Proportional electromagnetic valve for electrically controlled high-pressure common-rail fuel injection system of diesel engine

A technology for diesel engines and proportional solenoid valves, applied in engine components, machines/engines, charging systems, etc., can solve problems such as high prices of imported products, achieve simple and practical structure, reduce iron core quality, and be easy to process and manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

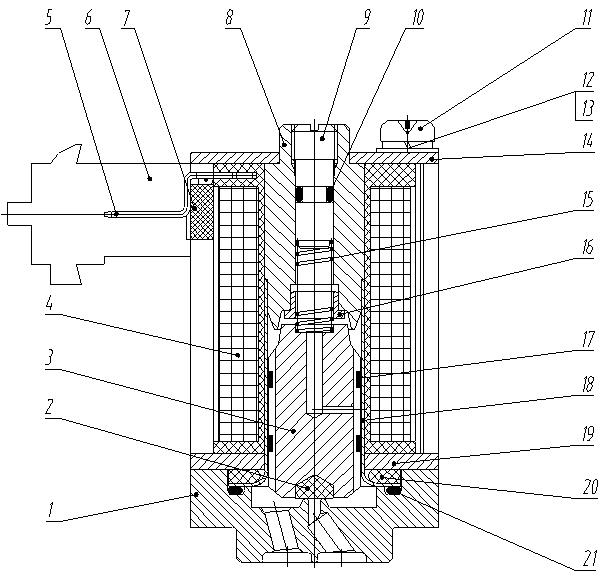

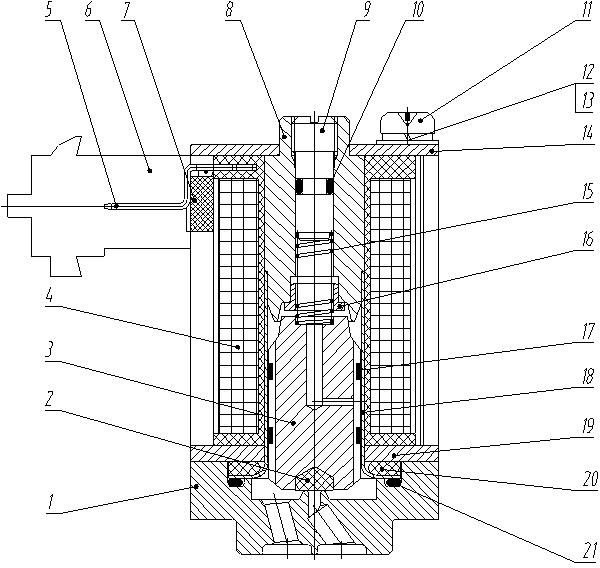

[0034] In the embodiment shown in the accompanying drawings, the cylindrical fixed iron core 8 and the moving iron core 3 are designed to be conical polar surfaces as shown in the figure, and then connected with other parts, including the adjusting screw 9, the guide tube 18, the limiter The position ring 16, the coil spring 15, the gasket 20, the electromagnetic coil assembly 4, the casing 14, the square iron core 19, and the valve body 1 are assembled together to form a proportional solenoid valve.

[0035] In the present invention, the cylindrical fixed iron core and the cylindrical moving iron core are attracted by a special conical pole surface. The two form a special magnetic circuit structure with the shell and the square iron core. When the driving current is input to the electromagnetic coil, The magnetic field in the valve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com