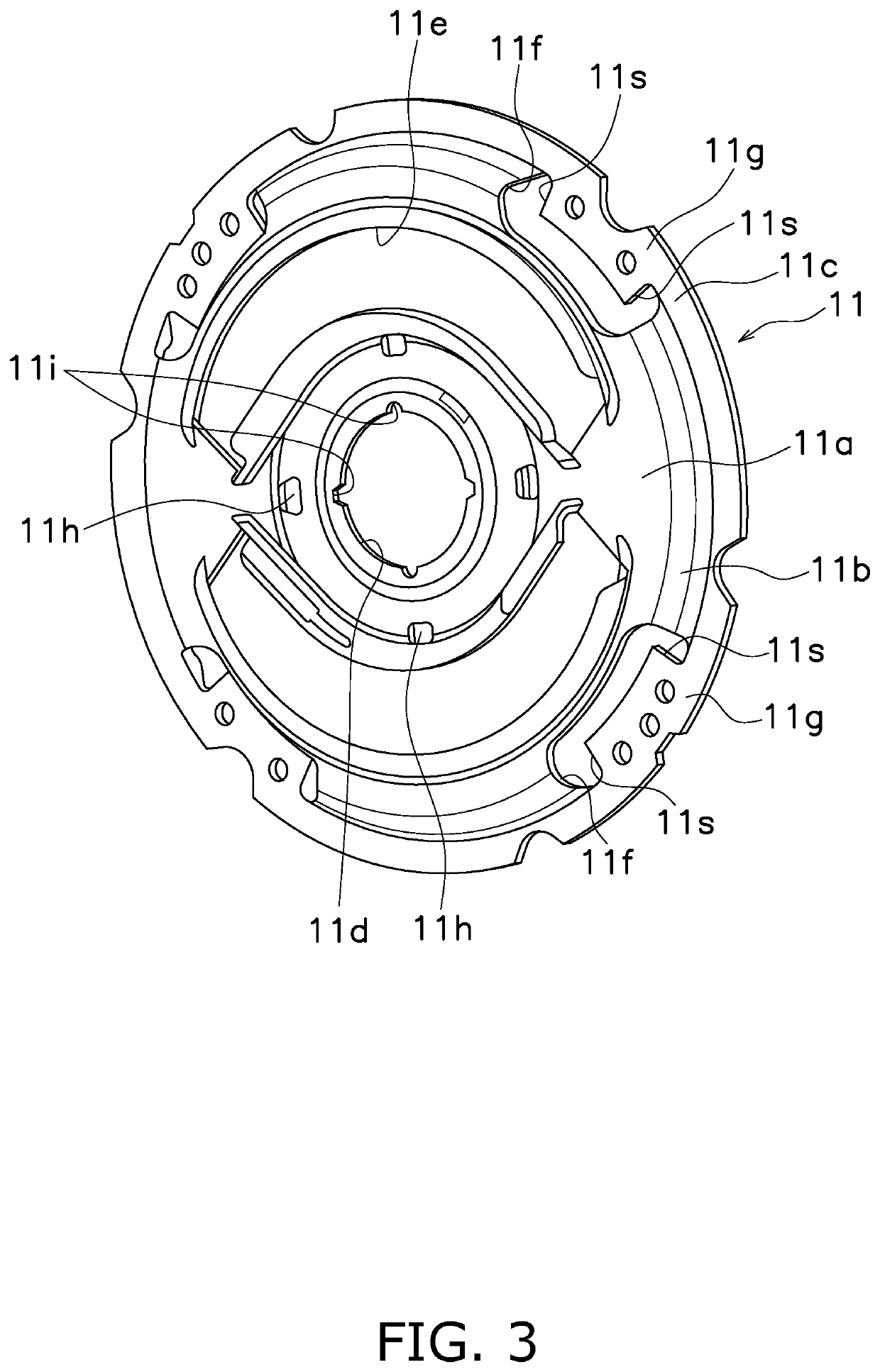

Eccentric bush assembly structure of scroll compressor

ActiveUS10309403B2Avoid generatingPoor surface roughnessRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringDrive motor

An eccentric bush assembly structure of a scroll compressor, in which an orbiting scroll is eccentrically coupled to a rotary shaft of a drive motor, including a bush body rotatably coupled to the orbiting scroll while being pinned to the rotary shaft of the drive motor by an eccentric shaft, the bush body having a friction prevention groove formed in a surface facing a tip surface of the rotary shaft so as not to come into frictional contact with the tip surface.

Owner:HANON SYST

Airtight door closed running method and device

InactiveCN102364020ASmooth disengagementTightly sealedWing openersWing suspension devicesMechanical engineeringWheel running

Owner:宁波欧尼克科技有限公司

Device for preventing steel wire rope of tower crane trolley from separating from slot

The invention discloses a device for preventing a steel wire rope of a tower crane trolley from separating from a slot. The device comprises a trolley wheel frame, wherein a slot wheel is mounted on the trolley wheel frame; bearings are symmetrically arranged on the slot wall, close to the top end and the bottom end, of one side of the slot wheel; threaded rods are rotatably connected between thetwo bearings; one end of each threaded rod sequentially passes through the corresponding bearing and the slot wheel wall to extend outwards; symmetrical threads with reverse directions are arranged onthe threaded rods between the two bearings; two symmetrical clamping plates are arranged in the slot wheel slot; a nut is fixedly arranged on the position, which corresponds to the threaded rods, ofeach clamping plate; each threaded rod is in threaded connection with each nut and passes through the corresponding nut; a plurality of rolling slots are symmetrically formed in opposite side walls oftwo clamping plates between the two threaded rods; rolling balls which roll are arranged in the rolling slots; and ends, away from the slot bottoms of the rolling slots, of the rolling balls pass through the slot holes of the rolling slots and extend outwards. The service life of the steel wire rope is prolonged while the steel wire rope is prevented from dropping from the slot wheel.

Owner:贵州黔力重工有限公司

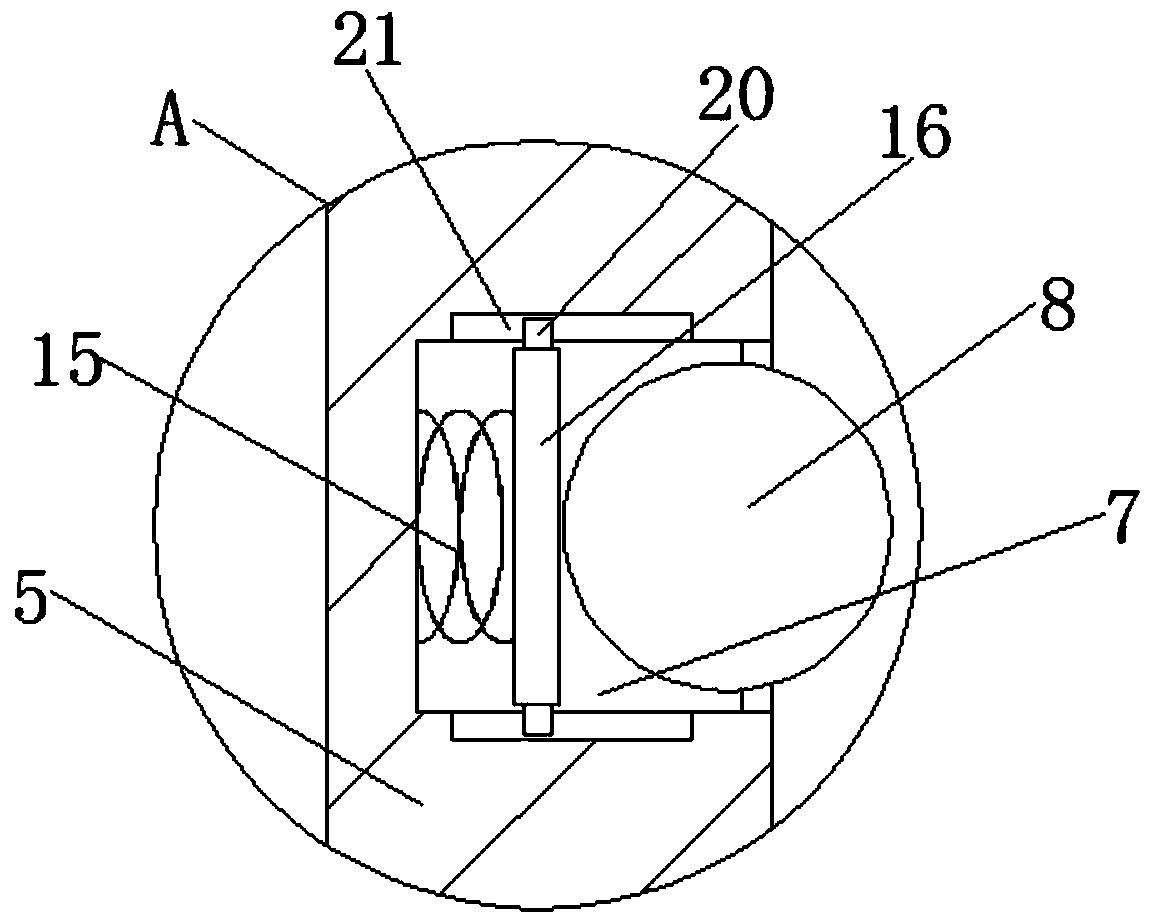

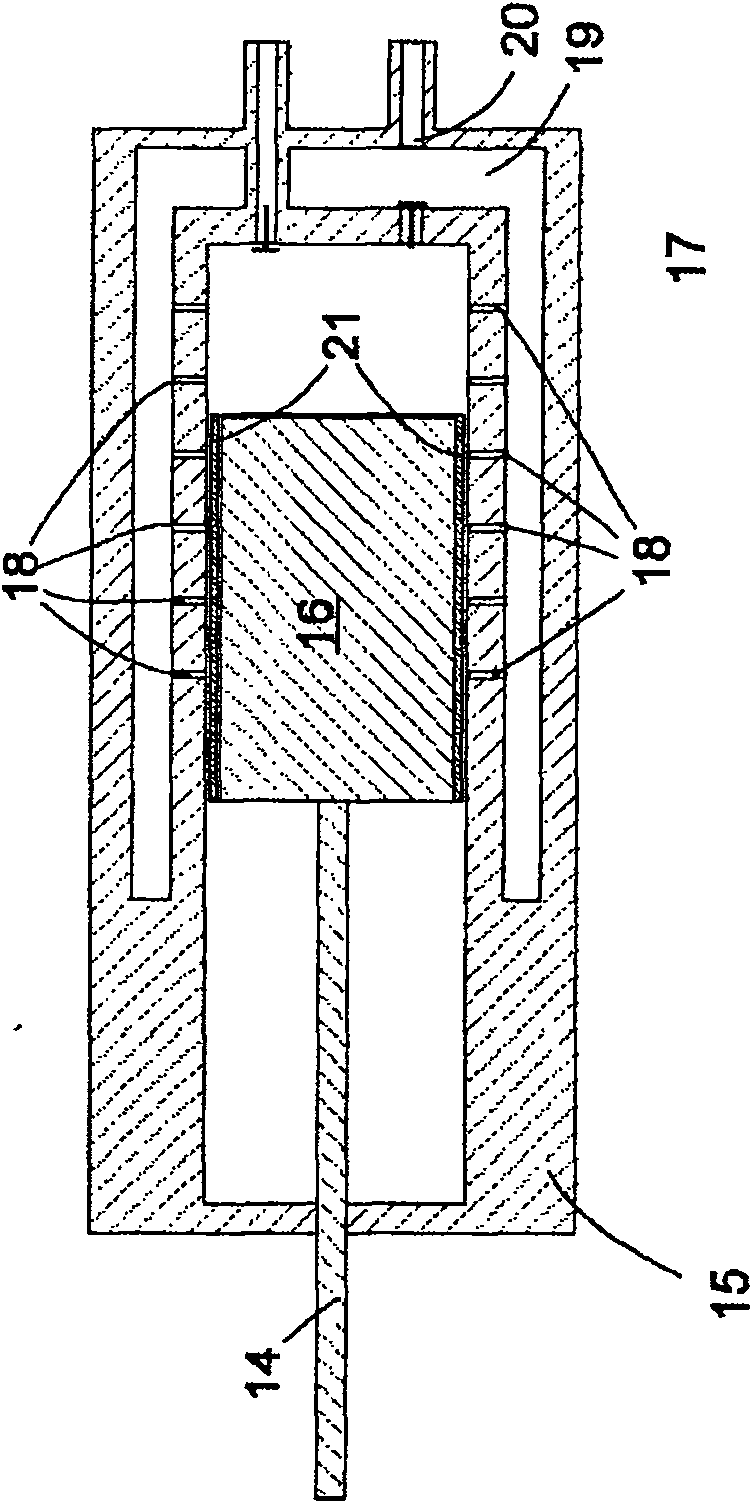

Linear compressor

ActiveCN100582483CAvoid frictional contactImprove efficiencyPiston pumpsEngine componentsLinear compressorEngineering

A linear compressor comprises a cylinder (15), a hydraulically borne piston (16) that can be longitudinally oscillated inside the cylinder (15) and a drive unit (1-14) driving the movement of the piston. The compressor is characterized in that at least one of the lateral faces of the piston (16) and the cylinder (15) that face each other is provided with an abrasion-resistant bearing coating (21).

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

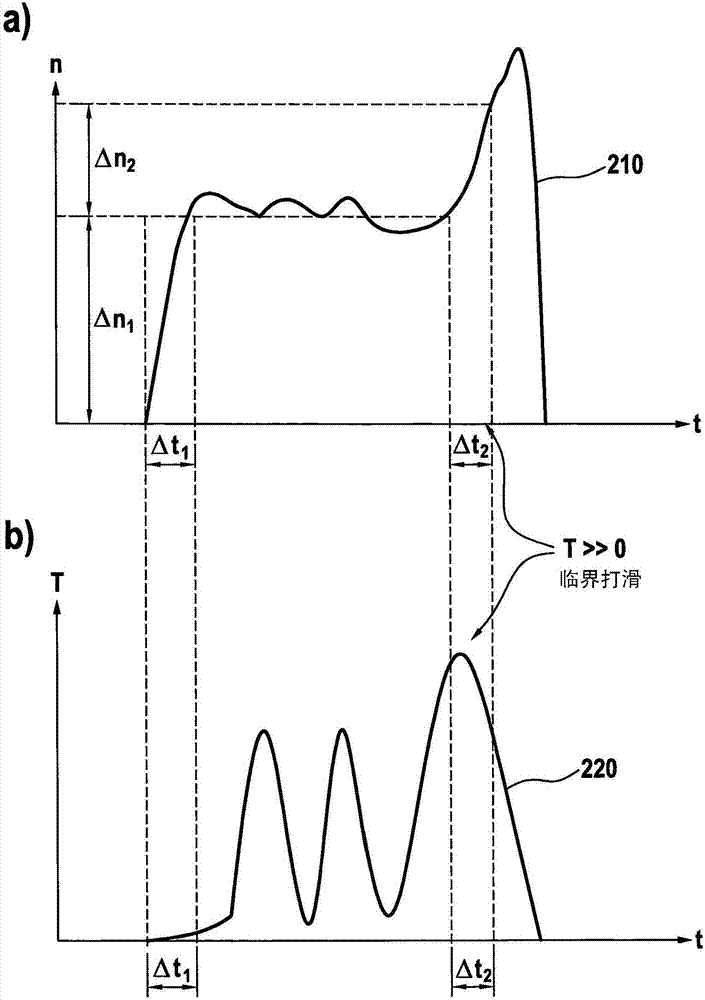

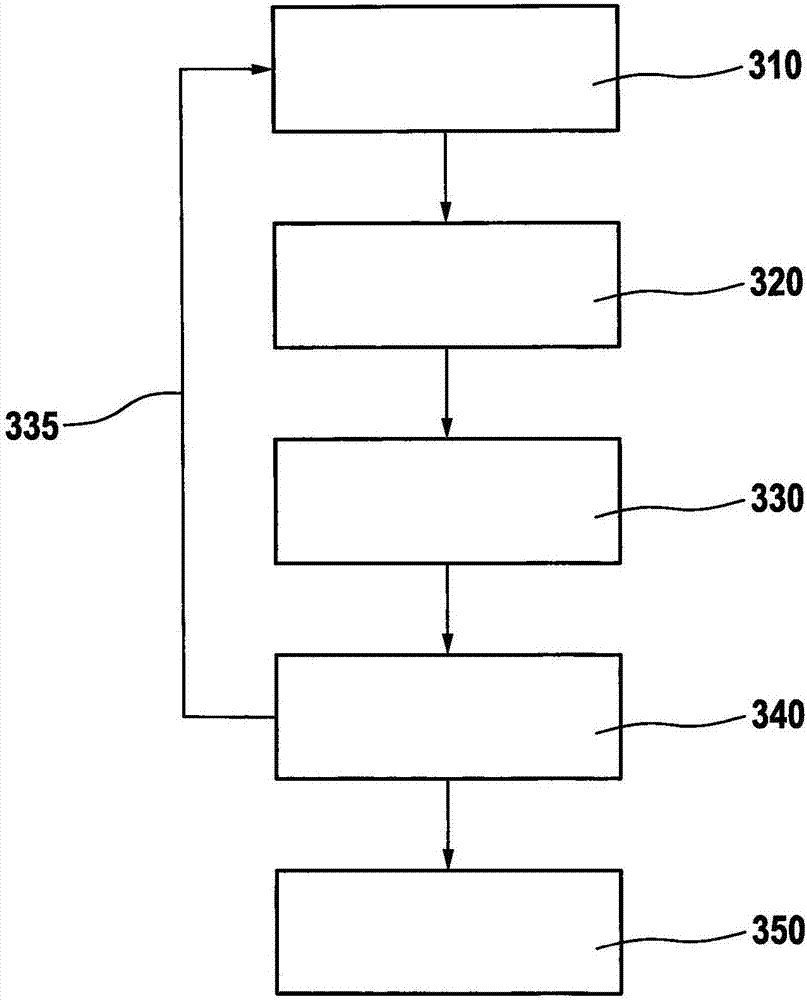

Method and regulating device for regulating a pedal-driven vehicle

ActiveCN103373433BImprove skiddingAvoid frictional contactRider propulsionDrive wheelDriver/operator

Owner:ROBERT BOSCH GMBH

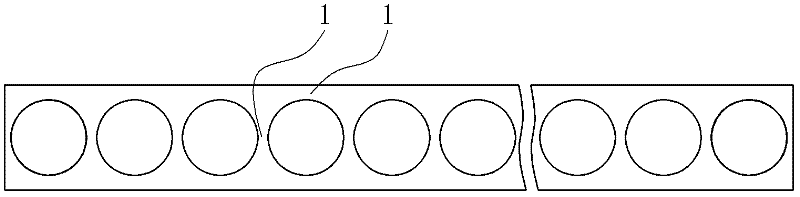

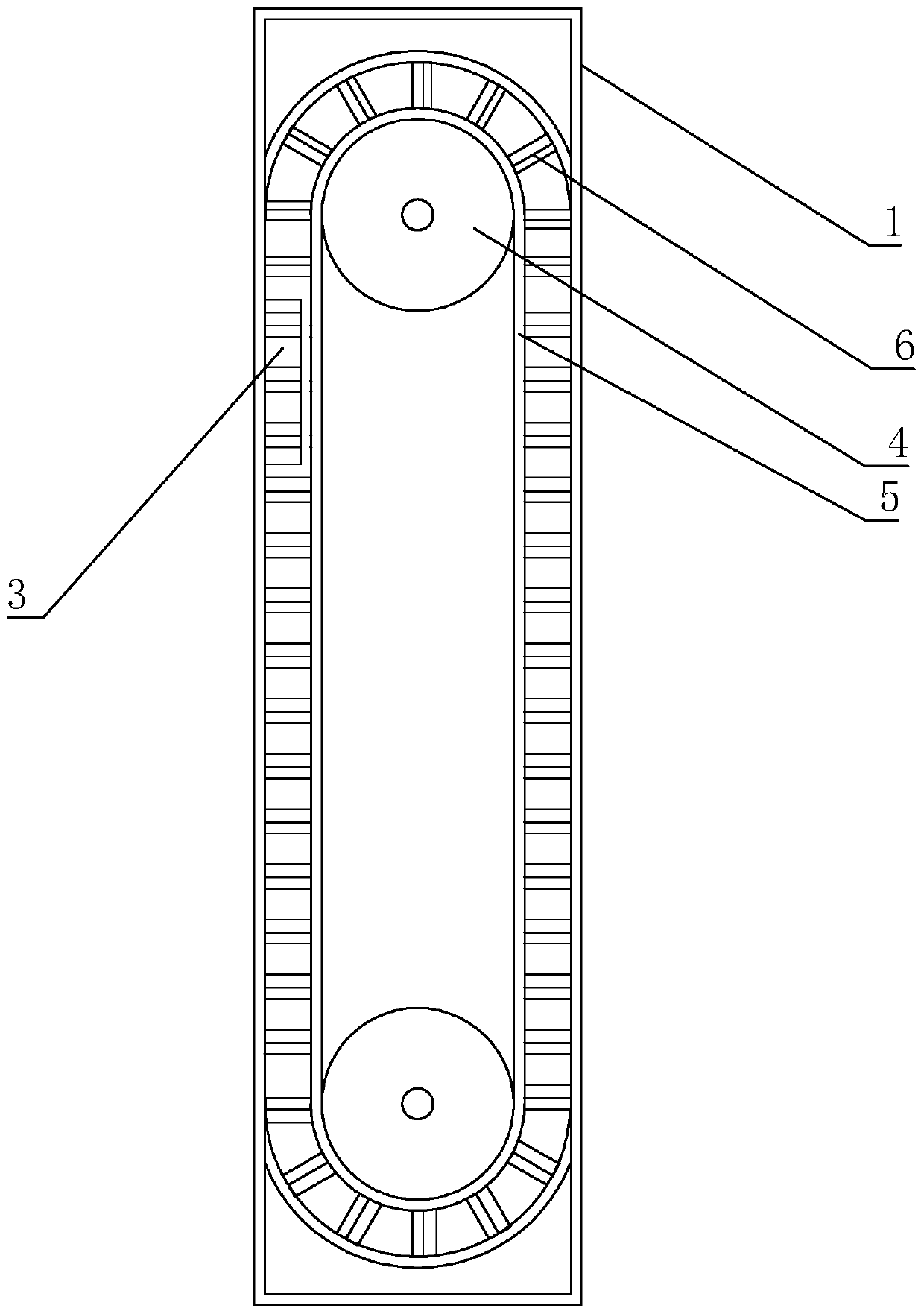

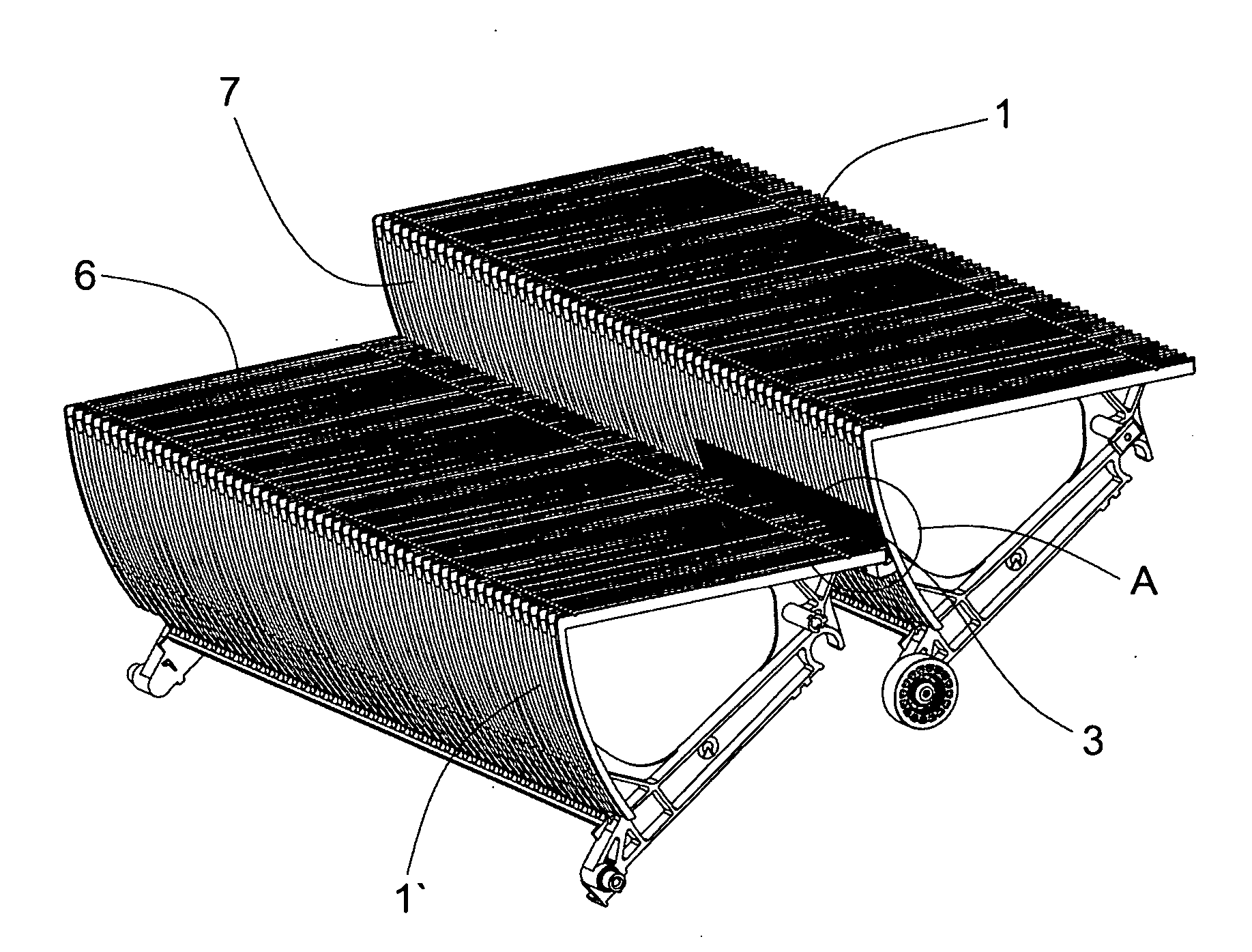

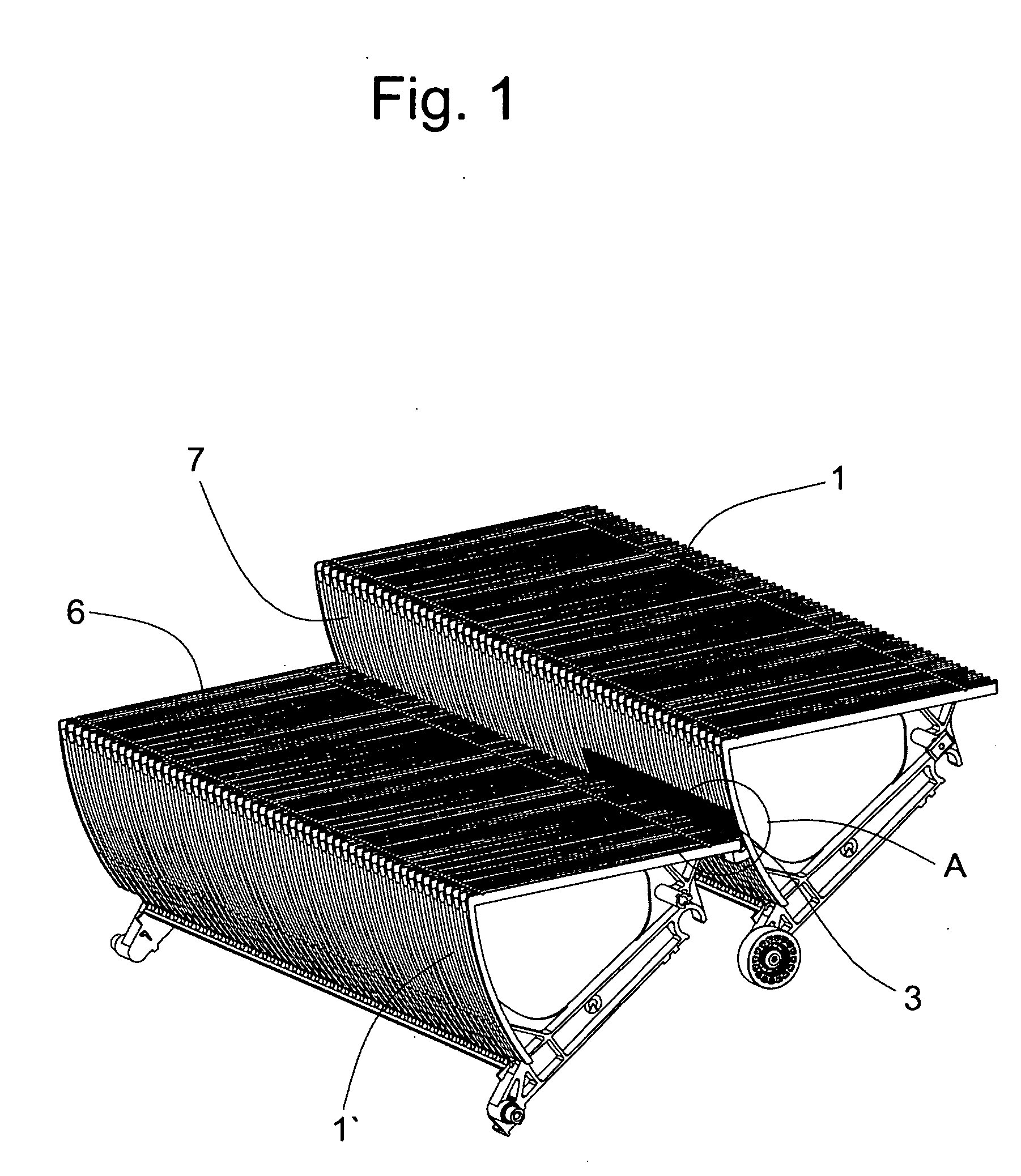

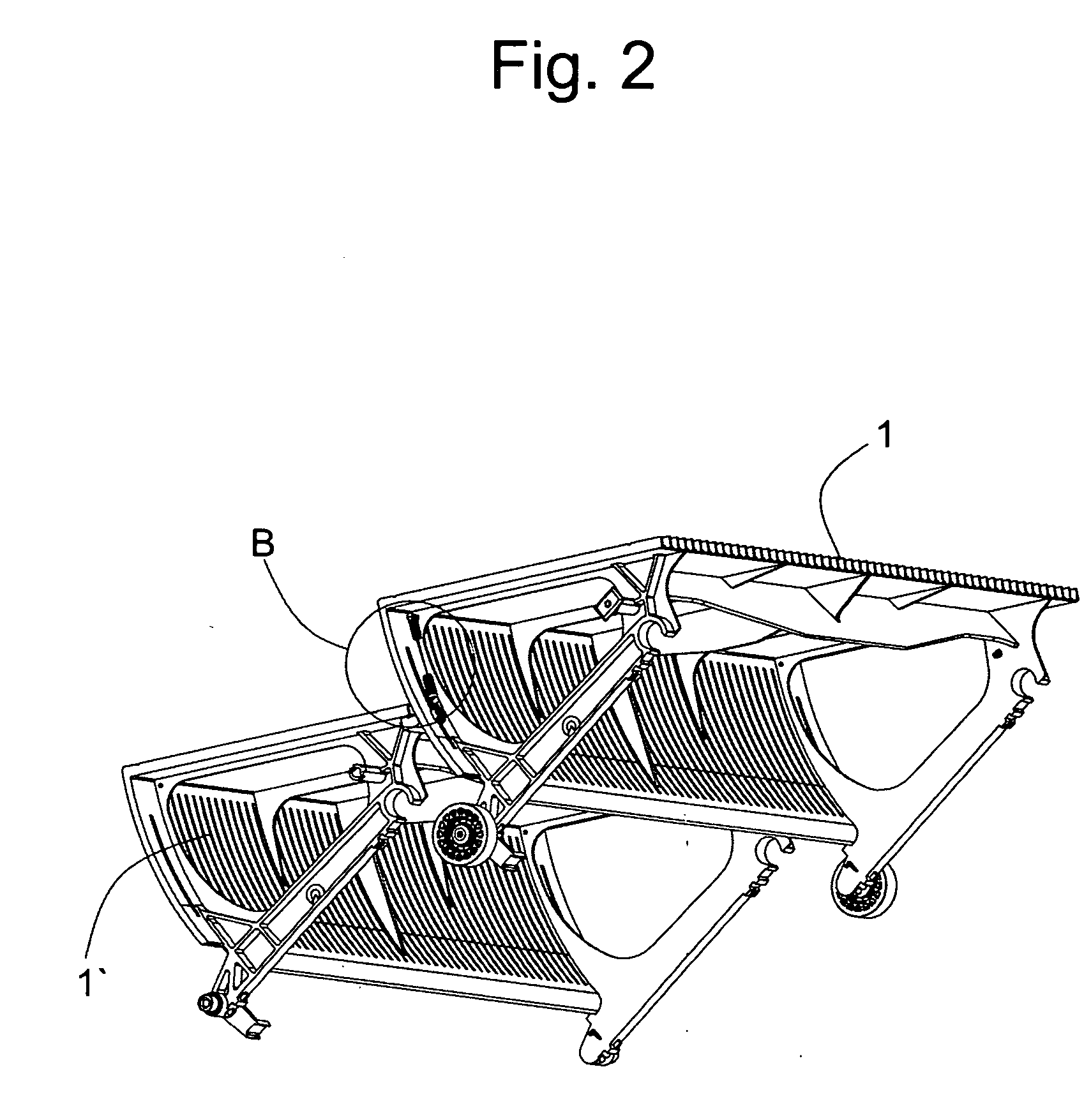

Lifting device for turning bearing rings

ActiveCN111392344AQuality impactGuarantee product qualityConveyorsConveyor partsClassical mechanicsStructural engineering

The invention discloses a lifting device for turning bearing rings, and mainly relates to the field of bearing machining. The lifting device comprises a shell, wherein a feeding port and a dischargingport are formed in the shell; two rollers are rotatably connected to the inside of the shell; a belt is connected between the two rollers; and a plurality of lifting plates are arranged on the belt.The lifting device is characterized in that the ends, facing the discharging port, of the lifting plates are inclined downwards; bearing temporarily storing devices are arranged on the lifting platesand comprise through holes; a baffle is slidably connected inside each through hole along the height direction; a first inclined plate is arranged at the bottom of each baffle; a sleeve pipe is arranged at the bottom of each lifting plate; a moving column is horizontally connected to the inside of each sleeve pipe in a sliding mode; a second inclined plate is arranged at one end, close to the corresponding baffle, of each moving column; and inclined retracting plates are respectively arranged above the feeding port and the discharging port. The lifting device for turning the bearing rings hasthe beneficial effects that it can be ensured that bearings do not relatively rub against the side wall of the shell in the lifting process of the bearing rings, so that quality of the machined bearings is guaranteed.

Owner:SHANDONG YUJIE BEARING MFG CO LTD

Escalator with riser brushes, step of such an escalator and method of modernizing an escalator

ActiveUS20060102448A1Avoid frictional contactThe process is simple and convenientMine liftsEscalatorsClassical mechanicsEngineering

An escalator with steps having a tread surface and riser surface has riser brushes arranged at the riser surface. The riser brushes provide a barrier for the gap which is normally present between the tread surface of a first step and the riser surface of an adjacent step. The riser brushes may be mounted to a brush strip which is guided along the riser as the steps transfer between vertical and horizontal travel.

Owner:INVENTIO AG

Waterway switching structure and water outlet switching device of combined shower

ActiveCN110529624AImprove sealingSmall switching forceOperating means/releasing devices for valvesMultiple way valvesEngineeringShower

Owner:ZHANGZHOU SOLEX SMART HOME CO LTD

Vertical bar extending and back-adjusting installation method for precast concrete composite slab

PendingCN110499857AQuick installationAvoid collisionFloorsBuilding material handlingVertical barFoam rubber

The invention relates to a vertical bar extending and back-adjusting installation method for a precast concrete composite slab. The installation method includes the following steps that (1), horizontal reinforcing bars of two ends of the composite slab are bended upwards for 90 degrees; (2) a beam formwork and a wood formwork are arranged, and a foam rubber strip is arranged on the upper surface of the wood formwork on the edge of a cavity opening of a beam molding cavity of the beam formwork; (3) a reinforcing cage is placed into the beam molding cavity, according to a traditional method, beam steel is tied up firstly, and the composite slab is transported to a site for vertical lifting and placement; (4) the horizontal reinforcing bars of two ends of the composite slab are bended to return to a horizontal state; and (5) then concrete pouring is conducted according to a conventional method and maintained for a period of time. The rapid installation of the composite slab can avoid collision between the composite slab horizontal reinforcing bars and top beam longitudinal bars of a frame beam so as to speed up construction efficiency and reduce the manual workload, at the same time,tilting installation is not needed, in the hoisting process of the composite slab, and the friction between the composite slab and the foam rubber strip is avoided so as to prevent the leakage of slurry of concrete during pouring of the beam and the composite slab.

Owner:福建省二建建设集团有限公司 +1

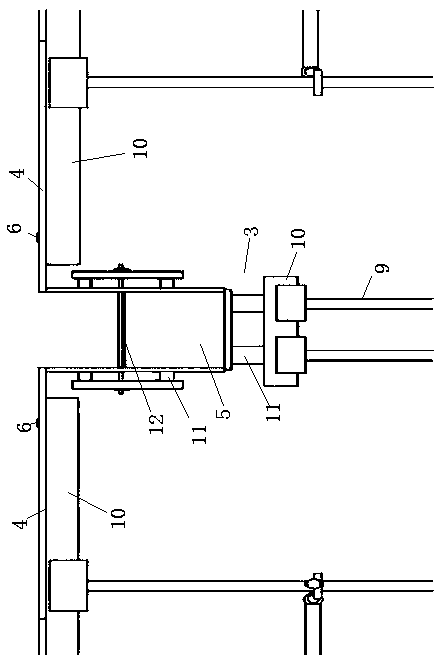

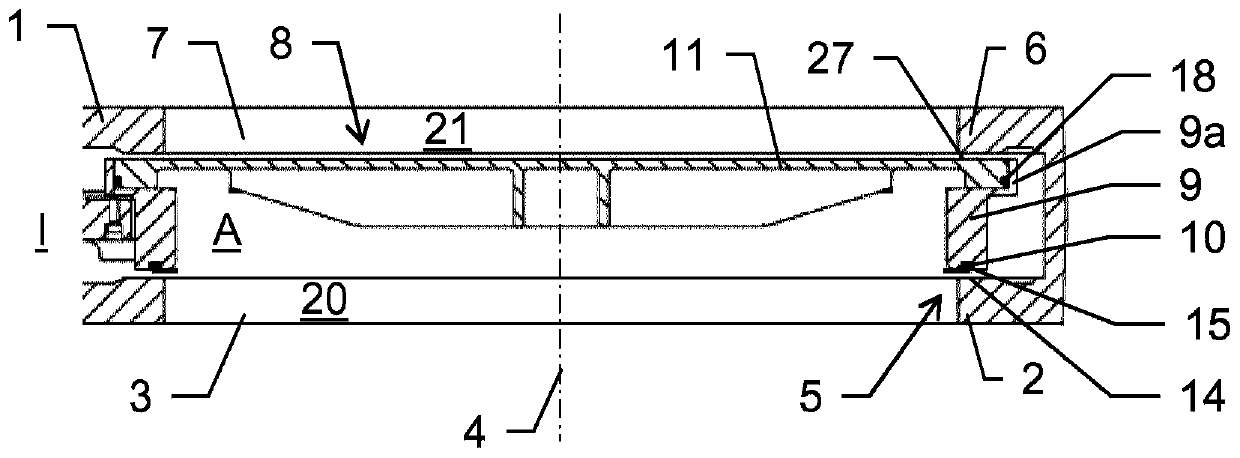

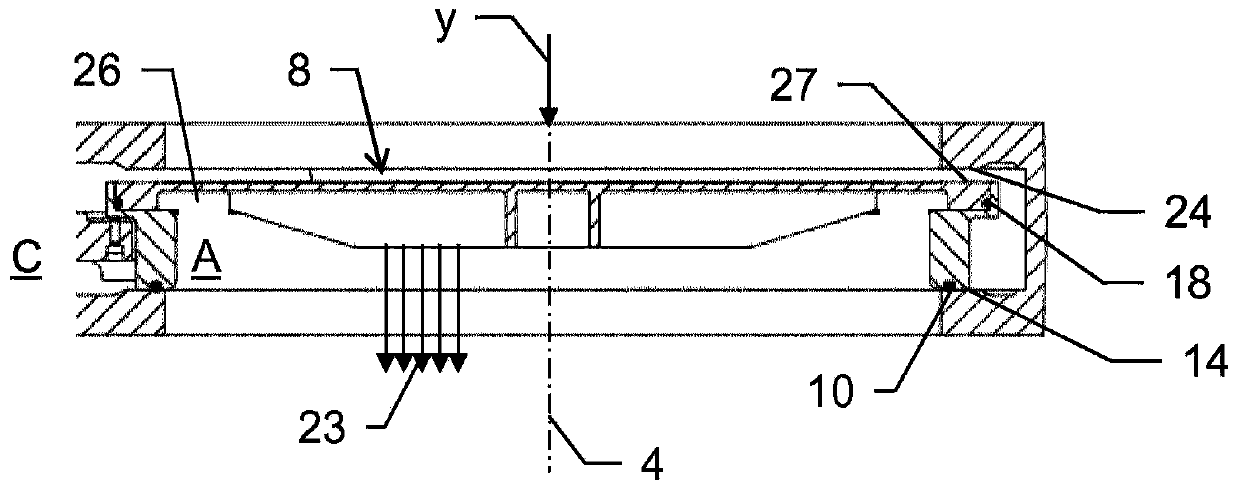

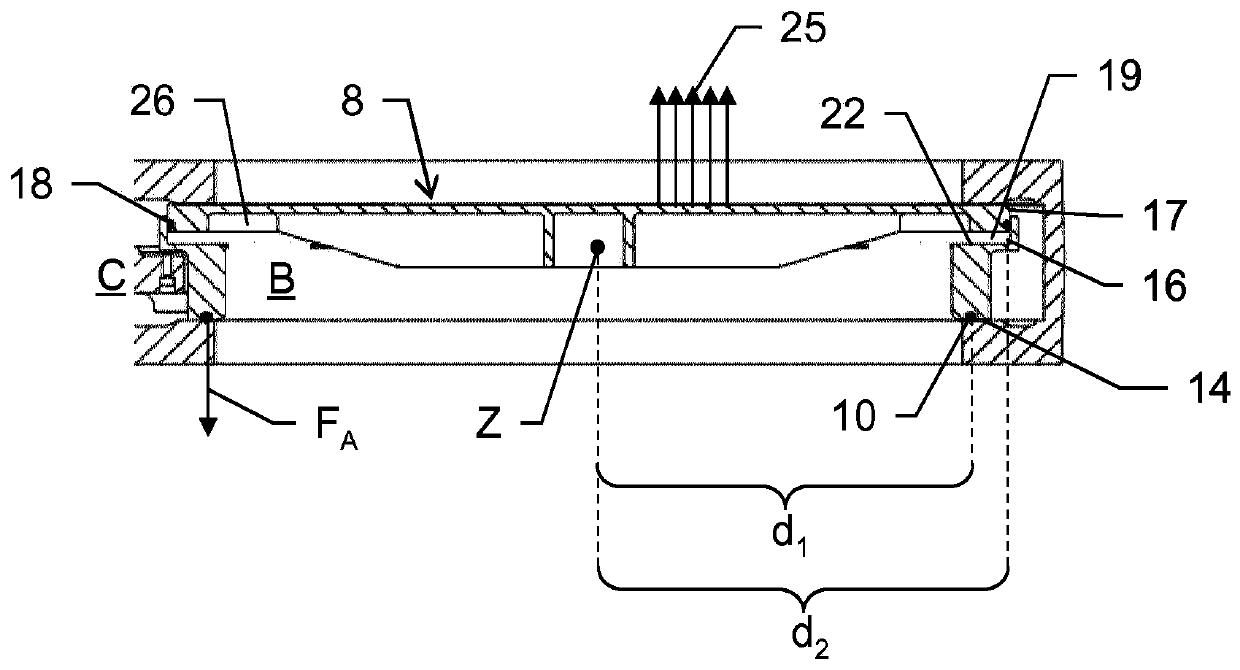

Damper device

PendingUS20220186785A1Reduce gapAvoid frictional contactYielding couplingVibration dampersElastic componentClassical mechanics

A damper device includes a first rotor, a second rotor rotatable relative to the first rotor, a plurality of elastic members circumferentially aligned, an intermediate member, and a hysteresis generating mechanism. The intermediate member is disposed axially between the first rotor and the second rotor. The hysteresis generating mechanism is disposed axially between the first rotor and the second rotor to generate a hysteresis torque in relative rotation between the first rotor and the second rotor. The intermediate member includes an annular portion and a support portion. The annular portion is provided radially outside the plurality of elastic members. The support portion protrudes radially inward from the annular portion. The support portion is disposed between at least circumferentially adjacent two of the plurality of elastic members. The support portion actuates the at least circumferentially adjacent two of the plurality of elastic members in series.

Owner:EXEDY CORP

Vacuum valve that closes the flow path with a two-piece disc

ActiveCN108700223BSealing action is reliably maintainedLess componentsOperating means/releasing devices for valvesSlide valveLinear motionValve seat

The invention relates to a vacuum valve for a substantially gas-tight interruption of a flow path, having a valve housing (1) comprising a first opening (3) with a geometric opening axis (4) and a valve seat (5). There is also a valve disc (8) having a first disc portion (9) with an outer boundary (9a) and a second disc portion (11), the second disc portion being parallel to the opening axis (9a) within the outer boundary (9a). 3) in the direction of linear movement and installed in a sealed manner. Controlled mobility of the valve disc (8) is provided by a drive mechanism connected to the first disc portion (9). The first disc (9) has a first contact surface (15) directed axially towards the valve seat (5), the first contact surface being designed to be present in the first contact area with the sealing surface in the closed position (C) (14) Axial sealing contact. The outer boundary (9a) has an inner surface (16) directed radially inward. The second disc portion (11) has a radially outwardly directed outer surface (17) which is designed to exist in sealing contact with the inner surface (16) in the region of the second contact zone. At least for a given radial angle around the center (Z) of the valve disc (8), the first radial distance from the center to the first contact surface is smaller than the second radial distance from the center to the second contact zone.

Owner:VAT HLDG AG

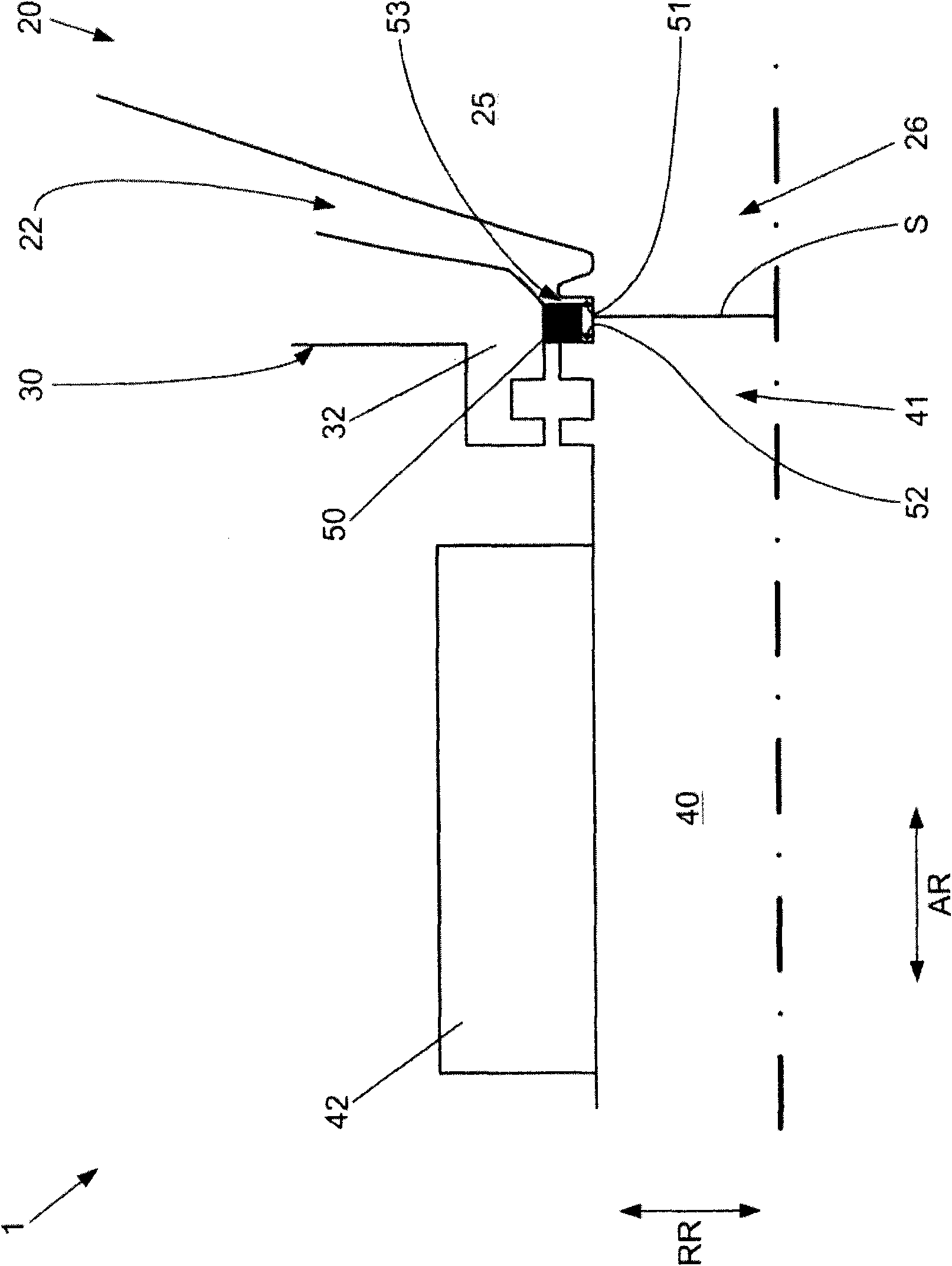

Turbo machine

InactiveCN102322304ALow melting pointReduce rotational frictionBlade accessoriesGas turbine plantsImpellerEngineering

The invention relates to a turbo machine (1), comprising a bearing housing (30), shafts (40',40'') supported on an inner chamber(31) of the bearing housing (30) rotatably, working impellers(25',25'') connected with longitudinal end parts(41',41'') of the shafts (40',40'') on a material and arranged on the outside of the inner chamber(31) and in a working impeller chamber(22), and a seal member(50) arranged on the circumferences of the shafts (40',40'') to thereby seal the inner chamber(31) relative to the working impeller chamber(22); wherein, the seal member is used for sealing the common effect of two seal surfaces(51',52',51'',52'') rotated oppositely. The invention aims to provide a turbo machine which prevents an undesired welded loose release between the working impellers and the shafts reliably by forming and arranging the seal surface materials of at least one seal surface of the two seal surfaces on isolation layers(T',T'') between the seal member and the working impellers.

Owner:MAN ENERGY SOLUTIONS SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com