Valve for mostly gas-proof interruption of a flow path

A flow path and valve technology, applied in the field of valves, can solve problems such as complex valve structures, and achieve the effects of fewer valve structures, longer service life, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

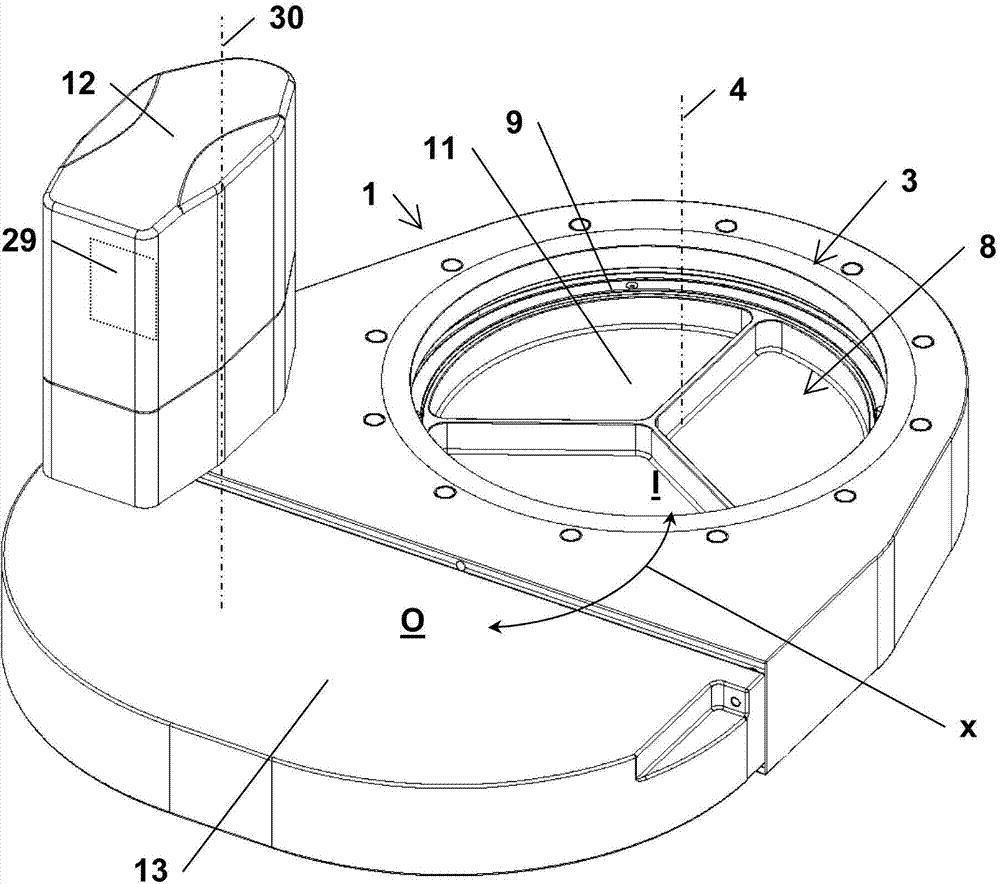

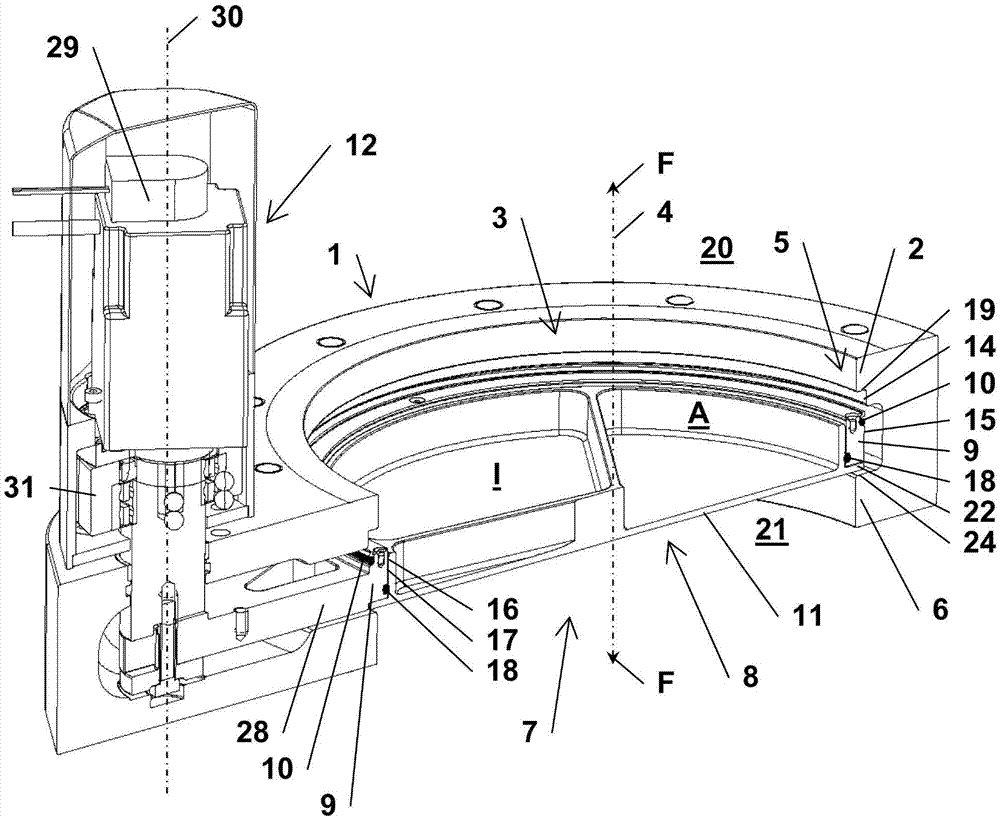

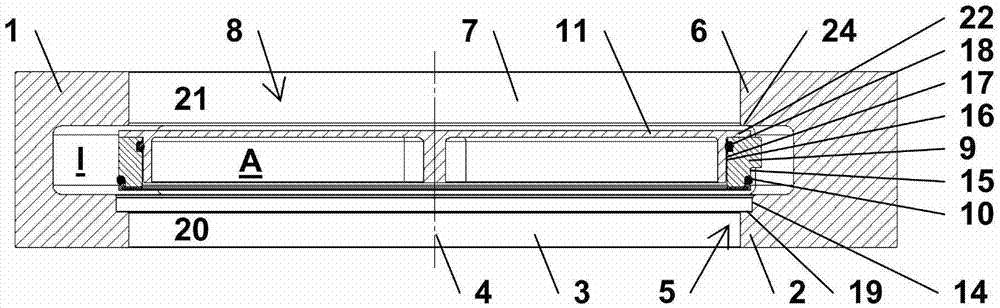

[0052] Figure 1-4D The same embodiment of the inventive valve is shown in different states from different perspectives and with different levels of detail. Therefore, these figures are explained together, and reference numbers and features already explained in previous figures are sometimes not reintroduced here.

[0053] exist Figure 1-4D A possible embodiment of the valve according to the invention in the form of a pendulum valve is shown in A pendulum valve. for substantially hermetic truncation as in the figure 2 The valve in the flow path F represented by the arrow has a valve body 1 with a first opening 3 and an opposite second opening 7 . The two openings 3 and 7 have a circular cross section. in such as Figure 3B , 3C In the closed position C of the valve disc 8 shown in , 4B and 4C, the two openings 3 and 7 are airtightly separated from each other by the valve disc 8, and the two openings 3 and 7 are in the open position O of the valve disc 8 are interconne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com