Airtight door closed running method and device

An operating method and operating device technology, applied in the field of airtight doors, can solve the problems of small airtight operation range, inability to achieve airtight effect, unfavorable hygiene requirements, etc., to avoid wear, avoid frictional contact, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

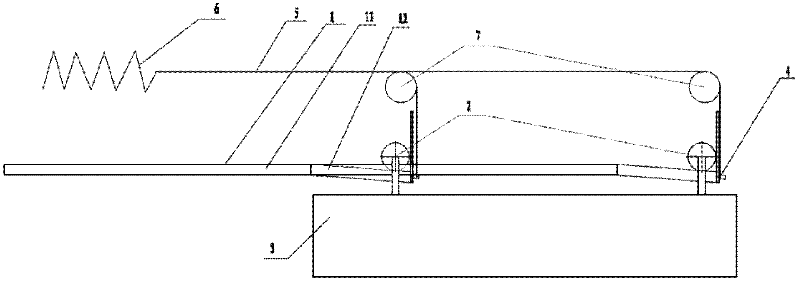

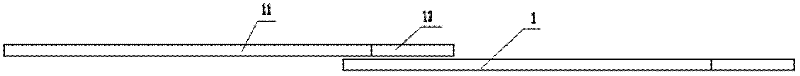

[0017] A method for airtight operation of an airtight door provided in this embodiment, which includes setting front and rear suspension wheels on the airtight door, and the front and rear suspension wheels respectively run on respective door rails composed of double rails, and the door rails composed of double rails are respectively set When the door is closed, the hanging wheels first run in parallel on the parallel guiding sections of the respective door rails. When the hanging wheels run to the closed position, the hanging wheels enter the airtight guiding section of the door rail, and the airtight guiding section The door rail guides the hanging wheel inward and downward at the same time, so that the airtight door can run smoothly and airtight; on the contrary, when the airtight door is opened, the airtight guide section of the door rail guides outward and upward to the hanging wheel at the same time, so that the airtight door Open it smoothly, and then the parallel guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com